Surface Morphology of Textured Transparent Conductive Oxide Thin Film Seen by Various Probes: Visible Light, X-rays, Electron Scattering and Contact Probe

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Transmission Electron Microscopy and Selected Area Electron Diffraction (TEM/SEAD)

2.3. Atomic Force Microscopy (AFM)

2.4. Grazing Incidence Small Angle X-ray Scattering (GISAXS)

2.5. UV-Vis-NIR Transmittance

3. Results and Discussion

3.1. TEM/SAED

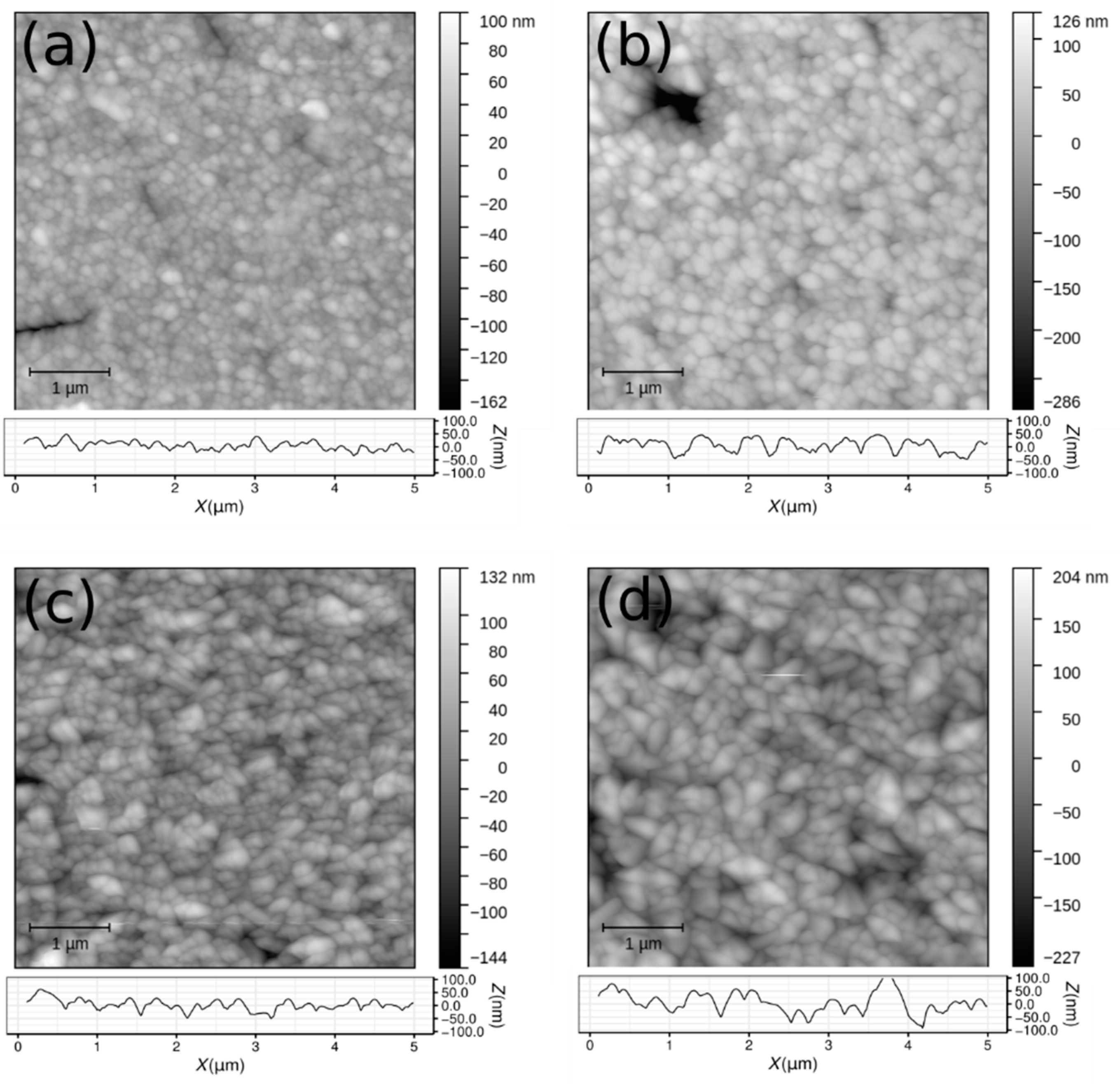

3.2. Atomic Force Microscopy

3.3. Grazing Incidence Small Angle X-ray Scattering

3.4. Optical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Aguir, K.; Bernardini, S.; Lawson, B.; Fiorido, T. Trends in Metal Oxide Thin Films: Synthesis and Applications of Tin Oxide. In Tin Oxide Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 219–246. ISBN 978-0-12-815924-8. [Google Scholar]

