The Use of Wood Pellets in the Production of High Quality Biocarbon Materials

Abstract

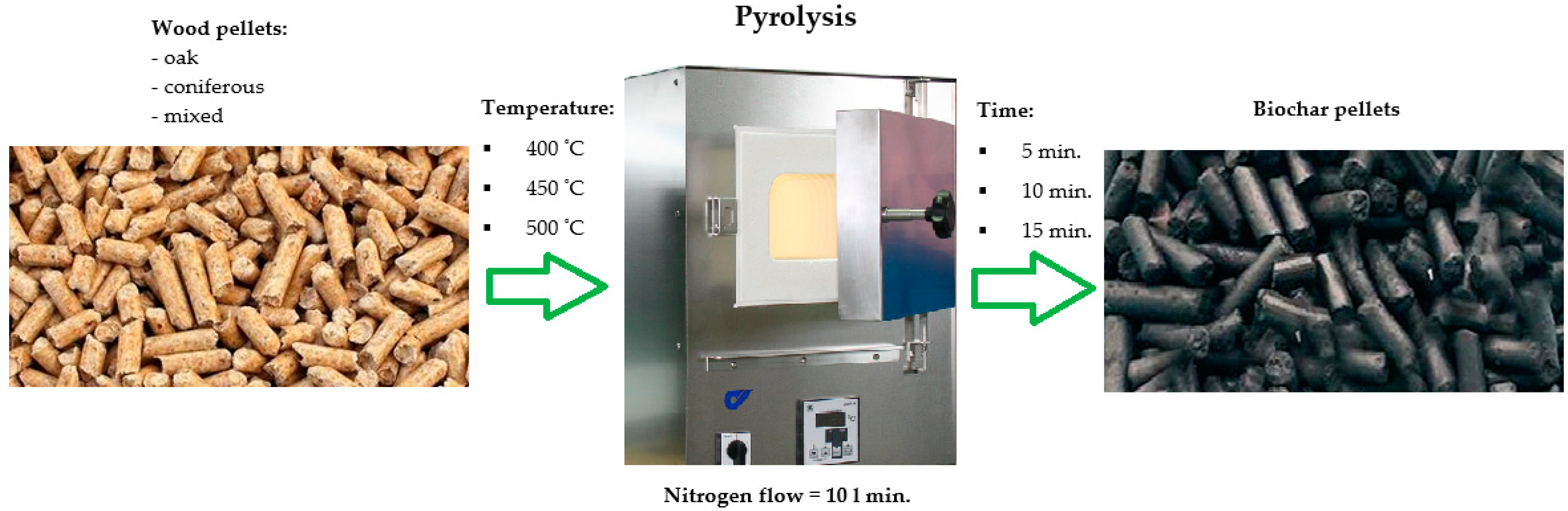

:1. Introduction

2. Materials and Methods

2.1. Research Object

- -

- oak sawdust pellet;

- -

- coniferous sawdust pellet;

- -

- mixed pellet, i.e., coniferous and deciduous (70% from coniferous sawdust, 30% from deciduous sawdust).

2.2. Pyrolysis Process

2.3. Analysis of Samples

2.4. Names of Tests

2.5. Statistical Analysis

3. Results

3.1. Oak Sawdust Pellets and Biocarbons

3.2. Coniferous Sawdust Pellets and Biocarbons

3.3. Mixed Sawdust Pellets and Biocarbons

3.4. Dust Explosion Parameters

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saletnik, B.; Zaguła, G.; Bajcar, M.; Tarapatskyy, M.; Bobula, G.; Puchalski, C. Biochar as a Multifunctional Component of the Environment. Review. Appl. Sci. 2019, 9, 1139. [Google Scholar] [CrossRef] [Green Version]

- Niedziółka, I.; Szpryngiel, M. Possibilities of using biomass for energy purposes. Agric. Eng. 2014, 1, 155–164. [Google Scholar]

- Retajczyk, M.; Wróblewska, A. Pyrolysis of biomass as a source of energy. Wiadomości Chem. Pol. Tow. Chem. 2018, 72, 127–146. [Google Scholar]

- Malińska, K. Biochar–A response to current environmental issues. Politech. Częstochowska Inst. Inżynierii Środowiska 2012, 15, 387–403. [Google Scholar]

- Civitarese, V.; Acampora, A.; Sperandio, G.; Assirelli, A.; Picchio, R. Production of Wood Pellets from Poplar Trees Managed as Coppices with Different Harvesting Cycles. Energies 2019, 12, 2973. [Google Scholar] [CrossRef] [Green Version]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Sánchez, J.; Curt, M.D.; Sanz, M.; Fernández, J. A proposal for pellet production from residual woody biomass in the island of Majorca (Spain). AIMS Energy 2015, 3, 480–504. [Google Scholar] [CrossRef] [Green Version]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Karkania, V.; Fanara, E.; Zabaniotou, A. Review of sustainable biomass pellets production—A study for agricultural residues pellets’ market in Greece. Renew. Sustain. Energy Rev. 2012, 16, 1426–1436. [Google Scholar] [CrossRef]

