Preparation of Iron Ore Tailings-Based Superhydrophobic Coatings

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of IOT/POS Powders

2.3. Preparation of Composite Coatings

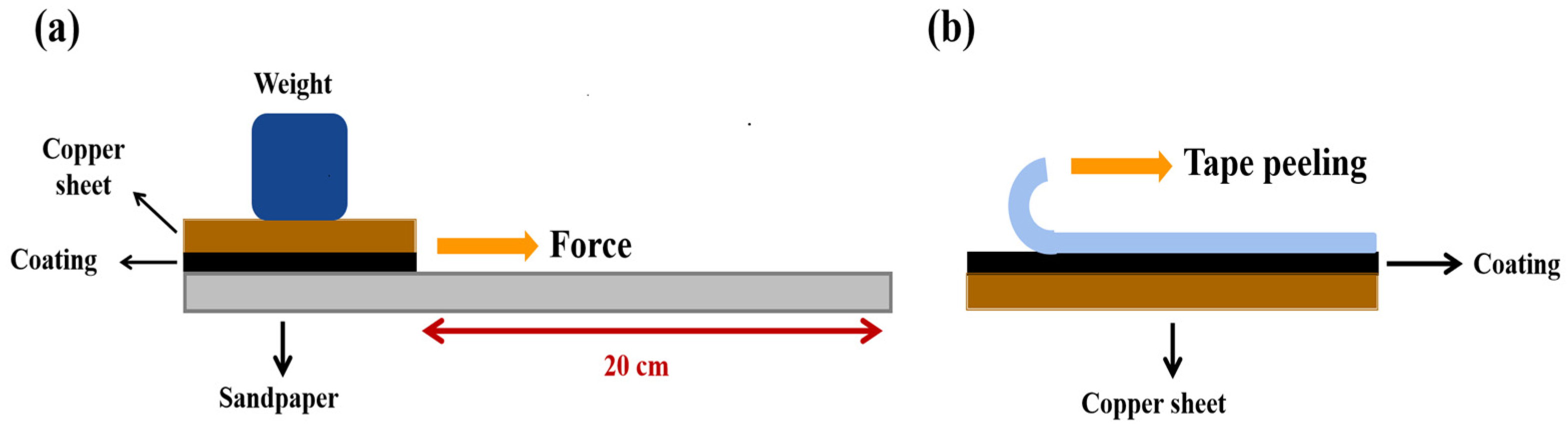

2.4. Durability Test of Composite Coatings

2.5. Characterizations

3. Results and Discussion

3.1. Effect of the HDTMS Amount on the Wettability of IOT/POS

