Analysis of the Embodied Energy and CO2 Emissions of Ready-Mixed Concrete: A Case Study in Cuenca, Ecuador

Abstract

:1. Introduction

1.1. Studies on the Concrete

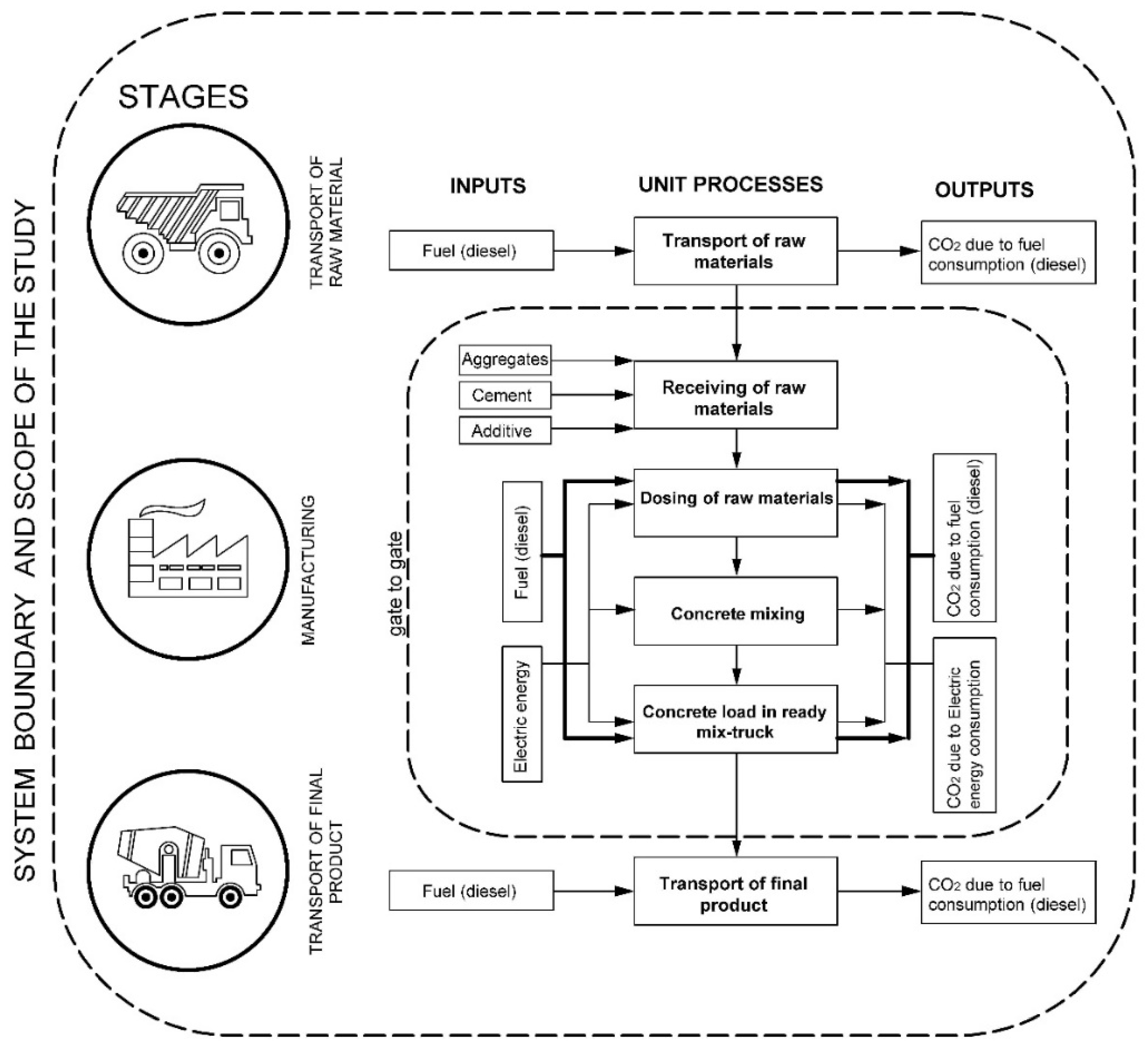

1.2. Life Cycle Assessment Framework

- (1)

- From “cradle to grave” when it includes all the inputs/outputs of the processes that participate throughout its lifecycle, extraction of raw material, processing of materials for the manufacture of components, use of the product, and recycling or final management;

- (2)

- From “cradle to gate” when the scope of the system boundary is limited to inputs/outputs from the extraction of raw materials until the product is placed on the market (leaving the concrete plant);

- (3)

- From “gate to gate” when considering only the inputs/outputs of the manufacturing process of the product [44]. In the second phase, data corresponding to the inputs and outputs are collected for all the processes of the product system. Inputs such as raw materials and energy are quantified, and the outputs as emissions (to air, water and soil), and the product obtained, are also considered. In the third phase, the data collected in the inventory of inputs and outputs are translated to indicators of potential environmental impacts. Finally, in the fourth phase, the results of the LCI and LCIA are interpreted according to the objectives and scope initially defined, concluding with an analysis of results, and the formulation of conclusions [25].

