Experimental Techniques to Obtain the Cross-Sectional Images of Textile Yarns

Abstract

1. Introduction

2. Materials and Methods

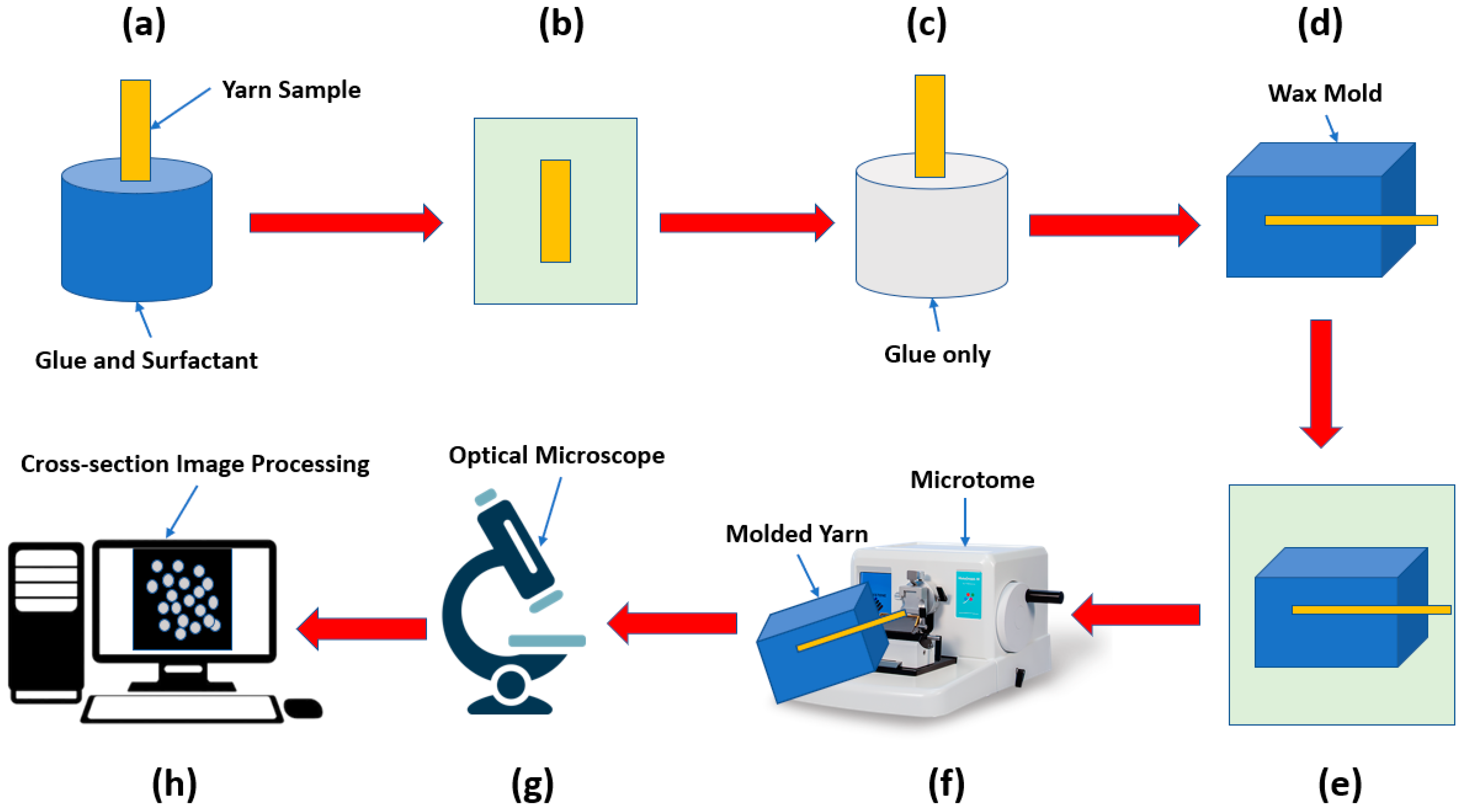

2.1. Microtome

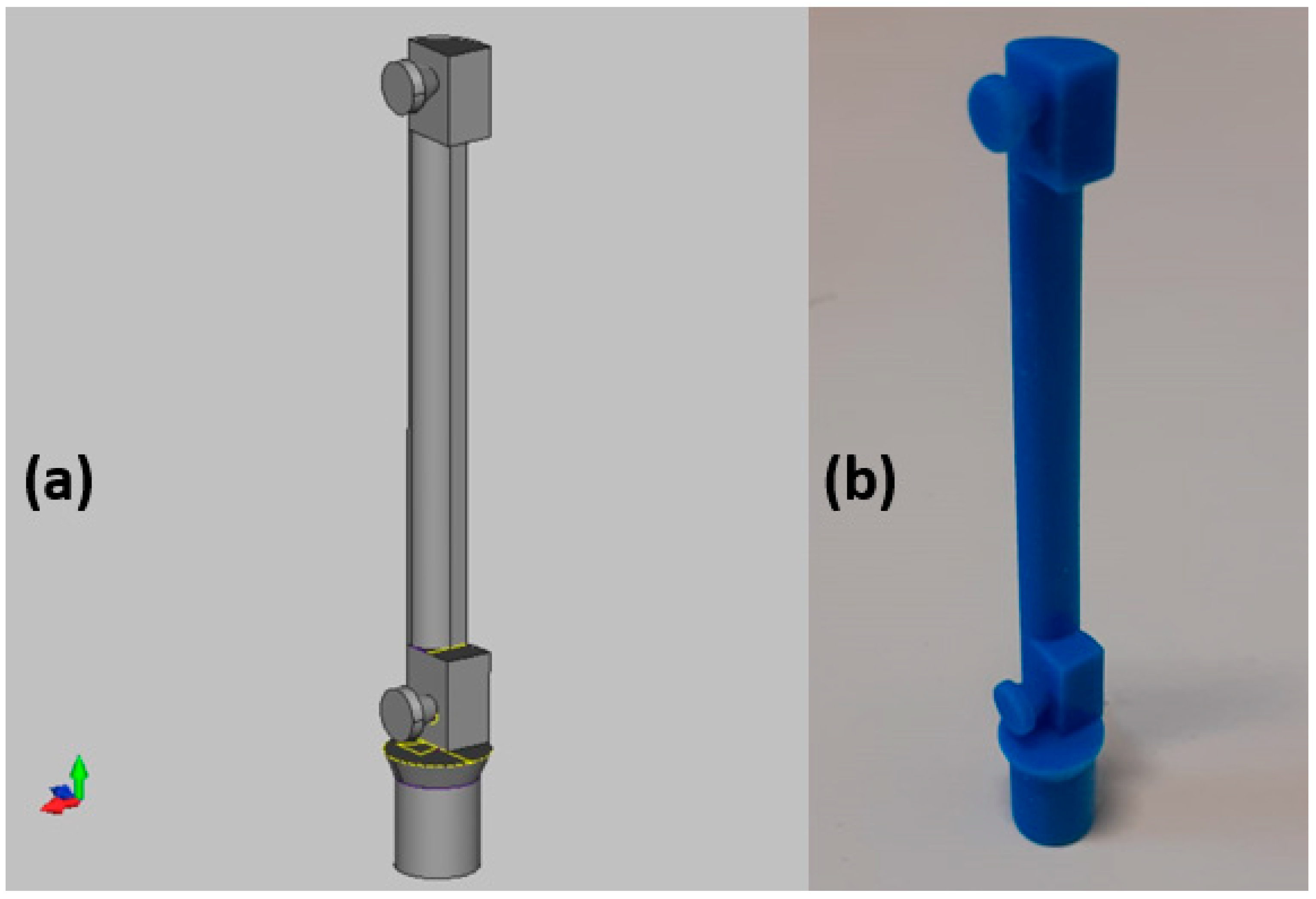

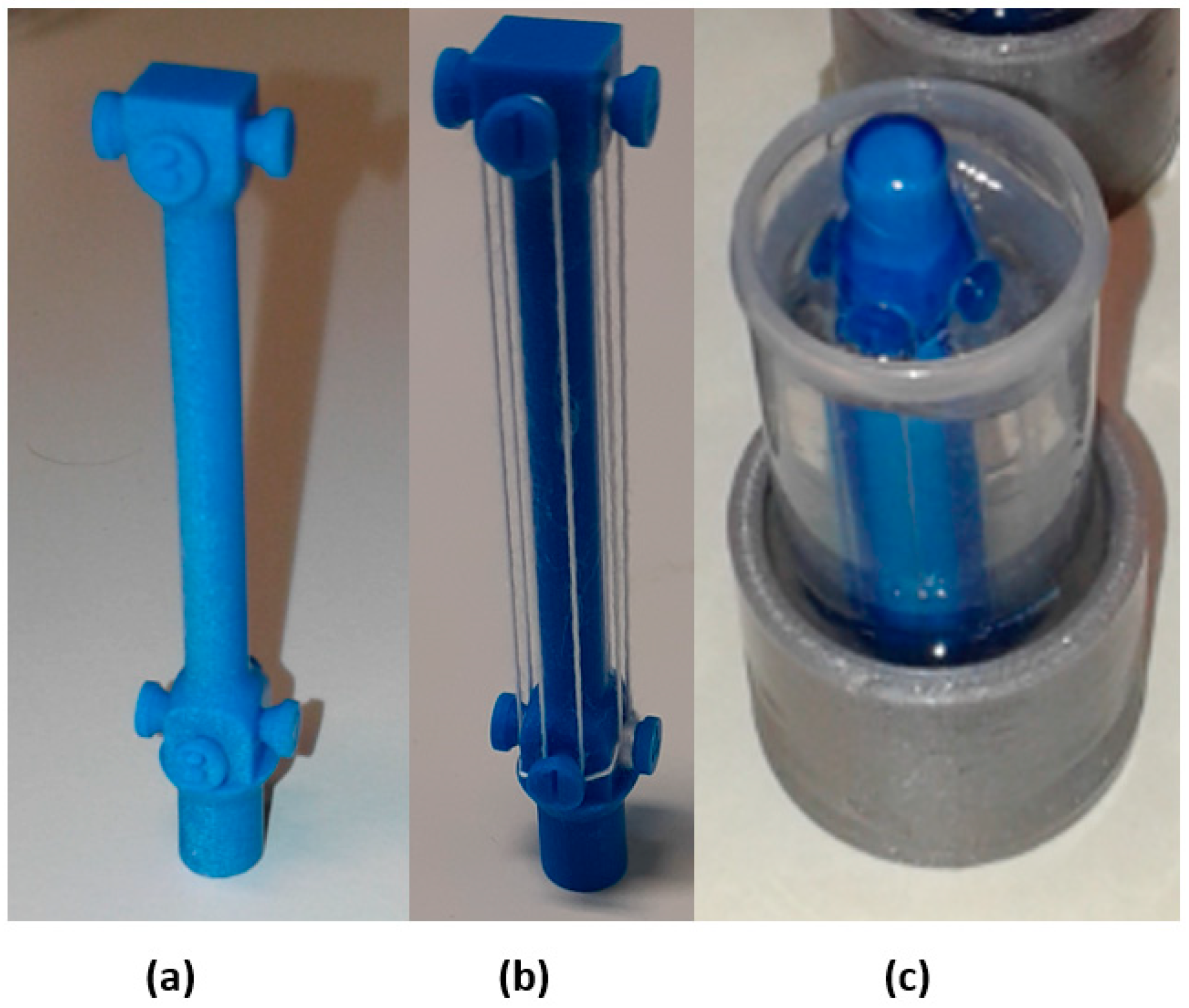

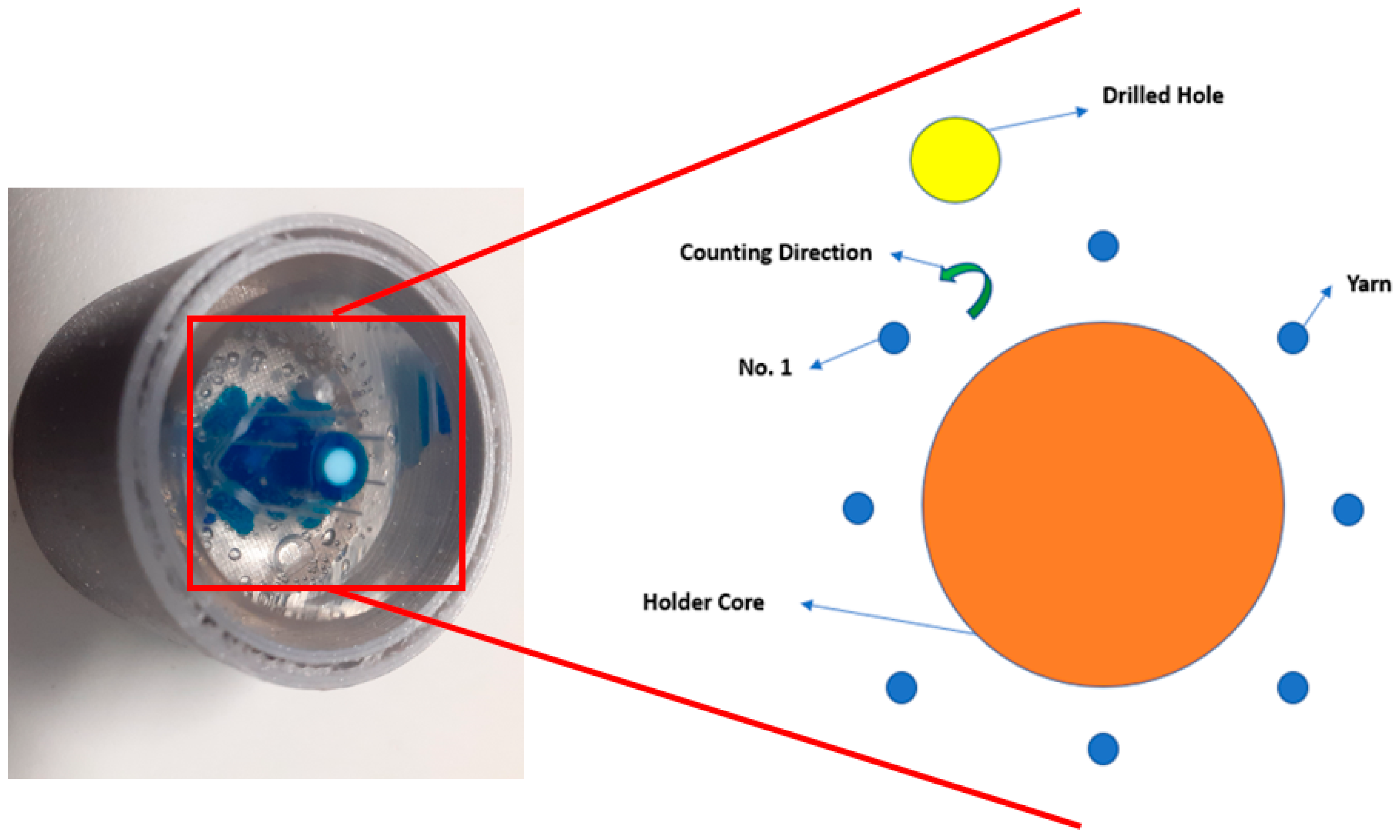

2.2. Micro-Computed Tomography (µCT)

- Unwind a length (2–4 m) from the beginning of the yarn bobbin (that length will be disposed).