3.2. Effect of the Reaction Time on Wettability of IOT/POS

3.3. Effect of IOT/POS Powder Concentration on Wettability of Composite Coatings

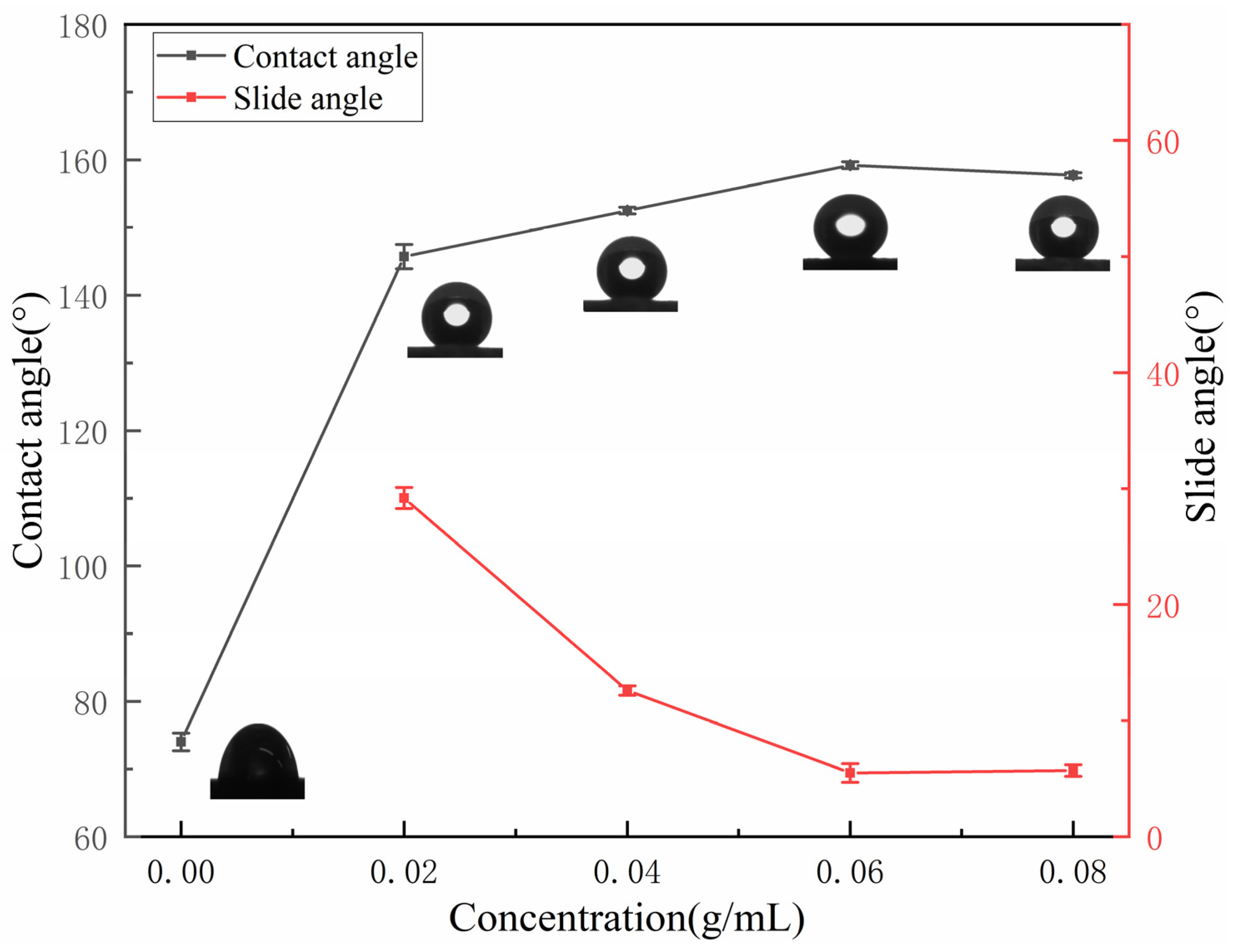

3.4. Durability Testing of Composite Coatings

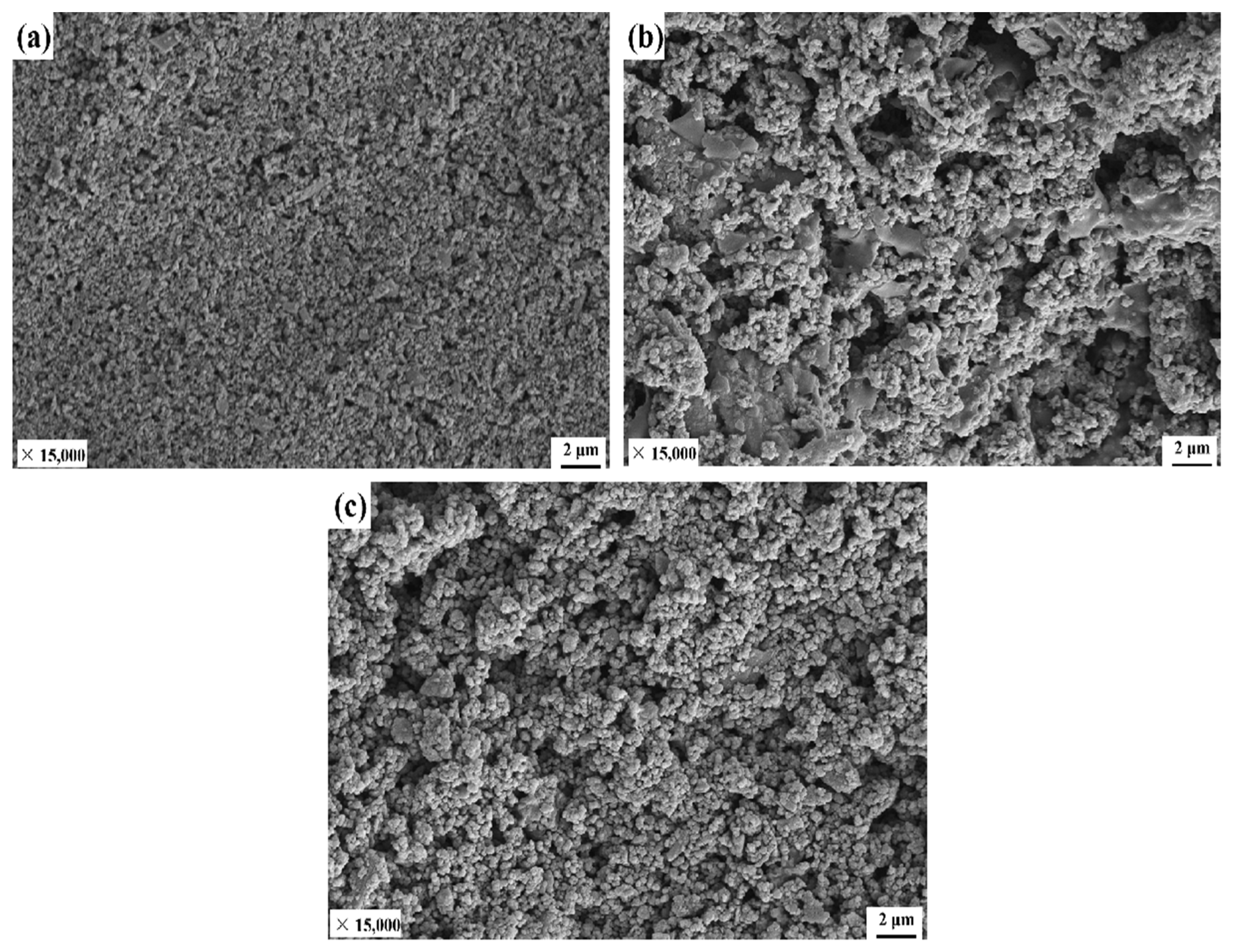

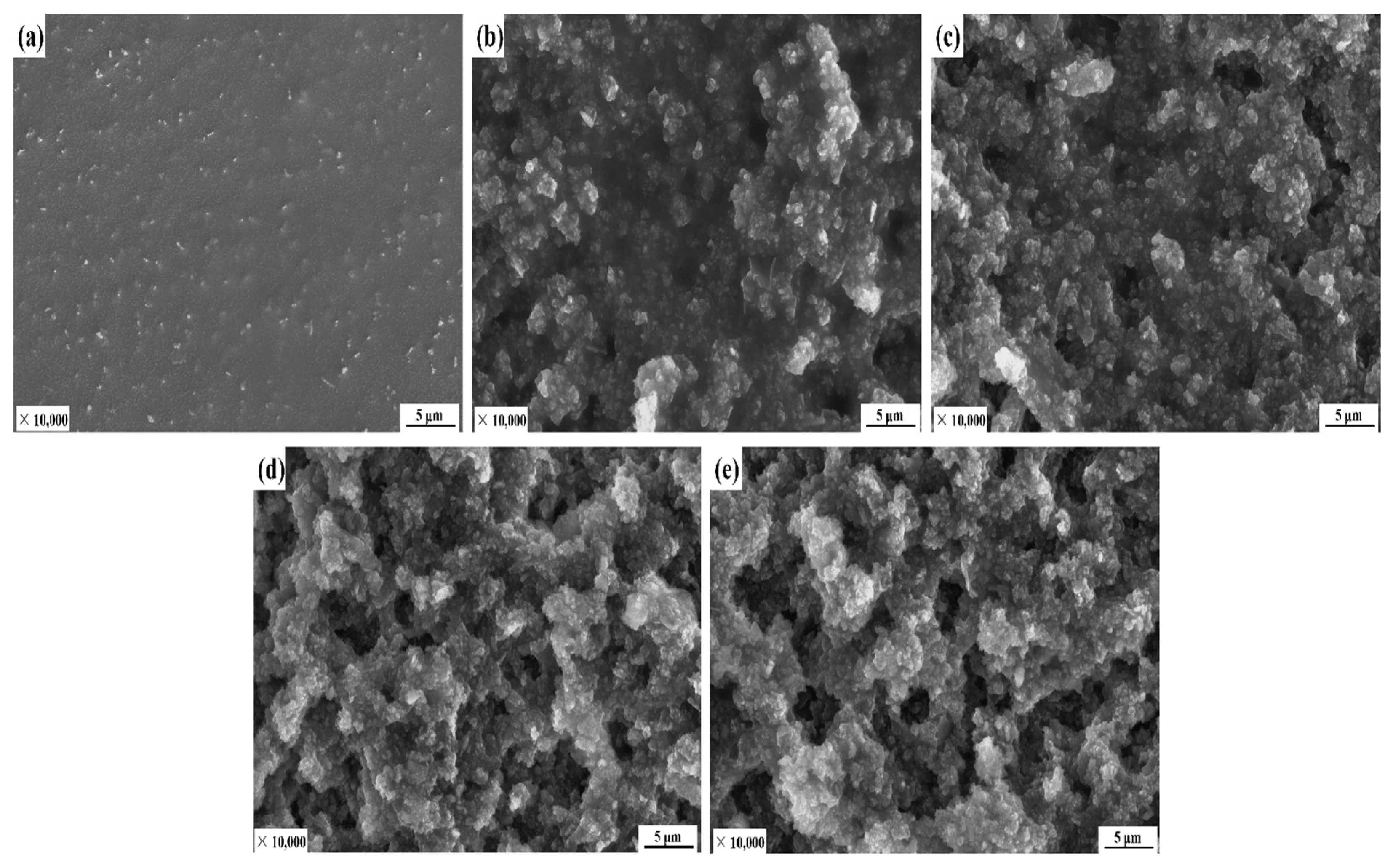

