Evaluation of Shear and Peel Strength of Al1060 Single-Lap and T-Lap Joints Produced by Rotated Clinching Process with Twin Rotating Punches

Abstract

:1. Introduction

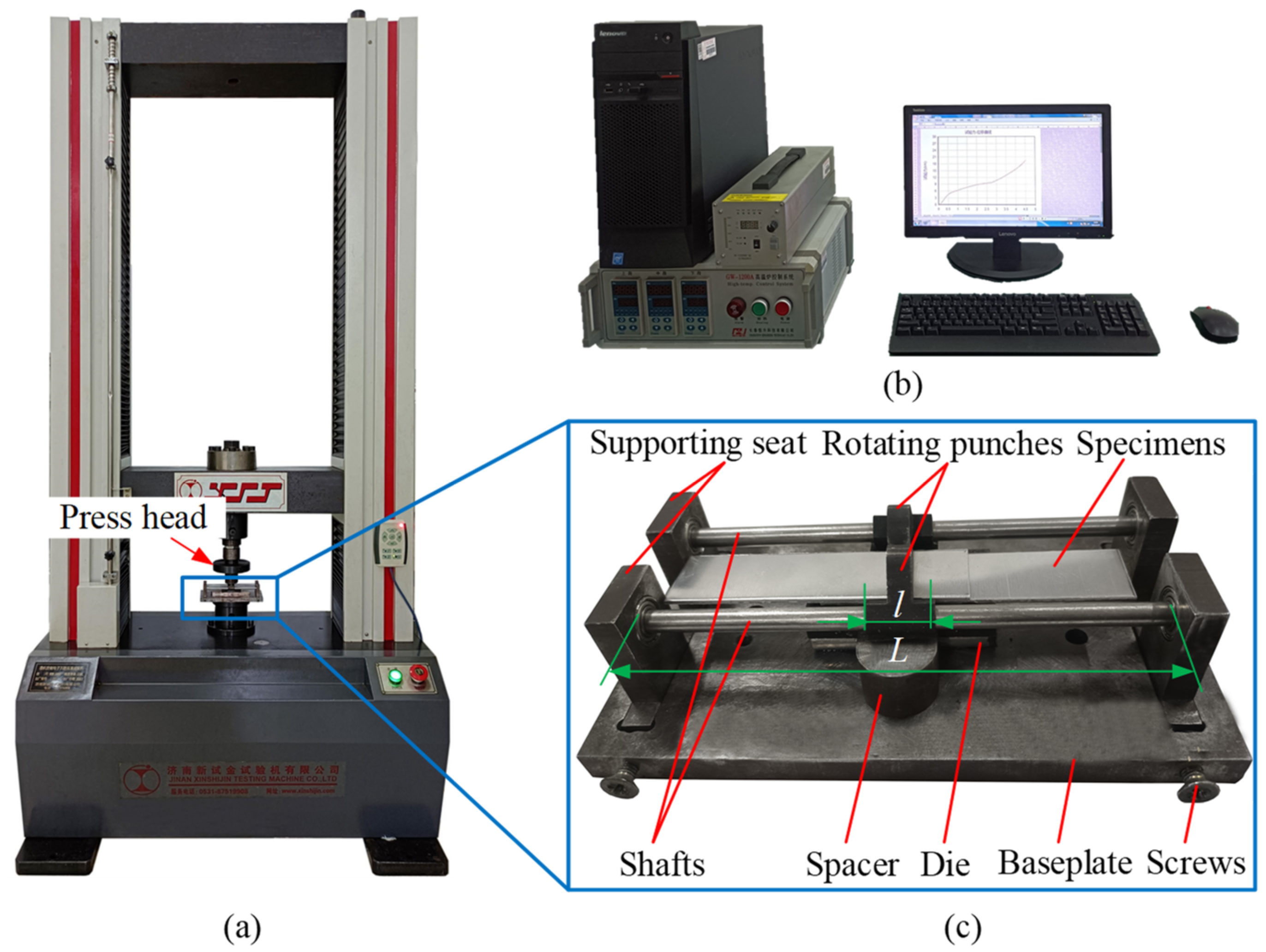

2. Forming Principle of RCP

3. Experimental Procedures

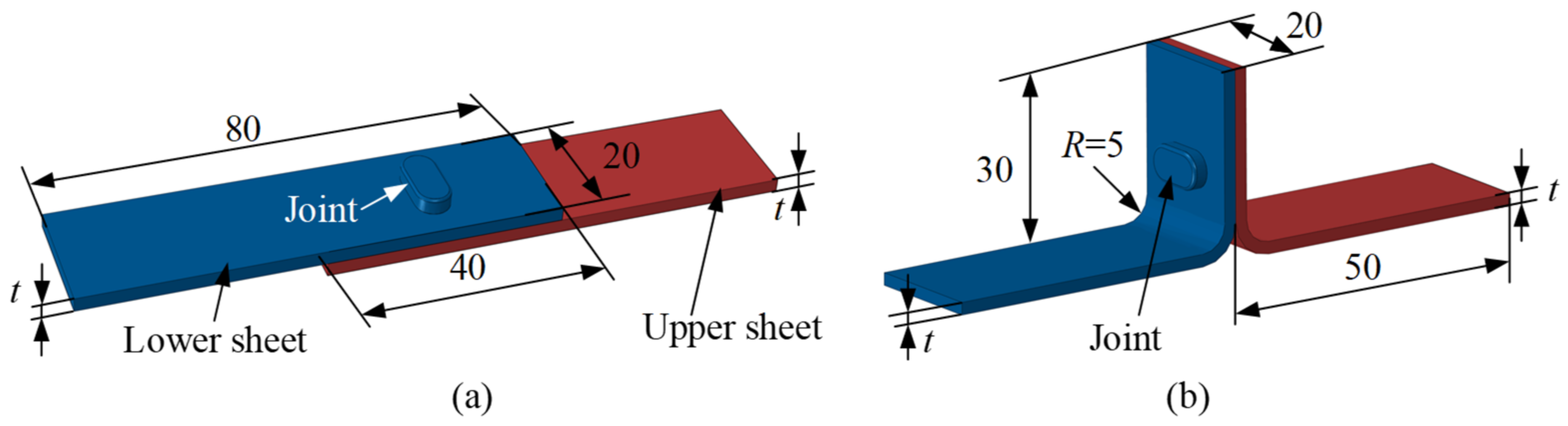

3.1. Joining Experiments