- Make a knot after that disposable length.

- Unwind the length of the sample (1–2 m) and make another knot.

2.3. Epoxy Grinding Polishing

3. Results and Discussion

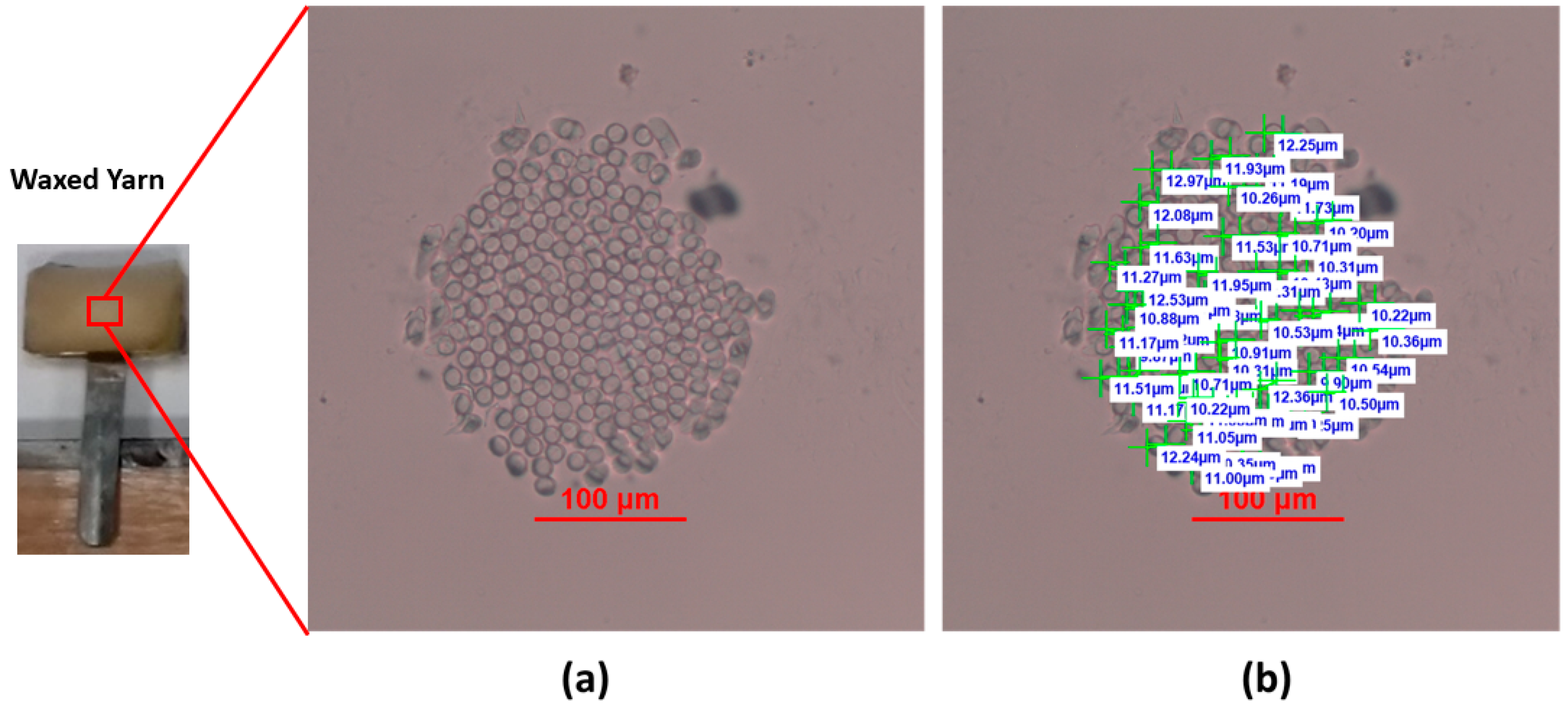

3.1. Microtome Results

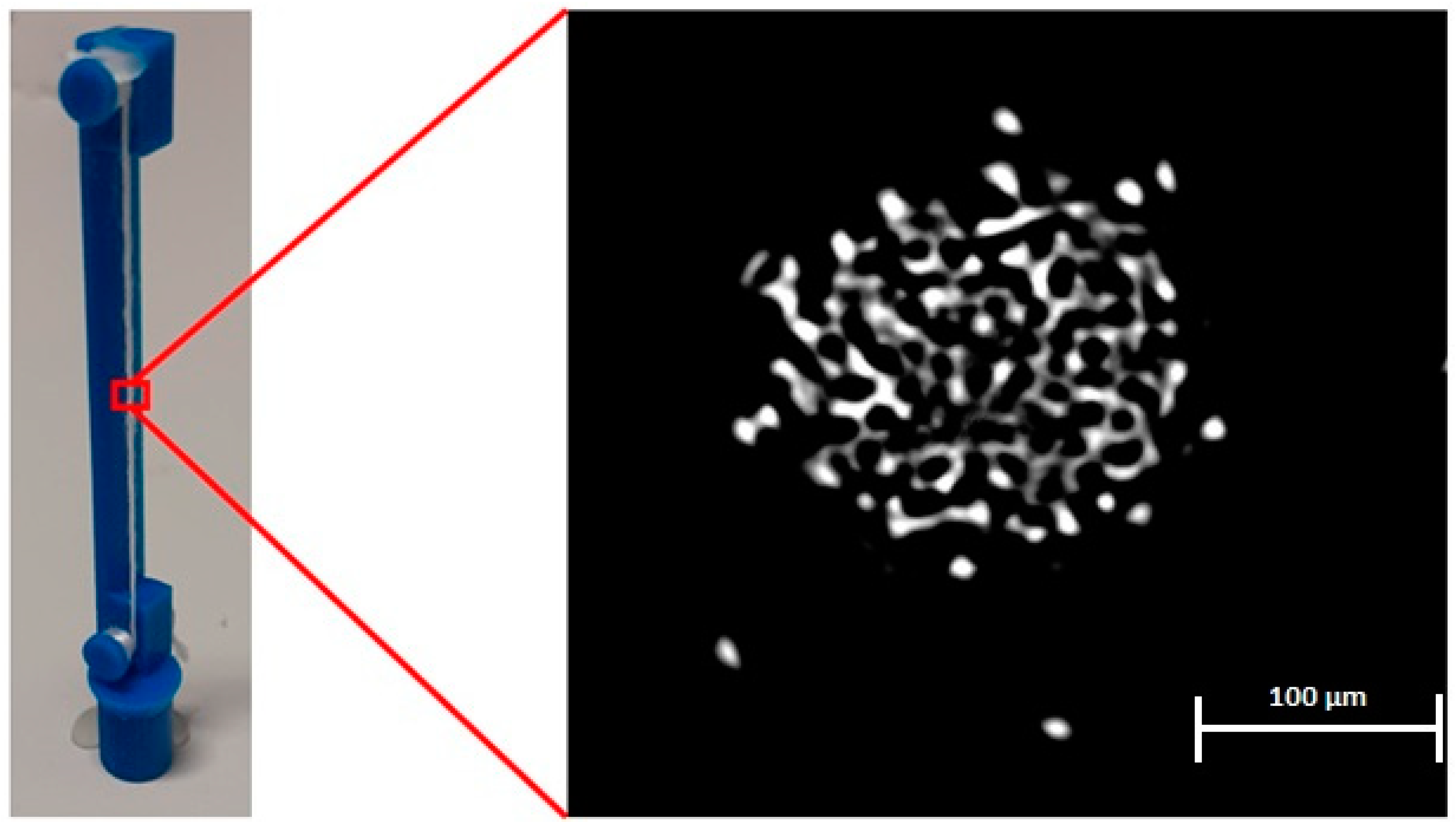

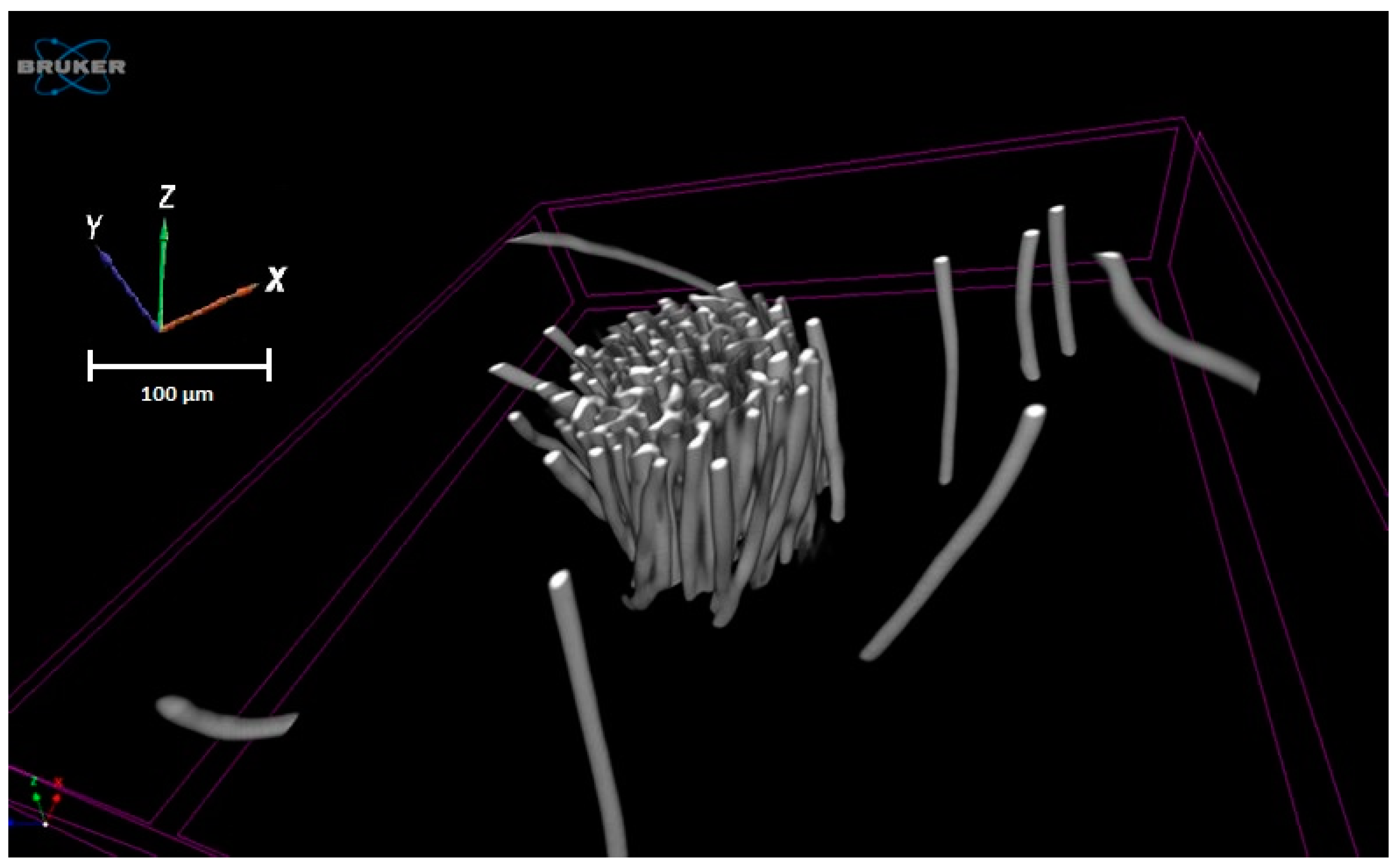

3.2. Micro-Computed Tomography (µCT) Results

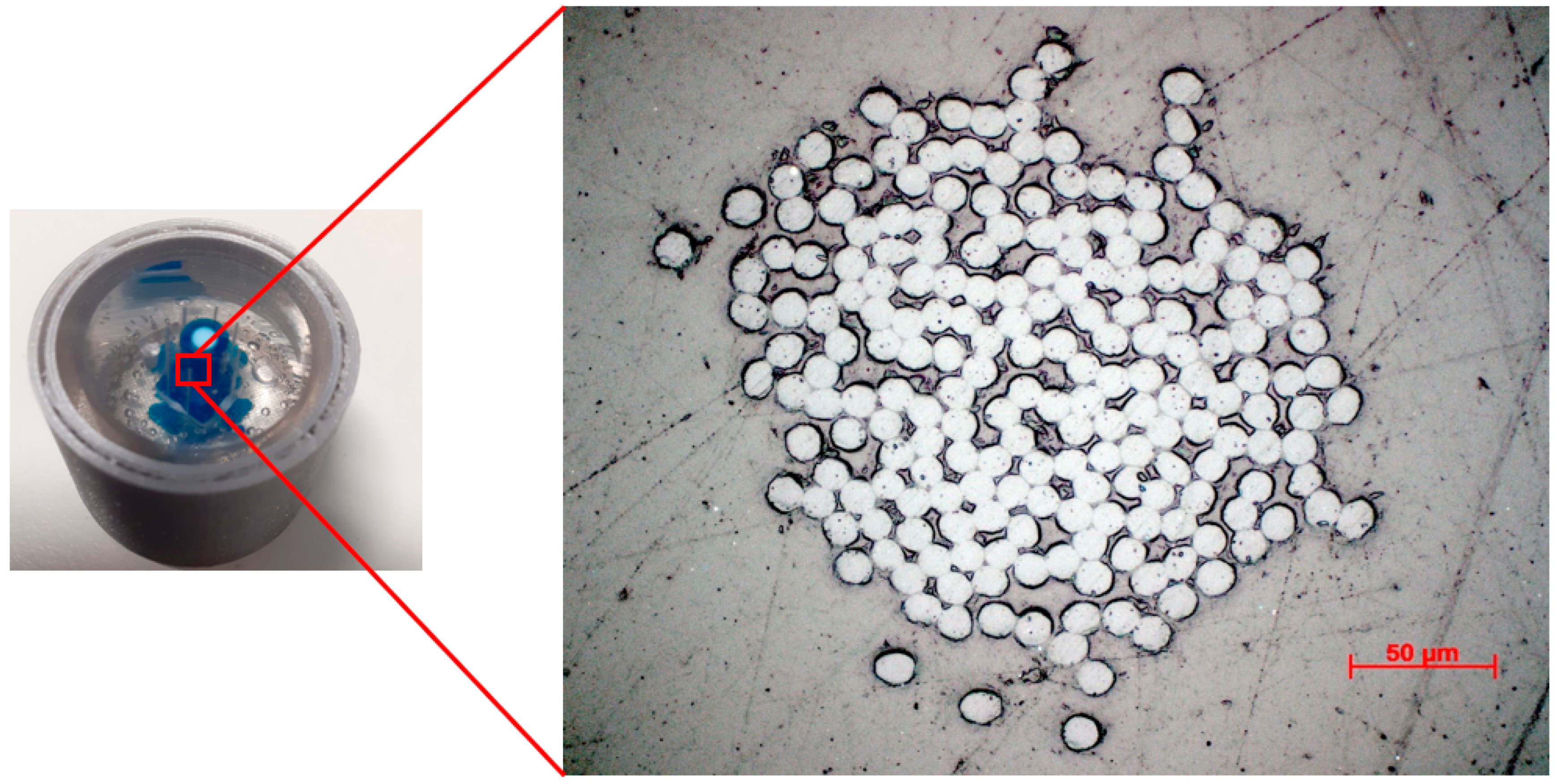

3.3. Epoxy Grinding Polishing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abrahart, E.N.; Whewell, C.S. Textile Finishing Processes. Available online: https://www.britannica.com/topic/textile/Textile-finishing-processes (accessed on 13 April 2022).

- Özkan, M.; Duru Baykal, P.; Özkan, İ. Investigation on the Performance Properties of Polytrimethylene Terephthalate (PTT) Based Staple Fibers and Cotton Blended OE-Rotor Yarns. J. Text. Inst. 2021, 113, 449–459. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, H.; Liu, Z.; Peng, X.; Zhou, H. Statistical Modelling of Tensile Properties of Natural Fiber Yarns Considering Probability Distributions of Fiber Crimping and Effective Yarn Elastic Modulus. Compos. Sci. Technol. 2021, 218, 109142. [Google Scholar] [CrossRef]

