Rhombohedral Phase Formation in Yttria-Stabilized Zirconia Induced by Dental Technical Tools and Its Impact on Dental Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

| Abbreviation | Product | LOT | Yttria Content mol % 1 | Flexural Strength MPa 1 |

|---|---|---|---|---|

| 3Y_VT | VITA YZ HT | 83,290 | 3 | 1100 |

| 3Y_DD | DD Bio ZX2 | 5,032,106,002 | 3 | 1250 |

| 4Y_VT | VITA YZ ST | 65,890 | 4 | >850 |

| 4Y_DD | DD cube ONE | 7,162,042,001 | 4 | >1250 |

| 5Y_VT | VITA YZ XT | 61,962 | 5 | >600 |

| 5Y_DD | DD cubeX2 | 8,032,028,002 | 5 | 800 |

2.2. Methods

2.2.1. Mechanical Loading

2.2.2. Thermographic Analysis

2.2.3. X-ray Diffraction (XRD)

2.2.4. Rietveld Refinement

3. Results

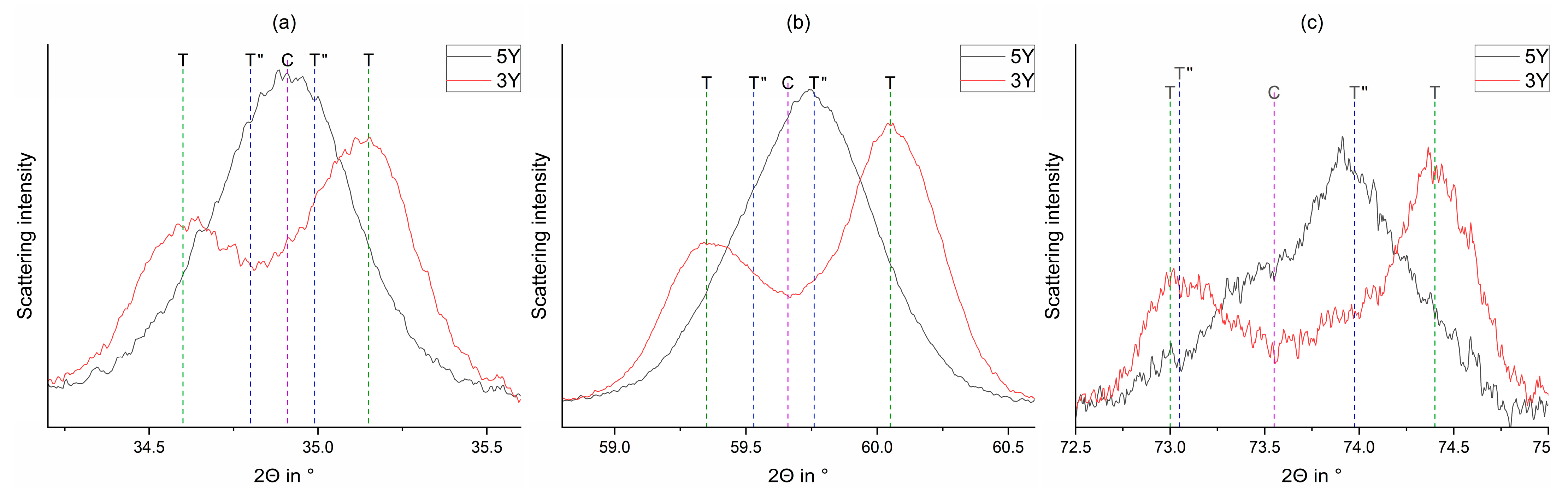

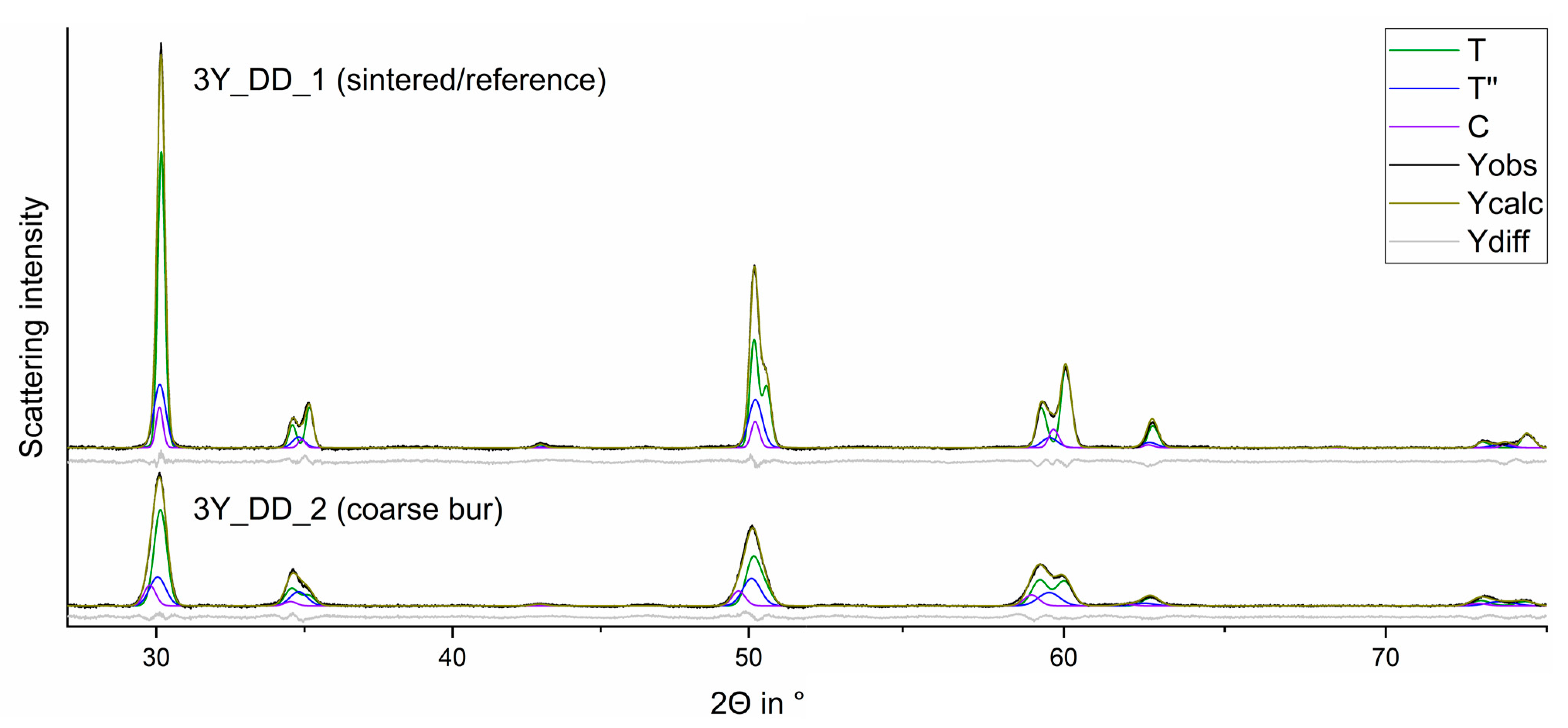

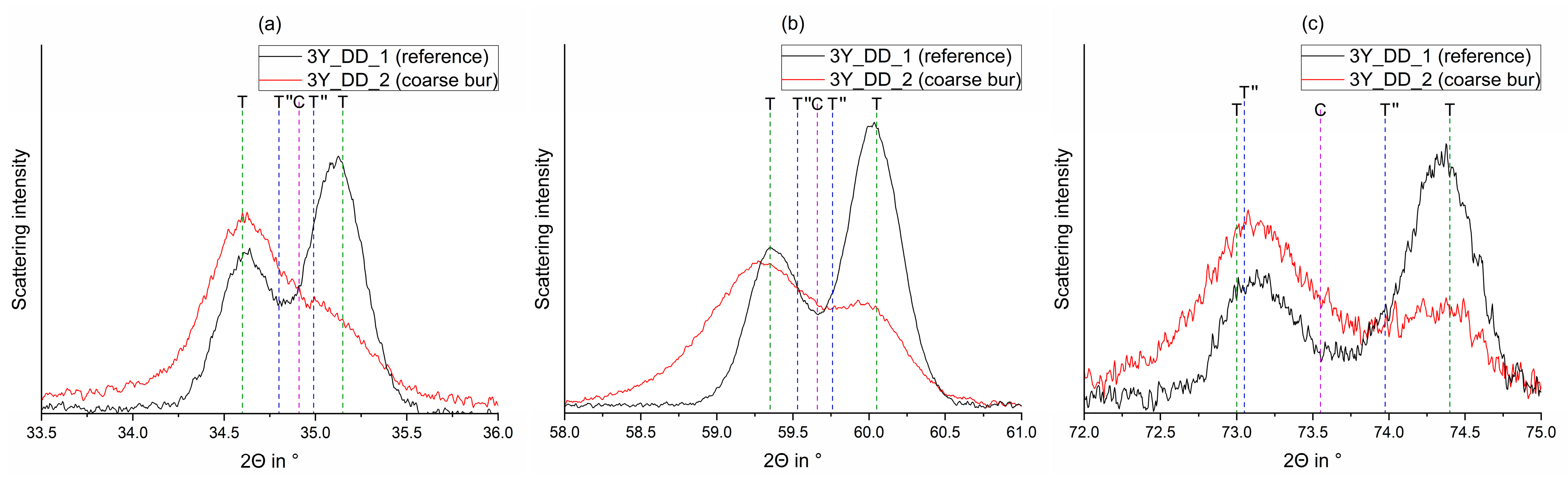

3.1. Coarse and Fine Diamond Burs

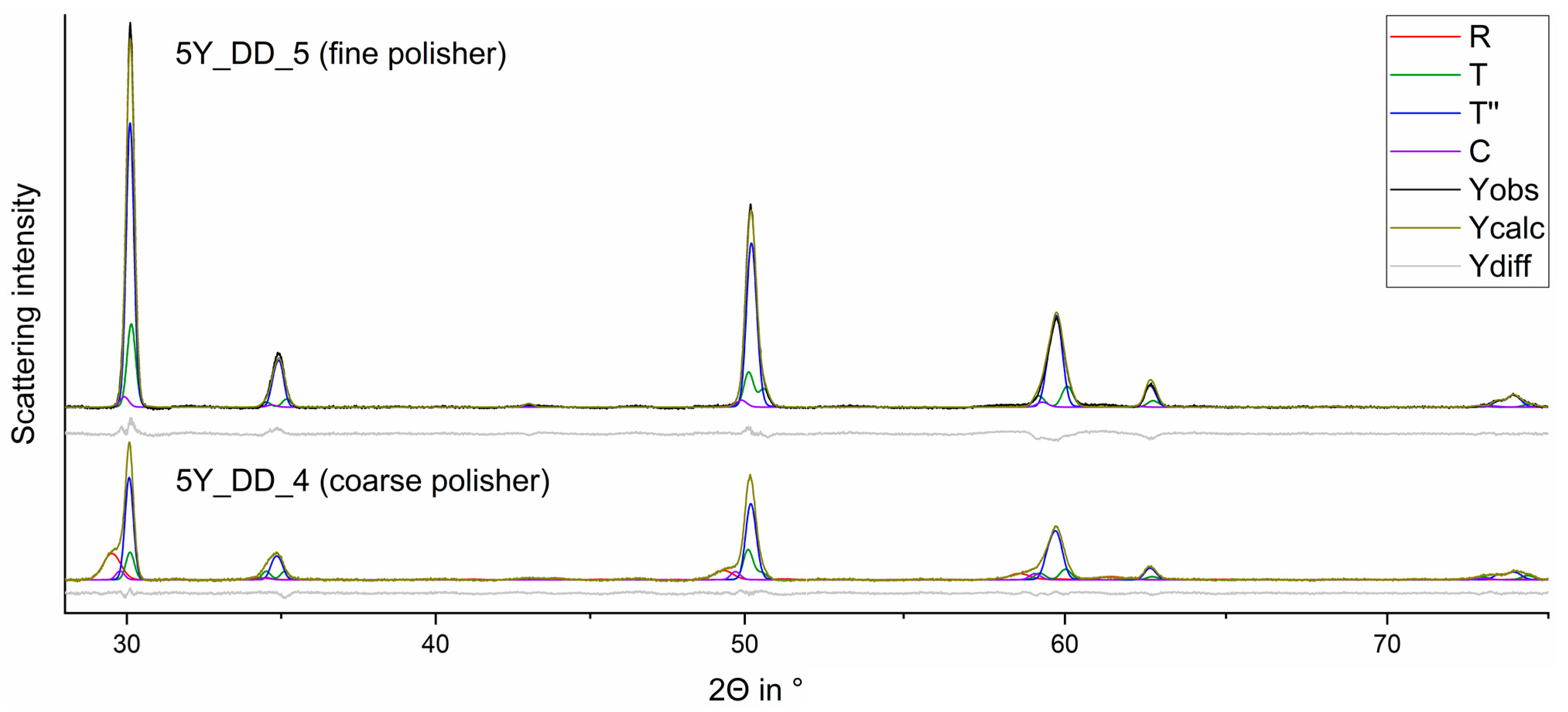

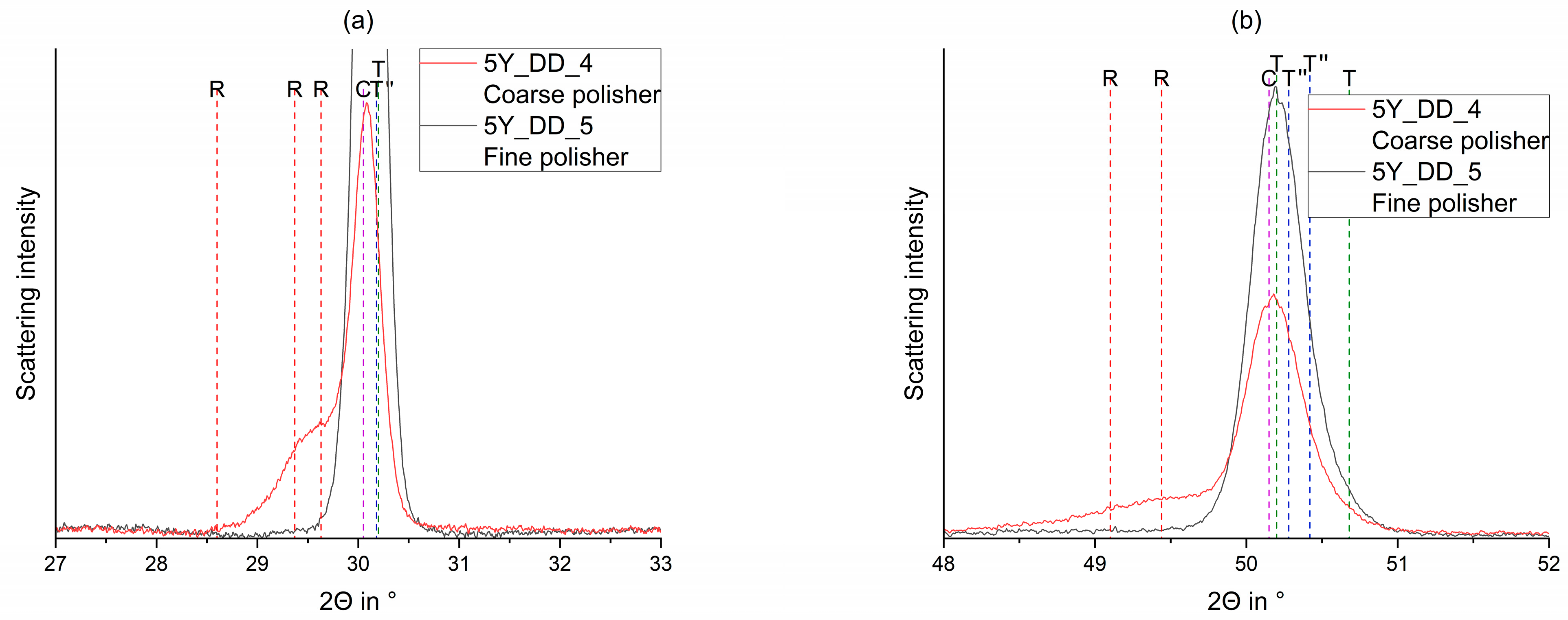

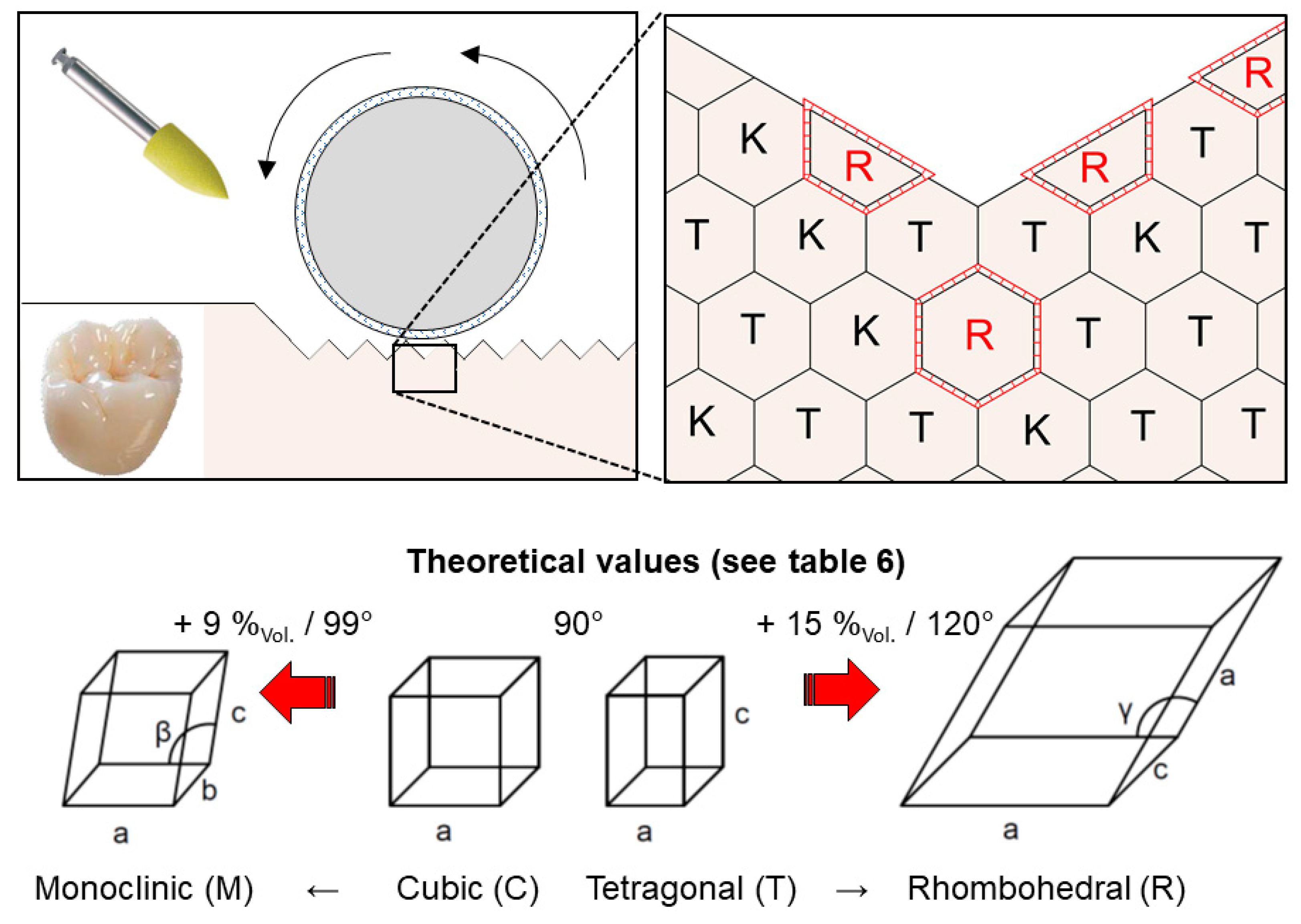

3.2. Coarse and Fine Polisher

4. Discussion

4.1. Coarse and Fine Diamond Burs

