The Preforming of an Interlaminar Toughened Carbon Fiber/Bismaleimide Resin Composite by a Benzoxazine-Based Tackifier

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Design and Properties of Benzoxazine-Based BT5501A Tackifier

3.2. Effects of Tackifier on the Thermal Property of BMI Resin Matrix

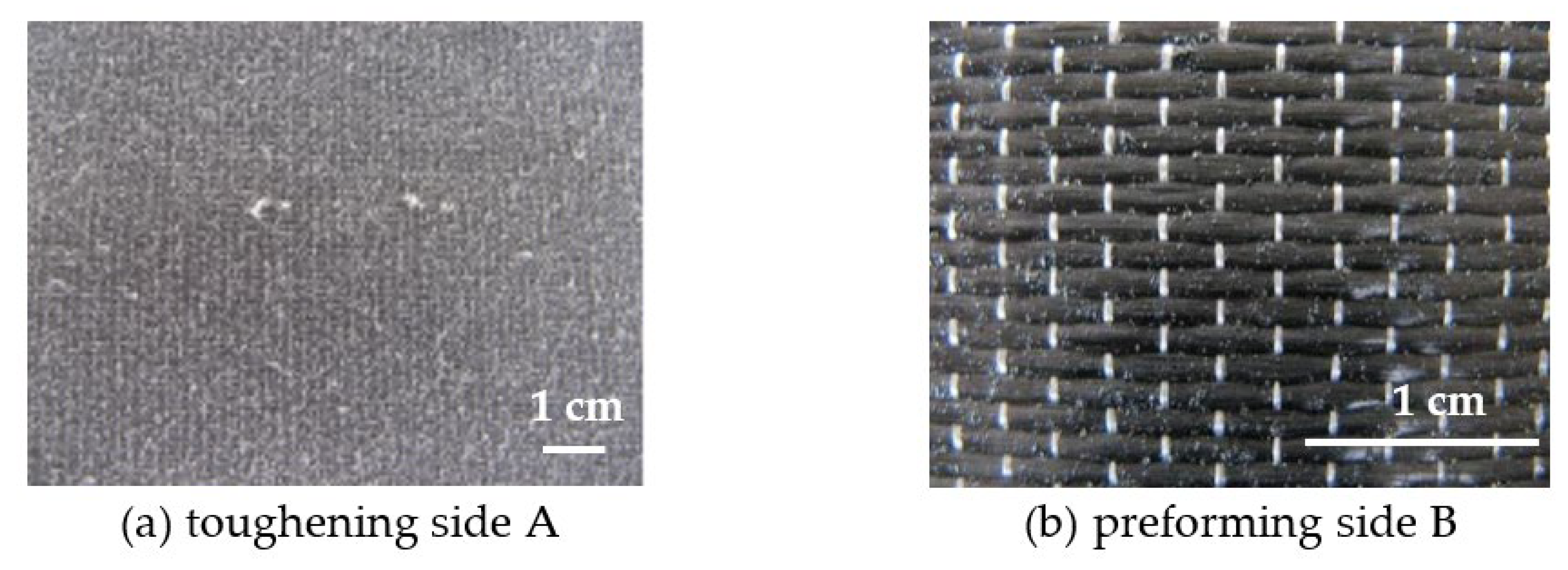

3.3. Preforming Effect of Tackifier on CF Fabric

3.4. Toughness Evaluation of Preforming–Toughening Bifunctional CF/PEK-C/BMI Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Velthem, P.; Ballout, W.; Daoust, D.; Sclavons, M.; Cordenier, F.; Henry, E.; Dumont, D.; Destoop, V.; Pardoen, T. Influence of thermoplastic diffusion on morphology gradient and on delamination toughness of RTM-manufactured composites. Compos. Part A 2015, 72, 175–183. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Xiao, J.; Tao, L.; Wei, Y.P.; Wang, S.J.; Zhang, H.; Zhu, S.; Yu, M.H. Preparation of High-Performance Carbon Fiber-Reinforced Epoxy Composites by Compression Resin Transfer Molding. Materials 2019, 12, 13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yi, X.S.; An, X.F.; Tang, B.M. A Method to Improve the Toughness of Laminated Composites. China Patent 01100981.0, 10 December 2008. [Google Scholar]

- Cheng, Q.F.; Fang, Z.P.; Yi, X.S.; An, F.; Tang, B.M.; Xu, Y.H. Ex-situ concept for toughening the RTMable BMI matrix composites. II. Improving the compression after impact. J. Appl. Polym. Sci. 2008, 108, 2211–2217. [Google Scholar] [CrossRef]

