Effects of High Temperatures on the Performance of Carbon Fiber Reinforced Polymer (CFRP) Composite Cables Protected with Fire-Retardant Materials

Abstract

:1. Introduction

2. Tensile Tests of CFRP Tendons at High Temperatures

2.1. Design and Fabrication of Specimens

2.2. Design of Test Conditions

2.3. Test Results and Analysis

3. Fire Resistance Assessment of Fire-Retardant Material of CFRP Tendons

3.1. Fire-Retardant Materials

3.2. Test Scheme

3.3. Test Results and Analysis

4. Numerical Simulation of the Fire Resistance of CFRP Tendons Coated with Fire-Retardant Materials

4.1. Finite Element Simulation Calculation

4.2. Comparisons and Analyses of Numerical Simulation Results and Experimental Results

5. Design Calculation of CFRP Cable Fire Protection System

5.1. Heating Curve of Finite Element Model

5.2. Calculation of Fire Protection Design for CFRP Cables

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qin, G.; Na, J.; Mu, W.; Tan, W.; Yang, J.; Ren, J. Effect of continuous high temperature exposure on the adhesive strength of epoxy adhesive, CFRP and adhesively bonded CFRP-aluminum alloy joints. Compos. Part B Eng. 2018, 154, 43–55. [Google Scholar] [CrossRef]

- Qin, G.; Na, J.; Tan, W.; Mu, W.; Ji, J. Failure prediction of adhesively bonded CFRP-Aluminum alloy joints using cohesive zone model with consideration of temperature effect. J. Adhes. 2019, 95, 723–746. [Google Scholar] [CrossRef]

- Galvez, P.; Abenojar, J.; Martinez, M.A. Effect of moisture and temperature on the thermal and mechanical properties of a ductile epoxy adhesive for use in steel structures reinforced with CFRP. Compos. Part B Eng. 2019, 176, 107194. [Google Scholar] [CrossRef]

- Hung, P.-Y.; Lau, K.-T.; Qiao, K.; Fox, B.; Hameed, N. Property enhancement of CFRP composites with different graphene oxide employment methods at a cryogenic temperature. Compos. Part A Appl. Sci. Manuf. 2019, 120, 56–63. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Kannan, V.P.; Renna, G. Investigation of Interlaminar Shear Properties of CFRP Composites at Elevated Temperatures Using the Lempel-Ziv Complexity of Acoustic Emission Signals. Materials 2022, 15, 4252. [Google Scholar] [CrossRef]

- Fuping, G.; Wei, L.; Peng, J.; Falin, C.; Yinghonglin, L. Deep Learning Approach for Damage Classification Based on Acoustic Emission Data in Composite Materials. Materials 2022, 15, 4270. [Google Scholar] [CrossRef]

- Hou, G.; Luo, B.; Zhang, K.; Luo, Y.; Cheng, H.; Cao, S.; Liu, Y. Investigation of high temperature effect on CFRP cutting mechanism based on a temperature controlled orthogonal cutting experiment. Compos. Struct. 2021, 268, 113967. [Google Scholar] [CrossRef]

- Eun, J.H.; Kim, D.H.; Lee, J.S. Effect of low melting temperature polyamide fiber-interlaced carbon fiber braid fabric on the mechanical performance and fracture toughness of CFRP laminates. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105987. [Google Scholar] [CrossRef]

- Kollmannsberger, A.; Lichtinger, R.; Hohenester, F.; Ebel, C.; Drechsler, K. Numerical analysis of the temperature profile during the laser-assisted automated fiber placement of CFRP tapes with thermoplastic matrix. J. Thermoplast. Compos. Mater. 2018, 31, 1563–1586. [Google Scholar] [CrossRef]

- Körbelin, J.; Derra, M.; Fiedler, B. Influence of temperature and impact energy on low velocity impact damage severity in CFRP. Compos. Part A Appl. Sci. Manuf. 2018, 115, 76–87. [Google Scholar] [CrossRef]

- Gallego, J.M.; Czaderski, C.; Breveglieri, M.; Michels, J. Fatigue behaviour at elevated temperature of RC slabs strengthened with EB CFRP strips. Compos. Part B Eng. 2018, 141, 37–49. [Google Scholar] [CrossRef]

- Azevedo, A.S.; Firmo, J.P.; Correia, J.R.; Tiago, C. Influence of elevated temperatures on the bond behaviour between concrete and NSM-CFRP strips. Cem. Concr. Compos. 2020, 111, 103603. [Google Scholar] [CrossRef]

