Determination of Optimum Machining Parameters for Face Milling Process of Ti6A14V Metal Matrix Composite

Abstract

:1. Introduction

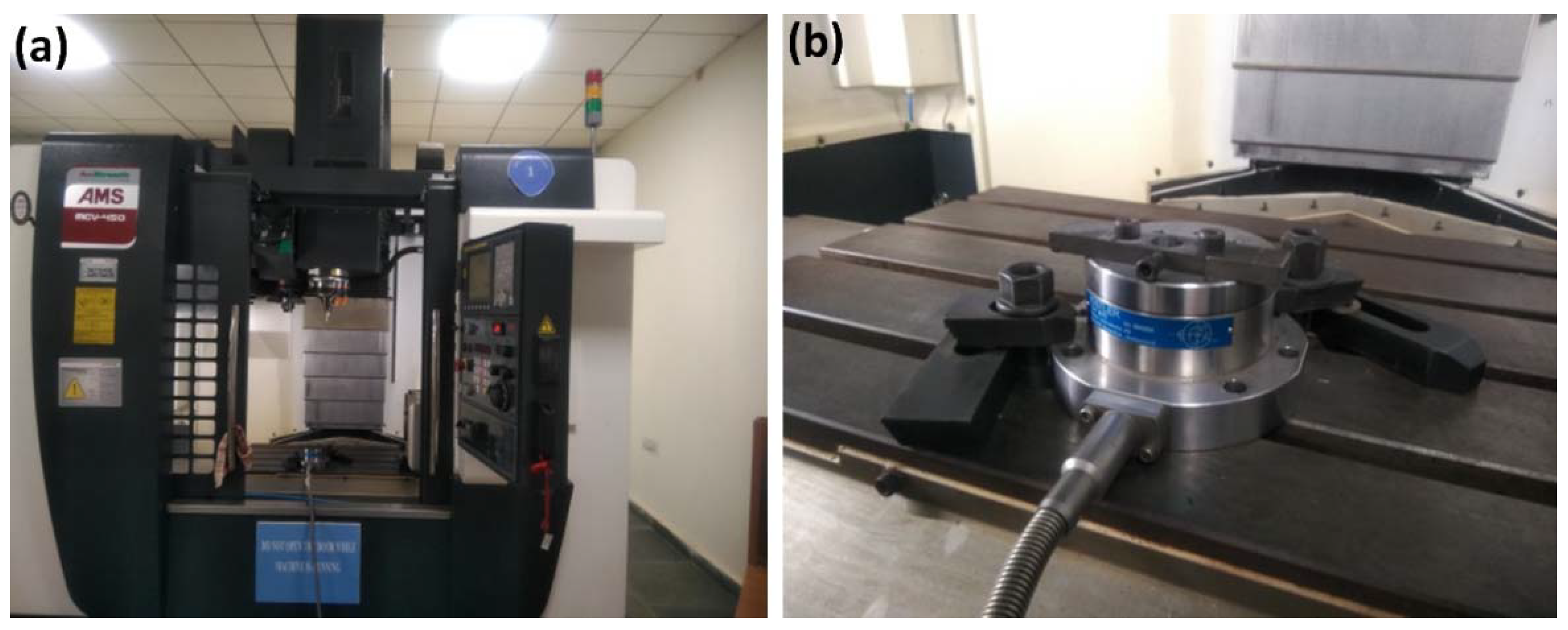

2. Materials and Methods

3. Results and Discussion

3.1. Phase Analysis and Surface Morphology

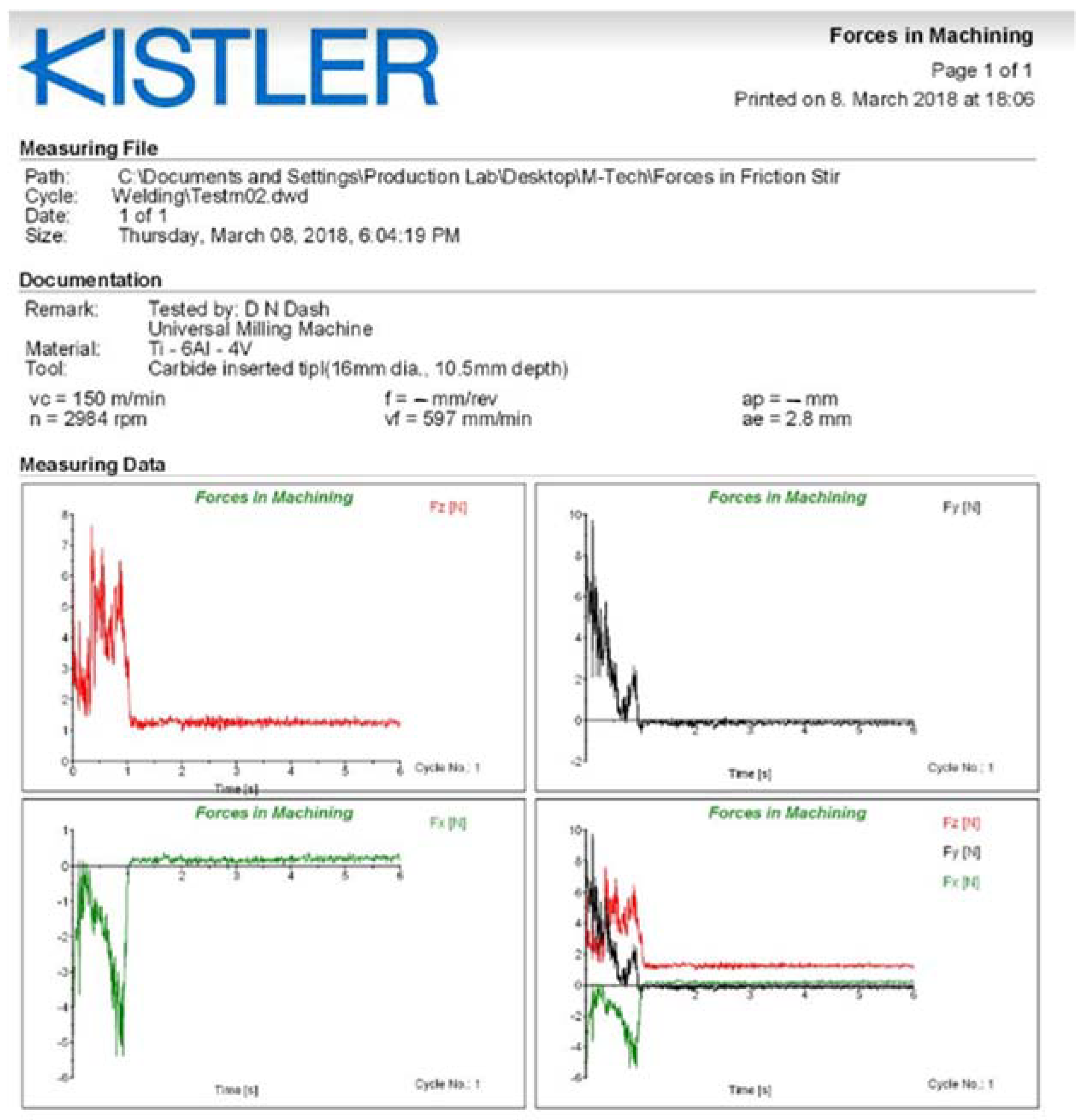

3.2. Facing Operation

3.3. Design of Experiment to Determine Responses

- Mf = Initial mass of the sample before milling

- Mi = Final mass of the sample after milling

- ρ = Density of Ti alloy material

- t = Milling time for the sample

3.4. Method of Optimization

3.4.1. Grey Relational Analysis Method (GRA)

3.4.2. Grey Relational Coefficients Are Determined

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, N.; Ummethala, R.; Karamched, P.S.; Sokkalingam, R.; Gopal, V.; Manivasagam, G.; Prashanth, K.G. Spark plasma sintering of Ti6Al4V metal matrix composites: Microstructure, mechanical and corrosion properties. J. Alloys Compd. 2021, 865, 158875. [Google Scholar] [CrossRef]

