A Scientometric Review on Mapping Research Knowledge for 3D Printing Concrete

Abstract

:1. Introduction

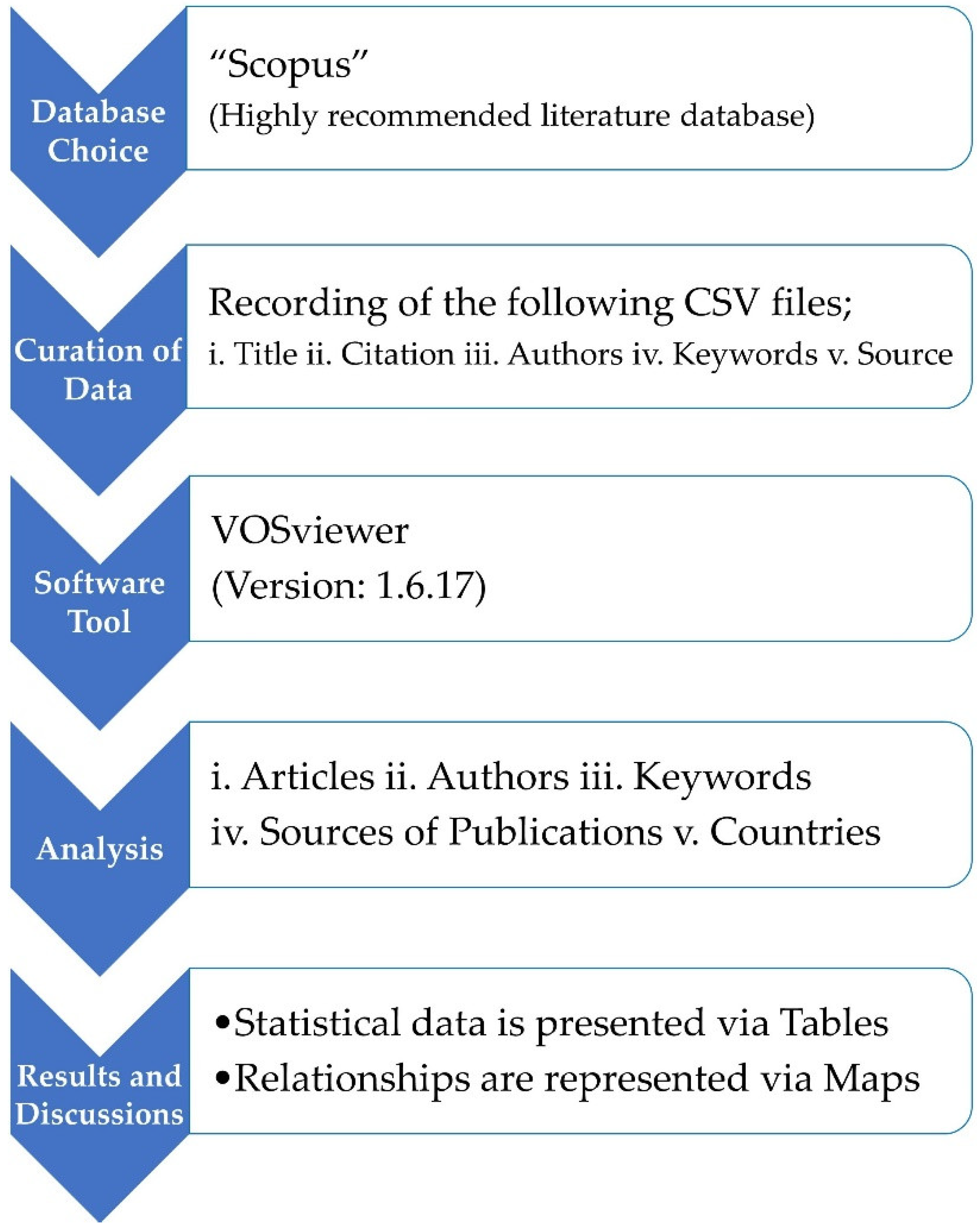

2. Methodology

3. Analysis of Results

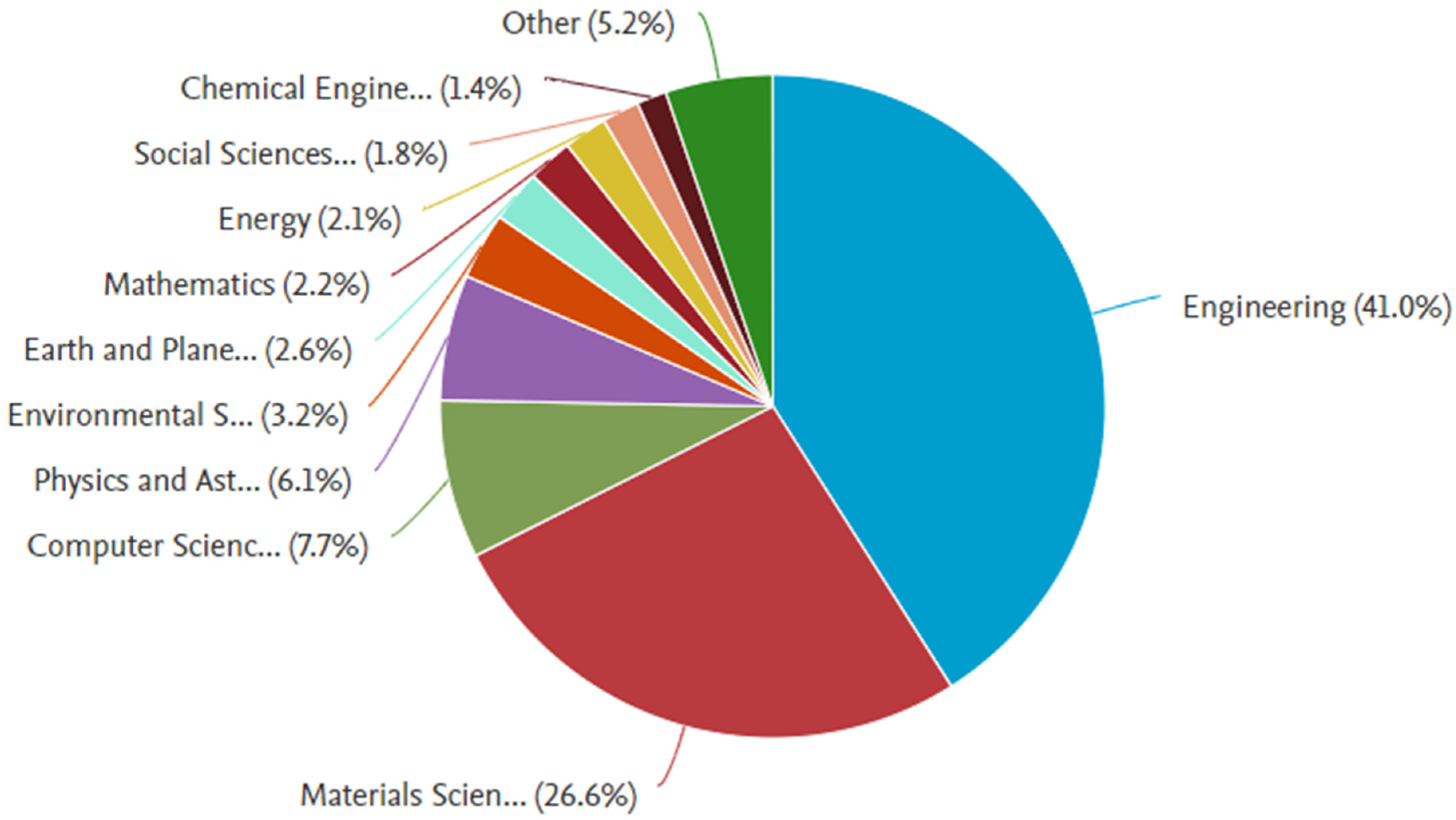

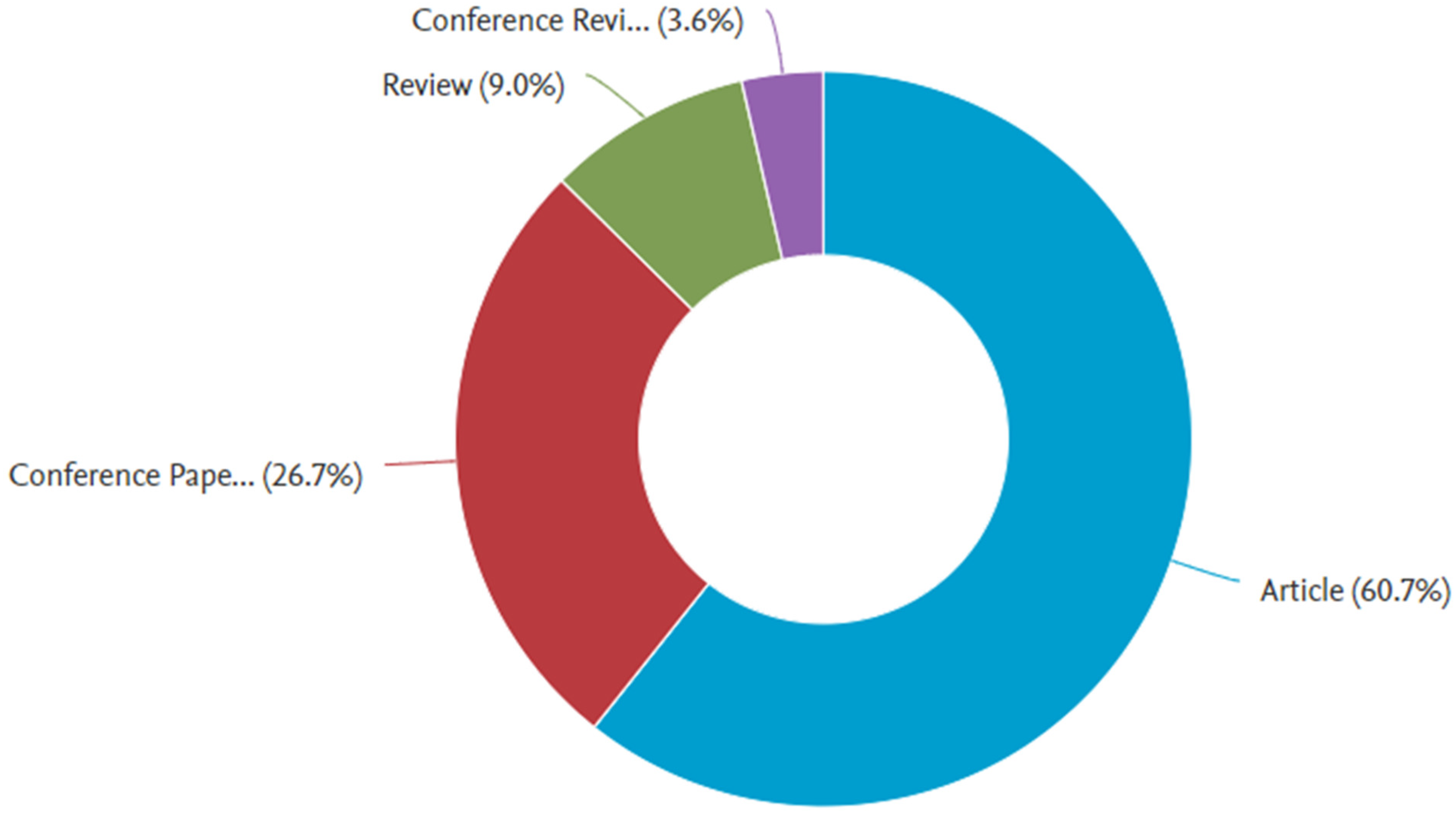

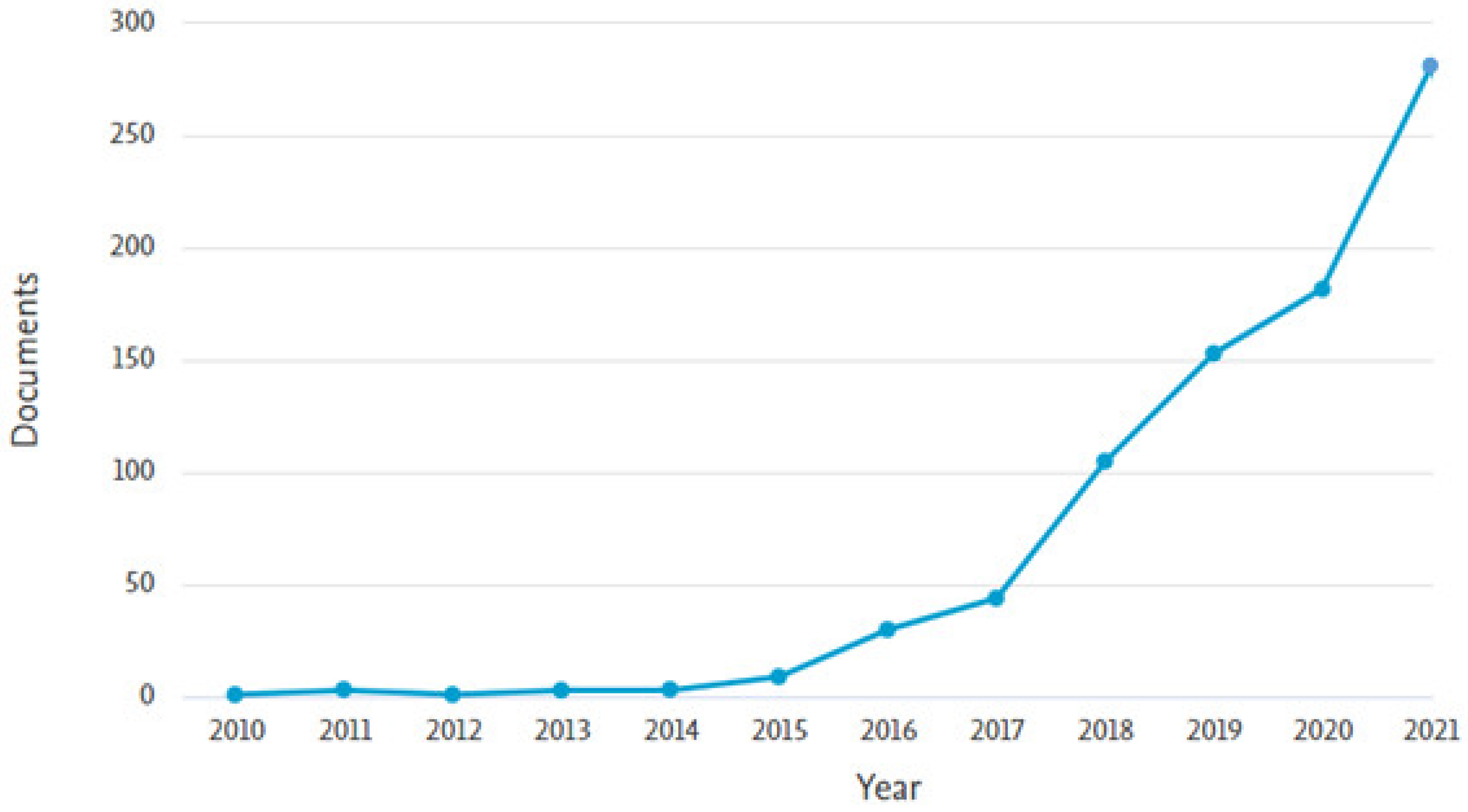

3.1. Annual Publications and Related Subject Areas

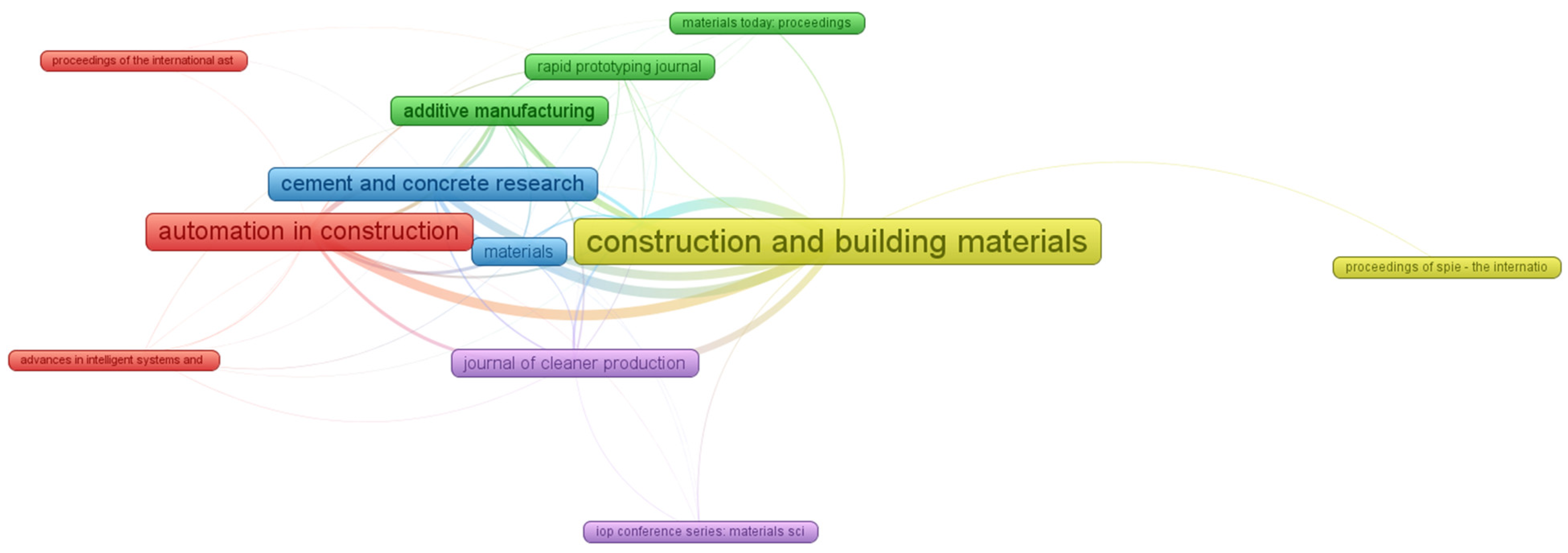

3.2. Publication Sources

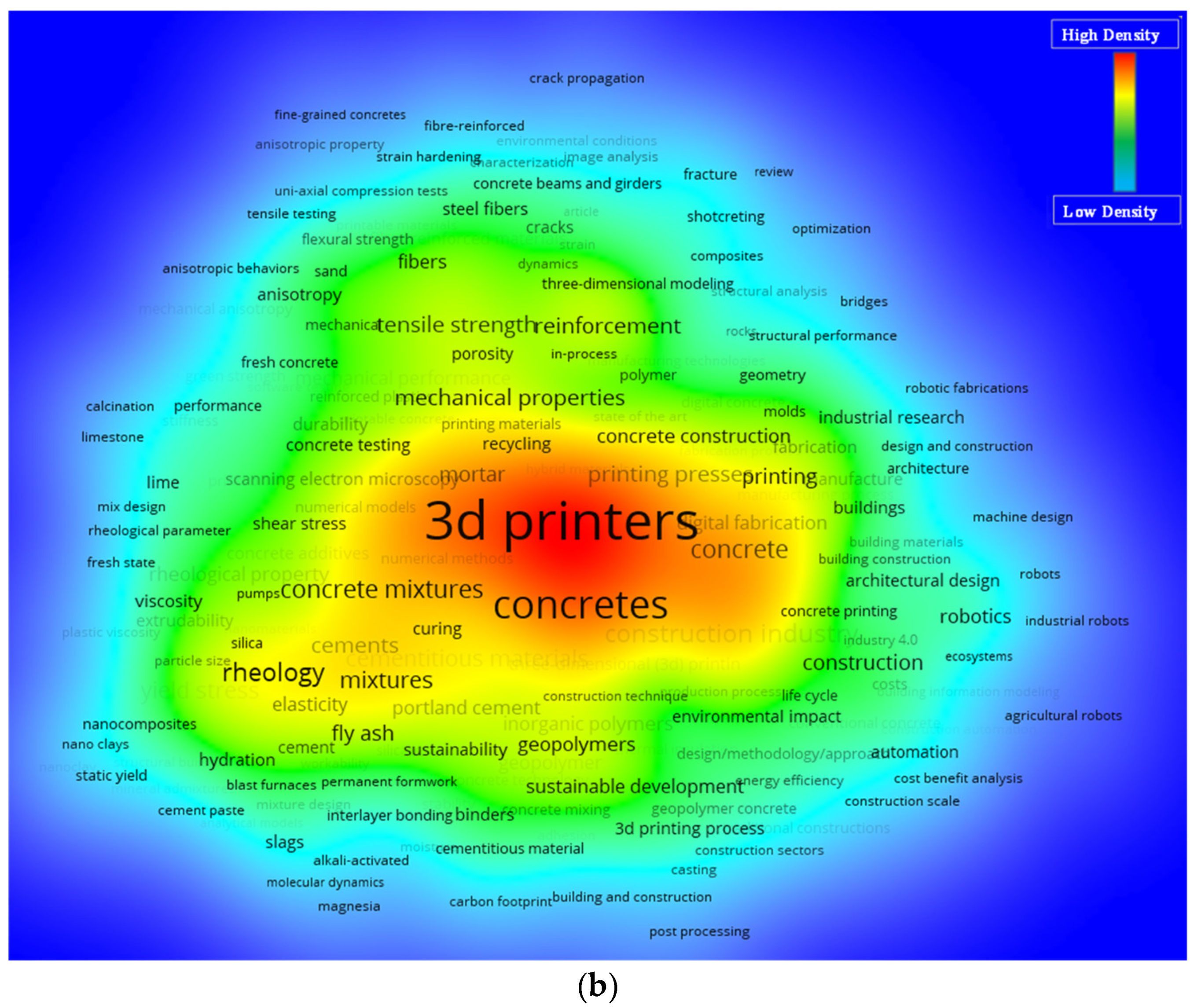

3.3. Keywords

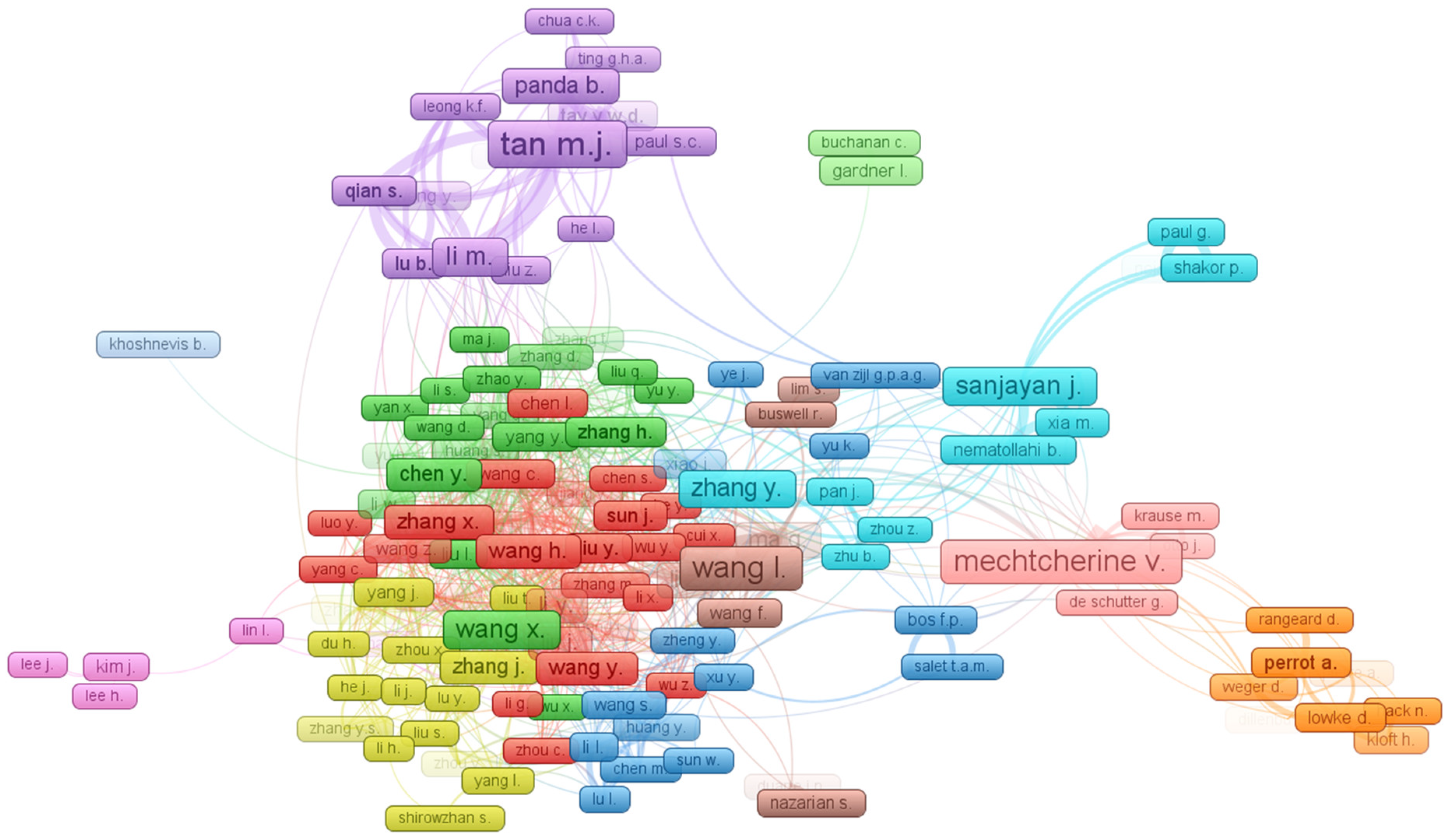

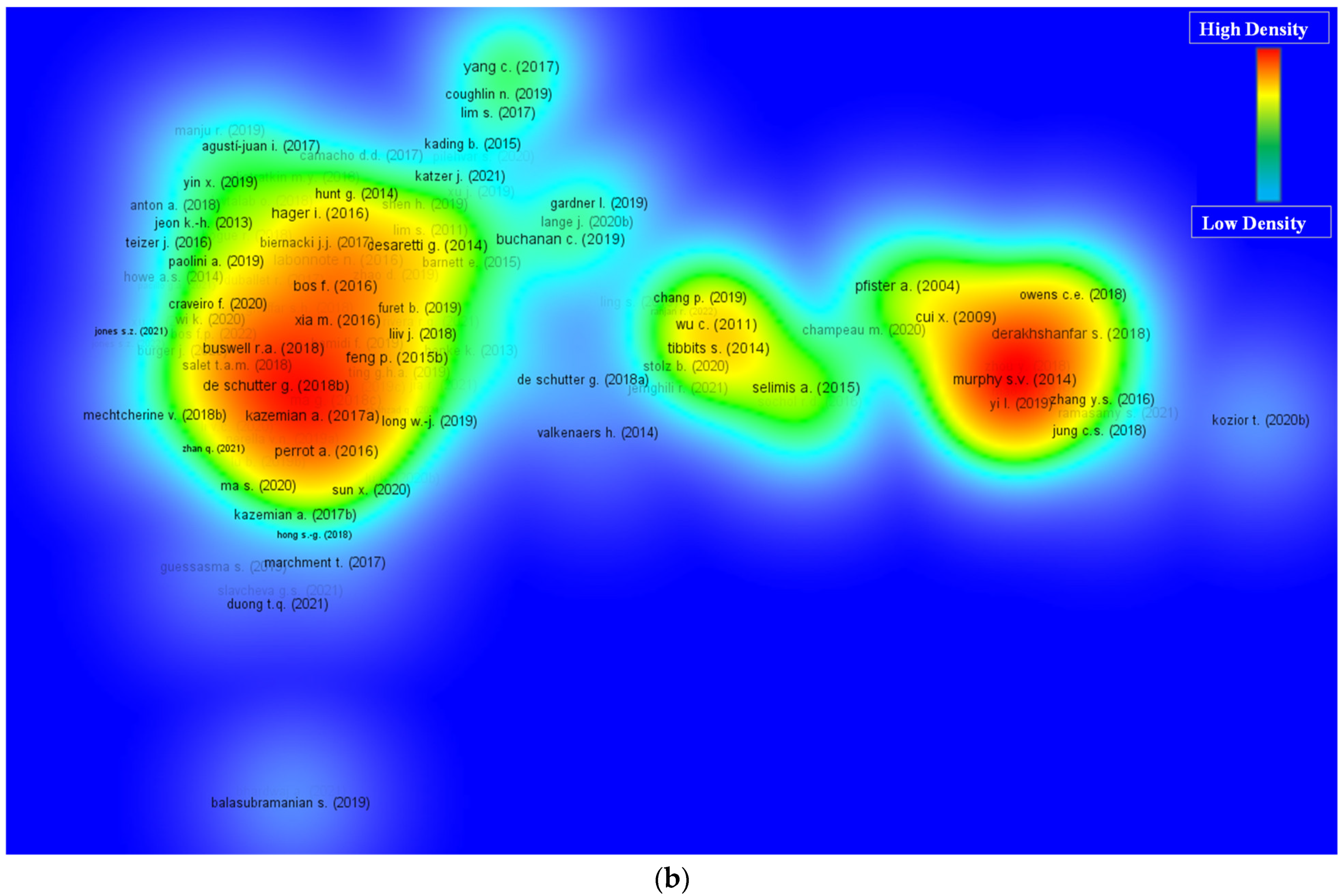

3.4. Authors

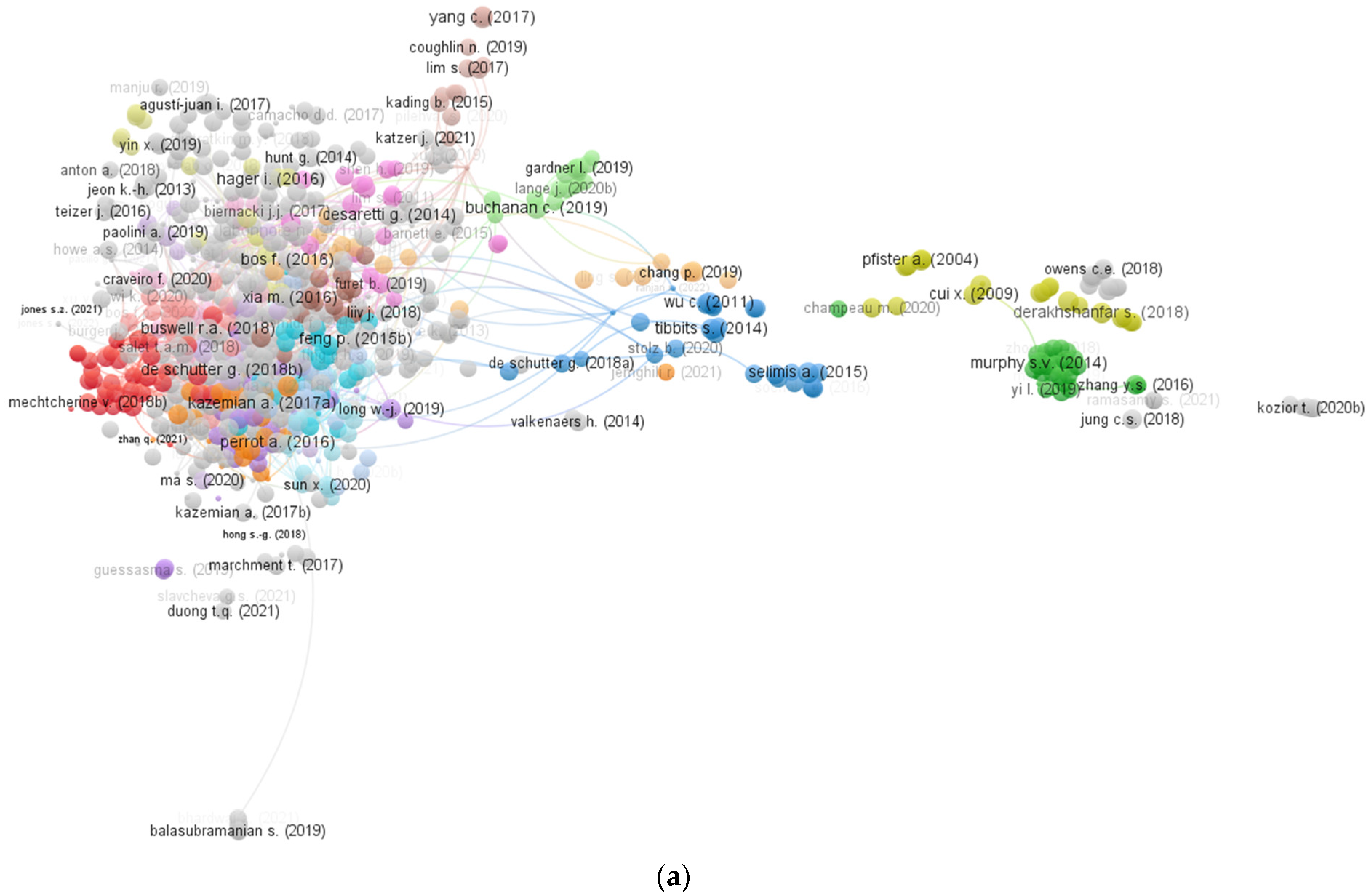

3.5. Articles

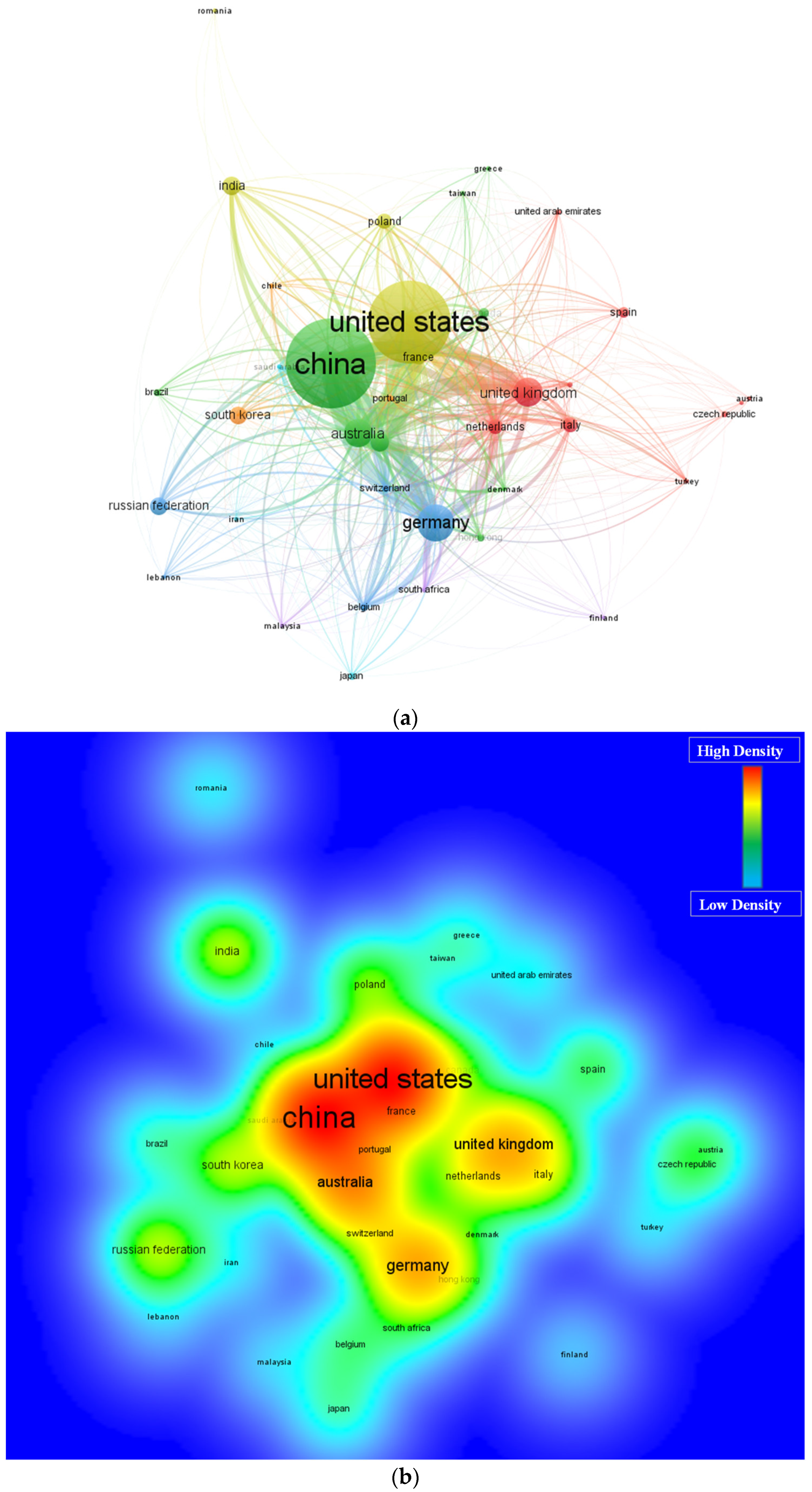

3.6. Countries

4. Discussions and Future Perspectives

- Three-dimensional printed components’ structural integrity, especially in regions vulnerable to natural disasters, seismic activity, military attacks and extreme climatic conditions, needs to be ensured by performing structural testing and developing specified standards and codes.