- Lamers, P.; Hoefnagels, R.; Junginger, M.; Hamelinck, C.; Faaij, A. Global solid biomass trade for energy by 2020: An assessment of potential import streams and supply costs to North-West Europe under diferent sustainability constraints. GCB Bioenergy 2015, 7, 618–634. [Google Scholar] [CrossRef] [Green Version]

- Sultana, A.; Kumar, A. Ranking of biomass pellets by integration of economic, environmental and technical factors. Biomass Bioenergy 2012, 39, 344–355. [Google Scholar] [CrossRef]

- Thrän, D.; Peetz, D.; Schaubach, K. Global Wood Pellet Industry and Trade Study 2017. Available online: http://task40.ieabioenergy.com/wp-content/uploads/2013/09/IEA-Wood-Pellet-Study_final-2017-06.pdf (accessed on 2 February 2022).

- Kamperidou, V. Quality Analysis of Commercially Available Wood Pellets and Correlations between Pellets Characteristics. Energies 2022, 15, 2865. [Google Scholar] [CrossRef]

- Niedziółka, I. Possibilities of using plant biomass for the production of briquettes and pellets. Wieś Jutra 2010, 8, 145–146. [Google Scholar]

- Obernberger, I.; Thek, G. The Pellet Handbook: The Production and Thermal Utilisation of Pellets; Earthscan: London, UK, 2010; p. 592. [Google Scholar]

- Duca, D.; Riva, G.; Foppa Pedretti, E.; Toscano, G. Wood pellet quality with respect to EN 14961-2 standard and certifications. Fuel 2014, 135, 9–14. [Google Scholar] [CrossRef]

- Sgarbossa, A.; Costa, C.; Menesatti, P.; Antonucci, F.; Pallottino, F.; Zanetti, M.; Grigolato, S.; Cavalli, R. Colorimetric patterns of wood pellets and their relations with quality and energy parameters. Fuel 2014, 137, 70–76. [Google Scholar] [CrossRef]

- Ginting, A.; Mawardi, I.; Jannifar, A.; Hasyim, S.; Razali Anzieb, M. Effectiveness of die hole on wood pellet density quality improvement. IOP Conf. Ser. Earth Environ. Sci. 2019, 268, 012166. [Google Scholar] [CrossRef]

- Szyszlak-Bargłowicz, J.; Zając, G.; Hawrot-Paw, M.; Koniuszy, A. Evaluation of the Quality of Wood Pellets Available on the Market. In Proceedings of the E3S Web of Conferences, Online, 9 June 2020; EDP Sciences: Lublin, Poland, 2020; Volume 171, p. 01015. [Google Scholar]

- Arshadi, M.; Gref, R.; Geladi, P.; Dahlqvist, S.-A.; Lestander, T. The influence of raw material characteristics on the industrial pelletizing process and pellet quality. Fuel Process. Technol. 2008, 89, 1442–1447. [Google Scholar] [CrossRef]

- Mroziński, A. Analysis of the structure of pellet machines for agglomeration of biomass for energy purposes. AEBIOM-Eur. Stow. Biomasy 2016, 10, 66–72. [Google Scholar]

- Alberici, S.; Boeve, S.; van Breevoort, P. Subsidies and Costs of EU Energy. European Commission. Available online: https://ec.europa.eu/energy/en/content/inal-report-ecofys (accessed on 3 February 2022).

- Saletnik, A.; Saletnik, B.; Puchalski, C. Modification of Energy Parameters in Wood Pellets with the Use of Waste Cooking Oil. Energies 2021, 14, 6486. [Google Scholar] [CrossRef]

- Kamińska, A. Method for Increasing the Calorific Value for Fragmented Wood Biomass; Publishing House Cracow University of Technology-Cracow University of Technology: Cracow, Poland, 2011; pp. 22–27. [Google Scholar]

- Kamperidou, V.; Lykidis, C.; Barmpoutis, P. Utilization of wood and bark of fast-growing hardwood species in energy production. J. For. Sci. 2018, 64, 164–170. [Google Scholar]

- Styks, J.; Wróbel, M.; Frączek, J.; Knapczyk, A. Effect of Compaction Pressure and Moisture Content on Quality Parameters of Perennial Biomass Pellets. Energies 2020, 13, 1859. [Google Scholar] [CrossRef] [Green Version]

- Pérez, J.; Melgar, A.; Nel Benjumea, P. Effect of operating and design parameters on the gasification/combustion process of waste biomass in fixed bed downdraft reactors: An experimental study. Fuel 2012, 96, 487–496. [Google Scholar] [CrossRef]

