1. Introduction

In recent years, the acceleration of the development of eco-friendly vehicles such as electric vehicles and hydrogen vehicles has led to a growing demand for lightweighting of the vehicle body to improve mileage. In addition, for passenger safety and the protection of batteries and fuel cells, many efforts have been made to secure the crashworthiness of the vehicle body. Automobile body weight can be reduced by using lightweight materials such as advanced high-strength steel (AHSS), aluminum alloys, magnesium alloys, glass-fiber composites, and carbon-fiber composites. Although AHSS results in the least weight reduction among these lightweight materials, it is relatively inexpensive to produce AHSS automotive body components [

1,

2,

3]. Furthermore, a vehicle structure composed of AHSS showed outstanding crash safety performance in a simulation of three crash tests: frontal wall impact, side barrier impact, and roof strength tests [

4]. To reduce the cost and meet safety regulations, automakers have increased the proportion of AHSS used in vehicle structures [

5]. Moreover, to reduce the manufacturing cost of mass-produced vehicle components, the cold forming process is generally used. However, the cold forming of AHSS sheets is relatively vulnerable to tool wear. The higher strength characteristics of AHSS sheets in comparison with conventional steel sheets may generate premature tool wear, which leads to many problems such as reduced productivity, reduced product quality, and increased maintenance cost. Therefore, in the mass production of automobile components using AHSS sheets, the investigation of tool wear resistance is essential for efficient process management.

Owing to the problems with tool wear caused by the increase in the strength of steel sheets applied to the automobile body, several studies to delay or avoid the wear responses in sheet metal forming have been investigated. The sensitivity of various tooling and process parameters affecting the tool wear resistance have been studied. Pereira et al. [

6] investigated the effect of machining error of the die profile shape on tool wear in sheet metal forming. A small and localized change in the die radius profile shape has a significant effect on tool-life reduction. Podgornik and Jerina [

7] confirmed the effect of surface roughness on galling resistance for coarse and fine ground forming tools with a monolayer physical vapor deposition (PVD) TiN hard coating, and multilayer plasma-assisted chemical vapor deposition (PACVD) W-doped DLC coating under dry sliding conditions. Podgornik et al. [

8] investigated the influence of the surface preparation condition of forming tool steel with PVD coatings (TiN, TiB

