Predicting Compressive and Splitting Tensile Strengths of Silica Fume Concrete Using M5P Model Tree Algorithm

Abstract

:1. Introduction

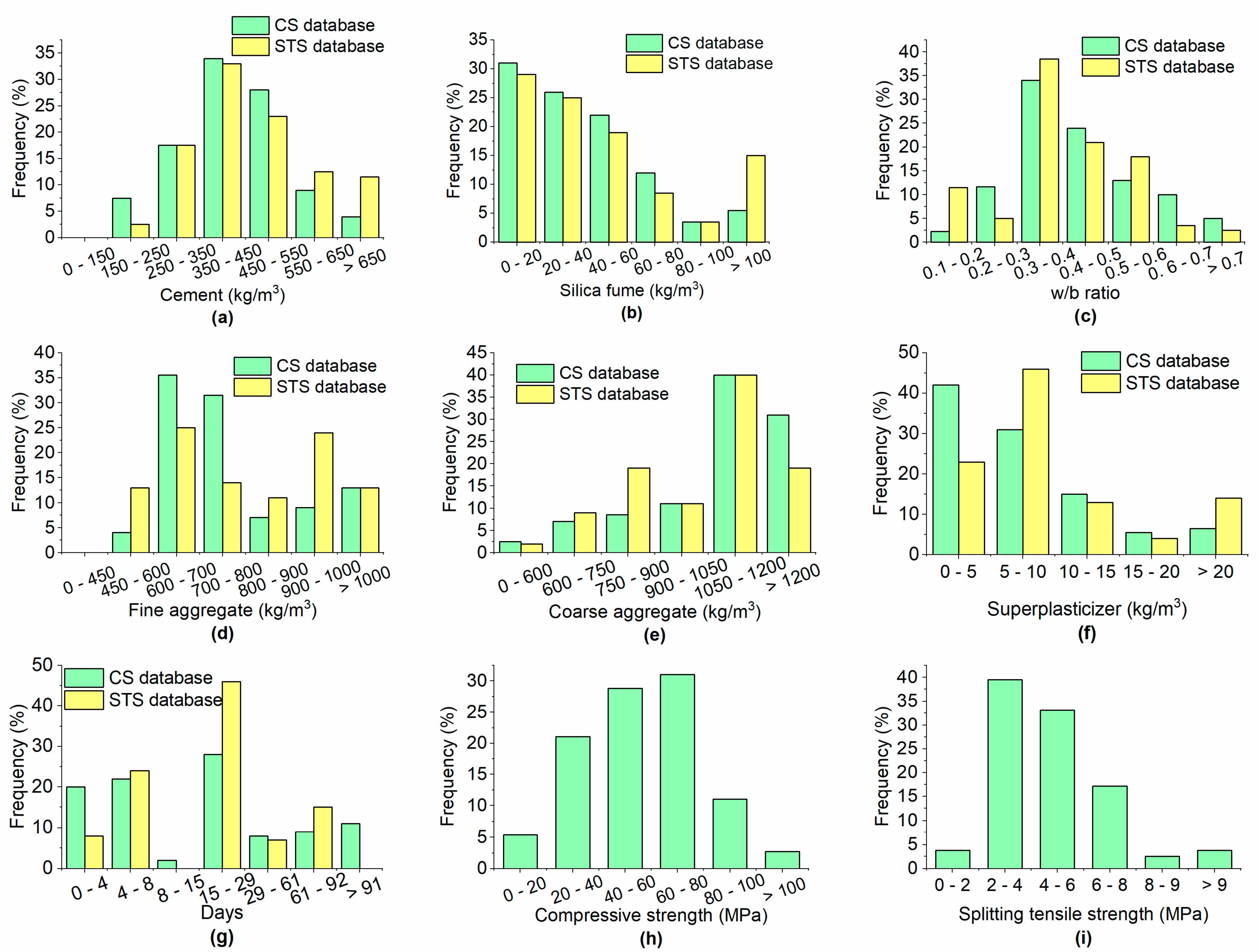

2. Data Collection

3. Methodology

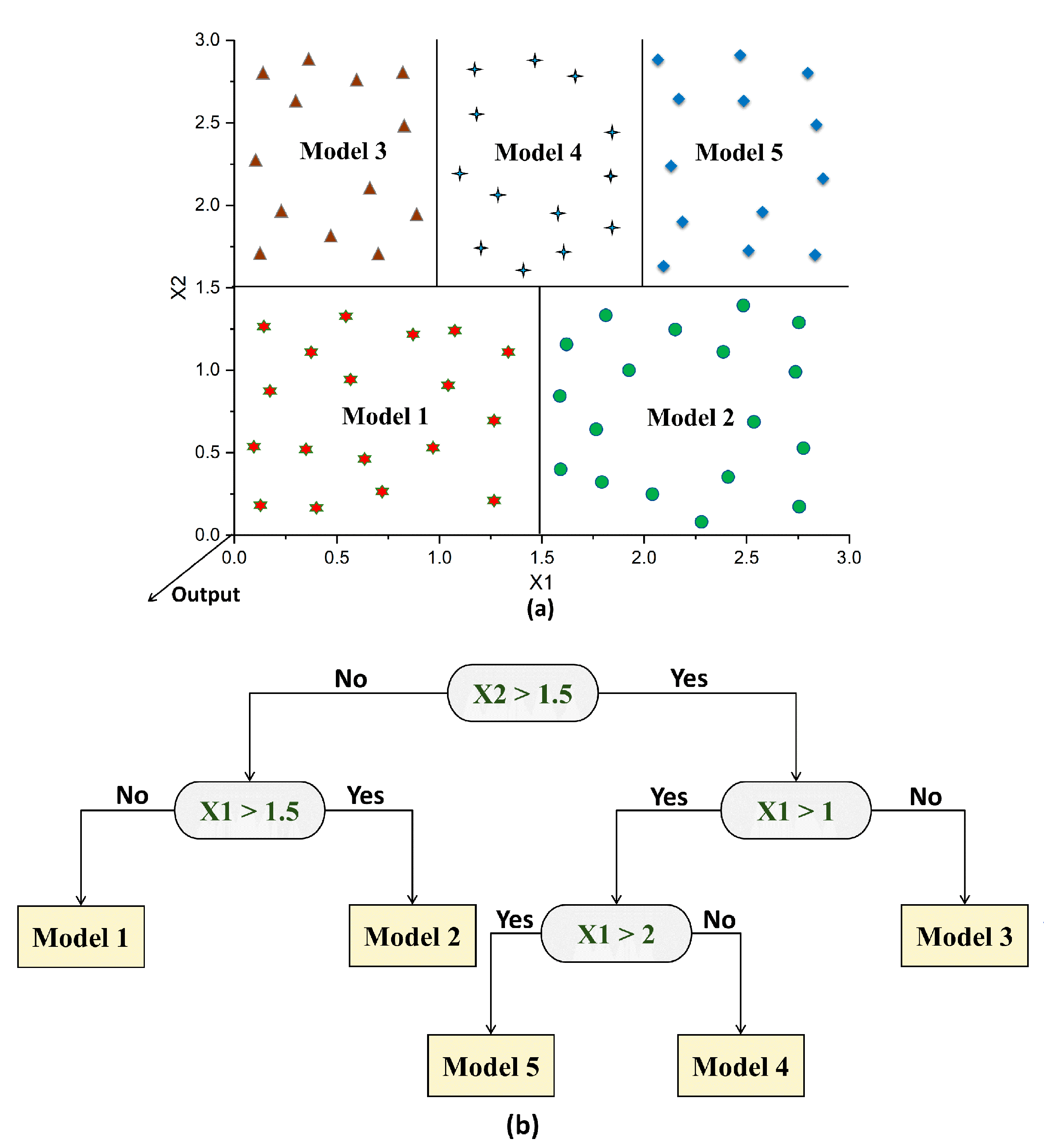

3.1. M5P Model Tree Algorithm

3.2. Comparison of the M5P Models with Other Modeling Techniques

4. Model Development and Evaluation Criteria

5. Results and Discussion

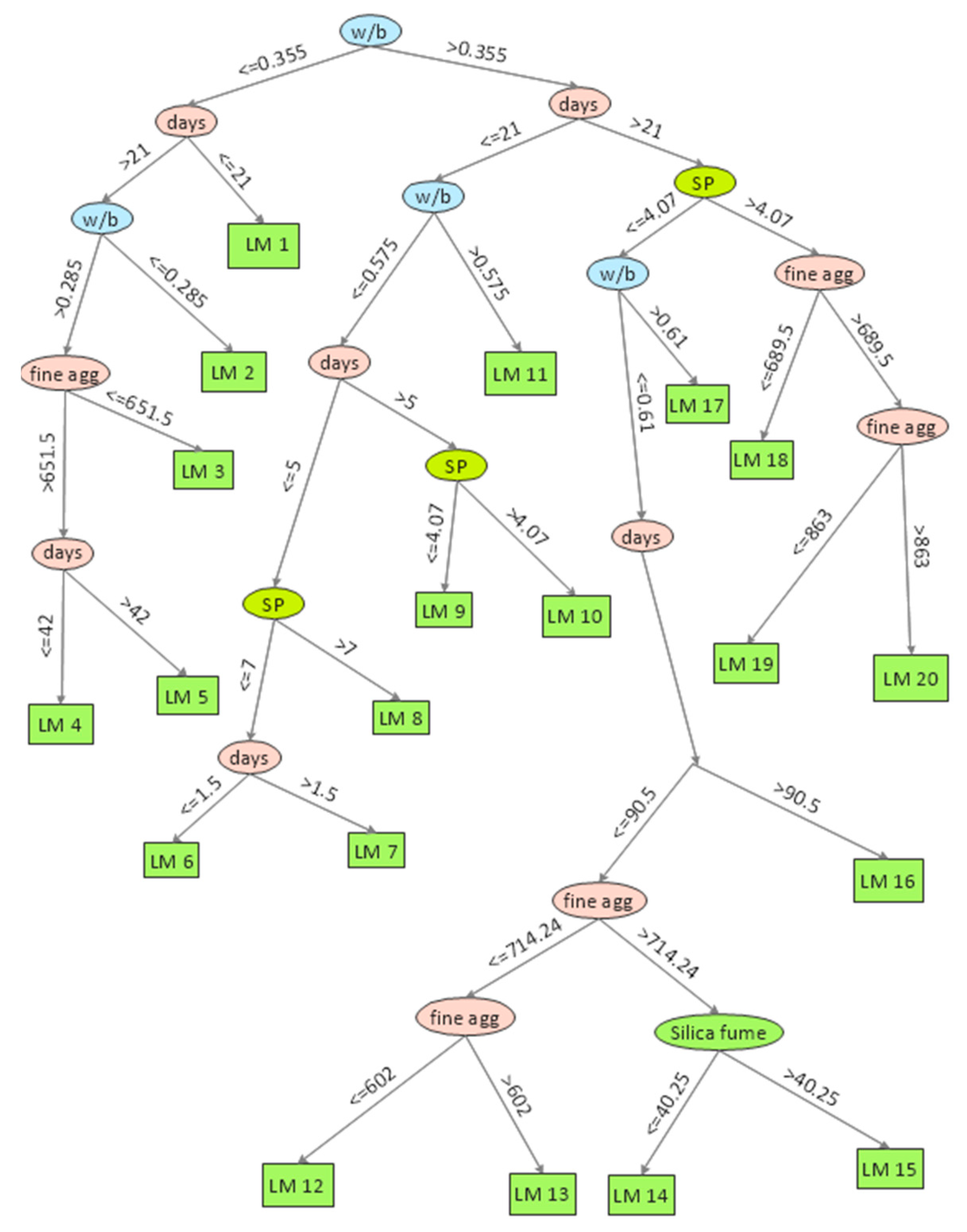

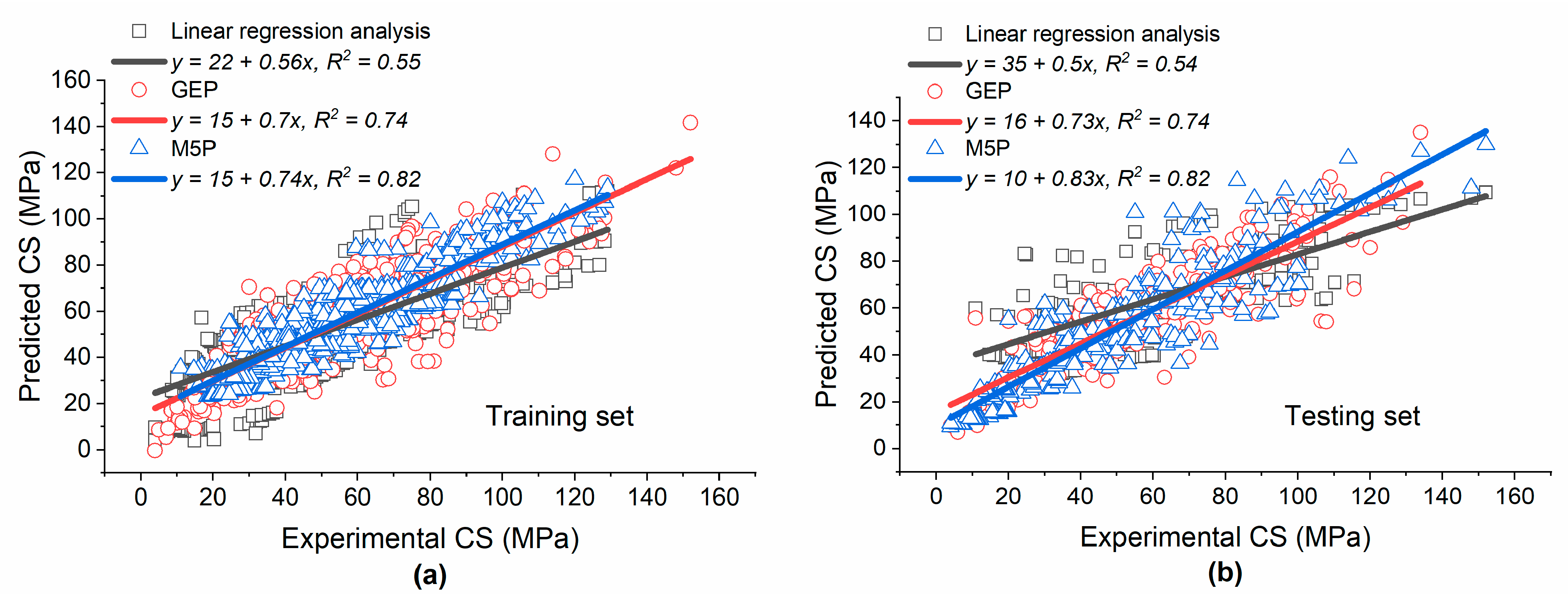

5.1. Compressive Strength

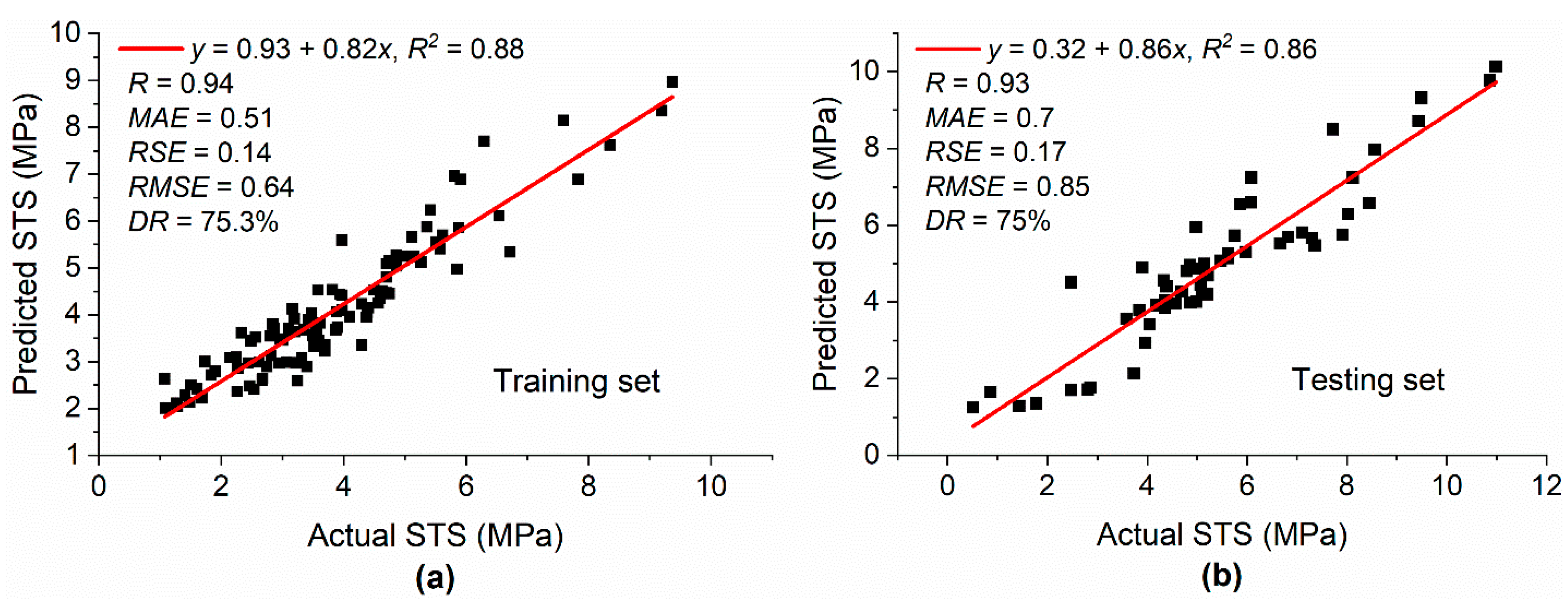

5.2. Splitting Tensile Strength

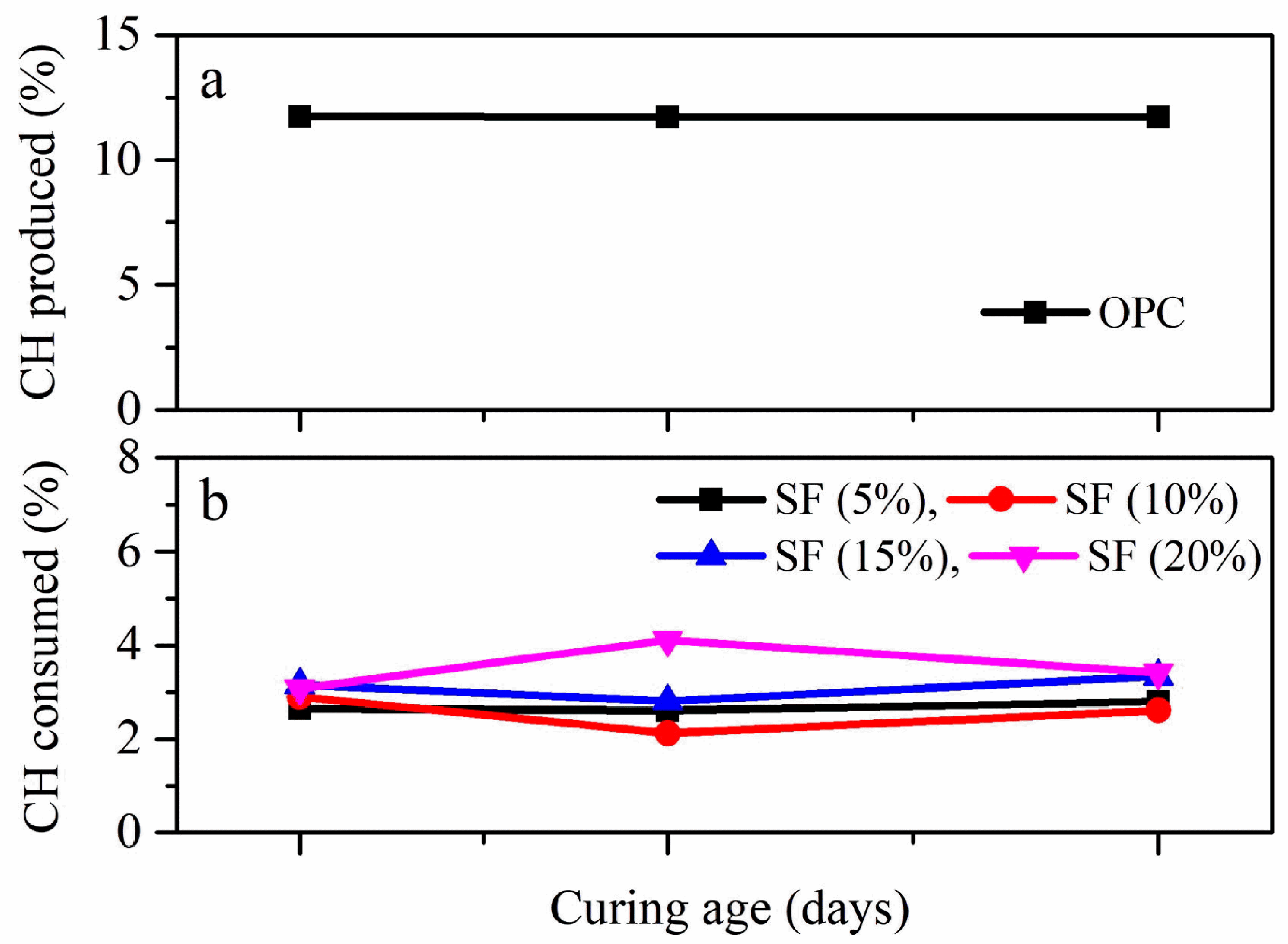

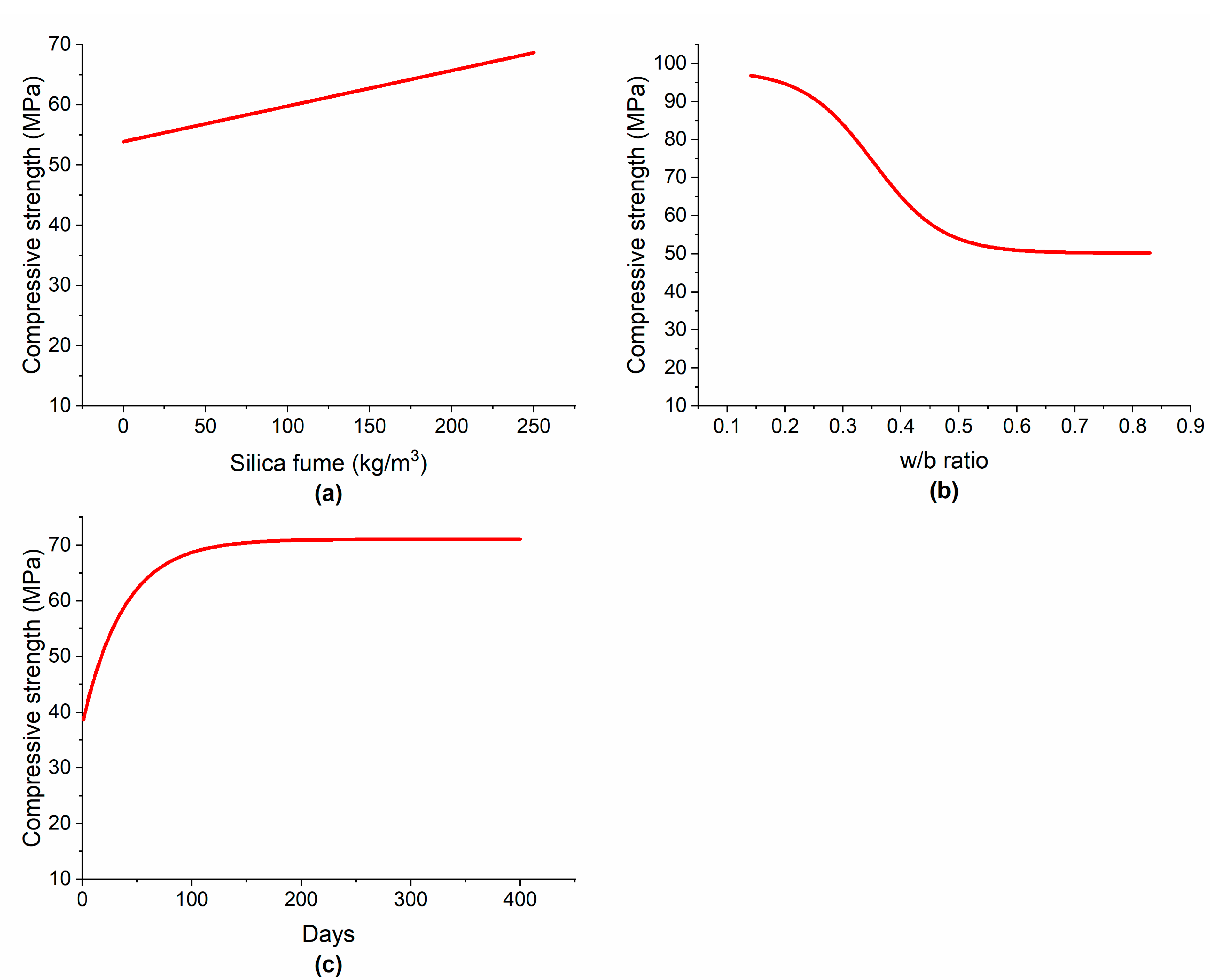

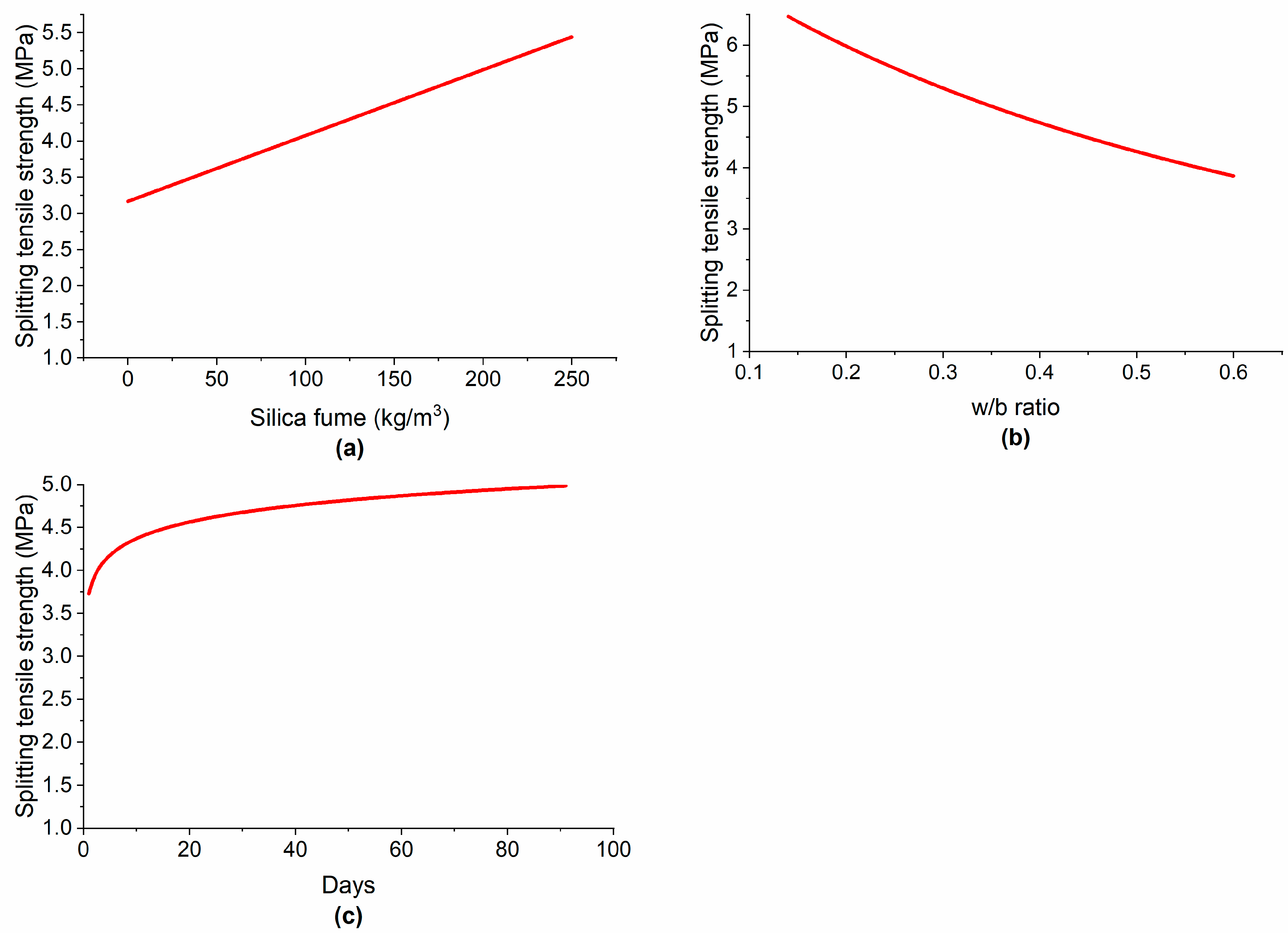

5.3. Parametric Analysis

6. Conclusions

- (1)

- The results of this study show that the application of the M5P technique for the prediction of the CS and STS of concrete made with SF yielded high predictive and generalization capabilities. A comparison of different techniques showed that M5P had superior predictive performance compared with linear regression analysis and gene expression programming for both the CS and STS databases;

- (2)