- Qiu, H.; Iemoto, Y.; Tanoue, S. Effects of Cross-Sectional Shape of Yarn Duct of Interlacer on the Properties of Interlaced Yarn. J. Text. Eng. 2007, 53, 1–8. [Google Scholar] [CrossRef][Green Version]

- Long, R.L.; Delhom, C.D.; Bange, M.P. Effects of Cotton Genotype, Defoliation Timing and Season on Fiber Cross-Sectional Properties and Yarn Performance. Text. Res. J. 2021, 91, 1943–1956. [Google Scholar] [CrossRef]

- Krucińnska, I. Fiber Blending Irregularities in Cross Sections and on Yarn Surfaces in Relation to Yarn Properties. Text. Res. J. 1988, 58, 291–298. [Google Scholar] [CrossRef]

- Zheng, S.; Zou, Z.; Shen, W.; Cheng, L. A Study of the Fiber Distribution in Yarn Cross Section for Vortex-Spun Yarn. Text. Res. J. 2012, 82, 1579–1586. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, X. Digital-Element Simulation of Textile Processes. Compos. Sci. Technol. 2001, 61, 311–319. [Google Scholar] [CrossRef]

- Balokas, G.; Kriegesmann, B.; Czichon, S.; Rolfes, R. Stochastic Modeling Techniques for Textile Yarn Distortion and Waviness with 1D Random Fields. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105639. [Google Scholar] [CrossRef]

- Kaldor, J.M.; James, D.L.; Marschner, S. Simulating Knitted Cloth at the Yarn Level. In Proceedings of the SIGGRAPH’08: International Conference on Computer Graphics and Interactive Techniques, ACM SIGGRAPH 2008 Papers 2008, Los Angeles, CA, USA, 11–15 August 2008. [Google Scholar]

- McMillan, D.B.; Harris, R.J. Introduction. In An Atlas of Comparative Vertebrate Histology; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Yousif, M.Q.; Qasem, S.A. Tissue Processing and Staining for Histological Analyses. In Skin Tissue Engineering and Regenerative Medicine; Academic Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Kilic, M.; Buyukbayraktar, R.B.; Kilic, G.B.; Aydin, S.; Eski, N. Comparing the Packing Densities of Yarns Spun by Ring, Compact and Vortex Spinning Systems Using Image Analysis Method. Indian J. Fibre Text. Res. 2014, 39, 351–357. [Google Scholar]

- Dey, P. Tissue Microtomy: Principle and Procedure. In Basic and Advanced Laboratory Techniques in Histopathology and Cytology; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Yu, X.W.; Wang, H.; Wang, Z.W. Analysis of Yarn Fiber Volume Fraction in Textile Composites Using Scanning Electron Microscopy and X-Ray Micro-Computed Tomography. J. Reinf. Plast. Compos. 2018, 38, 199–210. [Google Scholar] [CrossRef]

- Lu, X.; Bertei, A.; Finegan, D.P.; Tan, C.; Daemi, S.R.; Weaving, J.S.; O’Regan, K.B.; Heenan, T.M.M.; Hinds, G.; Kendrick, E.; et al. 3D Microstructure Design of Lithium-Ion Battery Electrodes Assisted by X-Ray Nano-Computed Tomography and Modelling. Nat. Commun. 2020, 11, 2079. [Google Scholar] [CrossRef] [PubMed]

- Haleem, N.; Liu, X.; Hurren, C.; Gordon, S.; Najar, S.S.; Wang, X. Investigating the Cotton Ring Spun Yarn Structure Using Micro Computerized Tomography and Digital Image Processing Techniques. Text. Res. J. 2018, 89, 3007–3023. [Google Scholar] [CrossRef]