2, TaC, and WC/C) on galling properties. Gonzalez-Pociño et al. [

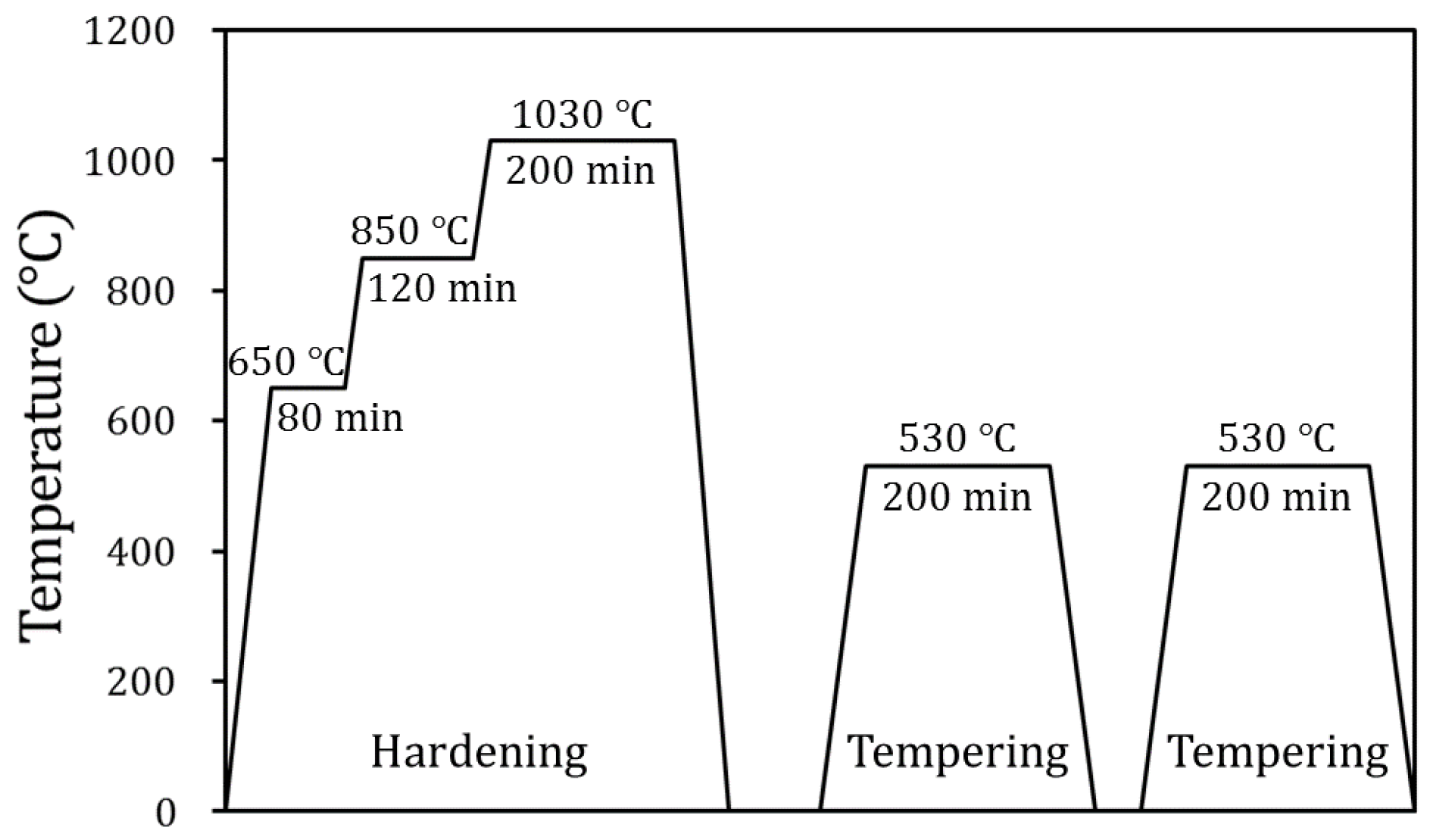

9] confirmed the heat treatment parameters (quenching, tempering, and nitriding process) that significantly affect adhesive wear resistance through an experiment in which these parameters were deliberately changed. Ogunbiyi et al. [

10] suggested that the wear performance of Inconel 738 low-carbon composites could be enhanced with the addition of graphene nanoplatelets. Büyükkayacı et al. [

11] investigated the influence of mechanical alloying time on wear resistance for Fe–Cu–C alloys. Sıralı et al. [

12] determined the effect of grain size reduction of titanium–zirconium–molybdenum alloys obtained with the addition of Ti on wear performance. Woodward et al. [

13] investigated the sliding wear response of G320 grey cast iron in different microstructure conditions resulting from quench and temper heat treatment. Hou et al. [

14] evaluated the galling behaviors in sheet metal forming under various tool conditions with respect to hardness, surface roughness, and coating. Ghiotti and Bruschi [

15] and Cora et al. [

16] investigated the effect of various coating techniques on wear resistance by using a wear test system imitating stamping process conditions. van der Heide et al. [

17] evaluated the effects of various lubricated conditions on galling by using a slider-on-sheet tribometer.

Although the wear resistance of a tool can be improved by controlling various tooling and process parameters affecting the tool wear resistance as presented in the papers described above, they are not sufficient to predict the evolutionary behavior of tool wear and the initiation of tool failure. An experimental method to estimate the wear resistance of a tool can enable the prediction of the tool lifetime and facilitate effective management of stamping tools in mass production. Therefore, extensive experimental methods have been proposed for estimating the wear of stamping tools in the sheet metal forming process. Bang et al. [

18] performed a pin-on-disk test based on the Taguchi method to construct a wear prediction model in sheet metal forming. However, it has the disadvantage that the pin repeatedly contacts the already worn sheet material surface. To compensate for this shortcoming, slider-on-sheet–type wear test methods, in which the tool comes into contact with the virgin sheet material, have been used [

