Effect of Zr and Ti Addition and Aging Treatment on the Microstructure and Tensile Properties of Al-2%Cu-Based Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

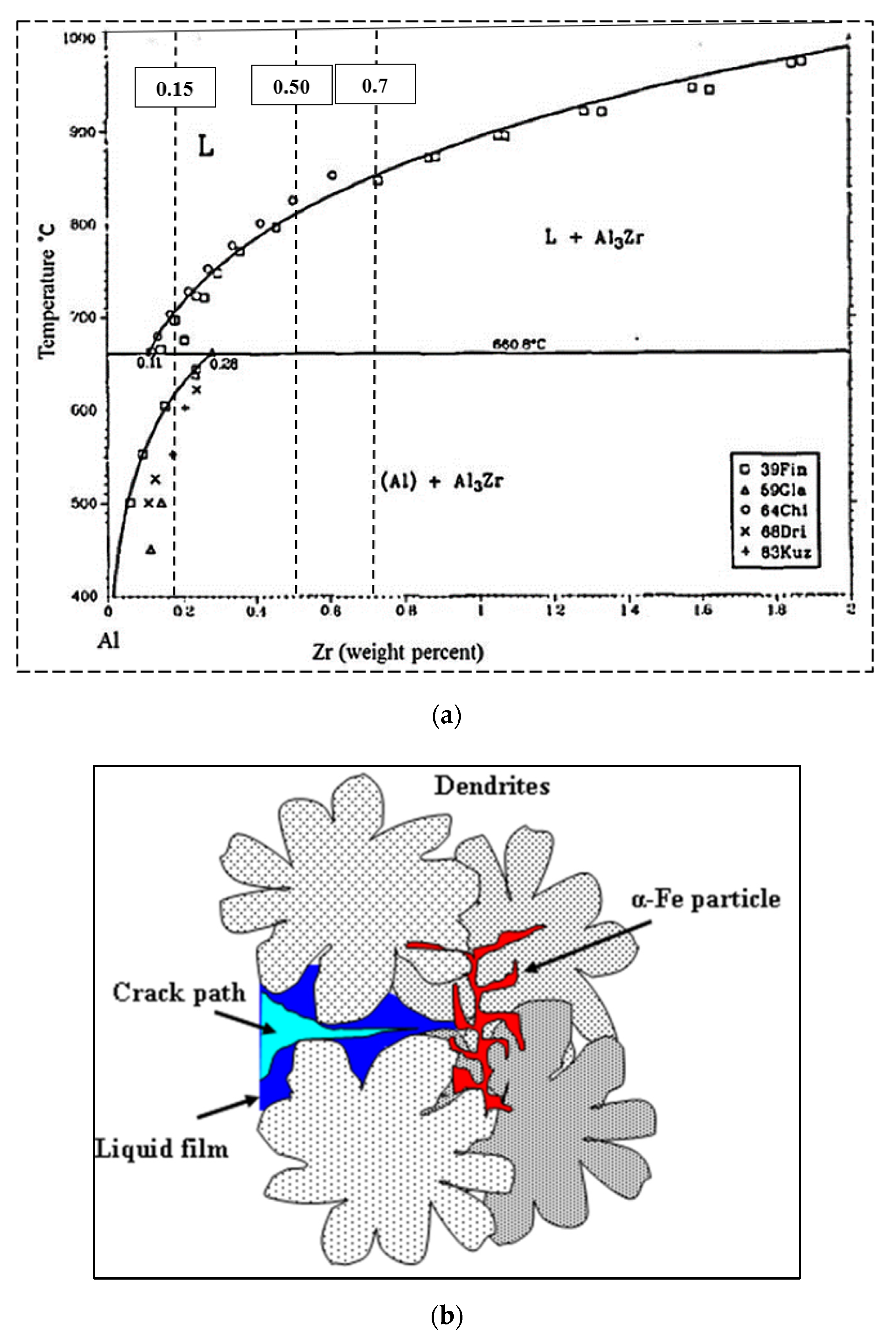

