An Experimental Study of the Mechanical Properties of Partially Rehabilitated Cable Tunnels

Abstract

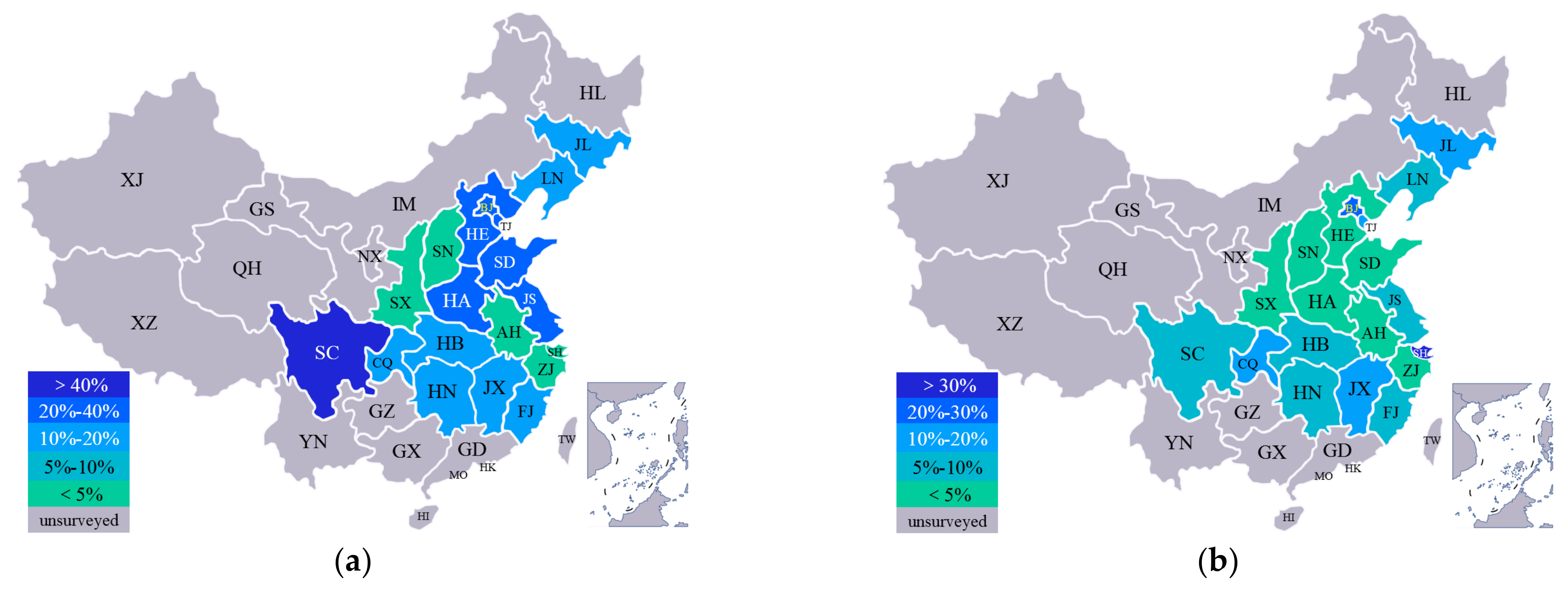

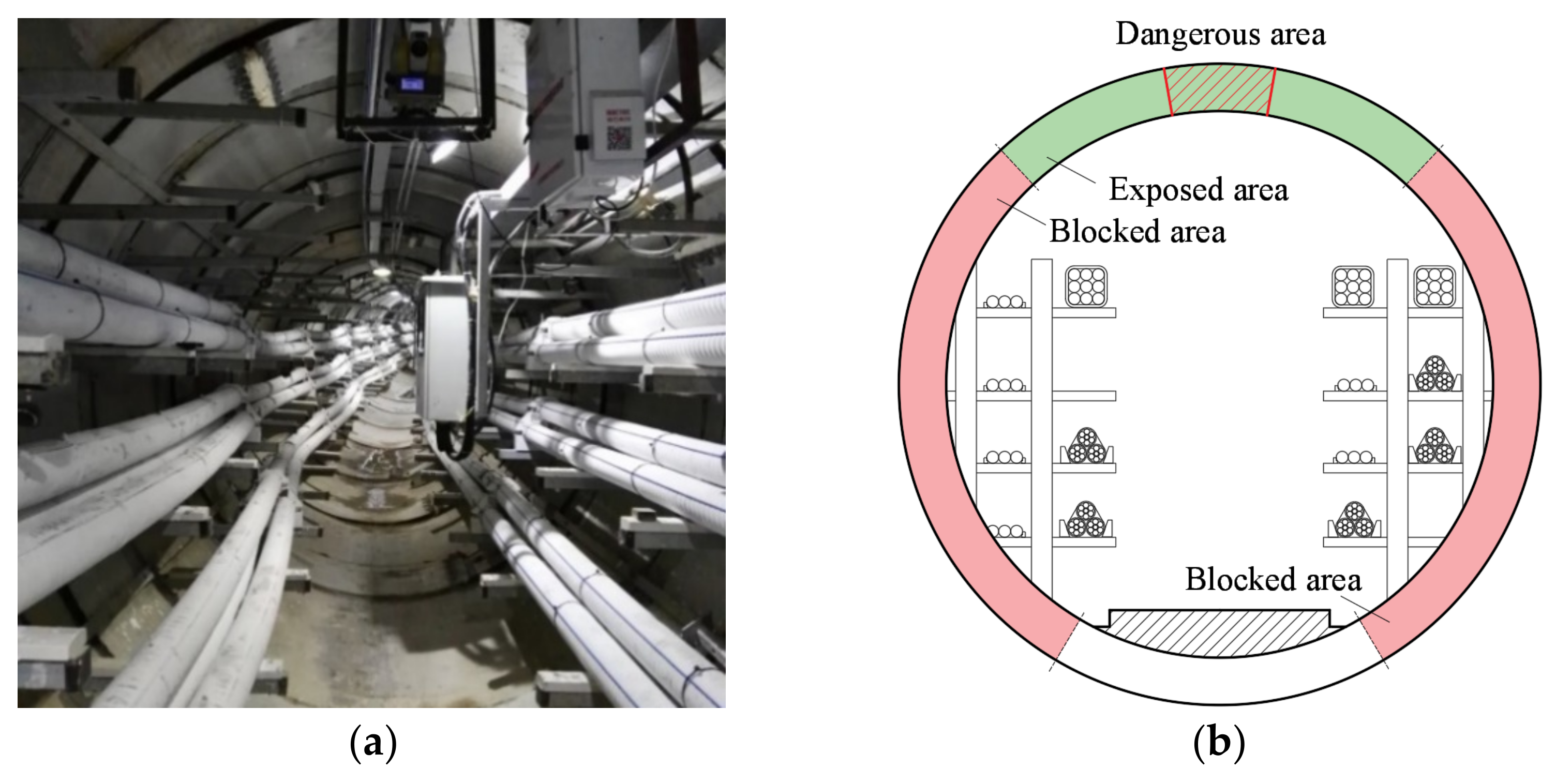

:1. Introduction

2. Experimental Study

2.1. Test Regime

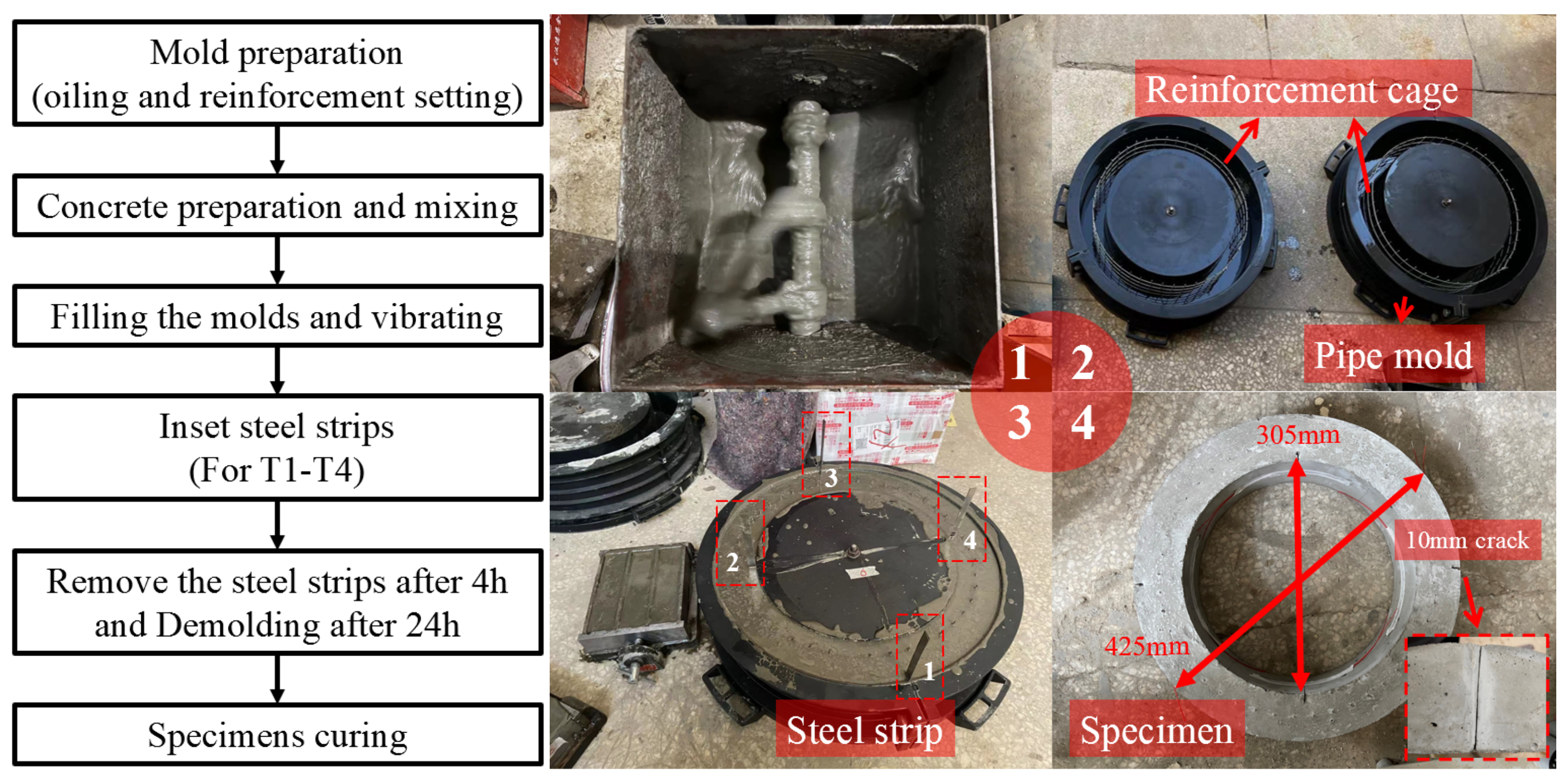

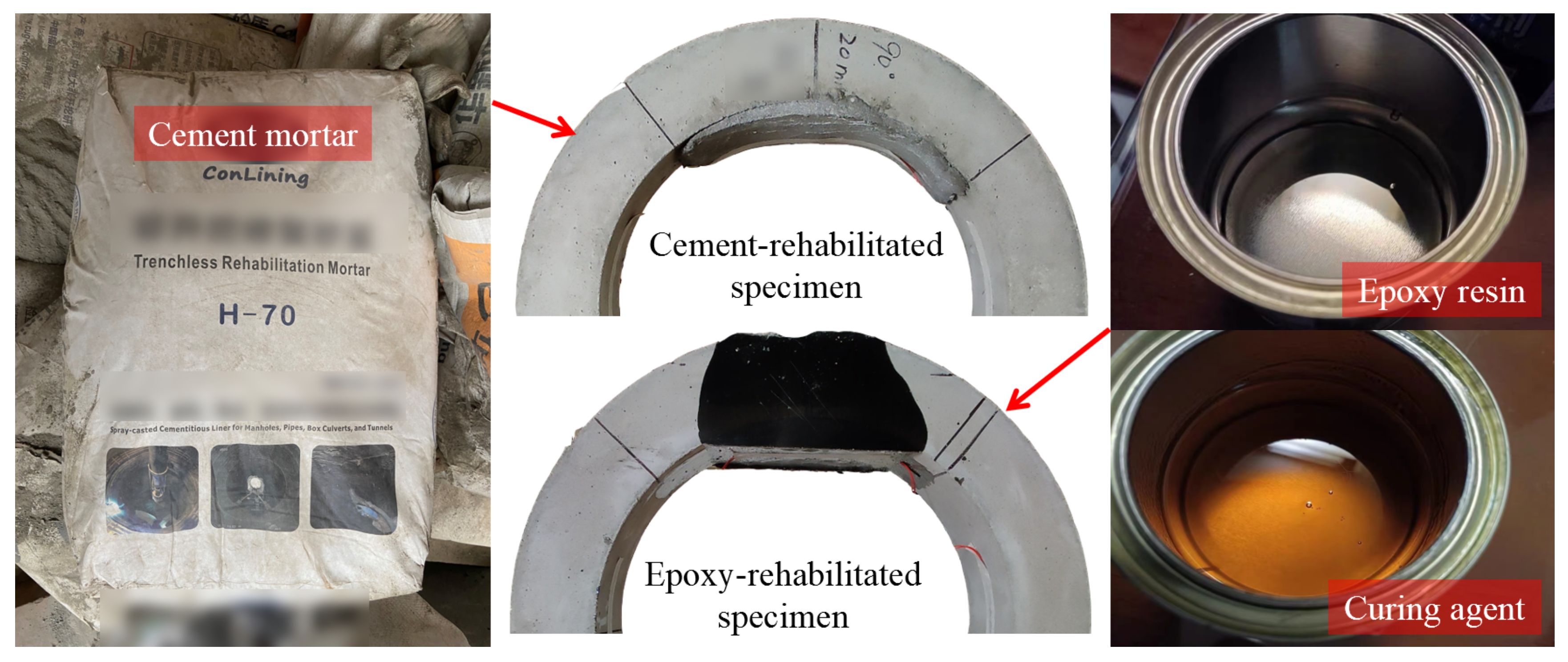

2.2. Specimen and Instruments

2.2.1. Pipe Specimens

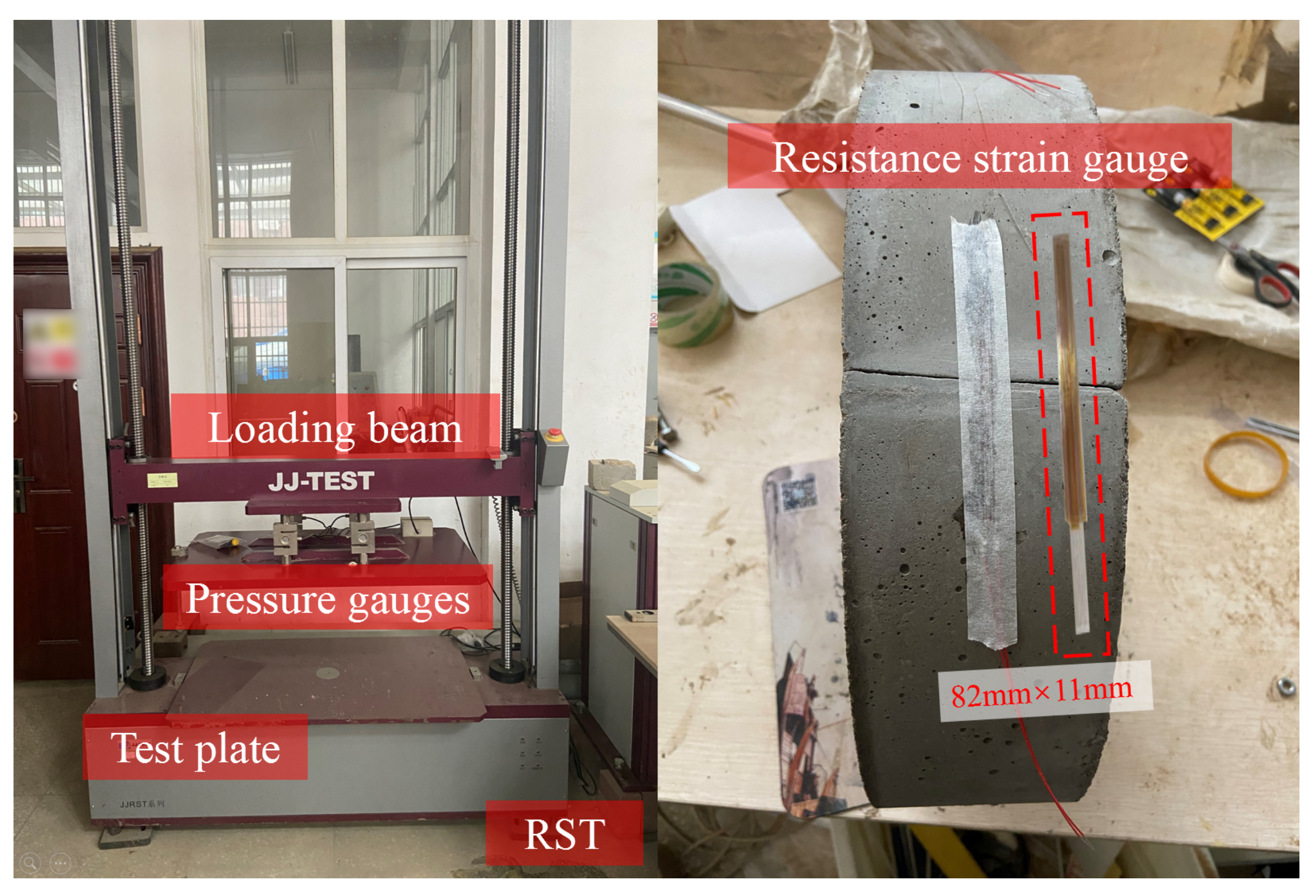

2.2.2. Test Instruments