19,

20,

21,

22,

23]. However, the wear test methods described above do not reflect the deformation modes encountered in automotive sheet metal forming. Thus, representative wear tests considering the actual conditions prevalent in automotive sheet metal forming were performed, such as U-bending [

6,

24,

25,

26,

27,

28], bending under tension [

29,

30,

31,

32,

33], and deep drawing [

34]. However, they are cumbersome and uneconomical to perform on stamping tools with a large number of strokes. A wear test should be fast, convenient, efficient, and economical to investigate the wear characteristics of a stamping tool and reflect the real stamping conditions prevalent in automotive sheet metal forming. Bang et al. [

35] proposed a systematic wear test methodology using a progressive die set in sheet metal forming. This apparatus was designed to conduct wear evaluation of four types of punches simultaneously with a single press stroke. Although various experimental methods have been presented for evaluating the tool wear in sheet metal forming, the wear evaluation of the press forming tool still has limitations in that it entails significant cost, time, and human effort.

To reduce the time required for tool wear prediction in sheet metal forming, several numerical simulation studies have been conducted on tool wear prediction. Hoffmann et al. [

36] proposed a wear simulation scheme using Archard’s wear equation to calculate the elemental wear, which is linearly proportional to the number of strokes. However, in sheet metal forming, the tool wear is nonlinear with respect to the number of strokes. Therefore, many efforts have been made to estimate the wear behavior of stamping tools reasonably and accurately. Ersoy-Nürnberg et al. [

37] proposed a modified Archard’s model with a variable wear coefficient with respect to the loading duration. The wear coefficient is a function of the accumulated wear work and is determined through deep-drawing experiments. Wang et al. [

38] approximated the changes in wear coefficient during testing by using pin-on-disk test results to reflect the variation of wear characteristics reasonably. The studies described above used a simulation scheme of updating the geometry based on changes to the geometry calculated from interactive iterations of forming and wear simulation. A wear simulation calculates elemental wear using contact-related information obtained from a forming simulation. The updated geometry from the wear simulation is used in the next forming simulation. These procedures are repeated until the desired iteration. Therefore, the conventional wear simulation scheme considering the geometry update requires substantial computational time to predict the wear of forming tools. In addition, because the studies described above evaluated only simple models, wear simulation for complex and large parts such as automobile components requires massive computational time. Therefore, it is necessary to establish a reasonable wear simulation process that takes less computational time and considers the nonlinear tool wear behavior in sheet metal forming.

The present study developed a wear simulation procedure capable of predicting the nonlinear wear behavior of stamping tools in reduced computational time. A nonlinear equation from a modified form of Archard’s wear model was constructed based on the wear test results of a stamping process for different punch shapes (R3.0 and R5.5) and coating conditions (PVD CrN and AlTiCrN coatings). The scale factor, which represents the changes in wear properties with respect to wear depth, was utilized in the wear simulation to avoid the update of geometry from the previous iteration of wear simulation. By formulating a wear coefficient of Archard’s wear model as a function of strokes and implementing the wear coefficient into the scale factor of wear simulation, the nonlinear wear behavior of the stamping tools could be estimated. Therefore, the suggested wear simulation method can save computational time in the prediction of the nonlinear wear behavior of stamping tools.

3. Forming Simulation

An FE simulation was conducted to predict the contact conditions on the punch surface during the stamping process, which was performed using LS-Dyna R11.0 explicit code [

42]. To reduce the computational time, the simulation was simplified to a half model using symmetric boundary conditions. Ersoy-Nürnberg et al. [

37] reported that the elastic deformation of a tool is not significantly correlated to the contact pressure distribution on the tool surface. On the other hand, Pereira et al. [

24] confirmed that the analytical rigid tool model (E = ∞) and the elastic tool model (E = 205 GPa) were compared to confirm the effect of the elasticity of the tool material on the contact pressure. The maximum contact pressure of the analytical rigid tool solution was predicted to be 30% higher than that of the elastic tool solution. According to the literature [

43,

44], the elastic modulus of the CrN and AlTiCrN coatings are 400.0 and 469.5 GPa, respectively, so the difference in maximum contact pressure between the tool model to which the elastic modulus of the coating is applied and the analytical rigid tool model is expected to be less than 30%. Moreover, for wear simulation of complex and large parts such as automobile components, the tools modelled with deformable solid elements require significant computational time, so rigid-body modelling of the tools is usually assumed in order to simplify the simulation model. In this sense, the tools (punch, pad, and die) were modelled with rigid bodies. They also demonstrated that when a blank was modelled with shell and solid elements, the wear simulation results for both element types were in excellent agreement with the experimental results. Thus, the blank was discretized by deformable shell elements, which also helps to reduce the computational time.