4.2. Coarse and Fine Polisher

5. Conclusions

- Polishing with coarse polishers can induce a partial rhombohedral phase transformation.

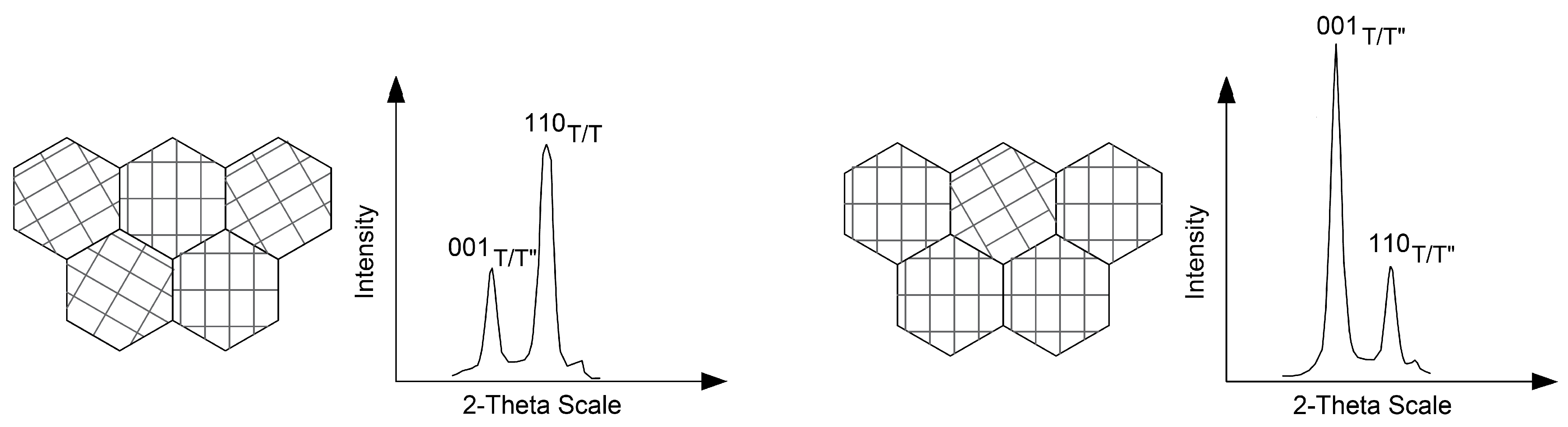

- All diamond burs used induce a break up of the layer structure of Y-PSZ and a subsequent preferred orientation shift to 0 0 1 T/T′′ at the expense of 1 1 0 T/T′′, but no phase transformation.

