Dynamic Tensile Behavior of Woven C/SiC Composite: Experiments and Strain-Rate-Dependent Yield Criterion

Abstract

:1. Introduction

2. Experiments

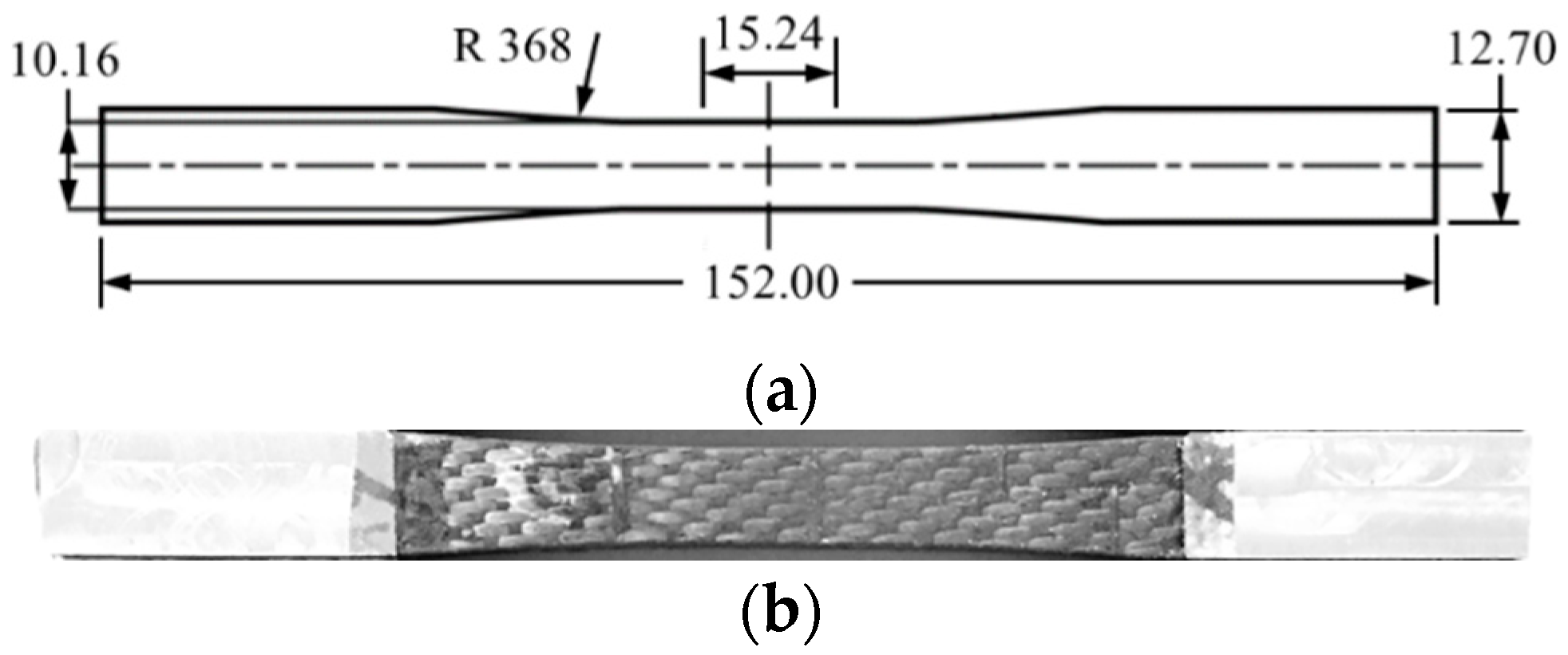

2.1. Material

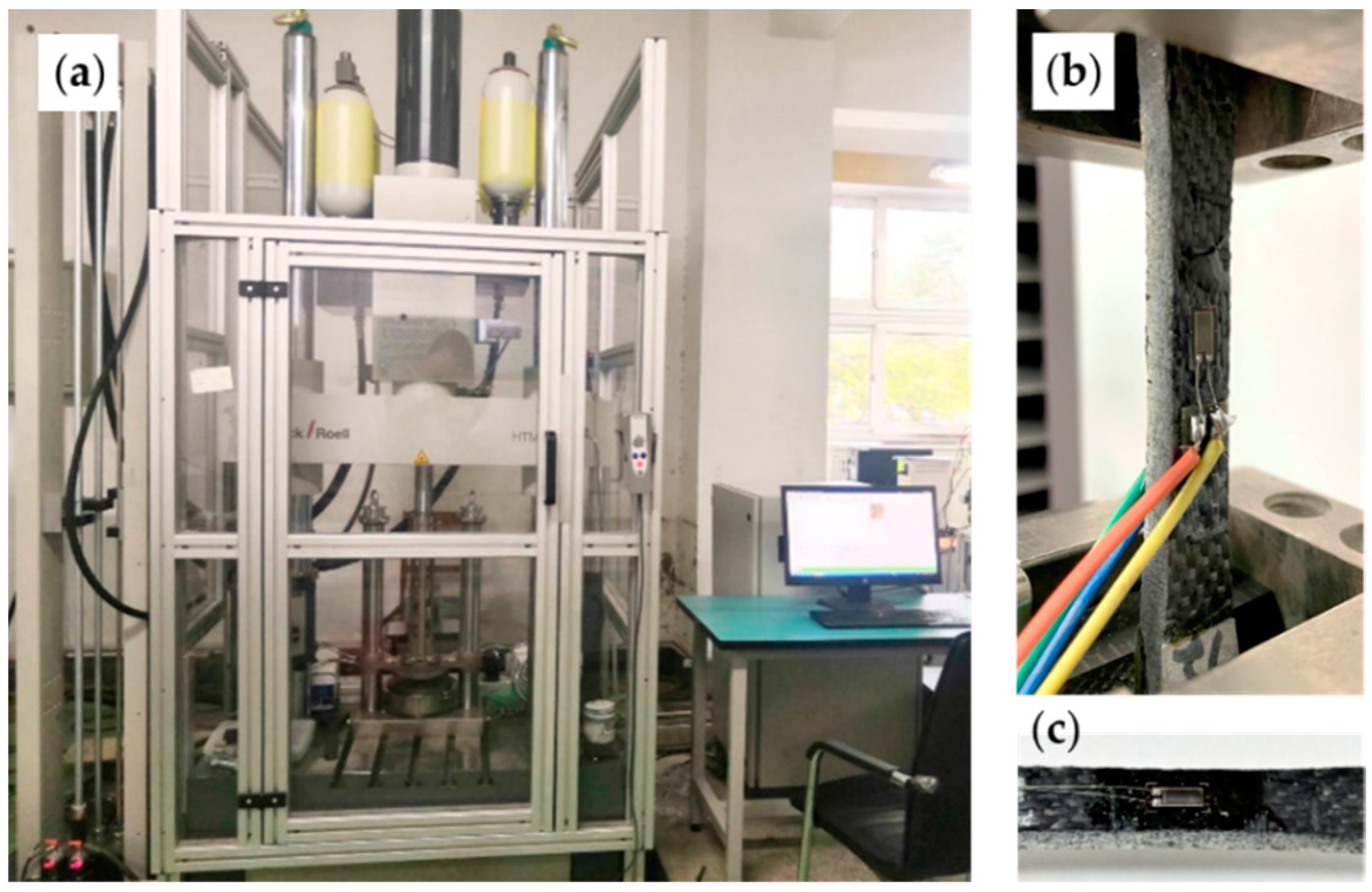

2.2. Test Procedure

3. Strain-Rate-Dependent Yield Criterion

4. Yield Criterion Considering Uncertainty

5. Results and Discussion

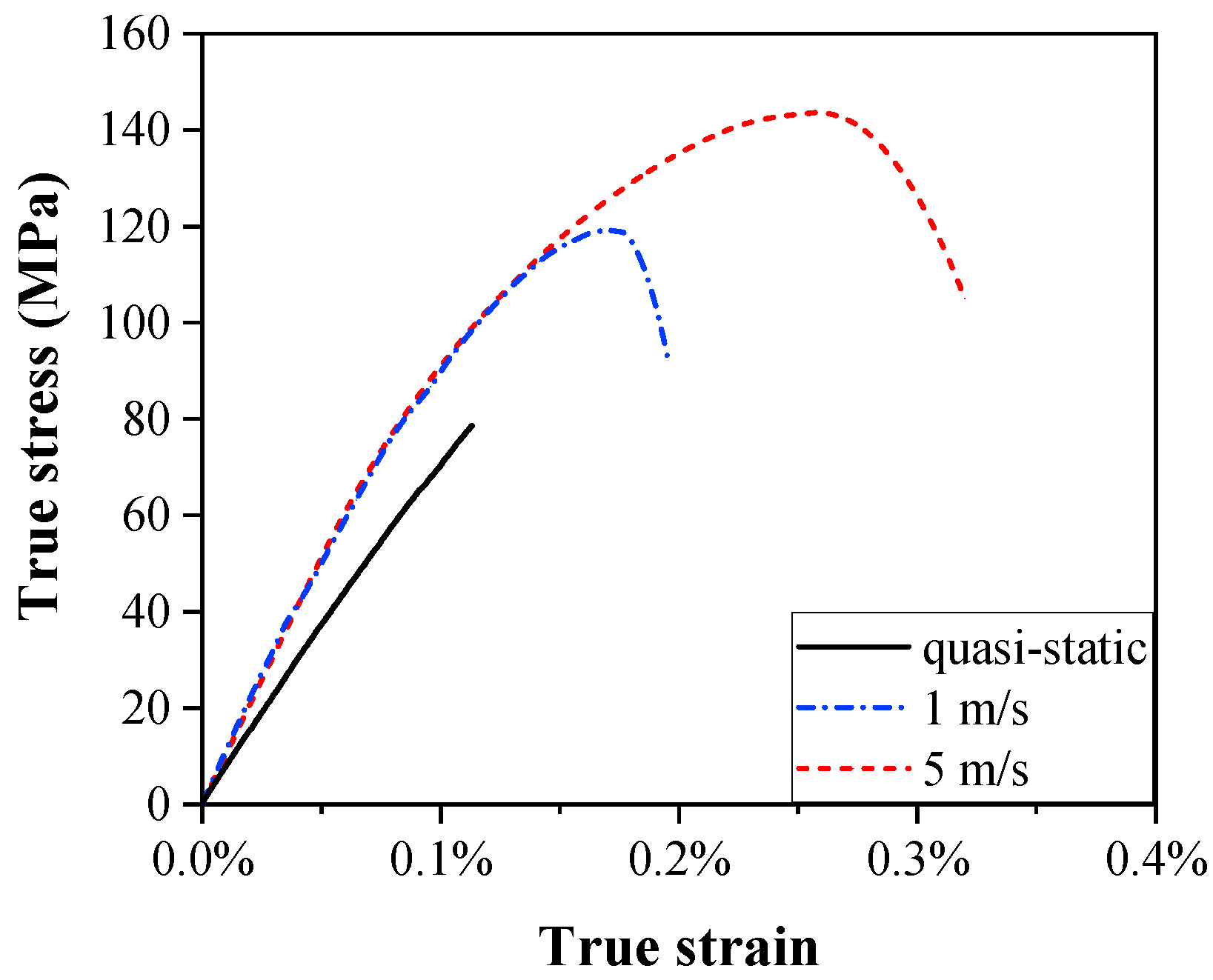

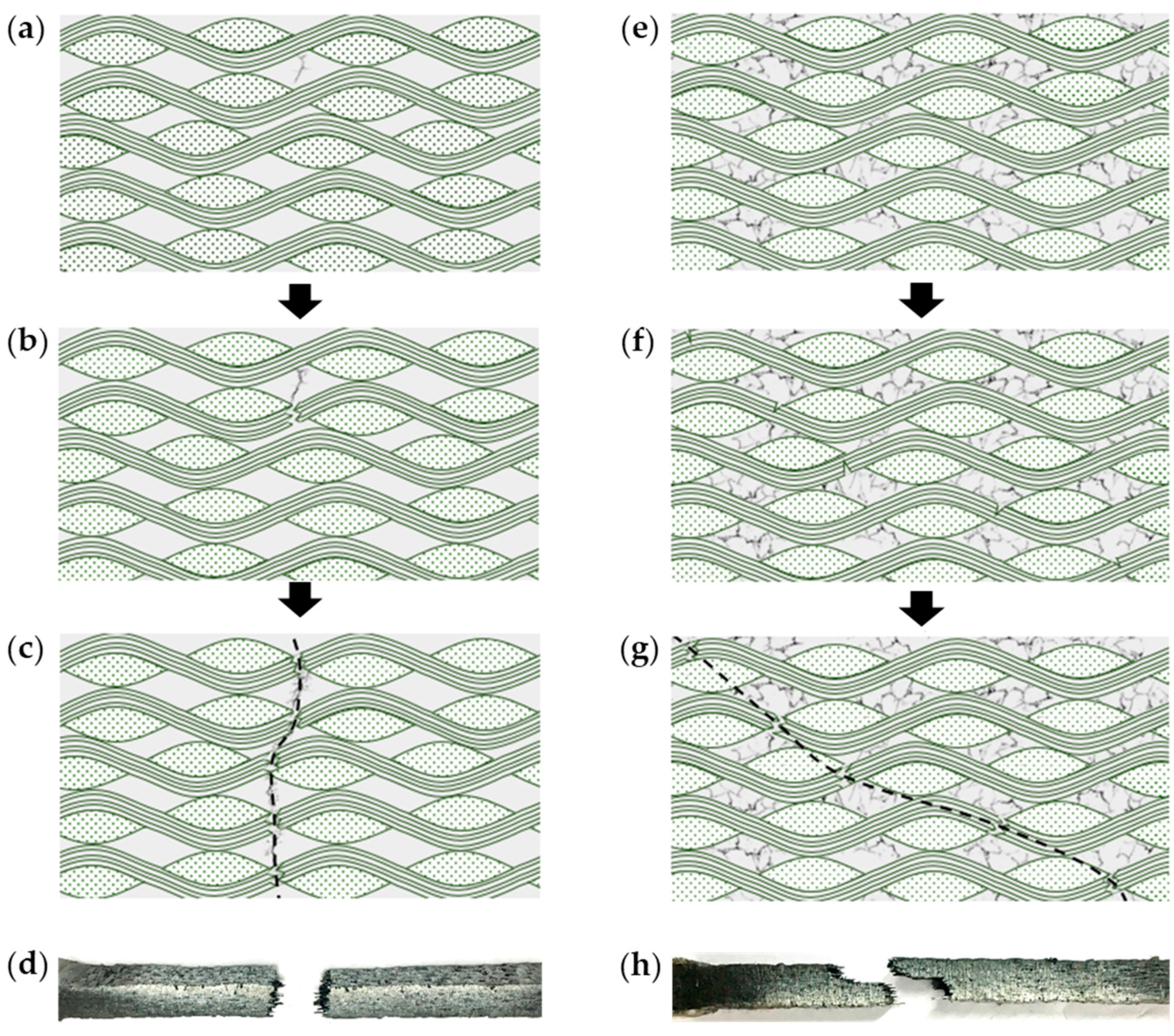