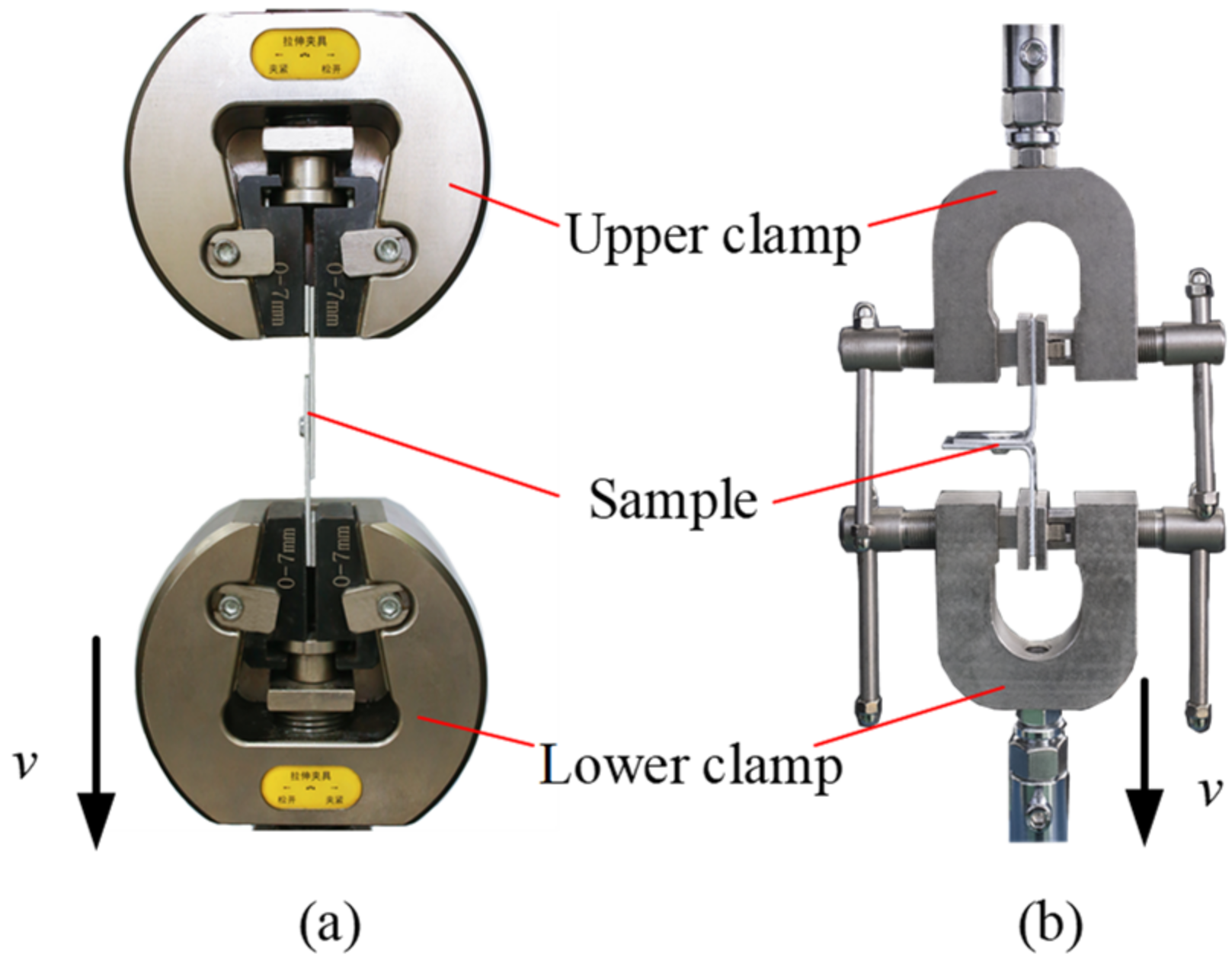

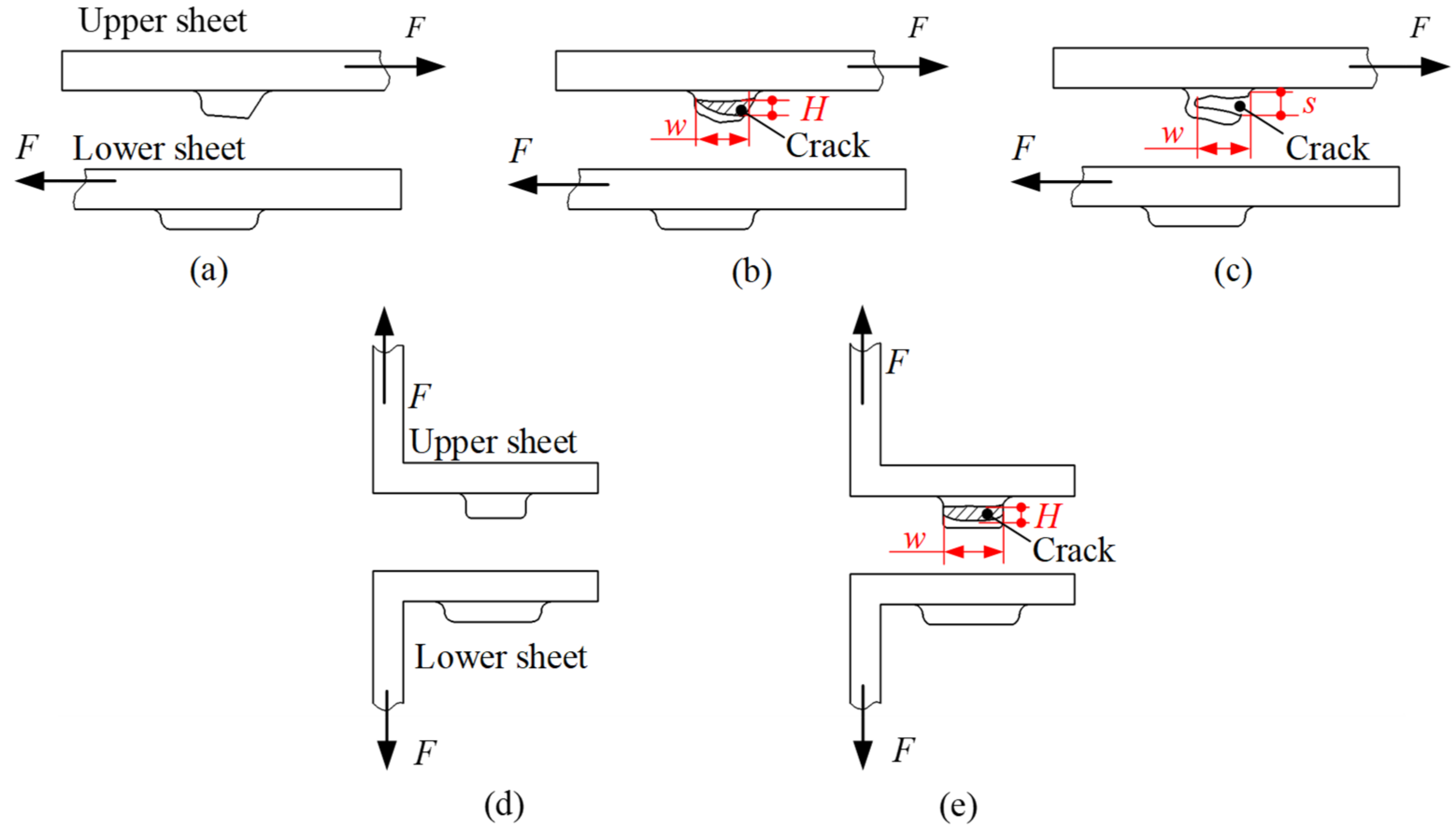

3.2. Shear and Peel Tests

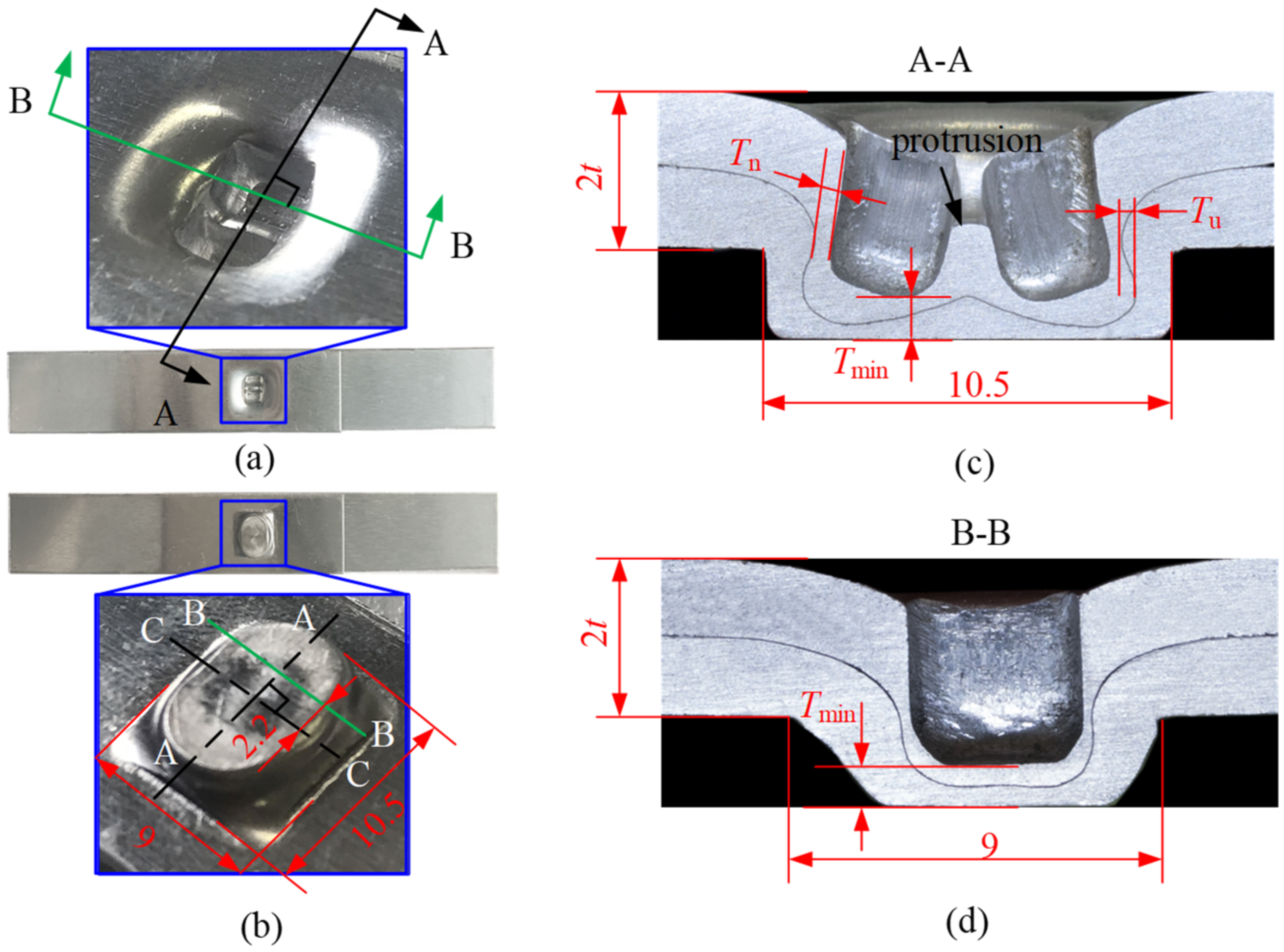

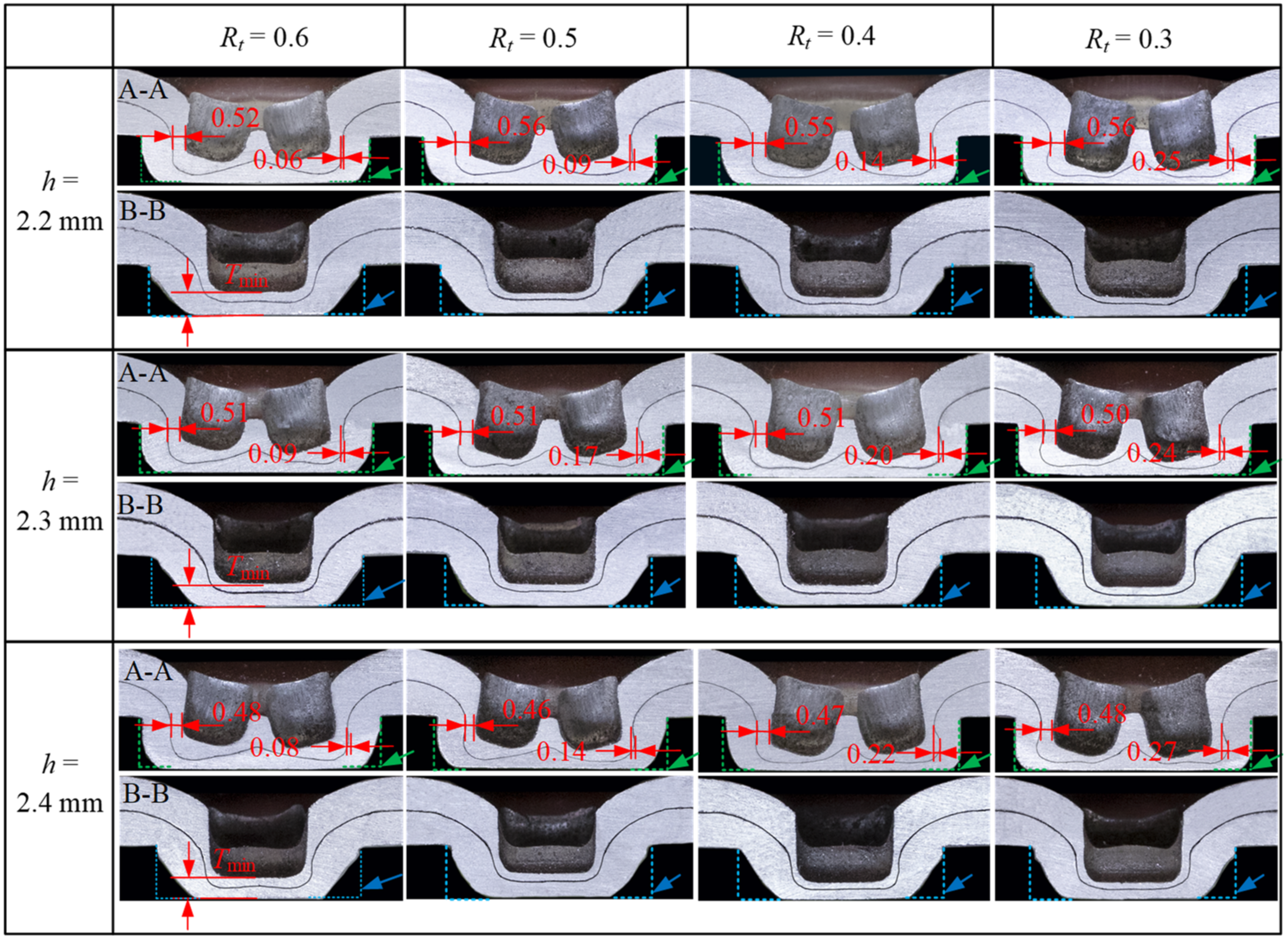