- Popovicheva, O.; Ivanov, A.; Vojtisek, M. Functional Factors of Biomass Burning Contribution to Spring Aerosol Composition in a Megacity: Combined FTIR-PCA Analyses. Atmosphere 2020, 11, 319. [Google Scholar] [CrossRef] [Green Version]

- Stelte, W.; Holm, J.; Sanadi, A.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef] [Green Version]

- Amyotte, P.R.; Eckhoff, R.K. Dust explosion causation, prevention and mitigation: An overview. J. Chem. Health Saf. 2010, 17, 15–28. [Google Scholar] [CrossRef]

- Müllerová, J. Health and Safety hazards of biomass storage. Section Renewable Energy Sources and Clean Technologies. In Proceedings of the 14th SGEM Geo Conference on Energy and Clean Technologies, Albena, Bulgaria, 17–26 June 2014. [Google Scholar]

- Dibble, C.J.; Shatova, T.A.; Jorgenson, J.L.; Stickel, J.J. Particle morphology characterization and manipulation in biomass slurries and the effect on rheological properties and enzymatic conversion. Biotechnol. Progr. 2011, 27, 1751–1759. [Google Scholar] [CrossRef] [PubMed]

- Haghighi Mood, S.; Hossein Golfeshan, A.; Tabatabaei, M.; Salehi Jouzani, G.; Hassan Najafi, G.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Amyotte, P.R. Some myths and realities about dust explosions. Process Saf. Environ. Prot. 2014, 92, 292–299. [Google Scholar] [CrossRef]

- Pak, S.; Jung, S.; Roh, C.; Kang, C. Case Studies for Dangerous Dust Explosions in South Korea during Recent Years. Sustainability 2019, 11, 4888. [Google Scholar] [CrossRef] [Green Version]

- Taveau, J. Secondary dust explosions: How to prevent them or mitigate their effects? Process Saf. Prog. 2012, 31, 36–50. [Google Scholar] [CrossRef]

- Kakitis, A.; Nulle, I. Electrostatic Biomass Mixing. Eng. Rural Dev. 2009, 8, 247–252. [Google Scholar]

- Jiang, H.; Bi, M.; Li, B.; Gan, B.; Gao, W. Combustion behaviors and temperature characteristics in pulverized biomass dust explosions. Renew. Energy 2018, 122, 45–54. [Google Scholar] [CrossRef]

- Slatter, D.J.F.; Sattar, H.; Medina, C.H.; Andrews, G.E.; Phylaktou, H.N.; Gibbs, B.M. Biomass explosion testing: Accounting for the post-test residue and implications on the results. J. Loss Prev. Proc. 2015, 36, 320–327. [Google Scholar] [CrossRef]

- Gao, W.; Mogi, T.; Yu, J.L.; Yan, X.Q.; Sun, J.H.; Dobashi, R. Flame propagation mechanisms in dust explosions. J. Loss Prev. Proc. 2015, 36, 188–196. [Google Scholar] [CrossRef]

- Liu, A.; Chen, J.; Lu, X.; Li, D.; Xu, W. Influence of components interaction on pyrolysis and explosion of biomass dust. Process Saf. Environ. Prot. 2021, 154, 384–392. [Google Scholar] [CrossRef]

- Yan, W.; Chen, Z.H.; Sheng, K.C. Carbonization temperature and time improving quality of charcoal briquettes. Trans. CSAE 2015, 31, 245–249. [Google Scholar]

- Zhou, C.; Zhang, Q.; Arnold, L.; Yang, W.; Blasiak, W. A study of the pyrolysis behaviors of pelletized recovered municipal solid waste fuels. Appl. Energy 2013, 107, 173–182. [Google Scholar] [CrossRef]

- Basu, P.; Rao, S.; Acharya, B.; Dhungana, A. Effect of torrefaction on the density and volume changes of coarse biomass particles. Can. J. Chem. Eng. 2013, 91, 1040–1044. [Google Scholar] [CrossRef]

- Chen, W.H.; Lin, B.J. Characteristics of products from the pyrolysis of oil palm fiber and its pellets in nitrogen and carbon dioxide atmospheres. Energy 2016, 94, 569–578. [Google Scholar] [CrossRef]

- Ghiasi, B.; Kumar, L.; Furubayashi, T.; Lim, C.J.; Bi, X.; Chang, S.K. Densified biocoal from woodchips: Is it better to do torrefaction before or after densification? Appl. Energy 2014, 134, 133–142. [Google Scholar] [CrossRef]

- Xing, X.; Fan, F.; Jiang, W. Characteristics of biochar pellets from corn straw under different pyrolysis temperatures. R. Soc. Open Sci. 2018, 5, 172–346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- British Standards Institution. Solid Biofuels—Determination of Total Carbon, Hydrogen and Nitrogen Content—Instrumental Methods; British Standards Institution: London, UK, 2011. [Google Scholar]

- British Standards Institution. Solid Biofuels—Determination of Ash; British Standards Institution: London, UK, 2010. [Google Scholar]

- British Standards Institution. Solid Biofuels—Determination of Volatile Substances; British Standards Institution: London, UK, 2011. [Google Scholar]

- British Standards Institution. Solid Biofuels—Determination of Calorific Value; British Standards Institution: London, UK, 2010. [Google Scholar]

- PN-EN 17831-1:2016-02; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets. Polish Committee for Standardisation: Warsaw, Poland, 2016.

