Carbon Transformation Induced by High Energy Excimer Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Laser Treatment

2.2. Characterization

3. Results and Discussion

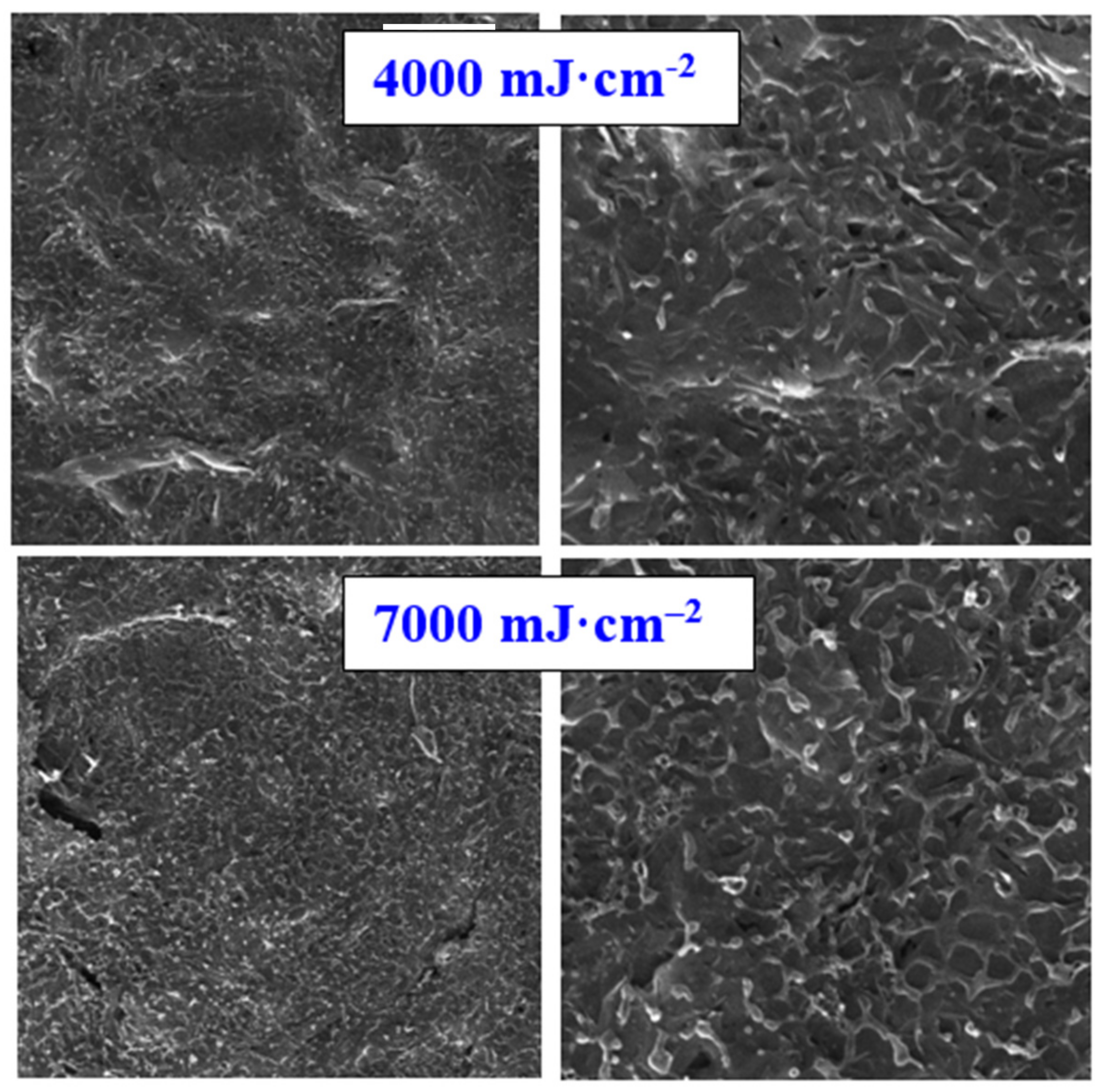

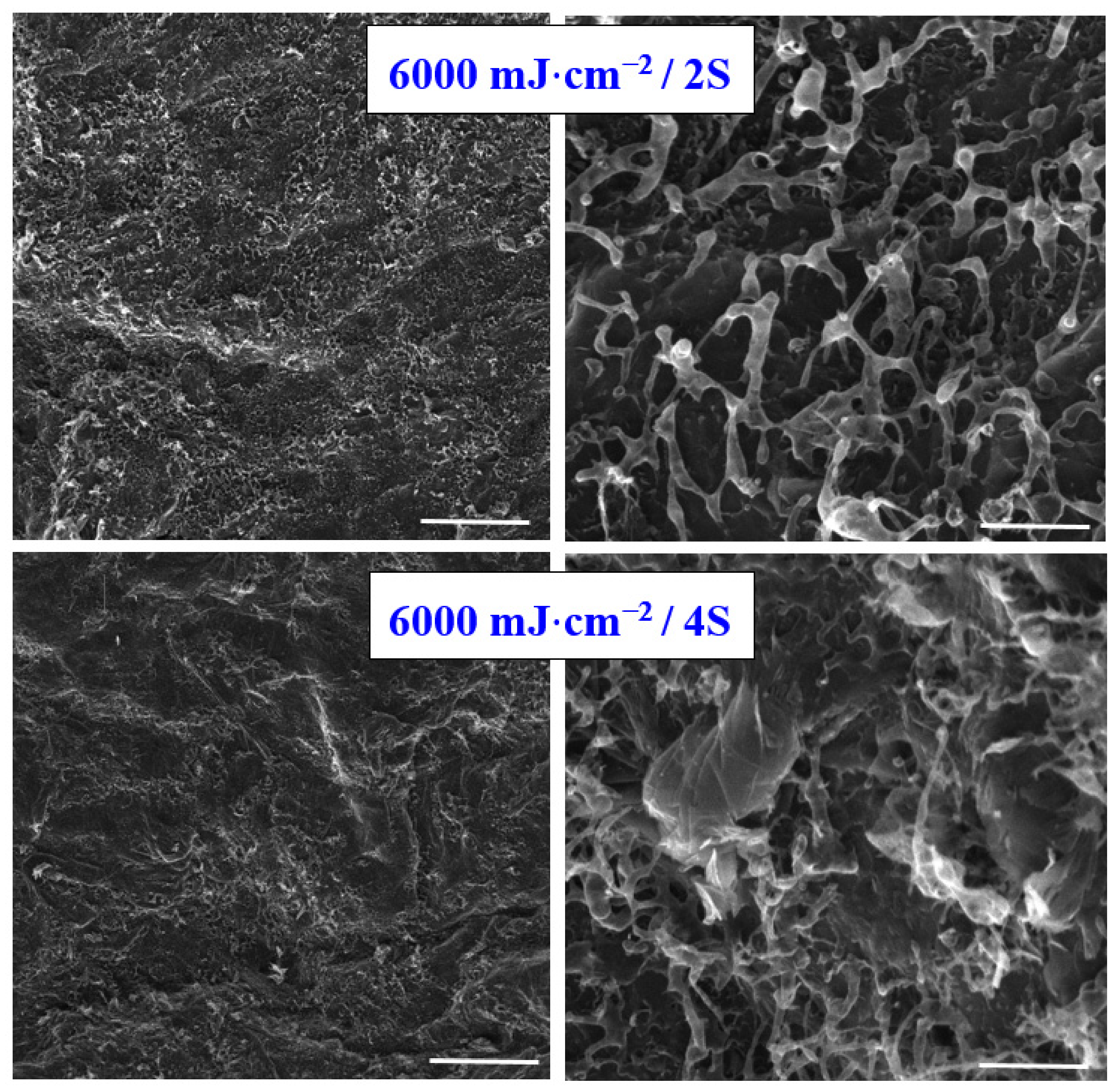

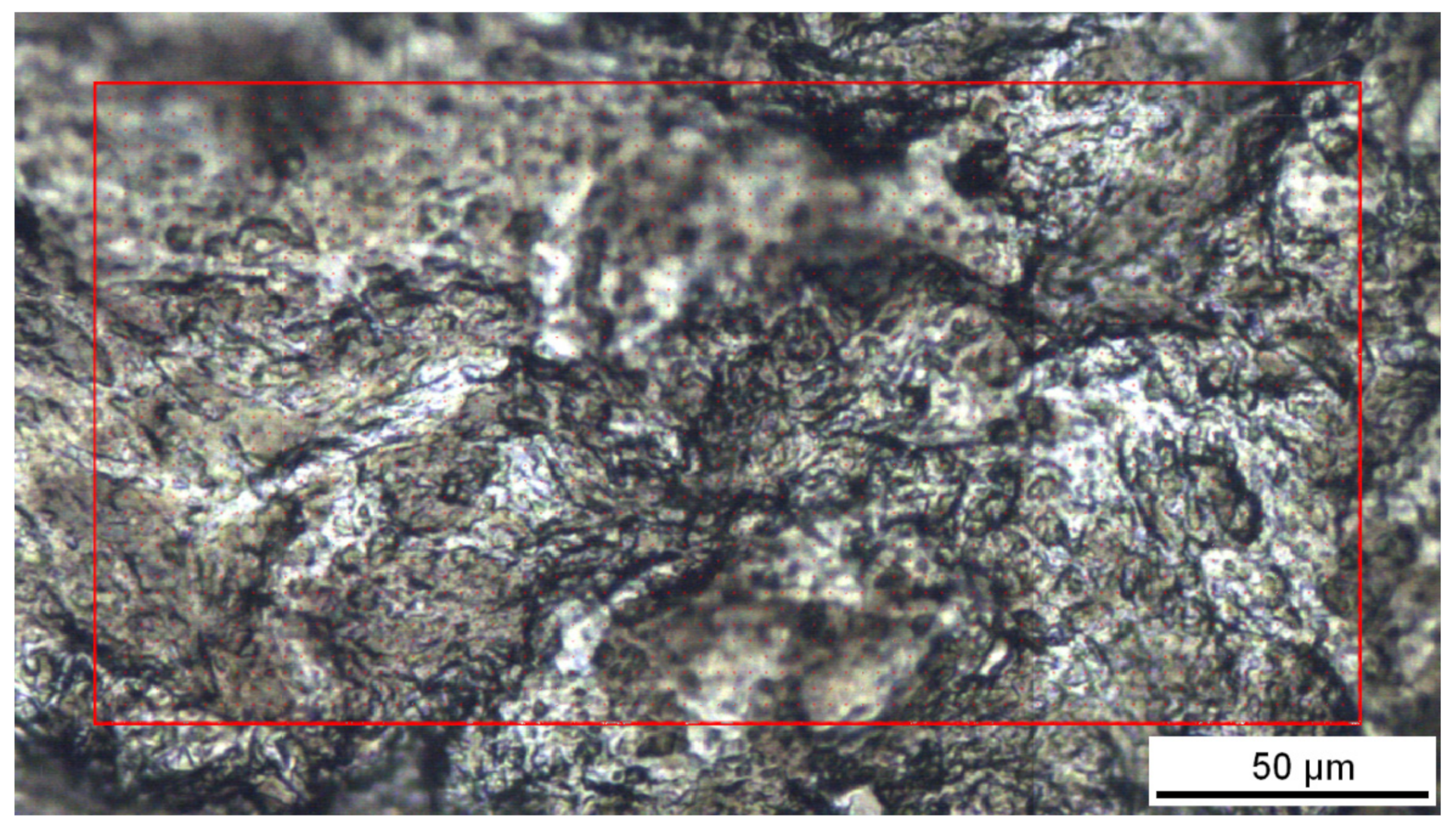