- Candela, D.R.; Riquelme, C.S.; Bonache, A.V. Ti6Al4V/SiC Metal Matrix Composites Additively Manufactured by Direct Laser Deposition. Met. Mater. Int. 2022, 1–25. [Google Scholar] [CrossRef]

- Anandajothi, M.; Ramanathan, S.; Ananthi, V.; Narayanasamy, P. Fabrication and characterization of Ti6Al4V/TiB2–TiC composites by powder metallurgy method. Rare Met. 2017, 36, 806–811. [Google Scholar] [CrossRef]

- Guseinov, E.R.; Petrovsky, P.V.; Travyanov, A.Y. Directional Hot Isostatic Pressing of Ti6Al4V-SiC Composite with Elements Prepared by Selective Laser Melting Technology. Metallurgist 2022, 65, 1413–1422. [Google Scholar] [CrossRef]

- Nourbakhsh, F.; Rajurkar, K.P.; Malshe, A.P.; Cao, J. Wire electro-discharge machining of titanium alloy. Procedia CIRP 2013, 5, 13–18. [Google Scholar] [CrossRef] [Green Version]

- Yang, K.Z.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Shankar, S.; Dixit, S.; Kumar, K.; Vatin, N.I. Application of coolants during tool-based machining—A review. Ain Shams Eng. J. 2022, 101830. [Google Scholar] [CrossRef]

- Sahu, A.K.; Mohanty, P.P.; Sahoo, S.K. Electro discharge machining of Ti-alloy (Ti6Al4V) and 316L Stainless Steel and Optimization of Process Parameters by Grey Relational Analysis (GRA) Method. In Advances in 3D Printing & Additive Manufacturing Technologies; Springer: Singapore, 2017; pp. 65–78. [Google Scholar]

- Shokrani, A.; Vimal, D.; Stephen, T.N. Investigation of the effects of cryogenic machining on surface integrity in CNC end milling of Ti-6Al-4V titanium alloy. J. Manuf. Processes 2016, 21, 172–179. [Google Scholar] [CrossRef] [Green Version]

- Jegan, T.C.; Anand, M.D.; Ravindran, D. Determination of EDM parameters in AISI202 stainless steel using grey relational analysis. ICMOC. Proc. Eng. 2012, 38, 4005–4012. [Google Scholar] [CrossRef] [Green Version]

- D’Mello, G.; Pai, P.S.; Puneet, N. Optimization studies in high speed turning of Ti-6Al-4V. Appl. Soft Comput. 2017, 51, 105–115. [Google Scholar] [CrossRef]

- Agrawal, A.; Goel, S.; Bin Rashid, W.; Price, M. Prediction of surface roughness during hard turning of AISI 4340 steel (69 HRC). Appl. Soft Comput. 2015, 30, 279–286. [Google Scholar] [CrossRef] [Green Version]

- Bonaiti, G.; Parenti, P.; Annoni, M.; Kapoor, S. Micro-milling machinability of DED additive titanium Ti-6Al-4V. Procedia Manuf. 2017, 10, 497–509. [Google Scholar] [CrossRef]

- Mukherjee, S.; Kamal, A.; Kumar, K. Optimization of material removal rate during turning of SAE 1020 material in CNC lathe using Taguchi technique. Procedia Eng. 2014, 97, 29–35. [Google Scholar] [CrossRef] [Green Version]

- Ghag, M.J.; Rao, M.V. Review on optimization techniques such as DOE and GRA used for process parameters of resistance spot welding. Volume 2015, 4, 701–705. [Google Scholar]

- Örtorp, A. Comparisons of precision of fit between cast and CNC-milled titanium implant frameworks for the edentulous mandible. Int. J. Prosthodont. 2003, 16, 194–200. [Google Scholar] [PubMed]

- Sharma, V.; Kumar, P.; Misra, J.P. Cutting force predictive modelling of hard turning operation using fuzzy logic. Mater. Today Proc. 2020, 26, 740–744. [Google Scholar] [CrossRef]

- Gauri, S.K.; Pal, S. Comparison of performances of five prospective approaches for the multi-response optimization. Int. J. Adv. Manuf. Technol. 2009, 48, 1205–1220. [Google Scholar] [CrossRef]

