Thermal Energy Analysis of Projectiles during Ricochetting Using a Thermal Camera

Abstract

:1. Introduction

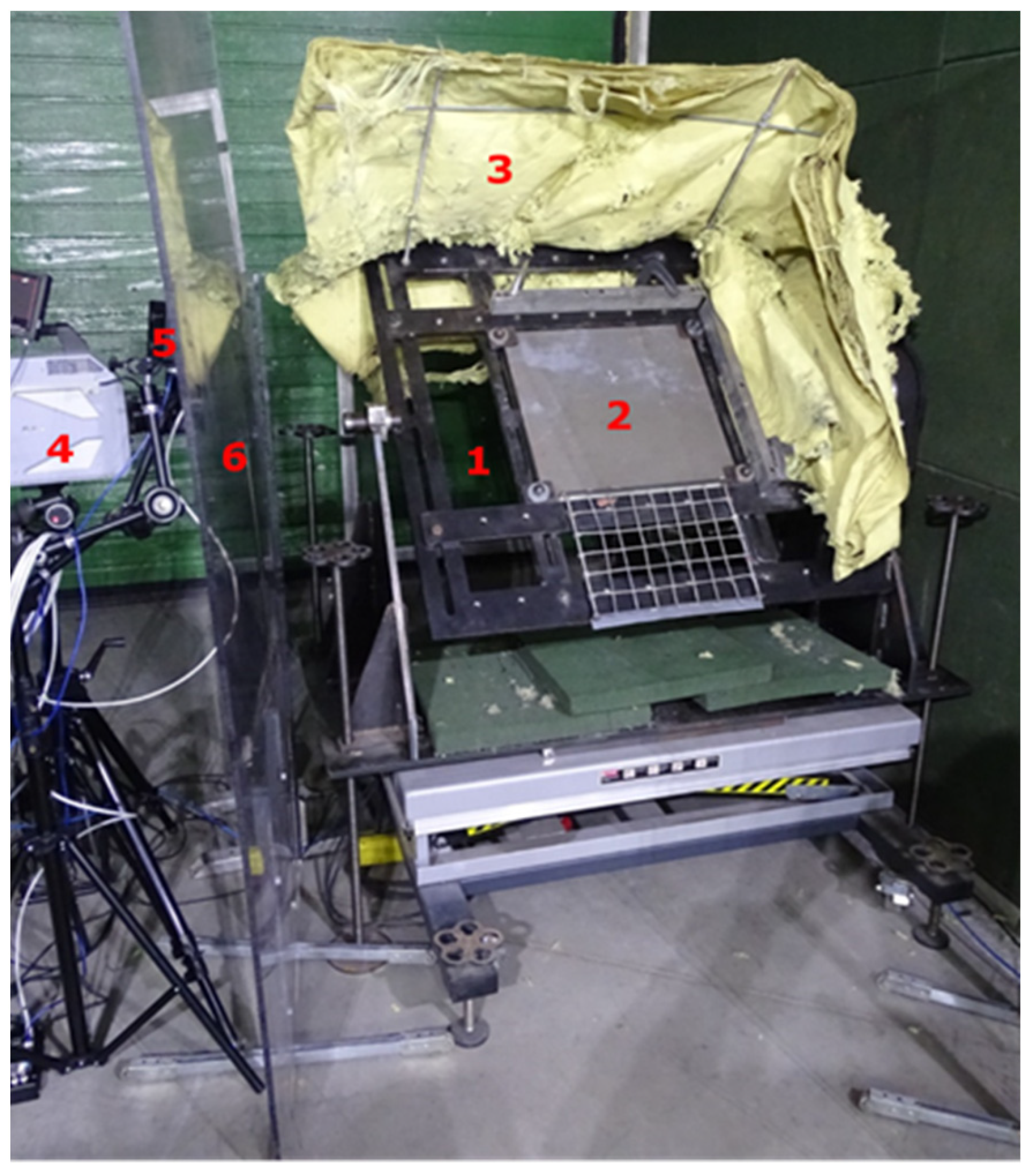

2. Experiment

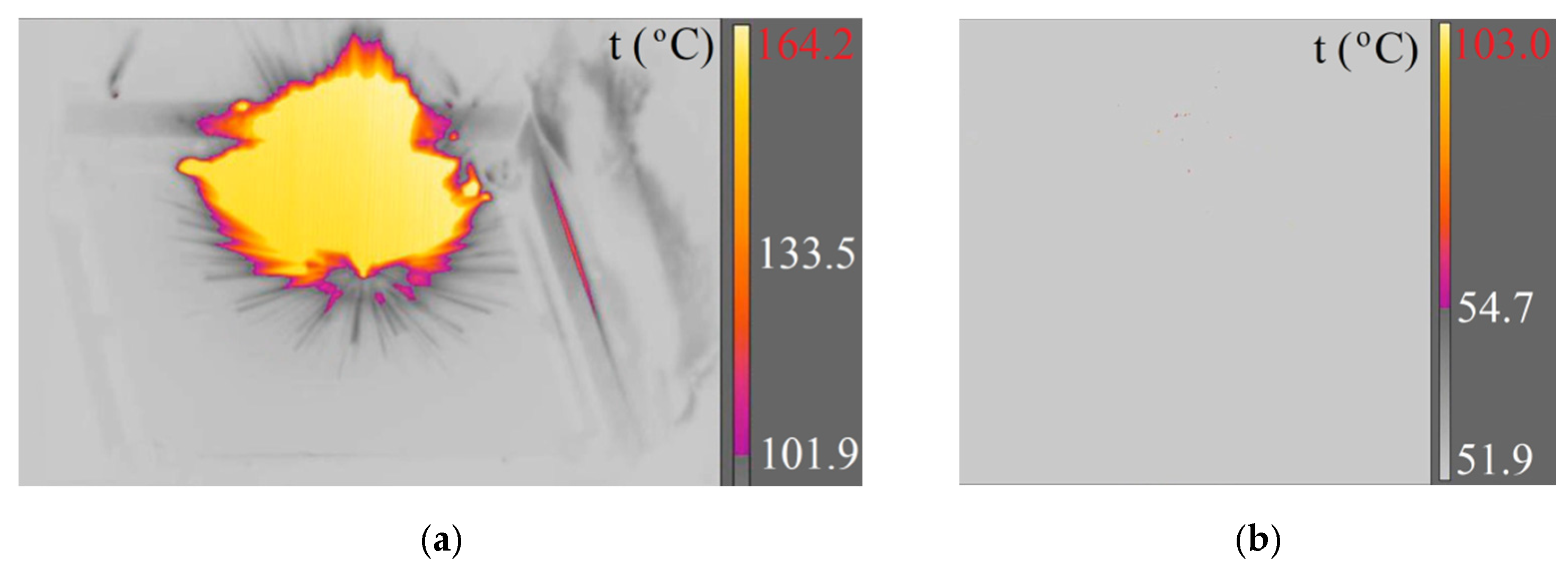

2.1. Projectile Ricochetting on an Armox 600 Armour Plate

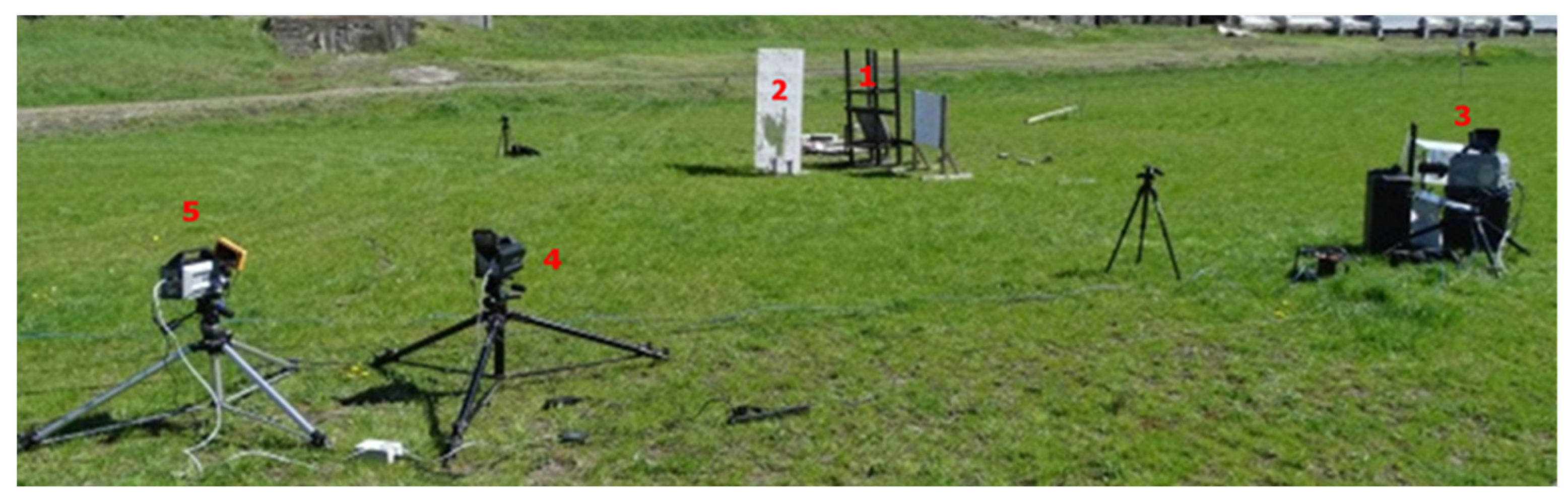

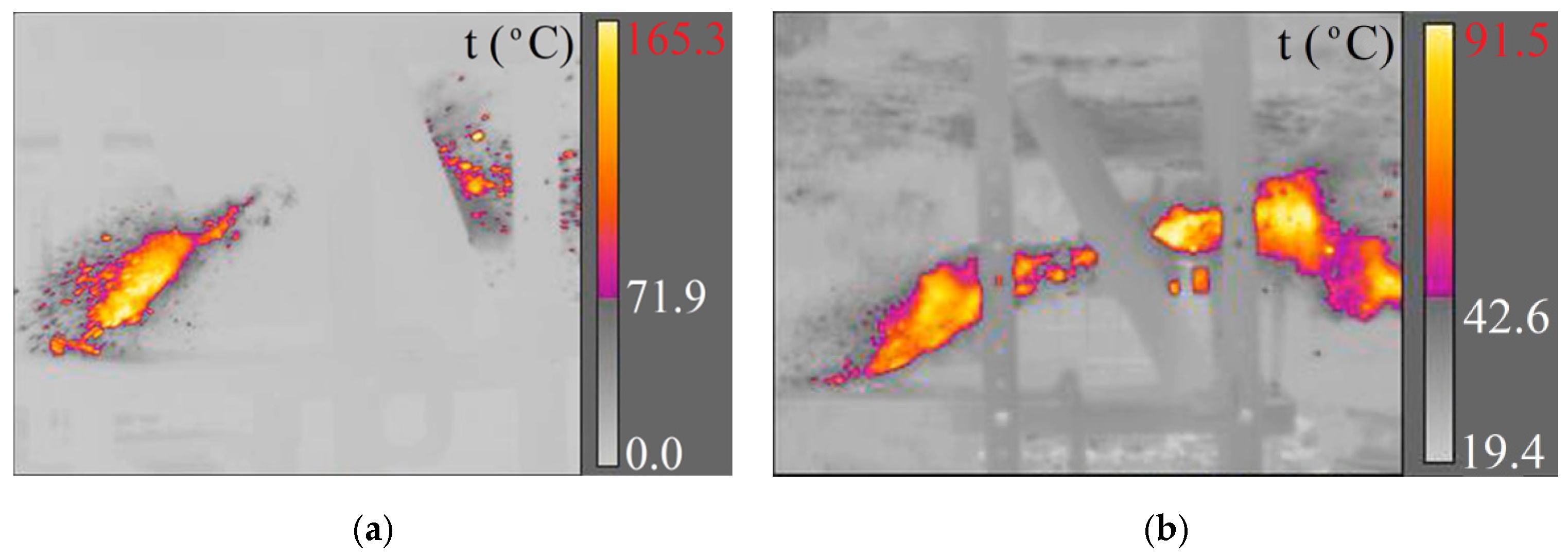

2.2. Projectile Ricochetting on Non-Metallic Surfaces

3. Experimental Results and Analysis

- Retrieving an image from a thermal camera;

- Converting the image from Red−Green−Blue (RGB) to Hue−Saturation−Lightness (HSL) palette and selecting the brightest colours in the tonal range;

- Calculating the area occupied by selected colours in the image in pixels;

- Converting (scaling) pixels to millimetres.

- Taking an image from a high-speed camera;

- Measuring the height of the semi-cone (scaling the pixels to millimetres accordingly);

- Calculating the radius of the semi-cone based on the area calculated for the thermal camera (triangle);

- Calculating the volume of the semi-cone (based on the height and radius of the semi-cone);

- Calculating the mass of the air (based on its volume and density) and adding the mass of the projectile, assuming that the projectile disintegrates into a cloud of hot debris in the shape of a semi-cone of thermal energy.

- Calculating the radius of the hemisphere based on the area of the circle calculated for the thermal camera;

- Calculating the volume of the hemisphere based on the radius of the hemisphere;

- Calculating the mass of the air (based on its volume and density) and adding the mass of the projectile, assuming that the projectile disintegrates into a cloud of hot debris in the shape of a hemisphere of thermal energy.