3.1. Surface Morphology and Roughness

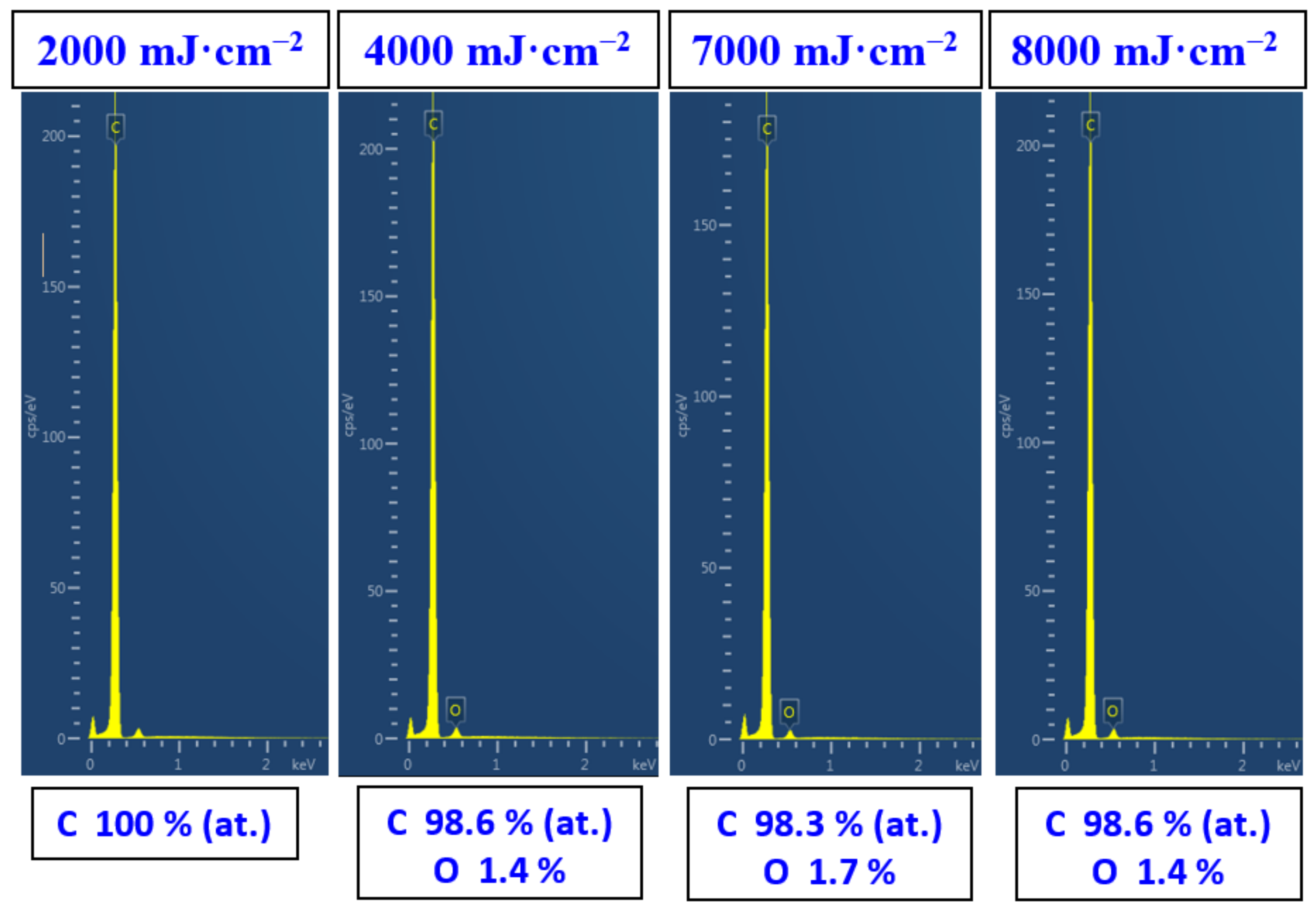

3.2. EDS Analysis

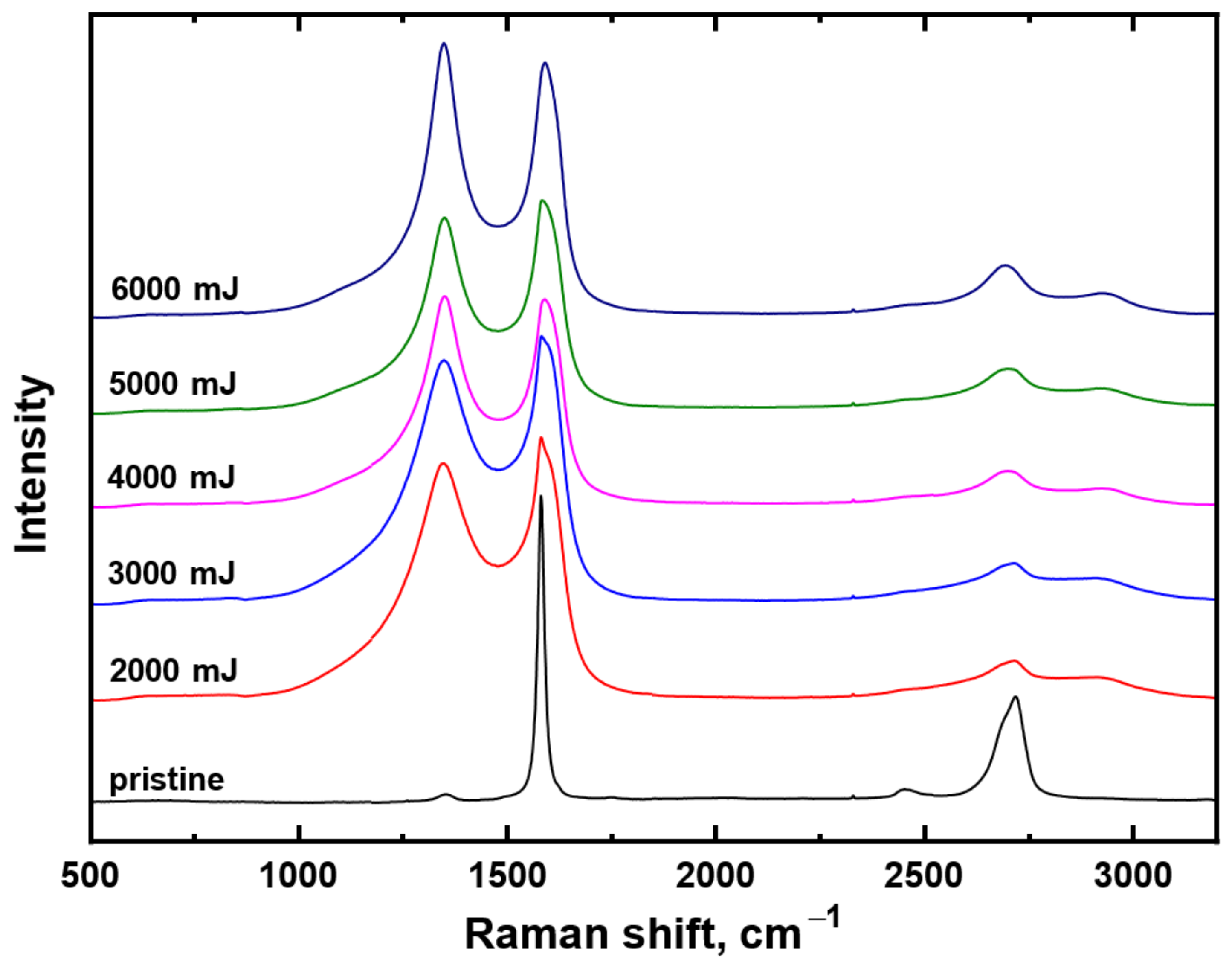