1.3. The Concrete Industry in Ecuador

2. Materials and Methods

2.1. Definition of the Goal and Scope

- (1)

- Receiving of raw materials: Mainly aggregates, cement and additives. Aggregates: Crushed stone with diameters of 38 and 19 mm and river sand. The product is weighed and stored in reinforced concrete compartments. Cement: It is transported in bulk from the main plant located in the city of Guayaquil. The trucks are weighed upon arrival and unload their product into cement storage silos. Additives: They are supplied wholesale by their supplier and arrive at the plant by means of cargo trucks. The most used additives are plasticizers, retardants, and accelerators.

- (2)

- Dosing of raw materials: By means of a front-wheel loader, the different types of aggregates are taken to the reception hopper, the aggregates are supplied by means of a conveyor belt and placed in the compartments proper to each type. In the dosing hopper, there is a scale to dose by weight the mixture of aggregates for each batch of concrete to be manufactured. Once the cement is weighed, it is transported to the pre-mixer drum. The aggregate mix, still dry, is transported to the pre-mixer drum, where it will be mixed with the cement, water, and additives. The water that will be used is stored in a tank; it is pumped, and its dosage depends directly on the automatic dosage system. The additives are dosed and then, they are pumped to the premix tank. When all the dosing has been completed, mixing is carried out until the characteristics of the desired concrete are obtained.

- (3)

- Concrete mixing: It is performed in the pre-mixing drum.

- (4)

- Concrete load in ready-mix truck: Once mixed and homogenized, it is passed to the mixer through an automatic system from the dispatch area.

2.2. Life Cycle Inventory (LCI)

2.2.1. Inputs and Calculation

2.2.2. Outputs and Calculation

- Emissions GHG, Fuel: Emissions of a given GHG by type of fuel;

- Fuel Consumption Fuel: Amount of fuel combusted;

- Emission Factor GHG, Fuel: Default emission factor of a given GHG by type of fuel.

