Study on Toughening and Temperature Sensitivity of Polyurethane Cement (PUC)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. PUC Composite

2.1.2. Fiber

2.2. Test Block Preparation and Mix Ratio

2.3. Test Method

3. Experimental Results and Analysis

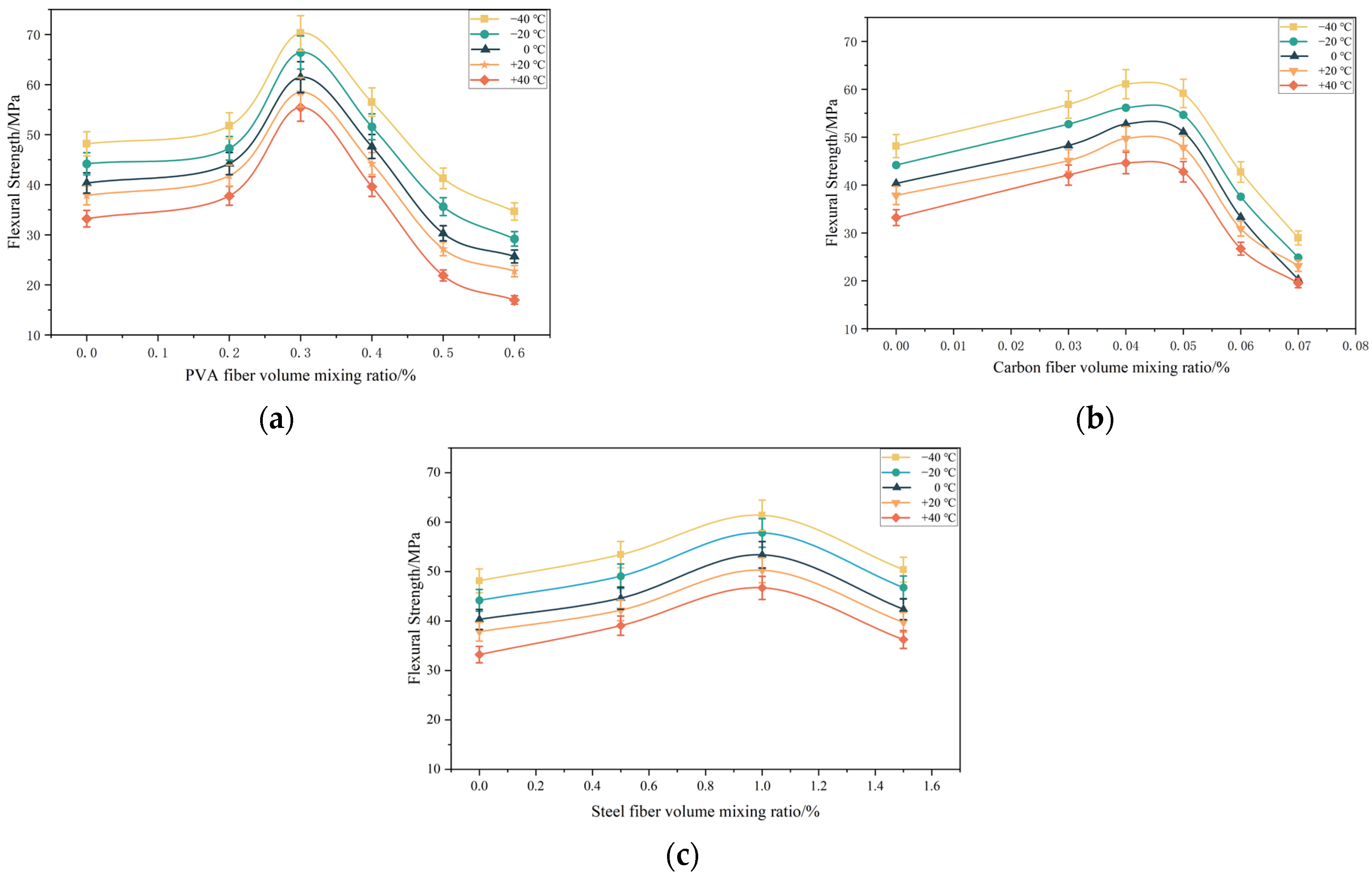

3.1. Flexural Strength—Fiber Volume-Mixing Ratio Curve

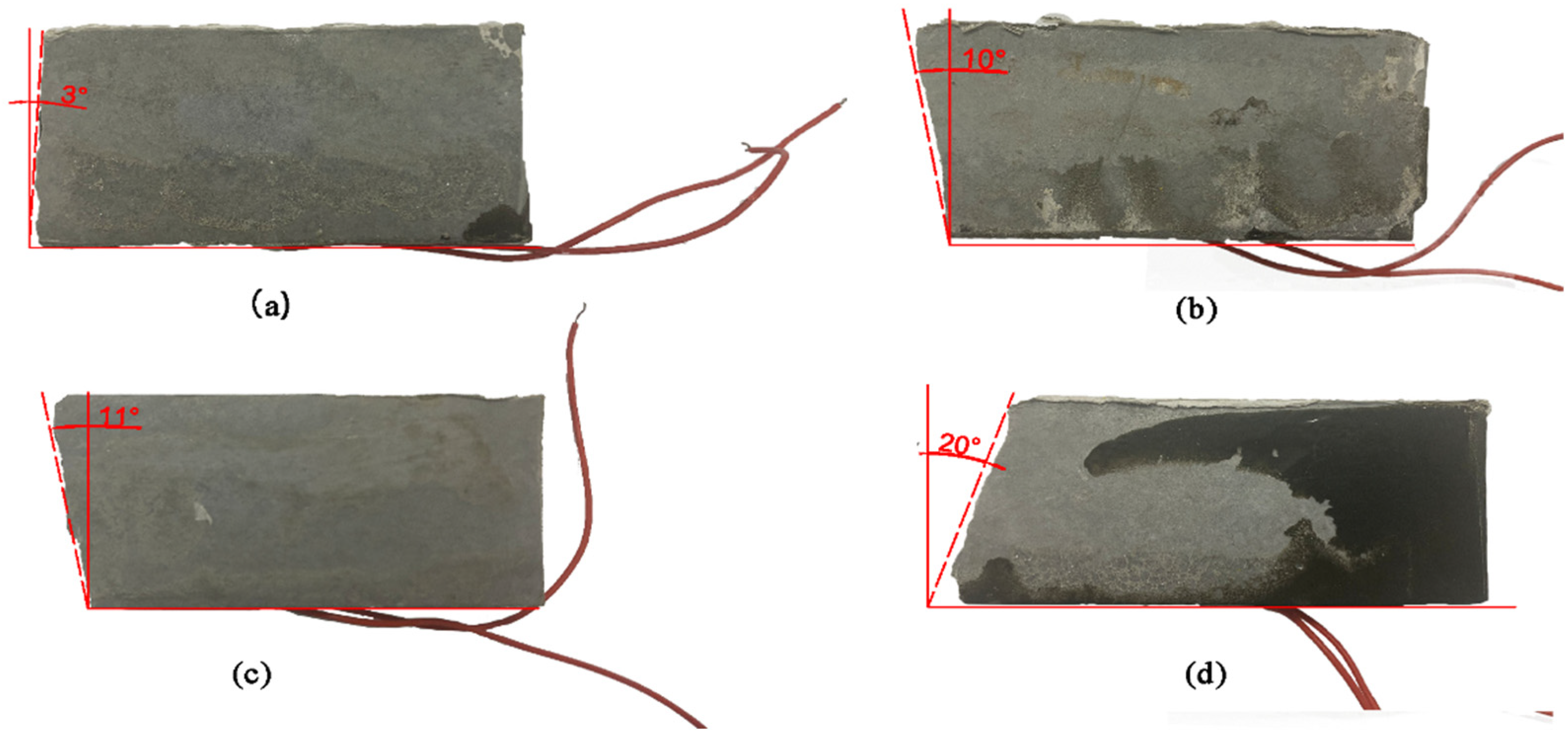

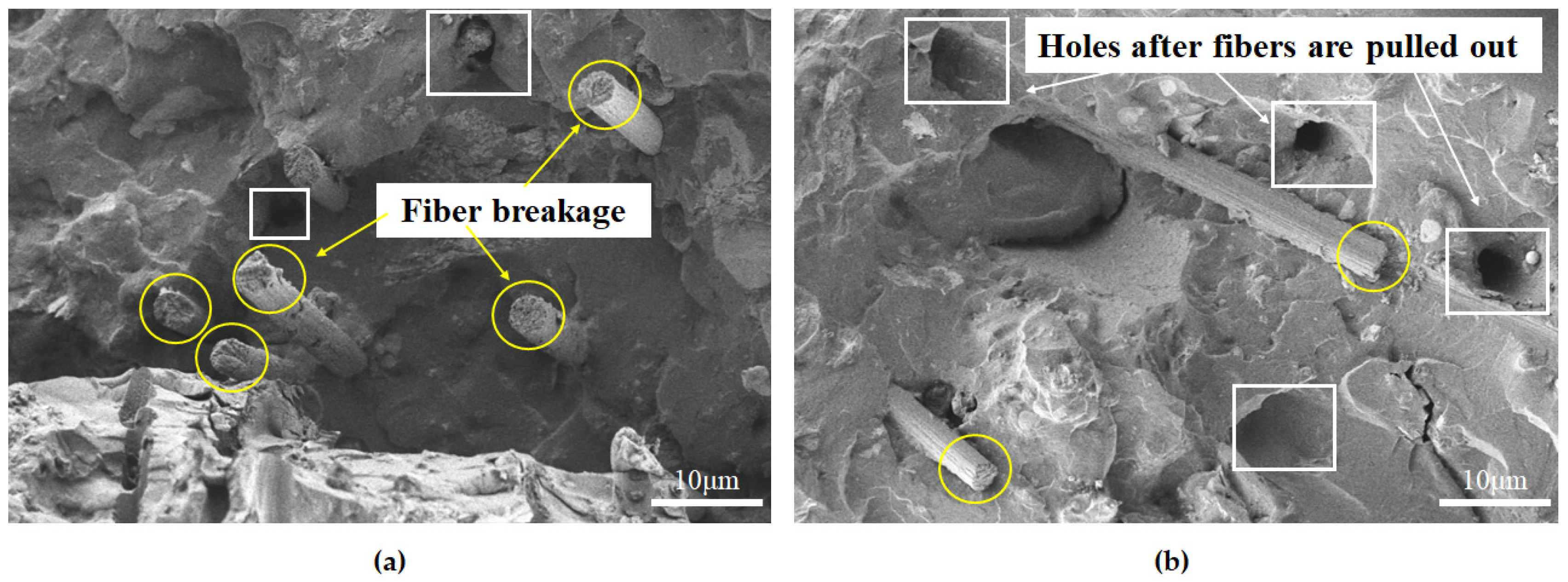

3.2. Fiber-Toughening Mechanism and Specimen Failure Mode

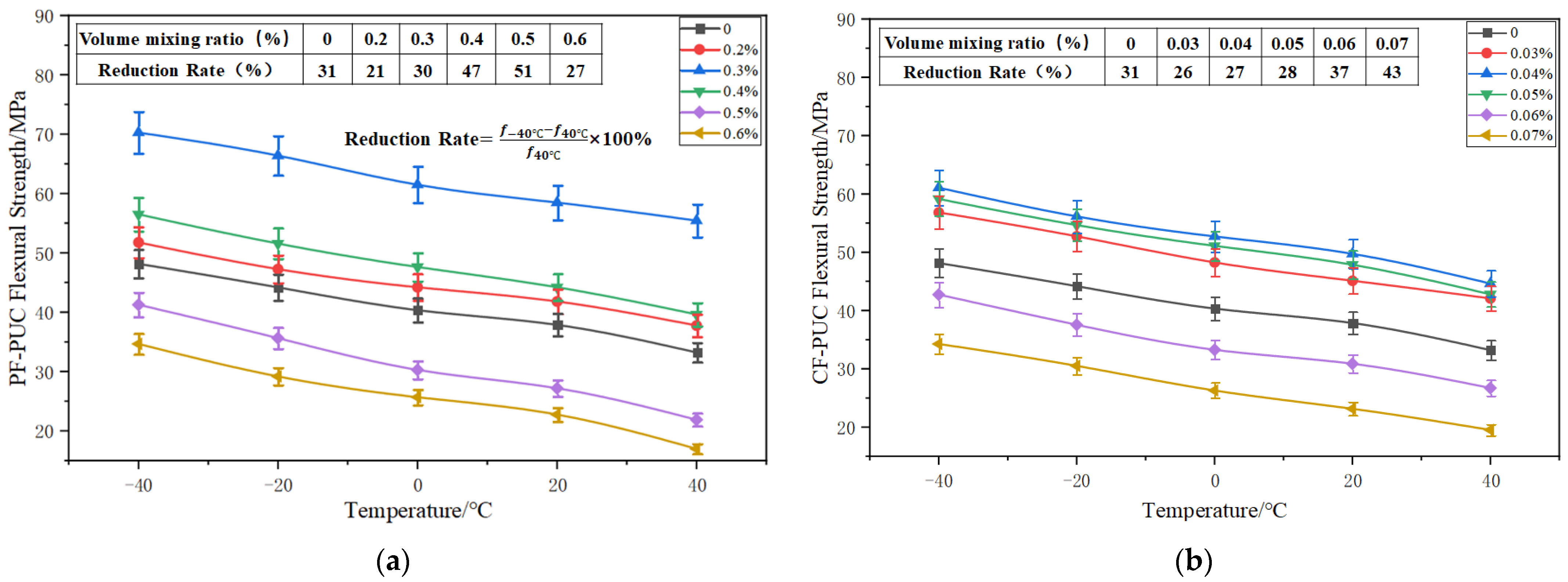

3.3. Flexural Strength–Temperature Curve

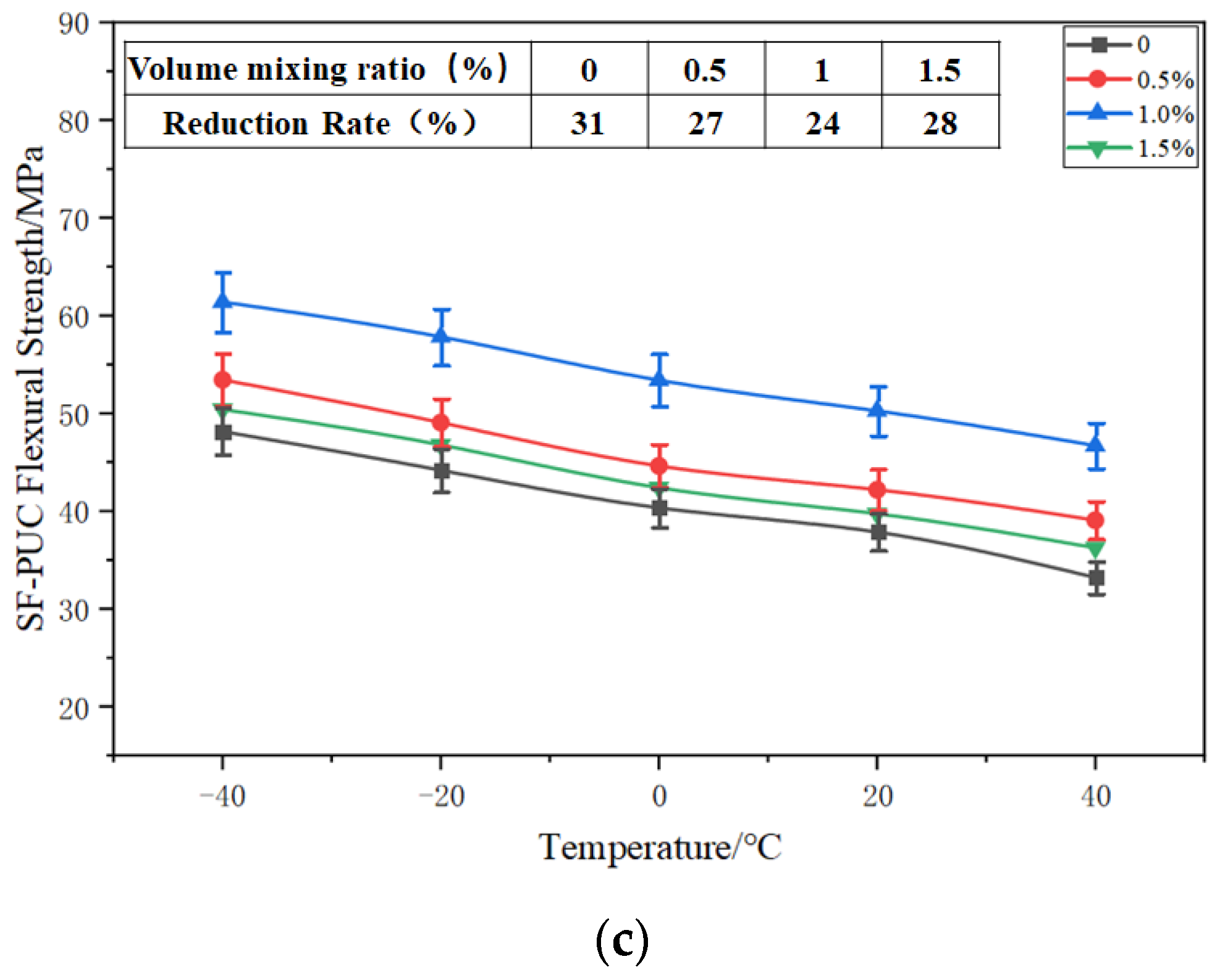

