Study on Ultrasonic Nondestructive Testing of Self-Compacting Concrete under Uniaxial Compression Test

Abstract

:1. Introduction

2. Experiment Preparation

2.1. Test Raw Material and Proportion

2.2. Specimen Design

2.3. The Test Process

3. Analysis of Test Results

3.1. Analysis of Sound Time of Test Block

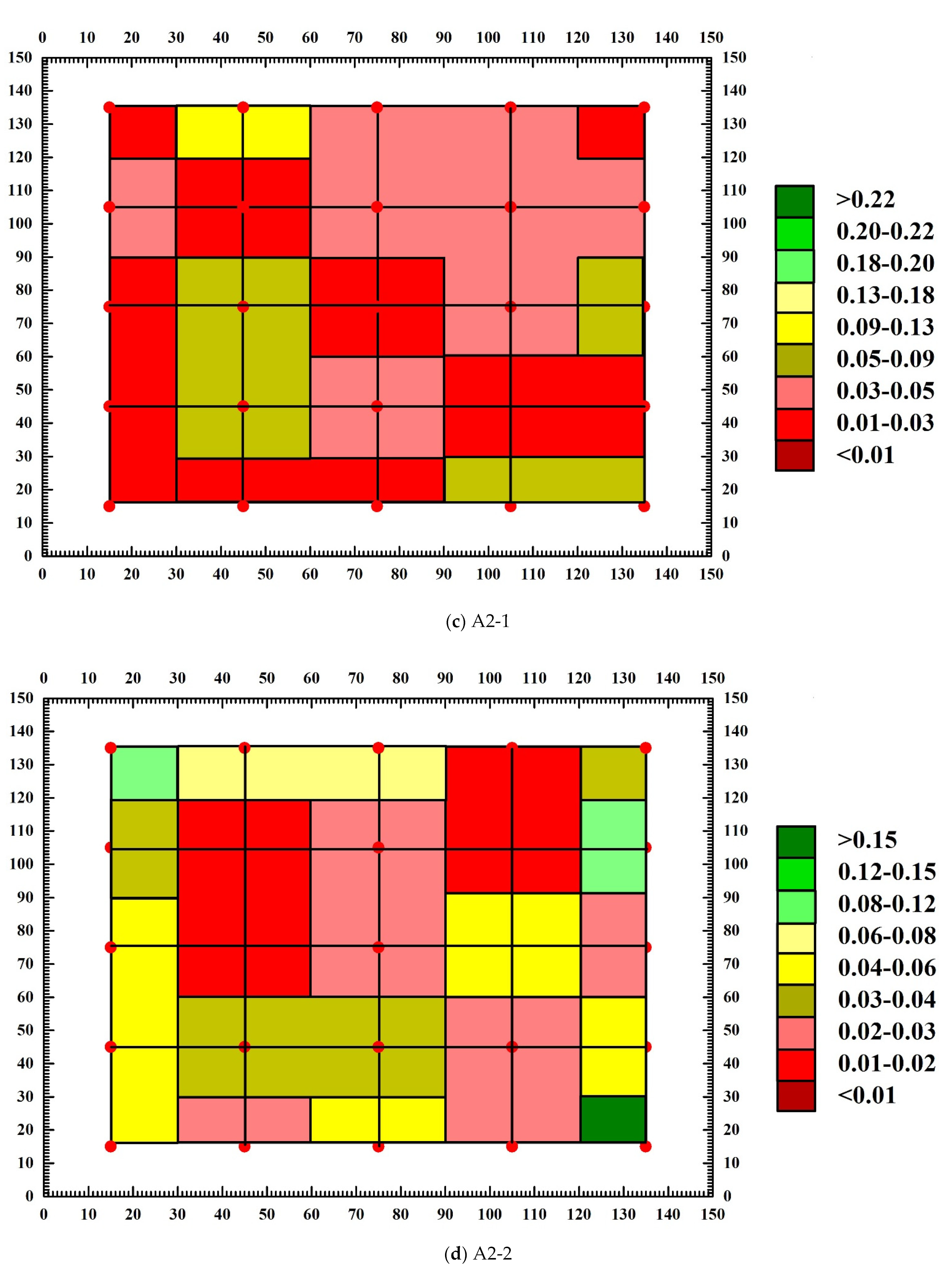

3.2. Analysis of Amplitude Value of Test Block

3.3. Analysis of Sound Velocity of the Text Block

3.4. Analysis of Abnormal Values of Measuring Points

4. Conclusions

- i.