The contact characteristics on the tool surface are sensitive to the mesh quality. Thus, the sensitivity of the contact interface mesh size to the contact pressure was confirmed for the punch geometry with a radius of 3.0 mm. The mesh size at the punch contact interface was evaluated for 0.2 mm, 0.4 mm and 0.8 mm. To reduce computational time, the mesh refinement method was applied to the simulation model. The initial blank mesh size was 5.0 mm. By setting the mesh refinement method to 6, 5, and 4 levels, the final blank mesh size was 0.156, 0.313, and 0.625 mm for each punch mesh size case, respectively. Pad and die contact pressure prediction does not require accuracy, thus it was modelled with a relatively coarse size of 0.5 mm. FE modeling for the simulation is shown in

Figure 5 with the FE model details summarized in

Table 5.

The number of integration points in the thickness direction of the blank was set to 5. Pereira et al. [

24] confirmed that a Coulomb friction coefficient of 0.15 was appropriate to predict an accurate contact pressure distribution by comparing experiments and numerical simulations of the channel forming process. In this study, a Coulomb friction coefficient of 0.15 was assumed at the contact interface between the punch and blank because it is difficult to calculate the appropriate friction coefficient by measuring the punch reaction force of the stamping process among the various metalworking operations of the employed progressive die tool. Amounts of contact pressure generated on the contact interface are affected by the strength of the steel sheet. As shown in

Table 1, the 1.2-mm-thick TRIP1180 steel sheet shows anisotropic characteristics. Therefore, Hill’s 1948 yield criteria [

45] were employed to consider the anisotropic plastic deformation behavior and to predict the accurate contact pressure. The anisotropic parameters of the Hill’s 1948 yield criteria used in the simulation are summarized in

Table 6. TRIP1180 with a thickness of 1.2 mm was used as the blank material, as summarized in

Table 1. The padding force was 12.0 kN, which is sufficient to hold the sheet metal during the stamping process. The punch stroke was 35.0 mm.

Figure 6 compares the contact pressure history at a node on the punch radius where the highest contact pressure occurs to evaluate contact characteristics according to mesh sizes and predicted contact pressures for all mesh size cases are of similar magnitude. The simulation was performed on a computer with an Intel Core i7-6700 CPU and 8 GB RAM. Computational time was approximately 8 h, 2 h, and 20 min, respectively, as summarized in

Table 5. Thus, a mesh size of 0.8 mm at the punch contact interface can effectively reduce computational time. However, as shown in

Figure 5, if the mesh size at the contact interface is coarse, the number of elements between 55 and 90° on the punch radius is insufficient such that it is difficult to accurately analyze contact characteristics over the punch radius. Therefore, in the simulation cases for this study, a 0.2 mm mesh size was applied at the punch contact interface, and 0.156 mm was used for the final blank mesh size by applying six levels of the mesh refinement method, which is sufficiently refined for accurate prediction of the contact conditions on the punch surface.

In sheet metal forming, the contact pressure and sliding distance are the most significant factors influencing tool wear [

24,

46,

47,

48,

49]. Thus, these two factors on the punch radius were investigated. To understand the time-dependent evolution of contact pressure along the punch radius during the stamping process,

Figure 7 shows contour plots of the contact pressure over the punch radius during stamping. The ordinate represents the punch stroke level during stamping, while the abscissa represents the angle on the punch radius. As shown in

Figure 7, the contact pressure levels over the radius of the R3.0 punch were higher than that over the radius of the R5.5 punch.