- AD: Activity data

- EF: Emission Factor

2.3. Life Cycle Impact Assessment (LCIA)

3. Results

3.1. Input Data

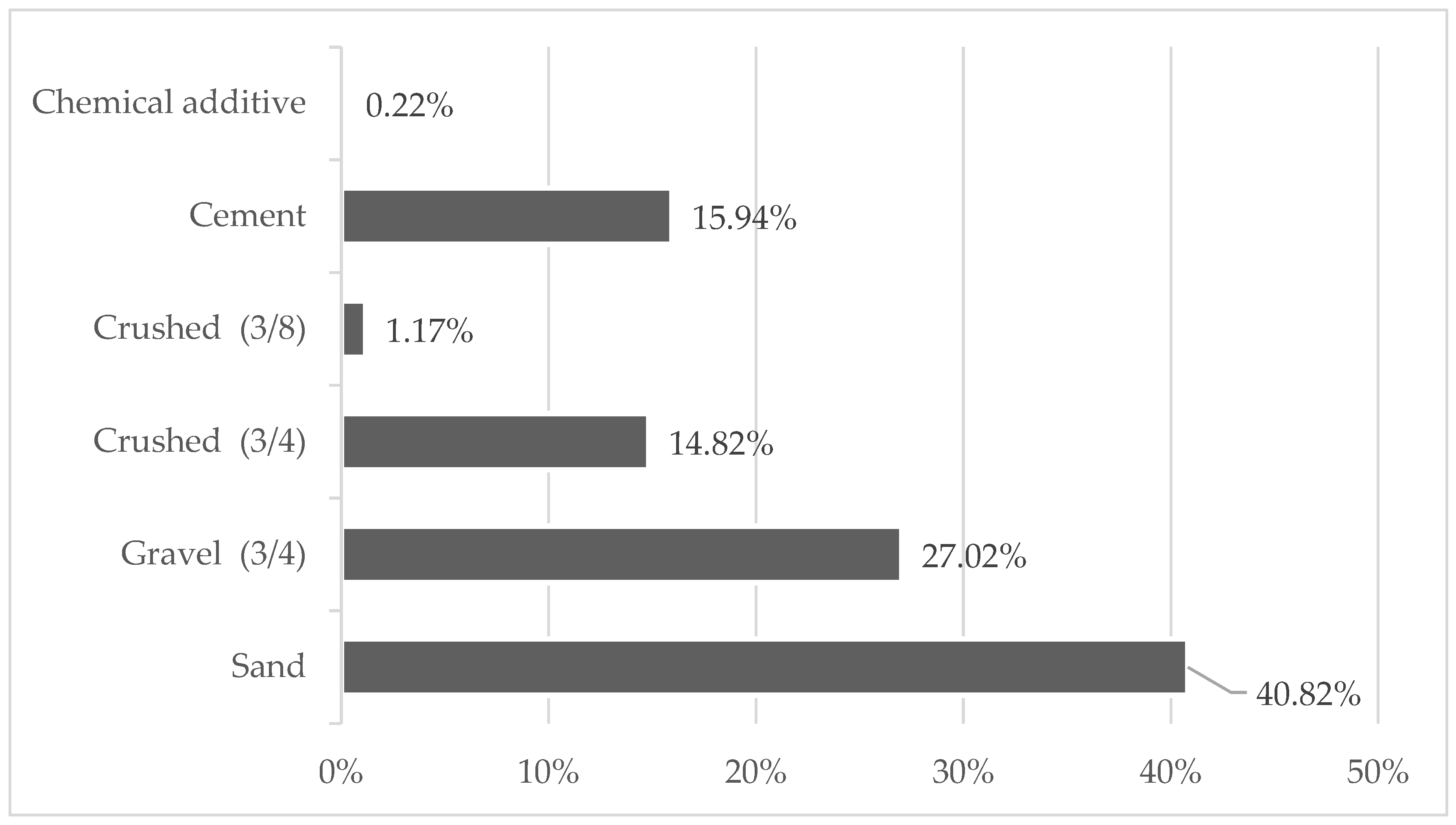

3.1.1. Raw Material Consumption

3.1.2. Fuel and Electricity

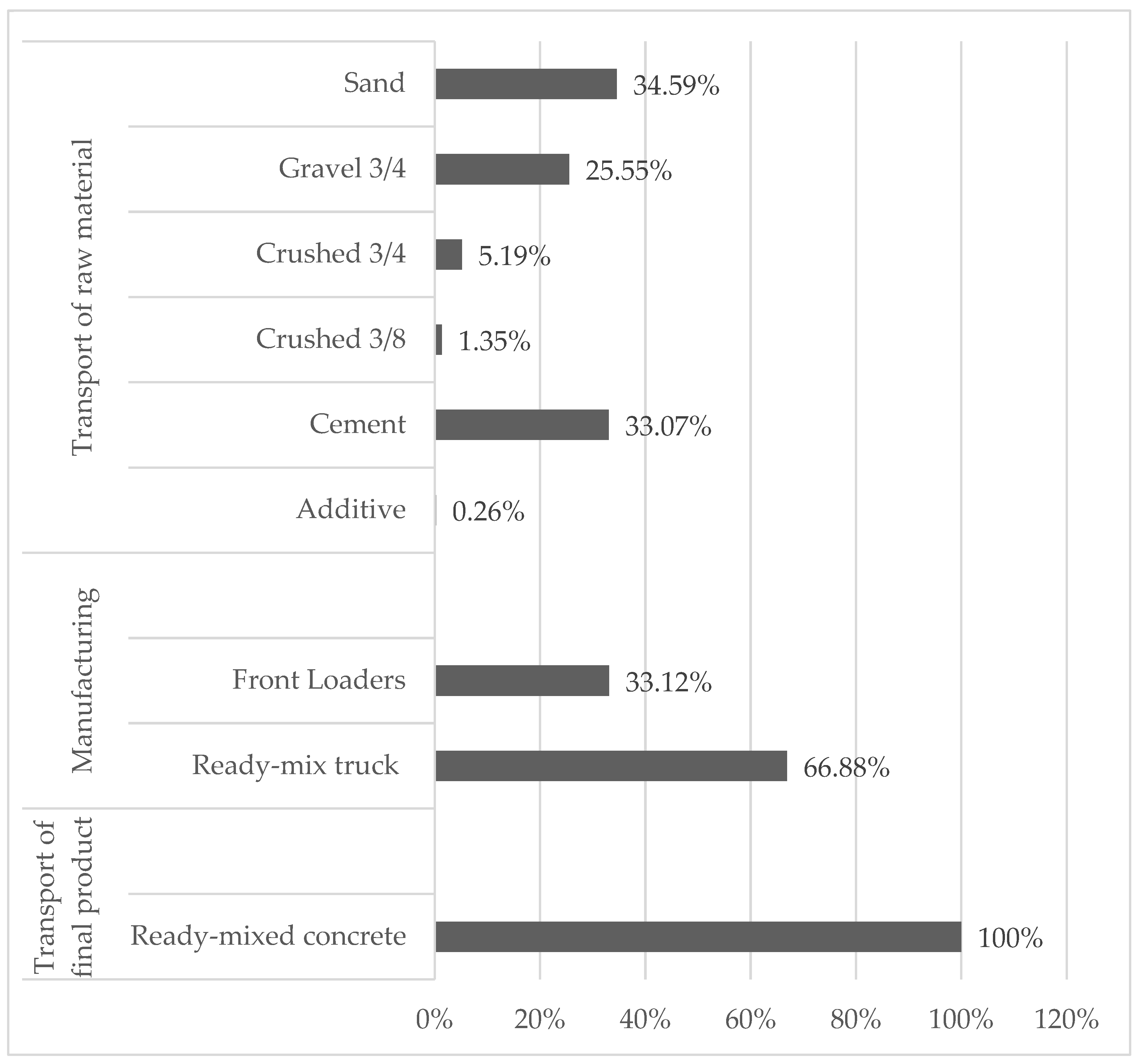

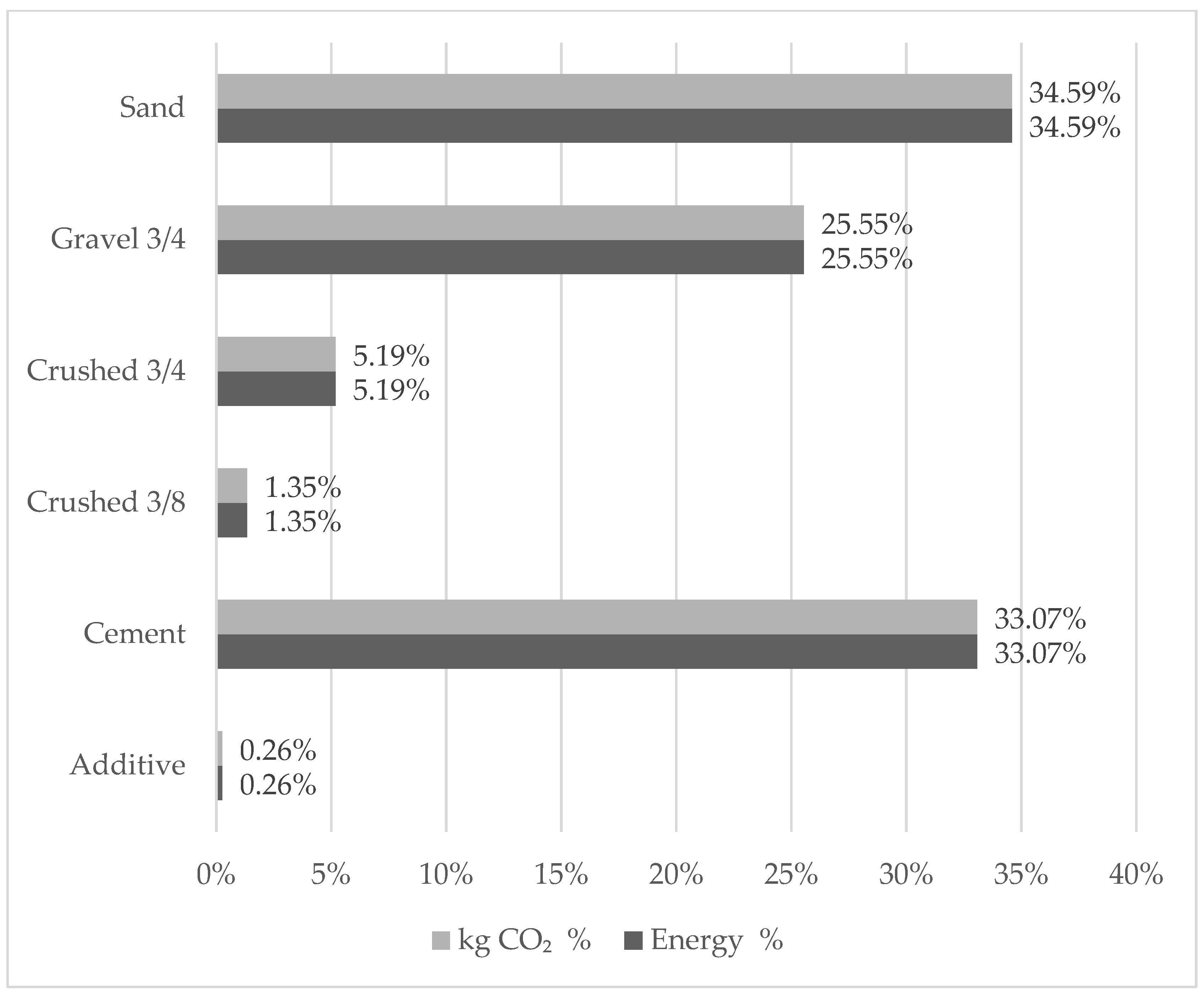

3.2. Output Data

3.2.1. Final Product

3.2.2. Embodied Energy and CO2 Emissions

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cedeño Valdivieso, A. La Madera. ¿Una Al Ternativa Para Proteger El Medioambiente? Rev. Arquit. 2013, 15, 111–119. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative LCA on Using Waste Materials in the Cement Industry: A Hong Kong Case Study. Resour. Conserv. Recycl. 2017, 120, 199–208. [Google Scholar] [CrossRef]

- Liu, B.; Wang, D.; Xu, Y.; Liu, C.; Luther, M. Embodied Energy Consumption of the Construction Industry and Its International Trade Using Multi-Regional Input–Output Analysis. Energy Build. 2018, 173, 489–501. [Google Scholar] [CrossRef]

- Zabalza, I.; Valero, A.; Aranda, A. Life Cycle Assessment of Building Materials: Comparative Analysis of Energy and Environmental Impacts and Evaluation of the Eco-Efficiency Improvement Potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, J.C.P.; Lo, I.M.C. Life Cycle Carbon Footprint Measurement of Portland Cement and Ready Mix Concrete for a City with Local Scarcity of Resources like Hong Kong. Int. J. Life Cycle Assess. 2014, 19, 745–757. [Google Scholar] [CrossRef]