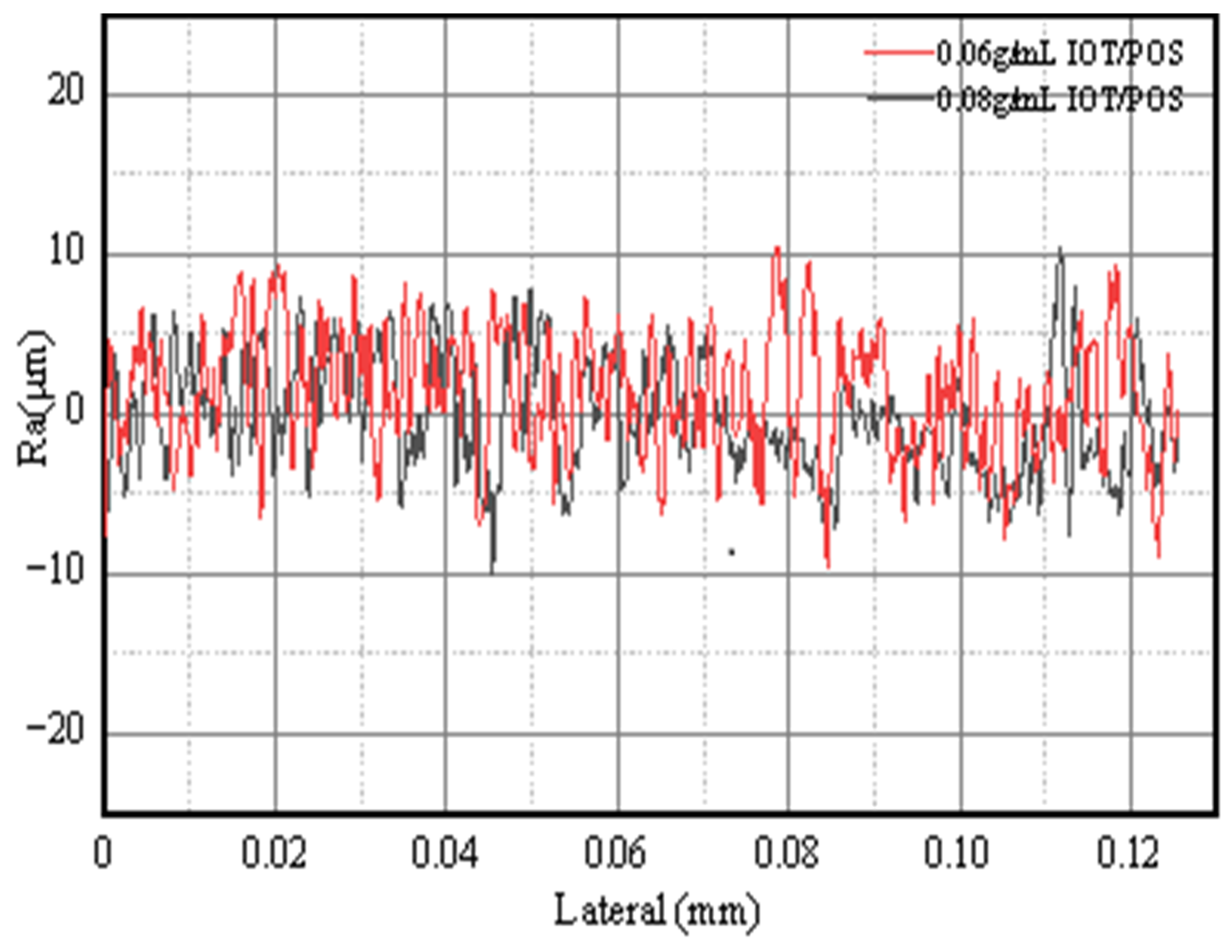

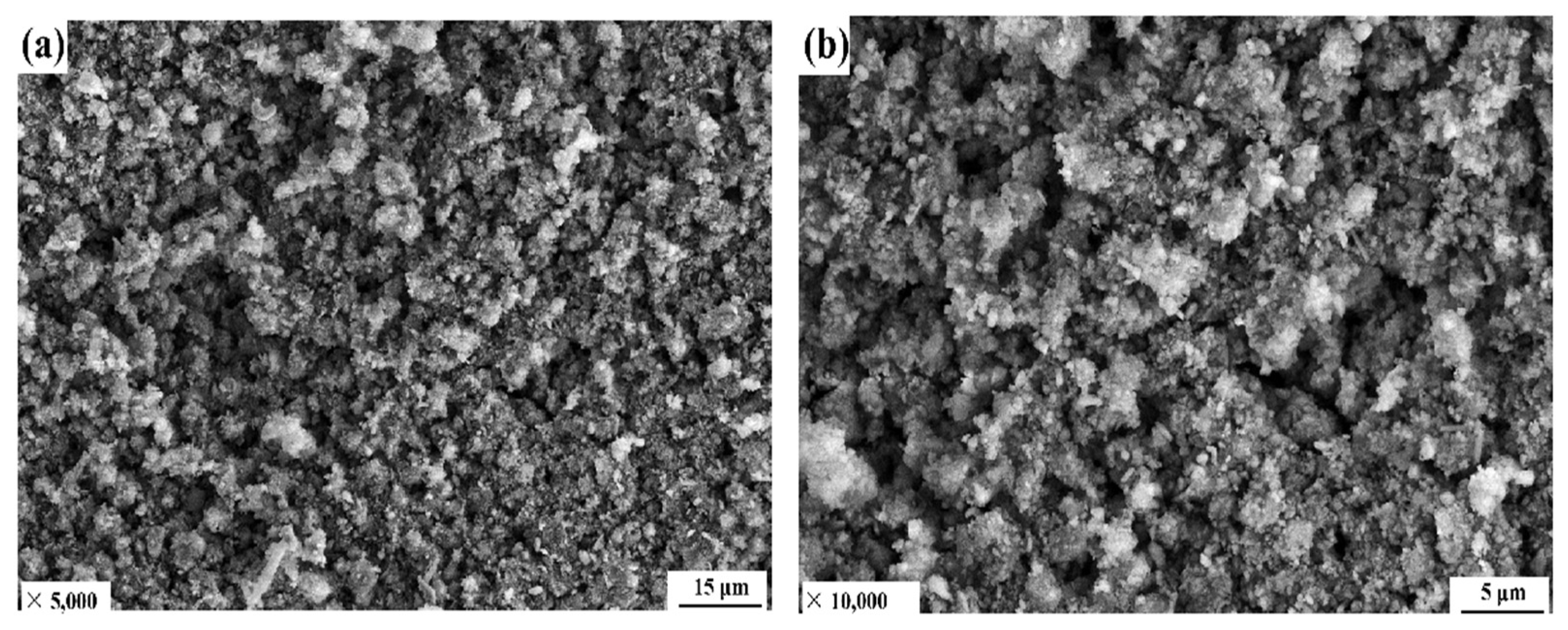

3.5. Analysis of Surface Energy and Surface Topography Changes

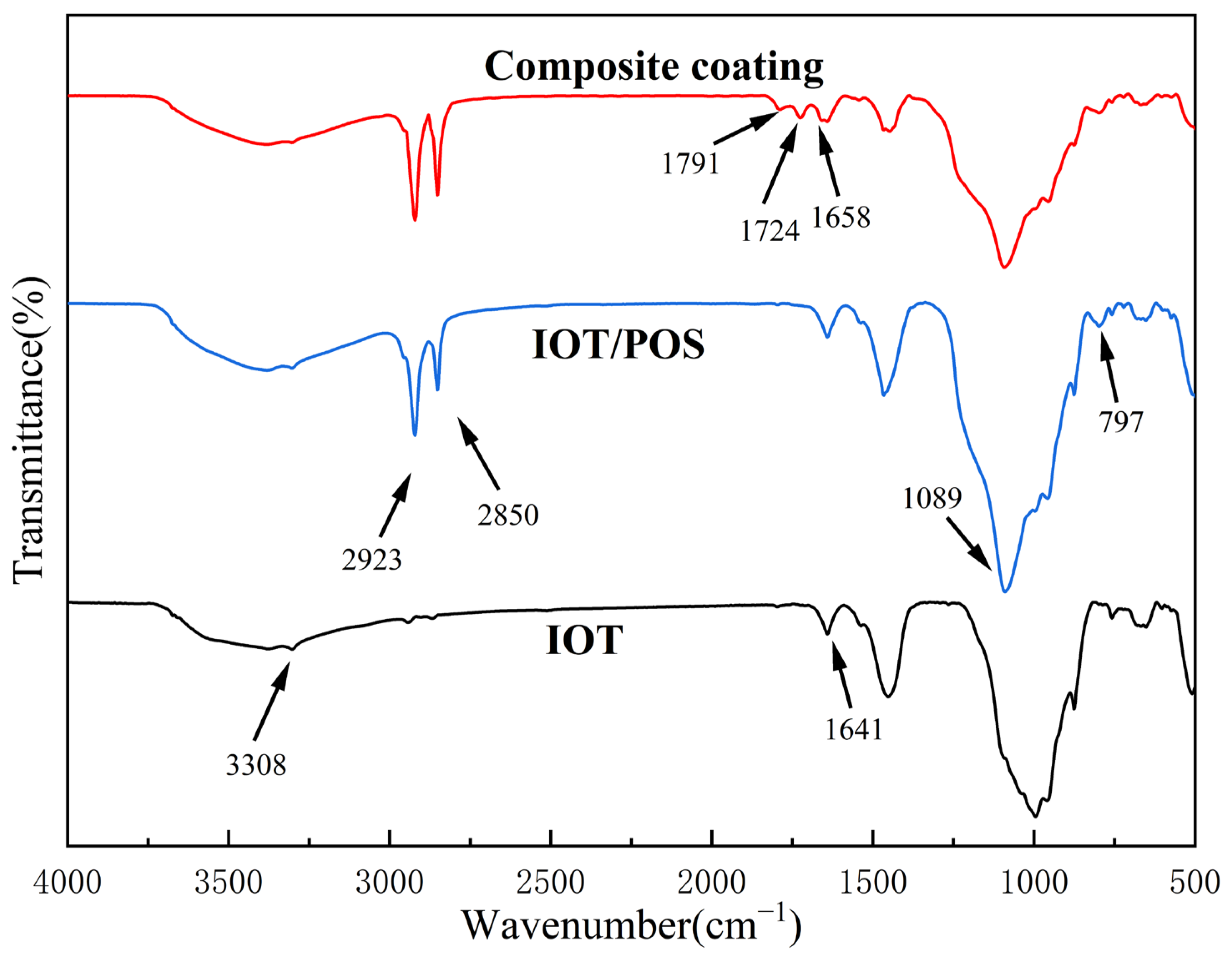

3.6. FT-IR Analysis

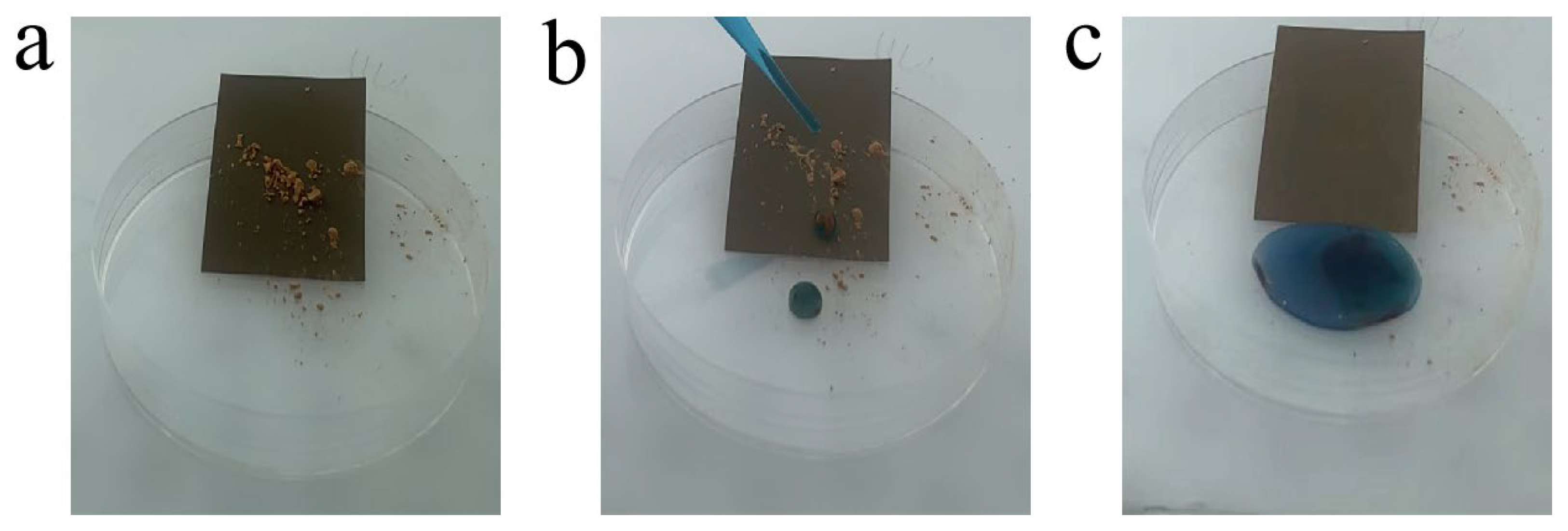

3.7. Self-Cleaning Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ren, T.; He, J. Substrate-Versatile