4. Estimated Probability of Ignition When a Projectile Ricochets in a Flammable Atmosphere

5. Conclusions

- When ricochetting on the Armox 600 plate of projectiles:

- 7.62 × 51 mm M80, 7.62 × 51 mm SWISS PAP and 7.62 × 54R LPS maximum ricochet thermal energies were 35%, 51% and 64% of the kinetic energy of the projectile, respectively;

- 7.62 × 54R B-32 (3400–9500 J) and 7.62 × 51T (2000–3700 J) thermal energies due to the burning of the incendiary mass of the projectile were several times higher than the thermal energy of the projectiles: 7.62 × 54R LPS (1100–2100 J), 7.62 × 51 mm SWISS PAP (1600–2000 J) or 7.62 × 51 mm M80 (740–1120 J);

- The thermal energies of the 7.62 × 54R B-32 and 7.62 × 51T projectiles ricochetting on the Armox 600 plate were sufficient to ignite (explode) propane−butane gas in an atmosphere of the minimal oxygen to cause the ignition of that gas;

- The capability of projectiles to ignite (explode) propane−butane gas depended not only on the velocity of the projectiles, but mainly on their design and, in particular, on the types and incendiary masses of the projectiles;

- When ricochetting 7.62 × 54R B-32 projectiles on the surface of non-metallic components, its thermal energy (800–1200 J) was several times lower than when ricochetting the projectile on the Armox 600 plate (3400–9500 J). This is due to the transfer of much of the kinetic energy of the projectile to the crushing of these elements (concrete slabs, granite slabs, etc.);

- The thermal energy of 7.62 × 54R LPS projectiles ricochetting on the surface of non-metallic components was similar to the thermal energy of projectiles ricochetting on the Armox 600 armour plate;

- The algorithm developed in National Instruments’ LabView software for calculating the mass of a cloud of heated air and debris correctly describes the thermal energy of this cloud as a result of the following:

- Converting the image from RGB to HSL and selecting the brightest colours in the tonal range;

- Converting (scaling) pixels into millimetres;

- Calculating the area occupied by selected colours in the image in pixels;

- The algorithm correctly describes the propagation of thermal energy in the shape of:A semi-cone for 7.62 × 51 mm SWISS PAP projectiles as a result of the following:

- Measurement of the height of the semi-cone (based on the high-speed camera image after scaling the pixels to millimetres);

- Calculating the radius and volume of the semi-cone (based on the area of the triangle calculated for the thermal camera);

- Calculating air mass (based on air volume and density) and adding the mass of hot projectile debris in the shape of a semi-cone of thermal energy;

Hemisphere for 7.62 × 51T projectiles as a result of the following:- Calculating the radius and volume of the hemisphere (based on the area calculated for the thermal camera);

- Calculating the air mass (based on air volume and density) and adding the mass of hot fragments of the hemisphere-shaped projectile thermal energy;

- The thermogram of a ricocheting 7.62 × 51T projectile on an Armox 600 plate showed that the time to sustain a fairly high temperature, above 825 °C, was very short at about 14 ms;