- In the case of prediction of the CS using M5P, the values of R2 for both the training and testing sets were 0.82, while for the STS, the value of R2 was 0.88 for the training set and 0.86 for the testing set. For predicting both the CS and STS of concrete with SF, the accuracy of the prediction techniques for both training and testing sets was as follows: M5P > GEP > linear regression analysis;

- (3)

- PA captured a linear correlation between the SF content and both the CS and STS. Both CS and STS increase by increasing the content of SF. For both the CS and STS of concrete with SF, it was observed that both parameters decreased by increasing the w/b ratio. In the case of CS, high early strength gain was observed owing to rapid SF pozzolanic reactions. While at later ages, the strength gain was not significant. For the STS, the strength gain was almost linear in the first 7 days and then increased nonlinearly with age, mostly up to 28 days.

7. Future Research

- (1)

- In this study, only individual machine learning (ML) techniques were used for predicting the mechanical properties of concrete with silica fume. It would be beneficial to predict these properties of concrete with silica fume by using the ensemble machine learning technique and comparing it with individual techniques;

- (2)

- In this study, parametric analysis (PA) was conducted and variation in mechanical properties was checked with only silica fume content, w/b ratio, and the age of specimens. In the future, it will be useful to conduct PA using a more accurate ML technique and to explore variations in mechanical properties with cement content, aggregate, and superplasticizer dosages as well. Moreover, sensitivity analysis needs to be investigated;

- (3)

- We predicted only the compressive and splitting tensile strengths of concrete with silica by using ML techniques. Other properties, such as rheology, elastic modulus, flexural strength, and durability characteristics of concrete with silica fume, need to be predicted.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mohammed, A.; Rafiq, S.; Sihag, P.; Kurda, R.; Mahmood, W.; Ghafor, K.; Sarwar, W. ANN, M5P-tree and nonlinear regression approaches with statistical evaluations to predict the compressive strength of cement-based mortar modified with fly ash. J. Mater. Res. Technol. 2020, 9, 12416–12427. [Google Scholar] [CrossRef]

- Sarıdemir, M. Effect of silica fume and ground pumice on compressive strength and modulus of elasticity of high strength concrete. Constr. Build. Mater. 2013, 49, 484–489. [Google Scholar] [CrossRef]