3.4. PUC Temperature Sensitivity Analysis

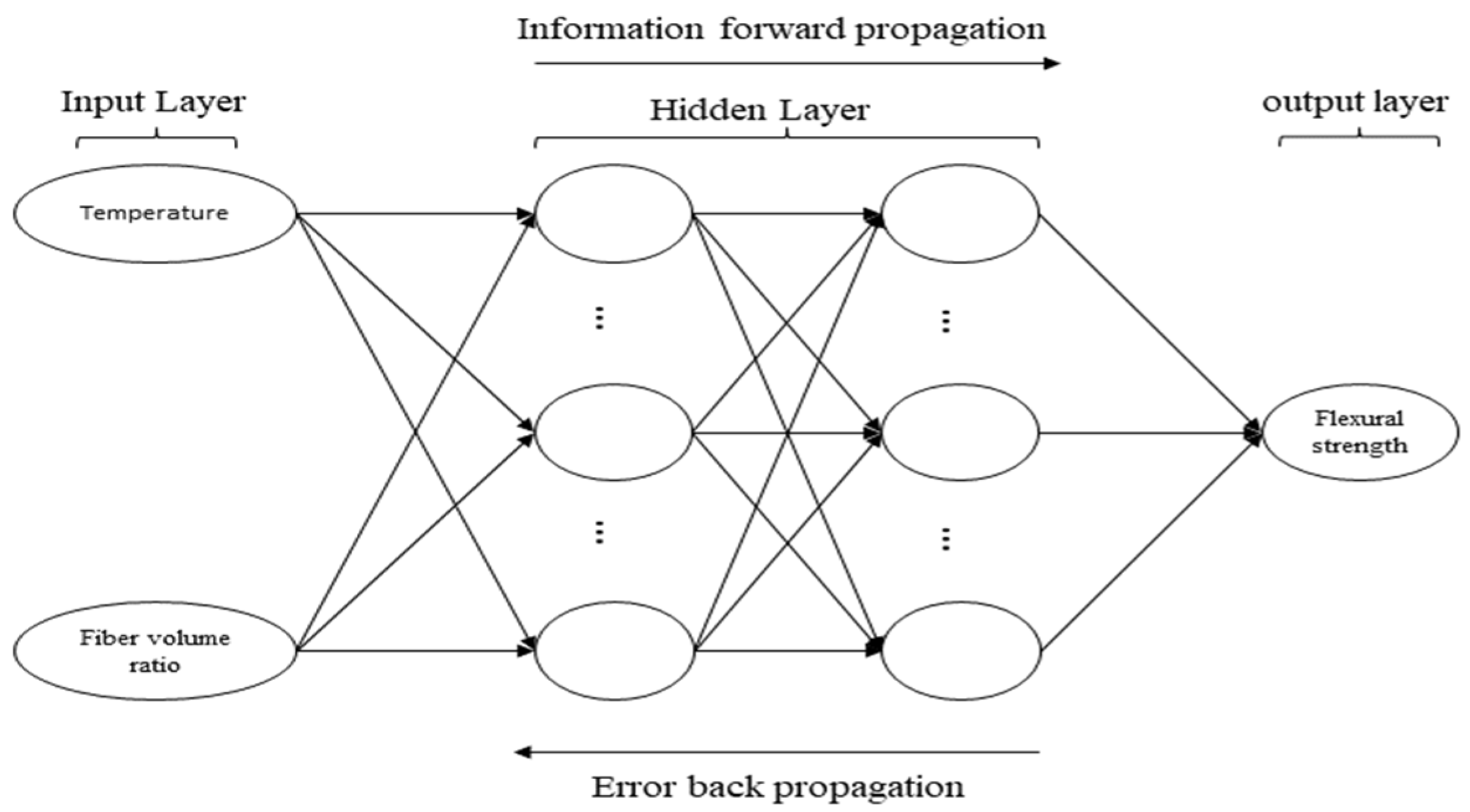

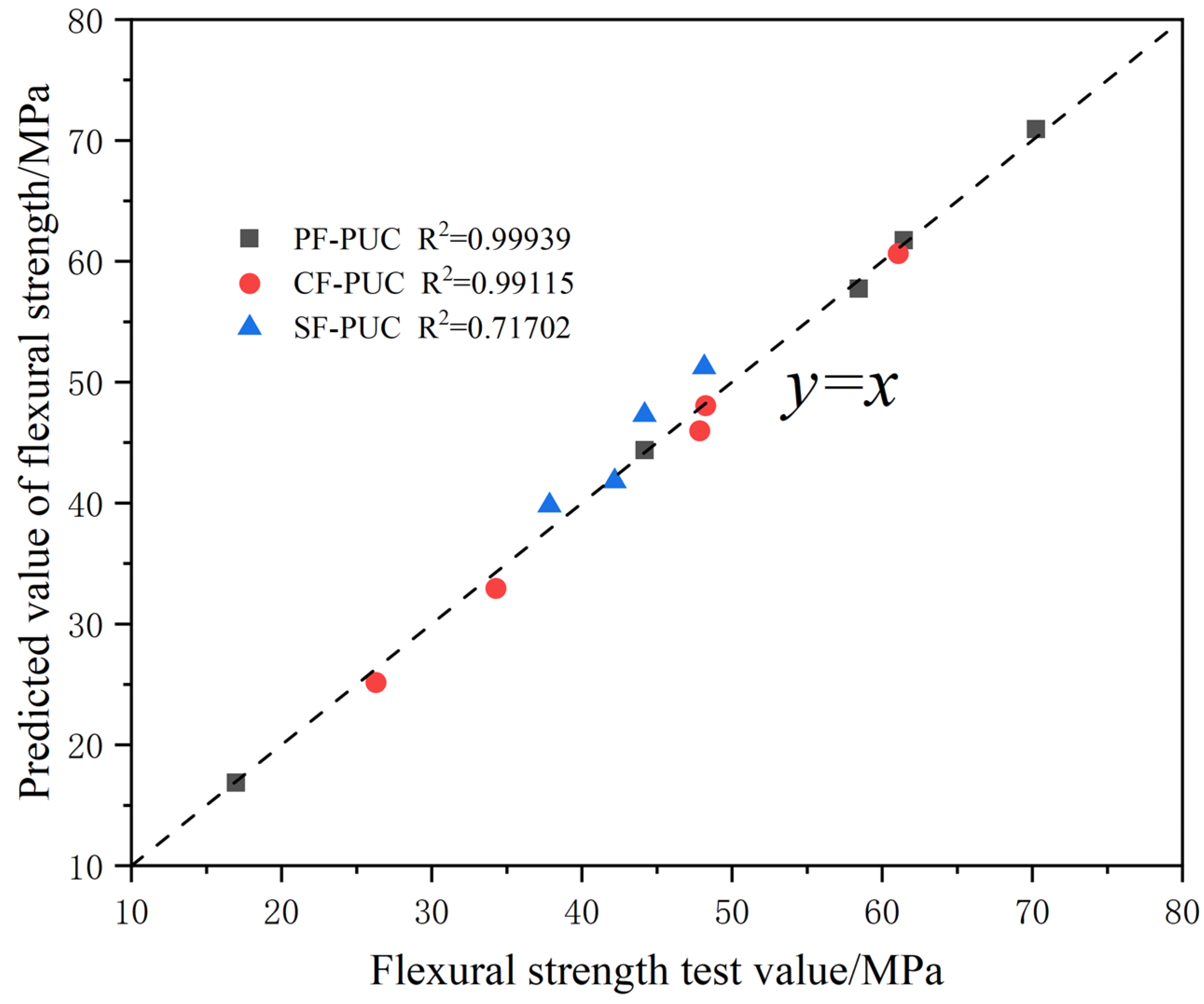

3.5. Prediction Model Based on BP Neural Network

4. Conclusions

- The three fibers can significantly improve the toughness of PUC. With the increase in three kinds of fiber reinforcement, the flexural strength of the composite at each temperature first increased and then decreased. The incorporation of excess fiber can affect workability and adversely affect the mechanical properties. The best volume-doping ratios of PVA fiber, carbon fiber, and steel fiber were determined by the tests as 0.3%, 0.04%, and 