- Aldana, J.; Serpell, A. Temas y Tendencias Sobre Residuos de Construcción y Demolición: Un Meta-Análisis. Rev. Constr. 2012, 12, 4–16. [Google Scholar] [CrossRef] [Green Version]

- Molina-Prieto, L.F.; Suárez-Serrano, M.; Villa-Camacho, M.E. Bucle Multidisciplinar Para La Sustentabilidad Urbana. Rev. Arquit. 2019, 21, 76–88. [Google Scholar] [CrossRef] [Green Version]

- Suppen, N. Analisis de Ciclo de Vida y Ecodiseno Para La Construccion En Mexico; Universidad Autónoma de San Luis de Potosí: San Luis, Mexico, 2013. [Google Scholar]

- Gursel, A.P.; Ostertag, C. Comparative Life-Cycle Impact Assessment of Concrete Manufacturing in Singapore. Int. J. Life Cycle Assess. 2017, 22, 237–255. [Google Scholar] [CrossRef]

- Tait, M.W.; Cheung, W.M. A Comparative Cradle-to-Gate Life Cycle Assessment of Three Concrete Mix Designs. Int. J. Life Cycle Assess. 2016, 21, 847–860. [Google Scholar] [CrossRef] [Green Version]

- Lvel, J.; Watson, R.; Abbassi, B.; Abu-Hamatteh, Z.S. Life Cycle Analysis of Concrete and Asphalt Used in Road Pavements. Environ. Eng. Res. 2020, 25, 52–61. [Google Scholar] [CrossRef]

- Doménech, J.L. Huella Ecológica y Desarrollo Sostenible; AENOR: Madrid, Spain, 2007; ISBN 9788481435177. [Google Scholar]

- Coffetti, D.; Crotti, E.; Gazzaniga, G.; Carrara, M.; Pastore, T.; Coppola, L. Pathways towards Sustainable Concrete. Cem. Concr. Res. 2022, 154, 106718. [Google Scholar] [CrossRef]

- Muñoz, C.; Quiroz, F. Using Analysis of Life Cycle Tool in Determining the Embodied Energy and Carbon Footprint in the Manufacturing Processes of the Ready-Mixed Concrete Case Manufacturing Plant Bío BÍo Region Study-Chile. Rev. Hábitat Sustentable 2014, 4, 16–25. [Google Scholar]

- Belaïd, F. Resources, Conservation & Recycling Advances How Does Concrete and Cement Industry Transformation Contribute to Mitigating Climate Change Challenges ? Resour. Conserv. Recycl. Adv. 2022, 15, 200084. [Google Scholar] [CrossRef]

- Beressa, L.; Saradhi, B.V. Life Cycle Assessment of Ethiopian Cement Manufacturing: A Potential Improvement on the Use of Fossil Fuel in Mugher Cement Factory. Appl. Environ. Res. 2021, 43, 100–112. [Google Scholar] [CrossRef]

- Bedoya-Montoya, C.M. Construcción de Vivienda Sostenible Con Bloques de Suelo Cemento: Del Residuo Al Material. Rev. Arquit. 2018, 20, 62–70. [Google Scholar] [CrossRef]

- Iberoamerican Federation of Ready Mixed Concrete Indicators of Concrete. Available online: https://www.construccionlatinoamericana.com/indicadores-en-concreto/128416.article (accessed on 20 June 2019).

- Instituto Nacional de Estadística y Censos. Encuesta Anual de Edificaciones 2015 (Permisos de Construcción); Instituto Nacional de Estadística y Censos: Buenos Aires, Argentina, 2016. [Google Scholar]

- Torres-Quezada, J.; Torres Avilés, A.; Isalgue, A.; Pages-Ramon, A. The Evolution of Embodied Energy in Andean Residential Buildings. Methodology Applied to Cuenca-Ecuador. Energy Build. 2022, 259, 111858. [Google Scholar] [CrossRef]

- Suárez, S. Propuesta Metodológica Para Evaluar El Comportamiento Ambiental y Económico de Los Residuos de Construcción y Demolición (RCD) En La Producción de Materiales Pétreos; Universitat Politecnica de Catalunya: Barcelona, Spain, 2015. [Google Scholar]

- Weiszer, M.; Fedorko, G.; Molnár, V.; Tučková, Z.; Poliak, M. Dispatching Policy Evaluation for Transport of Ready Mixed Concrete. Open Eng. 2020, 10, 120–128. [Google Scholar] [CrossRef]

- Kosmatka, S.H.; Kerkhoff, B.; Panarese, W.C.; Tanesi, J. Diseño y Control de Mezclas de Concreto, 1st ed.; Portland Cement Association: Skokie, IL, USA, 2004; pp. 1–448. [Google Scholar]

- Setiadi, T.; Abduh, M. The Study of Sustainable Procurement in the Procurement of Ready Mixed Concrete Supplier. IOP Conf. Ser. Earth Environ. Sci. 2020, 520, 012004. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Standard Organization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Standard Organization: Geneva, Switzerland, 2006.