- Mohamed, H.A. Effect of fly ash and silica fume on compressive strength of self-compacting concrete under different curing conditions. Ain Shams Eng. J. 2011, 2, 79–86. [Google Scholar] [CrossRef] [Green Version]

- Mehta, P.K.; Monteiro, P.J. Concrete Microstructure, Properties and Materials; McGraw-Hill Education: New York, NY, USA, 2017. [Google Scholar]

- Zhang, M.-H.; Gjørv, O.E. Effect of silica fume on cement hydration in low porosity cement pastes. Cem. Concr. Res. 1991, 21, 800–808. [Google Scholar] [CrossRef]

- Nedunuri, S.S.S.A.; Sertse, S.G.; Muhammad, S. Microstructural study of Portland cement partially replaced with fly ash, ground granulated blast furnace slag and silica fume as determined by pozzolanic activity. Constr. Build. Mater. 2020, 238, 117561. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Z.; Wang, J.; Zhou, Z.; Du, P.; Cheng, X. Synergistic effect of nano-silica and silica fume on hydration properties of cement-based materials. J. Therm. Anal. 2020, 140, 2225–2235. [Google Scholar] [CrossRef]

- Shah, H.A.; Yuan, Q.; Photwichai, N. Use of materials to lower the cost of ultra-high-performance concrete—A review. Constr. Build. Mater. 2022, 327, 127045. [Google Scholar] [CrossRef]