- Afre, R.A.; Sharma, N.; Sharon, M.; Sharon, M. Transparent Conducting Oxide Films for Various Applications: A Review. Rev. Adv. Mater. Sci. 2018, 53, 79–89. [Google Scholar] [CrossRef]

- Andersson, A.; Johansson, N.; Bröms, P.; Yu, N.; Lupo, D.; Salaneck, W.R. Fluorine Tin Oxide as an Alternative to Indium Tin Oxide in Polymer LEDs. Adv. Mater. 1998, 10, 859–863. [Google Scholar] [CrossRef]

- Hosono, H.; Ohta, H.; Orita, M.; Ueda, K.; Hirano, M. Frontier of Transparent Conductive Oxide Thin Films. Vacuum 2002, 66, 419–425. [Google Scholar] [CrossRef]

- Hosono, H.; Ueda, K. Transparent Conductive Oxides. In Springer Handbook of Electronic and Photonic Materials; Kasap, S., Capper, P., Eds.; Springer International Publishing: Cham, Switzerland, 2017; p. 1. ISBN 978-3-319-48931-5. [Google Scholar]

- Yu, S.; Yang, W.; Li, L.; Zhang, W. Improved Chemical Stability of ITO Transparent Anodes with a SnO2 Buffer Layer for Organic Solar Cells. Sol. Energy Mater. Sol. Cells 2016, 144, 652–656. [Google Scholar] [CrossRef]

- Dalapati, G.K.; Sharma, H.; Guchhait, A.; Chakrabarty, N.; Bamola, P.; Liu, Q.; Saianand, G.; Sai Krishna, A.M.; Mukhopadhyay, S.; Dey, A.; et al. Tin Oxide for Optoelectronic, Photovoltaic and Energy Storage Devices: A Review. J. Mater. Chem. A 2021, 9, 16621–16684. [Google Scholar] [CrossRef]

- Schropp, R.E.I.; Zeman, M. Amorphous and Microcrystalline Silicon Solar Cells; Springer: New York, NY, USA, 2016; ISBN 978-1-4615-5631-2. [Google Scholar]

- Jiang, Q.; Zhang, X.; You, J. SnO2: A Wonderful Electron Transport Layer for Perovskite Solar Cells. Small 2018, 14, 1801154. [Google Scholar] [CrossRef]

- Lin, J.; He, Y.; Chen, W.; Ng, A.M.C.; Djurišić, A.B. Characterizations of Tin Oxide Thin Films Prepared by Different Methods for Perovskite Solar Cell Applications. In Proceedings of the Oxide-based Materials and Devices XIII, San Francisco, CA, USA, 22 January–28 February 2022; Teherani, F.H., Rogers, D.J., Eds.; SPIE: San Francisco, CA, USA, 2022; p. 52. [Google Scholar]

- Milan, R.; Singh Selopal, G.; Cavazzini, M.; Orlandi, S.; Boaretto, R.; Caramori, S.; Concina, I.; Pozzi, G. Zinc Phthalocyanines as Light Harvesters for SnO2-Based Solar Cells: A Case Study. Sci. Rep. 2020, 10, 1176. [Google Scholar] [CrossRef] [Green Version]

- Shen, P.; Yao, M.; Wang, G.; Mi, R.; Guo, W.; Bai, Y.; Shen, L. High-Efficiency Polymer Solar Cells with Low Temperature Solution-Processed SnO 2 /PFN as a Dual-Function Electron Transporting Layer. J. Mater. Chem. A 2018, 6, 17401–17408. [Google Scholar] [CrossRef]

- Roos, A.; Rönnow, D. Diffuse Reflectance and Transmittance Spectra of an Interference Layer: 1 Model Formulation and Properties. Appl. Opt. 1994, 33, 7908. [Google Scholar] [CrossRef]

- Zhang, S.-T.; Vitrant, G.; Pernot, E.; Jiménez, C.; Muñoz-Rojas, D.; Bellet, D. Hazy Al2O3-FTO Nanocomposites: A Comparative Study with FTO-Based Nanocomposites Integrating ZnO and S:TiO2 Nanostructures. Nanomaterials 2018, 8, 440. [Google Scholar] [CrossRef] [Green Version]

- Mahmood, A.; Wang, J. A Review of Grazing Incidence Small- and Wide-Angle X-Ray Scattering Techniques for Exploring the Film Morphology of Organic Solar Cells. Sol. RRL 2020, 4, 2000337. [Google Scholar] [CrossRef]

- Sedin, D.L.; Rowlen, K.L. Influence of Tip Size on AFM Roughness Measurements. Appl. Surf. Sci. 2001, 182, 40–48. [Google Scholar] [CrossRef]