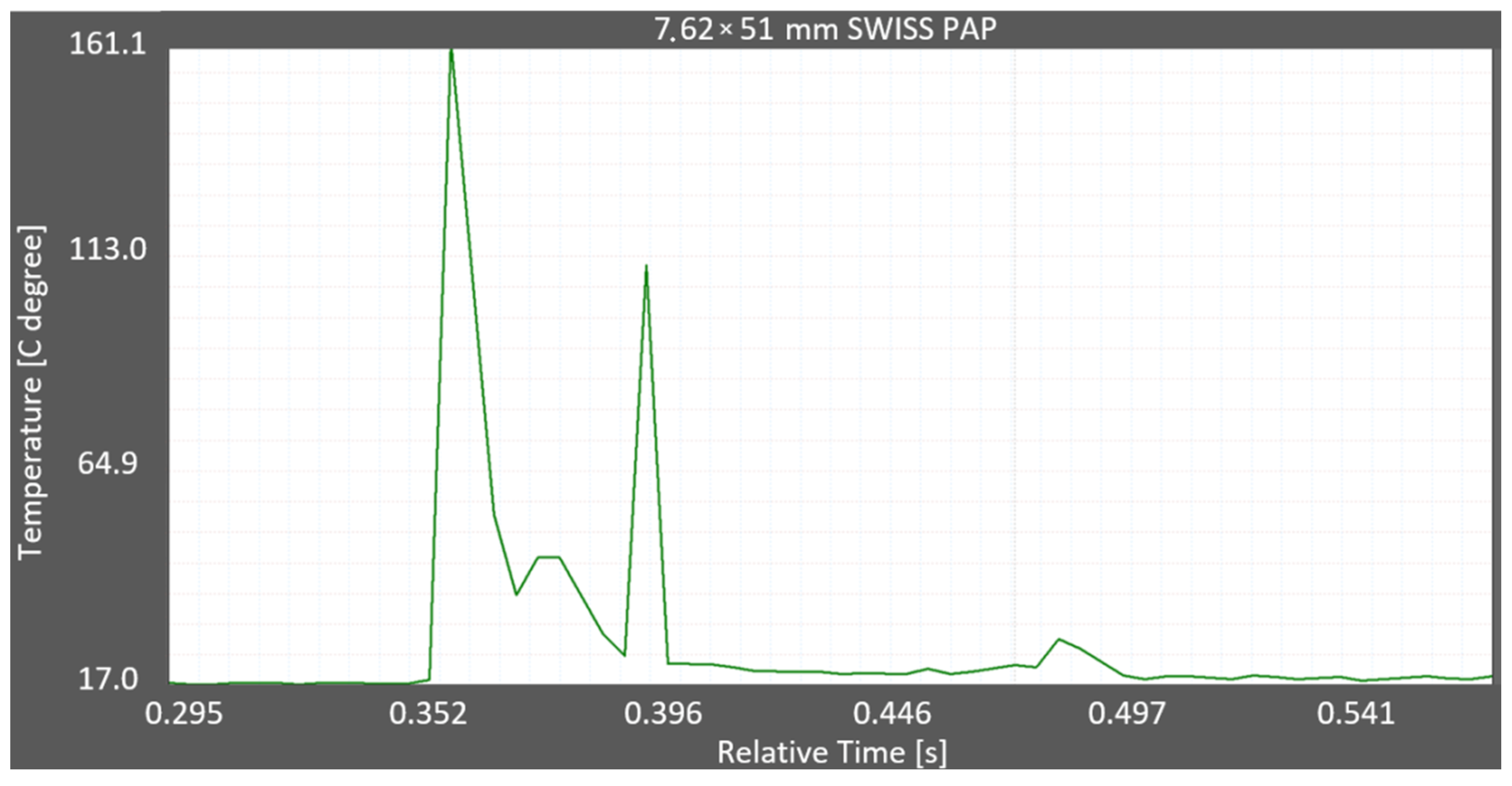

- The thermogram of the ricocheting of 7.62 × 51 mm SWISS PAP projectiles on the Armox 600 showed that there were two temperature peaks. The first, higher peak was caused by ricocheting on the Armox 600 armour plate, and the second, lower peak was caused by ricocheting on the elements fixing this plate. It is, therefore, necessary to install metal plates or non-metallic elements on the stand, on which the projectiles ricochet, so that the predicted surface of ricocheting projectiles, depending on their angle of incidence, does not include (usually steel) installation elements, such as flat bars bolted to the stand;

- The thermogram showed that the temperature rise due to the impact of the projectile on the Armox 600 armour plate occurred faster than the temperature fall due to the heat transfer from the projectile fragments to ambient air, i.e., cooling in air.

- The differences in the obtained maximum ricochet temperatures for several shots with the same projectile are due to the set different ranges of measured temperatures, and in most cases, the duration of these maximum temperatures was <20 ms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baek, J.W.; Jang, C.S.; Park, Y.J. A Methodology for the Zoning Danger Region in Small Arm Firing Range Using Aerial Photogrammetry with Drone. Adv. Civ. Eng. 2020, 2020, 8864409. [Google Scholar] [CrossRef]

- Range Design Criteria; U.S. Department of Energy, Office of Health, Safety and Security: Washington, DC, USA, 2012.

- S.I. No. 622/2011—Firearms (Authorisation of Rifle or Pistol Shooting Ranges) Regulations 2011. Available online: https://www.irishstatutebook.ie/eli/2011/si/622/made/en/print (accessed on 26 October 2021).

- Chapter 10.22, Outdoor Public Shooting Range Development Standards. Available online: https://www.codepublishing.com/WA/CowlitzCounty/html/CowlitzCounty10/CowlitzCounty1022.html (accessed on 26 October 2021).

- The Seven Firearms Safety Rules. Available online: https://www.police.govt.nz/advice-services/firearms-and-safety/firearms-safety/arms-code/seven-firearms-safety-rules (accessed on 26 October 2021).

- VC 9088 Compulsory Specification for Small Arms Shooting Ranges. Available online: https://www.saps.gov.za/services/flash/firearms/downloads/sabsstd.pdf (accessed on 26 October 2021).