- Due to the provision of controlled environmental conditions for performing the experiment on 3D printed components, its behavior may not depict the true performance. As in real site conditions, the components are exposed to variable climatic factors such as humidity, temperature and precipitation, debris and dust, and varied lighting, etc. [83]. Therefore, the performance of 3D printing concrete components may be evaluated under real environmental conditions to ensure the global efficiency of this method.

- Further research should also be conducted for large-scale building construction and experimentation to ensure the real capacity of 3D printing technology and to depict the application of this technology in the industry.

- Three-dimensional printing is still a new technology; therefore, the information on its life cycle cost, including the maintenance and upfront costs, is limited yet. Further, there may be variations in the costs of design, planning, machinery, labor, and materials from country to country [95]. Therefore, a thorough life cycle cost analysis should be conducted for 3D printing technology to have detailed insight into its cost–benefit ratio with respect to conventional construction [96].

- Furthermore, the information regarding the life cycle assessment (LCA) of 3D printing concrete is also limited and demands thorough exploration in terms of its sustainability impact, preparation of material, construction, utilization, and ultimately the structures’ demolition. This information is necessary to explore to have a clear picture of 3D printing concrete environmental impacts [97,98].

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tibbits, S.; McKnelly, C.; Olguin, C.; Dikovsky, D.; Hirsch, S. 4D Printing and Universal Transformation. In Proceedings of the 34th Annual Conference of the Association for Computer Aided Design in Architecture (ACADIA), Los Angeles, CA, USA, 23–25 October 2014. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J.; Gibson, I.; Chua, C.K. The disruptive evolution of 3D printing. In Proceedings of the 2nd International Conference on Progress in Additive Manufacturing, Singapore, 17–19 May 2016; pp. 16–19. [Google Scholar]

- Sanjayan, J.G.; Nematollahi, B.; Xia, M.; Marchment, T. Effect of surface moisture on inter-layer strength of 3D printed concrete. Constr. Build. Mater. 2018, 172, 468–475. [Google Scholar] [CrossRef]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Kim, K.; Park, S.; Kim, W.; Jeong, Y.; Lee, J. Evaluation of Shear Strength of RC Beams with Multiple Interfaces Formed before Initial Setting Using 3D Printing Technology. Materials 2017, 10, 1349. [Google Scholar] [CrossRef] [Green Version]

- Panda, B.; Tan, M.-J. Rheological behavior of high volume fly ash mixtures containing micro silica for digital construction application. Mater. Lett. 2018, 237, 348–351. [Google Scholar] [CrossRef]

- Soltan, D.G.; Li, V.C. A self-reinforced cementitious composite for building-scale 3D printing. Cem. Concr. Compos. 2018, 90, 1–13. [Google Scholar] [CrossRef]

- Katzer, J.; Szatkiewicz, T. Properties of concrete elements with 3-D printed formworks which substitute steel reinforcement. Constr. Build. Mater. 2019, 210, 157–161. [Google Scholar] [CrossRef]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D printing of buildings and building components as the future of sustainable construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar] [CrossRef] [Green Version]

- Nematollahi, B.; Xia, M.; Sanjayan, J. Current progress of 3D concrete printing technologies, ISARC. In Proceedings of the International Symposium on Automation and Robotics in Construction, Taipei, Taiwan, 28 June–1 July 2017. [Google Scholar]