- Yao, J.W.; Zhang, T.; Niu, Y.F. Effect of curing time on phase morphology and fracture toughness of PEK-C film interleaved carbon fibre/epoxy composite laminates. Compos. Struct. 2020, 248, 112550. [Google Scholar] [CrossRef]

- Chang, H.C.; Yao, J.W.; Zhang, T.; Niu, Y.F. Characterization of phase structure spectrum in interleaved carbon fibre reinforced epoxy matrix composites by Polyaryletherketone with Cardo using AFM. Mater. Res. Express 2019, 6, 115322. [Google Scholar] [CrossRef]

- Nash, N.H.; Young, T.M.; Stanley, W.F. The influence of a thermoplastic toughening interlayer and hydrothermal conditioning on the Mode-II interlaminar fracture toughness of carbon/benzoxazine composites. Compos. Part A 2016, 81, 111–120. [Google Scholar] [CrossRef]

- Van der Heijden, S.; Daelemans, L.; De Schoenmaker, B.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Interlaminar toughening of resin transfer moulded glass fibre epoxy laminates by polycaprolactone electrospun nanofibres. Compos. Sci Technol. 2014, 104, 66–73. [Google Scholar] [CrossRef] [Green Version]

- Beckermann, G.W.; Pickering, K.L. Mode I and Mode II interlaminar fracture toughness of composite laminates interleaved with electrospun nanofibre veils. Compos. Part A Appl. Sci. Manuf. 2015, 72, 11–21. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, T.; Wang, X.G. Electrospun nanofibre toughened carbon/epoxy composites: Effects of polyetherketone cardo (PEK-C) nanofibre diameter and interlayer thickness. Compos. Sci. Technol. 2010, 70, 1660–1666. [Google Scholar] [CrossRef]

- Daelemans, L.; van der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Nanofibre bridging as a toughening mechanism in carbon/epoxy composite laminates interleaved with electrospun polyamide nanofibrous veils. Compos. Sci. Technol. 2015, 117, 244–256. [Google Scholar] [CrossRef]

- Liu, G.; Hu, X.L.; Yi, X.S. A Kind of Fiber Fabric with Two Functions of Stereotyped-Toughening and its Preparation Method. China Patent 201110390154.2, 2 July 2014. [Google Scholar]

- Wuyun, Q.Q.G.; Yi, X.S. A medium temperature tackifier and tackification behavior. J. Mater. Eng. 2006, 3, 37–39. (In Chinese) [Google Scholar]

- Zhang, R.Z.; Li, X.Q.; Tang, B.M.; An, X.F.; Yi, X.S. Characterization and analysis of micro-defects in the RTMable composites. J. Mater. Eng. 2009, 2, 328–335. (In Chinese) [Google Scholar] [CrossRef]

- Takeichi, T.; Kawauchi, T.; Agag, T. High Performance Polybenzoxazines as a Novel Type of Phenolic Resin. Polym. J. 2008, 40, 1121–1131. [Google Scholar] [CrossRef] [Green Version]

- Agag, T.; Liu, J.; Graf, R.; Spiess, H.W.; Ishida, H. Benzoxazole Resin: A Novel Class of Thermoset Polymer via Smart Benzoxazine Resin. Macromolecules 2012, 45, 8991–8997. [Google Scholar] [CrossRef]

- Gu, Y. Benzoxazing resin—A new kind of thermoseting engineering plastics. Thermosetting Resin 2002, 17, 33–34. (In Chinese) [Google Scholar]

- Li, D.; Yang, Z.Q.; Xi, L. Two-dimensional correlation spectroscopy study on curing of MDA-benzoxazine. Acta Polym. Sin. 2016, 2, 164–172. (in Chinese). [Google Scholar]

- Reng, R.; Liu, S.Y.; Xiong, X.H. Catalytic system and catalytic mechanism for curing of bismaleimide resin. Thermosetting Resin 2015, 3, 30–35. (In Chinese) [Google Scholar]

- Liang, G.Z.; Gu, A.J. BMI modifier—Allyl series compounds. New Chem. Mater. 1996, 3, 27–30. (In Chinese) [Google Scholar]

- Gu, A.J.; Liang, G.Z.; Lan, L.W. Application of diallyl bisphenol A in modification of bismaleimide. Thermosetting Resin 1995, 2, 38–41. (In Chinese) [Google Scholar]

- Santhosh Kumar, K.S.; Reghunadhan Nair, C.P.; Sadhana, R.; Ninan, K.N. Benzoxazine–bismaleimide blends: Curing and thermal properties. Eur. Polym. J. 2007, 43, 5084–5096. [Google Scholar] [CrossRef]

- Ishida, H.; Rodriguez, Y. Catalyzing the curing reaetion of a new benzoxazine- based Phenolie resin. J. Appl. Polym. Sci. 1995, 58, 1751–1760. [Google Scholar] [CrossRef]