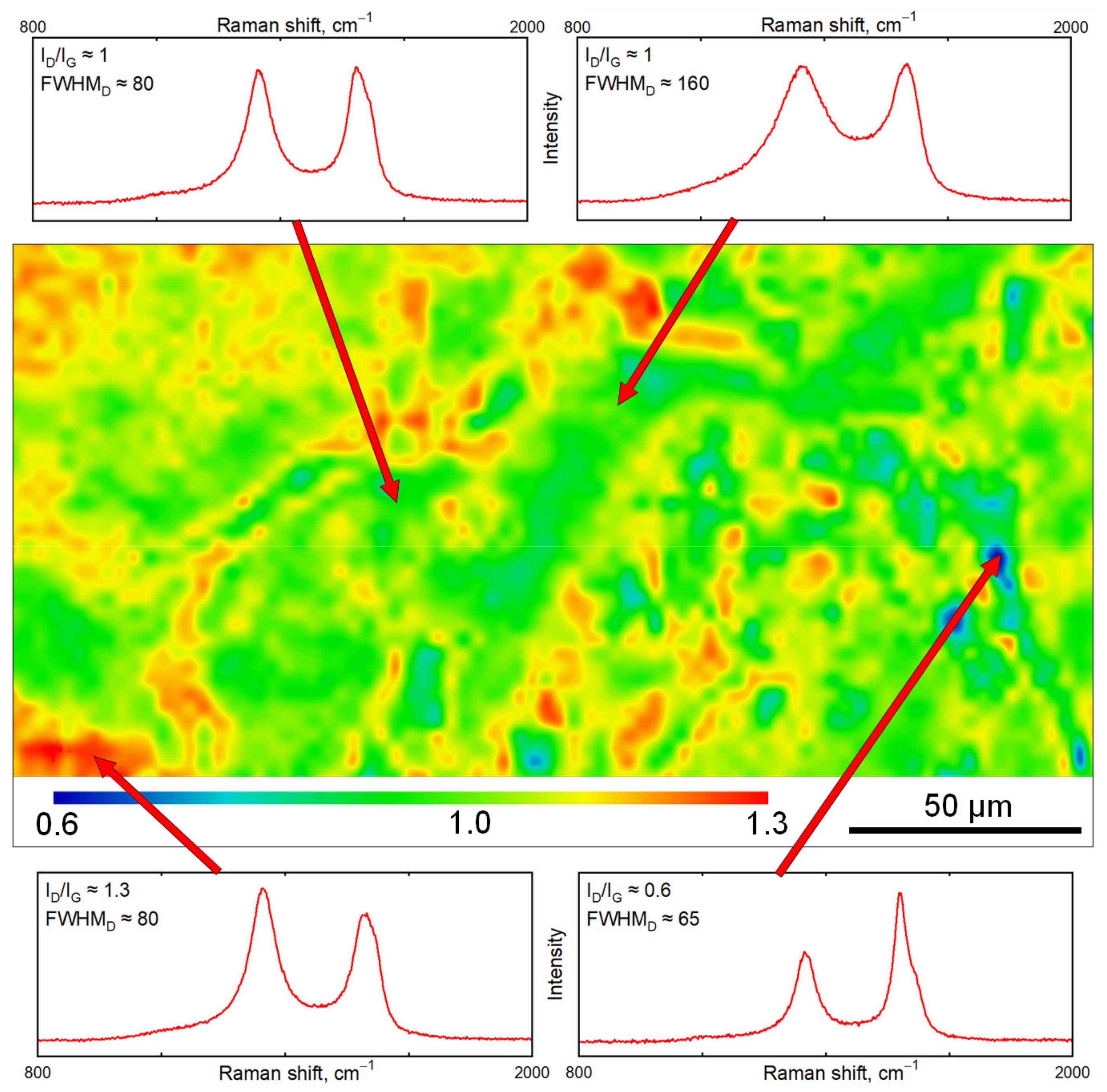

3.3. Raman Spectroscopy

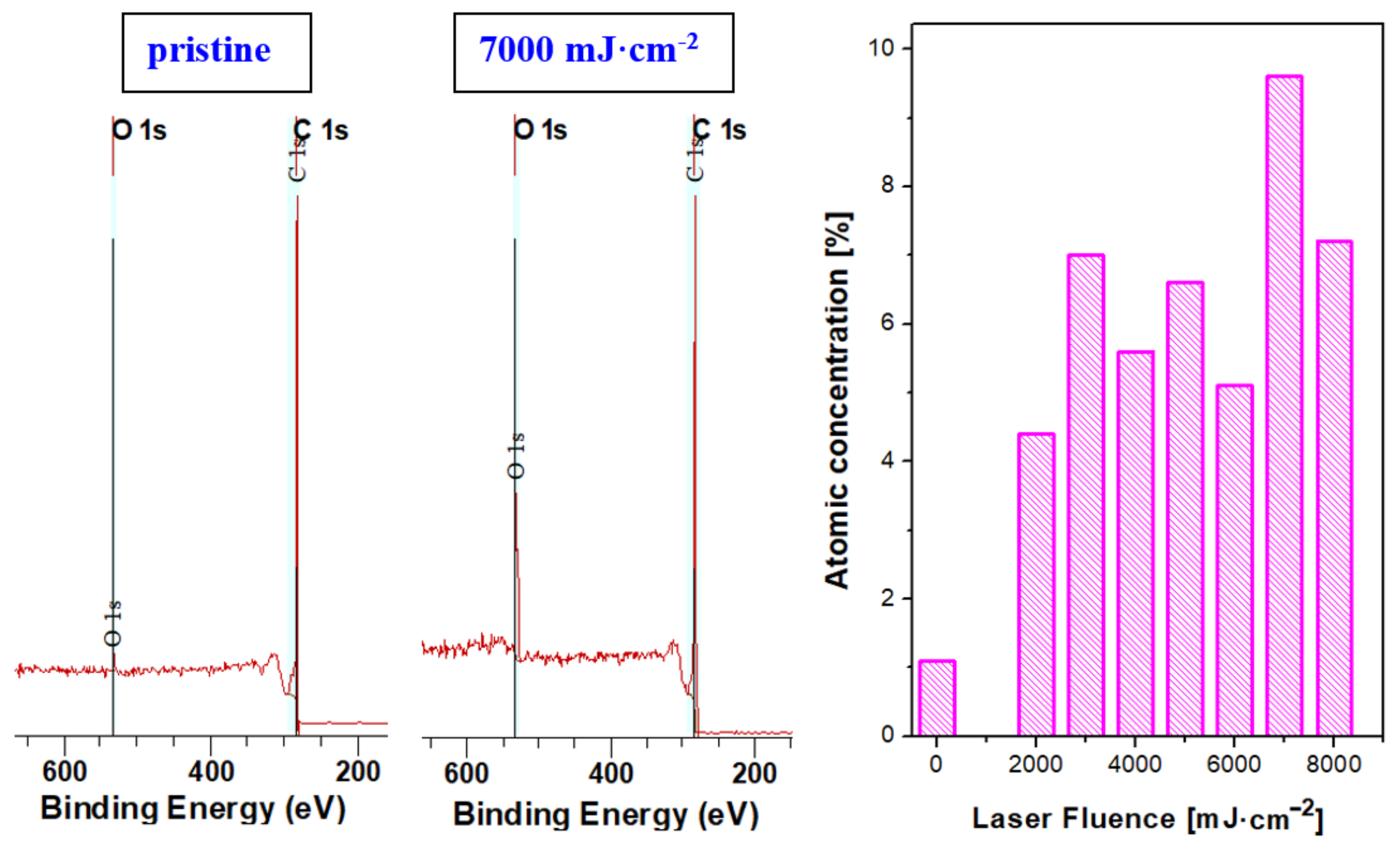

3.4. X-ray Photoinduced Spectroscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, H.; Ahn, J.H. Graphene for flexible and wearable device applications. Carbon 2017, 120, 244–257. [Google Scholar] [CrossRef]