- Kleijer, A.L.; Lasvaux, S.; Citherlet, S.; Viviani, M. Product-Specific Life Cycle Assessment of Ready Mix Concrete: Comparison between a Recycled and an Ordinary Concrete. Resour. Conserv. Recycl. 2017, 122, 210–218. [Google Scholar] [CrossRef]

- O’Brien, K.R.; Ménaché, J.; O’Moore, L.M. Impact of Fly Ash Content and Fly Ash Transportation Distance on Embodied Greenhouse Gas Emissions and Water Consumption in Concrete. Int. J. Life Cycle Assess. 2009, 14, 621–629. [Google Scholar] [CrossRef] [Green Version]

- Petek Gursel, A.; Masanet, E.; Horvath, A.; Stadel, A. Life-Cycle Inventory Analysis of Concrete Production: A Critical Review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Cedeño Valdiviezo, A. Aglomerantes, Morteros y Aplanados Adecuados Para Proteger El Medioambiente. Rev. Arquit. 2011, 13, 106–117. Available online: https://revistadearquitectura.ucatolica.edu.co/article/view/774 (accessed on 16 June 2022).

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative Environmental Assessment of Natural and Recycled Aggregate Concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Goggins, J.; Keane, T.; Kelly, A. The Assessment of Embodied Energy in Typical Reinforced Concrete Building Structures in Ireland. Energy Build. 2010, 42, 735–744. [Google Scholar] [CrossRef] [Green Version]

- Dias, A.B.; Pacheco, J.N.; Silvestre, J.D.; Martins, I.M.; de Brito, J. Environmental and Economic Life Cycle Assessment of Recycled Coarse Aggregates: A Portuguese Case Study. Materials 2021, 14, 5452. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, F.; Jamal, A.; Mazher, K.M.; Umer, W.; Iqbal, M. Performance Evaluation of Plastic Concrete Modified with E-Waste Plastic as a Partial Replacement of Coarse Aggregate. Materials 2022, 15, 175. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Akinmusuru, J.O.; Ndambuki, J.M. Green Concrete Production with Ceramic Wastes and Laterite. Constr. Build. Mater. 2016, 117, 29–36. [Google Scholar] [CrossRef]

- León-Velez, A.; Guillén-Mena, V. Energía Contenida y Emisiones de CO2 En El Proceso de Fabricación Del Cemento En Ecuador. Ambient. Construído 2020, 20, 611–625. [Google Scholar] [CrossRef]

- Sivakrishna, A.; Adesina, A.; Awoyera, P.O.; Kumar, K.R. Green Concrete: A Review of Recent Developments. Mater. Today Proc. 2020, 27, 54–58. [Google Scholar] [CrossRef]

- de Brito, J.; Kurda, R. The Past and Future of Sustainable Concrete: A Critical Review and New Strategies on Cement-Based Materials. J. Clean. Prod. 2021, 281, 123558. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life Cycle Assessment of Concrete Made with High Volume of Recycled Concrete Aggregates and Fly Ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Colangelo, F.; Petrillo, A.; Cioffi, R.; Borrelli, C.; Forcina, A. Life Cycle Assessment of Recycled Concretes: A Case Study in Southern Italy. Sci. Total Environ. 2018, 615, 1506–1517. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Liu, H.; Wu, Y.; Zhang, W.; Wang, Y.; Santosh, M. Characterization of Geo-Material Parameters: Gene Concept and Big Data Approach in Geotechnical Engineering. Geosyst. Geoenviron. 2022, 1, 100003. [Google Scholar] [CrossRef]

- Vieira, D.R.; Calmon, J.L.; Zulcão, R.; Coelho, F.Z. Consideration of Strength and Service Life in Cradle-to-Gate Life Cycle Assessment of Self-Compacting Concrete in a Maritime Area: A Study in the Brazilian Context. Environ. Dev. Sustain. 2018, 20, 1849–1871. [Google Scholar] [CrossRef]

- Hu, M.; Kleijn, R.; Bozhilova-Kisheva, K.P.; Di Maio, F. An Approach to LCSA: The Case of Concrete Recycling. Int. J. Life Cycle Assess. 2013, 18, 1793–1803. [Google Scholar] [CrossRef]

- Ihobe, S.A. Análisis de Ciclo de Vida y Huella de Carbono: 1ra ed.; Departamento de Medio Ambiente, Planificación Territorial, Agricultura, y Pesca Gobierno Vasco: Bilbao, España, 2009; pp. 1–53. Available online: https://www.u-cursos.cl/ingenieria/2011/2/IN5129/1/material_docente/bajar?id=385043&lsar=1&file=3 (accessed on 16 June 2022).