- EN 14034, Part 1. Determination of Explosion Characteristics of Dust Clouds—Part 1: Determination of the Maximum Explosion Pressure Pmax of Dust Clouds. 2011. Available online: https://www.researchgate.net/publication/282893830_Determination_Of_The_Maximum_Explosion_Pressure_And_The_Maximum_Rate_Of_Pressure_Rise_During_Explosion_Of_Wood_Dust_Clouds (accessed on 3 February 2022).

- EN14034, Part 2. Determination of Explosion Characteristics of Dust Clouds—Part 2: Determination of the Maximum Rate of Explosion Pressure Rise (dp/dt) Max of Dust Clouds. 2011. Available online: https://infostore.saiglobal.com/en-us/Standards/EN-14034-2-2006-A1-2011-328536_SAIG_CEN_CEN_756384 (accessed on 6 July 2020).

- EN 14034, Part 3. Determination of Explosion Characteristics of Dust Clouds—Part 3: Determination of the Lower Explosion Limit LEL of Dust Clouds. 2011. Available online: https://infostore.saiglobal.com/en-us/standards/din-en-14034-3-2011-04-400553_saig_din_din_862949 (accessed on 3 February 2022).

- Qian, X. Statistical Analysis and Evaluation of the Advanced Biomass and Natural Gas Co-Combustion Performance. Ph.D. Thesis, Morgan State University, Baltimore, MD, USA, 2019. [Google Scholar]

- Chen, W.H.; Lin, Y.Y.; Liu, H.C.; Baroutian, S. Optimization of food waste hydrothermal liquefaction by a two-step process in association with a double analysis. Energy 2020, 199, 117438. [Google Scholar] [CrossRef]

- Yuan, H.; Lu, T.; Zhao, D.; Huang, H.; Noriyuki, K.; Chen, Y. Influence of temperature on product distribution and bichar properties by municipal sludge pyrolysis. J. Mater. Cycles Waste Manag. 2013, 15, 357–361. [Google Scholar] [CrossRef]

- Al-Wabel, M.; Al-Omran, A.; El-Naggar, A.H.; Nadeem, M.; Usman, A.R.A. Pyrolysis temperature induced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresour. Technol. 2013, 131, 374–379. [Google Scholar] [CrossRef] [PubMed]

- Ronsse, F.; Van Hecke, S.; Dickinson, D.; Prins, W. Production and characterization of slow pyrolysis biochar: Influence of feedstock type and pyrolysis conditions. Bioenergy 2012, 5, 104–115. [Google Scholar] [CrossRef]

- Elnour, A.Y.; Alghyamah, A.A.; Shaikh, H.M.; Poulose, A.M.; Al-Zahrani, S.M.; Anis, A.; Al-Wabel, M.I. Effect of Pyrolysis Temperature on Biochar Microstructural Evolution, Physicochemical Characteristics, and Its Influence on Biochar/Polypropylene Composites. Appl. Sci. 2019, 9, 1149. [Google Scholar] [CrossRef] [Green Version]

- Angin, D. Effect of pyrolysis temperature and heating rate on biochar obtained from pyrolysis of safflower seed press cake. Biorsour. Technol. 2013, 128, 593–597. [Google Scholar] [CrossRef]

- Bajcar, M.; Zaguła, G.; Saletnik, B.; Tarapatskyy, M.; Puchalski, C. Relationship between Torrefaction Parameters and Physicochemical Properties of Torrefied Products Obtained from Selected Plant Biomass. Energies 2018, 11, 2919. [Google Scholar] [CrossRef] [Green Version]

- Jin, J.; Li, Y.; Zhang, J.; Wu, S.; Cao, Y.; Liang, P.; Zhang, J.; Hung Wong, M.; Wang, M.; Shan, S.; et al. Influence of pyrolysis temperature on properties and environmental safety of heavy metals in biochars derived from municipal sewage sludge. J. Hazard. Mater. 2016, 320, 417–426. [Google Scholar] [CrossRef]