- Dixit, S. Analysing the Impact of Productivity in Indian Transport Infra Projects. In Proceedings of the IOP Conference Series: Materials Science and Engineering; Creative Construction Conference (CCC 2021), Budapest, Hungary, 28–30 June 2021; Institute of Physics Publishing (IOP): Bristol, UK, 2022; Volume 1218, p. 12059. [Google Scholar]

- Dixit, S.; Arora, R.; Kumar, K.; Bansal, S.; Vatin, N.; Araszkiewicz, K.; Epifantsev, K. Replacing E-waste with coarse aggregate in architectural engineering and construction industry. Mater. Today Proc. 2021, 56, 2353–2358. [Google Scholar] [CrossRef]

- John, M.S.; Wilson, A.W.; Bhardwaj, A.P.; Abraham, A.; Vinayagam, B.K. An investigation of ball burnishing process on CNC lathes using finite element analysis. Simul. Modeling Pract. Theory 2016, 62, 88–101. [Google Scholar] [CrossRef]

- Khare, S.K.; Agarwal, S. Optimization of Machining Parameters in Turning of AISI 4340 Steel under Cryogenic Condition using Taguchi Technique. Procedia CIRP 2017, 63, 610–614. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Gibson, I.; Goldberg, M.; Doeven, E.H.; Littlefair, G. Investigation on the effect of cutting fluid pressure on surface quality measurement in high speed thread milling of brass alloy (C3600) and aluminium alloy (5083). Measurement 2016, 82, 55–63. [Google Scholar] [CrossRef]

- Chiu, H.-W.; Lee, C.-H. Prediction of machining accuracy and surface quality for CNC machine tools using data driven approach, Adv. Eng. Softw. 2017, 114, 246–257. [Google Scholar]

- Gowd, G.H.; Goud, M.V.; Theja, K.D.; Reddy, M.G. Optimal selection of machining parameters in CNC turning process of EN-31 using intelligent hybrid decision making tools. Procedia Eng. 2014, 97, 125–133. [Google Scholar] [CrossRef]

- Tripathi, D.R.; Vachhani, K.H.; Bandhu, D.; Kumari, S.; Kumar, V.R.; Abhishek, K. Experimental investigation and optimization of abrasive waterjet machining parameters for GFRP composites using metaphor-less algorithms. Mater. Manuf. Processes 2021, 36, 803–813. [Google Scholar] [CrossRef]

- Elkhateeb, M.G.; Shin, Y.C. Investigation of the Machining Behavior of Ti6Al4V/TiC Composites During Conventional and Laser-Assisted Machining. ASME. J. Manuf. Sci. Eng. May 2019, 141, 1–34. [Google Scholar] [CrossRef]

- da Silva, A.A.M.; dos Santos, J.F.; Strohaecker, T.R.; Reguly, A. Study of structure/property relationships of diffusion bonded Ti6Al4V + 10 wt-%TiC particulate composite. Sci. Technol. Weld. Join. 2005, 10, 413–417. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Pabla, B.S.; Sidhu, S.S.; Uddin, M.S. Bio-inspired low elastic biodegradable Mg-Zn-Mn-Si-HA alloy fabricated by spark plasma sintering. Mater. Manuf. Processes 2019, 34, 357–368. [Google Scholar] [CrossRef]

- Dixit, S. Study of factors affecting the performance of construction projects in AEC industry. Organ. Technol. Manag. Constr. 2020, 12, 2275–2282. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Singh, M.; Gupta, M.K.; Mia, M.; Dhanda, A. Multi-objective parametric appraisal of pulsed current gas tungsten arc welding process by using hybrid optimization algorithms. Int. J. Adv. Manuf. Technol. 2019, 101, 1107–1123. [Google Scholar] [CrossRef]

- Singh, P.; Dixit, S.; Sammanit, D.; Krishnan, P. The Automated Farmlands of Tomorrow: An IoT Integration with Farmlands. In Proceedings of the IOP Conference Series: Materials Science and Engineering; Creative Construction Conference (CCC 2021) 28–30 June 2021; Institute of Physics Publishing (IOP): Bristol, UK, 2022; Volume 1218. [Google Scholar]