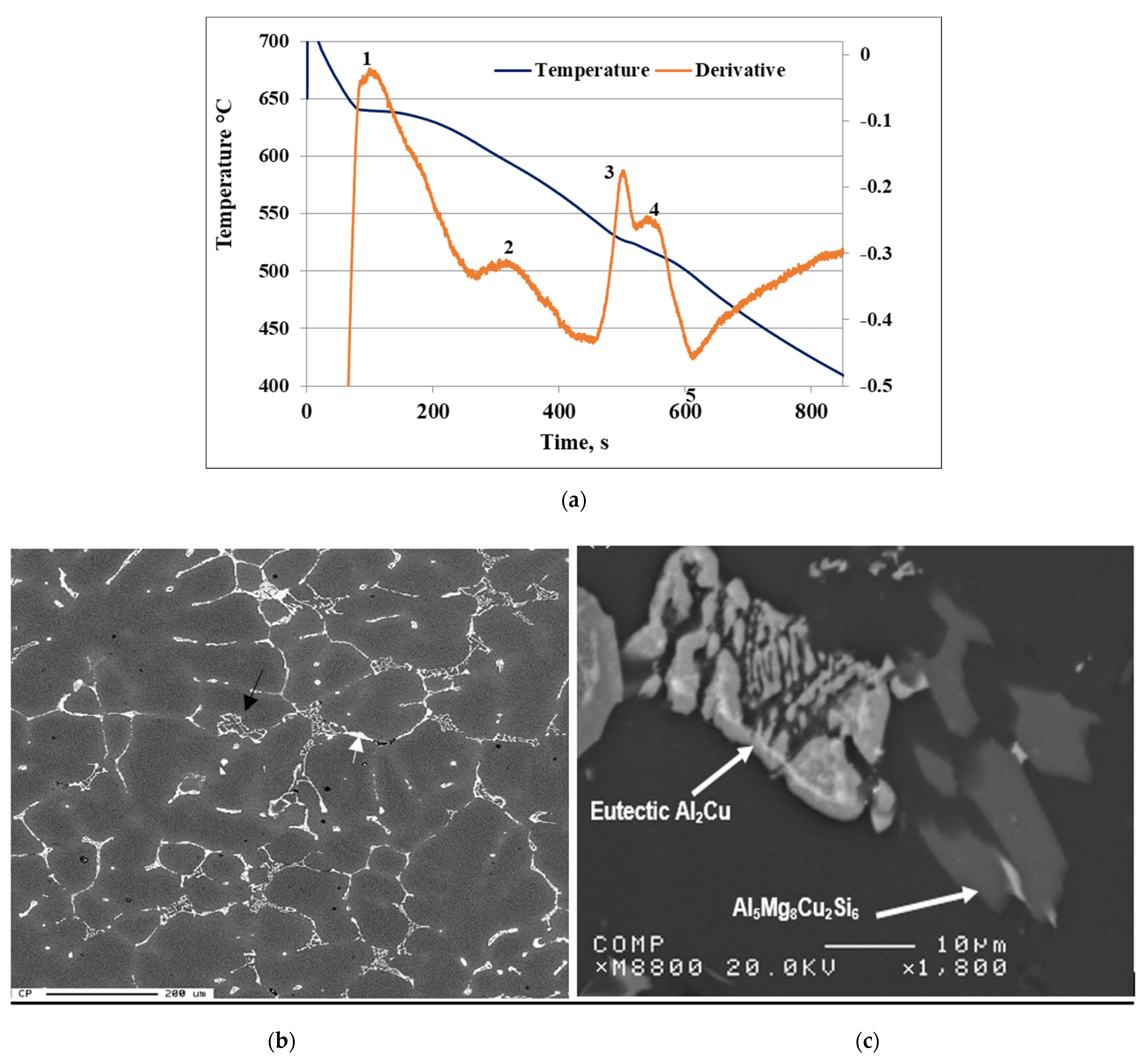

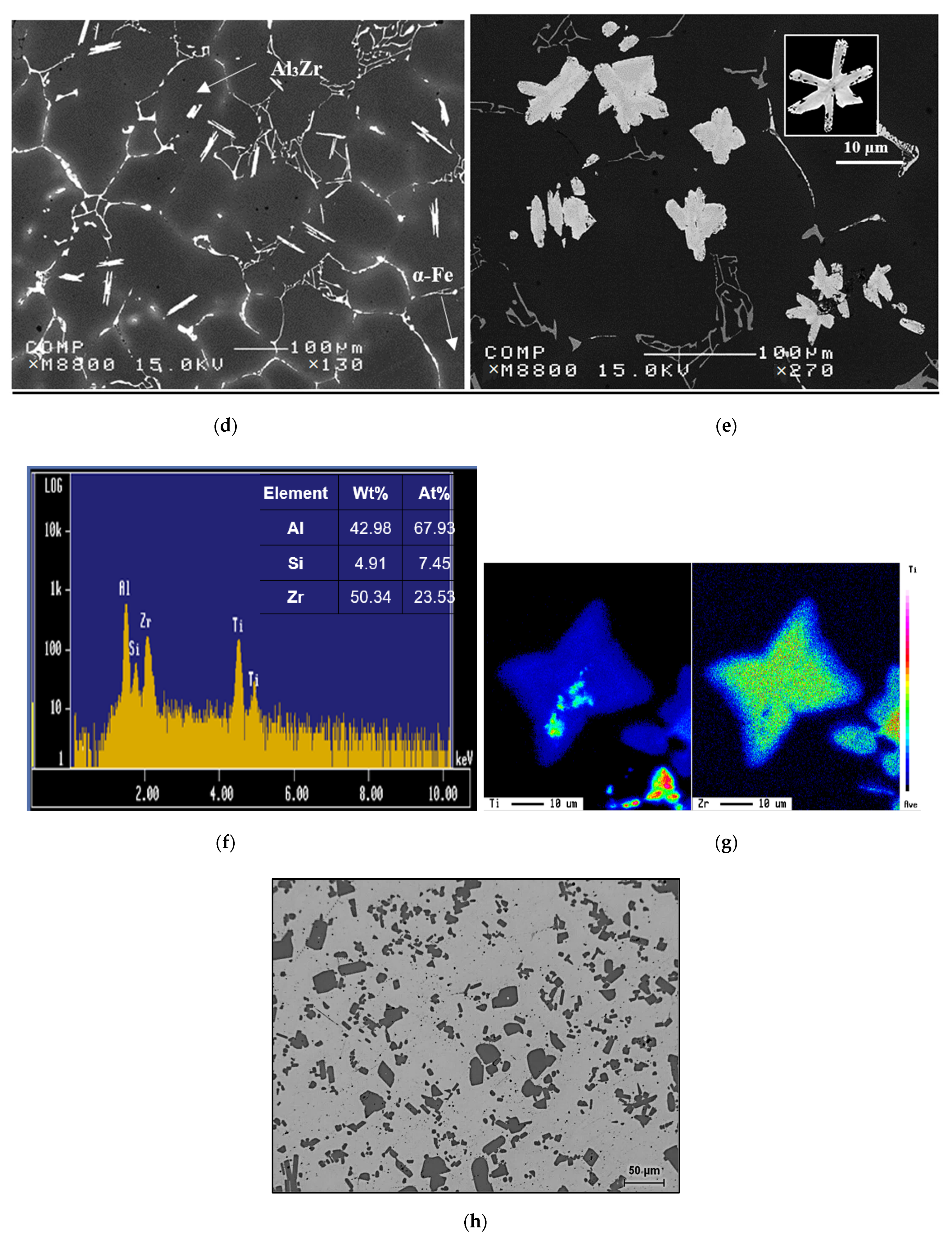

3.1. Zr Group of Alloys

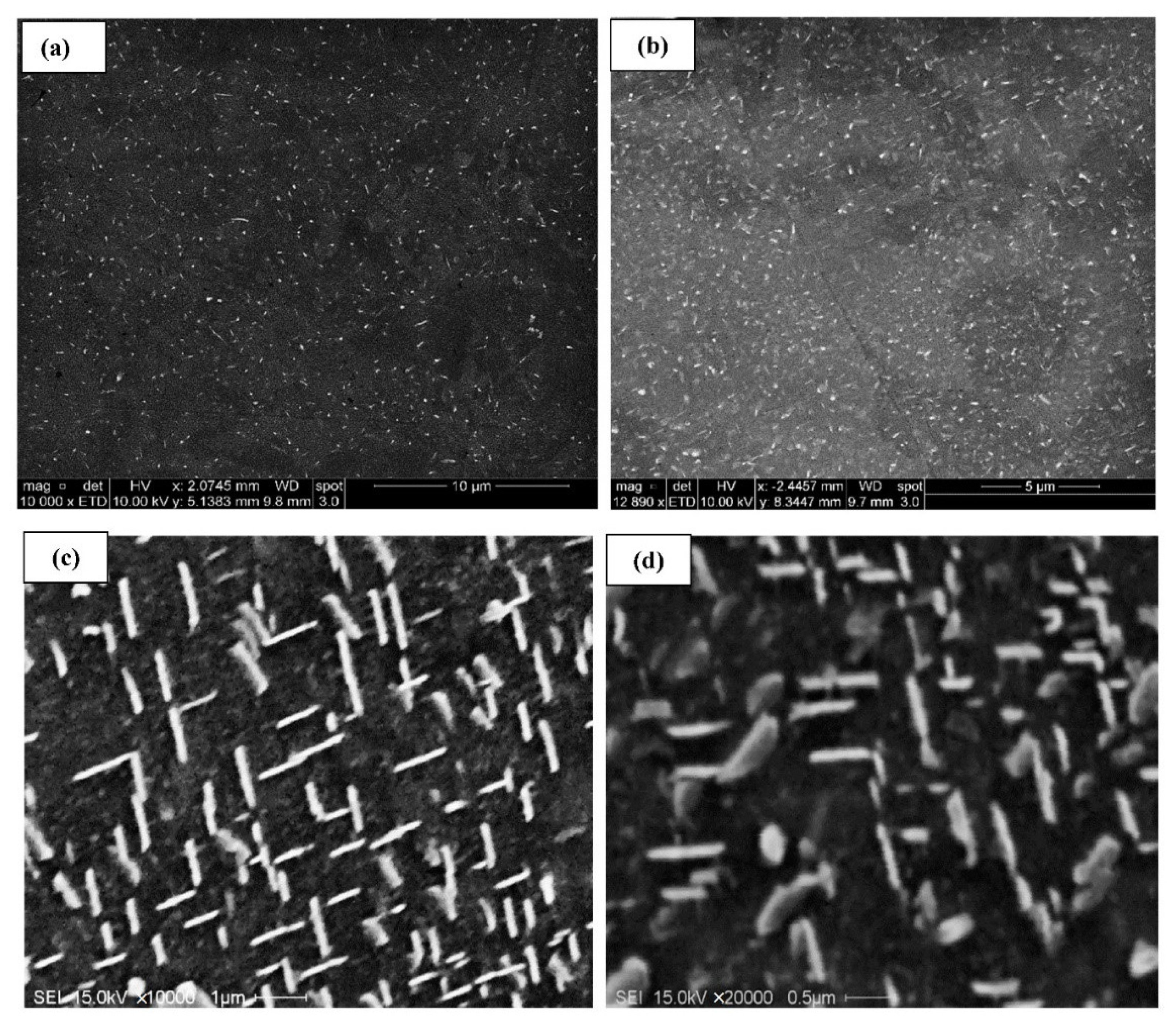

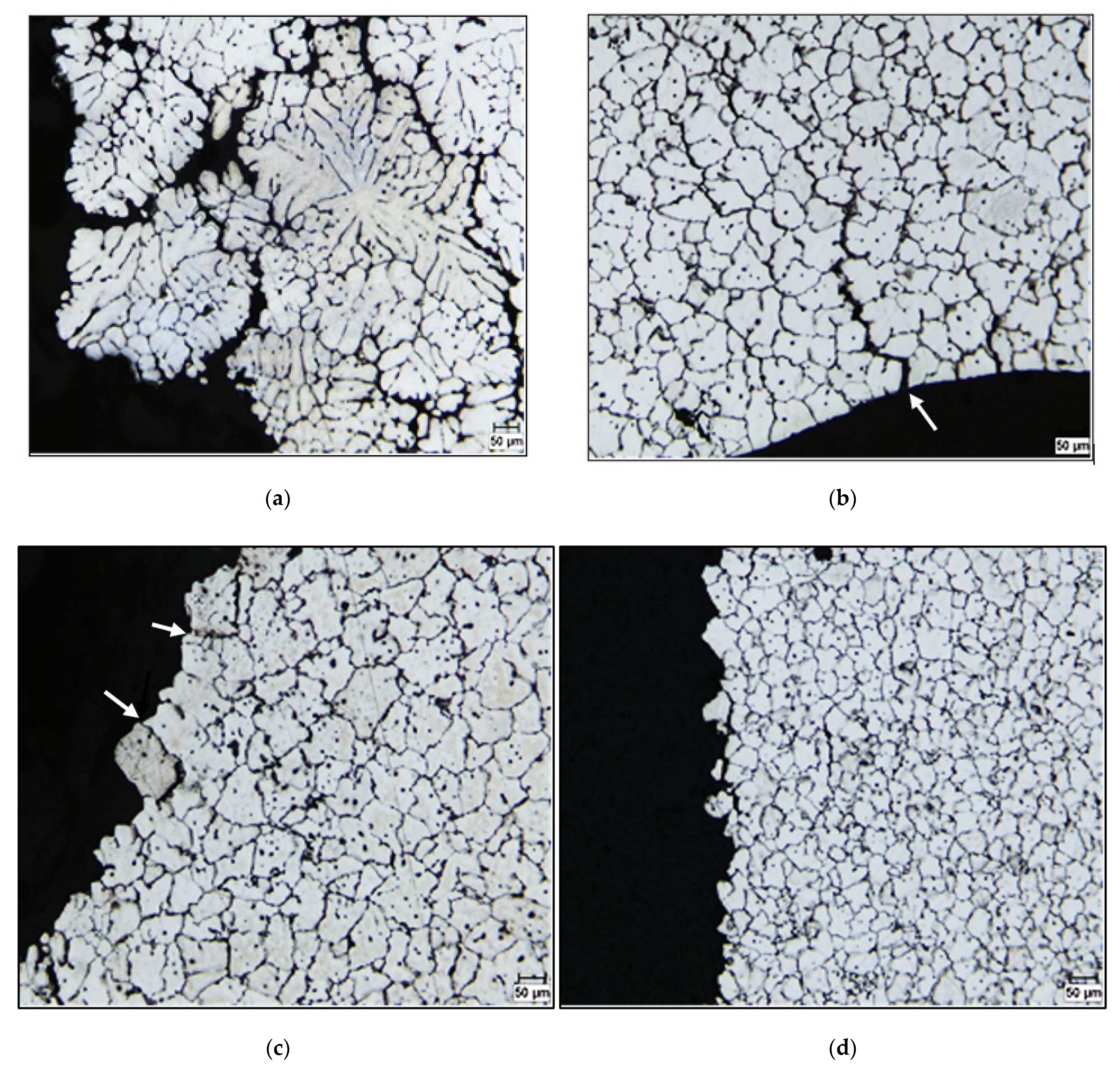