3.3. Dimensions of Cross-Sectional Profile

3.4. Failure

4. Results and Discussion

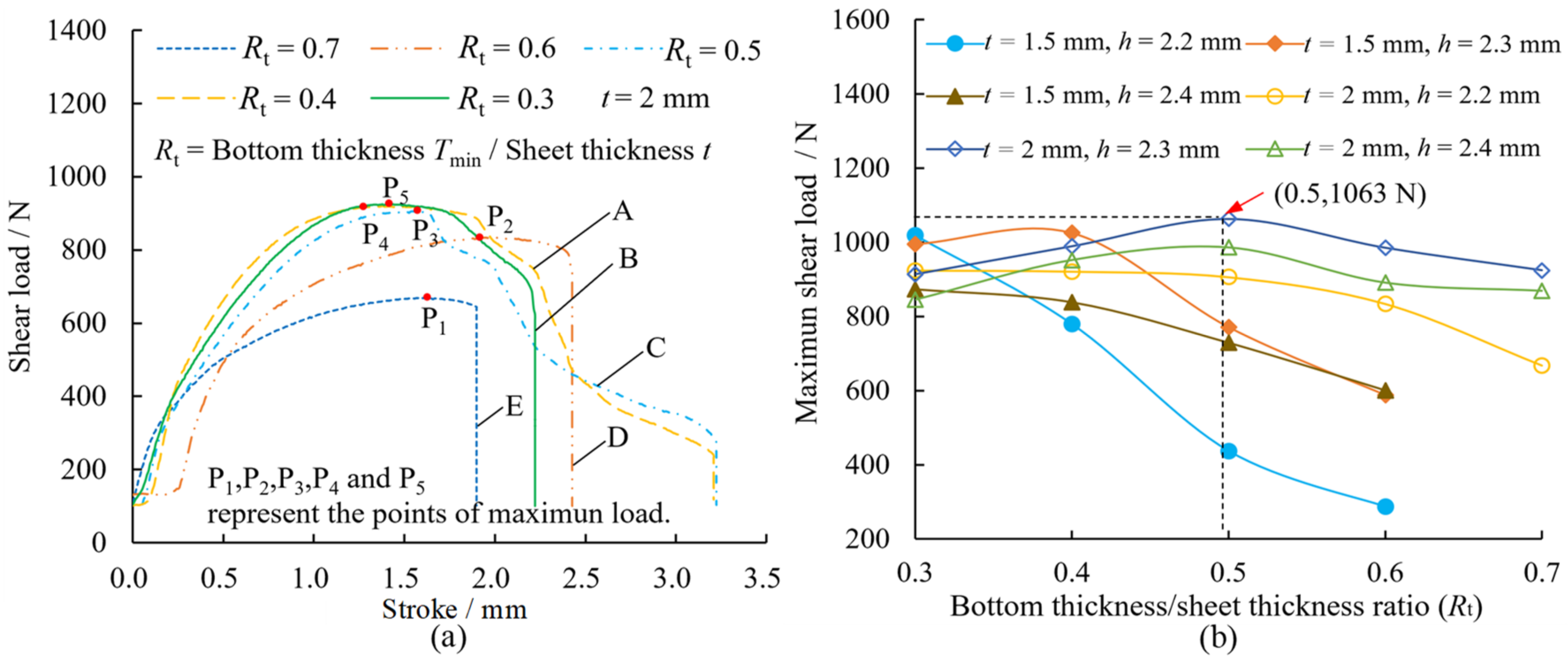

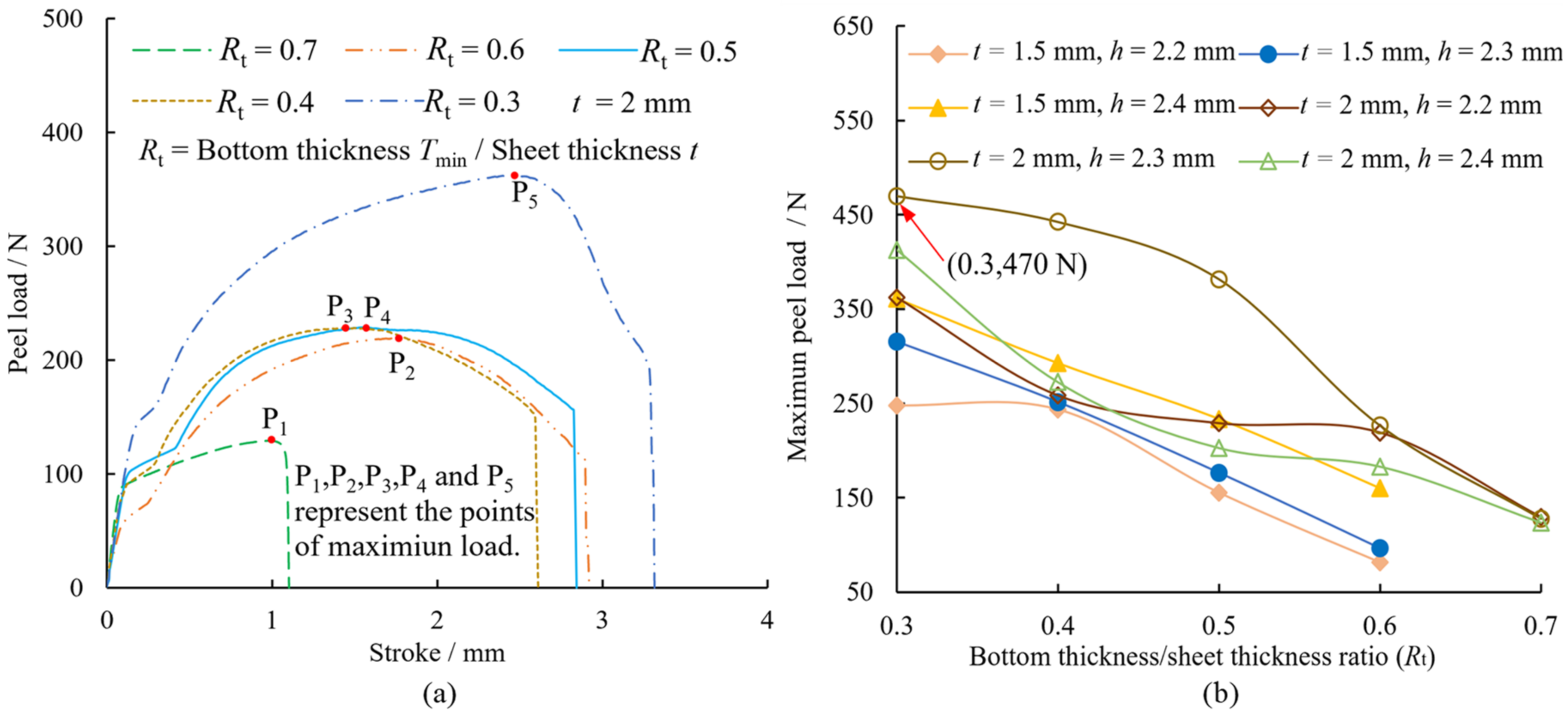

4.1. Evaluation by Shear and Peel Loads

4.2. Evaluation by Cross-Sectional Profile Dimension

4.3. Evaluation by Failure Mode

5. Conclusions

- (1)