- Treatment with fine polishers did not induce any relevant phase transformation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| 3Y_VT | M | R | T | T′′ | C |

|---|---|---|---|---|---|

| 3Y_VT_1 (as sintered) | 0 | 0 | 82 | 7 | 11 |

| 3Y_VT_2 (coarse bur) | 0 | 0 | 64 | 22 | 12 |

| 3Y_VT_3 (fine bur) | 0 | 0 | 60 | 29 | 11 |

| 3Y_VT_4 (coarse polisher) | 0 | 30 | 39 | 16 | 15 |

| 3Y_VT_5 (fine polisher) | 0 | 0 | 74 | 8 | 18 |

| 3Y_DD | M | R | T | T′′ | C |

|---|---|---|---|---|---|

| 3Y_DD_1 (as sintered) | 0 | 0 | 80 | 8 | 12 |

| 3Y_DD_2 (coarse bur) | 0 | 0 | 67 | 17 | 16 |

| 3Y_DD_3 (fine bur) | 0 | 0 | 69 | 20 | 11 |

| 3Y_DD_4 (coarse polisher) | 0 | 14 | 68 | 14 | 4 |

| 3Y_DD_5 (fine polisher) | 0 | 0 | 84 | 7 | 9 |

| 4Y_VT | M | R | T | T′′ | C |

|---|---|---|---|---|---|

| 4Y_VT_1 (as sintered) | 0 | 0 | 60 | 21 | 19 |

| 4Y_VT_2 (coarse bur) | 0 | 0 | 44 | 39 | 17 |

| 4Y_VT_3 (fine bur) | 0 | 0 | 42 | 47 | 12 |

| 4Y_VT_4 (coarse polisher) | 0 | 30 | 25 | 34 | 11 |

| 4Y_VT_5 (fine polisher) | 0 | 0 | 54 | 27 | 19 |

| 4Y_DD | M | R | T | T′′ | C |

|---|---|---|---|---|---|

| 4Y_DD_1 (as sintered) | 0 | 0 | 60 | 24 | 16 |

| 4Y_DD_2 (coarse bur) | 0 | 0 | 53 | 32 | 15 |

| 4Y_DD_3 (fine bur) | 0 | 0 | 52 | 37 | 11 |

| 4Y_DD_4 (coarse polisher) | 0 | 18 | 53 | 23 | 6 |

| 4Y_DD_5 (fine polisher) | 0 | 0 | 60 | 29 | 11 |

| 5Y_VT | M | R | T | T′′ | C |

|---|---|---|---|---|---|

| 5Y_VT_1 (as sintered) | 0 | 0 | 24 | 64 | 12 |

| 5Y_VT_2 (coarse bur) | 0 | 0 | 28 | 56 | 16 |

| 5Y_VT_3 (fine bur) | 0 | 0 | 30 | 59 | 11 |

| 5Y_VT_4 (coarse polisher) | 0 | 15 | 18 | 62 | 5 |

| 5Y_VT_5 (fine polisher) | 0 | 0 | 28 | 57 | 15 |

| 5Y_DD | M | R | T | T′′ | C |

|---|---|---|---|---|---|

| 5Y_DD_1 (as sintered) | 0 | 0 | 24 | 66 | 10 |

| 5Y_DD_2 (coarse bur) | 0 | 0 | 23 | 57 | 20 |

| 5Y_DD_3 (fine bur) | 0 | 0 | 22 | 61 | 17 |

| 5Y_DD_4 (coarse polisher) | 0 | 18 | 15 | 60 | 7 |

| 5Y_DD_5 (fine polisher) | 0 | 0 | 26 | 63 | 11 |

References

- Rauch, A.; Schrock, A.; Schierz, O.; Hahnel, S. Material preferences for tooth-supported 3-unit fixed dental prostheses: A survey of German dentists. J. Prosthet. Dent. 2021, 126, 91.e1–91.e6. [Google Scholar] [CrossRef] [PubMed]

- Rauch, A.; Schrock, A.; Schierz, O.; Hahnel, S. Material selection for tooth-supported single crowns-a survey among dentists in Germany. Clin. Oral Investig. 2021, 25, 283–293. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Inokoshi, M.; Batuk, M.; Hadermann, J.; Naert, I.; van Meerbeek, B.; Vleugels, J. Strength, toughness and aging stability of highly-translucent Y-TZP ceramics for dental restorations. Dent. Mater. 2016, 32, e327–e337. [Google Scholar] [CrossRef] [PubMed]

- Rosentritt, M.; Preis, V.; Behr, M.; Strasser, T. Fatigue and wear behaviour of zirconia materials. J. Mech. Behav. Biomed. Mater. 2020, 110, 103970. [Google Scholar] [CrossRef]

- Cappare, P.; Ferrini, F.; Mariani, G.; Nagni, M.; Cattoni, F. Implant rehabilitation of edentulous jaws with predominantly monolithic zirconia compared to metal-acrylic prostheses: A 2-year retrospective clinical study. J. Biol. Regul. Homeost. Agents 2021, 35, 99–112. [Google Scholar] [CrossRef]

- Garvie, R.C. Ceramic steel? Nature 1975, 258, 703–704. [Google Scholar] [CrossRef]