5.1. Experimental Results

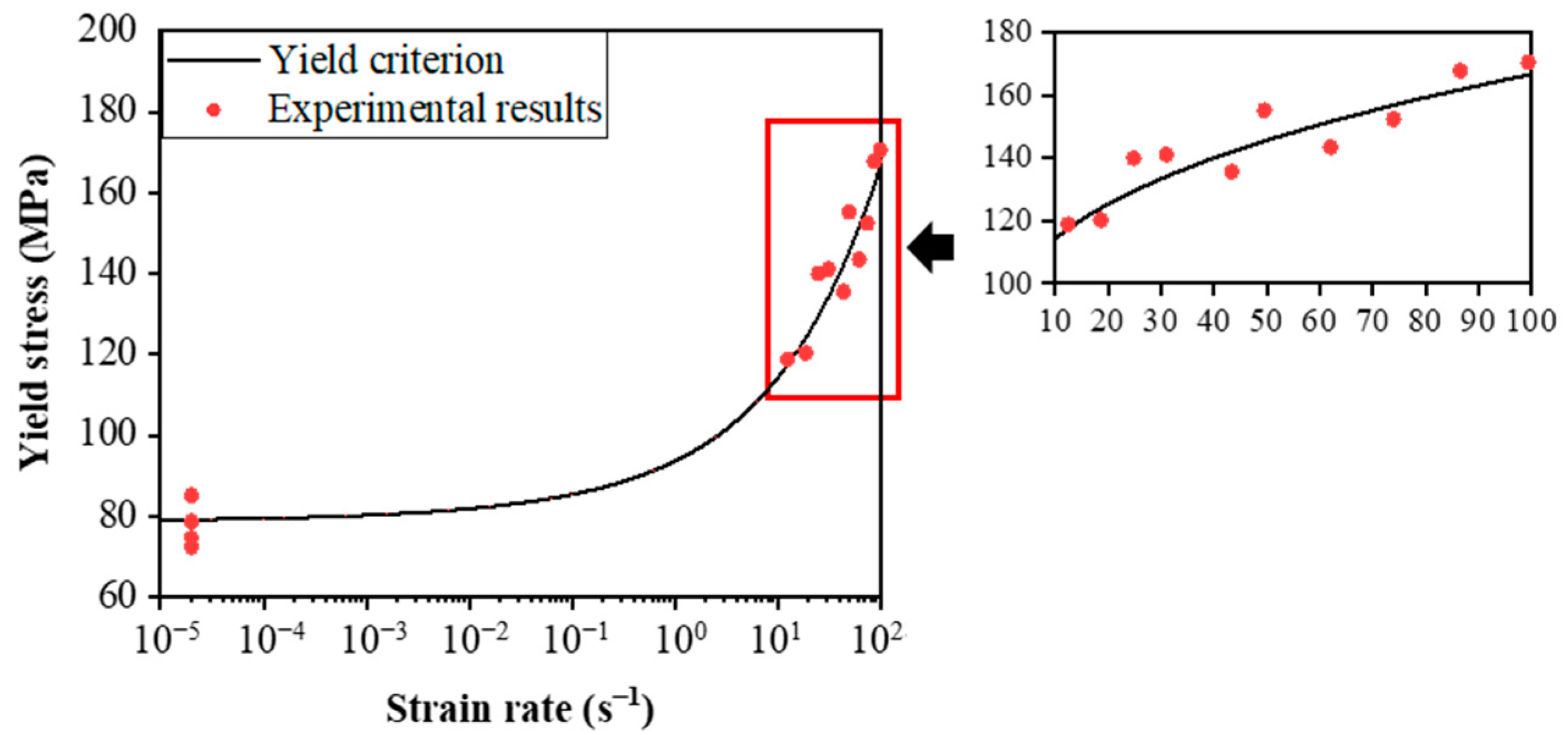

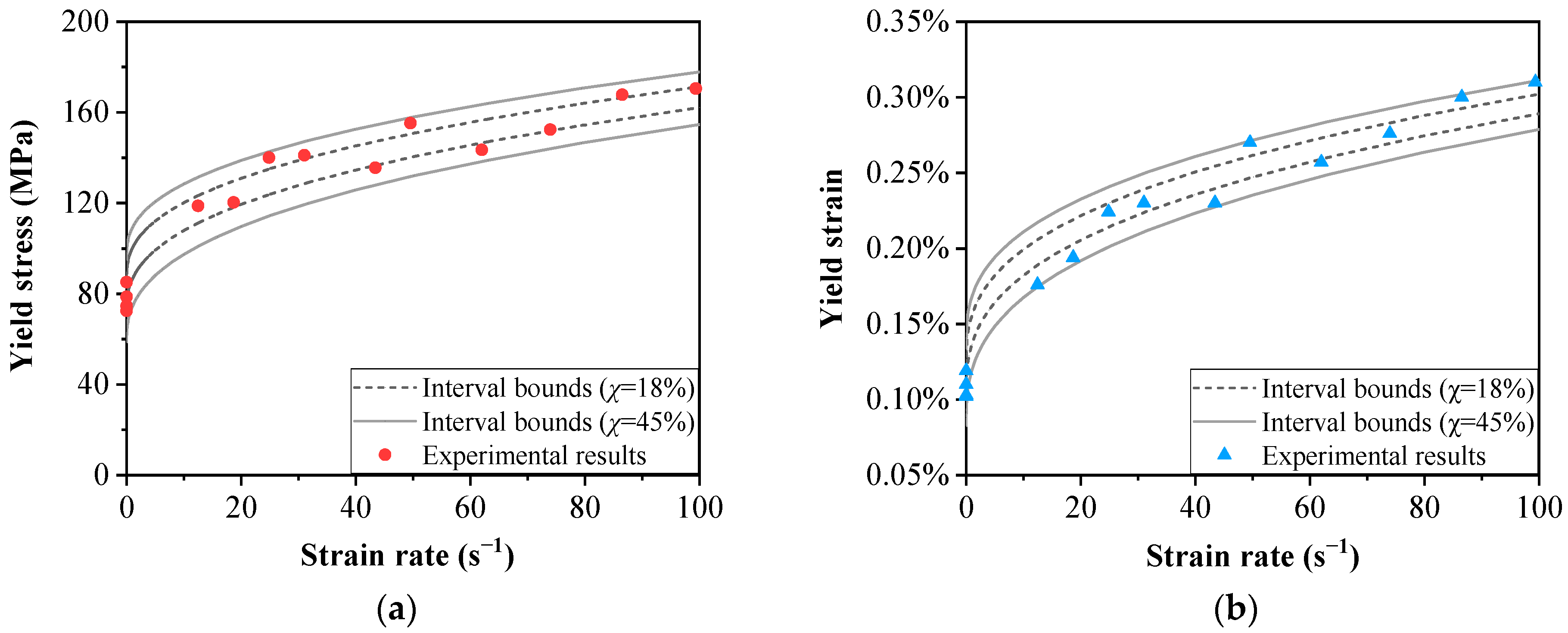

5.2. Yield Assessment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Degenhardt, R.; Castro, S.G.; Arbelo, M.A.; Zimmerman, R.; Khakimova, R.; Kling, A. Future structural stability design for composite space and airframe structures. Thin Walled Struct. 2014, 81, 29–38. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Guo, C.; Cui, C.; Bao, J.; Zhang, G.; Zhang, Y.; Li, S.; Wang, G. Microstructure