Approach to Robust Antireflective and Superhydrophobic Coatings with Excellent Self-Cleaning Property in Varied Environments. ACS Appl. Mater. Interfaces 2017, 9, 34367–34376. [Google Scholar] [CrossRef]

- Xing, Y.; Xue, Y.; Song, J.; Sun, Y.; Huang, L.; Liu, X.; Sun, J. Superhydrophobic coatings on wood substrate for self-cleaning and EMI shielding. Appl. Surf. Sci. 2017, 436, 865–872. [Google Scholar] [CrossRef]

- He, J.; Zhao, Y.; Yuan, M.; Hou, L.; Abbas, A.; Xue, M.; Ma, X.; He, J.; Qu, M. Fabrication of durable polytetrafluoroethylene superhydrophobic materials with recyclable and self-cleaning properties on various substrates. J. Coat. Technol. Res. 2020, 17, 755–763. [Google Scholar] [CrossRef]

- Kulinich, S.; Farzaneh, M. Ice adhesion on super-hydrophobic surfaces. Appl. Surf. Sci. 2009, 255, 8153–8157. [Google Scholar] [CrossRef]

- Zheng, H.; Chang, S.; Zhao, Y. Anti-Icing & Icephobic Mechanism and Applications of Superhydrophobic/Ultra Slippery Surface. J. Prog. Chem. 2017, 29, 102–118. [Google Scholar] [CrossRef]