- Soltani, P.; Johari, M.S.; Zarrebini, M. 3D Fiber Orientation Characterization of Nonwoven Fabrics Using X-Ray Micro-Computed Tomography. World J. Text. Eng. Technol. 2015, 1, 41–47. [Google Scholar]

- Rinaldi, R.G.; Blacklock, M.; Bale, H.; Begley, M.R.; Cox, B.N. Generating Virtual Textile Composite Specimens Using Statistical Data from Micro-Computed Tomography: 3D Tow Representations. J. Mech. Phys. Solids 2012, 60, 1561–1581. [Google Scholar] [CrossRef]

- Bale, H.; Blacklock, M.; Begley, M.R.; Marshall, D.B.; Cox, B.N.; Ritchie, R.O. Characterizing Three-Dimensional Textile Ceramic Composites Using Synchrotron x-Ray Micro-Computed-Tomography. J. Am. Ceram. Soc. 2011, 95, 392–402. [Google Scholar] [CrossRef]

- Depriester, D.; Rolland du Roscoat, S.; Orgéas, L.; Geindreau, C.; Levrard, B.; Brémond, F. Individual Fibre Separation in 3D Fibrous Materials Imaged by X-Ray Tomography. J. Microsc. 2022, 286, 220–239. [Google Scholar] [CrossRef]

- Toda, M.; Grabowska, K.E. Computed Microtomography in the Analysis of Fiber Migration in Yarn. Autex Res. J. 2013, 13, 28–32. [Google Scholar] [CrossRef]

- Shanbeh, M.; Hasani, H.; Manesh, F.Y. An Investigation into the Fatigue Behavior of Core-Spun Yarns under Cyclic Tensile Loading. J. Eng. Fibers Fabr. 2012, 7, 155892501200700406. [Google Scholar] [CrossRef]

- Ishtiaque, S.M.; Mawkhlieng, U.; Yadav, V.K. Fabric Comfort by Modifying Yarn Structure: Part i—Study on Structural Changes by Cross-Sectional Microtomy of Yarn. Indian J. Fibre Text. Res. 2019, 44, 424–430. [Google Scholar]

- Gharahaghaji, A.A.; Zargar, E.N.; Ghane, M.; Hossaini, A. Cluster-Spun Yarn—A New Concept in Composite Yarn Spinning. Text. Res. J. 2009, 80, 19–24. [Google Scholar] [CrossRef]

- Straumit, I.; Lomov, S.V.; Wevers, M. Quantification of the Internal Structure and Automatic Generation of Voxel Models of Textile Composites from X-Ray Computed Tomography Data. Compos. Part A Appl. Sci. Manuf. 2015, 69, 150–158. [Google Scholar] [CrossRef]

- Naouar, N.; Vidal-Salle, E.; Schneider, J.; Maire, E.; Boisse, P. 3D Composite Reinforcement Meso F.E. Analyses Based on X-Ray Computed Tomography. Compos. Struct. 2015, 132, 1094–1104. [Google Scholar] [CrossRef]

- Mukhamadiyarov, R.A.; Sevostyanova, V.V.; Shishkova, D.K.; Nokhrin, A.V.; Sidorova, O.D.; Kutikhin, A.G. Grinding and Polishing Instead of Sectioning for the Tissue Samples with a Graft: Implications for Light and Electron Microscopy. Micron 2016, 85, 1–7. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Value |

|---|---|

| Source voltage | 50 kV |

| Source current | 200 µA |

| Image pixel size/Scanning resolution | 1 µm |

| Rotation step/angle | 0.100° |

| Size of the projection image | 3280 × 1078 |

| Scanning width | 22% |

| Method | Average Fiber Diameter (µm) | 3D Reconstruction/Visualization | Average Time to Obtain the Cross-Sections | Type of Test |

|---|---|---|---|---|

| Microtome | 10.96 ± 0.83 | Not applicable | 5 days (limited number of cross-sections) | Destructive |

| µCT | 10.50 ± 1.13 | Applicable | 5–6 h for all cross-sections “each of 1 µm thickness” for a 3 mm length sample | Nondestructive |

| Epoxy grinding–polishing | 11.24 ± 0.60 | Not applicable | 2 days (limited number of cross-sections) | Destructive |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdelkader, M.; Mazari, A.; Zafar, S. Experimental Techniques to Obtain the Cross-Sectional Images of Textile Yarns. Materials 2022, 15, 4726. https://doi.org/10.3390/ma15144726

Abdelkader M, Mazari A, Zafar S. Experimental Techniques to Obtain the Cross-Sectional Images of Textile Yarns. Materials. 2022; 15(14):4726. https://doi.org/10.3390/ma15144726

Chicago/Turabian StyleAbdelkader, Mohamed, Adnan Mazari, and Sumayya Zafar. 2022. "Experimental Techniques to Obtain the Cross-Sectional Images of Textile Yarns" Materials 15, no. 14: 4726. https://doi.org/10.3390/ma15144726

APA StyleAbdelkader, M., Mazari, A., & Zafar, S. (2022). Experimental Techniques to Obtain the Cross-Sectional Images of Textile Yarns. Materials, 15(14), 4726. https://doi.org/10.3390/ma15144726