Evolution and Performance Improvement of Silicon Carbide Ceramics via Impregnation Method. Materials 2022, 15, 1717. [Google Scholar] [CrossRef] [PubMed]

- Koyanagi, T.; Katoh, Y.; Nozawa, T.; Snead, L.L.; Kondo, S.; Henager, C.H., Jr.; Ferraris, M.; Hinoki, T.; Huang, Q. Recent progress in the development of SiC composites for nuclear fusion applications. J. Nucl. Mater. 2018, 511, 544–555. [Google Scholar] [CrossRef]

- Luo, X.; He, J.; Liu, X.; Xu, Y.; Li, J.; Guo, X.; Li, L. Design, Fabrication, and Mechanical Properties of T-700TM Multiaxial-Warp-Knitting–Needled–C/SiC Composite and Pin. Materials 2022, 15, 2338. [Google Scholar] [CrossRef]

- Giannaros, E.; Kotzakolios, A.; Kostopoulos, V.; Sotiriadis, G.; Vignjevic, R.; Djordjevic, N.; Boccaccio, M.; Meo, M. Low-and high-fidelity modeling of sandwich-structured composite response to bird strike, as tools for a digital-twin-assisted damage diagnosis. Int. J. Impact Eng. 2022, 160, 104058. [Google Scholar] [CrossRef]

- Walker, J.D. From Columbia to Discovery: Understanding the impact threat to the space shuttle. Int. J. Impact Eng. 2009, 36, 303–317. [Google Scholar] [CrossRef]

- Dong, Y.; Shi, X.; Zhang, Z.; Pan, B. In-situ bending behavior and failure characterization of 3D needle-punched C/SiC composites. Mater. Today Commun. 2017, 13, 378–385. [Google Scholar] [CrossRef]

- Du, X.B.; Li, D.S.; Wei, Q.H.; Jiang, L. High temperature bending properties and failure mechanism of 3D needled C/SiC composites up to 2000 °C. J. Eur. Ceram. Soc. 2022, 42, 3036–3043. [Google Scholar] [CrossRef]

- Yan, K.F.; Zhang, C.Y.; Qiao, S.R.; Li, M.; Han, D. Failure and strength of 2D-C/SiC composite under in-plane shear loading at elevated temperatures. Mater. Des. 2011, 32, 3504–3508. [Google Scholar] [CrossRef]