- An ultrasonic testing analyzer was used to study the variation of ultrasonic parameters of SCC before and after uniaxial compression test failure; the evolution law of internal defects of SCC after failure was obtained, which provided a theoretical basis for the application of ultrasonic testing technology in the field of SCC.

- ii.

- After curing the SCC test block for 7 days and 28 days, the sound value before and after the failure had the following rules: The average value of sound time before and after the failure of each measuring point is smaller than that after the failure, but the difference between the average value before and after the failure is small. Defects and cracks appeared in some structures, the ultrasonic propagation path was longer than before the failure, and the sound time value of some measuring points was significantly larger than before the failure.

- iii.

- The amplitude before and after the failure of the test block has the following rules: The average value of the measured points after the failure is smaller than the average value before the failure. Structural defects and cracks cause scattering and reflection during the ultrasonic wave propagation, the ultrasonic wave shows obvious attenuation, and the amplitude of some measured points is significantly smaller than that before the failure.

- iv.

- The sound velocity values before and after the failure of the test block have the following rules: The average value of the sound velocity after the failure of each measuring point is smaller than the average value before the failure. The test block is damaged, and some of the structures are defective, resulting in the uncompacted structure of part of the block, and the sound velocity value of some measuring points is significantly smaller than before the destruction.

- v.

- During the SCC ultrasonic testing process, the ultrasonic velocity was affected by many factors. In the subsequent testing process, the influence of these factors must be reduced.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wenxu, L.I.; Kunlin, M.A.; Long, G.; Xie, Y.; Cong, M.A.; Ning, L.I. Stability Dynamic Monitoring and Simulation of Self-compacting Concrete: A Review. Mater. Rep. 2019, 33, 2206–2213. [Google Scholar]

- Kamal, M.M.; Safan, M.A.; Bashandy, A.A.; Khalil, A.M. Experimental investigation on the behavior of normal strength and high strength self-curing self-compacting concrete. J. Build. Eng. 2018, 16, 79–93. [Google Scholar] [CrossRef]

- Cabrera, M.; Martinez-Echevarria, M.J.; Lopez-Alonso, M.; Agrela, F.; Rosales, J. Self-Compacting Recycled Concrete Using Biomass Bottom Ash. Materials 2021, 14, 6084. [Google Scholar] [CrossRef] [PubMed]

- Shi, F.; Cao, P.; Wang, Z.; Gan, Y.; Zhou, C.; Liu, K. An Experimental Study of Dynamic Compression Performance of Self-Compacting Concrete. Materials 2020, 13, 3731. [Google Scholar] [CrossRef] [PubMed]

- Lehner, P.; Hornakova, M.; Hrabova, K. Sensitivity Analysis of Stochastic Calculation of SCC Regarding Aggressive Environment. Materials 2021, 14, 6838. [Google Scholar] [CrossRef]

- Ferrari, G.; Surico, F.; Brocchi, A.; Banfi, E.; Maltese, C.; Squinzi, M. Method for producing aggregates from cement compositions. U.S. Patent 9,216,925, 22 December 2015. [Google Scholar]

- Hou, H. Research on Preparation and Casting Construction Technology of Self-compacting Concrete in Marine Climate Environments. J. Coast. Res. 2020, 115, 1–3. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Y.; Zan, S. Study on ultrasonic detection about void defects of concrete filled rectangular steel tube. Build. Sci. 2018, 34, 103–107. [Google Scholar]

- Tariq, S.; Scott, A.N.; Mackechnie, J.R.; Shah, V. Durability of High Volume Glass Powder Self-Compacting Concrete. Appl. Sci. 2020, 10, 8058. [Google Scholar] [CrossRef]

- Yin, Y.; Zeng, H.; Zheng, X. Iop. Research on Construction Method of Concrete Filled Steel Column. In Proceedings of the 6th International Conference on Environmental Science and Civil Engineering (ESCE), Nanchang, China, 4–5 January 2020. [Google Scholar]

- Tan, P. Application of Self-Compacting Concrete in Secondary Lining Engineering of Tunnel Tube. Archit. Technol. 2016, 47, 636–638. [Google Scholar]

- Cheng, W. Technical Characteristics of Self-compacting Concrete and Its Application in High Speed Railway. China Railw. 2018, 10, 79–84. [Google Scholar]

- Tian, P.Y. Application of Self-compacting Concrete in Precast Components. China Concr. Cem. Prod. 2018, 12, 30–33. [Google Scholar]

