The Influence of the Type of Fibers on the Reduction of the Threshold Effect in the Transition Zone of a Railway Track

Abstract

:1. Introduction

1.1. A Brief Overview of Previous Studies

1.2. New Applications

2. Materials and Methods

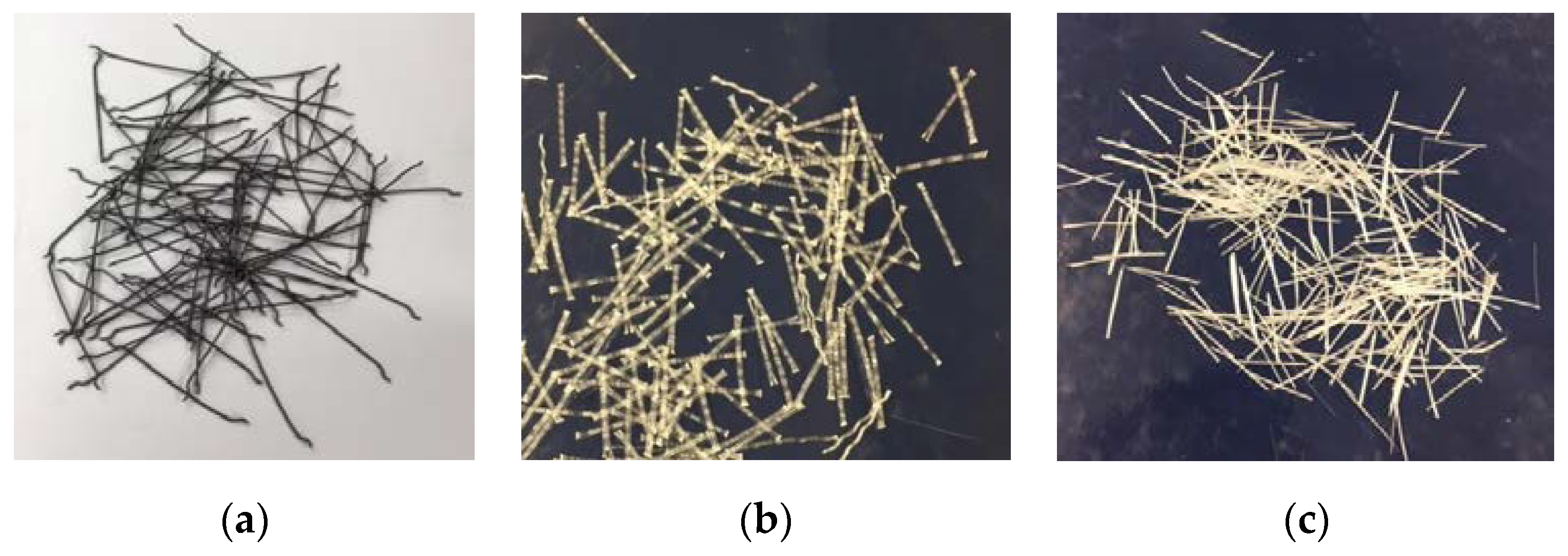

2.1. Materials

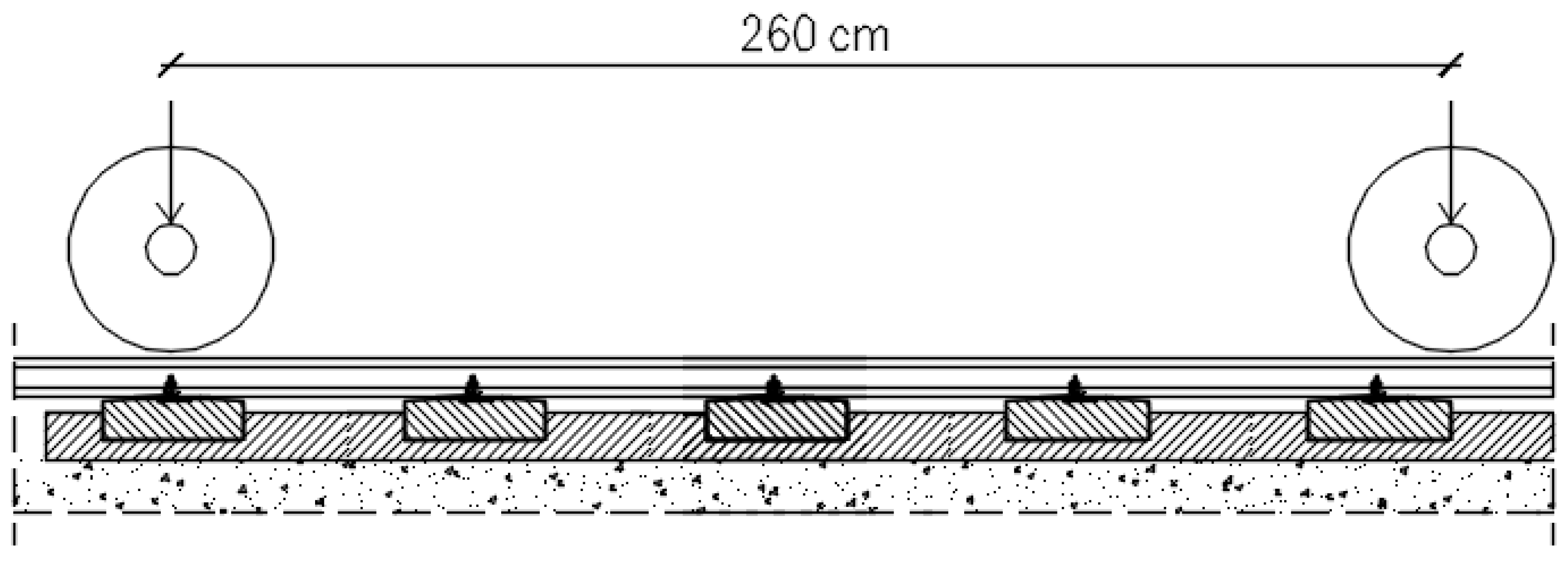

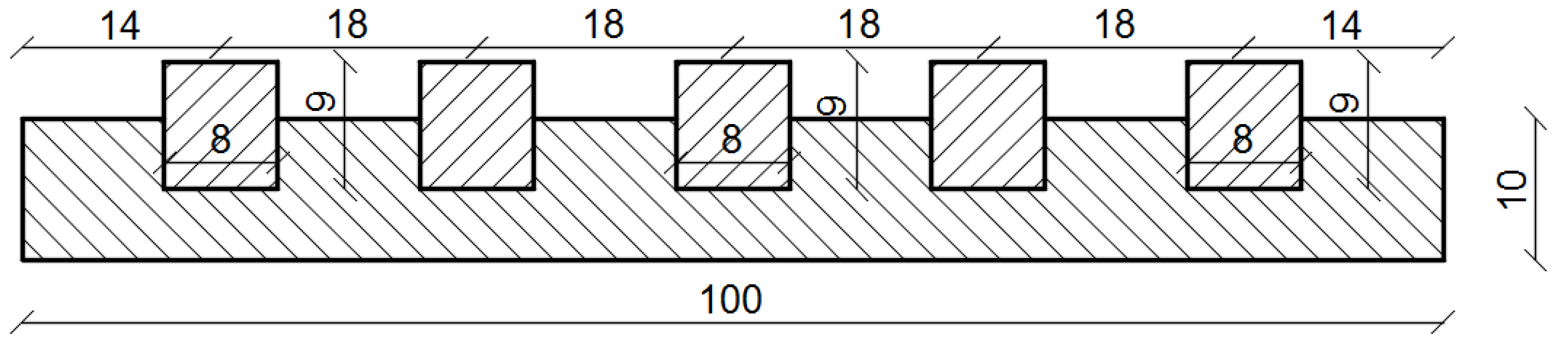