- Bisht, N.; Verma, A.; Chauhan, S.; Singh, V.K. Effect of functionalized silicon carbide nano-particles as additive in cross-linked PVA based composites for vibration damping application. J. Vinyl Addit. Technol. 2021, 27, 920–932. [Google Scholar] [CrossRef]

- Li, T.; Fan, D.; Lu, L.; Huang, J.Y.; E, J.C.; Zhao, F.; Qi, M.L.; Sun, T.; Fezzaa, K.; Xiao, X.H.; et al. Dynamic fracture of C/SiC composites under high strain-rate loading: Microstructures and mechanisms. Carbon 2015, 91, 468–478. [Google Scholar] [CrossRef] [Green Version]

- Xuan, C.; Yulong, L. Dynamic tensile behavior of two-dimensional carbon fiber reinforced silicon carbide matrix composites. Mater. Sci. Eng. A 2011, 528, 6998–7004. [Google Scholar] [CrossRef]

- Hu, W.; Huang, J.; Zhang, C.; Ren, T.; Guan, T.; Wu, K.; Wang, B.; Aamir, R.M.; Sheikh, M.Z.; Suo, T. Effect of shear strain rate on interlaminar shear behavior of 2D-C/SiC composites: A damage transition from notch ends initiation to gauge section initiation. Carbon 2020, 167, 770–784. [Google Scholar] [CrossRef]

- Luan, K.; Liu, J.; Sun, B.; Zhang, W.; Hu, J.; Fang, X.; Ming, C.; Song, E. High strain rate compressive response of the Cf/SiC composite. Ceram. Int. 2019, 45, 6812–6818. [Google Scholar] [CrossRef]

- Suo, T.; Fan, X.; Hu, G.; Li, Y.; Tang, Z.; Xue, P. Compressive behavior of C/SiC composites over a wide range of strain rates and temperatures. Carbon 2013, 62, 481–492. [Google Scholar] [CrossRef]

- Talreja, R. Assessment of the fundamentals of failure theories for composite materials. Compos. Sci. Technol. 2014, 105, 190–201. [Google Scholar] [CrossRef]

- Schulte, K. Part C of the world-wide failure exercise on failure prediction in composites. Compos. Sci. Technol. 2004, 3, 319. [Google Scholar] [CrossRef]

- Gurusideswar, S.; Velmurugan, R.; Gupta, N.K. Study of rate dependent behavior of glass/epoxy composites with nanofillers using non-contact strain measurement. Int. J. Impact Eng. 2017, 110, 324–337. [Google Scholar] [CrossRef]

- Gillespie, J.W., Jr.; Gama, B.A.; Cichanowski, C.E.; Xiao, J.R. Interlaminar shear strength of plain weave S2-glass/SC79 composites subjected to out-of-plane high strain rate compressive loadings. Compos. Sci. Technol. 2005, 65, 1891–1908. [Google Scholar] [CrossRef]

- Daniel, I.M. Yield and failure criteria for composite materials under static and dynamic loading. Prog. Aerosp. Sci. 2016, 81, 18–25. [Google Scholar] [CrossRef] [Green Version]

- Niu, X.; Sun, Z.; Song, Y. Strength properties and its dispersion of 2.5 DC/SiC composites. Mech. Based Des. Struct. Mach. 2019, 47, 283–301. [Google Scholar] [CrossRef]

- Xiong, C.; Li, T.; Zhao, T.; Khan, M.; Wang, J.; Ji, X.; Li, H.; Liu, W.; Shang, Y. Preparation of C/C–SiC composite by low tem-perature compression molding–liquid silicon infiltration and its application in automobile brake. Ceram. Int. 2016, 42, 1057–1062. [Google Scholar] [CrossRef]

- Guo, W.; Ye, Y.; Bai, S.; Zhu, L.; Li, S. Preparation and formation mechanism of C/C–SiC composites using polymer-Si slurry reactive melt infiltration. Ceram. Int. 2020, 46, 5586–5593. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, K.; Li, W.; Liu, Q.; Kou, G.; Zhang, Y. Preparation, ablation behavior and mechanism of C/C-ZrC-SiC and C/C-SiC composites. Ceram. Int. 2018, 44, 7481–7490. [Google Scholar] [CrossRef]

- (ASTM C 1275-18); Standard Test Method for Monotonic Tensile Behavior of Continuous Fiber-Reinforced Advanced Ceramics with Solid Rectangular Cross-Section Test Specimens at Ambient Temperature. ASTM International: West Conshohocken, PA, USA, 2018.