- Texas Man Injured as Projectile Ricochets off Armadillo. Available online: https://www.bbc.com/news/world-us-canada-33748027 (accessed on 26 October 2021).

- Finney, M.A.; Maynard, T.B.; McAllister, S.S.; Grob, I.J. A Study of Ignition by Rifle Bullets; Research Paper RMRS-RP; USDA Forest Service: Washington, DC, USA, 2013; pp. 1–32.

- Zak, C.D.; Urban, J.L.; Fernandez-Pello, C. Characterizing the flaming ignition of cellulose fuel beds by hot steel spheres. Combust. Sci. Technol. 2014, 186, 1618–1631. [Google Scholar] [CrossRef]

- Urban, J.L.; Zak, C.D.; Fernandez-Pello, C. Cellulose spot fire ignition by hot metal particles. Proc. Combust. Inst. 2015, 35, 2707–2714. [Google Scholar] [CrossRef]

- Frandsen, W.H. Ignition probability of organic soils. Can. J. For. Res. 1997, 27, 1471–1477. [Google Scholar] [CrossRef]

- Grishin, A.M.; Golovanov, A.N.; Sukov, Y.V.; Preis, Y.I. Experimental study of peat ignition and combustion. J. Eng. Phys. Thermophys. 2006, 79, 563–568. [Google Scholar] [CrossRef]

- Gunfire blamed for some wildfires; target shooting limited. USA Today. 3 July 2012. Available online: http://content.usatoday.com/communities/ondeadline/post/2012/07/gunfire-blamed-forsome-wildfires-states-consider-limits/1#.UCF4202PXwk (accessed on 26 October 2021).

- Guns Blamed for Starting Some Wildfires in the West. CBS News. 4 July 2012. Available online: http://www.cbsnews.com/news/guns-blamed-for-sparking-some-wildfires-in-west/ (accessed on 26 October 2021).

- Hadden, R.M.; Scott, S.; Lautenberger, C.; Fernandez-Pello, C.C. Ignition of Combustible Fuel Beds by Hot Particles: An Experimental and Theoretical Study. Fire Technol. 2011, 47, 341–355. [Google Scholar] [CrossRef] [Green Version]

- Rein, G. Smouldering Combustion Phenomena in Science and Technology. Int. Rev. Chem. Eng. 2009, 1, 3–18. [Google Scholar]

- Manzello, S.L.; Cleary, T.G.; Shields, J.R.; Maranghides, A.; Mell, W.; Yang, J.C. Experimental investigation of firebrands: Generation and ignition of fuel beds. Fire Saf. J. 2008, 43, 226–233. [Google Scholar] [CrossRef]

- Babrauskas, V. Ignition of common solids, Characteristics of external ignition sources, Information on specific materials and devices. In Ignition Handbook: Principles and Applications to Fire Safety Engineering, Fire Investigation, Risk Management and Forensic Science; Fire Science Publishers: Issaquah, WA, USA, 2003; pp. 238–239; discussion 287–289; discussion 500–509; discussion 842–844. [Google Scholar]

- Hartford, R.A. Smoldering combustion limits in peat as influenced by moisture, mineral content, and organic bulk density. In Proceedings of the 10th conference on fire and forest meteorology, Ottawa, ON, Canada, 17 –21 April 1989; Petawawa National Forestry Institute: Chalk River, ON, Canada, 1989; pp. 282–286. [Google Scholar]

- Frandsen, W.H. The influence of moisture and mineral soil on the combustion limits of smoldering forest duff. Can. J. For. Res. 1987, 17, 1540–1544. [Google Scholar] [CrossRef]

- Johnson, W.; Sengupta, A.K.; Ghosh, S.K. High velocity oblique impact and ricochet mainly of long rod projectiles: An overview. Int. J. Mech. Sci. 1982, 24, 425–436. [Google Scholar] [CrossRef]

- Kuchta, J.M.; Furno, A.L.; Martindill, G.H. Flammability of fabrics and other materials in oxygen-enriched atmospheres, Part 1, Ignition temperatures and flame spread rates. Fire Technol. 1969, 5, 203–216. [Google Scholar] [CrossRef]

- McGuire, J.H.; Law, M.; Miller, J.E. Domestic Fire Hazard Created by Flying Coals and Sparks; FR note 252; Fire Research Station: Borehamwood, UK, 1956. [Google Scholar]