Figure 8a plots the maximum contact pressure with respect to the punch stroke level for each punch shape. A highly localized contact pressure was distributed on both punch shapes between approximately 10.0 mm and 13.0 mm of the punch stroke. In this punch stroke range, the maximum contact pressures acting on the R3.0 and R5.5 punches were 1.707 GPa and 1.372 GPa, respectively. These maximum contact pressures moved along the punch radius transiently from 55.0° to approximately 83.0° for both the R3.0 and R5.5 punches, as shown in

Figure 8b, which plots the angular location of the maximum contact pressure as the punch stroke progresses. A relatively high contact pressure was experienced over most of the angular range of the punch radius during the short punch strokes. Pereira [

24] defined the initial region of the stamping process as a transient region where the angular location and magnitude of the contact pressure on the punch radius change significantly; this region is between approximately 10.0 and 13.0 mm of the punch stroke in the present study. In this transient region, a blank was formed and wrapped over the punch radius such that a transient change in the contact pressure response occured with the changes in the contact conditions of the punch radius. As shown in

Figure 7, a steady and relatively lower contact pressure than that of the transient region was distributed over the punch radius for both the R3.0 and R5.5 punches between approximately 13.0 mm and 35.0 mm of the punch stroke. Pereira [

24] referred to the region with such a steady contact pressure response as the steady-state region.

Figure 8a illustrates the magnitude of the maximum contact pressure in this punch stroke range in more detail. A relatively steady contact pressure was observed for both punches. In addition, the contact pressure of the R3.0 punch was approximately 0.15 GPa higher than that of the R5.5 punch. In the steady-state region, the relatively high contact pressure for each punch stroke was concentrated at approximately 67.3° and 72.9° on the punch radius for the R3.0 and R5.5 punches, respectively, as shown in

Figure 8b. Although the geometrical wrapping angle of the blank was 90° for both punches, the contact angle on the punch radius of the R5.5 punch was larger. The difference in contact angle on the punch radius can be inferred from the geometrical difference between the R3.0 and R5.5 punches. Bang et al. [

18] revealed that the wear of a coated tool is caused by the interaction between the contact pressure and the sliding distance in the stamping process. Therefore, the transient region, where the highly localized contact pressure and short sliding distance occur, is not considered to have a critical effect on the wear response. Therefore, tool wear is expected to occur in the steady-state region.

Figure 8c shows the contact conditions at approximately 67.3° and 72.9° on the punch radius for the R3.0 and R5.5 punches, respectively, where the highest contact pressure and longest sliding distance in the steady-state region occur. Because the curvature of the R3.0 punch was sharper than that of the R5.5 punch, the R3.0 punch has a higher contact pressure.

4. Tool Wear Prediction Model

Archard’s wear model [

47] is the most widely used model to predict the tool wear in sheet metal forming, and it is also built into LS-Dyna, as expressed in Equation (1):

In Equation (1), the wear depth

is directly proportional to the contact interface pressure

and the relative sliding distance

on the contact interface, and it is inversely proportional to the hardness of the wearing material

.

is a dimensionless wear coefficient. Equation (1) needs to be discretized in the elemental form to be implemented in FE simulations. The wear depth change

at a certain time

can be calculated as follows:

where

is the contact interface pressure at a certain time

and

is the sliding velocity at a certain time

. By integrating Equation (2) over time duration of the stamping process, the wear depth

on the contact interface can be calculated as follows:

Because the wear depth was close to 0 before failure initiation, the contact pressure and the sliding distance on the contact interface were considered to be constant. Therefore, the wear depth predicted by Equation (3) is linear. As shown in the wear test results in

Figure 4, the evolutionary wear behavior with respect to the strokes is not linear. Therefore, a nonlinear equation from a modified form of Archard’s wear model is proposed as follows:

where

is the dimensionless wear coefficient as a function of the number of strokes

. Here,

is a variable that can express the wear behavior with respect to the number of strokes. The wear test results in

Figure 4 show that wear depth is close to 0 before failure. When failure occurs, the wear depth increases rapidly. In order for the analytical solution (Equation (4)) to express the evolutionary wear behavior before and after failure and accurately simulate the experimental results (