- Du, X.; Zhang, Q.; Wan, Z. A Nonlinear Constitutive Model for Rayon-Rubber Composite in the Medium Strain Rate Range. J. Elastomers Plast. 1995, 27, 91–99. [Google Scholar] [CrossRef]

- Yu, J.; Fei, Q.; Zhang, P.; Li, Y.; Zhang, D.; Guo, F. An Innovative Yield Criterion Considering Strain Rates Based on Von Mises Stress. J. Press. Vessel Technol. 2020, 142, 014501. [Google Scholar] [CrossRef]

- Zhang, C.; Ren, T.; Zhang, X.; Hu, W.; Wang, Z.; Wang, B.; Suo, T. Study of dynamic compressive behaviors of 2D C/SiC composites at elevated temperatures based on in-situ observation. J. Eur. Ceram. Soc. 2020, 40, 5103–5119. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Shi, C.; Suo, T. The dynamic tensile properties of 2D-C/SiC composites at elevated temperatures. Int. J. Impact Eng. 2015, 79, 75–82. [Google Scholar] [CrossRef]

| Specimen | Cross-Section Area (mm2) | Loading Speed (m/s) | Strain Rate (s−1) | Yield Stress (MPa) | Yield Strain |

|---|---|---|---|---|---|

| S-1 | 60.83 | 10−5 | 2 × 10−5 | 78.7 | 0.11% |

| S-2 | 62.41 | 10−5 | 2 × 10−5 | 85.2 | 0.12% |

| S-3 | 63.37 | 10−5 | 2 × 10−5 | 72.4 | 0.10% |

| S-4 | 61.45 | 10−5 | 2 × 10−5 | 74.6 | 0.10% |

| D-1 | 62.01 | 1.0 | 12.5 | 118.8 | 0.18% |

| D-2 | 62.01 | 1.5 | 18.7 | 120.3 | 0.19% |

| D-3 | 63.20 | 2.0 | 24.9 | 140.0 | 0.22% |

| D-4 | 59.99 | 2.5 | 31.0 | 141.1 | 0.23% |

| D-5 | 64.04 | 3.5 | 43.4 | 135.6 | 0.23% |

| D-6 | 60.94 | 4.0 | 49.5 | 155.2 | 0.27% |

| D-7 | 61.25 | 5.0 | 62.0 | 143.5 | 0.26% |

| D-8 | 61.88 | 6.0 | 73.9 | 152.4 | 0.28% |

| D-9 | 58.52 | 7.0 | 86.5 | 167.8 | 0.30% |

| D-10 | 63.05 | 8.0 | 99.4 | 170.5 | 0.31% |

| υds (MPa) | n | A1 (GPa) | A2 (GPa·sn) | B1 (GPa) | B2 (GPa·sn) |

|---|---|---|---|---|---|

| 3.11 × 10−2 | 0.3 | 25.69 | −1.64 × 10−2 | 71.55 | −1.13 × 10−2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.; Zhang, P.; Chen, Q.; Fei, Q. Dynamic Tensile Behavior of Woven C/SiC Composite: Experiments and Strain-Rate-Dependent Yield Criterion. Materials 2022, 15, 4679. https://doi.org/10.3390/ma15134679

Yu J, Zhang P, Chen Q, Fei Q. Dynamic Tensile Behavior of Woven C/SiC Composite: Experiments and Strain-Rate-Dependent Yield Criterion. Materials. 2022; 15(13):4679. https://doi.org/10.3390/ma15134679

Chicago/Turabian StyleYu, Jingwei, Peiwei Zhang, Qiang Chen, and Qingguo Fei. 2022. "Dynamic Tensile Behavior of Woven C/SiC Composite: Experiments and Strain-Rate-Dependent Yield Criterion" Materials 15, no. 13: 4679. https://doi.org/10.3390/ma15134679

APA StyleYu, J., Zhang, P., Chen, Q., & Fei, Q. (2022). Dynamic Tensile Behavior of Woven C/SiC Composite: Experiments and Strain-Rate-Dependent Yield Criterion. Materials, 15(13), 4679. https://doi.org/10.3390/ma15134679