- Meier, U. Proposal for a carbon fibre reinforced composite bridge across the Strait of Gibraltar at its narrowest site. Proc. Inst. Mech. Eng. 1987, 201, 73–78. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, J.; Xu, J.; Han, Q. Anchorage systems of CFRP cables in cable structures—A review. Constr. Build. Mater. 2018, 160, 82–99. [Google Scholar] [CrossRef]

- Hancov, N.L. Thermal effects on polymer matrix composites: Part1-Thermal cycling. Mater. Des. 1998, 19, 85–91. [Google Scholar] [CrossRef]

- Fan, J.; Hu, X.; Yue, C.Y. Thermal degradation study of interpenetrating polymer network based on modified bismaleimide resin and cyanate ester. Polym. Int. 2003, 52, 15–22. [Google Scholar] [CrossRef]

- Wang, Y.C.; Wong, P.M.H.; Kodur, V. An experimental study of the mechanical properties of fiber reinforced polymer (FRP) and steel reinforcing bars at elevated temperatures. Compos. Struct. 2008, 80, 131–140. [Google Scholar] [CrossRef]

- Wang, Y.C.; Kodur, V. Variation of strength and stiffness of fibre reinforced polymer reinforcing bars with temperature. Cem. Concr. Compos. 2005, 27, 864–874. [Google Scholar] [CrossRef]

- Wang, Y.C.; Wong, P.M.H.; Kodur, V. Mechanical properties of fibre reinforced polymer reinforcing bars at elevated temperatures. In Proceedings of the SFPE/ASCE, Designing Structures for Fire, Baltimore, MD, USA, 30 September–1 October 2003; pp. 183–192. [Google Scholar]

- Yu, B.; Kodur, V. Effect of temperature on strength and stiffness properties of near-surface mounted FRP reinforcement. Compos. Part B Eng. 2014, 58, 510–517. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Najafabadi, E.P.; Oskouei, A.V. The effect of mechanical and thermal properties of FRP bars on their tensile performance under elevated temperatures. Constr. Build. Mater. 2017, 157, 1001–1010. [Google Scholar] [CrossRef]

- Sumida, A.; Mutsuyoshi, H. Mechanical Properties of newly developed heat-resistant FRP bars. J. Adv. Concr. Technol. 2008, 6, 157–170. [Google Scholar] [CrossRef] [Green Version]

- Zhou, F.; Zhang, J.; Song, S.; Yang, D.; Wang, C. Effect of Temperature on Material Properties of Carbon Fiber Reinforced Polymer (CFRP) Tendons: Experiments and Model Assessment. Materials 2019, 12, 1025. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fang, Y.; Fang, Z.; Huang, D.; Jiang, Z.; Zhou, X. Experimental investigation on mechanical performance of carbon fiber reinforced polymer wire after exposure to elevated temperature. Compos. Struct. 2021, 274, 114388. [Google Scholar] [CrossRef]

- Khaneghahi, M.H.; Najafabadi, E.P.; Shoaei, P.; Oskouei, A.V. Effect of intumescent paint coating on mechanical properties of FRP bars at elevated temperature. Polym. Test. 2018, 71, 72–86. [Google Scholar] [CrossRef]

- Najafabadi, E.P.; Oskouei, A.V.; Khaneghahi, M.H.; Shoaei, P.; Ozbakkaloglu, T. The tensile performance of FRP bars embedded in concrete under elevated temperatures. Constr. Build. Mater. 2019, 211, 1138–1152. [Google Scholar] [CrossRef]

- Xu, J.; Wang, W.; Han, Q. Mechanical properties of pultruded high-temperature-resistant carbon-fiber-reinforced polymer tendons at elevated temperatures. Constr. Build. Mater. 2020, 258, 119526. [Google Scholar] [CrossRef]

- Nguyen, P.L.; Vu, X.H.; Ferrier, E. Thermo-mechanical performance of Carbon Fiber Reinforced Polymer (CFRP), with and without fire protection material, under combined elevated temperature and mechanical loading conditions. Compos. Part B Eng. 2019, 169, 164–173. [Google Scholar] [CrossRef]

- Firmo, J.P.; Correia, J.R.; França, P. Fire behaviour of reinforced concrete beams strengthened with CFRP laminates: Protection systems with insulation of the anchorage zones. Compos. Part B Eng. 2012, 43, 1545–1556. [Google Scholar] [CrossRef]