Figure 4), it is necessary to define

for each punch. An exponential function was used for

to approximate the rapidly increasing wear behavior with respect to strokes after failure initiation. If

of Equation (4) is not defined, the wear behavior with respect to strokes is predicted linearly. As shown in

Figure 9, it can be confirmed that the analytical solution (Equation (4)) accurately predicts the experimental wear data due to the definition of

. The fitted dimensionless wear coefficient

for CrN- and AlTiCrN-coated punches are as follows:

The R-squared () is equal to 0.9999 for both exponential regressions. The Root Mean Square Deviation (RMSD) is and for each exponential regression, respectively. A of is related to the delay of the failure initiation, and B of means the rapidly increasing wear behavior after failure. In this study, the same value of was assumed for B of due to the insufficient wear depth results to describe the wear behavior after failure initiation. The of the AlTiCrN-coated punch is smaller than that of the CrN-coated punch, which means that as the wear test progressed, the wear rate of the AlTiCrN-coated punch was slower. Thus, it is possible to simulate a failure initiation behavior occurring later in the AlTiCrN-coated punch.

The application of the constructed tool wear prediction model to wear simulation is described in detail in the next section.

5. Wear Simulation

Based on the constructed wear equation, a wear simulation was performed by following the process shown in

Figure 10. First, the wear-related variables, hardness

, and dimensionless wear coefficient

, were entered in the “CONTACT_ADD_WEAR” card of the simulation keyword file. The hardness

is a value corresponding to each coating hardness. Although the dimensionless wear coefficient

is a function of the number of strokes

, as expressed in Equations (5) and (6), a value of 1 is set, as described in detail later. By performing numerical analysis with the constructed input file, the wear depth

from Equation (4) is computed. Because

is set to 1, the evolutionary wear behavior with respect to the number of strokes is not taken into account in the wear depth information. The computed wear depth information is contained in the dynain file. To perform the wear simulation and initialize the wear depth for the wear simulation process, the dynain file with wear depth information is included in the original input file. To predict the tool wear behavior, continuously track the wear status, and visualize the worn tool geometry with respect to the number of strokes, the “Wear analysis” application of LS-PrePost was used by reading in the input file including the dynain file. The scale factor

in the “Wear analysis” application was used to define the rapid increase in wear depth after failure initiation and predict the evolutionary wear behavior with respect to the strokes. The scale factor

is defined as a change in wear properties and characteristics with respect to the wear depth as wear progresses and can be explained by the difference in wear depth between

n + 1 and

n strokes, as expressed as follows:

Figure 11 plots the scale factors

for each stamping punch condition. The abscissa is the analytical solution for the wear depth calculated from Equation (4) for each stamping punch condition. The ordinate is the change in the dimensionless wear coefficient

with respect to the change in the number of strokes

. In the case of the CrN-coated punches, the

(red line) of the R3.0 punch is smaller than that (blue line) of the R5.5 punch at the same wear depth value. That is, for punches with the same surface hardness, to calculate the same wear depth,

is inversely proportional to the contact pressure and sliding distance, which can be calculated from Equation (4). Therefore, the scale factor of the R5.5 punch, which has a smaller contact pressure, is larger than that of the R3.0 punch. In the case of punches with the R3.0 punch shape, the

(green line) of the AlTiCrN-coated punch is larger than the

(red line) of the CrN-coated punch. For punches subjected to the same contact conditions, it can be confirmed from Equation (4) that

is proportional to the surface hardness to calculate the same wear depth. This phenomenon is reflected in the simulation by inputting the wear depth versus scale factor

into the “Wear analysis” application in the piecewise linear format. The wear depth

from i-th strokes can be calculated by multiplying the scale factor

by the wear depth

from the forming simulation, and the amount and location of the punch wear can be visually confirmed in LS-PrePost. Therefore, this wear simulation method using the scale factor

does not need to update the geometry and calculate the accumulated wear from the previous iteration of the wear simulation.