- Badurowicz, P.; Pacek, D. Determining Ricochetting Projectiles’ Temperature Using Numerical and Experimental Approaches. Materials 2022, 15, 928. [Google Scholar] [CrossRef] [PubMed]

| Shot Number | Weapon | Ammunition | Maximum Temperature of Gases FLIR X6580sc (°C) | Maximum Temperature of Gases FLIR A6901scSLS (°C) |

|---|---|---|---|---|

| 1 | Ballistic barrel 7.62 × 51 mm | 7.62 × 51 mm SWISS PAP | 164.2 | <150 |

| 2 | 270.4 | - | ||

| 3 | 7.62 × 51T | 337.1 | 386.5 | |

| 4 | 850.5 | 229.9 | ||

| 5 | 7.62 × 51 mm M80 | 138.6 | 127.2 | |

| 6 | 337.9 | 149.5 | ||

| 7 | Ballistic barrel 7.62 × 54R | 7.62 × 54R B-32 | 146.2 | 262.1 |

| 8 | 700.8 | <150 | ||

| 9 | 84.4 | 263.3 | ||

| 10 | 7.62 × 54R LPS | 839.5 | 721.1 | |

| 11 | 315.5 | 165.4 | ||

| 12 | 725.8 | 285.6 | ||

| 13 | Ballistic barrel 7.62 × 51 mm | .308 Win. Norma Ecostrike | 272.9 | 95.7 |

| 14 | 274.6 | <150 | ||

| 15 | Ballistic barrel 5.56 × 45 mm | 5.56 × 45 mm SS109 | 315.3 | <150 |

| 16 | 951.4 | 165.4 | ||

| 17 | 5.56 × 45 mm M193 | 150.9 | <150 | |

| 18 | 150.8 | <150 |

| No. | Type of Projectile; Kinetic Energy (J) | Projectile Cross-Section | Maximum Temperature (°C) | Thermal Energy (J) |

|---|---|---|---|---|

| 1 | 7.62 × 51 mm SWISS PAP; 3963 |  | 165–270 | 1600–2000 |

| 2 | 7.62 × 51T; 3097 |  | 340–850 | 2000–3700 |

| 3 | 7.62 × 51 mm M80; 3455 |  | 140–340 | 740–1120 |

| 4 | 7.62 × 54R B-32; 3412 |  | 140–840 | 3400–9500 |

| 5 | 7.62 × 54R LPS; 3287 |  | 315–840 | 1100–2100 |

| 6 | .308 Win. Norma Ecostrike; 3589 |  | >273 | >1025 |

| No. | Type of Projectile | Ricochet Material (Thickness (mm)) | Maximum Temperature (°C) | Thermal Energy (J) |