- Xing, W.; Tam, V.W.; Le, K.N.; Hao, J.L.; Wang, J. Life Cycle Assessment of Recycled Aggregate Concrete on Its Environmental Impacts: A Critical Review. Constr. Build. Mater. 2022, 317, 125950. [Google Scholar] [CrossRef]

- Hottle, T.; Hawkins, T.R.; Chiquelin, C.; Lange, B.; Young, B.; Sun, P.; Elgowainy, A.; Wang, M. Environmental Life-Cycle Assessment of Concrete Produced in the United States. J. Clean. Prod. 2022, 363, 131834. [Google Scholar] [CrossRef]

- Petroche, D.M.; Ramirez, A.D. A Life Cycle Perspective Study Based on Ecuadorian Data. Buildings 2022, 12, 311. [Google Scholar] [CrossRef]

- Hossain, M.U.; Liu, J.C.; Xuan, D.; Ng, S.T.; Ye, H.; Abdulla, S.J. Designing Sustainable Concrete Mixes with Potentially Alternative Binder Systems: Multicriteria Decision Making Process. J. Build. Eng. 2022, 45, 103587. [Google Scholar] [CrossRef]

- Asociación Española de Normalización. UNE-EN 15804:2012+A2: Sostenibilidad En La Construcción. Declaraciones Ambientales de Producto. Reglas de Categoría de Producto Básicas Para Productos de Construcción; Asociación Española de Normalización: Madrid, Spain, 2020. [Google Scholar]

- Woodward, R.; Duffy, N. Cement and Concrete Flow Analysis in a Rapidly Expanding Economy: Ireland as a Case Study. Resour. Conserv. Recycl. 2011, 55, 448–455. [Google Scholar] [CrossRef]

- Instituto de Investigación Geológico y Energético Balance Energético Nacional 2019. Quito, Ecuador, 2019. Available online: https://www.recursosyenergia.gob.ec/wp-content/uploads/2020/12/Balance-Energetico-Nacional-2019-1.pdf (accessed on 16 June 2022).

- Feredación Interamericana del Cemento. Informe Estadístico 2019. 2019. Available online: https://ficem.org/uso-estadisticas/ (accessed on 16 June 2022).

- Ramos, L.; TOrres, D. Encuesta Nacional de Edificaciones (ENED), 2019; Quito, Ecuador, 2020. Available online: https://www.ecuadorencifras.gob.ec/documentos/web-inec/Estadisticas_Economicas/Encuesta_Edificaciones/2019/3.%202019_ENED_Boletin_tecnico.pdf (accessed on 16 June 2022).

- NTE INEN 1855-1; Hormigones. Hormigón Premezclado. Requisitos. Instituto Ecuatoriano de Normalización: Quito, Ecuador, 2015.

- Raúl, C.; Díaz, R.; Stephen, C.; Rosado, C. Estudio Del Potencial de Reciclaje de Los Desechos de Construcción y Demolición En La Ciudad de Guayaquil. In Proceedings of the 12th Latin American and Caribbean Conference for Engineering and Technology, Guayaquil, Ecuador, 21–24 July 2014; pp. 1–10. [Google Scholar]

- Holcim Ecuador, S.A. Memoria de Sostenibilidad 2019–2020. Available online: https://drive.google.com/file/d/1hd2arspIaXOcROdBgsrF7rrCmzCPXgiI/view (accessed on 20 January 2022).

- Gómez, D.R.; Watterson, J.D. Energy: Stationary Combustion. In 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006; Volume 2, pp. 69–70. [Google Scholar]

- Marrero, M.; Martínez-Escobar, L.; Mercader, M.P.; Leiva, C. Minimización Del Impacto Ambiental En La Ejecución de Fachadas Mediante El Empleo de Materiales Reciclados. Inf. Constr. 2013, 65, 89–97. [Google Scholar] [CrossRef] [Green Version]

- Pappu, A.; Saxena, M.; Asolekar, S.R. Solid Wastes Generation in India and Their Recycling Potential in Building Materials. Build. Environ. 2007, 42, 2311–2320. [Google Scholar] [CrossRef]

- Bertoldi, P.; Cayuela, B.D.; Monni, S.; Piers de Raveschoot, R. Baseline Emissions Inventory. In How to develop a Sustainable Energy Action Plan—(SEAP) Guidebook; Publications Office of the European Union: Luxembourg, 2010; pp. 81–108. [Google Scholar]

- Rypdal, K.; Paciornik, N. General Guidance and Reporting: Introduction the 2006 Guidelines. In 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006; Volume 1, pp. 3–16. [Google Scholar]

- Centro Nacional De Control De La Energía. Factor de Emisión de CO2 Del Sistema Nacional Interconectado 2016; Quito, Ecuador, 2016; p. 76. Available online: http://www.cenace.gob.ec/wp-content/uploads/downloads/2020/04/Informe-Factor-de-CO2-2016.pdf (accessed on 16 June 2022).

- Bergstedt, E.; Linder, I. Material Flow Study of Sand and Gravel in Sweden. Available online: https://share.scb.se/OV9993/Data/Publikationer/statistik/MI/MI1202/2000I02/MIFT9903.pdf (accessed on 15 January 2022).

- Holcim México Nuestra Huella de CO2. Available online: https://www.holcim.com.mx/nuestra-huella-de-co2 (accessed on 1 June 2022).