1.0%, respectively. This suggests that the incorporation of fiber to enhance PUC is a feasible approach.

- PVA fiber has a more obvious increase in the flexural strength of PUC, up to 58.5 MPa at room temperature. Under optimal doping, the ultimate micro-strain of PF-PUC and CF-PUC specimens is smaller, and the specimen stiffness is larger; moreover, the ultimate micro-strain of SF-PUC specimens is larger, and the toughening effect is more obvious. In actual engineering, it is recommended to use PVA fibers for reinforcement scenarios that seek to increase bearing capacity, and steel fibers for reinforcement scenarios that seek to increase deformation capacity.

- Temperature has a great influence on the flexural strength of PUC, and the flexural strength decreases by an average of 30% when the temperature is between −40 °C and +40 °C. The flexural strength of PUC with and without three kinds of fibers is inversely related to the temperature. This shows that the temperature sensitivity of PUC flexural strength is mainly determined by the polyurethane material itself, and the type and dosing of fibers have less influence on it. The temperature factor should be taken into account when applying PUC to the reinforcement of old bridges to avoid hazards.

- The established two-factor (fiber content and temperature) BP neural network flexural strength prediction model can predict the flexural strength of PUC under different mixing ratios with high accuracy. The predictive model reduces the cost of the test process to improve efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, K.; Sun, Q. Strengthening of a Reinforced Concrete Bridge with Polyurethane-cement Composite (PUC). Open Civ. Eng. J. 2016, 10, 768–781. [Google Scholar]

- Zhang, K.; Qi, T.; Zhu, Z.; Xue, X. Study on reinforcement of fabricated hollow slab bridge by polyurethane-cement composite (PUC). Stavební Obz.—Civ. Eng. J. 2021, 30, 2. [Google Scholar] [CrossRef]

- Hongxiang, Z.; Chao, C.; Tianlai, Y. The application of simply supported T beam strengthended by MPC. Low Temp. Archit. Technol. 2015, 3, 59–61. [Google Scholar]

- Zhang, K.; Sun, Q. Experimental Study of Reinforced Concrete T-Beams Strengthened with a Composite of Prestressed Steel Wire Ropes Embedded in Polyurethane Cement (PSWR–PUC). Int. J. Civ. Eng. 2017, 16, 1109–1123. [Google Scholar] [CrossRef]

- Zhang, K.; Sun, Q. The use of Wire Mesh-Polyurethane Cement (WM-PUC) composite to strengthen RC T-beams under flexure. J. Build. Eng. 2018, 15, 122–136. [Google Scholar] [CrossRef]