- Gunther, D.; LeBlanc, G.; Prasai, D.; Zhang, J.R.; Cliffel, D.E.; Bolotin, K.I.; Jennings, G.K. Photosystem I on graphene as a highly transparent, photoactive electrode. Langmuir 2013, 29, 4177–4180. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Teweldebrhan, D.; Calizo, I.; Bao, W.; Miao, F.; Lau, C.N. Extremely high thermal conductivity of graphene: Prospects for thermal management applications in silicon nanoelectronics. In Proceedings of the 2008 IEEE Silicon Nanoelectronics Workshop, Honolulu, HI, USA, 15–16 June 2008; pp. 1–2. [Google Scholar]

- Park, S.; Shehzad, M.A.; Khan, M.F.; Nazir, G.; Eom, J.; Noh, H.; Seo, Y. Effect of grain boundaries on electrical properties of polycrystalline graphene. Carbon 2017, 112, 142–148. [Google Scholar] [CrossRef]

- Meng, Y.; Deng, L.; Liu, Z.; Xiao, H.; Guo, X.; Liao, M.; Tian, Y. All-optical tunable microfiber knot resonator with graphene-assisted sandwich structure. Opt. Express 2017, 25, 18451–18461. [Google Scholar] [CrossRef]

- Liang, Y.; Liang, X.; Zhang, Z.; Li, W.; Huo, X.; Peng, L. High mobility flexible graphene field-effect transistors and ambipolar radio-frequency circuits. Nanoscale 2015, 7, 10954–10962. [Google Scholar] [CrossRef]

- Iannaccone, G.; Bonaccorso, F.; Colombo, L.; Fiori, G. Quantum engineering of transistors based on 2D materials heterostructures. Nat. Nanotechnol. 2018, 13, 183–191. [Google Scholar] [CrossRef]

- Tang, R.; Han, S.; Teng, F.; Hu, K.; Zhang, Z.; Hu, M.; Fang, X. Size-Controlled Graphene Nanodot Arrays/ZnO Hybrids for High-Performance UV Photodetectors. Adv. Sci. 2018, 5, 1700334. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Guo, X.; Zhang, Y.; Zhang, W.; Ge, C.; Zhao, L.; Sun, L. Porous graphene paper for supercapacitor applications. J. Mater. Sci. Technol. 2017, 33, 793–799. [Google Scholar] [CrossRef]

- Stoller, M.D.; Park, S.; Zhu, Y.; An, J.; Ruoff, R.S. Graphene-based ultracapacitors. Nano Lett. 2008, 8, 3498–3502. [Google Scholar] [CrossRef]

- Xu, Y.; Bai, H.; Lu, G.; Li, C.; Shi, G. Flexible graphene films via the filtration of water-soluble noncovalent functionalized graphene sheets. J. Am. Chem. Soc. 2008, 130, 5856–5857. [Google Scholar] [CrossRef] [PubMed]

- Salz, J.J.; Maguen, E.; Nesburn, A.B.; Warren, C.; Macy, J.I.; Hofbauer, J.D.; Berlin, M. A two-year experience with excimer laser photorefractive keratectomy for myopia. Ophthalmology 1993, 100, 873–882. [Google Scholar] [CrossRef]

- Bhaumik, A.; Haque, A.; Taufique, M.F.N.; Karnati, P.; Patel, R.; Nath, M.; Ghosh, K. Reduced graphene oxide thin films with very large charge carrier mobility using pulsed laser deposition. J. Mater. Sci. Eng. 2017, 6, 1–11. [Google Scholar] [CrossRef]

- Russo, P.; Hu, A.; Compagnini, G.; Duley, W.W.; Zhou, N.Y. Femtosecond laser ablation of highly oriented pyrolytic graphite: A green route for large-scale production of porous graphene and graphene quantum dots. Nanoscale 2014, 6, 2381–2389. [Google Scholar] [CrossRef] [PubMed]

- Kazemizadeh, F.; Malekfar, R.; Parvin, P. Pulsed laser ablation synthesis of carbon nanoparticles in vacuum. J. Phys. Chem. Solids 2017, 104, 252–256. [Google Scholar] [CrossRef]

- Kiran, G.R.; Chandu, B.; Acharyya, S.G.; Rao, S.V.; Srikanth, V.V. One-step synthesis of bulk quantities of graphene from graphite by femtosecond laser ablation under ambient conditions. Philos. Mag. Lett. 2017, 97, 229–234. [Google Scholar] [CrossRef]

- Jalili, M.; Ghanbari, H.; Bellah, S.M.; Malekfar, R. High-quality liquid phase-pulsed laser ablation graphene synthesis by flexible graphite exfoliation. J. Mater. Sci. Technol. 2019, 35, 292–299. [Google Scholar] [CrossRef]

- Qian, M.; Niu, Y.P.; Gong, S.Q. Influence of laser wavelength on two-dimensional carbon nanosheet formation from laser-induced exfoliation of naphthalene. Appl. Surf. Sci. 2018, 428, 549–554. [Google Scholar] [CrossRef]

- Jeschke, H.O.; Garcia, M.E.; Bennemann, K.H. Theory for the ultrafast ablation of graphite films. Phys. Rev. Lett. 2001, 87, 015003. [Google Scholar] [CrossRef] [Green Version]

- Smirnov, V.A.; Arbuzov, A.A.; Shul’ga, Y.M.; Baskakov, S.A.; Martynenko, V.M.; Muradyan, V.E.; Kresova, E.I. Photoreduction of graphite oxide. High Energy Chem. 2011, 45, 57–61. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Guo, L.; Xia, H.; Chen, Q.D.; Feng, J.; Sun, H.B. Photoreduction of graphene oxides: Methods, properties, and applications. Adv. Opt. Mater. 2014, 2, 10–28. [Google Scholar] [CrossRef]