- Zhang, Y.; Lawn, B.R. Novel Zirconia Materials in Dentistry. J. Dent. Res. 2018, 97, 140–147. [Google Scholar] [CrossRef]

- Kelly, J.R.; Denry, I. Stabilized zirconia as a structural ceramic: An overview. Dent. Mater. 2008, 24, 289–298. [Google Scholar] [CrossRef]

- Pecho, O.E.; Ghinea, R.; Ionescu, A.M.; La Cardona, J.D.C.; Paravina, R.D.; Pérez, M.D.M. Color and translucency of zirconia ceramics, human dentine and bovine dentine. J. Dent. 2012, 40 (Suppl. 2), e34–e40. [Google Scholar] [CrossRef]

- Roehling, S.; Schlegel, K.A.; Woelfler, H.; Gahlert, M. Zirconia compared to titanium dental implants in preclinical studies-A systematic review and meta-analysis. Clin. Oral Implants Res. 2019, 30, 365–395. [Google Scholar] [CrossRef]

- Roehling, S.; Woelfler, H.; Hicklin, S.; Kniha, H.; Gahlert, M. A Retrospective Clinical Study with Regard to Survival and Success Rates of Zirconia Implants up to and after 7 Years of Loading. Clin. Implant Dent. Relat. Res. 2016, 18, 545–558. [Google Scholar] [CrossRef] [PubMed]

- Haro Adánez, M.; Nishihara, H.; Att, W. A systematic review and meta-analysis on the clinical outcome of zirconia implant-restoration complex. J. Prosthodont. Res. 2018, 62, 397–406. [Google Scholar] [CrossRef] [PubMed]

- Passia, N.; Chaar, M.S.; Kern, M. Outcome of posterior fixed dental prostheses made from veneered zirconia over an observation period of up to 13 years. J. Dent. 2019, 86, 126–129. [Google Scholar] [CrossRef]

- Klimke, J.; Trunec, M.; Krell, A. Transparent Tetragonal Yttria-Stabilized Zirconia Ceramics: Influence of Scattering Caused by Birefringence. J. Am. Ceram. Soc. 2011, 94, 1850–1858. [Google Scholar] [CrossRef]

- Kisi, E.H.; Howard, C.J. Crystal Structures of Zirconia Phases and their Inter-Relation. Key Eng. Mater. 1998, 153–154, 1–36. [Google Scholar] [CrossRef]

- Lipkin, D.M.; Krogstad, J.A.; Gao, Y.; Johnson, C.A.; Nelson, W.A.; Levi, C.G. Phase Evolution upon Aging of Air-Plasma Sprayed t ′-Zirconia Coatings: I-Synchrotron X-ray Diffraction. J. Am. Ceram. Soc. 2013, 96, 290–298. [Google Scholar] [CrossRef]

- Krogstad, J.A.; Gao, Y.; Bai, J.; Wang, J.; Lipkin, D.M.; Levi, C.G. In Situ Diffraction Study of the High-Temperature Decomposition of t′ -Zirconia. J. Am. Ceram. Soc. 2015, 98, 247–254. [Google Scholar] [CrossRef]

- Keuper, M.; Berthold, C.; Nickel, K.G. Long-time aging in 3 mol.% yttria-stabilized tetragonal zirconia polycrystals at human body temperature. Acta Biomater. 2014, 10, 951–959. [Google Scholar] [CrossRef]

- Lughi, V.; Sergo, V. Low temperature degradation -aging- of zirconia: A critical review of the relevant aspects in dentistry. Dent. Mater. 2010, 26, 807–820. [Google Scholar] [CrossRef]

- Shen, J.; Xie, H.; Wu, X.; Yang, J.; Liao, M.; Chen, C. Evaluation of the effect of low-temperature degradation on the translucency and mechanical properties of ultra-transparent 5Y-TZP ceramics. Ceram. Int. 2020, 46, 553–559. [Google Scholar] [CrossRef]

- Tholey, M.J.; Berthold, C.; Swain, M.V.; Thiel, N. XRD2 micro-diffraction analysis of the interface between Y-TZP and veneering porcelain: Role of application methods. Dent. Mater. 2010, 26, 545–552. [Google Scholar] [CrossRef] [PubMed]

- Vila-Nova, G.D.C. Effect of finishing/polishing techniques and low temperature degradation on the surface topography, phase transformation and flexural strength of ultra-translucent ZrO2 ceramic. Dent. Mater. 2020, 36, e126–e139. [Google Scholar] [CrossRef] [PubMed]

- Edalati, K.; Toh, S.; Ikoma, Y.; Horita, Z. Plastic deformation and allotropic phase transformations in zirconia ceramics during high-pressure torsion. Scr. Mater. 2011, 65, 974–977. [Google Scholar] [CrossRef]

- Weber, B.C. Observations on the Stabilization of Zirconia. J. Am. Ceram. Soc. 1956, 56, 197–206. [Google Scholar] [CrossRef]

- Fabris, S. A stabilization mechanism of zirconia based on oxygen vacancies only. Acta Mater. 2002, 50, 5171–5178. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Chen, I.W.; Penner-Hahn, J.E. Effect of Dopants on Zirconia Stabilization—An X-ray Absorption Study: II, Tetravalent Dopants. J. Am. Ceram. Soc. 1994, 5, 1281–1288. [Google Scholar] [CrossRef]

- Howard, C.J.; Hill, R.J. The polymorphs of zirconia: Phase abundance and crystal structure by Rietveld analysis of neutron and X-ray diffraction data. J. Mater. Sci. 1991, 82, 127–134. [Google Scholar] [CrossRef]