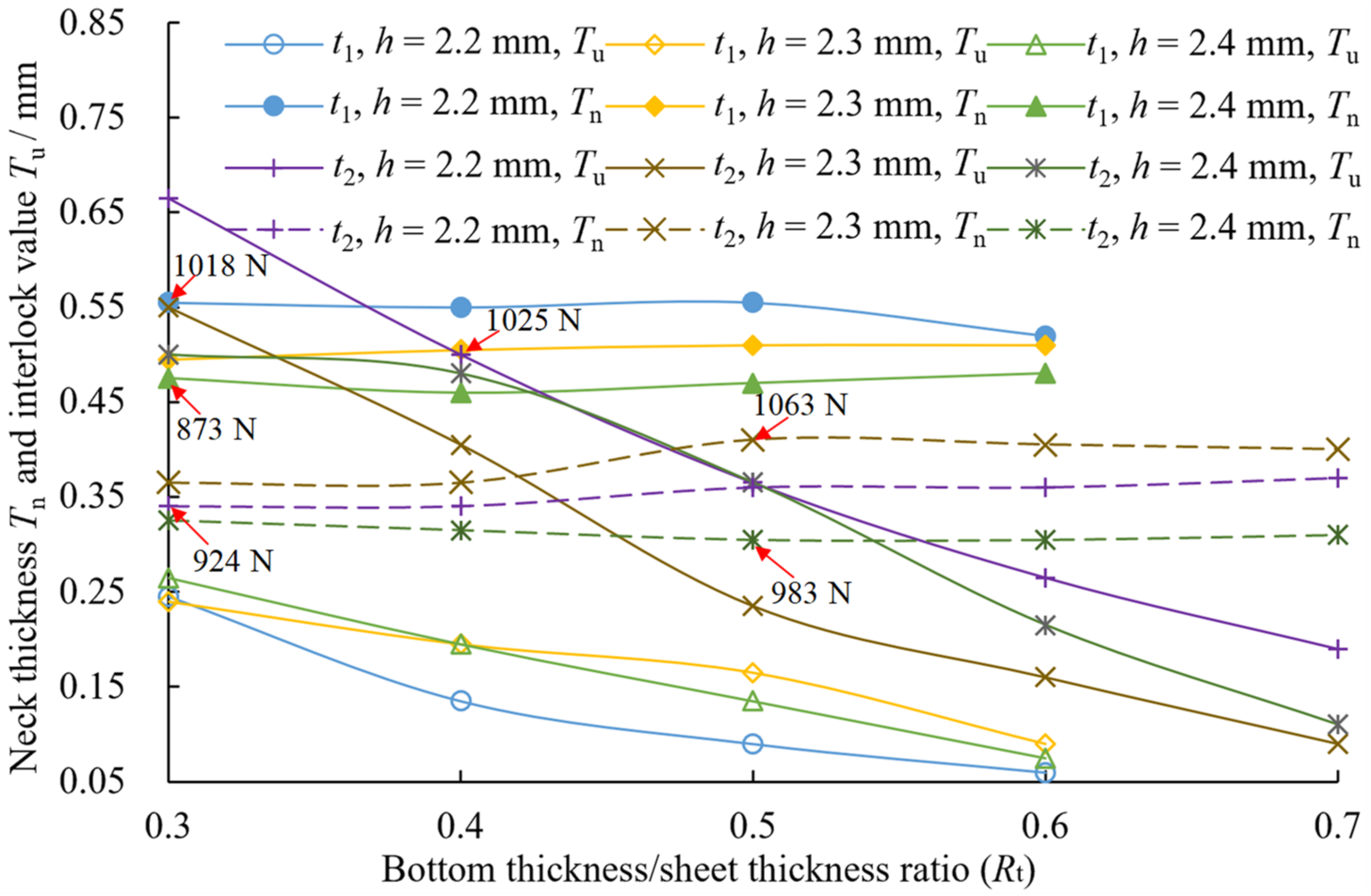

- The joints with sheet thickness of 1.5 mm and 2 mm obtained higher shear strengths at Rt = 0.3–0.4 and Rt = 0.3–0.6, respectively. The joints with a sheet thickness of 2 mm exhibited better shear strengths, reaching the maximum of 1063 N at h = 2.3 mm and Rt = 0.5. The peel strength increases with decreasing Rt, and when Rt = 0.3–0.5, the peel strength is higher. When h = 2.3 mm and Rt = 0.3, the peel strength of the joint with a sheet thickness of 2 mm reaches a maximum 470 N. The shear strengths are approximately 2–7 times the peel strength.

- (2)

- With decreasing Rt, the interlock value on the cross-sectional profile in the double-punch A-A direction increased significantly, while the interlock value on the cross-sectional profile in the single-punch B-B direction increased by only a little, and the neck thickness changes within a 6% error. The neck thickness of the joint of the thick sheet (t = 2 mm) was less than for the thin sheet (t = 1.5 mm), and the interlock value was reversed. The peel load is directly proportional to the interlock value, and the shear load is affected by both the neck thickness and the interlock value.

- (3)