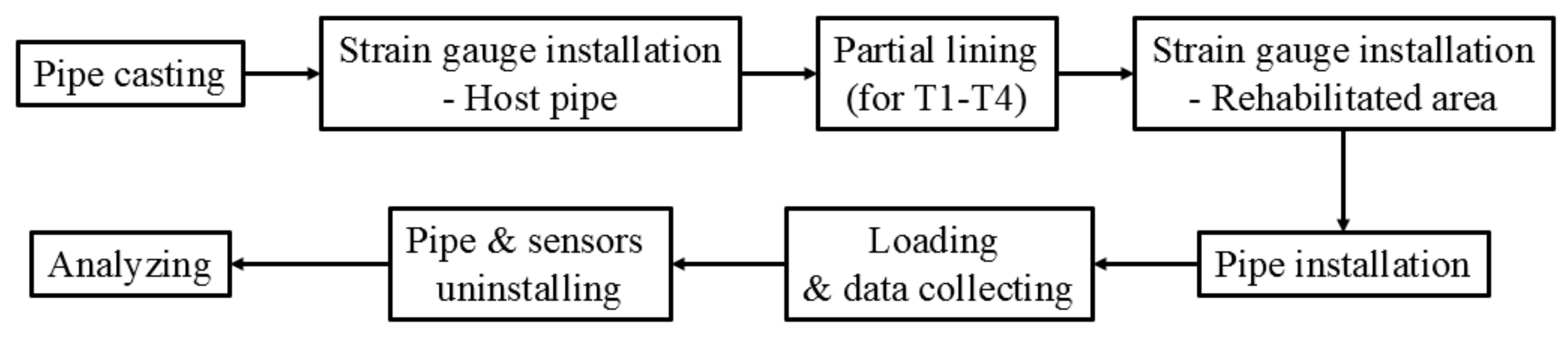

2.3. Test Procedures

2.3.1. Strain Gauge Installation

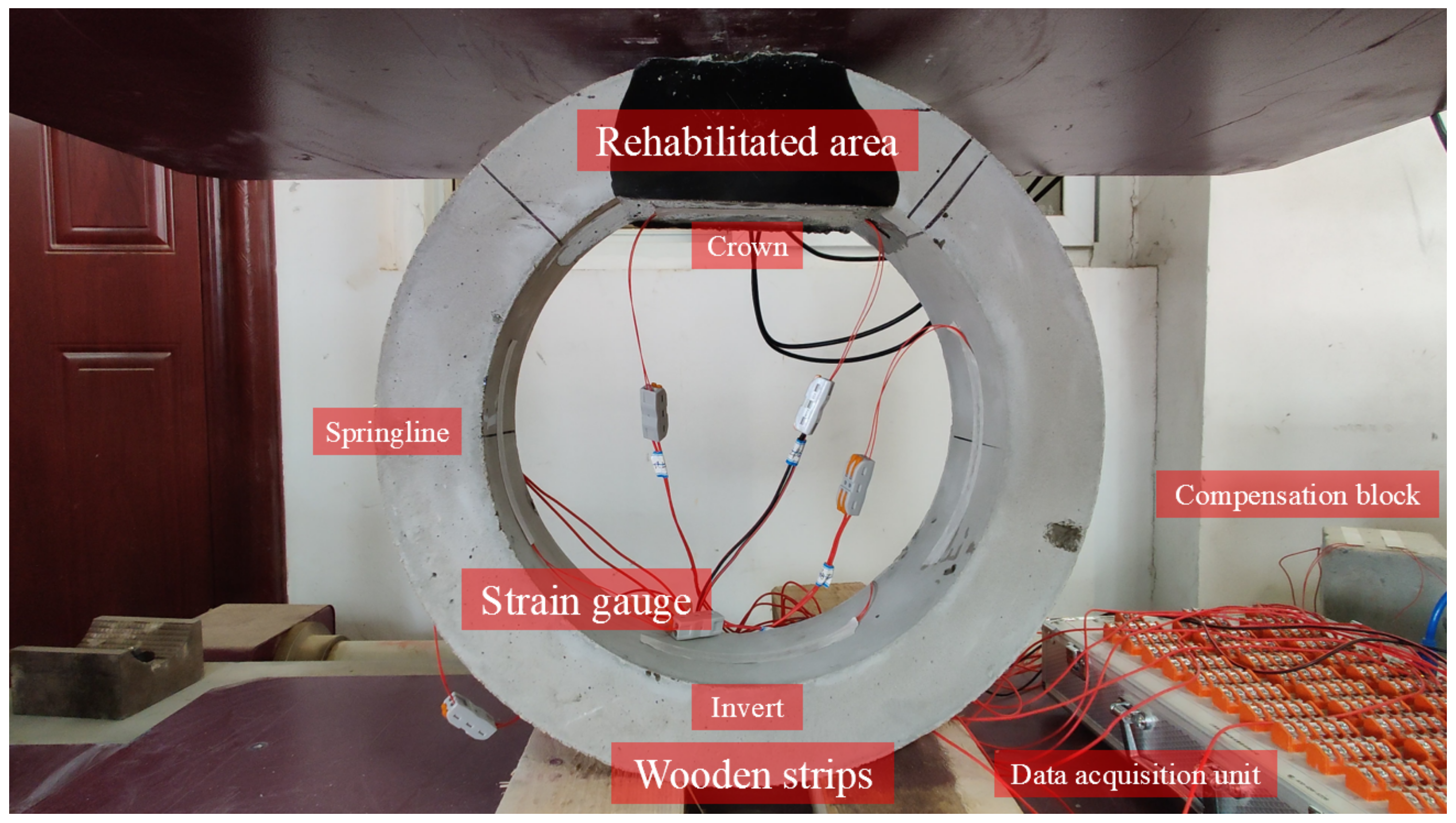

2.3.2. Pipe Installation

2.3.3. Loading

3. Results and Analysis

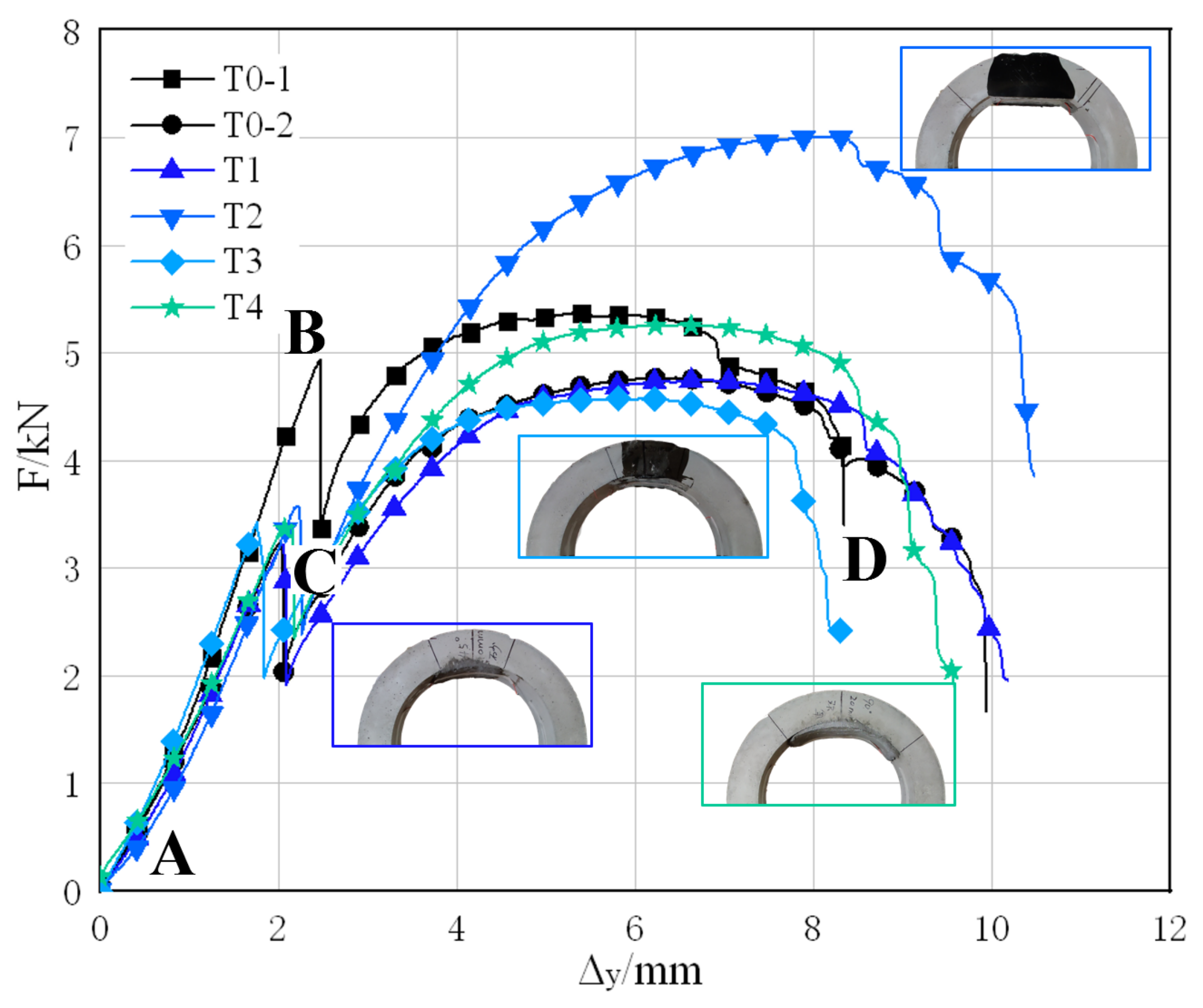

3.1. Load-Displacement Curves

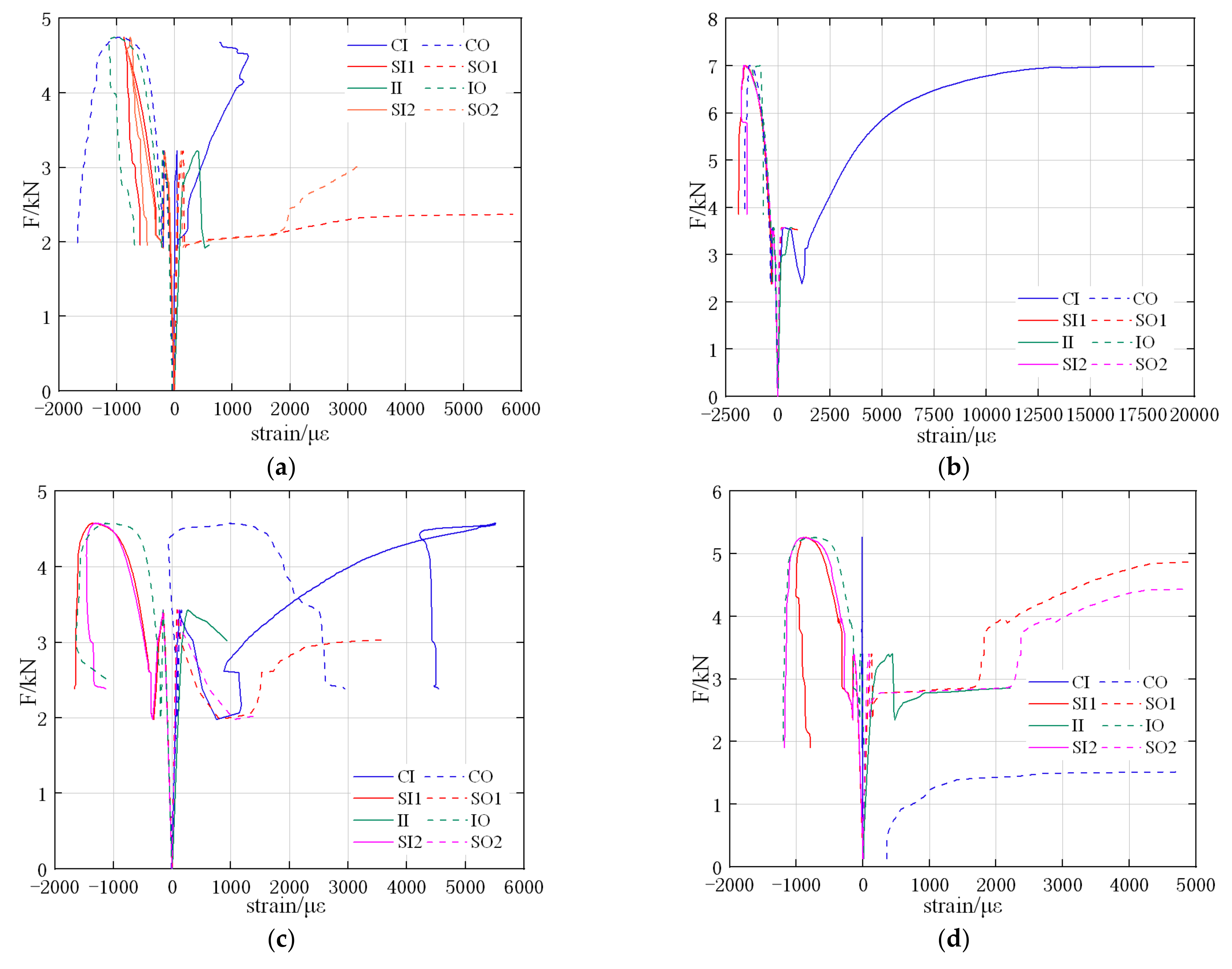

3.2. Load-Strain Curves

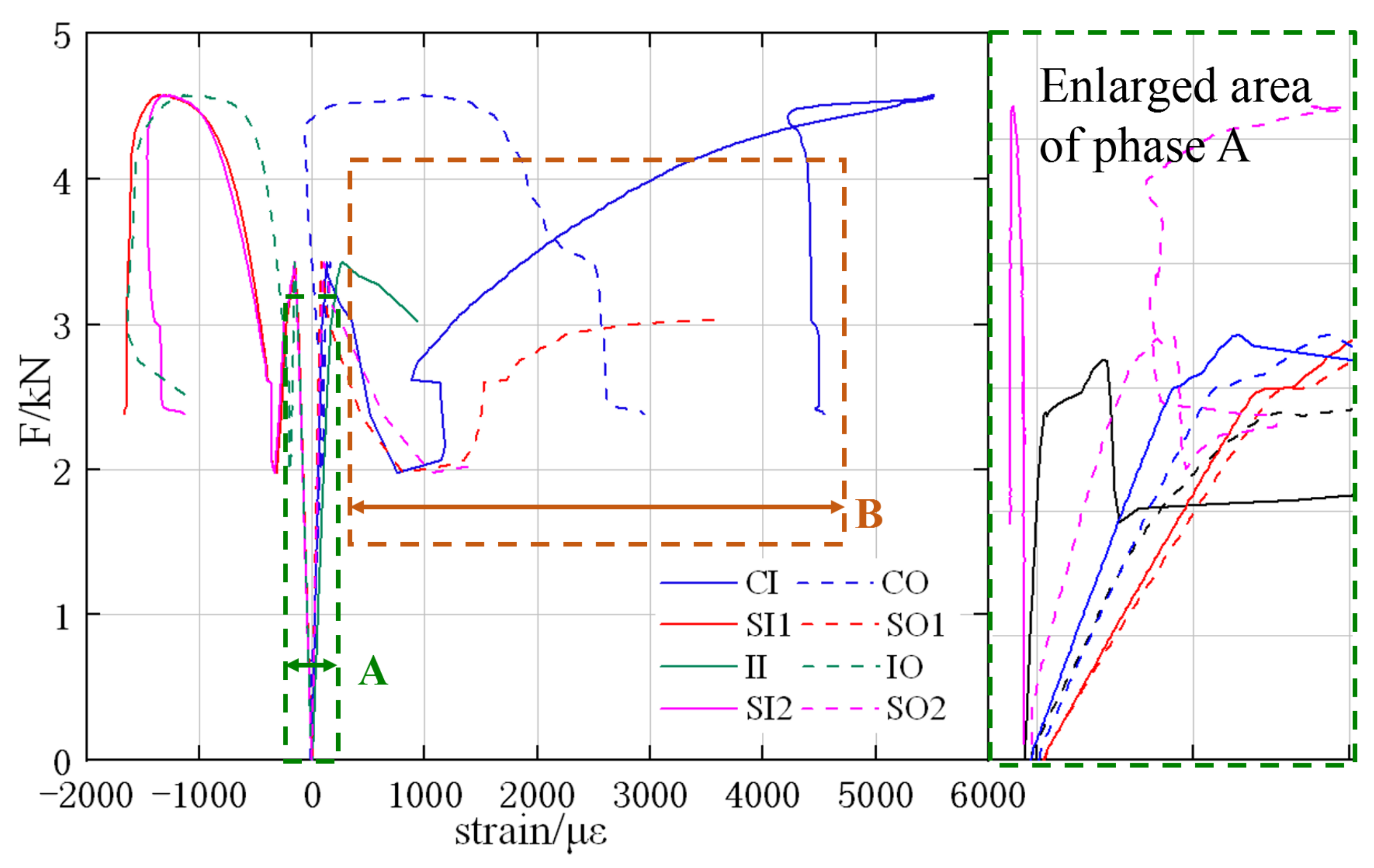

3.3. The Deforming Compatibility of the Partial Liner and the Pipe