- Yao, Y.; Hu, M.; Di Maio, F.; Cucurachi, S. Life cycle assessment of 3D printing geo-polymer concrete: An ex-ante study. J. Ind. Ecol. 2020, 24, 116–127. [Google Scholar] [CrossRef] [Green Version]

- Farooqi, M.U.; Ali, M. Effect of pre-treatment and content of wheat straw on energy absorption capability of concrete. Constr. Build. Mater. 2019, 224, 572–583. [Google Scholar] [CrossRef]

- Farooqi, M.U.; Ali, M. Effect of Fibre Content on Splitting-Tensile Strength of Wheat Straw Reinforced Concrete for Pavement Applications. Key Eng. Mater. 2018, 765, 349–354. [Google Scholar] [CrossRef]

- Farooqi, M.U.; Ali, M. Effect of Fibre Content on Compressive Strength of Wheat Straw Reinforced Concrete for Pavement Applications. IOP Conf. Ser. Mater. Sci. Eng. 2018, 422, 012014. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Ndambuki, J.M.; Akinmusuru, J.O.; Omole, D. Characterization of ceramic waste aggregate concrete. HBRC J. 2018, 14, 282–287. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Al Yousef, R.; Al Abduljabbar, H.; Sufian, M. Effect of Coconut Fiber Length and Content on Properties of High Strength Concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.; Qin, D.; Hu, Y.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A systematic review of waste materials in cement-based composites for construction applications. J. Build. Eng. 2021, 45, 103447. [Google Scholar] [CrossRef]

- Alyousef, R.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P.; Alabduljabbar, H. Potential use of recycled plastic and rubber aggregate in cementitious materials for sustainable construction: A review. J. Clean. Prod. 2021, 329, 129736. [Google Scholar] [CrossRef]

- Althoey, F.; Hosen, M.A. Physical and mechanical characteristics of sustainable concrete comprising industrial waste materials as a replacement of conventional aggregate. Sustainability 2021, 13, 4306. [Google Scholar] [CrossRef]

- Althoey, F.; Farnam, Y. Performance of Calcium Aluminate Cementitious Materials in the Presence of Sodium Chloride. J. Mater. Civ. Eng. 2020, 32, 1–10. [Google Scholar] [CrossRef]

- Ali, E.; Althoey, F. A Simplified Stress Analysis of Functionally Graded Beams and Influence of Material Function on Deflection. Appl. Sci. 2021, 11, 11747. [Google Scholar]

- Althoey, F.; Balapour, M.; Farnam, Y. Reducing detrimental sulfate-based phase formation in concrete exposed to sodium chloride using supplementary cementitious materials. J. Build. Eng. 2022, 45, 103639. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M. Geopolymers reinforced by short and long fibres–innovative materials for additive manufacturing. Curr. Opin. Chem. Eng. 2020, 28, 167–172. [Google Scholar] [CrossRef]

- Ivanova, O.; Williams, C.; Campbell, T.A. Additive manufacturing (AM) and nanotechnology: Promises and challenges. Rapid Prototyp. J. 2013, 19, 353–364. [Google Scholar] [CrossRef] [Green Version]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Sayed, M.M. Mapping Research Knowledge on Rice Husk Ash Application in Concrete: A Scientometric Review. Materials 2022, 15, 3431. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Wang, H.; Ahmad, W.; Ahmad, A.; Vatin, N.I.; Mohamed, A.M.; Deifalla, A.F.; Mehmood, I. Plastic Waste Management Strategies and Their Environmental Aspects: A Scientometric Analysis and Comprehensive Review. Int. J. Environ. Res. Public Health 2022, 19, 4556. [Google Scholar] [CrossRef]

- Zakka, W.P.; Lim, N.H.A.S.; Khun, M.C. A scientometric review of geopolymer concrete. J. Clean. Prod. 2020, 280, 124353. [Google Scholar] [CrossRef]

- Udomsap, A.D.; Hallinger, P. A bibliometric review of research on sustainable construction, 1994–2018. J. Clean. Prod. 2020, 254, 120073. [Google Scholar] [CrossRef]

- Yang, H.; Liu, L.; Yang, W.; Liu, H.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A comprehensive overview of geopolymer composites: A bibliometric analysis and literature review. Case Stud. Constr. Mater. 2021, 16, e00830. [Google Scholar] [CrossRef]

- Xu, Y.; Zeng, J.; Chen, W.; Jin, R.; Li, B.; Pan, Z. A holistic review of cement composites reinforced with graphene oxide. Constr. Build. Mater. 2018, 171, 291–302. [Google Scholar] [CrossRef]

- Xiao, X.; Skitmore, M.; Li, H.; Xia, B. Mapping Knowledge in the Economic Areas of Green Building Using Scientometric Analysis. Energies 2019, 12, 3011. [Google Scholar] [CrossRef] [Green Version]

- Darko, A.; Chan, A.P.; Huo, X.; Owusu-Manu, D.-G. A scientometric analysis and visualization of global green building research. Build. Environ. 2018, 149, 501–511. [Google Scholar] [CrossRef]

- Zhang, B.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A scientometric analysis approach to analyze the present research on recycled aggregate concrete. J. Build. Eng. 2021, 46, 103679. [Google Scholar] [CrossRef]

- Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Aslam, F.; Joyklad, P. A scientometric review of waste material utilization in concrete for sustainable construction. Case Stud. Constr. Mater. 2021, 15, e00683. [Google Scholar] [CrossRef]

- Aghaei Chadegani, A.; Salehi, H.; Yunus, M.M.; Farhadi, H.; Fooladi, M.; Farhadi, M.; Ale Ebrahim, N. A comparison between two main academic literature collections: Web of science and scopus databases. Asian Soc. Sci. 2013, 9, 18–26. [Google Scholar] [CrossRef] [Green Version]

- Afgan, S.; Bing, C. Scientometric review of international research trends on thermal energy storage cement based composites via integration of phase change materials from 1993 to 2020. Constr. Build. Mater. 2021, 278, 122344. [Google Scholar] [CrossRef]

- Bergman, E.M.L. Finding Citations to Social Work Literature: The Relative Benefits of Using Web of Science, Scopus, or Google Scholar. J. Acad. Libr. 2012, 38, 370–379. [Google Scholar] [CrossRef] [Green Version]

- Meho, L.I. Using Scopus’s CiteScore for assessing the quality of computer science conferences. J. Inf. 2019, 13, 419–433. [Google Scholar] [CrossRef]

- Zuo, J.; Zhao, Z.-Y. Green building research–current status and future agenda: A review. Renew. Sustain. Energy Rev. 2014, 30, 271–281. [Google Scholar] [CrossRef]

- Darko, A.; Zhang, C.; Chan, A.P. Drivers for green building: A review of empirical studies. Habitat Int. 2017, 60, 34–49. [Google Scholar] [CrossRef]

- Ahmad, W.; Khan, M.; Smarzewski, P. Effect of Short Fiber Reinforcements on Fracture Performance of Cement-Based Materials: A Systematic Review Approach. Materials 2021, 14, 1745. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S.; Abdullah, M.M.A.B.; Razak, R.A.; Vizureanu, P.; Sandu, A.V.; Matasaru, P.-D. A State-of-the-Art Review on Innovative Geopolymer Composites Designed for Water and Wastewater Treatment. Materials 2021, 14, 7456. [Google Scholar] [CrossRef] [PubMed]

- Pal, K.; Sarkar, P.; Anis, A.; Wiszumirska, K.; Jarzębski, M. Polysaccharide-Based Nanocomposites for Food Packaging Applications. Materials 2021, 14, 5549. [Google Scholar] [CrossRef] [PubMed]

- Markoulli, M.P.; Lee, C.I.; Byington, E.; Felps, W.A. Mapping Human Resource Management: Reviewing the field and charting future directions. Hum. Resour. Manag. Rev. 2017, 27, 367–396. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A. A Comprehensive Review of Types, Properties, Treatment Methods and Application of Plant Fibers in Construction and Building Materials. Materials 2022, 15, 4362. [Google Scholar] [CrossRef] [PubMed]

- Maier, D. Building Materials Made of Wood Waste a Solution to Achieve the Sustainable Development Goals. Materials 2021, 14, 7638. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef] [Green Version]