- Shah, H.A.; Yuan, Q.; Zuo, S. Air entrainment in fresh concrete and its effects on hardened concrete-a review. Constr. Build. Mater. 2021, 274, 121835. [Google Scholar] [CrossRef]

- Mazloom, M.; Ramezanianpour, A.A.; Brooks, J.J. Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Köksal, F.; Altun, F.; Yiğit, I.; Şahin, Y. Combined effect of silica fume and steel fiber on the mechanical properties of high strength concretes. Constr. Build. Mater. 2008, 22, 1874–1880. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of silica fume in concrete: Review of hardened properties. Resour. Conserv. Recycl. 2011, 55, 923–932. [Google Scholar] [CrossRef]

- Bhanja, S.; Sengupta, B. Influence of silica fume on the tensile strength of concrete. Cem. Concr. Res. 2005, 35, 743–747. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Mohamed, Y.S.; El-Gamal, H. Fatigue and tensile behaviors of fiber-reinforced thermosetting composites embedded with nanoparticles. J. Compos. Mater. 2019, 53, 709–718. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.Y.M.; Zaghloul, M.M.Y. Experimental and modeling analysis of mechanical-electrical be-haviors of polypropylene composites filled with graphite and MWCNT fillers. Polym. Test. 2017, 63, 467–474. [Google Scholar] [CrossRef]