- Zeng, D.; Li, Y.; Huan, D.; Liu, H.; Luo, H.; Cui, Y.; Zhu, C.; Wang, J. Robust epoxy-modified superhydrophobic coating for aircraft anti-icing systems. Colloids Surf. A 2021, 628, 127377. [Google Scholar] [CrossRef]

- Gong, A.; Zheng, Y.; Yang, Z.; Guo, X.; Gao, Y.; Li, X. Spray fabrication of superhydrophobic coating on aluminum alloy for corrosion mitigation. Mater. Today Commun. 2020, 26, 101828. [Google Scholar] [CrossRef]

- Zheng, K.; Zhang, J.; Keaney, E.; Dodiuk, H.; Kenig, S.; Barry, C.; Mead, J. The effect of superhydrophobic surface topography on underwater corrosion resistance of steel. J. Coat. Technol. Res. 2021, 18, 685–693. [Google Scholar] [CrossRef]

- Taghvaei, E.; Moosavi, A.; Nouri-Borujerdi, A.; Daeian, M.; Vafaeinejad, S. Superhydrophobic surfaces with a dual-layer micro- and nanoparticle coating for drag reduction. Energy 2017, 125, 1–10. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, X.; Ji, J.; Tao, T.; Zhang, T.; Xu, J.; Jiao, Y.; Liu, K. Underwater Drag Reduction and Buoyancy Enhancement on Biomimetic Antiabrasive Superhydrophobic Coatings. ACS Appl. Mater. Interfaces 2021, 13, 48270–48280. [Google Scholar] [CrossRef]

- Crick, C.; Parkin, I.P. Preparation and Characterisation of Super-Hydrophobic Surfaces. Chemistry 2010, 16, 3568–3588. [Google Scholar] [CrossRef]

- Ke, C.; Zhang, C.; Wu, X.; Jiang, Y. Highly transparent and robust superhydrophobic coatings fabricated via a facile sol-gel process. Thin Solid Films 2021, 723, 138583. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, C.; Zhang, X.; Wang, C.; Liu, F.; Yuan, R.; Wang, H. Durable superhydrophobic PVDF/FEVE/GO@TiO2 composite coating with excellent anti-scaling and UV resistance properties. Chem. Eng. J. 2021, 411, 128632. [Google Scholar] [CrossRef]

- Zheng, H.; Pan, M.; Wen, J.; Yuan, J.; Zhu, L.; Yu, H. Robust, Transparent, and Superhydrophobic Coating Fabricated with Waterborne Polyurethane and Inorganic Nanoparticle Composites. Ind. Eng. Chem. Res. 2019, 58, 8050–8060. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, J.; Xuan, Q.; Lu, J.; Feng, J. Superhydrophobic Coating for Antifouling of Chinese Paintings. Langmuir 2018, 34, 8294–8301. [Google Scholar] [CrossRef]

- Kim, J.-H.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Realization of superhydrophobic aluminum surfaces with novel micro-terrace nano-leaf hierarchical structure. Appl. Surf. Sci. 2018, 451, 207–217. [Google Scholar] [CrossRef]

- Wan, Y.; Chen, M.; Liu, W.; Shen, X.; Min, Y.; Xu, Q. The research on preparation of superhydrophobic surfaces of pure copper by hydrothermal method and its corrosion resistance. Electrochim. Acta 2018, 270, 310–318. [Google Scholar] [CrossRef]

- Zhu, J.; Hu, X. A novel route for fabrication of the corrosion-resistant superhydrophobic surface by turning operation. Surf. Coat. Technol. 2017, 313, 294–298. [Google Scholar] [CrossRef]

- Zhu, J. A novel fabrication of superhydrophobic surfaces on aluminum substrate. Appl. Surf. Sci. 2018, 447, 363–367. [Google Scholar] [CrossRef]

- Li, J.; Cui, M.; Tian, H.; Wu, Y.; Zha, F.; Feng, H.; Tang, X. Facile fabrication of anti-corrosive superhydrophobic diatomite coatings for removal oil from harsh environments. Sep. Purif. Technol. 2017, 189, 335–340. [Google Scholar] [CrossRef]

- Li, B.; Zhang, J.; Wu, L.; Wang, A. Durable Superhydrophobic Surfaces Prepared by Spray Coating of Polymerized Organosilane/Attapulgite Nanocomposites. ChemPlusChem 2013, 78, 1503–1509. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Jia, Y.; Zhang, M.; Li, X.; Yang, J.; Zhang, X. Facile modification of sepiolite and its application in superhydrophobic coatings. Appl. Clay Sci. 2019, 174, 1–9. [Google Scholar] [CrossRef]

- Shi, J.; He, F.; Ye, C.; Hu, L.; Xie, J.; Yang, H.; Liu, X. Preparation and characterization of CaO–Al2O3–SiO2 glass-ceramics from molybdenum tailings. Mater. Chem. Phys. 2017, 197, 57–64. [Google Scholar] [CrossRef]