- Babinszki, B.; Jakab, E.; Sebastyén, Z.; Blazsó, M.; Berényi, B.; Kumar, J.; Krishna, B.B.; Bhaskar, T.; Czégény, Z. Comparison of hydrothermal carbonization and torrefaction of azolla biomass: Analysis of the solid products. J. Anal. Appl. Pyrolysis 2020, 149, 104844. [Google Scholar] [CrossRef]

- Zhao, S.-X.; Ta, N.; Wang, X.-D. Effect of temperature of the structural and physicochemical properties of biochar with apple tree branches as feedstock material. Energies 2019, 10, 1293. [Google Scholar] [CrossRef] [Green Version]

- Pehlivan, E.; Özbay, N.; Yargıç, A.S.; Şahin, R.Z. Production and characterization of chars from cherry pulp via pyrolysis. J. Environ. Manag. 2017, 203, 1017–1025. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, J.; Liu, R. Effects of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate. Biorsour. Technol. 2015, 176, 288–291. [Google Scholar] [CrossRef] [PubMed]

- Khalid Rafiq, M.; Bachmann, R.T.; Tariq Rafiq, M.; Shang, Z.; Joseph, S. Influence of Pyrolysis Temperature on Physico-Chemical Properties of Corn Stover (Zea mays L.) Biochar and Feasibility for Carbon Capture and Energy Balance. PLoS ONE 2016, 11, e0156894. [Google Scholar]

- Santos, J.; Ouadi, M.; Jahangiri, H.; Hornung, A. Valorisation of lignocellulosic biomass investigating different pyrolysis temperatures. J. Energy Inst. 2020, 93, 1960–1969. [Google Scholar] [CrossRef]

- Ahmad, R.K.; Sulaiman, S.A.; Yusuf, S.; Dol, S.S.; Umar, H.A.; Inayat, M. The influence of pyrolysis process conditions on the quality of coconut shells charcoal. Platf. A J. Eng. 2020, 4, 73–81. [Google Scholar]

- Sarkar, J.K.; Wang, Q. Different Pyrolysis Process Conditions of South Asian Waste Coconut Shell and Characterization of Gas, Bio-Char, and Bio-Oil. Energies 2020, 13, 1970. [Google Scholar] [CrossRef]

- Poskart, A.; Szwaja, S.; Magdziarz, A.; Musiał, D.; Zajemska, M. The role of torrefied biomass on the market of traditional fossil fuels. Energy Mark. 2018, 1, 65–71. [Google Scholar]

- Arous, S.; Koubaa, A.; Bouafif, H.; Bouslimi, B.; Braghiroli, F.L.; Bradai, C. Effect of Pyrolysis Temperature and Wood Species on the Properties of Biochar Pellets. Energies 2021, 14, 6529. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Lim, C.J.; Sokhansanj, S. Pelletization of torrefied sawdust and properties of torrefied pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, H.; Wang, X.; Zhang, S.; Chen, H. Biomass-based pyrolytic polygeneration system on cotton stalk pyrolysis: Influence of temperature. Bioresour. Technol. 2012, 107, 411–418. [Google Scholar] [CrossRef] [PubMed]

- Irfan, M.; Chen, Q.; Yan, Y.; Pang, R.; Lin, Q.; Zhao, X. Co-production of biochar, bio-oil and syngas from halophyte grass (Achnatherum splendens, L.) under three different pyrolysis temperatures. Bioresour. Technol. 2016, 211, 457–463. [Google Scholar] [CrossRef] [PubMed]

- PN-EN 14961; Solid Biofuels-Fuel Specifications and Grades. Polish Committee for Standardisation: Warsaw, Poland, 2010.

- Szwalec, A.; Mundała, P.; Kędzior, R.; Telk, M.; Gawroński, P. Diversify the content of Cd, Pb, Zn and Cu in biomass used for energy purposes. Acta Sci. Pol. Form. Circumiectus 2016, 15, 343–351. [Google Scholar] [CrossRef]

- Zhang, W.; Tong, Y.; Wang, H.; Chen, L.; Ou, L.; Wang, X.; Zhu, Y. Emission of Metals from Pelletized and Uncompressed Biomass Fuels Combustion in Rural Household Stoves in China. Sci. Rep. 2014, 4, 5611. [Google Scholar] [CrossRef]

- Ilari, A.; Foppa Pedretti, E.; De Francesco, C.; Duca, D. Pellet Production from Residual Biomass of Greenery Maintenance in a Small-Scale Company to Improve Sustainability. Resources 2021, 10, 122. [Google Scholar] [CrossRef]

- Liu, A.; Chen, J.; Huang, X.; Lin, J.; Zhang, X.; Xu, W. Explosion parameters and combustion kinetics of biomass dust. Biorsour. Technol. 2019, 294, 122168. [Google Scholar] [CrossRef]