- Morozov, N.V. Laser-induced damage in optical materials under UV excimer laser radiation. In Laser-Induced Damage in Optical Materials: 1994; International Society for Optics and Photonics: Bellingham, WA, USA, 1995; Volume 2428, pp. 153–169. [Google Scholar]

- Xie, B.; Wang, Y.; Lai, W.; Lin, W.; Lin, Z.; Zhang, Z.; Wong, C.P. Laser-processed graphene based micro-supercapacitors for ultrathin, rollable, compact and designable energy storage components. Nano Energy 2016, 26, 276–285. [Google Scholar] [CrossRef]

- Hosseini, S.M.B.M.; Baizaee, S.M.; Naderi, H.R.; Kordi, A.D. Excimer laser assisted very fast exfoliation and reduction of graphite oxide at room temperature under air ambient for Supercapacitors electrode. Appl. Surf. Sci. 2018, 427, 507–516. [Google Scholar] [CrossRef]

- Haque, A.; Narayan, J. Electron field emission from Q-carbon. Diam. Relat. Mater. 2018, 86, 71–78. [Google Scholar] [CrossRef]

- Narayan, J.; Bhaumik, A.; Gupta, S.; Haque, A.; Sachan, R. Progress in Q-carbon and related materials with extraordinary properties. Mater. Res. Lett. 2018, 6, 353–364. [Google Scholar] [CrossRef] [Green Version]

- Bhaumik, A.; Nori, S.; Sachan, R.; Gupta, S.; Kumar, D.; Majumdar, A.K.; Narayan, J. Room-Temperature Ferromagnetism and Extraordinary Hall Effect in Nanostructured Q-Carbon: Implications for Potential Spintronic Devices. ACS Appl. Nano Mater. 2018, 1, 807–819. [Google Scholar] [CrossRef]

- Bhaumik, A.; Sachan, R.; Narayan, J. A novel high-temperature carbon-based superconductor: B-doped Q-carbon. J. Appl. Phys. 2017, 122, 045301. [Google Scholar] [CrossRef]

- Narayan, J.; Bhaumik, A. Novel phase of carbon, ferromagnetism, and conversion into diamond. J. Appl. Phys. 2015, 118, 215303. [Google Scholar] [CrossRef] [Green Version]

- Yoshinaka, H.; Inubushi, S.; Wakita, T.; Yokoya, T.; Muraoka, Y. Formation of Q-carbon by adjusting sp3 content in diamond-like carbon films and laser energy density of pulsed laser annealing. Carbon 2020, 167, 504–511. [Google Scholar] [CrossRef]

- Sokolov, D.A.; Rouleau, C.M.; Geohegan, D.B.; Orlando, T.M. Excimer laser reduction and patterning of graphite oxide. Carbon 2013, 53, 81–89. [Google Scholar] [CrossRef]

- Kasischke, M.; Maragkaki, S.; Volz, S.; Ostendorf, A.; Gurevich, E.L. Simultaneous nanopatterning and reduction of graphene oxide by femtosecond laser pulses. Appl. Surf. Sci. 2018, 445, 197–203. [Google Scholar] [CrossRef] [Green Version]

- Semerádtová, A.; Štofík, M.; Neděla, O.; Staněk, O.; Slepička, P.; Kolská, Z.; Malý, J. A simple approach for fabrication of optical affinity-based bioanalytical microsystem on polymeric PEN foils. Colloids Surf. B Biointerfaces 2018, 165, 28–36. [Google Scholar] [CrossRef] [PubMed]

- Slepička, P.; Slepičková Kasálková, N.; Pinkner, A.; Sajdl, P.; Kolská, Z.; Švorčík, V. Plasma induced cytocompatibility of stabilized poly-L-lactic acid doped with graphene nanoplatelets. React. Funct. Polym. 2018, 131, 266–275. [Google Scholar] [CrossRef]

- Lišková, J.; Slepičková Kasálková, N.; Slepička, P.; Švorčík, V.; Bačáková, L. Heat-treated carbon coatings on poly (L-lactide) foils for tissue engineering. Mater. Sci. Eng. C 2019, 100, 117–128. [Google Scholar] [CrossRef] [PubMed]

- Slepickova Kasalkova, N.; Žáková, P.; Stibor, I.; Slepička, P.; Kolská, Z.; Karpíšková, J.; Švorčík, V. Carbon nanostructures grafted biopolymers for medical applications. Mater. Technol. 2019, 34, 376–385. [Google Scholar] [CrossRef]

- Fajstavr, D.; Neznalová, K.; Švorčík, V.; Slepička, P. LIPSS Structures Induced on Graphene-Polystyrene Composite. Materials 2019, 12, 3460. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cutroneo, M.; Havránek, V.; Torrisi, A.; Mackova, A.; Malinsky, P.; Slepicka, P.; Sofer, Z.; Torrisi, L. Polydimethylsiloxane–graphene oxide composite improving performance by ion beam irradiation. Surf. Interface Anal. 2020, 52, 1156–1162. [Google Scholar] [CrossRef]

- Slepicka, P.; Slepickova Kasalkova, N.; Siegel, J.; Kolska, Z.; Bacakova, L.; Svorcik, V. Nano-structured and functionalized surfaces for cytocompatibility improvement and bactericidal action. Biotechnol. Adv. 2015, 33, 1120–1129. [Google Scholar] [CrossRef]