- Imran, M.; Mahendran, M.; Keerthan, P. Heat transfer modelling of CFRP strengthened and insulated steel tubular columns. Constr. Build. Mater. 2018, 184, 278–294. [Google Scholar] [CrossRef]

- Tianjin Fire Research Institute of the Ministry of Public Security. GB 50016—2014; Code for Fire Protection Design of Buildings; China Planning Press: Beijing, China, 2018. [Google Scholar]

| Specimen No | Temperature/°C | Diameter/mm | Loading Time/h | Preload/kN |

|---|---|---|---|---|

| NT-1 | Ordinary temperature | 9 | \ | \ |

| HT-1 | 250 | 9 | 2 | 44.5 |

| HT-2 | 300 | 9 | 2 | 44.5 |

| HT-3 | 350 | 9 | 2 | 44.5 |

| HT-4 | 400 | 9 | 2 | 44.5 |

| Specimen No | Tensile Force/kN | Tensile Strength/MPa | ||

|---|---|---|---|---|

| NT-1 | 120.3 | 1887 | / | / |

| HT-1 | 112.3 | 1766 | 0.936 | 0.880 |

| HT-2 | 101.0 | 1588 | 0.839 | 0.812 |

| HT-3 | 85.3 | 1341 | 0.709 | 0.715 |

| HT-4 | 71.3 | 1121 | 0.593 | 0.579 |

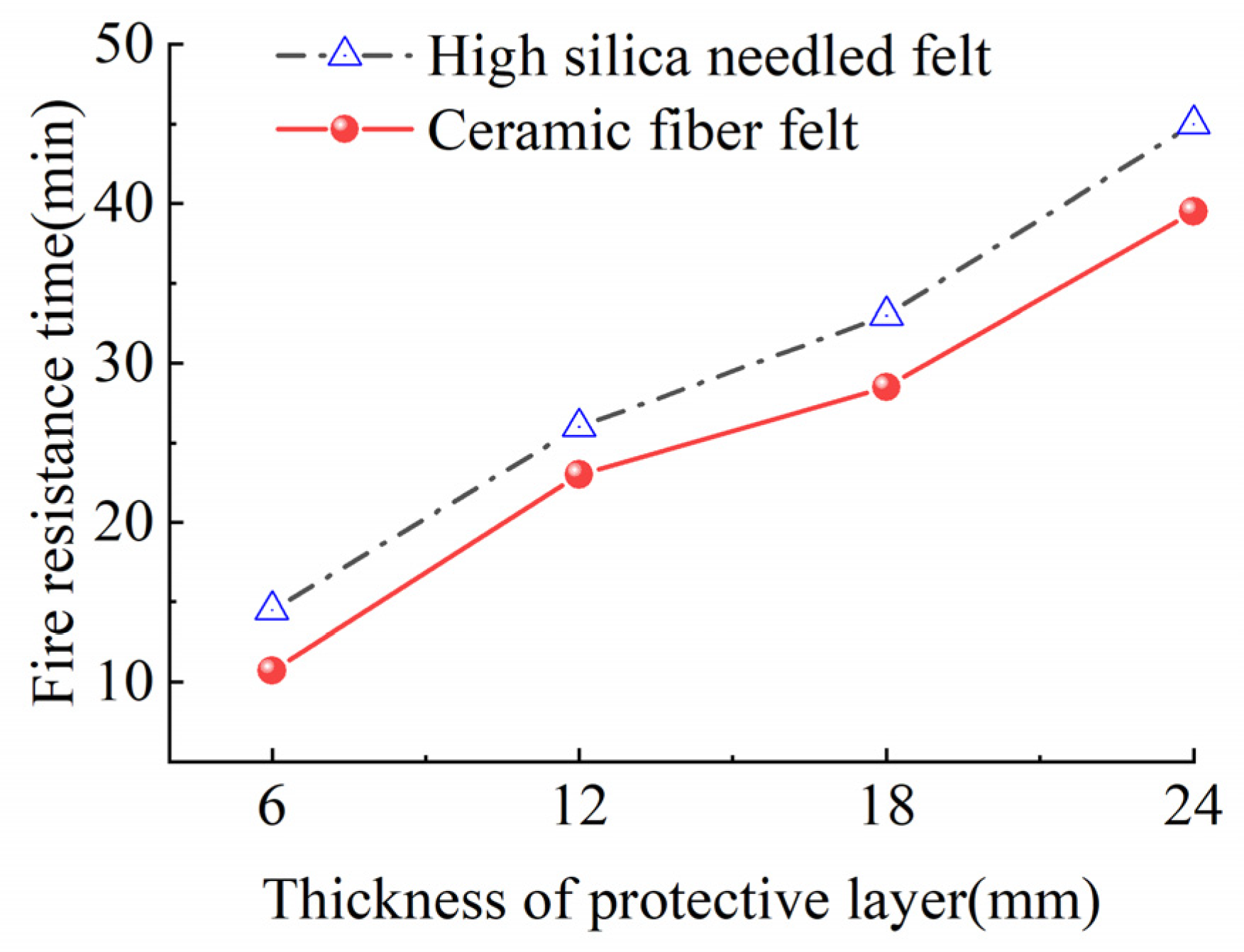

| Number | Fire-Retardant Materials | Thickness/mm | Preload/kN | Temperature/°C |

|---|---|---|---|---|

| FH-1 | Type 1: High-silica needled felt | 6 | 44.5 | 1100 |

| FH-2 | 12 | 44.5 | 1100 | |

| FH-3 | 18 | 44.5 | 1100 | |

| FH-4 | 24 | 44.5 | 1100 | |

| FH-5 | Type 2: Ceramic fiber felt | 6 | 44.5 | 1100 |

| FH-6 | 12 | 44.5 | 1100 | |

| FH-7 | 18 | 44.5 | 1100 | |

| FH-8 | 24 | 44.5 | 1100 |

| Temperature/°C | Thermal Parameters W/(m·k) |

|---|---|

| 20 | 0.05 |

| 200 | 0.12 |

| 400 | 0.22 |

| 600 | 0.3 |

| 800 | 0.38 |

| Temperature/°C | Thermal Parameters W/(m·k) |

|---|---|

| 20 | 0.06 |

| 200 | 0.12 |

| 400 | 0.15 |

| 600 | 0.2 |

| 800 | 0.25 |

| Specimen No | Fire-Resistance Times of Experiment/Min | Fire-Resistance Times of Finite Element Simulation/Min | Standard Deviation | Error Value/Min | Error Rate |