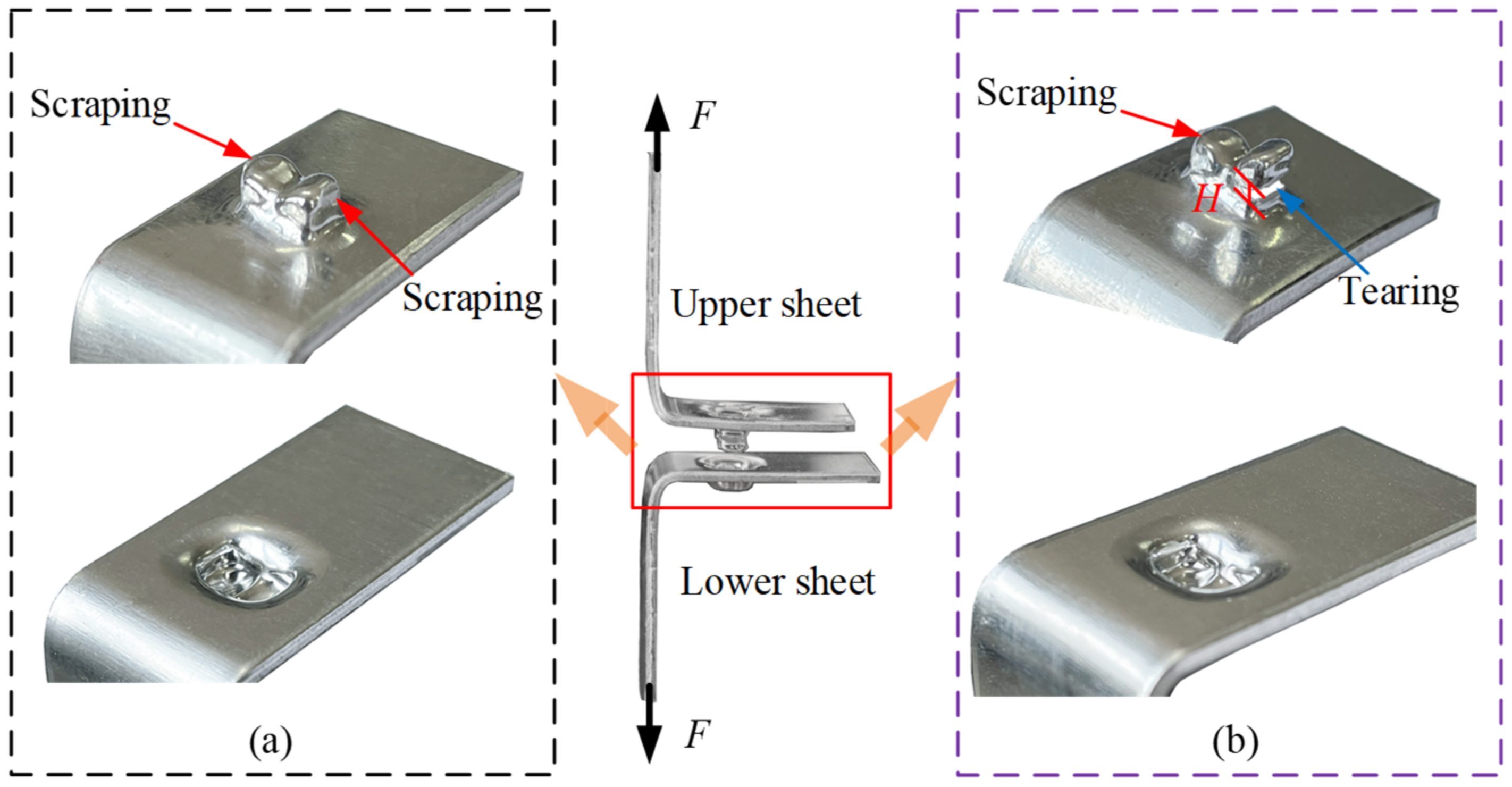

- There are three failure modes: unbuttoning, tearing, and shearing. In the peel tests, mainly unbuttoning occurs, while in the shear tests, mainly tearing and shearing failures were observed. When the ratio of the neck thickness to interlock value was ~0.6, the joints tend to fail by shearing. When the ratio is ~1, the joints were mainly torn. When the ratio >2, the joints tended to be unbuttoned. In the case of tear and shear failure, the joint strengths were higher.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moradi, M.; Meiabadi, M.S.; Demers, V. A numerical investigation of friction stir welding parameters in joining dissimilar aluminium alloys using finite element method. Int. J. Manuf. Res. 2021, 16, 32–51. [Google Scholar] [CrossRef]

- Vahdati, M.; Moradi, M.; Shamsborhan, M. Modeling and Optimization of the Yield Strength and Tensile Strength of Al7075 Butt Joint Produced by FSW and SFSW Using RSM and Desirability Function Method. Trans. Indian Inst. Met. 2020, 73, 2587–2600. [Google Scholar] [CrossRef]

- He, Y.L.; Yang, L.F.; Zong, P.J.; Dang, J.; Ma, J.P. Rotated clinching process for two-layer metallic sheets. Int. J. Adv. Manuf. Technol. 2022, 119, 3819–3831. [Google Scholar] [CrossRef]

- Carboni, M.; Beretta, S.; Monno, M. Fatigue behaviour of tensile-shear loaded clinched joints. Eng. Fract. Mech. 2006, 73, 178–190. [Google Scholar] [CrossRef]

- Abe, Y.; Saito, T.; Mori, K.I.; Kato, T. Mechanical clinching with dies for control of metal flow of ultra-high-strength steel and high-strength steel sheets. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 644–649. [Google Scholar] [CrossRef]

- Mori, K.; Abe, Y.; Kato, T. Mechanism of superiority of fatigue strength for aluminum alloy sheets joined by mechanical clinching and self-pierce riveting. J. Mater. Process. Technol. 2012, 212, 1811–1988. [Google Scholar] [CrossRef]

- Su, Z.M.; Lin, P.C.; Lai, W.J.; Pan, J. Fatigue analyses of self-piercing rivets and clinch joints in lap-shear specimens of aluminum sheets. Int. J. Fatigue 2015, 72, 53–65. [Google Scholar] [CrossRef]

- Lambiase, F. Influence of process parameters in mechanical clinching with extensible dies. Int. J. Adv. Manuf. Technol. 2013, 66, 2123–2131. [Google Scholar] [CrossRef]

- Wen, T.; Wang, H.; Yang, C.; Liu, L.T. On a reshaping method of clinched joints to reduce the protrusion height. Int. J. Adv. Manuf. Technol. 2014, 71, 1709–1715. [Google Scholar] [CrossRef]

- Zhao, S.; Xu, F.; Tohru, I.; Chao, C.; Zhao, X.; Han, X. Comparative study on two compressing methods of clinched joints with dissimilar aluminum alloy sheets. Int. J. Adv. Manuf. Technol. 2017, 93, 1929–1937. [Google Scholar]

- Li, Q.; Xu, C.; Gao, S.; Han, X.; Ma, F.; Gu, D.; Zhao, Q. Research on the forming quality of clinched joint for dissimilar sheet metal. Int. J. Adv. Manuf. Technol. 2022, 119, 2945–2959. [Google Scholar] [CrossRef]

- Jiang, T.; Liu, Z.X.; Wang, P.C. Quality inspection of clinched joints of steel and aluminum. Int. J. Adv. Manuf. Technol. 2015, 76, 1393–1402. [Google Scholar] [CrossRef]

- He, X.C.; Zhao, L.; Yang, H.Y.; Xing, B.Y.; Wang, Y.Q.; Deng, C.J.; Gu, F.S.; Ball, A. Investigations of strength and energy absorption of clinched joints. Comp. Mater. Sci. 2014, 94, 58–65. [Google Scholar] [CrossRef] [Green Version]

- Ran, X.; Chen, C.; Zhang, H.; Ouyang, Y. Investigation of the clinching process with rectangle punch. Thin Wall Struct. 2021, 166, 108034. [Google Scholar] [CrossRef]

- Peng, H.; Chen, C.; Li, H.; Gao, X. Joining thin-walled structures without protuberance by two-strokes flattening clinching process. Int. J. Adv. Manuf. Technol. 2021, 116, 1213–1223. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, J.M.; Lee, S.H.; Kim, B.H.; Kim, B.M.; Ko, D.C. Design of hole-clinching process for joining CFRP and aluminum alloy sheet. Int. J. Precis. Eng. Man. 2014, 15, 1151–1157. [Google Scholar] [CrossRef]

- Liu, Y.; Zhuang, W.M.; Wu, S.J. Effects of hole diameter and ply angle on the mechanical behaviour of hole-clinched joints in carbon fibre reinforced polymers and aluminum alloy sheets. Int. J. Adv. Manuf. Technol. 2020, 106, 5345–5352. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, H.Y.; Qin, D.L. Joining different aluminum alloy sheets by flat clinching process. Int. J. Adv. Manuf. Technol. 2021, 116, 1071–1079. [Google Scholar] [CrossRef]