- Gheorghe, C.; Marculescu, C.; Badea, A.; Dinca, C.; Apostol, T. Effect of pyrolysis conditions on bio-char production biomass. In Proceedings of the 3rd WSEAS International Conference on Renewable Energy Sources, Tenerife, Canary Islands, Spain, 1–3 July 2009. [Google Scholar]

- Choi, H.S.; Choi, Y.S.; Park, H.C. Fast pyrolysis characteristics of lignocellulosic biomass with varying reaction conditions. Renew. Energy 2012, 42, 131–135. [Google Scholar] [CrossRef]

- Półka, M. An Analysis of Flammability and Explosion Parameters of Coke Dust and Use of Preliminary Hazard Analysis for Qualitative Risk Assessment. Sustainability 2020, 12, 4130. [Google Scholar] [CrossRef]

- Saeed, M.A.; Slatter, D.J.F.; Andrews, G.E.; Phylaktou, H.N.; Gibbs, B.M. Combustion of pulverized biomass crop residues and their explosion characteristics. Combust. Sci. Technol. 2016, 188, 2200–2216. [Google Scholar] [CrossRef]

- Saeed, M.A.; Andrews, G.E.; Phylaktou, H.N.; Gibbs, B.M. Flame speed and Kst reactivity data for pulverised corn cobs and peanut shells. J. Loss Prev. Process Ind. 2017, 49, 880–887. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, P.; Sun, L.; Zhang, W.; Jin, J. Factors influencing and a statistical method for describing dust explosion parameters: A review. J. Loss Prev. Process Ind. 2018, 56, 386–401. [Google Scholar] [CrossRef]

| Explosion Class | K st Max Value [Bar s−1] |

|---|---|

| St1 | ≤200 |

| St2 | 200–300 |

| St3 | >300 |

| Parameter | Research Method |

|---|---|

| Content of carbon, nitrogen and hydrogen | PN-EN 15104:2011 [48] |

| Ash content | PN-EN 13775:2010 [49] |

| Content of volatile substances | PN-EN 15138:2011 [50] |

| Calorific value | PN-EN 13918:2010 [51] |

| Mechanical durability | PN-EN 17831-1:20169-02 [52] |

| Maximum explosion pressure | PN-EN 14034-1 [53] |

| Maximum rate of pressure rise | PN-EN 14034-2 [54] |

| Explosion index Kst max | PN-EN 14034-2 [54] |

| Lower explosion limits | PN-EN 14034-3 [55] |

| Nitrogen | Carbon | Hydrogen | Ash | Volatile Substances | Durability | Calorific Value | Heavy Metals | |||

|---|---|---|---|---|---|---|---|---|---|---|

| As | Cd | Pb | ||||||||

| % | MJ kg−1 | mg kg−1 | ||||||||

| OP0 | <0.04 | 51.46 a ± 0.18 | 5.96 d ± 0.03 | 0.53 a ± 0.04 | 81.73 c ± 0.05 | 99.12 c ± 0.22 | 18.27 a ± 0.09 | <0.01 | <0.01 | 0.11 a ± 0.00 |

| OP1 | 75.25 b ± 0.37 | 4.33 c ± 0.03 | 3.75 b ± 0.02 | 37.05 b ± 0.04 | 44.92 a ± 0.11 | 27.22 b ± 0.09 | 0.16 b ± 0.01 | |||

| OP2 | 77.72 bc ± 0.43 | 4.16 c ± 0.02 | 3.81 b ± 0.03 | 36.12 b ± 0.12 | 45.16 a ± 0.28 | 28.20 b ± 0.11 | 0.15 b ± 0.01 | |||

| OP3 | 77.97 bc ± 0.23 | 4.27 c ± 0.02 | 4.48 c ± 0.07 | 35.35 b ± 0.15 | 45.34 a ± 0.16 | 28.35 b ± 0.06 | 0.15 b ± 0.02 | |||

| OP4 | 75.63 bc ± 0.08 | 3.83 b ± 0.02 | 5.55 d ± 0.07 | 34.76 ab ± 0.08 | 51.91 b ± 0.19 | 27.62 b ± 0.11 | 0.23 c ± 0.01 | |||

| OP5 | 78.59 bc ± 0.12 | 3.82 b ± 0.01 | 6.31 e ± 0.06 | 32.63 ab ± 0.13 | 52.11 b ± 0.23 | 29.25 b ± 0.15 | 0.21 c ± 0.01 | |||

| OP6 | 79.21 bc ± 0.12 | 3.77 b ± 0.01 | 6.59 e ± 0.06 | 31.07 ab ± 0.13 | 52.28 b ± 0.44 | 29.64 b ± 0.12 | 0.24 c ± 0.02 | |||

| OP7 | 75.59 bc ± 0.09 | 3.50 a ± 0.01 | 5.75 d ± 0.05 | 30.89 a ± 0.10 | 55.67 b ± 0.31 | 29.29 b ± 0.16 | 0.32 d ± 0.02 | |||