- Uddin, M.; Basak, A.; Pramanik, A.; Singh, S.; Krolczyk, G.M.; Prakash, C. Evaluating hole quality in drilling of Al 6061 alloys. Materials 2018, 11, 2443. [Google Scholar] [CrossRef] [Green Version]

- Pradhan, S.; Singh, S.; Prakash, C.; Królczyk, G.; Pramanik, A.; Pruncu, C.I. Investigation of machining characteristics of hard-to-machine Ti-6Al-4V-ELI alloy for biomedical applications. J. Mater. Res. Technol. 2019, 8, 4849–4862. [Google Scholar] [CrossRef]

- Sandhu, K.; Singh, G.; Singh, S.; Kumar, R.; Prakash, C.; Ramakrishna, S.; Królczyk, G.; Pruncu, C.I. Surface characteristics of machined polystyrene with 3D printed thermoplastic tool. Materials 2020, 13, 2729. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, A.; Basak, A.K.; Prakash, C. Understanding the wire electrical discharge machining of Ti6Al4V alloy. Heliyon 2019, 5, e01473. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jin, S.Y.; Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S.; Debnath, S. Burr formation and its treatments—A review. Int. J. Adv. Manuf. Technol. 2020, 107, 2189–2210. [Google Scholar] [CrossRef]

- Antil, P.; Singh, S.; Singh, S.; Prakash, C.; Pruncu, C.I. Metaheuristic approach in machinability evaluation of silicon carbide particle/glass fiber–reinforced polymer matrix composites during electrochemical discharge machining process. Meas. Control. 2019, 52, 1167–1176. [Google Scholar] [CrossRef]

- Singh, S.; Prakash, C.; Antil, P.; Singh, R.; Królczyk, G.; Pruncu, C.I. Dimensionless analysis for investigating the quality characteristics of aluminium matrix composites prepared through fused deposition modelling assisted investment casting. Materials 2019, 12, 1907. [Google Scholar] [CrossRef] [Green Version]

- Zadafiya, K.; Bandhu, D.; Kumari, S.; Chatterjee, S.; Abhishek, K. Recent trends in drilling of carbon fiber reinforced polymers (CFRPs): A state-of-the-art review. J. Manuf. Processes 2021, 69, 47–68. [Google Scholar] [CrossRef]

- Mausam, K.; Sharma, K.; Bharadwaj, G.; Singh, R.P. Multi-objective optimization design of die-sinking electric discharge machine (EDM) machining parameter for CNT-reinforced carbon fibre nanocomposite using grey relational analysis. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 348. [Google Scholar] [CrossRef]

- Dixit, S.; Stefańska, A. Digitisation of contemporary fabrication processes in the AEC sector. Mater. Today Proc. 2021, 56, 1882–1885. [Google Scholar] [CrossRef]

- Dixit, S.; Stefańska, A.; Singh, P. Manufacturing technology in terms of digital fabrication of contemporary biomimetic structures. Int. J. Constr. Manag. 2021, 1–9. [Google Scholar] [CrossRef]

| Load Variations in Kgf (N) | Dimension of Sample | No. of Sample Made | |

|---|---|---|---|

| Length in mm | Diameter in mm | ||

| 4000 Kgf (39,226.6 N) | 15 | 10 | 1 |

| 6000 Kgf (58,839.9 N) | 15 | 10 | 4 |

| 10,000 Kgf (98,066.5 N) | 15 | 10 | 1 |

| Elements | Ti | Al | V | Fe | O | C | N | H |

|---|---|---|---|---|---|---|---|---|

| Weight Percentage | Bal. | 6.75 | 4.50 | 0.30 | 0.20 | 0.08 | 0.05 | 0.015 |

| Density | Young’s Modulus (GPa) | Shear Modulus (GPa) | Bulk Modulus (GPa) | Poisson’s Ratio | Yield Strength MPa (Tensile) | Ultimate Strength MPa (Tensile) | Uniform Elongation % | |