3.4. The Flexural Rigidity Increasing of the Partial Lined Section

4. Conclusions

- (1)

- Structural problems such as cracking and corroding are common in municipal tunnels, such as cable tunnels, in major cities in central and eastern China. However, the pipelines, shelves, and other auxiliary facilities in the tunnel will shelter the lateral walls, making it difficult to rehabilitate an intact ring with traditional trenchless methods—partial lining is a feasible, potential method for rehabilitating these structures;

- (2)

- The results of TEBTs for partial lining rehabilitated RCPs indicate that applying the appropriate material and dimensions of a partial liner can effectively improve the load-carrying capacity of RCPs. The failure load of RCP specimens rehabilitated with partial ER lining increased by 46.96% compared to the defected RCP, which is 30.54% higher than the failure load of an intact pipe. The failure load of RCPs rehabilitated with CM partial lining also increased by 10.27%, basically restored to the level of an intact pipe;

- (3)

- As the lining material, epoxy resin has a better deforming compatibility with the original pipe, while the cement mortar liner will gradually separate from the pipe as the is crack propagating, thus, using the fiber reinforced cement mortar (FRCM) is a better solution to improve the tensile strength and the bonding quality of the liner. Besides, a larger lining thickness and lining range can also strengthen the interface performance between the liner and the pipe, making them work in better coordination;

- (4)

- The flexural rigidities of all rehabilitated sections reach 1.6–9.3 times that of the defective section, even for those groups whose load-carrying capacity is not significantly improved, their flexural rigidities also obviously increase after the partial lining rehabilitation;

- (5)