- Zeng, Z.-p.; Huang, X.-d.; Yan, B.; Wang, W.-d.; Shuaibu, A.A.; He, X.-f. Research on the fatigue performance of self-compacting concrete structure in CRTSIII slab ballastless track under the action of heavy haul train. Constr. Build. Mater. 2021, 303, 124465. [Google Scholar] [CrossRef]

- He, J.; Huang, H.; Jiang, H.; Zhou, Y.; Jin, F.; Zhang, C. Experimental investigation into mode-I interfacial fracture behavior between rock and self-compacting concrete in rock-filled concrete. Eng. Fract. Mech. 2021, 258, 108047. [Google Scholar] [CrossRef]

- Chen, X.; Wang, J.; Tian, H. Tests for acoustic emission characteristic recognition parameters of rubber self-compacting concrete in fatigue fracture process. J. Vib. Shock. 2021, 40, 129–136. [Google Scholar]

- Fu, Z.W.; Wang, X. Study of ultrasonic nondestructive testing detecting the defects of concrete components. Rock Soil Mech 2007, 6 Supplement S1. [Google Scholar]

- Liu, C.; Wu, T. Experiments on Mechanical Properties of Recycled Self-Compacting Concrete under Freeze-Thaw Conditions. Bull. Chin. Ceram. Soc. 2018, 37, 2640–2645. [Google Scholar]

- Long, G.; Yang, Z.; Bai, C.; Ma, K.; Xie, Y. Durability and Damage Constitutive Model of Filling Layer Self-compacting Concrete Subjected to Coupling Action of Freeze-thaw Cycles and Load. J. Chin. Ceram. Soc. 2019, 47, 855–864. [Google Scholar]

- Nguyen, N.T.; Sbartai, Z.M.; Lataste, J.F.; Breysse, D.; Bos, F. Assessing the spatial variability of concrete structures using NDT techniques – Laboratory tests and case study. Constr. Build. Mater. 2013, 49, 240–250. [Google Scholar] [CrossRef]

- Ridgley, K.E.; Abouhussien, A.A.; Hassan, A.A.A.; Colbourne, B. Characterisation of damage due to abrasion in SCC by acoustic emission analysis. Mag. Concr. Res. 2019, 71, 85–94. [Google Scholar] [CrossRef]

- Nepomuceno, M.C.S.; Lopes, S.M.R. Iop. Analysis of Within-Test Variability of Non-Destructive Test Methods to Evaluate Compressive Strength of Normal Vibrated and Self-Compacting Concretes. In Proceedings of the World Multidisciplinary Civil Engineering-Architecture-Urban Planning Symposium (WMCAUS), Prague, Czech Republic, 12–16 June 2017. [Google Scholar]

- Ramaniraka, M.; Rakotonarivo, S.; Payan, C.; Garnier, V. Effect of the Interfacial Transition Zone on ultrasonic wave attenuation and velocity in concrete. Cem. Concr. Res. 2019, 124, 105809. [Google Scholar] [CrossRef]

- Suaris, W.; Fernando, V. Ultrasonic Pulse Attenuation as A Measure of Damage Growth During Cyclic Loading of Concrete. Aci Mater. J. 1987, 84, 185–193. [Google Scholar]

- Ravindrarajah, R.S. Evaluation of Compressive Strength For High-Strength Concrete By Pulse Velocity Method. NDT E Int. 1997, 30, 260. [Google Scholar]

- Yu, J.; Xu, F.; Xu, B.; Surez, E.; Gallego, A. Application of acoustic emission tomography in concrete structures. J. Southeast Univ. Nat. Sci.Ed. 2014, 44, 822–825. [Google Scholar]

- Suraneni, P. Ultrasonic Wave Reflection Measurements on Self-Compacting Pastes and Concretes. Master’s Thesis, University of Illinois Urbana-Champaign, Champaign, IL, USA, 2011. [Google Scholar]

- Bu, L.; Zhao, Y. Experimental Study on On-Site Detection Method of Compressive Strength of High-Strength Self-Compacting Concrete. J. Shenyang Jianzhu Univ. Nat. Sci. 2020, 36, 412–420. [Google Scholar]

- Guneyisi, E.; Gesoglu, M. Properties of self-compacting portland pozzolana and limestone blended cement concretes containing different replacement levels of slag. Mater. Struct. 2011, 44, 1399–1410. [Google Scholar] [CrossRef]

- Li, H.; Yin, J.; Yan, P.; Sun, H.; Wan, Q. Experimental Investigation on the Mechanical Properties of Self-Compacting Concrete under Uniaxial and Triaxial Stress. Materials 2020, 13, 1830. [Google Scholar] [CrossRef] [PubMed]