- Ben Chaabene, W.; Flah, M.; Nehdi, M.L. Machine learning prediction of mechanical properties of concrete: Critical review. Constr. Build. Mater. 2020, 260, 119889. [Google Scholar] [CrossRef]

- Shah, H.A.; Rehman SK, U.; Javed, M.F.; Iftikhar, Y. Prediction of compressive and splitting tensile strength of concrete with fly ash by using gene expression programming. Struct. Concr. 2021. [Google Scholar] [CrossRef]

- Ahmad, A.; Farooq, F.; Niewiadomski, P.; Ostrowski, K.; Akbar, A.; Aslam, F.; Alyousef, R. Prediction of Compressive Strength of Fly Ash Based Concrete Using Individual and Ensemble Algorithm. Materials 2021, 14, 794. [Google Scholar] [CrossRef]

- Rajeshwari, R.; Mandal, S. Prediction of Compressive Strength of High-Volume Fly Ash Concrete Using Artificial Neural Network. In Sustainable Construction and Building Materials; Springer: Berlin/Heidelberg, Germany, 2019; pp. 471–483. [Google Scholar] [CrossRef]

- Song, H.; Ahmad, A.; Farooq, F.; Ostrowski, K.A.; Maślak, M.; Czarnecki, S.; Aslam, F. Predicting the compressive strength of concrete with fly ash admixture using machine learning algorithms. Constr. Build. Mater. 2021, 308, 125021. [Google Scholar] [CrossRef]

- Kandiri, A.; Golafshani, E.M.; Behnood, A. Estimation of the compressive strength of concretes containing ground granulated blast furnace slag using hybridized multi-objective ANN and salp swarm algorithm. Constr. Build. Mater. 2020, 248, 118676. [Google Scholar] [CrossRef]

- Gilan, S.S.; Jovein, H.B.; Ramezanianpour, A.A. Hybrid support vector regression—Particle swarm optimization for prediction of compressive strength and RCPT of concretes containing metakaolin. Constr. Build. Mater. 2012, 34, 321–329. [Google Scholar] [CrossRef]

- Sarıdemir, M. Genetic programming approach for prediction of compressive strength of concretes containing rice husk ash. Constr. Build. Mater. 2010, 24, 1911–1919. [Google Scholar] [CrossRef]

- Hammoudi, A.; Moussaceb, K.; Belebchouche, C.; Dahmoune, F. Comparison of artificial neural network (ANN) and response surface methodology (RSM) prediction in compressive strength of recycled concrete aggregates. Constr. Build. Mater. 2019, 209, 425–436. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.L.; Poon, C.A. Effect of Fly Ash and Silica Fume on Compressive and Fracture Behaviors of Concrete. Cem. Concr. Res. 1998, 28, 271–283. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Türkmen, I. Influence of different curing conditions on the physical and mechanical properties of concretes with admixtures of silica fume and blast furnace slag. Mater. Lett. 2003, 57, 4560–4569. [Google Scholar] [CrossRef]

- Benaicha, M.; Roguiez, X.; Jalbaud, O.; Burtschell, Y.; Alaoui, A.H. Influence of silica fume and viscosity modifying agent on the mechanical and rheological behavior of self compacting concrete. Constr. Build. Mater. 2015, 84, 103–110. [Google Scholar] [CrossRef]

- Siddique, R.; Jameel, A.; Singh, M.; Barnat-Hunek, D.; Kunal; Aït-Mokhtar, A.; Belarbi, R.; Rajor, A. Effect of bacteria on strength, permeation characteristics and micro-structure of silica fume concrete. Constr. Build. Mater. 2017, 142, 92–100. [Google Scholar] [CrossRef]

- Uygar, E.; Aydin, E. Effect of silica fume on the fresh and hardened properties of high performance concrete. In Proceedings of the 3rd International Conference on Construction Materials, Performance, Innovations and Structural Implications, Vancouver, BC, Canada, 22–24 August 2005; pp. 22–24. [Google Scholar]

- Elyamany, H.E.; Elmoaty, A.E.M.A.; Mohamed, B. Effect of filler types on physical, mechanical and microstructure of self compacting concrete and Flow-able concrete. Alex. Eng. J. 2014, 53, 295–307. [Google Scholar] [CrossRef] [Green Version]

- Meddah, M.S.; Ismail, M.A.; El-Gamal, S.; Fitriani, H. Performances evaluation of binary concrete designed with silica fume and metakaolin. Constr. Build. Mater. 2018, 166, 400–412. [Google Scholar] [CrossRef]

- Altun, M.G.; Oltulu, M. Effect of different types of fiber utilization on mechanical properties of recycled aggregate concrete containing silica fume. J. Green Build. 2020, 15, 119–136. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Combined effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef] [Green Version]

- Sobolev, K. The development of a new method for the proportioning of high-performance concrete mixtures. Cem. Concr. Compos. 2004, 26, 901–907. [Google Scholar] [CrossRef]

- Wong, H.; Razak, H.A. Efficiency of calcined kaolin and silica fume as cement replacement material for strength performance. Cem. Concr. Res. 2005, 35, 696–702. [Google Scholar] [CrossRef] [Green Version]

- Ramadoss, P. Combined effect of silica fume and steel fiber on the splitting tensile strength of high-strength concrete. Interna-Tional J. Civ. Eng. 2014, 12, 96–103. [Google Scholar]

- Luo, X.; Si, Y.; Gu, W. Effect of Silica Fume on Mechanical Properties of Concrete Incorporating Steel Slag Powder. Wuhan Univ. J. Nat. Sci. 2019, 24, 86–92. [Google Scholar] [CrossRef]

- Naik, M.P.P.; Vyawahare, M. Comparative Study of Effect of Silica Fume and Quarry Dust on Strength of Self Compacting Concrete. Int. J. Eng. Res. Appl. 2013, 3, 1497–1500. [Google Scholar]

- Poon, C.; Kou, S.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Özturan, T. Properties of rubberized concretes containing silica fume. Cem. Concr. Res. 2004, 34, 2309–2317. [Google Scholar] [CrossRef]

- Zaw, O. Effect of Silica Fume on the Properties of Concrete. Int. J. Eng. Res. Adv. Technol. 2019, 5, 55–59. [Google Scholar] [CrossRef]

- Dilbas, H.; Şimşek, M.; Çakır, Ö. An investigation on mechanical and physical properties of recycled aggregate concrete (RAC) with and without silica fume. Constr. Build. Mater. 2014, 61, 50–59. [Google Scholar] [CrossRef]