- Chen, C.; Ouyang, Y.W.; Qin, D.L. Finite element analysis of material flow in flat-rivet clinching process. Int. J. Adv. Manuf. Technol. 2021, 116, 1961–1974. [Google Scholar] [CrossRef]

- Babalo, V.; Fazli, A.; Soltanpour, M. Experimental study of the mechanical performance of the new highspeed mechanical clinching. Int. J. Lightweight Mater. Manuf. 2021, 4, 218–236. [Google Scholar]

- Zhao, L.; He, X.C.; Lu, Y. Research of mechanical behavior for rounded and rectangular clinched joint. Adv. Mat. Res. 2014, 1035, 144–148. [Google Scholar] [CrossRef]

- Aris, J.V. Ensuring the integrity in clinching process. J. Mater. Process. Technol. 2006, 174, 277–285. [Google Scholar] [CrossRef]

- Carboni, M.; Annoni, M. Ultrasonic metal welding of AA6022-T4 lap joints: Part II—Fatigue behaviour, failure analysis and modelling. Sci. Technol. Weld. Join. 2013, 16, 116–125. [Google Scholar] [CrossRef]

| Rt | h = 2.2 mm | h = 2.3 mm | h = 2.4 mm | |||

|---|---|---|---|---|---|---|

| Max. Stroke t = 1.5/t = 2 | Stroke at Max. Load t = 1.5/t = 2 | Max. Stroke t = 1.5/t = 2 | Stroke at Max. Load t = 1.5/t = 2 | Max. Stroke t = 1.5/t = 2 | Stroke at Max. Load t = 1.5/t = 2 | |

| 0.3 | 3.22/2.39 | 1.46/1.38 | 3.83/2.61 | 2.63/1.84 | 2.5/1.72 | 1.40/0.74 |

| 0.4 | 1.87/3.21 | 1.43/1.38 | 3.87/2.42 | 2.14/2.22 | 2.43/2.67 | 1.78/1.04 |

| 0.5 | 1.21/3.22 | 1.07/1.55 | 2.61/3.35 | 1.54/1.90 | 1.97/2.67 | 1.42/1.48 |

| 0.6 | 0.41/2.43 | 0.19/1.96 | 1.56/3.69 | 1.78/2.81 | 1.03/3.50 | 1.18/1.85 |

| 0.7 | ―/1.9 | ―/1.62 | ―/3.48 | ―/2.14 | ―/3.07 | ―/2.18 |

| Rt | h = 2.2 mm | h = 2.3 mm | h = 2.4 mm | |||

|---|---|---|---|---|---|---|

| Max. Stroke t = 1.5/t = 2 | Stroke at Max. Load t = 1.5/t = 2 | Max. Stroke t = 1.5/t = 2 | Stroke at Max. Load t = 1.5/t = 2 | Max. Stroke t = 1.5/t = 2 | Stroke at Max. Load t = 1.5/t = 2 | |

| 0.3 | 3.76/3.32 | 2.96/2.44 | 4.14/8.65 | 3.53/6.73 | 8.24/4.54 | 7.20/3.29 |

| 0.4 | 3.60/2.61 | 2.71/1.46 | 3.89/7.29 | 3.08/5.77 | 4.65/3.79 | 3.29/2.37 |

| 0.5 | 2.85/2.84 | 2.05/1.54 | 2.78/7.24 | 2.13/5.44 | 4.08/3.49 | 3.46/1.81 |

| 0.6 | 2.19/2.92 | 1.23/1.74 | 1.92/6.60 | 1.10/4.9 | 2.49/3.15 | 1.95/1.58 |

| 0.7 | ―/1.1 | ―/0.98 | ―/2.87 | ―/1.79 | ―/2.69 | ―/1.36 |

| Sheet Thickness /mm | Die Depth /mm | Sample Number | Peel Test/Shear Test | |||

|---|---|---|---|---|---|---|

| Unbuttoning | Single-Punch Tearing | Double-Punch Tearing | Shearing | |||

| 1.5 | 2.2 | 12 | 12/12 | NA/NA | NA/NA | NA/NA |

| 2.3 | 12 | 12/9 | NA/3 | NA/NA | NA/NA | |

| 2.4 | 12 | 9/9 | 3/3 | NA/NA | NA/NA | |

| 2 | 2.2 | 15 | 15/3 | NA/3 | NA/9 | NA/NA |

| 2.3 | 15 | 12/NA | 3/3 | NA/NA | NA/12 | |

| 2.4 | 15 | 9/NA | 6/6 | NA/NA | NA/9 | |

| Rt | h = 2.2 mm/h = 2.3 mm/h = 2.4 mm | ||

|---|---|---|---|

| Shear Loads/N | Crack Dimensions/mm | Failure Types | |

| 0.3 | 924/913/845 | 3.2/2.40/3.32 | □/▽/▽ |

| 0.4 | 921/968/952 | 2.9/3.58/3.54 | □/▽/▽ |

| 0.5 | 906/1063/986 | 1.9/4.72/3.58 | □/▽/▽ |

| 0.6 | 834/989/891 | 1.7/3.62/3.52 | ▲/▽/▲ |

| 0.7 | 668/924/859 | 0/2.80/2.48 | ○/▲/▲ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Yang, L.; Dang, J.; Gao, A.; Zhang, W. Evaluation of Shear and Peel Strength of Al1060 Single-Lap and T-Lap Joints Produced by Rotated Clinching Process with Twin Rotating Punches. Materials 2022, 15, 4237. https://doi.org/10.3390/ma15124237

He Y, Yang L, Dang J, Gao A, Zhang W. Evaluation of Shear and Peel Strength of Al1060 Single-Lap and T-Lap Joints Produced by Rotated Clinching Process with Twin Rotating Punches. Materials. 2022; 15(12):4237. https://doi.org/10.3390/ma15124237

Chicago/Turabian StyleHe, Yulin, Lianfa Yang, Jing Dang, Aliang Gao, and Wenze Zhang. 2022. "Evaluation of Shear and Peel Strength of Al1060 Single-Lap and T-Lap Joints Produced by Rotated Clinching Process with Twin Rotating Punches" Materials 15, no. 12: 4237. https://doi.org/10.3390/ma15124237