- Hussain, H.K.; Liu, G.W.; Yong, Y.W. Experimental study to investigate mechanical properties of new material polyurethane–cement composite (PUC). Constr. Build. Mater. 2014, 50, 200–208. [Google Scholar] [CrossRef]

- Hussain, H.K.; Zhanga, L.Z.; Liu, G.W. An experimental study on strengthening reinforced concrete T-beams using new material poly-urethane-cement (PUC). Constr. Build. Mater. 2013, 40, 104–117. [Google Scholar] [CrossRef]

- Hussain, H.K.; Zhanga, L.Z.; Liu, G.W. Study of Concrete Strain for T-Beams Retrofitting by Poly-Urethane-Cement Material (PUC). Res. J. Appl. Sci. Eng. Technol. 2013, 5, 2354–2359. [Google Scholar] [CrossRef]

- Liu, G.; Otsuka, H.; Mizuta, Y.; Shimitsu, A. A Foundational Study on Static MechanicalnCharacteristics of the Super Lightweight and High Strength Material Using Fly-ash. J. Soc. Mater. Sci. Jpn. 2006, 55, 738–745. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Tianyu, Q.; Zhimin, Z.; Xingwei, X.; Xinyuan, S. Strengthening of a Reinforced Concrete Bridge with a Composite of Prestressed Steel Wire Ropes Embedded in Polyurethane Cement. J. Perform. Constr. Facil. 2021, 35, 04021063. [Google Scholar] [CrossRef]

- Zkl, Y.O.; Aksoylu, C.; Arslan, M.H. Experimental and numerical investigations of steel fiber reinforced concrete dapped-end purlins. J. Build. Eng. 2021, 36, 102119. [Google Scholar]

- Jabbour, R.; Assaad, J.J.; Hamad, B. Cost-to-performance assessment of polyvinyl alcohol fibers in concrete structures. Mech. Adv. Mater. Struct. 2021, 1–20. [Google Scholar] [CrossRef]

- Yang, N.; Sun, Q.S. Experimental study on the mechanical properties of carbon fiber polyurethane cement composites. Polyurethane Ind. 2019, 34, 35–38. [Google Scholar]

- Gao, H.; Sun, Q. Study on Fatigue Test and Life Prediction of Polyurethane Cement Composite (PUC) under High or Low Temperature Conditions. Adv. Mater. Sci. Eng. 2020, 2020, 2398064. [Google Scholar] [CrossRef] [Green Version]

- Duan, Z.H.; Kou, S.C.; Poon, C.S. Using artificial neural networks for predicting the elastic modulus of recycled aggregate concrete. Constr. Build. Mater. 2013, 44, 524–532. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Zhu, H.; Li, C.; Yuan, Y. Prediction model of mechanical properties of UHPC based on neural network. Conerete 2013, 3, 18–22. [Google Scholar]

- Huang, L.; Xie, G.; Zhao, W.; Zhao, W.; Gu, Y.; Huang, Y. Regional logistics demand forecasting: A BP neural network approach. Complex Intell. Syst. 2021, 1–16. [Google Scholar] [CrossRef]

- Liu, M.; Shi, J. A cellular automata traffic flow model combined with a BP neural network based microscopic lane changing decision model. J. Intell. Transp. Syst. 2019, 23, 309–318. [Google Scholar] [CrossRef]

- Tan, X.; Ji, Z.; Zhang, Y. Non-invasive continuous blood pressure measurement based on mean impact value method, BP neural network, and genetic algorithm. Technol. Health Care Off. J. Eur. Soc. Eng. Med. 2018, 26, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Li, J.Z.; Yong, H.E. Application of optimized grey discrete Verhulst–BP neural network model in settlement prediction of foundation pit. Environ. Earth Sci. 2019, 78, 441. [Google Scholar] [CrossRef]

- Bonart, R.J. Macromolecular science reversearch. Macromol. Chem. Polym. Mater. 1970, C4, 313–336. [Google Scholar]

- Chen, C.; Dai, S.; Chang, H.; Chang, H.; Su, W. Polyurethane elastomers through multi-hydrogen-bonded association of dendritic structures. Polymer 2005, 46, 11849–11857. [Google Scholar] [CrossRef]

- Tereshatov, V.V.; Makarova, M.A.; Senichev, V.Y.; Volkova, E.R.; Vnutskikh, Z.A.; Slobodinyuk, A.L. The role of the soft phase in the hardening effect and the rate de-pendence of the ultimate physico-mechanical properties of urethane-containing segmented elastomers. Colloid Polym. Sci. 2015, 239, 153–164. [Google Scholar] [CrossRef]

- Charlon, M.; Heinrich, B.; Matter, Y.; Couzigne, E.; Donnio, B.; Avérous, L. Synthesis structure and properties of fully biobased thermoplastic polyure-thanes, obtained from a diisocyanate based on modified dimer fatty acids, and different renewable diols. Eur. Polym. J. 2014, 61, 197–205. [Google Scholar] [CrossRef]