- According to the comprehensive results of TEBTs and analysis, the partial lining method is feasible for structural rehabilitation in municipal tunnels. It is also a convenient, environmentally friendly, and cost-efficient method, and it has the value of being popularized. At present, the research on this method is still blank; how to further improve the load-carrying capacity of the liner-pipe composite structure and design the dimensional parameters of the partial liner is also a good research interest with great potential.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, M.; He, L.; Ma, B.; Wang, T.; Zhu, Z. Structure Failure and Rehabilitation Technologies of the Cable Tunnel. Bull. Geo. Sci. Tech. 2020, 39, 31–37. (In Chinese) [Google Scholar]

- Ma, B.S. Trenchless Pipeline Rehabilitation and Renewal Technology; China Communications Press: Beijing, China, 2014. [Google Scholar]

- Jiang, Y.J.; Xu, Y.; Peng, C.; Bin, L.; Rong, R. Discussion on the Defects and Its Inspection and Evaluation Methods for Power Cable Tunnels. Chin. J. Undergr. Space Eng. 2019, 15, 311–318. (In Chinese) [Google Scholar]

- Chen, X.X.; Li, G.F.; Wu, Q.B. Classification and Prevent Method of Common Diseases in the Electric Power Tunnel. Elect. Pow. Surv. Des. 2015, 2, 10–14. (In Chinese) [Google Scholar]

- Wang, J.J.; Yuan, W.H.; Liu, Y.; Guo, J. Development Present Situation and the Analysis of Common Disasters of Existing Electric Power Tunnel in Beijing. Constr. Qual. 2016, 34, 75–78. (In Chinese) [Google Scholar]

- Ma, B.S. The Science of Trenchless Engineering; China Communications Press: Beijing, China, 2008. [Google Scholar]

- Najafi, M. Trenchless Technology Piping; ASCE Press: Reston, VA, USA, 2010. [Google Scholar]

- Bae, S.-H.; Lee, J.-I.; Choi, S.-J. Characteristics of Mortars with Blast Furnace Slag Powder and Mixed Fine Aggregates Containing Ferronickel-Slag Aggregate. Materials 2021, 14, 5879. [Google Scholar] [CrossRef]

- Cobos, R.B.; Pinto, F.T.; Moreno, M.S. Analysis of the Influence of Crystalline Admixtures at Early Age Performance of Cement-Based Mortar by Electrical Resistance Monitoring. Materials 2021, 14, 5705. [Google Scholar] [CrossRef]

- Fayed, E.K.; El-Hosiny, F.I.; El-Kattan, I.M.; Al-Kroom, H.; Elrahman, M.A.; Abdel-Gawwad, H.A. An Innovative Method for Sustainable Utilization of Blast-Furnace Slag in the Cleaner Production of One-Part Hybrid Cement Mortar. Materials 2021, 14, 5669. [Google Scholar] [CrossRef]

- Li, Y.-F.; Wang, H.-F.; Syu, J.-Y.; Ramanathan, G.K.; Tsai, Y.-K.; Lok, M.H. Mechanical Properties of Aramid/Carbon Hybrid Fiber-Reinforced Concrete. Materials 2021, 14, 5881. [Google Scholar] [CrossRef]

- Haroon, M.; Moon, J.S.; Kim, C. Performance of Reinforced Concrete Beams Strengthened with Carbon Fiber Reinforced Polymer Strips. Materials 2021, 14, 5866. [Google Scholar] [CrossRef]

- Shi, F.; Li, T.; Wang, W.; Liu, R.; Liu, X.; Tian, H.; Liu, N. Research on the Effect of Desert Sand on Pore Structure of Fiber Reinforced Mortar Based on X-CT Technology. Materials 2021, 14, 5572. [Google Scholar] [CrossRef]

- Li, J.; Huang, B.; Shen, J.; Yi, J.; Jia, Y.; Xue, R.; Wang, G. Anisotropic Mechanical Response and Strain Localization of a Metallic Glassy-Fiber-Reinforced Polyethylene Terephthalate Fabric. Materials 2021, 14, 5619. [Google Scholar] [CrossRef]

- Lionetto, F. Carbon Fiber Reinforced Polymers. Materials 2021, 14, 5545. [Google Scholar] [CrossRef]

- Park, E.-T.; Kim, J.; Kang, B.-S.; Song, W. Experimental Study on a Microwave Composite Forming Process Based on a SiC Mold for Manufacturing Fiber Metal Laminate. Materials 2021, 14, 5547. [Google Scholar] [CrossRef]

- Lou, K.; Wu, X.; Xiao, P.; Zhang, C. Investigation on Fatigue Performance of Asphalt Mixture Reinforced by Basalt Fiber. Materials 2021, 14, 5596. [Google Scholar] [CrossRef]

- Nie, H.; Gu, S.; Mao, H. Analytical Model of Piezoresistivity for an Inner-Adhesive-Type Carbon Fibre Reinforced Plastic Tunnel Reinforcement. Materials 2022, 15, 4602. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, H.; Song, D.; Sheng, Q.; Fu, X.; Ding, H.; Chai, S.; Yuan, W. Dynamic Response of Lining Structure in a Long Tunnel with Different Adverse Geological Structure Zone Subjected to Non-Uniform Seismic Load. Energies 2022, 15, 4599. [Google Scholar] [CrossRef]

- Sun, B.; Guo, C.; Chen, Y.; Chu, X.; Ma, X. Study on Spraying Construction Method of a Non-Water Reacting Polymer Layer in the Tunnel. Materials 2022, 15, 4138. [Google Scholar] [CrossRef]

- Zheng, X.; Wu, K.; Shao, Z.; Yuan, B.; Zhao, N. Tunnel Squeezing Deformation Control and the Use of Yielding Elements in Shotcrete Linings: A Review. Materials 2022, 15, 391. [Google Scholar] [CrossRef]

- Wang, A.; Shi, C.; Zhao, C.; Deng, E.; Yang, W.; He, H. Response Characteristics of Cross Tunnel Lining under Dynamic Train Load. Appl. Sci. 2020, 10, 4406. [Google Scholar] [CrossRef]

- Zhang, Z.; Gong, R.; Zhang, H.; He, W. The Sustainability Performance of Reinforced Concrete Structures in Tunnel Lining Induced by Long-Term Coastal Environment. Sustainability 2020, 12, 3946. [Google Scholar] [CrossRef]