- Wang, Z.; Ran, Q.C.; Zhu, R.Q.; Gu, Y. Curing behaviors and thermal properties of benzoxazine and N, N′-(2, 2, 4-trimethylhexane-1, 6-diyl) dimaleimide blend. J. Appl. Polym. Sci. 2013, 129, 1124–1130. [Google Scholar] [CrossRef]

- Liu, S.P.; Liu, R.S. Discussion on reaction mechanism of bismaleimide modified by allylic compounds. Insul. Mater. 2006, 39, 29–32. (In Chinese) [Google Scholar]

- Zhang, Q.; Guan, Q.B.; Yuan, L.; Gu, A.J.; Liang, G.Z. A very low concentration of polybenzimidazole film interleaved bismaleimide/diallyl bisphenol a system with outstanding improvement in impact strength and excellent allround properties. Polym. Compos. 2019, 39, 4569–4580. [Google Scholar] [CrossRef]

- Hu, X.L.; Yu, R.L.; Liu, G.; Yi, X.S. Morphology of a functional POSS/bismaleimide nanocomposite and its monitoring phase separation with a thermoplastic blend. Adv. Mater. Res. 2011, 266, 166–170. [Google Scholar] [CrossRef]

- Sun, S.J.; Guo, M.C.; Yi, X.S.; Zhang, Z.G. Preparation and characterization of a naphthalene-modified poly(aryl ether ketone) and its phase separation morphology with bismaleimide resin. Polym. Bull. 2017, 74, 1519–1533. [Google Scholar] [CrossRef]

| BT5501A Content (g/m2) | Spring-Back Angle/° | |||

|---|---|---|---|---|

| 10 min | 1 h | 4 h | 16 h | |

| 0 | 43.7 ± 5.9 | 48.3 ± 3.5 | 51.4 ± 5.3 | 52.1 ± 4.3 |

| 1 | 34.5 ± 1.8 | 35 ± 0.3 | 36.8 ± 0.5 | 37.8 ± 1.7 |

| 2 | 31.8 ± 0.1 | 33.3 ± 0.5 | 33.9 ± 0.4 | 35.9 ± 0.6 |

| 3 | 27.8 ± 1.3 | 31.2 ± 1.1 | 32.2 ± 1.3 | 32.7 ± 1.3 |

| 4 | 0 | 0 | 0 | 0 |

| 6 | 0 | 0 | 0 | 0 |

| Properties | Data | Mean Value | |||

|---|---|---|---|---|---|

| Pit depth of CF/BMI (mm) | 0.88 | 0.87 | 0.95 | 0.89 | |

| Pit depth of CF/PEK-C/BMI (mm) | 0.53 | 0.69 | 0.59 | 0.63 | |

| Pit depth of CF/BT5501A/PEK-C/BMI (mm) | 0.73 | 0.75 | 0.74 | 0.55 | |

| CAI strength of CF/BMI (MPa) | 171.0 | 162.3 | 153.6 | 142.9 | |

| CAI strength of CF/PEK-C/BMI (MPa) | 230.0 | 206.9 | 226.0 | 208.0 | |

| CAI strength of CF/BT5501A/PEK-C/BMI (MPa) | 215.2 | 207.4 | 205.8 | 216.4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zi, Y.; Zhang, Y.; Li, W.; Liu, G.; Zhou, Y.; Bai, H.; Hu, X. The Preforming of an Interlaminar Toughened Carbon Fiber/Bismaleimide Resin Composite by a Benzoxazine-Based Tackifier. Materials 2022, 15, 4196. https://doi.org/10.3390/ma15124196

Zi Y, Zhang Y, Li W, Liu G, Zhou Y, Bai H, Hu X. The Preforming of an Interlaminar Toughened Carbon Fiber/Bismaleimide Resin Composite by a Benzoxazine-Based Tackifier. Materials. 2022; 15(12):4196. https://doi.org/10.3390/ma15124196

Chicago/Turabian StyleZi, Yaxian, Yulian Zhang, Weidong Li, Gang Liu, Yujing Zhou, Hua Bai, and Xiaolan Hu. 2022. "The Preforming of an Interlaminar Toughened Carbon Fiber/Bismaleimide Resin Composite by a Benzoxazine-Based Tackifier" Materials 15, no. 12: 4196. https://doi.org/10.3390/ma15124196

APA StyleZi, Y., Zhang, Y., Li, W., Liu, G., Zhou, Y., Bai, H., & Hu, X. (2022). The Preforming of an Interlaminar Toughened Carbon Fiber/Bismaleimide Resin Composite by a Benzoxazine-Based Tackifier. Materials, 15(12), 4196. https://doi.org/10.3390/ma15124196