| OP8 | 81.27 c ± 0.06 | 3.46 a ± 0.02 | 5.82 d ± 0.02 | 29.39 a ± 0.09 | 55.88 b ± 0.18 | 29.81 b ± 0.09 | 0.35 d ± 0.01 | |||

| OP9 | 81.41 c ± 0.20 | 3.19 a ± 0.01 | 6.63 e ± 0.06 | 28.34 a ± 0.10 | 56.14 b ± 0.42 | 30.45 b ± 0.16 | 0.34 d ± 0.02 | |||

| Nitrogen | Carbon | Hydrogen | Ash | Volatile Substances | Durability | Calorific Value | Heavy Metals | |||

|---|---|---|---|---|---|---|---|---|---|---|

| As | Cd | Pb | ||||||||

| % | MJ kg−1 | mg kg−1 | ||||||||

| OP0 | <0.04 | 53.25 a ± 0.18 | 6.21 d ± 0.02 | 0.37 a ± 0.07 | 82.81 c ± 0.15 | 98.54 c ± 0.21 | 19.31 a ± 0.08 | <0.01 | <0.01 | 0.23 a ± 0.01 |

| OP1 | 75.98 b ± 0.05 | 4.49 c ± 0.02 | 3.16 b ± 0.07 | 39.62 b ± 0.15 | 44.34 a ± 0.19 | 28.88 b ± 0.08 | 0.32 b ± 0.01 | |||

| OP2 | 78.86 bc ± 0.13 | 4.32 c ± 0.04 | 3.54 bc ± 0.08 | 39.61 b ± 0.11 | 44.62 a ± 0.14 | 29.36 b ± 0.07 | 0.31 b ± 0.02 | |||

| OP3 | 80.21 bc ± 0.21 | 4.17 c ± 0.03 | 3.89 c ± 0.04 | 38.01 ab ± 0.16 | 45.11 a ± 0.32 | 29.41 b ± 0.07 | 0.34 b ± 0.01 | |||

| OP4 | 80.48 bc ± 0.13 | 3.61 b ± 0.02 | 3.70 c ± 0.06 | 36.77 ab ± 0.11 | 51.44 b ± 0.27 | 29.66 b ± 0.08 | 0.39 c ± 0.01 | |||

| OP5 | 80.96 bc ± 0.15 | 3.60 b ± 0.03 | 3.75 c ± 0.03 | 35.51 ab ± 0.13 | 51.59 b ± 0.41 | 29.85 b ± 0.06 | 0.38 c ± 0.01 | |||

| OP6 | 83.00 bc ± 0.13 | 3.40 ab ± 0.01 | 4.28 d ± 0.04 | 33.14 ab ± 0.07 | 51.96 b ± 0.28 | 30.07 b ± 0.05 | 0.40 c ± 0.01 | |||

| OP7 | 81.99 bc ± 0.18 | 3.25 a ± 0.02 | 4.22 d ± 0.05 | 31.28 ab ± 0.08 | 55.43 b ± 0.23 | 30.85 b ± 0.09 | 0.47 d ± 0.01 | |||

| OP8 | 84.32 c ± 0.02 | 3.21 a ± 0.02 | 4.31 d ± 0.04 | 30.47 a ± 0.07 | 55.75 b ± 0.33 | 31.26 b ± 0.08 | 0.48 d ± 0.02 | |||

| OP9 | 85.21 c ± 0.11 | 3.02 a ± 0.01 | 4.73 d ± 0.05 | 29.24 a ± 0.09 | 55.98 b ± 0.22 | 31.49 b ± 0.03 | 0.48 d ± 0.02 | |||

| Nitrogen | Carbon | Hydrogen | Ash | Volatile Substances | Durability | Calorific Value | Heavy Metals | |||

|---|---|---|---|---|---|---|---|---|---|---|

| As | Cd | Pb | ||||||||

| % | MJ kg−1 | mg kg−1 | ||||||||

| OP0 | <0.04 | 52.52 a ± 0.12 | 6.16 d ± 0.03 | 0.31 a ± 0.05 | 82.66 c ± 0.13 | 98.87 c ± 0.21 | 19.13 a ± 0.04 | <0.01 | <0.01 | 0.21 a ± 0.01 |

| OP1 | 75.67 b ± 0.20 | 4.49 c ± 0.04 | 2.71 b ± 0.06 | 38.51 b ± 0.11 | 44.51 a ± 0.13 | 27.86 b ± 0.09 | 0.29 b ± 0.00 | |||

| OP2 | 78.47 b ± 0.11 | 4.37 c ± 0.03 | 2.95 b ± 0.05 | 38.04 b ± 0.06 | 44.94 a ± 0.24 | 28.55 b ± 0.08 | 0.30 b ± 0.02 | |||