As shown in

Figure 12, in the conventional wear simulation, the modified geometry should be updated from the geometry predicted in the previous iteration of the wear simulation to predict the accumulated wear amount up to the desired number of strokes. This process takes a large amount of time to repeat up to the desired iteration. In contrast, the proposed wear simulation procedure, using a scale factor

representing the change in wear properties with respect to the wear depth, eliminates the need for repeating geometry updates from previous iterations of the wear simulation.

It was assumed that the contact pressure, sliding distance, and hardness on the contact interface of the punch were constant because the wear depth was close to 0 before failure initiation. This assumption was considered to be appropriate from the experimental results as shown in

Figure 4. However, the wear depth just before failure initiation was not measured for all punches, so the constructed wear equation may not be accurate in predicting the wear depth just before failure initiation and it is necessary to verify the wear behavior just prior to failure for more accurate wear prediction.

6. Verification of Wear Simulation

Figure 13 confirms that the constructed wear simulation method can reliably predict the evolutionary wear behavior of sheet metal forming. The analytical solution and simulation results based on the revised Archard’s wear model were compared with the experimental results. It can be confirmed that the analytical solution and simulation results based on the revised Archard’s wear model accurately simulate the evolutionary wear behaviors of experimental results for each punch. The results obtained using the proposed wear simulation process are quantitatively reliable in predicting the rapidly increasing wear depth behavior after failure and in determining the number of strokes at which failure occurs.

Figure 14 illustrates the predicted wear distributions and worn surface conditions on the punch radius for each punch condition after the failure; the predicted wear distribution confirms the amount and location of the computed wear depth. For all punches, predicted wear is concentrated on the punch radius. The wear of Punch 2 (

Figure 14b) is more widely distributed than Punch 1 and Punch 3 (

Figure 14a,c) because the shape of Punch 2 has a larger radius of 5.5 mm. The predicted wear is localized on the specific angular location, but punch surface conditions after the wear test show a long wear track in the sliding contact direction. The reason for this is that the wear is continuously propagated in the sliding contact direction after wear is initiated at the specific angular location. To check the accuracy of the amount and angular location of the predicted wear distribution,

Figure 15 compares the wear depth for experimental and simulation results after the failure occurred. The wear location confirmed in the experiments is approximately 88° on the punch radius for all three punch conditions. However, the angular location of the maximum wear depth predicted from the simulation was approximately 15°–20° ahead of that of the experiments. As the punch stroke progresses, the steel sheet comes into contact with the punch at 55° first and then in the 90° direction. Therefore, it is inferred that during the stamping process, wear debris generated by the high contact pressure at about 70° of the punch radius moves in the 90° direction, and severe wear occurred at approximately 88° on the punch radius due to the wear debris. To verify the simulation accuracy,

Figure 16 compares the difference in maximum wear depths between experiments and simulations. For each punch, the predicted maximum wear depth after the failure showed differences of 6.2%, 7.1% and 5.8%, respectively, from the experiments. Therefore, it was confirmed that the proposed wear simulation method is reliable in evaluating the wear depth and lifetime of stamping tools.

7. Discussion

A simplified Archard’s wear model was compared with experimental results of CrN-coated punches to confirm the limitations of predicting evolutionary wear behavior in sheet metal forming. The elemental form of the simplified Archard’s wear model for CrN-coated punches was fitted using experimental wear data, subsequently; the dimensionless wear coefficient of 0.074 was obtained, as follows:

The simulation results based on Equation (8) were obtained for CrN-coated punches and compared with experimental and simulation results based on the modified Archard’s wear model, as shown in

Figure 17. Punch 1 (CrN-coated punch with a radius of 3.0 mm) failed after 16,500 strokes and the wear depth measured was 8.6 μm. However, the predicted wear depth based on the simplified Archard’s wear model is 12.9 μm. For Punch 2 (CrN-coated punch with a radius of 5.5 mm), failure occurred after 18,000 strokes, and the wear depth measured was 17.4 μm. The predicted wear depth at 18,000 strokes based on the simplified Archard’s wear model was 11.4 μm. It can be observed that wear depth predicted by the simplified Archard’s wear model in terms of the number of strokes at which failure occurred, significantly differed from experimental results. In addition, the experimental and simulation results based on the modified Archard’s wear model demonstrated no wear at 5000 and 10,000 strokes (i.e., before failure). It was confirmed that the simplified Archard’s wear model has limitations in simulating nonlinear wear behavior of the tool in sheet metal forming.