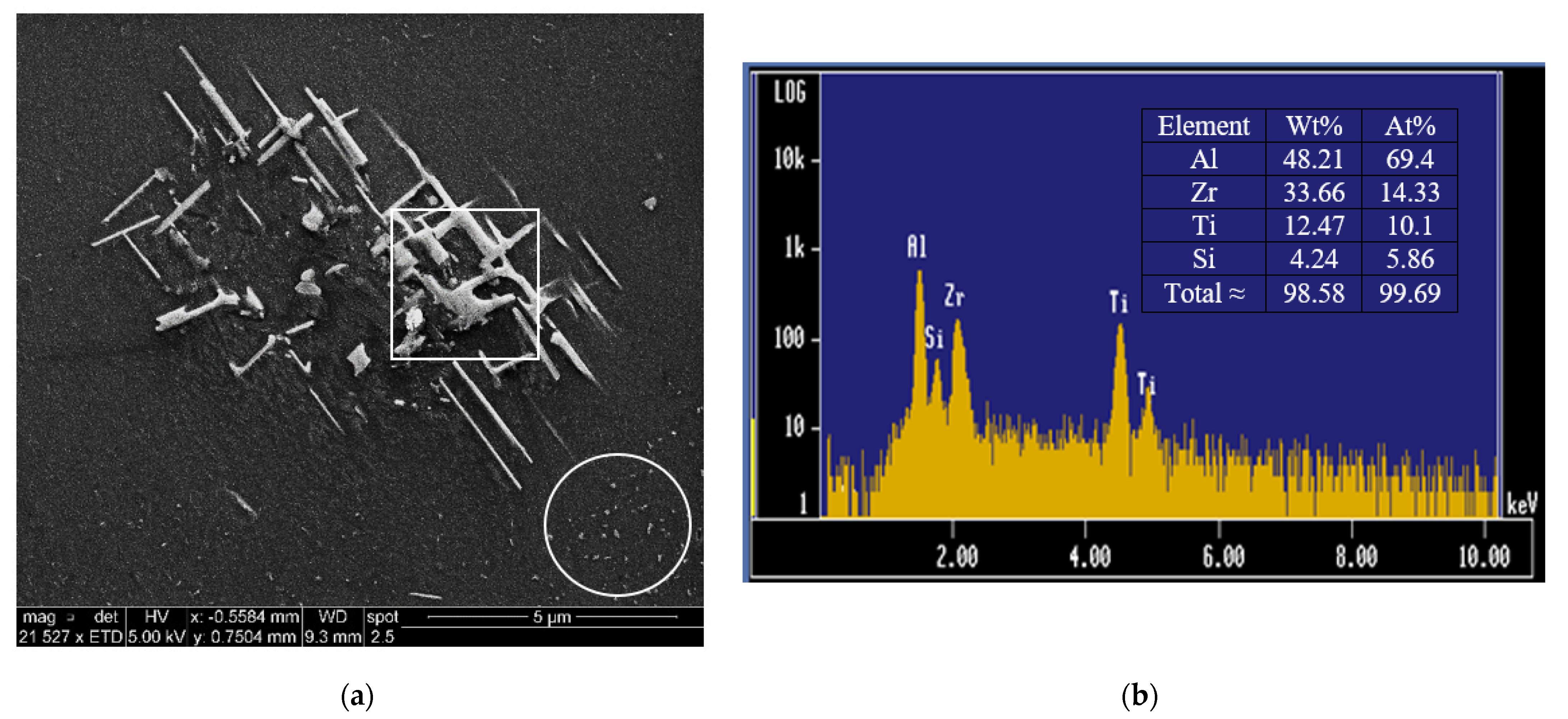

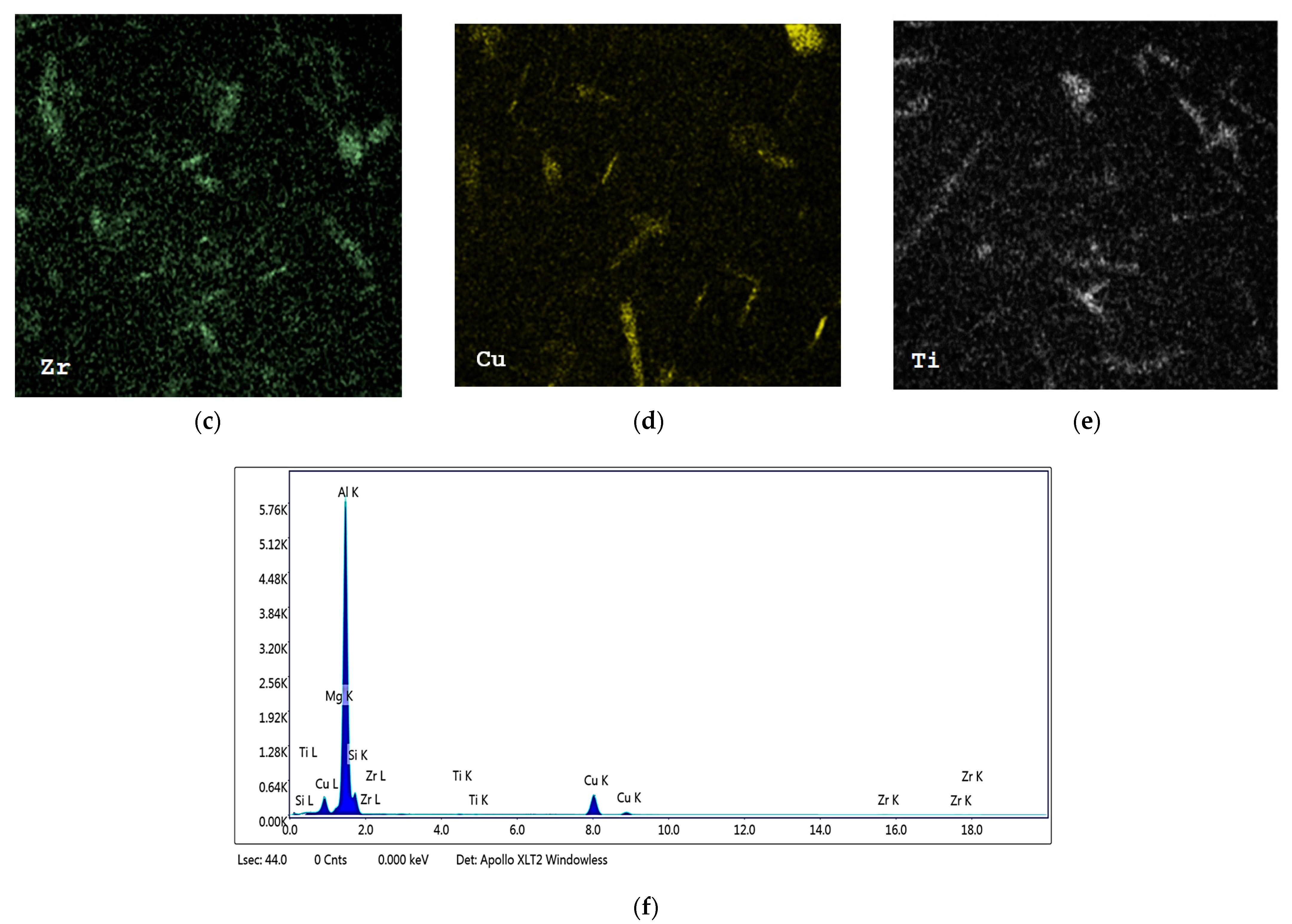

3.1.1. Microstructural Characterization

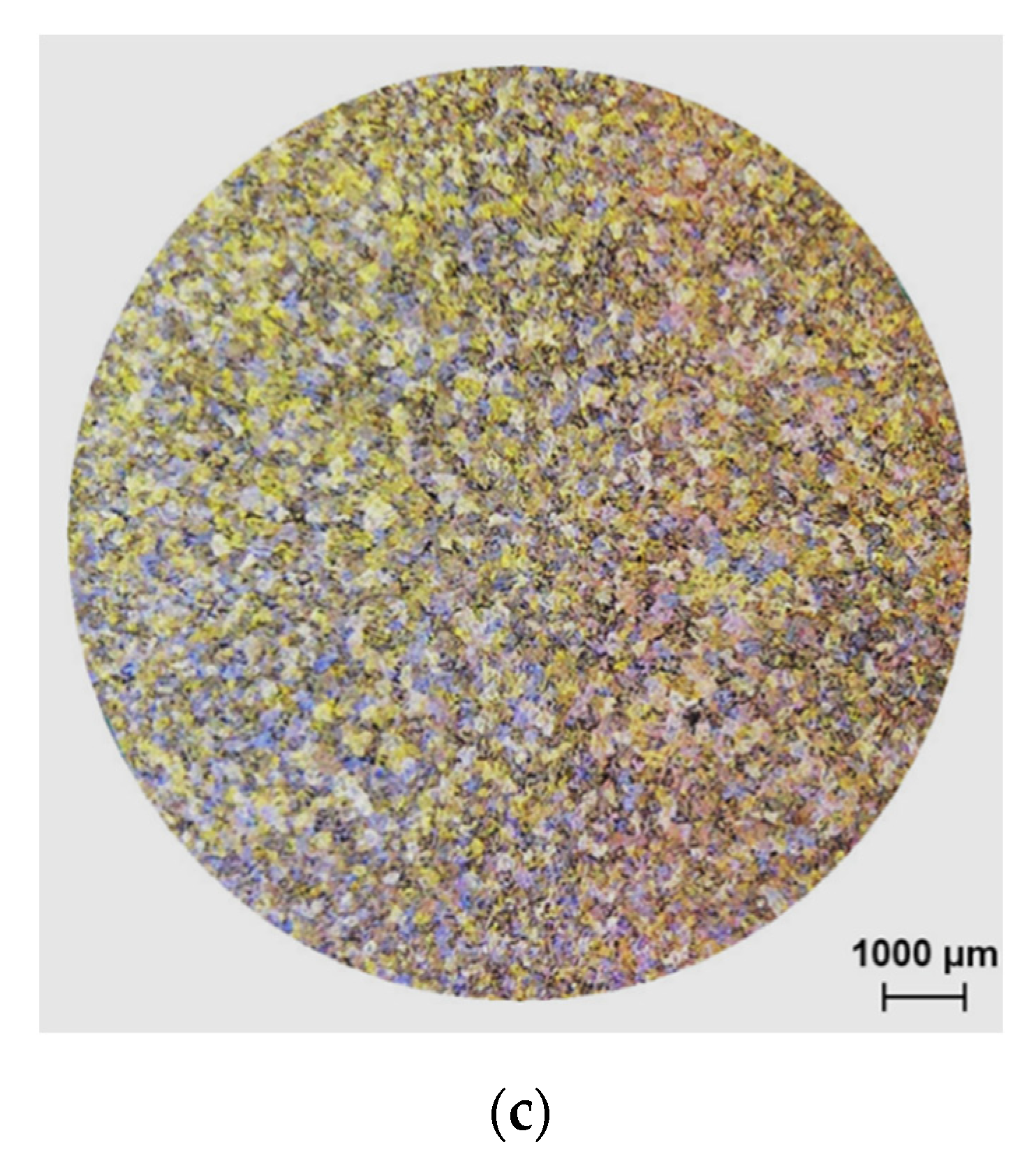

Low Solidification Rate