- Li, L.; Jiang, T.; Chen, B.; Zhou, M.; Chen, C. Overall utilization of vanadium–titanium magnetite tailings to prepare lightweight foam ceramics. Process Saf. Environ. Prot. 2020, 139, 305–314. [Google Scholar] [CrossRef]

- Li, P.; Luo, S.-H.; Zhang, L.; Wang, Q.; Huang, X.; Zhang, Y.; Liu, X.; Liang, J.; Duan, X. Study on preparation and performance of iron tailings-based porous ceramsite filter materials for water treatment. Sep. Purif. Technol. 2021, 276, 119380. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, Y.; Bao, S.; Chen, T. Utilization of Iron Ore Tailings as Raw Material for Portland Cement Clinker Production. Adv. Mater. Sci. Eng. 2016, 2016, 1596047. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Tang, Q.; Zhao, W.; Su, Z.; Liang, C.; Duan, X.; Liang, J. Ultrafine Grinded and Silane Grafted Iron Ore Tailings as Reinforcing Filler of Styrene Butadiene Rubber. Materials 2022, 15, 1756. [Google Scholar] [CrossRef]

- Milionis, A.; Languasco, J.; Loth, E.; Bayer, I. Analysis of wear abrasion resistance of superhydrophobic acrylonitrile butadiene styrene rubber (ABS) nanocomposites. Chem. Eng. J. 2015, 281, 730–738. [Google Scholar] [CrossRef] [Green Version]

- Wimalasiri, V.K.; Weerathunga, H.U.; Kottegoda, N.; Karunaratne, V. Silica Based Superhydrophobic Nanocoatings for Natural Rubber Surfaces. J. Nanomater. 2017, 2017, 2102467. [Google Scholar] [CrossRef]

- Kulinich, S.A.; Masson, D.; Du, X.; Emelyanenko, A.M. Testing the Durability of Anti-Icing Coatings. In Ice Adhesion: Mechanism, Measurement and Mitigation; Mittal, K.L., Choi, C.-H., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2020; pp. 495–519. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Ding, J.; Xu, Z.; Zhang, J.; He, Q. Preparation strategy and evaluation method of durable superhydrophobic rubber composites. Adv. Colloid Interface Sci. 2021, 299, 102549. [Google Scholar] [CrossRef]

- Dalawai, S.P.; Aly, M.A.S.; Latthe, S.S.; Xing, R.; Sutar, R.S.; Nagappan, S.; Ha, C.-S.; Sadasivuni, K.K.; Liu, S. Recent Advances in durability of superhydrophobic self-cleaning technology: A critical review. Prog. Org. Coat. 2019, 138, 105381. [Google Scholar] [CrossRef]

- Ellinas, K.; Tserepi, A.; Gogolides, E. Durable superhydrophobic and superamphiphobic polymeric surfaces and their applications: A review. Adv. Colloid Interface Sci. 2017, 250, 132–157. [Google Scholar] [CrossRef]

- Chen, W.; Fadeev, A.Y.; Hsieh, M.C.; Öner, D.; Youngblood, J.; McCarthy, T.J. Ultrahydrophobic and Ultralyophobic Surfaces: Some Comments and Examples. Langmuir 1999, 15, 3395–3399. [Google Scholar] [CrossRef]

- Su, X.; Li, H.; Lai, X.; Chen, Z.; Zeng, X. 3D Porous Superhydrophobic CNT/EVA Composites for Recoverable Shape Reconfiguration and Underwater Vibration Detection. Adv. Funct. Mater. 2019, 29, 1900554. [Google Scholar] [CrossRef]

| Typical Liquids | (mJ/m2) | (mJ/m2) | γl (mJ/m2) |

|---|---|---|---|

| diiodomethane | 50.8 | 0.0 | 50.8 |

| water | 21.8 | 51.0 | 72.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Z.; Tang, Q.; Zhao, W.; Liang, C.; Liu, Q.; Wang, F.; Duan, X.; Liang, J. Preparation of Iron Ore Tailings-Based Superhydrophobic Coatings. Materials 2022, 15, 4235. https://doi.org/10.3390/ma15124235

Su Z, Tang Q, Zhao W, Liang C, Liu Q, Wang F, Duan X, Liang J. Preparation of Iron Ore Tailings-Based Superhydrophobic Coatings. Materials. 2022; 15(12):4235. https://doi.org/10.3390/ma15124235

Chicago/Turabian StyleSu, Zhiyuan, Qingguo Tang, Weiwei Zhao, Cong Liang, Qian Liu, Fei Wang, Xinhui Duan, and Jinsheng Liang. 2022. "Preparation of Iron Ore Tailings-Based Superhydrophobic Coatings" Materials 15, no. 12: 4235. https://doi.org/10.3390/ma15124235

APA StyleSu, Z., Tang, Q., Zhao, W., Liang, C., Liu, Q., Wang, F., Duan, X., & Liang, J. (2022). Preparation of Iron Ore Tailings-Based Superhydrophobic Coatings. Materials, 15(12), 4235. https://doi.org/10.3390/ma15124235