- Žáková, P.; Slepičková Kasálková, N.; Slepička, P.; Kolská, Z.; Karpíšková, J.; Stibor, I.; Švorčík, V. Cytocompatibility of polyethylene grafted with triethylenetetramine functionalized carbon nanoparticles. Appl. Surf. Sci. 2017, 422, 809–816. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Raman spectroscopy of amorphous, nanostructured, diamond-like carbon, and nanodiamond. Philos. Trans. R. Soc. A 2004, 362, 2477–2512. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cançado, L.G.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1291. [Google Scholar] [CrossRef] [PubMed]

- Couzi, M.; Bruneel, J.L.; Talaga, D.; Bokobza, L. A multi wavelength Raman scattering study of defective graphitic carbon materials: The first order Raman spectra revisited. Carbon 2016, 107, 388–394. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Basko, D.M. Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat. Nanotechnol. 2013, 8, 235–246. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jorio, A. Raman spectroscopy in graphene-based systems: Prototypes for nanoscience and nanotechnology. Int. Sch. Res. Not. 2012, 2012, 234216. [Google Scholar] [CrossRef] [Green Version]

- Dresselhaus, M.S.; Dresselhaus, G.; Saito, R.; Jorio, A. Raman spectroscopy of carbon nanotubes. Phys. Rep. 2005, 49, 47–99. [Google Scholar] [CrossRef]

- He, M.; Yeo, C. Evaluation of Thermal Degradation of DLC Film Using a Novel Raman Spectroscopy Technique. Coatings 2018, 8, 143. [Google Scholar] [CrossRef] [Green Version]

- Diniz dos Santos, E.; Luqueta, G.; Rajasekaran, R.; dos Santos, T.B.; Cesar Doria, A.C.O.; Radi, P.A.; Pessoa, R.S.; Vieira, L.; Maciel, H.S. Macrophages adhesion rate on Ti-6Al-4V substrates: Polishing and DLC coating effects. Res. Biomed. Eng. 2016, 32, 144–152. [Google Scholar] [CrossRef] [Green Version]

- Slepičková Kasálková, N.; Slepička, P.; Švorčík, V. Carbon Nanostructures, Nanolayers, and Their Composites. Nanomaterials 2021, 11, 2368. [Google Scholar] [CrossRef]

- Gupta, S.; Sachan, R.; Narayan, J. Scale-up of Q-carbon and nanodiamonds by pulsed laser annealing. Diam. Relat. Mater. 2019, 99, 107531. [Google Scholar] [CrossRef]

- Paetzel, R.; Brune, J.; Simon, F.; Herbst, L.; Machida, M.; Shida, J. Activation of silicon wafer by excimer laser. In Proceedings of the 18th International Conference on Advanced Thermal Processing of Semiconductors (RTP), Gainesville, FL, USA, 28 September–1 October 2010; pp. 98–102. [Google Scholar]

- Conde, J.C.; Martín, E.; Chiussi, S.; Gontad, F.; González, P. FEM for modelling 193 nm excimer laser treatment of SiO2/Si/Si1−x Gex heterostructures on SOI substrates. Phys. Status Solidi C 2011, 8, 936–939. [Google Scholar] [CrossRef]

- Pecholta, B.; Gupta, S.; Molian, P. Review of laser microscale processing of silicon carbide. J. Laser Appl. 2011, 23, 012008. [Google Scholar] [CrossRef]

- Calabretta, C.; Agati, M.; Zimbone, M.; Boninelli, S.; Castiello, A.; Pecora, A.; Fortunato, G.; Calcagno, L.; Torrisi, L.; La Via, F. Laser Annealing of P and Al Implanted 4H-SiC Epitaxial Layers. Materials 2019, 12, 3362. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Silva, M.; Ishikawa, S.; Miyazaki, T.; Kikkawa, T.; Kuroki, S.L. Formation of amorphous alloys on 4H-SiC with NbNi film using pulsed-laser annealing. Appl. Phys. Lett. 2016, 109, 012101. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, X.; Fang, X.; Chen, X. Synthesis of single-layer graphene film by chemical vapor deposition with molten gallium catalyst on silicon dioxide. J. Mater. Sci. 2020, 55, 2787–2795. [Google Scholar] [CrossRef]

- Islam, F.; Tahmasebi, A.; Moghtaderi, B.; Yu, J. Structural Investigation of the Synthesized Few-Layer Graphene from Coal under Microwave. Nanomaterials 2022, 12, 57. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slepičková Kasálková, N.; Hurtuková, K.; Fajstavr, D.; Lapčák, L.; Sajdl, P.; Kolská, Z.; Švorčík, V.; Slepička, P. Carbon Transformation Induced by High Energy Excimer Treatment. Materials 2022, 15, 4614. https://doi.org/10.3390/ma15134614

Slepičková Kasálková N, Hurtuková K, Fajstavr D, Lapčák L, Sajdl P, Kolská Z, Švorčík V, Slepička P. Carbon Transformation Induced by High Energy Excimer Treatment. Materials. 2022; 15(13):4614. https://doi.org/10.3390/ma15134614

Chicago/Turabian StyleSlepičková Kasálková, Nikola, Klaudia Hurtuková, Dominik Fajstavr, Ladislav Lapčák, Petr Sajdl, Zdeňka Kolská, Václav Švorčík, and Petr Slepička. 2022. "Carbon Transformation Induced by High Energy Excimer Treatment" Materials 15, no. 13: 4614. https://doi.org/10.3390/ma15134614

APA StyleSlepičková Kasálková, N., Hurtuková, K., Fajstavr, D., Lapčák, L., Sajdl, P., Kolská, Z., Švorčík, V., & Slepička, P. (2022). Carbon Transformation Induced by High Energy Excimer Treatment. Materials, 15(13), 4614. https://doi.org/10.3390/ma15134614