|---|---|---|---|---|---|---|---|---|

| Min | 4.429 | 104 | 40 | 96.8 | 0.31 | 880 | 900 | 5 |

| Max | 4.512 | 113 | 45 | 153 | 0.37 | 920 | 950 | 18 |

| Input Machining Parameters | Level 001 | Level 002 | Level 003 |

|---|---|---|---|

| V (m/min) | 150 | 175 | 200 |

| F (mm/edge) | 0.15 | 0.20 | 0.25 |

| D (mm) | 1.00 | 1.20 | 1.40 |

| Sl. No. | MRR (mm3/min) | Fx (N) | Fy (N) | Fz (N) | Ra (µm) |

|---|---|---|---|---|---|

| 1 | 5494.9095 | −6.00 | 5.00 | 2.37 | 5.88 |

| 2 | 8165.0226 | −4.25 | 6.50 | 5.40 | 4.92 |

| 3 | 12,038.8386 | −6.90 | 2.74 | 4.75 | 4.58 |

| 4 | 10,396.7194 | 3.70 | 22.5 | −13.00 | 5.06 |

| 5 | 10,063.401 | −1.75 | 2.75 | 3.40 | 4.84 |

| 6 | 9147.9444 | −10.50 | 10.90 | 3.70 | 4.72 |

| 7 | 12,051.4479 | −5.00 | 4.50 | 2.19 | 5.56 |

| 8 | 11,318.707 | −2.60 | 4.00 | 2.70 | 4.98 |

| 9 | 16,390.8962 | −8.00 | 10.00 | 12.50 | 5.08 |

| Sl. No. | MRR | Fx | Fy | Fz | Ra |

|---|---|---|---|---|---|

| 1 | 3.3119 × 10−8 | 36 | 25 | 5.6169 | 34.5744 |

| 2 | 1.5 × 10−8 | 18.0625 | 42.25 | 29.16 | 24.2064 |

| 3 | 6.8997 × 10−9 | 47.61 | 7.5076 | 22.5625 | 20.9764 |

| 4 | 9.2514 × 10−9 | 13.69 | 506.25 | 169 | 25.6036 |

| 5 | 9.8744 × 10−9 | 3.0625 | 7.5625 | 11.56 | 23.4256 |

| 6 | 1.195 × 10−8 | 110.25 | 118.81 | 13.69 | 22.2784 |

| 7 | 6.8853 × 10−9 | 25 | 20.25 | 4.7961 | 30.9136 |

| 8 | 7.8056 × 10−9 | 6.76 | 16 | 7.29 | 24.8004 |

| 9 | 3.7222 × 10−9 | 64 | 100 | 156.25 | 25.8064 |

| Sl. No. | MRR | Fx | Fy | Fz | Ra |

|---|---|---|---|---|---|

| 1 | 74.79921 | −15.563 | −13.9794 | −7.49497 | −15.3875 |

| 2 | 78.23915 | −12.5678 | −16.2583 | −14.6479 | −13.8393 |

| 3 | 81.61169 | −16.777 | −8.75501 | −13.5339 | −13.2173 |

| 4 | 80.33793 | −11.364 | −27.0437 | −22.2789 | −14.083 |

| 5 | 80.0549 | −4.86076 | −8.78665 | −10.6296 | −13.6969 |

| 6 | 79.22647 | −20.4238 | −20.7485 | −11.364 | −13.4788 |

| 7 | 81.62078 | −13.9794 | −13.0643 | −6.80888 | −14.9015 |

| 8 | 81.07594 | −8.29947 | −12.0412 | −8.62728 | −13.9446 |

| 9 | 84.29205 | −18.0618 | −20 | −21.9382 | −14.1173 |

| Sl. No. | MRR | Fx | Fy | Fz | Ra |

|---|---|---|---|---|---|

| 1 | 1 | 0.313 | 0.715 | 0.956 | 0 |

| 2 | 0.66 | 0.505 | 0.59 | 0.494 | 0.714 |

| 3 | 0.327 | 0.235 | 1 | 0.566 | 1 |

| 4 | 0.453 | 0.583 | 0 | 0 | 0.601 |

| 5 | 0.481 | 1 | 0.998305 | 0.764 | 0.738 |

| 6 | 0 | 0 | 0.345 | 0.706 | 0.88 |

| 7 | 0.326 | 0.415 | 0.765 | 1 | 0.224 |

| 8 | 0.38 | 0.779 | 0.821 | 0.883 | 0.665 |

| 9 | 0.062 | 0.152 | 0.386 | 0.926 | 0.586 |

| Sl. No. | GRGi | |||||

|---|---|---|---|---|---|---|

| MRR | Fx | Fy | Fz | Ra | ||