High Solidification Rate

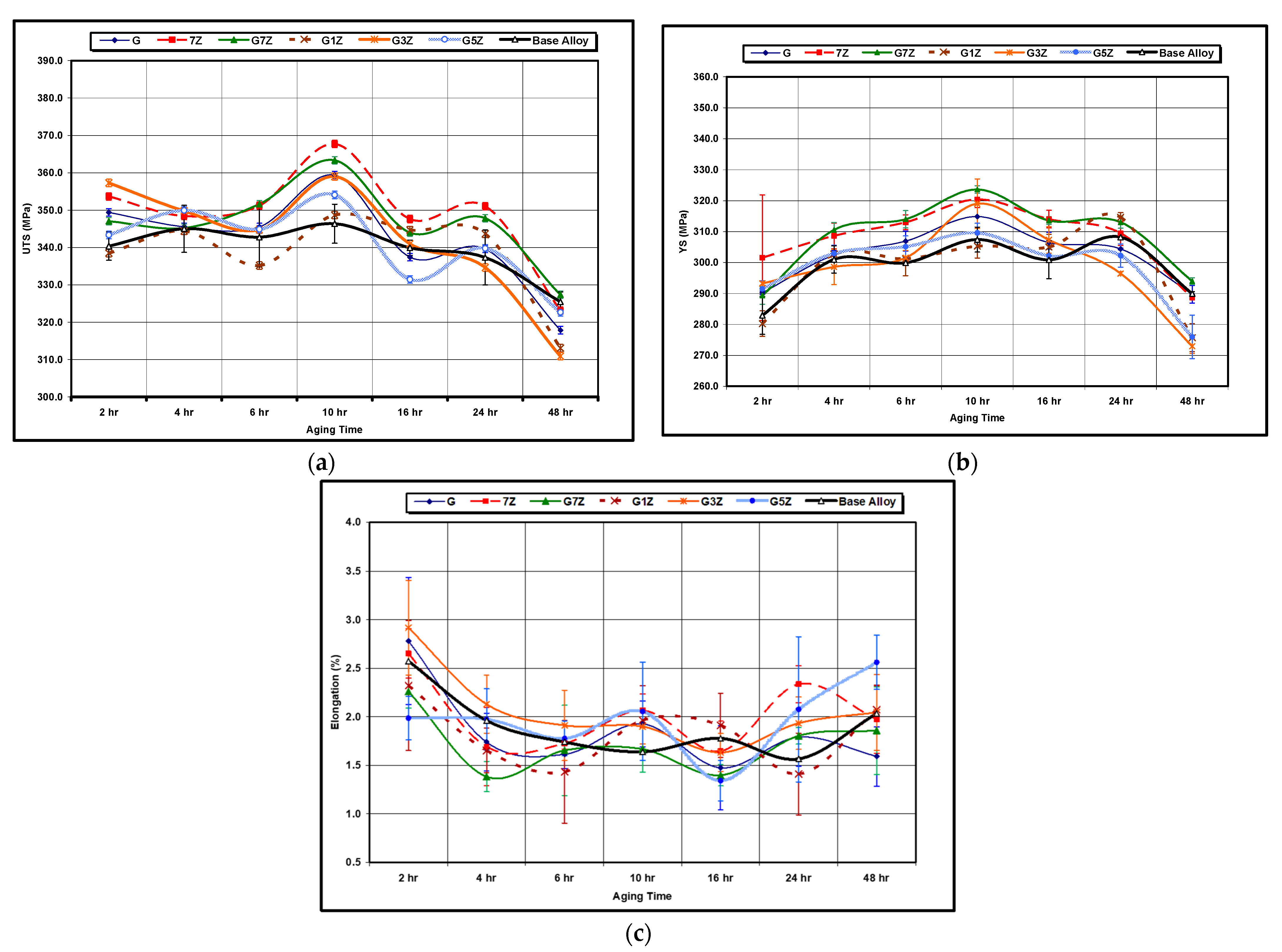

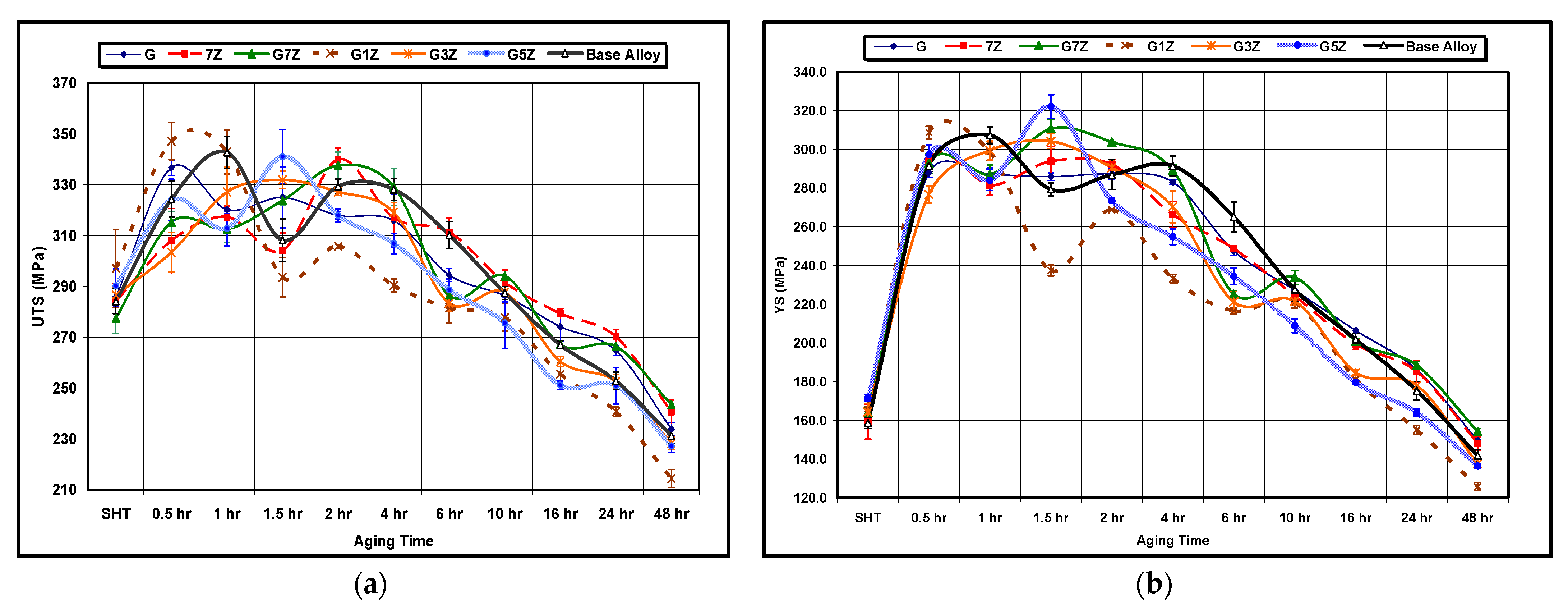

3.1.2. Tensile Properties

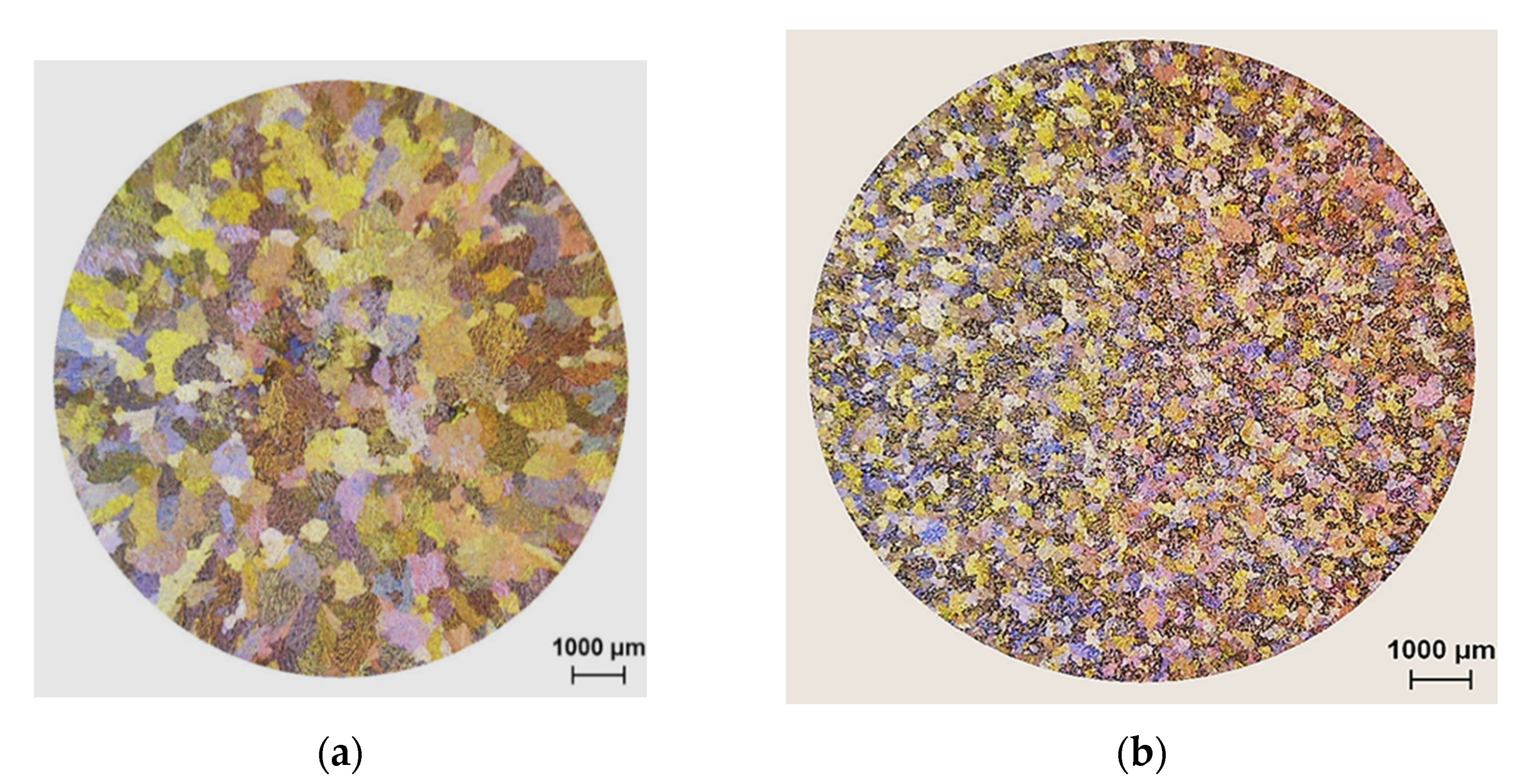

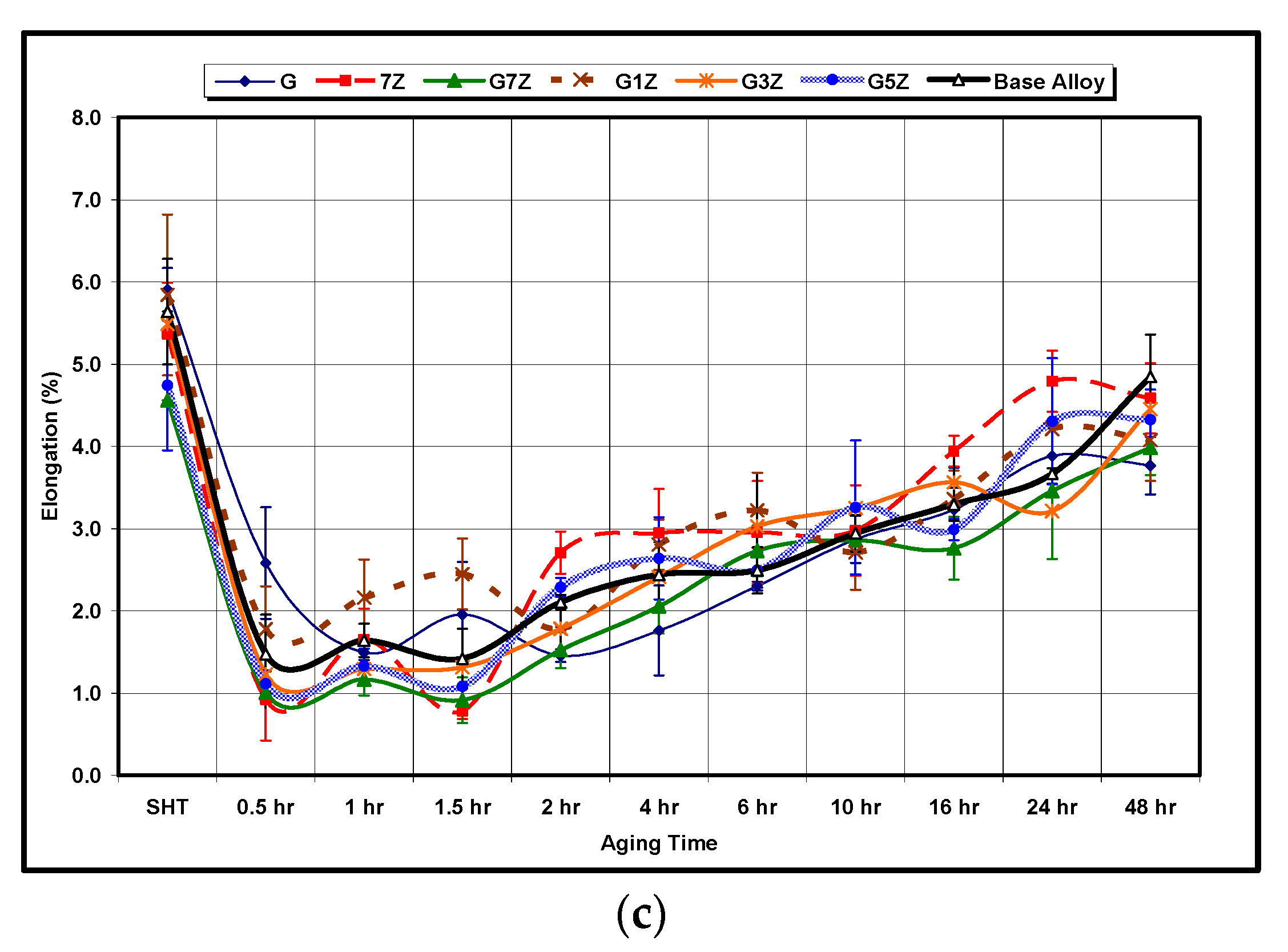