- Huang, X.X.; Cai, J.; Yang, W.W.; Zhou, H.Y.; He, Z.Z. Planning and Scientific Research of Power Cable Tunnel Project in Shanghai WorldExpo. Spec. Struct. 2009, 26, 3–6. [Google Scholar]

- Alshboul, O.; Almasabha, G.; Shehadeh, A.; Al Hattamleh, O.; Almuflih, A.S. Optimization of the Structural Performance of Buried Reinforced Concrete Pipelines in Cohesionless Soils. Materials 2022, 15, 4051. [Google Scholar] [CrossRef]

- Djahida, D.; Tewfik, G.; Witek, M.; Abdelghani, M. Analytical Model and Numerical Analysis of Composite Wrap System Applied to Steel Pipeline. Materials 2021, 14, 6393. [Google Scholar] [CrossRef]

- Messiha, M.; Frank, A.; Heimink, J.; Arbeiter, F.; Pinter, G. Structure-Property Relationships of Polyamide 12 Grades Exposed to Rapid Crack Extension. Materials 2021, 14, 5899. [Google Scholar] [CrossRef]

- Ou, X.; Liu, Y.; Li, C.; Zhou, X.; Chen, Q.; Zhou, Y.; Zhang, Q. Analysis of the Interaction Effects of Shield Structure Oblique Passing under an Existing Tunnel. Appl. Sci. 2022, 12, 5569. [Google Scholar] [CrossRef]

- Asheghabadi, M.S.; Cheng, X. Analysis of Undrained Seismic Behavior of Shallow Tunnels in Soft Clay Using Nonlinear Kinematic Hardening Model. Appl. Sci. 2020, 10, 2834. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Ding, F.; Lu, D.; Lyu, F.; Huang, S.; Cao, Z.; Wang, H. Finite Element Analysis of the Mechanical Properties of Axially Compressed Square High-Strength Concrete-Filled Steel Tube Stub Columns Based on a Constitutive Model for High-Strength Materials. Materials 2022, 15, 4313. [Google Scholar] [CrossRef]

- Moore, I.D. Buried pipes and culverts. In Geotechnical and Geo-Environmental Engineering Handbook; Springer: Boston, MA, USA, 2001; pp. 541–567. [Google Scholar]

- GB 11836; Concrete and Reinforced Concrete Sewer Pipes. Standardization Administration of PRC (SAC): Beijing, China, 2009.

- ASTM C497-19; Standard test method for concrete pipe, concrete box sections, manhole sections, or tile. American Society of Testing Materials (ASTM): West Conshohocken, PA, USA, 2019.

- Moore, I.D.; Hoult, N.A.; MacDougall, K. Establishment of Appropriate Guidelines for Use of the Direct and Indirect Design Methods for Reinforced Concrete Pipe; AASHTO Standing Committee on Highways: Washington, DC, USA, 2014. [Google Scholar]

- David, B.G.; Ian, D.M. Evaluation and Application of the Flexural Rigidity of a Reinforced Concrete Pipe. J. Pipeline Syst. Eng. Pract. 2015, 7, 04015015. [Google Scholar]

| Code | Defects | Lining Material | Lining Angle | Lining Thickness | |

|---|---|---|---|---|---|

| T0-1 | No defects | N/A | N/A | N/A | Control groups |

| T0-2 | 10 mm cracks | N/A | N/A | N/A | |

| T1 | 10 mm cracks | CM | 45° | 10 mm |  |

| T2 | 10 mm cracks | ER | 90° | 20 mm | |

| T3 | 10 mm cracks | ER | 45° | 10 mm | |

| T4 | 10 mm cracks | CM | 90° | 20 mm |

| Onset of Crack | Liner Breakdown | Pipe Collapse | |

|---|---|---|---|

| T1 | 19 s | 22 s | 122 s |

| T2 | 27 s | Not separated | 125 s |

| T3 | 20 s | 97 s (slightly) | 100 s |

| T4 | 17 s | 30 s | 115 s |

| Test | |||||||

|---|---|---|---|---|---|---|---|

| T0-2 | 7.61 × 10−5 | 6.79 × 10−5 | 13.11 × 10−5 | 6.82 × 10−5 | 5.07 × 109 | - | - |

| T1 | 5.02 × 10−5 | 2.90 × 10−5 | 6.86 × 10−5 | 11.17 × 10−5 | 5.07 × 109 | 1.3 × 1010 | 2.64 |

| T2 | 4.20 × 10−5 | 3.20 × 10−5 | 3.74 × 10−5 | 4.52 × 10−5 | 5.07 × 109 | 4.7 × 1010 | 9.29 |

| T3 | 9.30 × 10−5 | 4.30 × 10−5 | 8.89 × 10−5 | 4.86 × 10−5 | 5.07 × 109 | 8.1 × 109 | 1.60 |

| T4 | 2.01 × 10−5 | 5.70 × 10−5 | 9.97 × 10−5 | 10.13 × 10−5 | 5.07 × 109 | 3.1 × 1010 | 6.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Ma, B.; Zeng, Z.; Gong, C.; Mei, Z.; Hu, J.; Zhang, P. An Experimental Study of the Mechanical Properties of Partially Rehabilitated Cable Tunnels. Materials 2022, 15, 4830. https://doi.org/10.3390/ma15144830

Zhu Z, Ma B, Zeng Z, Gong C, Mei Z, Hu J, Zhang P. An Experimental Study of the Mechanical Properties of Partially Rehabilitated Cable Tunnels. Materials. 2022; 15(14):4830. https://doi.org/10.3390/ma15144830

Chicago/Turabian StyleZhu, Zihao, Baosong Ma, Zheng Zeng, Chenkun Gong, Zhe Mei, Jinqiu Hu, and Peng Zhang. 2022. "An Experimental Study of the Mechanical Properties of Partially Rehabilitated Cable Tunnels" Materials 15, no. 14: 4830. https://doi.org/10.3390/ma15144830

APA StyleZhu, Z., Ma, B., Zeng, Z., Gong, C., Mei, Z., Hu, J., & Zhang, P. (2022). An Experimental Study of the Mechanical Properties of Partially Rehabilitated Cable Tunnels. Materials, 15(14), 4830. https://doi.org/10.3390/ma15144830