| 1 | 0.333333 | 0.615006 | 0.411523 | 0.343407 | 1 | 0.540653742 |

| 2 | 0.431034 | 0.497512 | 0.458716 | 0.503018 | 0.411862 | 0.460428448 |

| 3 | 0.604595 | 0.680272 | 0.333333 | 0.469043 | 0.333333 | 0.48411537 |

| 4 | 0.524659 | 0.461681 | 1 | 1 | 0.454133 | 0.688094419 |

| 5 | 0.509684 | 0.333333 | 0.33371 | 0.39557 | 0.403877 | 0.395234919 |

| 6 | 1 | 1 | 0.591716 | 0.414594 | 0.362319 | 0.673725703 |

| 7 | 0.605327 | 0.546448 | 0.395257 | 0.333333 | 0.690608 | 0.51419459 |

| 8 | 0.568182 | 0.39093 | 0.378501 | 0.361533 | 0.429185 | 0.425666163 |

| 9 | 0.88968 | 0.766871 | 0.564334 | 0.350631 | 0.460405 | 0.606384252 |

| Level | Speed (A) | Feed (B) | Depth of Cut (C) |

|---|---|---|---|

| 1 | 0.4951 | 0.5810 | 0.5467 |

| 2 | 0.5857 | 0.4271 | 0.5850 |

| 3 | 0.5154 | 0.5881 | 0.4645 |

| Delta | 0.0906 | 0.1610 | 0.1610 |

| Rank | 3 | 1 | 2 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | P | % of Contribution |

|---|---|---|---|---|---|---|---|

| V | 2 | 0.013564 | 0.013564 | 0.006782 | 7.23 | 0.122 | 15.45 |

| F | 2 | 0.049636 | 0.049636 | 0.024818 | 26.45 | 0.036 | 56.53 |

| D | 2 | 0.022726 | 0.022726 | 0.011363 | 12.11 | 0.076 | 25.88 |

| Error | 2 | 0.001877 | 0.001877 | 0.000938 | -- | -- | 2.13 |

| Total | 8 | 0.087804 | -- | -- | -- | -- | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, L.; Nayak, R.; Saxena, K.K.; Nanda, J.; Jena, S.P.; Behera, A.; Sehgal, S.; Prakash, C.; Dixit, S.; Abdul-Zahra, D.S. Determination of Optimum Machining Parameters for Face Milling Process of Ti6A14V Metal Matrix Composite. Materials 2022, 15, 4765. https://doi.org/10.3390/ma15144765

Das L, Nayak R, Saxena KK, Nanda J, Jena SP, Behera A, Sehgal S, Prakash C, Dixit S, Abdul-Zahra DS. Determination of Optimum Machining Parameters for Face Milling Process of Ti6A14V Metal Matrix Composite. Materials. 2022; 15(14):4765. https://doi.org/10.3390/ma15144765

Chicago/Turabian StyleDas, Layatitdev, Rakesh Nayak, Kuldeep K. Saxena, Jajneswar Nanda, Shakti Prasad Jena, Ajit Behera, Shankar Sehgal, Chander Prakash, Saurav Dixit, and Dalael Saad Abdul-Zahra. 2022. "Determination of Optimum Machining Parameters for Face Milling Process of Ti6A14V Metal Matrix Composite" Materials 15, no. 14: 4765. https://doi.org/10.3390/ma15144765

APA StyleDas, L., Nayak, R., Saxena, K. K., Nanda, J., Jena, S. P., Behera, A., Sehgal, S., Prakash, C., Dixit, S., & Abdul-Zahra, D. S. (2022). Determination of Optimum Machining Parameters for Face Milling Process of Ti6A14V Metal Matrix Composite. Materials, 15(14), 4765. https://doi.org/10.3390/ma15144765