Tool wear during the press forming process leads to reduced product quality. From the results of the Punch 1 wear test, it was confirmed that although the wear depth was 8.6 μm, severe scratches occurred on the product surface. The contact pressures of the formed product were compared when formed with punch geometry without wear and with worn punch geometry.

Figure 18a shows the contact pressure of the formed product before and after failure initiation. It can be observed that the contact pressure before failure is higher than that after failure in the middle region of the product in contact with the curvature region of the punch.

Figure 18b plots the contact pressure in the middle region of the product (dotted line), which is in contact with the punch curvature region. The contact pressure of the product formed prior to the failure (red solid line) is higher than that post failure (red dash line) in a product length of approximately 3 to 10 mm. To confirm the effect of this minor wear depth on product deformation shapes, the effective plastic strain and stress of the formed products before and after failure was analyzed. The effective plastic strain and stress of the formed products were compared when formed with punch geometry without wear and with worn punch geometry.

Figure 19a shows the effective plastic strain of the formed product before and after failure. It can be observed that the effective plastic strain prior to failure is higher than that after failure in the middle region of the product in contact with the curvature region of the punch. As shown in

Figure 19b, the effective plastic stress before failure is also higher in the middle region of the product. To quantitatively compare product conditions before and after failure,

Figure 19c plots the effective plastic strain and stress in the middle region of the product (dotted line), which is in contact with the punch curvature region. The effective plastic strain of the product formed with punch geometry without wear (red solid line) is approximately 0.35 in the range of approximately 3 to 4 mm in product length, which is twice as high as that after failure (red dash line). The effective plastic stress of the product formed prior to failure (blue solid line) is higher than that post failure (blue dash line) in a product length of approximately 7 to 13 mm. The effective plastic strain and stress of the product decreased after failure because the radius of the curvature region of the punch increased owing to wear.

Figure 20 compares experimental and simulation results for the cross-section of the product formed before and after failure. For the experimental results, the cross-sectional angle of the product formed before failure was 128°, however, this decreased to 127° once failure occurred. Simulation results also demonstrated that the cross-sectional angle of the product formed with punch geometry without wear was 122°, however, the cross-sectional angle of the product formed with worn punch geometry was reduced to 120°. It is inferred that because the effective plastic stress of the formed product decreases after failure, the elastic recovery and cross-sectional angle of the product decreases. Because the products used in this study are small, the geometric errors owing to springback are insignificant. However, larger parts such as automobile components may exhibit significant geometric errors owing to tool wear. Therefore, tool wear must be more effectively managed to improve product surface quality and geometrical accuracy.

8. Conclusions

An efficient wear simulation method was developed to predict quantitative wear reasonably in reduced computational time. The following conclusions are drawn from the results of this study.

In the stamping of a 1.2-mm-thick uncoated TRIP1180 steel sheet, there are no noticeable changes in the punch surface profile before failure initiation. However, after failure, the wear depth rapidly increases. Punch 1 (R3.0, CrN), which failed at 16,500 strokes, had less wear resistance than Punch 2 (R5.5, CrN), which failed at 18,000 strokes, because the former has a higher contact pressure than the latter. Punch 3 (R3.0, AlTiCrN) exhibited wear response at 59,000 strokes and, thus, demonstrated significantly improved wear resistance over Punch 1 (R3.0, CrN) because the AlTiCrN coating has a higher hardness than the CrN coating. By considering the punch wear characteristics, a nonlinear equation from a modified form of Archard’s wear model was proposed to predict the nonlinear wear behavior considering punch shapes (contact pressure) and coating hardness. The proposed wear model is suitable for predicting the rapidly increasing wear depth behavior after failure and determining the number of strokes required to achieve the desired wear depth. The geometry update and accumulated wear from the previous iteration of the wear simulation are rendered unnecessary by utilizing the scale factor when implementing the wear simulation method. Thus, the proposed method can decrease the computational time required for the simulation.