- Park, J.Y.; Nagy, Z. Comprehensive analysis of the relationship between thermal comfort and building control research—A data-driven literature review. Renew. Sustain. Energy Rev. 2017, 82, 2664–2679. [Google Scholar] [CrossRef]

- Oraee, M.; Hosseini, M.R.; Papadonikolaki, E.; Palliyaguru, R.; Arashpour, M. Collaboration in BIM-based construction networks: A bibliometric-qualitative literature review. Int. J. Proj. Manag. 2017, 35, 1288–1301. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2009, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Davtalab, O.; Kazemian, A.; Khoshnevis, B. Perspectives on a BIM-integrated software platform for robotic construction through Contour Crafting. Autom. Constr. 2018, 89, 13–23. [Google Scholar] [CrossRef]

- Azhar, S. Building information modeling (BIM): Trends, benefits, risks, and challenges for the AEC industry. Leadersh. Manag. Eng. 2011, 11. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of Building Information Modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef] [Green Version]

- Wuni, I.Y.; Shen, G.Q.; Osei-Kyei, R. Scientometric review of global research trends on green buildings in construction journals from 1992 to 2018. Energy Build. 2019, 190, 69–85. [Google Scholar] [CrossRef]

- Su, H.-N.; Lee, P.-C. Mapping knowledge structure by keyword co-occurrence: A first look at journal papers in Technology Foresight. Scientometrics 2010, 85, 65–79. [Google Scholar] [CrossRef]

- Duballet, R.; Baverel, O.; Dirrenberger, J. Classification of building systems for concrete 3D printing. Autom. Constr. 2017, 83, 247–258. [Google Scholar] [CrossRef] [Green Version]

- Yu, F.; Hayes, B.E. Applying data analytics and visualization to assessing the research impact of the Cancer Cell Biology (CCB) Program at the University of North Carolina at Chapel Hill. J. E Sci. Librariansh. 2018, 7, 4. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D Printing with Polymers: Challenges among Expanding Options and Opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- Buswell, R.A.; De Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef] [Green Version]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete—A new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef] [Green Version]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques. Mater. Struct. 2015, 49, 1213–1220. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- Schuldt, S.J.; Jagoda, J.A.; Hoisington, A.J.; Delorit, J.D. A systematic review and analysis of the viability of 3D-printed construction in remote environments. Autom. Constr. 2021, 125, 103642. [Google Scholar] [CrossRef]

- Geneidy, O.; Ismaeel, W.S.; Abbas, A. A critical review for applying three-dimensional concrete wall printing technology in Egypt. Arch. Sci. Rev. 2019, 62, 438–452. [Google Scholar] [CrossRef]

- Ahmed, A.; Azam, A.; Bhutta, M.M.A.; Khan, F.A.; Aslam, R.; Tahir, Z. Discovering the technology evolution pathways for 3D printing (3DP) using bibliometric investigation and emerging applications of 3DP during COVID-19. Clean. Environ. Syst. 2021, 3, 100042. [Google Scholar] [CrossRef]

- Zahabizadeh, B.; Pereira, J.; Gonçalves, C.; Pereira, E.N.B.; Cunha, V.M.C.F. Influence of the printing direction and age on the mechanical properties of 3D printed concrete. Mater. Struct. 2021, 54, 73. [Google Scholar] [CrossRef]

- Alchaar, A.S.; Al-Tamimi, A.K. Mechanical properties of 3D printed concrete in hot temperatures. Constr. Build. Mater. 2020, 266, 120991. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Bohuchval, M.; Sonebi, M.; Amziane, S.; Perrot, A. Rheological properties of 3D printing concrete containing sisal fibres. Acad. J. Civ. Eng. 2019, 37, 249–255. [Google Scholar]

- Li, L.; Wei, Y.-J.; Li, Z.; Farooqi, M.U. Rheological and viscoelastic characterizations of fly ash/slag/silica fume-based geopolymer. J. Clean. Prod. 2022, 354, 131629. [Google Scholar] [CrossRef]

- Ziejewska, C.; Marczyk, J.; Korniejenko, K.; Bednarz, S.; Sroczyk, P.; Łach, M.; Mikuła, J.; Figiela, B.; Szechyńska-Hebda, M.; Hebda, M. 3D Printing of Concrete-Geopolymer Hybrids. Materials 2022, 15, 2819. [Google Scholar] [CrossRef] [PubMed]

- Ilcan, H.; Sahin, O.; Kul, A.; Yildirim, G.; Sahmaran, M. Rheological properties and compressive strength of construction and demolition waste-based geopolymer mortars for 3D-Printing. Constr. Build. Mater. 2022, 328, 127114. [Google Scholar] [CrossRef]

- Gustavsson, L.; Sathre, R. Variability in energy and carbon dioxide balances of wood and concrete building materials. Build. Environ. 2006, 41, 940–951. [Google Scholar] [CrossRef]

- Gislason, S.; Bruhn, S.; Breseghello, L.; Sen, B.; Liu, G.; Naboni, R. Lightweight 3D Printed Concrete Beams Show an Environmental Promise: A Cradle-to-Grave Comparative Life Cycle Assessment; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Bedarf, P.; Szabo, A.; Zanini, M.; Heusi, A.; Dillenburger, B. Robotic 3D printing of mineral foam for a lightweight composite concrete slab. In Proceedings of the 27th CAADRIA Conference, Sydney, NSW, Australia, 9–15 April 2022; pp. 61–70. [Google Scholar]

- Mohan, M.K.; Rahul, A.; van Dam, B.; Zeidan, T.; De Schutter, G.; Van Tittelboom, K. Performance criteria, environmental impact and cost assessment for 3D printable concrete mixtures. Resour. Conserv. Recycl. 2022, 181, 106255. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Davtalab, O.; Khoshnevis, B. Computer vision for real-time extrusion quality monitoring and control in robotic construction. Autom. Constr. 2019, 101, 92–98. [Google Scholar] [CrossRef]

- Panda, B.; Tay, Y.W.D.; Paul, S.C.; Tan, M.J. Current challenges and future potential of 3D concrete printing: Aktuelle Herausforderungen und Zukunftspotenziale des 3D-Druckens bei Beton. Mater. Werkst. 2018, 49, 666–673. [Google Scholar] [CrossRef]

- Tay, Y.W.; Panda, B.; Paul, S.C.; Tan, M.J.; Qian, S.Z.; Leong, K.F.; Chua, C.K. Processing and Properties of Construction Materials for 3D Printing. Mater. Sci. Forum 2016, 861, 177–181. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Chu, S.; Ali, M. Properties of hybrid steel-basalt fiber reinforced concrete exposed to different surrounding conditions. Constr. Build. Mater. 2022, 322, 126340. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M.; Ahmed, S. Effectiveness of Calcium Carbonate Whisker in Cementitious Composites. Period. Polytech. Civ. Eng. 2020, 64, 265–275. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.; Cao, M.; Ai, H.; Hussain, A. Basalt Fibers in Modified Whisker Reinforced Cementitious Composites. Period. Polytech. Civ. Eng. 2022, 66, 344–354. [Google Scholar] [CrossRef]

- Xie, C.; Cao, M.; Guan, J.; Liu, Z.; Khan, M. Improvement of boundary effect model in multi-scale hybrid fibers reinforced cementitious composite and prediction of its structural failure behavior. Compos. Part B Eng. 2021, 224, 109219. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M. Effectiveness of multiscale hybrid fiber reinforced cementitious composites under single degree of freedom hydraulic shaking table. Struct. Concr. 2020, 22, 535–549. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Effectiveness of hybrid steel-basalt fiber reinforced concrete under compression. Case Stud. Constr. Mater. 2022, 16, e00941. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Hybrid fiber concrete with different basalt fiber length and content. Struct. Concr. 2021, 23, 346–364. [Google Scholar] [CrossRef]

- Cao, M.; Xie, C.; Li, L.; Khan, M. Effect of different PVA and steel fiber length and content on mechanical properties of CaCO3 whisker reinforced cementitious composites. Mater. Construcción 2019, 69, e200. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.; Cao, M.; Hussain, A.; Chu, S. Effect of silica-fume content on performance of CaCO3 whisker and basalt fiber at matrix interface in cement-based composites. Constr. Build. Mater. 2021, 300, 124046. [Google Scholar] [CrossRef]