|---|---|---|---|---|

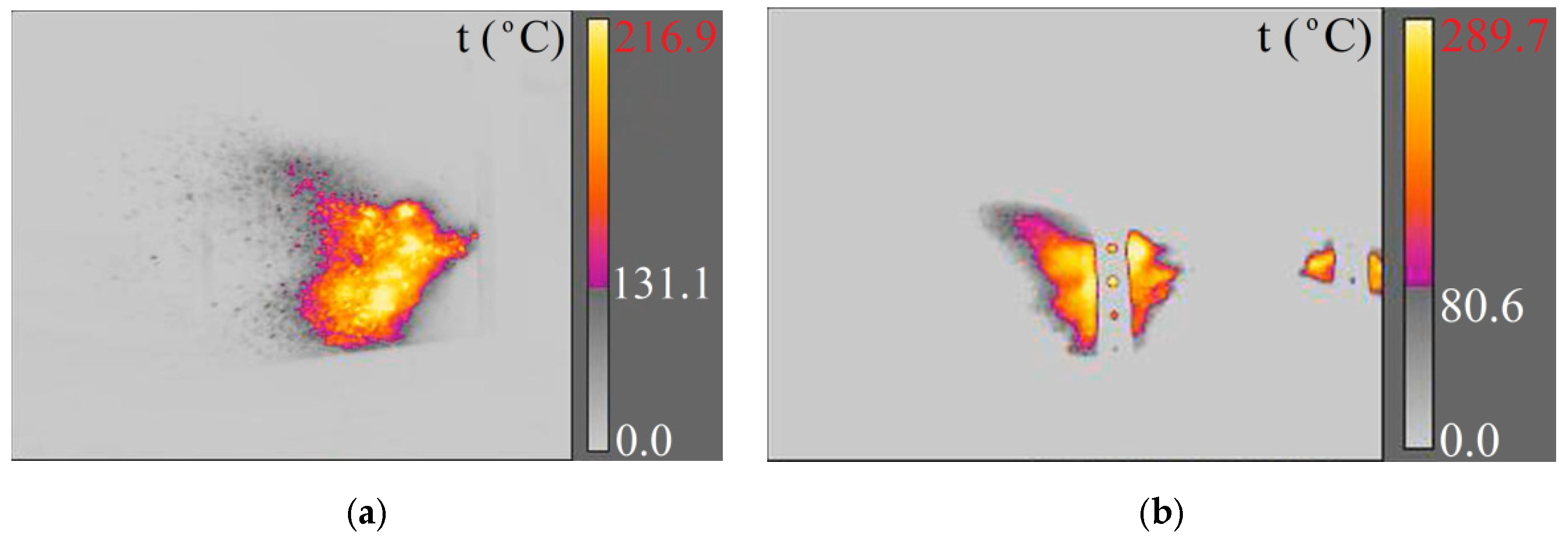

| 1 | 7.62 × 54R LPS | concrete sidewalk slab (70) | 165.3 | 800 |

| 2 | 7.62 × 54R B-32 | concrete sidewalk slab (70) | 216.9 | 980 |

| 3 | 7.62 × 54R B-32 | gray granite slab (60) | 216.3 | 980 |

| 4 | 7.62 × 54R B-32 | gray granite slab (60) | 219.0 | 990 |

| 5 | 7.62 × 54R B-32 | concrete block (120) | 272.1 | 1100 |

| 6 | 7.62 × 54R B-32 | concrete block (120) | 323.8 | 1200 |

| 7 | 7.62 × 54R B-32 | stoneware gres on concrete slab (gres 8) (concrete 40) | 327.5 | 1200 |

| 8 | 7.62 × 54R B-32 | stoneware gres on concrete slab (gres 8) (concrete 40) | 323.4 | 1200 |

| 9 | 7.62 × 54R B-32 | black granite slab (57) | 325.1 | 1200 |

| 10 | 7.62 × 54R LPS | black granite slab (57) | 325.0 | 1100 |

| No. | Name of Substance | Chemical Formula | Molecular Weight (g/mol) | Flash Point (°C) | Minimum Ignition Energy (mJ) |

|---|---|---|---|---|---|

| 1 | acetone | CH3COCH3 | 58.1 | 540 | 0.25 |

| 2 | acetylene | C2H2 | 26.0 | 305 | 0.011 |

| 3 | ethyl alcohol | C2H5OH | 46.1 | 425 | 0.4 |

| 4 | methyl alcohol | CH3CH(OH)CH3 | 60.1 | 400 | 0.65 |

| 5 | isopropyl alcohol | CH3CH(OH)CH3 | 60.1 | 400 | 0.65 |

| 6 | automotive gasoline | - | 95.3–98.2 | 300 | 0.15 |

| 7 | n-butane | C4H10 | 58.1 | 430 | 0.25 |

| 8 | methane | CH4 | 16.04 | 650 | 0.28 |

| 9 | kerosene | - | - | >250 | 0.65 |

| 10 | gas oil | - | - | 250 | 0.48 |

| 11 | propane | C3H8 | 44.1 | 500 | 0.22 |

| 12 | trichloroethylene | ClCH=CCl2 | 131.4 | 410 | 300 |

| 13 | hydrogen | H2 | 2.016 | 580 | 0.018 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jasinski, M.; Szczurowski, K.; Wisniewski, A.; Badurowicz, P.; Bartkowiak, T.; Tusnio, N. Thermal Energy Analysis of Projectiles during Ricochetting Using a Thermal Camera. Materials 2022, 15, 4693. https://doi.org/10.3390/ma15134693

Jasinski M, Szczurowski K, Wisniewski A, Badurowicz P, Bartkowiak T, Tusnio N. Thermal Energy Analysis of Projectiles during Ricochetting Using a Thermal Camera. Materials. 2022; 15(13):4693. https://doi.org/10.3390/ma15134693

Chicago/Turabian StyleJasinski, Marcin, Krzysztof Szczurowski, Adam Wisniewski, Przemyslaw Badurowicz, Tadeusz Bartkowiak, and Norbert Tusnio. 2022. "Thermal Energy Analysis of Projectiles during Ricochetting Using a Thermal Camera" Materials 15, no. 13: 4693. https://doi.org/10.3390/ma15134693

APA StyleJasinski, M., Szczurowski, K., Wisniewski, A., Badurowicz, P., Bartkowiak, T., & Tusnio, N. (2022). Thermal Energy Analysis of Projectiles during Ricochetting Using a Thermal Camera. Materials, 15(13), 4693. https://doi.org/10.3390/ma15134693