|---|---|---|---|---|---|

| FH-1 | 14.5 | 13.2 | 0.65 | −1.3 | −8.97% |

| FH-2 | 26.0 | 22.7 | 1.65 | −3.3 | 12.69% |

| FH-3 | 32.0 | 33.2 | 0.6 | +1.2 | +3.75% |

| FH-4 | 45.0 | 48.1 | 1.55 | +3.1 | +6.89% |

| Specimen No | Fire-Resistance Times of Experiment/Min | Fire-Resistance Times of Finite Element Simulation/Min | Standard Deviation | Error Value/Min | Error Rate |

|---|---|---|---|---|---|

| FH-5 | 10.7 | 11.9 | 0.6 | +1.2 | +11.21% |

| FH-6 | 24.2 | 20.6 | 1.2 | −2.4 | +14.8% |

| FH-7 | 28.5 | 29.9 | 0.7 | +1.4 | −4.91% |

| FH-8 | 39.5 | 43.0 | 1.75 | +3.5 | +8.86% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuge, P.; Tao, G.; Wang, B.; Jie, Z.; Zhang, Z. Effects of High Temperatures on the Performance of Carbon Fiber Reinforced Polymer (CFRP) Composite Cables Protected with Fire-Retardant Materials. Materials 2022, 15, 4696. https://doi.org/10.3390/ma15134696

Zhuge P, Tao G, Wang B, Jie Z, Zhang Z. Effects of High Temperatures on the Performance of Carbon Fiber Reinforced Polymer (CFRP) Composite Cables Protected with Fire-Retardant Materials. Materials. 2022; 15(13):4696. https://doi.org/10.3390/ma15134696

Chicago/Turabian StyleZhuge, Ping, Guocheng Tao, Bing Wang, Zhiyu Jie, and Zihua Zhang. 2022. "Effects of High Temperatures on the Performance of Carbon Fiber Reinforced Polymer (CFRP) Composite Cables Protected with Fire-Retardant Materials" Materials 15, no. 13: 4696. https://doi.org/10.3390/ma15134696

APA StyleZhuge, P., Tao, G., Wang, B., Jie, Z., & Zhang, Z. (2022). Effects of High Temperatures on the Performance of Carbon Fiber Reinforced Polymer (CFRP) Composite Cables Protected with Fire-Retardant Materials. Materials, 15(13), 4696. https://doi.org/10.3390/ma15134696