- Wang, Q.L.; Bao, J.C. Effect of Silica Fume on Mechanical Properties and Carbonation Resistance of Concrete. In Applied Mechanics and Materials; Trans Tech Publ.: Zurich, Switzerland, 2012; pp. 161–164. [Google Scholar] [CrossRef]

- Ajileye, F.V. Investigations on microsilica (silica fume) as partial cement replacement in concrete. Glob. J. Res. Eng. 2012, 12, 16–23. [Google Scholar]

- Hanumesh, B.; Varun, B.; Harish, B. The mechanical properties of concrete incorporating silica fume as partial replacement of cement. Int. J. Emerg. Technol. Adv. Eng. 2015, 5, 270. [Google Scholar]

- Elsayed, A. Influence of silica fume, fly ash, super pozz and high slag cement on water permeability and strength of concrete. Jordan J. Civ. Eng. 2011, 5, 245–257. [Google Scholar]

- Huchante, S.R.; Chandupalle, S.; Ghorpode, V.G.; TCV, R. Mix design of high performance concrete using silica fume and superplasticizer. Pan 2014, 18, 100. [Google Scholar]

- Wongkeo, W.; Thongsanitgarn, P.; Ngamjarurojana, A.; Chaipanich, A. Compressive strength and chloride resistance of self-compacting concrete containing high level fly ash and silica fume. Mater. Des. 2014, 64, 261–269. [Google Scholar] [CrossRef]

- Nili, M.; Salehi, A. Assessing the effectiveness of pozzolans in massive high-strength concrete. Constr. Build. Mater. 2010, 24, 2108–2116. [Google Scholar] [CrossRef]

- Salam, L.A. Effect of steel fiber and silica fume on hardened concrete compressive and flexural strength. J. Eng. Dev. 2015, 19, 68–85. [Google Scholar]

- Pradhan, D.; Dutta, D. Influence of silica fume on normal concrete. Int. J. Eng. Res. Appl. 2013, 3, 79–82. [Google Scholar]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Meleka, N.; Bashandy, A.A.; Arab, M.A. Ultra high strength concrete using economical materials. Int. J. Curr. Eng. Technol. 2013, 3, 393–402. [Google Scholar]

- Johari, M.M.; Brooks, J.; Kabir, S.; Rivard, P. Influence of supplementary cementitious materials on engineering properties of high strength concrete. Constr. Build. Mater. 2011, 25, 2639–2648. [Google Scholar] [CrossRef]

- Yi, S.-T.; Yang, E.-I.; Choi, J.-C. Effect of specimen sizes, specimen shapes, and placement directions on compressive strength of concrete. Nucl. Eng. Des. 2006, 236, 115–127. [Google Scholar] [CrossRef]

- Che, Y.; Zhang, N.; Yang, F.; Prafulla, M. Splitting tensile strength of selfconsolidating concrete and its size effect. In Proceedings of the 2016 World Congress (Structures 16), Jeju Island, Korea, 28 August–1 September 2016. [Google Scholar]

- Kadleček, V.; Modry, S. Size effect of test specimens on tensile splitting strength of concrete: General relation. Mater. Struct. 2002, 35, 28. [Google Scholar] [CrossRef]

- Quinlan, J.R. Learning with continuous classes. In 5th Australian Joint Conference on Artificial Intelligence; World Scientific: Singapore, 1992; pp. 343–348. [Google Scholar]

- Wang, Y.; Witten, I.H. Induction of Model Trees for Predicting Continuous Classes; University of Waikato: Hamilton, New Zealand, 1996. [Google Scholar]

- Ferreira, C. Gene Expression Programming: Mathematical Modeling by an Artificial Intelligence; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Sarıdemir, M. Effect of specimen size and shape on compressive strength of concrete containing fly ash: Application of genetic programming for design. Mater. Des. 2014, 56, 297–304. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Alavi, A.H.; Mirzahosseini, M.R.; Nejad, F.M. Nonlinear Genetic-Based Models for Prediction of Flow Number of Asphalt Mixtures. J. Mater. Civ. Eng. 2011, 23, 248–263. [Google Scholar] [CrossRef]

- Bentur, A.; Goldman, A.; Cohen, M.D. The Contribution of the Transition Zone to the Strength of High Quality Silica Fume Concretes. MRS Proc. 1987, 114, 97. [Google Scholar] [CrossRef]

- Nežerka, V.; Bílý, P.; Hrbek, V.; Fládr, J. Impact of silica fume, fly ash, and metakaolin on the thickness and strength of the ITZ in concrete. Cem. Concr. Compos. 2019, 103, 252–262. [Google Scholar] [CrossRef]

- Lü, Q.; Qiu, Q.; Zheng, J.; Wang, J.; Zeng, Q. Fractal dimension of concrete incorporating silica fume and its correlations to pore structure, strength and permeability. Constr. Build. Mater. 2019, 228, 116986. [Google Scholar] [CrossRef]

- Rong, Z.; Sun, W.; Xiao, H.; Wang, W. Effect of silica fume and fly ash on hydration and microstructure evolution of cement based composites at low water–binder ratios. Constr. Build. Mater. 2014, 51, 446–450. [Google Scholar] [CrossRef]

- Hooton, R. Influence of silica fume replacement of cement on physical properties and resistance to sulfate attack, freezing and thawing, and alkali-silica reactivity. Mater. J. 1993, 90, 143–151. [Google Scholar]

| Compressive Strength Database | ||||||||

|---|---|---|---|---|---|---|---|---|

| Statistical Indicator | C (kg/m3) | SF (kg/m3) | W/B | FA (kg/m3) | CA (kg/m3) | SP (kg/m3) | Days | Strength (MPa) |

| Minimum | 188 | 0 | 0.14 | 468.98 | 0 | 0 | 1 | 3.57 |

| Maximum | 1000 | 250 | 0.83 | 2750 | 1248 | 80 | 400 | 136.8 |

| Mean | 422.55 | 39.35 | 0.42 | 806.32 | 969.9 | 8.7 | 53.4 | 53.72 |

| Standard error | 4.44 | 1.37 | 0.005 | 10.02 | 11.51 | 0.46 | 3.11 | 0.83 |

| Standard deviation | 125.26 | 38.72 | 0.14 | 282.7 | 324.9 | 13.15 | 87.92 | 23.53 |

| Kurtosis | 2.54 | 7.27 | 0.6 | 21.15 | 3.15 | 13.75 | 6.53 | −0.178 |

| Skewness | 0.99 | 2.13 | 0.92 | 3.85 | −1.97 | 3.51 | 2.65 | 0.325 |

| Splitting Tensile Strength Database | ||||||||

| Minimum | 197 | 0 | 0.14 | 535 | 0 | 0 | 1 | 0.51 |

| Maximum | 800 | 250 | 0.83 | 1315 | 1248 | 80 | 91 | 10 |

| Mean | 458.02 | 54.36 | 0.38 | 816.58 | 892.56 | 13.19 | 32.11 | 4.23 |

| Standard error | 11.54 | 4.94 | 0.01 | 16.76 | 29.36 | 1.83 | 2.24 | 0.15 |

| Standard deviation | 144.07 | 61.65 | 0.14 | 209.34 | 366.71 | 22.83 | 27.95 | 1.87 |