- Guo, X.; Li, P.; Shi, H.; Zhang, B.; Mao, Z.; Yao, W. Hydrogen Bonding between Soft and Hard Segments in Polyether Polyurethane. Polyurethane Ind. 2016, 31, 9–12. [Google Scholar] [CrossRef]

- Rahman, M.M.; Kim, H.D.; Lee, W.K. Properties of water-borne polyurethane adhesives:Effect of chain extender and polyol content. J. Adhes. Sci. Technol. 2009, 23, 177–193. [Google Scholar] [CrossRef]

- Yang, C.Z.G.; Grasel, T.G.; Bell, J.L.; Register, R.A.; Cooper, S.L. Carboxylate-containing chain-extended polyurethanes. J. Polym. Sci. (Part B) Polym. Phys. 2003, 29, 581–588. [Google Scholar] [CrossRef]

| Ingredients | Cement | Isocyanate | Modified Polyether | Defoaming Agent |

|---|---|---|---|---|

| Percentage (%) | 33 | 33 | 33 | 1 |

| Fiber | Length (mm) | Diameter (μm) | Density (kg/m3) | Elastic Modulus (Gpa) | Ultimate Elongation (%) |

|---|---|---|---|---|---|

| PVA Fiber | 15 | 8 | 1290 | 35 | 6 |

| Carbon Fiber | 15 | 7 | 1750 | 260 | 1 |

| Steel Fiber | 15 | 200 | 7850 | 200 | 4 |

| Numbering | Fiber Volume Ratio (%) | Fiber Weight (kg/m3) | Flexural Strength (Mpa) | |||||

|---|---|---|---|---|---|---|---|---|

| −40 °C | −20 °C | 0 °C | +20 °C | +40 °C | ||||

| Control | / | / | / | 48.15 | 44.18 | 40.33 | 37.85 | 33.21 |

| PVA-fiber-reinforced PUC (PF-PUC) | A1 | 0.2% | 2.58 | 49.76 | 45.26 | 40.21 | 37.81 | 32.76 |

| A2 | 0.3% | 3.87 | 70.26 | 66.39 | 61.47 | 58.47 | 55.43 | |

| A3 | 0.4% | 5.16 | 56.48 | 51.57 | 47.62 | 44.21 | 39.62 | |

| A4 | 0.5% | 6.45 | 41.25 | 35.62 | 30.29 | 27.18 | 21.87 | |

| A5 | 0.6% | 7.74 | 34.65 | 29.18 | 25.67 | 22.74 | 16.98 | |

| Carbon-fiber-reinforced PUC (CF-PUC) | B1 | 0.03% | 0.53 | 56.82 | 52.73 | 48.25 | 45.12 | 42.09 |

| B2 | 0.04% | 0.70 | 61.07 | 56.15 | 52.72 | 49.73 | 44.62 | |

| B3 | 0.05% | 0.88 | 59.15 | 54.66 | 51.09 | 47.85 | 42.78 | |

| B4 | 0.06% | 1.05 | 42.73 | 37.57 | 33.28 | 30.87 | 26.72 | |

| B5 | 0.07% | 1.23 | 34.28 | 30.51 | 26.29 | 23.14 | 19.52 | |

| Steel fiber reinforced PUC (SF-PUC) | C1 | 0.5% | 39.25 | 53.43 | 49.07 | 44.62 | 42.18 | 39.06 |

| C2 | 1% | 78.50 | 61.39 | 57.82 | 53.39 | 50.26 | 46.71 | |

| C3 | 1.5% | 117.75 | 50.39 | 46.77 | 42.39 | 39.73 | 36.25 | |

| C4 | 2% | 157.00 | / | / | / | / | / | |

| C5 | 2.5% | 196.25 | / | / | / | / | / | |

| PF-PUC | CF-PUC | SF-PUC | |

|---|---|---|---|

| Relative error mean | 2.06% | 3% | 9% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, N.; Li, J.; Li, X.; Cui, Y.; Xiong, D.; Cui, X. Study on Toughening and Temperature Sensitivity of Polyurethane Cement (PUC). Materials 2022, 15, 4318. https://doi.org/10.3390/ma15124318

Hou N, Li J, Li X, Cui Y, Xiong D, Cui X. Study on Toughening and Temperature Sensitivity of Polyurethane Cement (PUC). Materials. 2022; 15(12):4318. https://doi.org/10.3390/ma15124318

Chicago/Turabian StyleHou, Ning, Jin Li, Xiang Li, Yongshu Cui, Dalu Xiong, and Xinzhuang Cui. 2022. "Study on Toughening and Temperature Sensitivity of Polyurethane Cement (PUC)" Materials 15, no. 12: 4318. https://doi.org/10.3390/ma15124318