- Wijayasundara, M.; Crawford, R.H.; Mendis, P. Comparative Assessment of Embodied Energy of Recycled Aggregate Concrete. J. Clean. Prod. 2017, 152, 406–419. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, C.; Liang, Y.; Luo, J.; Wang, X.; Feng, Y.; Li, Y.; Wang, Q.; Abomohra, A.E.F. Life Cycle Assessment and Impact Correlation Analysis of Fly Ash Geopolymer Concrete. Materials 2021, 14, 7375. [Google Scholar] [CrossRef]

| Activities | Total Annual (MJ/m3) | Total Annual (kg CO2/m3) |

|---|---|---|

| Stage 1 | ||

| Transport of raw material | 453.99 | 33.67 |

| Stage 2 | ||

| Electricity | 5.75 | 1.08 |

| Direct transport | 20.27 | 1.50 |

| Stage 3 | ||

| Transport of final product | 88.68 | 6.58 |

| Total | 568.69 | 42.83 |

| Study | Location | Concrete Specification | Embodied Energy | CO2 Emissions | System Boundary |

|---|---|---|---|---|---|

| [47] | Ecuador | Compressive Strength 18 MPa | - | 225.84 kg CO2-Eq/m3 | Cradle-to-gate |

| [47] | Ecuador | Compressive Strength 21 MPa | - | 237.22 kg CO2-Eq/m3 | Cradle-to-gate |

| [47] | Ecuador | Compressive Strength 24 MPa | - | 256.08 kg CO2-Eq/m3 | Cradle-to-gate |

| [47] | Ecuador | Compressive Strength 28 MPa | - | 267.54 kg CO2-Eq/m3 | Cradle-to-gate |

| [47] | Ecuador | Compressive Strength 40 MPa | - | 355.38 kg CO2-Eq/m3 | Cradle-to-gate |

| [66] | China | Geopolymer concrete (GPC) Compressive Strength 40 MPa | - | 260.14 kg CO2/m3 | Cradle-to-gate |

| [32] | Ireland | Typical concrete 30 MPa | 1.08 MJ/Kg | - | Cradle-to-gate |

| [65] | Australia | Recycled concrete aggregate (RCA) Compressive Strength 20–40 MPa | 4766–5401 MJ/m3 | - | Cradle-to-gate ** |

| SimaPro 7.3 ECOINVENT database [14] | 50 countries, including Switzerland, France, Portugal and Sweden. | General concrete | 55.95 MJ/m3 | 256.78 kg CO2/m3 | Gate-to-gate |

| ICE 2.0 [14] | UK Britain | General concrete | 547.2 MJ/m3 | 74.9 kg CO2/m3 | Gate-to-gate * |

| [31] | Serbia | Natural aggregate concrete (NAC) | 1570.42 MJ/m3 | 307.61 kg CO2-Eq/m3 | Cradle-to-gate ** |

| [31] | Serbia | Recycled aggregate concrete (RAC) | 1613.02 MJ/m3 | 319.63 kg CO2-Eq/m3 | Cradle-to-gate ** |

| [14] | Chile | General concrete | 342 MJ/m3 | 25.9 kg CO2/m3 | Gate-to-gate * |

| This research | Ecuador | General concrete | 568.69 MJ/m3 | 42.83 kg CO2/m3 | Gate-to-gate *, ** |

| Comparison of Results | MJ/m3 | kg CO2 /m3 | |

|---|---|---|---|

| Case 1 | Case study Chile | 342.2 | 25.9 |

| Case study Ecuador a | 480.01 | 36.25 | |

| Case 2 | SimaPro Studies 7.3 ECOINVENT database | 55.95 | 256.78 |

| Case study Ecuador b | 26.02 | 2.58 | |

| Case 3 | ICE | 547.2 | 74.9 |

| Case study Ecuador a | 480.01 | 36.25 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vázquez-Calle, K.; Guillén-Mena, V.; Quesada-Molina, F. Analysis of the Embodied Energy and CO2 Emissions of Ready-Mixed Concrete: A Case Study in Cuenca, Ecuador. Materials 2022, 15, 4896. https://doi.org/10.3390/ma15144896

Vázquez-Calle K, Guillén-Mena V, Quesada-Molina F. Analysis of the Embodied Energy and CO2 Emissions of Ready-Mixed Concrete: A Case Study in Cuenca, Ecuador. Materials. 2022; 15(14):4896. https://doi.org/10.3390/ma15144896

Chicago/Turabian StyleVázquez-Calle, Karla, Vanessa Guillén-Mena, and Felipe Quesada-Molina. 2022. "Analysis of the Embodied Energy and CO2 Emissions of Ready-Mixed Concrete: A Case Study in Cuenca, Ecuador" Materials 15, no. 14: 4896. https://doi.org/10.3390/ma15144896

APA StyleVázquez-Calle, K., Guillén-Mena, V., & Quesada-Molina, F. (2022). Analysis of the Embodied Energy and CO2 Emissions of Ready-Mixed Concrete: A Case Study in Cuenca, Ecuador. Materials, 15(14), 4896. https://doi.org/10.3390/ma15144896