- Schickert, G. Critical reflections on non-destructive testing of concrete. Mater. Struct. 1984, 17, 217–223. [Google Scholar] [CrossRef]

- Liang, M.T.; Wu, J. Theoretical elucidation on the empirical formulae for the ultrasonic testing method for concrete structures. Cem. Concr. Res. 2002, 32, 1763–1769. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Faleschini, F.; Zanini, M.A.; Skaf, M.; Ortega-Lopez, V. Porosity-based models for estimating the mechanical properties of self-compacting concrete with coarse and fine recycled concrete aggregate. J. Build. Eng. 2022, 44. [Google Scholar] [CrossRef]

- Wan, P.; Lei, X.; Xu, B.; Song, H. A Strain Rate-Dependent Damage Evolution Model for Concrete Based on Experimental Results. Adv. Civ. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Zhu, W.-F.; Chen, X.-J.; Li, Z.-W.; Meng, X.-Z.; Fan, G.-P.; Shao, W.; Zhang, H.-Y. A SAFT Method for the Detection of Void Defect inside a Ballastless Track Structure Using Ultrasonic Array Sensors. Sensors 2019, 19, 4677. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.; Jia, Y.; Chen, G.; Chi, D.; Wang, Y. Research on the Damage Condition of Reinforced Concrete Filled Steel Tubes Under Axial Load Using Ultrasonic Testing. Eng. Mech. 2019, 36, 172–179. [Google Scholar]

- Akkaya, Y.; Voigt, T.; Subramaniam, K.V.; Shah, S.P. Nondestructive measurement of concrete strength gain by an ultrasonic wave reflection method. Mater. Struct. 2003, 36, 507–514. [Google Scholar] [CrossRef]

- Hao, W.X.; Liang, L.I.; Sun, J.H.; Xiao, X.U. Experimental studies the work stress of concrete axial compression columns by ultrasonic testing. J. Hebei Agric. Univ. 2018, 41, 104–107. [Google Scholar]

- Xing-yu, G.; Shu-wei, L.; Qiao, D.; Xiang-rong, X.; Da-wei, X.; Tian-jie, Z. Attenuation Characteristics and Influencing Factors of Ultrasonic Testing of Asphalt Concrete. China J. Highw. Transp. 2020, 33, 316. [Google Scholar]

- Huang, Z.Y.; Ji, X.L.; Huang, L. Qualitative analytical method of imaging the concrete flaws by ultrasonic test. J. Hunan Univ. Nat. Ences 2008, 35, 5–8. [Google Scholar]

- Qu, X.; Liu, Q. Study on axial compression performance of rectangle concrete filled steel tubular columns. Build. Sci. 2018, 34, 37–42. [Google Scholar]

- Zhao, G.; Zhang, D.; University, J. Review: Concrete Structural Health Monitoring with Ultrasonic Techinque. Struct. Eng. 2018, 34, 151–156. [Google Scholar]

- Zheng, D.; Ren, T. Influence of frequency and water content on ultrasonic damage testing in concrete. J. Hydraul. Eng. 2014, S1, 5. [Google Scholar]

- Zhu, Z.; Yu, B.; Mi, S.; Yu, T.; Zhou, Y. Ultrasonic attenuation characteristics of ultrasonic in concrete. Zhongnan Daxue Xuebao (Ziran Kexue Ban)/J. Cent. South Univ. Sci.Technol. 2014, 45, 3900–3907. [Google Scholar]

- Chen, D.; Montano, V.; Huo, L.; Fan, S.; Song, G. Detection of subsurface voids in concrete-filled steel tubular (CFST) structure using percussion approach. Constr. Build. Mater. 2020, 262, 119761. [Google Scholar] [CrossRef]

- Al-Mufti, R.L.; Fried, A.N. Non-destructive evaluation of reclaimed asphalt cement concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 770–782. [Google Scholar] [CrossRef] [Green Version]

- QINTienan; Huaxiong, M.A.; Tao, C.; Cong, T.; Wenfeng, Z.; Yan, Y. Uncertainty Evaluation of Ultrasonic Thickness Measurement of Coatings on Concrete. J. Build. Mater. 2016, 19, 177–180. [Google Scholar]

- Janku, M.; Cikrle, P.; Grosek, J.; Anton, O.; Stryk, J. Comparison of infrared thermography, ground-penetrating radar and ultrasonic pulse echo for detecting delaminations in concrete bridges. Constr. Build. Mater. 2019, 225, 1098–1111. [Google Scholar] [CrossRef]