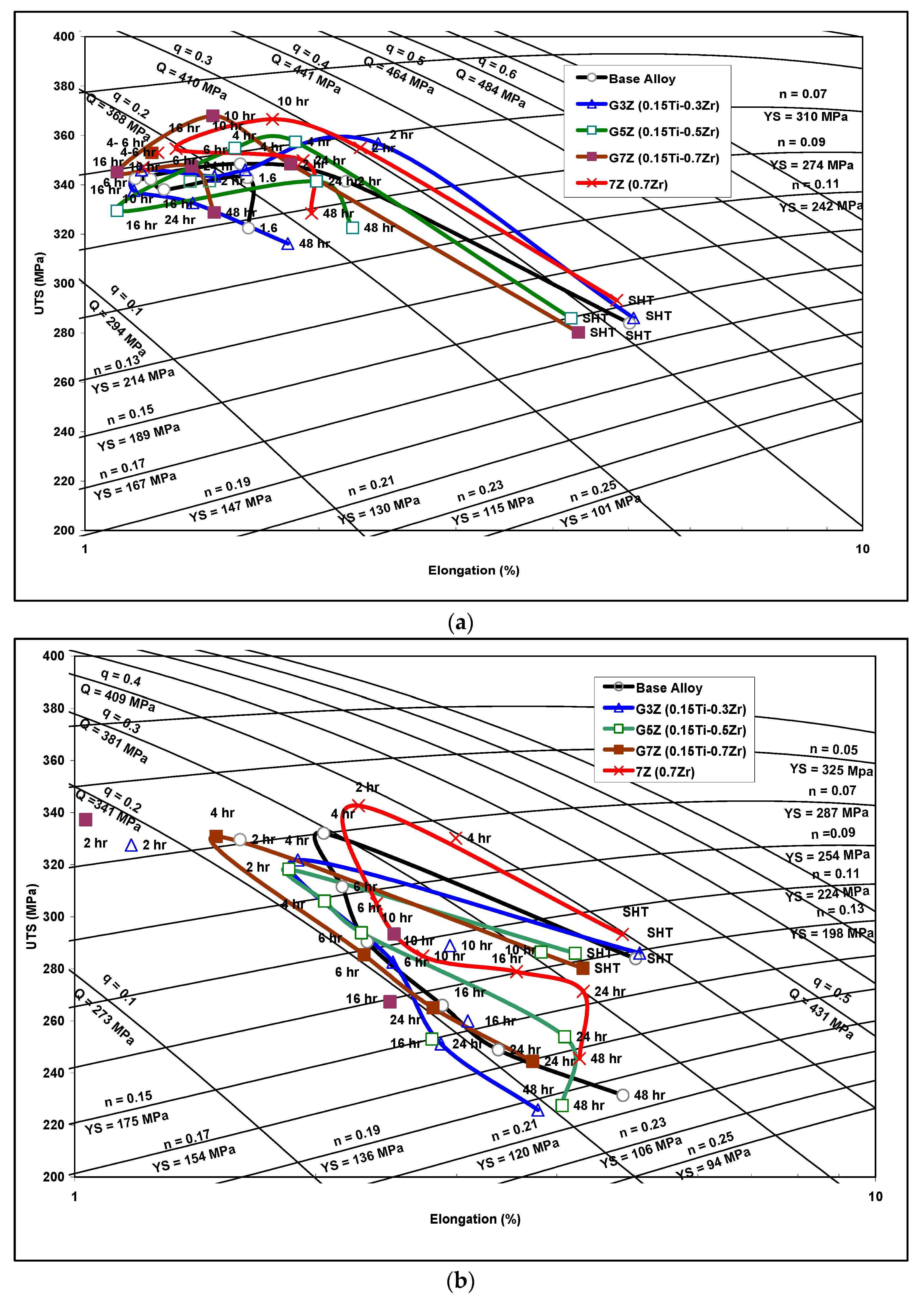

3.2. Zr-Ti Group of Alloys

4. Conclusions

- Additions of 0.3 and 0.5 wt% Zr to the Al-2%Cu alloy lead to (a) a change in the grain structure from columnar to equiaxed throughout the casting and (b) a significant reduction in the grain size (from 275 μm to 140 μm with 0.3 wt% Zr and to 65 μm with 0.5 wt% Zr additions, respectively).