| OP3 | 79.16 b ± 0.14 | 4.30 c ± 0.03 | 3.46 bc ± 0.05 | 36.83 ab ± 0.08 | 45.28 a ± 0.16 | 28.71 b ± 0.11 | 0.29 b ± 0.02 | |||

| OP4 | 78.11 b ± 0.10 | 3.82 b ± 0.02 | 3.89 bc ± 0.07 | 35.94 ab ± 0.12 | 51.63 b ± 0.42 | 28.42 b ± 0.11 | 0.36 c ± 0.01 | |||

| OP5 | 79.84 bc ± 0.07 | 3.79 b ± 0.02 | 4.30 c ± 0.06 | 34.24 ab ± 0.04 | 51.86 b ± 0.26 | 29.37 b ± 0.07 | 0.36 c ± 0.02 | |||

| OP6 | 81.17 bc ± 0.08 | 3.69 ab ± 0.02 | 4.70 c ± 0.06 | 32.29 ab ± 0.09 | 52.06 b ± 0.21 | 29.71 b ± 0.03 | 0.38 c ± 0.01 | |||

| OP7 | 78.84 b ± 0.07 | 3.48 a ± 0.04 | 4.25 c ± 0.05 | 31.22 ab ± 0.09 | 55.6 b ± 0.33 | 29.93 b ± 0.15 | 0.43 d ± 0.02 | |||

| OP8 | 82.87 c ± 0.03 | 3.43 a ± 0.05 | 4.35 c ± 0.01 | 30.08 a ± 0.05 | 55.68 b ± 0.39 | 30.34 b ± 0.07 | 0.44 d ± 0.02 | |||

| OP9 | 83.32 c ± 0.09 | 3.24 a ± 0.02 | 4.95 c ± 0.07 | 28.97 a ± 0.11 | 56.07 b ± 0.28 | 30.73 b ± 0.11 | 0.44 d ± 0.01 | |||

| Material | Pmax | (dp/dt)max | LEL—Lower Explosion Limit |

|---|---|---|---|

| Bar | bar s−1 | g m3 | |

| OP0 | 7.78 | 282.39 | 750 |

| OP1 | 8.21 | 289.74 | |

| OP2 | 8.54 | 294.38 | 500 |

| OP3 | 8.86 | 302.16 | |

| OP4 | 9.29 | 307.24 | |

| OP5 | 9.94 | 320.54 | |

| OP6 | 10.06 | 323.26 | |

| OP7 | 10.35 | 327.77 | |

| OP8 | 10.96 | 332.40 | |

| OP9 | 11.15 | 335.97 | |

| CP0 | 8.10 | 293.88 | 750 |

| CP1 | 8.55 | 301.53 | |

| CP2 | 8.88 | 306.36 | |

| CP3 | 9.22 | 314.46 | 500 |

| CP4 | 9.67 | 319.75 | |

| CP5 | 10.35 | 333.58 | |

| CP6 | 10.47 | 336.41 | |

| CP7 | 10.77 | 341.10 | |

| CP8 | 11.40 | 345.93 | |

| CP9 | 11.60 | 349.64 | |

| MP0 | 7.94 | 288.01 | 750 |

| MP1 | 8.38 | 295.50 | |

| MP2 | 8.71 | 300.24 | |

| MP3 | 9.04 | 308.18 | |

| MP4 | 9.48 | 313.36 | 500 |

| MP5 | 10.14 | 326.92 | |

| MP6 | 10.26 | 329.69 | |

| MP7 | 10.56 | 334.29 | |

| MP8 | 11.18 | 339.02 | |

| MP9 | 11.37 | 342.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saletnik, B.; Saletnik, A.; Zaguła, G.; Bajcar, M.; Puchalski, C. The Use of Wood Pellets in the Production of High Quality Biocarbon Materials. Materials 2022, 15, 4404. https://doi.org/10.3390/ma15134404

Saletnik B, Saletnik A, Zaguła G, Bajcar M, Puchalski C. The Use of Wood Pellets in the Production of High Quality Biocarbon Materials. Materials. 2022; 15(13):4404. https://doi.org/10.3390/ma15134404

Chicago/Turabian StyleSaletnik, Bogdan, Aneta Saletnik, Grzegorz Zaguła, Marcin Bajcar, and Czesław Puchalski. 2022. "The Use of Wood Pellets in the Production of High Quality Biocarbon Materials" Materials 15, no. 13: 4404. https://doi.org/10.3390/ma15134404

APA StyleSaletnik, B., Saletnik, A., Zaguła, G., Bajcar, M., & Puchalski, C. (2022). The Use of Wood Pellets in the Production of High Quality Biocarbon Materials. Materials, 15(13), 4404. https://doi.org/10.3390/ma15134404