- Green, L.S.; Faergestad, E.M.; Poole, A.; Chandler, P.M. Preparation and Application of Machine-Made Sand Concrete with C50 Fly Ash. Fly Ash Compr. Util. 2006, 2, 28–29. [Google Scholar]

- Xingjun, L.; Ding, Y.; Cao, M. Progress of the researching on proportional rate design methods of self-compacting concrete. Concrete 2013, 8, 696–706. [Google Scholar]

- Wen, X.Q.; Wang, J.L.; Shan, J.H.; Liu, Y.; Long, F. Research on comparative experiments of proportion design method of self-compacting concrete. Concrete 2011, 28, 103–193. [Google Scholar]

- Edamatsu, Y.; Nishida, N.; Ouchi, M. A rational mix-design method for self-compacting concrete considering interaction between coarse aggregate and mortar particles. Mater. Struct. 1999, 309–320. [Google Scholar]

- Shi, C.; Yang, X.; Yu, Z.; Khayat, H. Design and application of self-compacting lightweight concretes. In Proceedings of the SCC’2005-China: 1st International Symposium on Design, Performance and Use of Self-Consolidating Concrete, Changsha, China, 26–28 May 2005; pp. 55–64. [Google Scholar]

- Ashtiani, M.S.; Scott, A.N.; Dhakal, R.P. Mechanical and fresh properties of high-strength self-compacting concrete containing class C fly ash. Constr. Build. Mater. 2013, 47, 1217–1224. [Google Scholar] [CrossRef]

- Tang, M.; Yang, S.; Guo, J.; Zhang, C.; Lu, M. Mix Design of Self-compacting Concrete Considering the Effect of Limestone Powder on Rheology. J. Build. Mater. 2022, 25, 191–198. [Google Scholar]

- Habibi, A.; Ghomashi, J. Development of an optimum mix design method for self-compacting concrete based on experimental results. Constr. Build. Mater. 2018, 168, 113–123. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, G.; Li, Y. Study on Acoustic Emission Characteristics of Self-Compacting Concrete under Uniaxial Compression Test. J. Renew. Mater. 2022, 10, 2287–2302. [Google Scholar] [CrossRef]

| Performance | Bulk Density | Performance Density | Fineness Modulus | Initial Setting Time | Final Setting Time | Fineness | |

|---|---|---|---|---|---|---|---|

| Raw Material | |||||||

| Ordinary Portland cement | ---- | 3100 kg/m3 | ---- | >150 min | <240 min | ---- | |

| River sand | 1600 kg/m3 | 2600 kg/m3 | 2.3–3.0 | ---- | ---- | ---- | |

| Fly ash (grade 1) | ---- | 2400 kg/m3 | ---- | ---- | ---- | ---- | |

| Gravel | 1500 kg/m3 | 1600 kg/m3 | ---- | ---- | ---- | ---- | |

| Polycarboxylic water reducer | ---- | ---- | ---- | ---- | ---- | ---- | |

| Raw Material | Cement | Fly Ash | Sand | Gravel | Water | Water Reducer |

|---|---|---|---|---|---|---|

| Mix proportion | 20.18 kg | 5.69 kg | 40.74 kg | 25.87 kg | 9.31 kg | 0.164 kg |

| Index | Test Performance | Numerical Range | Measured Value |

|---|---|---|---|

| Slump flow (mm) | Filling property | SF2 (660–755) | 720 |

| Extension time T500 (s) | Filling property | 2–5 | 4.2 |

| V-funnel time (s) | Filling property | 9–20 | 18.4 |

| H2/H1 | Interstitial permeability | ≥0.8 | 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Wang, G.; Li, Y. Study on Ultrasonic Nondestructive Testing of Self-Compacting Concrete under Uniaxial Compression Test. Materials 2022, 15, 4412. https://doi.org/10.3390/ma15134412

Sun Y, Wang G, Li Y. Study on Ultrasonic Nondestructive Testing of Self-Compacting Concrete under Uniaxial Compression Test. Materials. 2022; 15(13):4412. https://doi.org/10.3390/ma15134412

Chicago/Turabian StyleSun, Yongshuai, Guihe Wang, and Yixuan Li. 2022. "Study on Ultrasonic Nondestructive Testing of Self-Compacting Concrete under Uniaxial Compression Test" Materials 15, no. 13: 4412. https://doi.org/10.3390/ma15134412

APA StyleSun, Y., Wang, G., & Li, Y. (2022). Study on Ultrasonic Nondestructive Testing of Self-Compacting Concrete under Uniaxial Compression Test. Materials, 15(13), 4412. https://doi.org/10.3390/ma15134412