- In the as-cast and solution heat-treated conditions, there is an increase in the tensile stress and hardness with Zr content. In contrast, elongation is seen to decrease.

- Peak aging occurs at 180 °C, followed by softening with the increase in aging temperature. The addition of Zr reduces the softening behavior of the 220A alloy, especially at T > 220 °C, as noted for alloy 220 M from the hardness tests. Alloy 220A exhibits a dramatic reduction in hardness, coupled with a pronounced increase in ductility, after 220 °C.

- The Zr-containing alloys are less ductile than the 220A alloy. With the increase in temperature, the tensile samples can attain higher strains, yet they suffer from a decrease in strength and hardness. The highest strength/hardness and, in turn, lowest values of ductility were all observed at 180 °C, corresponding to the peak aging condition.

- During aging, precipitation takes place by the formation of GP zones at 180 °C, a mixture of θ″ and θ′ at 220 °C, and a mixture of θ′ and θ at 300 °C. There is a noticeable increase in stress and hardness in the Zr-containing alloys at 220 °C and 240 °C, despite the coarsening of the precipitates at 220 °C. At 300 °C, there is a change in the precipitate morphology to a rod-like shape.

- The strength of the base alloy increases as the Zr content increases from 0.3% to 0.7% Zr after 10 h of aging at 180 °C. This increase may be ascribed to an increase in the density of Al3Zr particles, which act as heterogeneous nucleation sites for age-hardening phases, as well as to the modifying action of Zr on the S′ (i.e., Al2CuMg) phase.

- Combined additions of Zr-Ti transform the morphology of the microstructure of the base alloy from dendritic into a non-dendritic one. In addition, the regularity of the transformation is observed to increase as the Zr content increases at the higher Ti level of 0.15%.

- The quality of the base alloy is improved with the combined addition of Zr-Ti, for which the highest quality index in the Zr-Ti group of alloys is exhibited by the G3Z alloy (0.15%Ti-0.3%Zr) with a Q value of 420 MPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mao, X.; Yi, Y.-P.; He, H.; Huang, S.-Q.; Guo, W. Second phase particles and mechanical properties of 2219 aluminum alloys processed by an improved ring manufacturing process. Mater. Sci. Eng. A 2020, 781, 139226. [Google Scholar] [CrossRef]

- Gao, Y.H.; Cao, L.F.; Yang, C.; Zhang, J.Y.; Liu, G.; Sun, J. Co-stabilization of θ′-Al2Cu and Al3Sc precipitates in Sc-microalloyed Al–Cu alloy with enhanced creep resistance. Mater. Today Nano 2019, 6, 100035. [Google Scholar] [CrossRef]

- Wang, S.C.; Starink, M.J. Two types of S phase precipitates in Al-Cu-Mg alloys. Acta. Mater. 2007, 55, 933–941. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Deng, Y.; Guo, X. Revisit the stress-orienting effect of θ′ in Al-Cu single crystal during stress aging. Mater. Charact. 2018, 135, 270–277. [Google Scholar] [CrossRef]

- Shower, P.; Morris, J.; Shin, D.; Radhakrishnan, B.; Poplawsky, J.; Shyam, A. Mechanisms for stabilizing θ′(Al2Cu) precipitates at elevated temperatures investigated with phase field modeling. Materialia 2019, 6, 100335. [Google Scholar] [CrossRef]

- Alyaldin, L.; Abdelaziz, M.H.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Effect of Transition Metals Addition on Tensile Properties of Al–Si–Cu-Based Alloys at 25 °C and 250 °C: Role of Heat Treatment. Int. J. Metalcast. 2021, 15, 60–75. [Google Scholar] [CrossRef]

- Mohamed, A.M.A.; Samuel, F.H. A Review on the Heat Treatment of Al-SiCu/Mg Casting Alloys. Heat Treatment; InTech Science: Rijeka, Croatia, 2012; pp. 229–246. [Google Scholar]

- Guo, Z.; Zhao, G.; Chen, X.G. Effects of two-step homogenization on precipitation behavior of Al3Zr dispersoids and recrystallization resistance in 7150 aluminum alloy. Mater. Charact. 2015, 102, 122–130. [Google Scholar] [CrossRef]

- Garza-Elizondo, G.H.; Elsharkawi, E.A.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Effects of Alloying Elements Additions on Ambient Temperature Performance of Al–Si–Cu–Mg Base Alloys. Int. J. Metalcast. 2021, 15, 1385–1401. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Mochugovskiy, A.G.; Levchenko, V.S.; Tabachkova, N.Y.; Mufalo, W.; Portnoy, V.K. Precipitation behavior of L12Al3Zr phase in Al-Mg-Zr alloy. Mater. Charact. 2018, 139, 30–37. [Google Scholar] [CrossRef]

- Abdelaziz, M.H.; Elsharkawi, E.A.; Doty, H.W.; Samuel, F.H. Mechanical Performance of Zr-Containing 354-Type Al-Si-Cu-Mg Cast Alloy: Role of Geometrical Discontinuities. J. Mater. Eng. Perform. 2020, 29, 6640–6651. [Google Scholar] [CrossRef]

- Zou, L.; Pan, Q.-L.; He, Y.-B.; Wang, C.-Z.; Liang, W.-J. Effect of minor Sc and Zr addition on microstructures and mechanical properties of Al-Zn-Mg-Cu alloys. Trans. Nonferrous Met. Soc. China 2007, 17, 340–345. [Google Scholar] [CrossRef]

- Hernandez-Sandoval, J.; Abdelaziz, M.H.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Effect of Zr Addition and Aging Treatment on the Tensile Properties of Al-Si-Cu-Mg Cast Alloys, Chapter 3. In Advanced Aluminium Composites and Alloys; Dobrzański, L.A., Ed.; IntechOpen: London, UK, 2020; p. 92814. [Google Scholar] [CrossRef]

- Ibrahim, A.I.; Elgallad, E.M.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Effects of Addition of Transition Metals on Intermetallic Precipitation in Al–2%Cu–1%Si-Based Alloys. Int. J. Metalcast. 2018, 12, 574–588. [Google Scholar] [CrossRef]

- Ding, L.; Zhao, M.; Jia, Z.; Weng, Y.; Xiang, K.; Wu, X.; Liu, Q. On the formation of anti-phase boundaries and interphase boundaries in Al3Zr precipitates of Al-Cu-Zr alloy studied at atomic scale. J. Alloys Compd. 2021, 887, 161442. [Google Scholar] [CrossRef]

- Girgis, A.; Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H. On the Elevated Temperature Tensile Properties of Al-Cu Cast Alloys: Role of Heat Treatment. Adv. Mater. Sci. Eng. 2019, 2019, 8247914. [Google Scholar] [CrossRef] [Green Version]

- Abdelaziz, M.H.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Mechanical Performance of Zr-Containing 354-Type Al-Si-Cu-Mg Cast Alloy: Role of Additions and Heat Treatment. Adv. Mater. Sci. Eng. 2018, 2018, 17–23. [Google Scholar] [CrossRef] [Green Version]

- Hansen, M.; Anderko, K. Constitution of Binary Alloys, 2nd ed.; McGraw-Hill Book Company, Inc.: New York, NY, USA, 1958. [Google Scholar]

- Knipling, K.E.; Dunand, D.C.; Seidman, D.N. Criteria for developing castable, creep-resistant aluminum-based alloys—A review. Z. Metallkunde 2006, 97, 246–265. [Google Scholar] [CrossRef] [Green Version]

- Colley, L.J. Microstructure-Property Models for Heat Treatment of A356 Aluminum Alloy. Ph.D. Thesis, The University of British Columbia, Vancouver, BC, Canada, 2011. [Google Scholar]

- Drouzy, M.; Jacob, S.; Richard, M. Interpretation of Tensile Results by Means of Quality Index and Probable Yield Strength-Application to Al-Si7 Mg Foundry Alloys. Int. Cast Metals J. 1980, 5, 43–50. [Google Scholar]

- Cáceres, C.H.; Din, T.; Rashid, A.K.M.B.; Campbell, J. Effect of aging on quality index of an Al–Cu casting alloy. Mater. Sci. Technol. 1999, 15, 711–716. [Google Scholar] [CrossRef]