| Kurtosis | −0.07 | 2.46 | 1.31 | −0.15 | 1.37 | 3.64 | 0.15 | 0.46 |

| Skewness | 0.73 | 1.76 | 0.67 | 0.85 | −1.54 | 2.29 | 1.12 | 0.68 |

| Parameters | GEP Model for CS | GEP Model for STS |

|---|---|---|

| Head size | 10 | 10 |

| Chromosome | 30 | 50 |

| Genes | 3 | 5 |

| Linking function | Addition | Addition |

| Number of generations | 50,000 | 50,000 |

| Linear Model | a | b | c | d | e | f | g | h |

|---|---|---|---|---|---|---|---|---|

| LM1 | 78.471 | 0.0055 | −222.5715 | 0.0343 | 0.0077 | 0.021 | 2.6966 | |

| LM2 | 61.8093 | 0.1844 | −92.516 | 0.0277 | 0.0303 | 0.021 | 0.0331 | |

| LM3 | 87.4672 | −0.0032 | −161.529 | 0.0268 | 0.0134 | 0.021 | 0.0413 | |

| LM4 | 165.2335 | −0.0091 | −380.5541 | 0.0226 | 0.0134 | 0.021 | 0.0423 | |

| LM5 | 104.29 | 0.0955 | −172.6348 | 0.0266 | 0.0134 | 0.021 | 0.0422 | |

| LM6 | 25.74 | −0.003 | −12.1069 | 0.0001 | 0.0005 | 0.7868 | 1.7661 | |

| LM7 | 28.5248 | −0.003 | −12.1069 | 0.0001 | 0.0005 | 0.7868 | 1.4339 | |

| LM8 | 31.443 | −0.003 | −12.1069 | 0.0001 | 0.0005 | 1.2469 | 1.5649 | |

| LM9 | 38.8668 | −0.0022 | −12.1069 | 0.0001 | 0.0005 | 0.4578 | 0.3137 | |

| LM10 | 45.222 | −0.0022 | −12.1069 | 0.0001 | 0.0005 | 0.5065 | 0.3137 | |

| LM11 | 22.314 | −0.0017 | −18.5849 | 0.0001 | 0.0005 | 0.2503 | 2.1477 | |

| LM12 | 46.1883 | −0.0667 | −15.2811 | 0.0163 | 0.0005 | 0.1293 | 0.0216 | |

| LM13 | 57.5337 | −0.0667 | −15.2811 | 0.0063 | 0.0005 | 0.1293 | 0.0216 | |

| LM14 | 59.0744 | −0.0955 | −15.2811 | −0.0053 | 0.0005 | 0.1293 | 0.0216 | |

| LM15 | 54.7424 | −0.1202 | −15.2811 | −0.0053 | 0.0005 | 0.1293 | 0.0216 | |

| LM16 | 67.5622 | −0.0577 | −15.2811 | −0.0054 | 0.0005 | 0.1293 | 0.0296 | |

| LM17 | 83.8422 | −0.0238 | −62.7051 | −0.0018 | 0.0005 | 0.1293 | 0.0224 | |

| LM18 | 75.9732 | −13.91 | −0.0043 | 0.0005 | 0.1795 | 0.0144 | ||

| LM19 | 61.0595 | −13.91 | −0.0006 | 0.0005 | 0.1795 | 0.0144 | ||

| LM20 | 66.9734 | −13.91 | −0.0014 | 0.0005 | 0.1795 | 0.0144 |

| Models for CS | Training Set | Testing Set | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R | MAE | RSE | RMSE | DR (%) | R | MAE | RSE | RMSE | DR (%) | |

| Linear regression analysis | 0.74 | 13.6 | 0.45 | 16.5 | 47 | 0.73 | 16 | 0.47 | 19.6 | 50 |

| GEP | 0.86 | 10.3 | 0.26 | 13.35 | 78 | 0.86 | 9.9 | 0.26 | 13.6 | 70 |

| M5P | 0.91 | 8.37 | 0.19 | 10.46 | 78.6 | 0.9 | 9 | 0.18 | 12.4 | 75 |

| Linear Model | a | b | c | d | e | f | g | h |

|---|---|---|---|---|---|---|---|---|

| LM1 | 15.27 | −0.012 | 0.003 | −17.43 | 0.0109 | 0.0293 | ||

| LM2 | −2.75 | 0.0113 | 0.0112 | −5.02 | 0.0176 | 0.017 | ||

| LM3 | −3.877 | 0.0114 | 0.0056 | 2.1 | 0.0011 | −0.0077 | 0.0173 | |

| LM4 | 11.53 | −0.0034 | 0.0091 | −15.12 | −0.0006 | −0.083 | 0.0173 |

| Models for STS | Training Set | Testing Set | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R | MAE | RSE | RMSE | DR (%) | R | MAE | RSE | RMSE | DR (%) | |

| Linear regression analysis | 0.81 | 1.1 | 0.37 | 1.23 | 46 | 0.83 | 0.84 | 0.32 | 1.1 | 68 |

| GEP | 0.88 | 0.71 | 0.22 | 0.9 | 75 | 0.84 | 0.83 | 0.3 | 1.09 | 66 |

| M5P | 0.94 | 0.51 | 0.14 | 0.64 | 75.3 | 0.93 | 0.7 | 0.17 | 0.85 | 75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, H.A.; Nehdi, M.L.; Khan, M.I.; Akmal, U.; Alabduljabbar, H.; Mohamed, A.; Sheraz, M. Predicting Compressive and Splitting Tensile Strengths of Silica Fume Concrete Using M5P Model Tree Algorithm. Materials 2022, 15, 5436. https://doi.org/10.3390/ma15155436

Shah HA, Nehdi ML, Khan MI, Akmal U, Alabduljabbar H, Mohamed A, Sheraz M. Predicting Compressive and Splitting Tensile Strengths of Silica Fume Concrete Using M5P Model Tree Algorithm. Materials. 2022; 15(15):5436. https://doi.org/10.3390/ma15155436

Chicago/Turabian StyleShah, Hammad Ahmed, Moncef L. Nehdi, Muhammad Imtiaz Khan, Usman Akmal, Hisham Alabduljabbar, Abdullah Mohamed, and Muhammad Sheraz. 2022. "Predicting Compressive and Splitting Tensile Strengths of Silica Fume Concrete Using M5P Model Tree Algorithm" Materials 15, no. 15: 5436. https://doi.org/10.3390/ma15155436

APA StyleShah, H. A., Nehdi, M. L., Khan, M. I., Akmal, U., Alabduljabbar, H., Mohamed, A., & Sheraz, M. (2022). Predicting Compressive and Splitting Tensile Strengths of Silica Fume Concrete Using M5P Model Tree Algorithm. Materials, 15(15), 5436. https://doi.org/10.3390/ma15155436