- Juraić, K.; Čulo, M.; Rapljenović, Ž.; Plaisier, J.R.; Siketić, Z.; Pavić, L.; Bohač, M.; Hodzic, A.; Gracin, D. Structural Origin of Magnetotransport Properties in APCVD Deposited Single and Bi-Layer Tin Oxide Thin Films. Materials 2020, 13, 5182. [Google Scholar] [CrossRef] [PubMed]

- Nečas, D.; Klapetek, P. Gwyddion: An Open-Source Software for SPM Data Analysis. Open Phys. 2012, 10, 181–188. [Google Scholar] [CrossRef]

- Amenitsch, H.; Bernstorff, S.; Laggner, P. High-flux Beamline for Small-angle X-ray Scattering at ELETTRA. Rev. Sci. Instrum. 1995, 66, 1624–1626. [Google Scholar] [CrossRef]

- Juraić, K.; Plodinec, M.; Kereković, I.; Meljanac, D.; Mandić, V.; Gracin, D.; Janicki, V.; Bernstorff, S.; Čeh, M.; Hodzic, A.; et al. Modelling of Simultaneously Obtained Small and Wide Angle Synchrotron-Radiation Scattering Depth Profiles of Ordered Titania Nanotube Thin Films. Mater. Chem. Phys. 2019, 240, 122155. [Google Scholar] [CrossRef]

- Jin, Y.; Song, B.; Jia, Z.; Zhang, Y.; Lin, C.; Wang, X.; Dai, S. Improvement of Swanepoel Method for Deriving the Thickness and the Optical Properties of Chalcogenide Thin Films. Opt. Express 2017, 25, 440. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; W.H. Freeman: San Francisco, CA, USA, 1982; ISBN 978-0-7167-1186-5. [Google Scholar]

- Mandelbrot, B.B. Fractals and Chaos: The Mandelbrot Set and Beyond: Selecta Volume C; Springer: New York, NY, USA, 2004; ISBN 978-0-387-20158-0. [Google Scholar]

- Douketis, C.; Wang, Z.; Haslett, T.L.; Moskovits, M. Fractal Character of Cold-Deposited Silver Films Determined by Low-Temperature Scanning Tunneling Microscopy. Phys. Rev. B 1995, 51, 11022–11031. [Google Scholar] [CrossRef]

- Mannelquist, A.; Almqvist, N.; Fredriksson, S. Influence of Tip Geometry on Fractal Analysis of Atomic Force Microscopy Images. Appl. Phys. A 1998, 66, S891–S895. [Google Scholar] [CrossRef]

- Sayles, R.S.; Thomas, T.R. The Spatial Representation of Surface Roughness by Means of the Structure Function: A Practical Alternative to Correlation. Wear 1977, 42, 263–276. [Google Scholar] [CrossRef]

- Wu, J.-J. Analyses and Simulation of Anisotropic Fractal Surfaces. Chaos Solitons Fractals 2002, 13, 1791–1806. [Google Scholar] [CrossRef]

- Wong, P.C.Y.; Kwon, Y.-N.; Criddle, C.S. Use of Atomic Force Microscopy and Fractal Geometry to Characterize the Roughness of Nano-, Micro-, and Ultrafiltration Membranes. J. Membr. Sci. 2009, 340, 117–132. [Google Scholar] [CrossRef]

- Yoneda, Y. Anomalous Surface Reflection of X Rays. Phys. Rev. 1963, 131, 2010–2013. [Google Scholar] [CrossRef]

- Craievich, A.F. Small-Angle X-Ray Scattering by Nanostructured Materials. In Handbook of Sol-Gel Science and Technology; Klein, L., Aparicio, M., Jitianu, A., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 1–46. ISBN 978-3-319-19454-7. [Google Scholar]

- Bale, H.D.; Schmidt, P.W. Small-Angle X-Ray-Scattering Investigation of Submicroscopic Porosity with Fractal Properties. Phys. Rev. Lett. 1984, 53, 596–599. [Google Scholar] [CrossRef]

- Lazzari, R.; Leroy, F.; Renaud, G. Grazing-Incidence Small-Angle X-ray Scattering from Dense Packing of Islands on Surfaces: Development of Distorted Wave Born Approximation and Correlation between Particle Sizes and Spacing. Phys. Rev. B 2007, 76, 125411. [Google Scholar] [CrossRef]

- Dehghani, Z.; Shadrokh, Z.; Nadafan, M. The Effect of Magnetic Metal Doping on the Structural and the Third-Order Nonlinear Optical Properties of ZnS Nanoparticles. Optik 2017, 131, 925–931. [Google Scholar] [CrossRef]