- Ammar, H.R.; Samuel, A.M.; Samuel, F.H.; Simielli, E.; Sigworth, G.K.; Lin, J.C. Influence of aging parameters on the tensile properties and quality index of Al–9 Pct Si–1.8 Pct Cu–0.5 Pct Mg 354-type casting alloys. Metall. Mater. Trans. A 2012, 43, 61–73. [Google Scholar] [CrossRef]

- Alexopoulos, N.D. Generation of quality maps to support material selection by exploiting the quality indices concept of cast aluminum alloys. Mater. Des. 2007, 28, 534–543. [Google Scholar] [CrossRef]

- Kamali, H.; Kamali, E.; Emamy, M. Effects of Zr additions on structure and tensile properties of an Al-4.5Cu-0.3Mg-0.05Ti (wt.%) alloy. China Foundry 2022, 19, 9–16. [Google Scholar] [CrossRef]

- Wang, P.-S.; Lee, S.-L.; Lin, J.-C.; Jahn, M.-T. Effects of Solution Temperature on Mechanical Properties of 319.0 Aluminum Casting Alloys Containing Trace Beryllium. J. Mater. Res. 2000, 15, 2027–2035. [Google Scholar] [CrossRef]

- Apelian, D.; Shivkumar, S.; Sigworth, G. Fundamental Aspect of Heat Treatment of Cast Al-Si-Mg Alloys. AFS Trans. 1989, 137, 727–742. [Google Scholar]

- Tillova, E.; Panuskova, M. Effect of Solution Treatment on Intermetallic Phases Morphology in AlSi9Cu3 Cast Alloy. Metalurgija 2008, 47, 207–210. [Google Scholar]

- Ghosh, G.; Vaynman, S.; Asta, M.; Fine, M.E. Stability and Elastic Properties of L12-(Al,Cu)3(Ti,Zr) Phases: Ab initio Calculations and Experiments. Intermetallics 2007, 15, 44–54. [Google Scholar] [CrossRef]

- Knipling, K.E.; Dunand, D.C.; Seidman, D.N. Precipitation evolution in Al–Zr and Al–Zr–Ti alloys during aging at 450–600 °C. Acta Mater. 2008, 56, 1182–1195. [Google Scholar] [CrossRef]

- Kasprzak, W.; Amirkhiz, B.S.; Niewczas, M. Structure and properties of cast Al–Si based alloy with Zr–V–Ti additions and its evaluation of high temperature performance. J. Alloys Compd. 2014, 595, 67–79. [Google Scholar] [CrossRef]

- Li, S.S.; Li, L.; Han, J.; Wang, C.-T.; Xiao, Y.-Q.; Jian, X.-D.; Qian, P.; Su, Y.-J. First-Principles study on the nucleation of precipitates in ternary Al alloys doped with Sc, Li, Zr, and Ti elements. Appl. Surf. Sci. 2020, 526, 146455. [Google Scholar] [CrossRef]

- Souza, P.H.L.; Silva de Oliveira, C.A.; do Vale Quaresma, J.M. Precipitation hardening in dilute Al–Zr alloys. J. Mater. Res. Technol. 2018, 7, 66–72. [Google Scholar] [CrossRef]

- Du, J.; Wen, B.; Melnik, R.; Kawazoe, Y. Cluster characteristics and physical properties of binary Al–Zr intermetallic compounds from first principles studies. Comput. Mater. Sci. 2015, 103, 170–178. [Google Scholar] [CrossRef]

- Ringer, S.P.; Hono, K. Microstructural Evolution and Age Hardening in Aluminum Alloys: Atom Probe Field-Ion Microscopy and Transmission Electron Microscopy Studies. Mater. Charact. 2000, 44, 101–131. [Google Scholar] [CrossRef]

- Abe, T.; Miyazaki, K.; Hirano, K. Imaging of Pure Al and Aged Al-4 wt.% Cu Alloys by Field Ion Microscopy. Acta Metall. 1989, 30, 357–366. [Google Scholar] [CrossRef]

- Eskin, D.G. Decomposition of Supersaturated Solid Solution in Al-Cu-Mg-Si Alloys. J. Mater. Sci. 2003, 38, 279–290. [Google Scholar] [CrossRef]

- Zeren, M. Effect of Copper and Silicon Content on Mechanical Properties in Al-Cu-Si-Mg Alloy. J. Mater. Processing Technol. 2005, 169, 292–298. [Google Scholar] [CrossRef]

- Li, Y.J.; Brusethaug, S.; Olsen, A. Influence of Cu on the Tensile Properties and Precipitation Behavior of AlSi7Mg0.5 Alloy during Aging Treatment. Scr. Mater. 2006, 54, 99–103. [Google Scholar] [CrossRef]

- Guiqing, W.; Qingzhou, S. Influence of Cu Content on Ageing Behavior of AlSiMgCu Cast Alloys. Mater. Des. 2007, 28, 1001–1005. [Google Scholar]

- Samuel, F.H.; Université du Québec à Chicoutimi, Saguenay, QC, Canada. Unpublished data.

| Element | Cu | Si | Fe | Mn | Mg | Ti | Al |

|---|---|---|---|---|---|---|---|

| wt% | 2.00 | 1.05 | 0.42 | 0.60 | 0.40 | 0.02 | Bal. |

| 220A (Base alloy) | 2.00 wt% Cu, 1.05 wt% Si, 0.42 wt% Fe, 0.60 wt% Mn, 0.40 wt% Mg, 0.02 wt% Ti, Al balance |

| 220L | 220 A + 0.30 wt% Zr |

| 220M | 220 A + 0.50 wt% Zr |

| Alloys | Element (wt%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cu | Si | Fe | Mn | Mg | Ti | Zr | Al | ||

| Base alloy | 1.91 | 1.03 | 0.57 | 0.58 | 0.34 | 0.02 | - | Bal. | |

| Zr and Ti Group | G | 1.85 | 099 | 0.55 | 0.54 | 0.31 | 0.18 | - | Bal. |

| G1Z | 2.06 | 1.15 | 0.52 | 0.57 | 0.35 | 0.13 | 0.14 | Bal. | |

| G3Z | 2.07 | 1.11 | 0.51 | 0.57 | 0.34 | 0.14 | 0.26 | Bal. | |

| G5Z | 2.08 | 1.10 | 0.51 | 0.58 | 0.34 | 0.11 | 0.47 | Bal. | |

| 7Z | 1.83 | 0.97 | 0.54 | 0.57 | 0.32 | 0.02 | 0.58 | Bal. | |

| G7Z | 1.80 | 0.90 | 0.47 | 0.51 | 0.30 | 0.20 | 0.71 | Bal. | |

| Condition | Temperature (°C) | Time (h) |

|---|---|---|

| As-cast | N/A | N/A |

| Solution heat treatment | 490 °C | 8 |

| Aging | 180 °C | 2, 4, 6, 10, 16, 24, 48 |

| 220 °C | 2, 4, 6, 10, 16, 24, 48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samuel, E.; Nabawy, A.M.; Samuel, A.M.; Doty, H.W.; Songmene, V.; Samuel, F.H. Effect of Zr and Ti Addition and Aging Treatment on the Microstructure and Tensile Properties of Al-2%Cu-Based Alloys. Materials 2022, 15, 4511. https://doi.org/10.3390/ma15134511

Samuel E, Nabawy AM, Samuel AM, Doty HW, Songmene V, Samuel FH. Effect of Zr and Ti Addition and Aging Treatment on the Microstructure and Tensile Properties of Al-2%Cu-Based Alloys. Materials. 2022; 15(13):4511. https://doi.org/10.3390/ma15134511

Chicago/Turabian StyleSamuel, Ehab, Ahmed M. Nabawy, Agnes M. Samuel, Herbert W. Doty, Victor Songmene, and Fawzy H. Samuel. 2022. "Effect of Zr and Ti Addition and Aging Treatment on the Microstructure and Tensile Properties of Al-2%Cu-Based Alloys" Materials 15, no. 13: 4511. https://doi.org/10.3390/ma15134511

APA StyleSamuel, E., Nabawy, A. M., Samuel, A. M., Doty, H. W., Songmene, V., & Samuel, F. H. (2022). Effect of Zr and Ti Addition and Aging Treatment on the Microstructure and Tensile Properties of Al-2%Cu-Based Alloys. Materials, 15(13), 4511. https://doi.org/10.3390/ma15134511