- Chevalier, J.; Cales, B.; Drouin, J.M. Low-Temperature Aging of Y-TZP Ceramics. J. Am. Ceram. Soc. 1999, 9, 2150–2154. [Google Scholar] [CrossRef]

- Keuper, M.; Eder, K.; Berthold, C.; Nickel, K.G. Direct evidence for continuous linear kinetics in the low-temperature degradation of Y-TZP. Acta Biomater. 2013, 9, 4826–4835. [Google Scholar] [CrossRef]

- Krogstad, J.A.; Leckie, R.M.; Krämer, S.; Cairney, J.M.; Lipkin, D.M.; Johnson, C.A.; Levi, C.G. Phase Evolution upon Aging of Air Plasma Sprayed t′-Zirconia Coatings: II-Microstructure Evolution. J. Am. Ceram. Soc. 2013, 96, 299–307. [Google Scholar] [CrossRef]

- Kitano, Y.; Mori, Y.; Ishitani, A.; Masaki, T. Rhombohedral Phase in Y2O3-Partially-Stabilized ZrO2. J. Amer. Ceram. Soc. 1988, 1, C34–C36. [Google Scholar] [CrossRef]

- Kim, D.-J.; Jung, H.-J.; Kim, H.-J. t → r phase transformation of tetragonal zirconia alloys by grinding. Mat. Sci. Lett. 1995, 14, 285–288. [Google Scholar] [CrossRef]

- Yoshida, K. Influence of alumina air-abrasion for highly translucent partially stabilized zirconia on flexural strength, surface properties, and bond strength of resin cement. J. Appl. Oral Sci. 2020, 28, e20190371. [Google Scholar] [CrossRef] [PubMed]

- Inokoshi, M.; Shimizu, H.; Nozaki, K.; Takagaki, T.; Yoshihara, K.; Nagaoka, N.; Zhang, F.; Vleugels, J.; van Meerbeek, B.; Minakuchi, S. Crystallographic and morphological analysis of sandblasted highly translucent dental zirconia. Dent. Mater. 2018, 34, 508–518. [Google Scholar] [CrossRef] [PubMed]

- Ruiz, L.; Readey, M.J. Effect of Heat Treatment on Grain Size, Phase Assemblage, and Mechanical Properties of 3 mol% Y-TZP. J. Am. Ceram. Soc. 1996, 9, 2331–2340. [Google Scholar] [CrossRef]

- Hasegawa, H.; Hioki, T.; Kamigaito, O. Cubic-to-rhombohedral phase transformation in zirconia by ion implantation. J. Mater. Sci. Lett. 1985, 4, 1092–1094. [Google Scholar] [CrossRef]

- Sailer, I.; Makarov, N.A.; Thoma, D.S.; Zwahlen, M.; Pjetursson, B.E. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part I: Single crowns (SCs). Dent. Mater. 2015, 31, 603–623. [Google Scholar] [CrossRef] [Green Version]

- Dimberg, L.; Arnrup, K.; Bondemark, L. The impact of malocclusion on the quality of life among children and adolescents: A systematic review of quantitative studies. Eur. J. Orthod. 2015, 37, 238–247. [Google Scholar] [CrossRef]

- Miyazaki, T.; Nakamura, T.; Matsumura, H.; Ban, S.; Kobayashi, T. Current status of zirconia restoration. J. Prosthodont. Res. 2013, 57, 236–261. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Spies, B.C.; Vleugels, J.; Reveron, H.; Wesemann, C.; Müller, W.-D.; van Meerbeek, B.; Chevalier, J. High-translucent yttria-stabilized zirconia ceramics are wear-resistant and antagonist-friendly. Dent. Mater. 2019, 35, 1776–1790. [Google Scholar] [CrossRef]

- Wertz, M.; Fuchs, F.; Hoelzig, H.; Wertz, J.M.; Kloess, G.; Hahnel, S.; Rosentritt, M.; Koenig, A. The Influence of Surface Preparation, Chewing Simulation, and Thermal Cycling on the Phase Composition of Dental Zirconia. Materials 2021, 14, 2133. [Google Scholar] [CrossRef] [PubMed]

- Block, S. Pressure-Temperature Phase Diagram of Zirconia. J. Am. Ceram. Soc. 1985, 9, 497–499. [Google Scholar] [CrossRef]

- Ohtaka, O. Stability of Monoclinic and Orthorhombic Zirconia: Studies by High-Pressure Phase Equilibria and Calorimetry. J. Am. Ceram. Soc. 1991, 3, 505–509. [Google Scholar] [CrossRef]

- Shukla, S.; Seal, S. Mechanisms of room temperature metastable tetragonal phase stabilisation in zirconia. Int. Mater. Rev. 2005, 50, 45–64. [Google Scholar] [CrossRef]

- Ban, S. Chemical durability of high translucent dental zirconia. Dent. Mater. J. 2020, 39, 12–23. [Google Scholar] [CrossRef] [Green Version]

- Song, X.-F.; Yin, L.; Han, Y.-G.; Li, J. Finite element analysis of subsurface damage of ceramic prostheses in simulated intraoral dental resurfacing. J. Biomed. Mater. Res. B Appl. Biomater. 2008, 85, 50–59. [Google Scholar] [CrossRef]

- Wertz, M.; Hoelzig, H.; Kloess, G.; Hahnel, S.; Koenig, A. Influence of Manufacturing Regimes on the Phase Transformation of Dental Zirconia. Materials 2021, 14, 4980. [Google Scholar] [CrossRef]

- Lamas, D.G.; Walsöe de Reca, N.E. X-ray diffraction study of compositionally homogeneous, nanocrystalline yttria-doped zirconia powders. J. Mat. Sci. 2000, 691, 5563–5567. [Google Scholar] [CrossRef]