- Humphrey, S. Direct Calculation of the Optical Constants for a Thin Film Using a Midpoint Envelope. Appl. Opt. 2007, 46, 4660. [Google Scholar] [CrossRef]

- Doyan, A.; Susilawati; Muliyadi, L.; Hakim, S.; Munandar, H.; Taufik, M. The Effect of Dopant Material to Optical Properties: Energy Band Gap Tin Oxide Thin Film. J. Phys. Conf. Ser. 2021, 1816, 012114. [Google Scholar] [CrossRef]

- Gracin, D.; Juraic, K.; Bogdanovic-Radovic, I. Estimation of Amorphous Silicon Thin Film Density by Optical Methods. Vacuum 2005, 80, 146–150. [Google Scholar] [CrossRef]

- Shokhovets, S.; Goldhahn, R.; Cimalla, V.; Cheng, T.S.; Foxon, C.T. Reflectivity Study of Hexagonal GaN Films Grown on GaAs: Surface Roughness, Interface Layer, and Refractive Index. J. Appl. Phys. 1998, 84, 1561–1566. [Google Scholar] [CrossRef]

| Sample Name | Sample Type | Deposition Temperature (°C) | Thickness UV-Vis-NIR (nm) | Thickness TEM (nm) |

|---|---|---|---|---|

| S-610 | undoped single layer | 610 | 300 ± 22 | 308 ± 18 |

| S-590 | undoped single layer | 590 | 390 ± 38 | 270 ± 40 |

| B-610 | undoped/doped bilayer | 610 | 710 ± 30 | 582 ± 51 |

| B-590 | undoped/doped bilayer | 590 | 920 ± 47 | 811 ± 36 |

| Sample | Surface Roughness | Zmax−Zmin [nm] | Fractal Dimension | |||

|---|---|---|---|---|---|---|

| σq [nm] | σa [nm] | Variance | Cube Counting | Triangulation | ||

| S-610 | 19.3 | 13.7 | 319 | 2.58 | 2.29 | 2.37 |

| S-590 | 40.2 | 28.4 | 444 | 2.65 | 2.37 | 2.47 |

| B-610 | 29.2 | 22.0 | 458 | 2.67 | 2.43 | 2.54 |

| B-590 | 43.9 | 34.2 | 414 | 2.61 | 2.37 | 2.49 |

| Sample Name | Eg (eV) | neff | σopt (nm) |

|---|---|---|---|

| S-610 | 3.4 ± 0.1 | 2.5 ± 0.1 | 21.8 |

| S-590 | 3.5 ± 0.1 | 2.9± 0.1 | 38.1 |

| B-610 | 3.3 ± 0.1 | 2.2± 0.1 | 29.7 |

| B-590 | 3.3± 0.1 | 2.4± 0.1 | 46.9 |

| Experimental Technique | Information Provided by Analysis | Size of Sample Area Analysed | Resolution | Pros | Cons |

|---|---|---|---|---|---|

| TEM | thickness, roughness, crystallinity, surface profile | Only 1D line 1–10 μm | 1 nm | In-depth profile of sample | Pure statistics, complicated sample preparation |

| AFM | Only top surface morphology, roughness, fractal dimension | 1–10 μm squared area | 10 nm | Image of large area sample surface | Finite tip size |

| GISAXS | Shapes at the surface, fractal dimensions | 5 × 50 mm | 1 nm | Good statistics over large area of sample | Information in reciprocal space |

| TR | Roughness, thickness | 10 × 10 mm | 100–1000 nm | Simple and not expensive technique |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juraić, K.; Dubček, P.; Bohač, M.; Gajović, A.; Bernstorff, S.; Čeh, M.; Hodzic, A.; Gracin, D. Surface Morphology of Textured Transparent Conductive Oxide Thin Film Seen by Various Probes: Visible Light, X-rays, Electron Scattering and Contact Probe. Materials 2022, 15, 4814. https://doi.org/10.3390/ma15144814

Juraić K, Dubček P, Bohač M, Gajović A, Bernstorff S, Čeh M, Hodzic A, Gracin D. Surface Morphology of Textured Transparent Conductive Oxide Thin Film Seen by Various Probes: Visible Light, X-rays, Electron Scattering and Contact Probe. Materials. 2022; 15(14):4814. https://doi.org/10.3390/ma15144814

Chicago/Turabian StyleJuraić, Krunoslav, Pavo Dubček, Mario Bohač, Andreja Gajović, Sigrid Bernstorff, Miran Čeh, Aden Hodzic, and Davor Gracin. 2022. "Surface Morphology of Textured Transparent Conductive Oxide Thin Film Seen by Various Probes: Visible Light, X-rays, Electron Scattering and Contact Probe" Materials 15, no. 14: 4814. https://doi.org/10.3390/ma15144814