- Rouhana, C.M.; Aoun, M.S.; Faek, F.S.; Eljazzar, M.S.; Hamzeh, F.R. The reduction of construction duration by implementing contourontour crafting (3D printing). In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction: Understanding and Improving Project Based Production, IGLC, Oslo, Norway, 25–27 June 2014; pp. 1031–1042. [Google Scholar]

- Wu, P.; Zhao, X.; Baller, J.H.; Wang, X. Developing a conceptual framework to improve the implementation of 3D printing technology in the construction industry. Arch. Sci. Rev. 2018, 61, 133–142. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Verhoef, L.A.; Budde, B.W.; Chockalingam, C.; Nodar, B.G.; van Wijk, A.J. The effect of additive manufacturing on global energy demand: An assessment using a bottom-up approach. Energy Policy 2018, 112, 349–360. [Google Scholar] [CrossRef]

| S/N | Publication Source | Number of Publications | Total Number of Citations |

|---|---|---|---|

| 1 | Automation in Construction | 35 | 1580 |

| 2 | Additive Manufacturing | 39 | 871 |

| 3 | Buildings | 13 | 798 |

| 4 | Lecture Notes in Civil Engineering | 22 | 727 |

| 5 | Materials and Design | 12 | 716 |

| 6 | Advanced Functional Materials | 12 | 381 |

| 7 | Construction and Building Materials | 60 | 309 |

| 8 | Cement and Concrete Research | 20 | 307 |

| 9 | Cement and Concrete Composites | 18 | 165 |

| 10 | Journal of Building Engineering | 12 | 131 |

| 11 | Rapid Prototyping Journal | 22 | 115 |

| 12 | Polymers | 10 | 74 |

| 13 | 3D Printing and Additive Manufacturing | 11 | 71 |

| 14 | Materials | 45 | 56 |

| 15 | Applied Sciences (Switzerland) | 12 | 56 |

| S/N | Keyword | Occurrences |

|---|---|---|

| 1 | 3DPrinters | 558 |

| 2 | Concretes | 272 |

| 3 | 3-D Printing | 209 |

| 4 | 3D Printing | 188 |

| 5 | Concrete Printings | 184 |

| 6 | 3D Concrete Printing | 154 |

| 7 | Additive Manufacturing | 139 |

| 8 | Compressive Strength | 104 |

| 9 | Construction Industry | 89 |

| 10 | Additives | 85 |

| 11 | Rheology | 81 |

| 12 | Concrete | 75 |

| 13 | 3D-Printing | 70 |

| 14 | Concrete Mixtures | 70 |

| 15 | Extrusion | 66 |

| 16 | Yield Stress | 66 |

| 17 | Reinforcement | 61 |

| 18 | Cementitious Materials | 60 |

| 19 | Cements | 58 |

| 20 | Reinforced Concrete | 57 |

| 21 | Mechanical Properties | 55 |

| 22 | Printing | 51 |

| 23 | Mixtures | 50 |

| 24 | Mortar | 50 |

| 25 | Tensile Strength | 50 |

| 26 | Concrete Products | 48 |

| 27 | Concrete Industry | 47 |

| 28 | Construction | 45 |

| 29 | Concrete Construction | 39 |

| 30 | Fly Ash | 37 |

| 31 | Rheological Property | 37 |

| 32 | Portland Cement | 36 |

| 33 | Geopolymers | 35 |

| 34 | Inorganic Polymers | 35 |

| 35 | Digital Fabrication | 34 |

| 36 | Structural Design | 34 |

| 37 | Buildability | 32 |

| 38 | Digital Construction | 30 |

| 39 | Sustainable Development | 30 |

| 40 | Mechanical Performance | 28 |

| 41 | Geopolymer | 27 |

| 42 | Hardening | 27 |

| 43 | Shrinkage | 26 |

| 44 | Fabrication | 25 |

| 45 | Cement Based Material | 24 |

| 46 | Concrete Buildings | 24 |

| 47 | Fibers | 24 |

| 48 | Anisotropy | 23 |

| 49 | Binders | 23 |

| 50 | Concrete Additives | 22 |

| S/N | Article | Title | Total Number of Citations Received |

|---|---|---|---|

| 1 | Ngo, Kashani, Imbalzano, Nguyen and Hui [26] | Additive manufacturing (3D printing): A review of materials, methods, applications and challenges | 2520 |

| 2 | Stansbury and Idacavage [61] | 3D printing with polymers: Challenges among expanding options and opportunities | 793 |

| 3 | Buswell, De Silva, Jones and Dirrenberger [62] | 3D printing using concrete extrusion: A roadmap for research | 466 |

| 4 | Bos, et al. [63] | Additive manufacturing of concrete in construction: potentials and challenges of 3D concrete printing | 453 |

| 5 | Gosselin, et al. [64] | Large-scale 3D printing of ultra-high performance concrete—a new processing route for architects and builders | 424 |

| 6 | Perrot, et al. [65] | Structural built-up of cement-based materials used for 3D-printing extrusion techniques | 384 |

| 7 | Tay, Panda, Paul, Noor Mohamed, Tan and Leong [53] | 3D printing trends in building and construction industry: a review | 310 |

| 8 | De Schutter, et al. [66] | Vision of 3D printing with concrete—Technical, economic and environmental potentials | 305 |

| 9 | Kazemian, et al. [67] | Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture | 285 |

| 10 | Wolfs, et al. [68] | Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing | 284 |

| S/N | Country | Number of Publications | Total Number of Citations |

|---|---|---|---|

| 1 | China | 377 | 6179 |

| 2 | United States | 348 | 10,514 |

| 3 | Germany | 148 | 2813 |

| 4 | United Kingdom | 114 | 2540 |

| 5 | Australia | 113 | 3435 |

| 6 | Singapore | 72 | 2725 |

| 7 | India | 70 | 433 |

| 8 | Russian Federation | 69 | 132 |

| 9 | South Korea | 67 | 1268 |

| 10 | France | 58 | 1807 |

| 11 | Italy | 57 | 1022 |

| 12 | Netherlands | 56 | 1958 |

| 13 | Poland | 56 | 466 |

| 14 | Spain | 41 | 362 |

| 15 | Canada | 37 | 978 |

| 16 | Belgium | 30 | 698 |

| 17 | Brazil | 28 | 338 |

| 18 | Japan | 28 | 502 |

| 19 | Switzerland | 28 | 1557 |

| 20 | Hong Kong | 26 | 220 |

| 21 | Czech Republic | 25 | 113 |

| 22 | Portugal | 23 | 251 |

| 23 | South Africa | 21 | 382 |

| 24 | Norway | 20 | 540 |

| 25 | United Arab Emirates | 20 | 279 |

| 26 | Romania | 18 | 48 |

| 27 | Taiwan | 17 | 111 |

| 28 | Greece | 16 | 400 |

| 29 | Iran | 16 | 228 |

| 30 | Turkey | 15 | 50 |

| 31 | Austria | 14 | 70 |

| 32 | Malaysia | 13 | 110 |

| 33 | Denmark | 12 | 518 |

| 34 | Sweden | 12 | 60 |

| 35 | Finland | 11 | 56 |

| 36 | Chile | 10 | 35 |

| 37 | Lebanon | 10 | 119 |

| 38 | Saudi Arabia | 10 | 229 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, C.; Zhang, S.; Liang, Y.; Ahmad, W.; Althoey, F.; Alyami, S.H.; Javed, M.F.; Deifalla, A.F. A Scientometric Review on Mapping Research Knowledge for 3D Printing Concrete. Materials 2022, 15, 4796. https://doi.org/10.3390/ma15144796

He C, Zhang S, Liang Y, Ahmad W, Althoey F, Alyami SH, Javed MF, Deifalla AF. A Scientometric Review on Mapping Research Knowledge for 3D Printing Concrete. Materials. 2022; 15(14):4796. https://doi.org/10.3390/ma15144796

Chicago/Turabian StyleHe, Chuan, Shiyu Zhang, Youwang Liang, Waqas Ahmad, Fadi Althoey, Saleh H. Alyami, Muhammad Faisal Javed, and Ahmed Farouk Deifalla. 2022. "A Scientometric Review on Mapping Research Knowledge for 3D Printing Concrete" Materials 15, no. 14: 4796. https://doi.org/10.3390/ma15144796