- Xie, R.; Li, Y.; Liu, H.; Zhang, X. Insights into the structural, microstructural and physical properties of multiphase powder mixtures. J. Alloys Compd. 2017, 691, 378–387. [Google Scholar] [CrossRef]

- Yashima, M.; Sasaki, S.; Kakihana, M.; Yamaguchi, Y.; Arashi, H.; Yoshimura, M. Oxygen-induced structural change of the tetragonal phase around the tetragonal–cubic phase boundary in ZrO2–YO 1.5 solid solutions. Acta Cryst. B Struct. Sci. 1995, 51, 381. [Google Scholar] [CrossRef]

- Pitschke, W.; Hermann, H.; Mattern, N. The influence of surface roughness on diffracted X-ray intensities in Bragg–Brentano geometry and its effect on the structure determination by means of Rietveld analysis. Powder Diffr. 1993, 8, 74–83. [Google Scholar] [CrossRef]

- Dollase, W.A. Correction of intensities for preferred orientation in powder diffractometry: Application of the March model. J. Appl. Cryst. 1986, 19, 267–272. [Google Scholar] [CrossRef]

- March, A. Mathematische Theorie der Regelung nach der Korngestah bei affiner Deformation. Z. Krist. 1932, 81, 285–297. [Google Scholar] [CrossRef]

- Li, P.; Chen, I.-W.; Penner-Hahn, J. Effect of Dopants on Zirconia Stabilization—An X-ray Absorption Study: I, Trivalent Dopants. J. Am. Ceram. Soc. 1994, 77, 118–128. [Google Scholar] [CrossRef] [Green Version]

- Denry, I.L.; Holloway, J.A. Microstructural and crystallographic surface changes after grinding zirconia-based dental ceramics. J. Biomed. Mater. Res. B Appl. Biomater. 2006, 76, 440–448. [Google Scholar] [CrossRef] [PubMed]

- Botelho, M.G.; Dangay, S.; Shih, K.; Lam, W.Y.H. The effect of surface treatments on dental zirconia: An analysis of biaxial flexural strength, surface roughness and phase transformation. J. Dent. 2018, 75, 65–73. [Google Scholar] [CrossRef]

- Song, X.-F.; Yin, L.; Han, Y.-G.; Wang, H. In vitro rapid intraoral adjustment of porcelain prostheses using a high-speed dental handpiece. Acta Biomater. 2008, 4, 414–424. [Google Scholar] [CrossRef] [PubMed]

| Treatment Number | Processing Step |

|---|---|

| 1 | Sintered (glazed) FDP |

| 2 | Sintered (glazed) FDP processed with a coarse diamond bur |

| 3 | Sintered (glazed) FDP processed with a fine diamond bur |

| 4 | Sintered (glazed) FDP processed with a coarse polisher |

| 5 | Sintered (glazed) FDP processed with a fine polisher |

| Dental Technical Tool | Revolutions rpm | Vertical Load N | Time of Processing min |

|---|---|---|---|

| Coarse diamond bur | 400,000 | 5–15 | 4 |

| Fine diamond bur | 400,000 | 5–15 | 4 |

| Coarse polisher | 10,000 | 5–15 | 4 |

| Fine polisher | 5000 | 5–15 | 4 |

| Max. Temperatures on the Diamond Burs in °C | Max. Temperatures on the FDPs in °C | |

|---|---|---|

| Coarse diamond bur | >320 | ~190 |

| Fine diamond bur | >320 | ~190 |

| Max. Temperatures on the Polisher in °C | Max. Temperatures on the FDP in °C | |

|---|---|---|

| Coarse polisher | ~175 | ~90 |

| Fine polisher | ~115 | ~65 |

| Crystal System | O- Bonds per Zr- Atom | Atoms per Elementary Cell | Volume in Å3 | Volume per Atom in Å3 |

|---|---|---|---|---|

| Cubic | 8 | 12 | 133 | 11 |

| Tetragonal | 8 | 6 | 67 | 11 |

| Monoclinic | 7 | 12 | 144 | 12 |

| Rhombohedral | 6 | 57 | 748 | 13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wertz, M.; Schmidt, M.B.; Hoelzig, H.; Wagner, M.; Abel, B.; Kloess, G.; Hahnel, S.; Koenig, A. Rhombohedral Phase Formation in Yttria-Stabilized Zirconia Induced by Dental Technical Tools and Its Impact on Dental Applications. Materials 2022, 15, 4471. https://doi.org/10.3390/ma15134471

Wertz M, Schmidt MB, Hoelzig H, Wagner M, Abel B, Kloess G, Hahnel S, Koenig A. Rhombohedral Phase Formation in Yttria-Stabilized Zirconia Induced by Dental Technical Tools and Its Impact on Dental Applications. Materials. 2022; 15(13):4471. https://doi.org/10.3390/ma15134471

Chicago/Turabian StyleWertz, Markus, Michael Benno Schmidt, Hieronymus Hoelzig, Maximilian Wagner, Bernd Abel, Gert Kloess, Sebastian Hahnel, and Andreas Koenig. 2022. "Rhombohedral Phase Formation in Yttria-Stabilized Zirconia Induced by Dental Technical Tools and Its Impact on Dental Applications" Materials 15, no. 13: 4471. https://doi.org/10.3390/ma15134471

APA StyleWertz, M., Schmidt, M. B., Hoelzig, H., Wagner, M., Abel, B., Kloess, G., Hahnel, S., & Koenig, A. (2022). Rhombohedral Phase Formation in Yttria-Stabilized Zirconia Induced by Dental Technical Tools and Its Impact on Dental Applications. Materials, 15(13), 4471. https://doi.org/10.3390/ma15134471