2.2. Research Methods

3. Results

3.1. Consistency of Concrete Mix

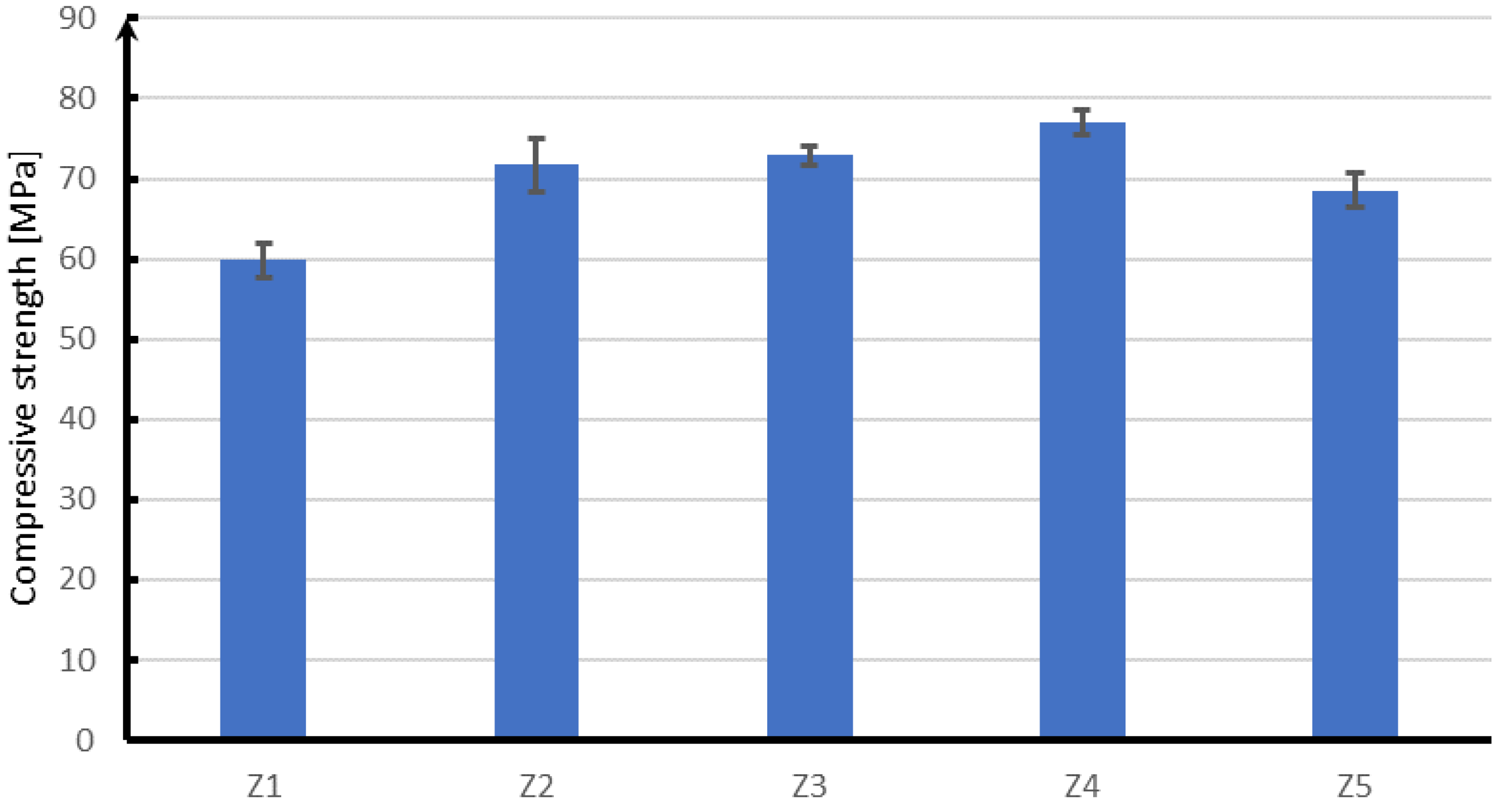

3.2. Compressive Strength

3.3. Frost Resistance

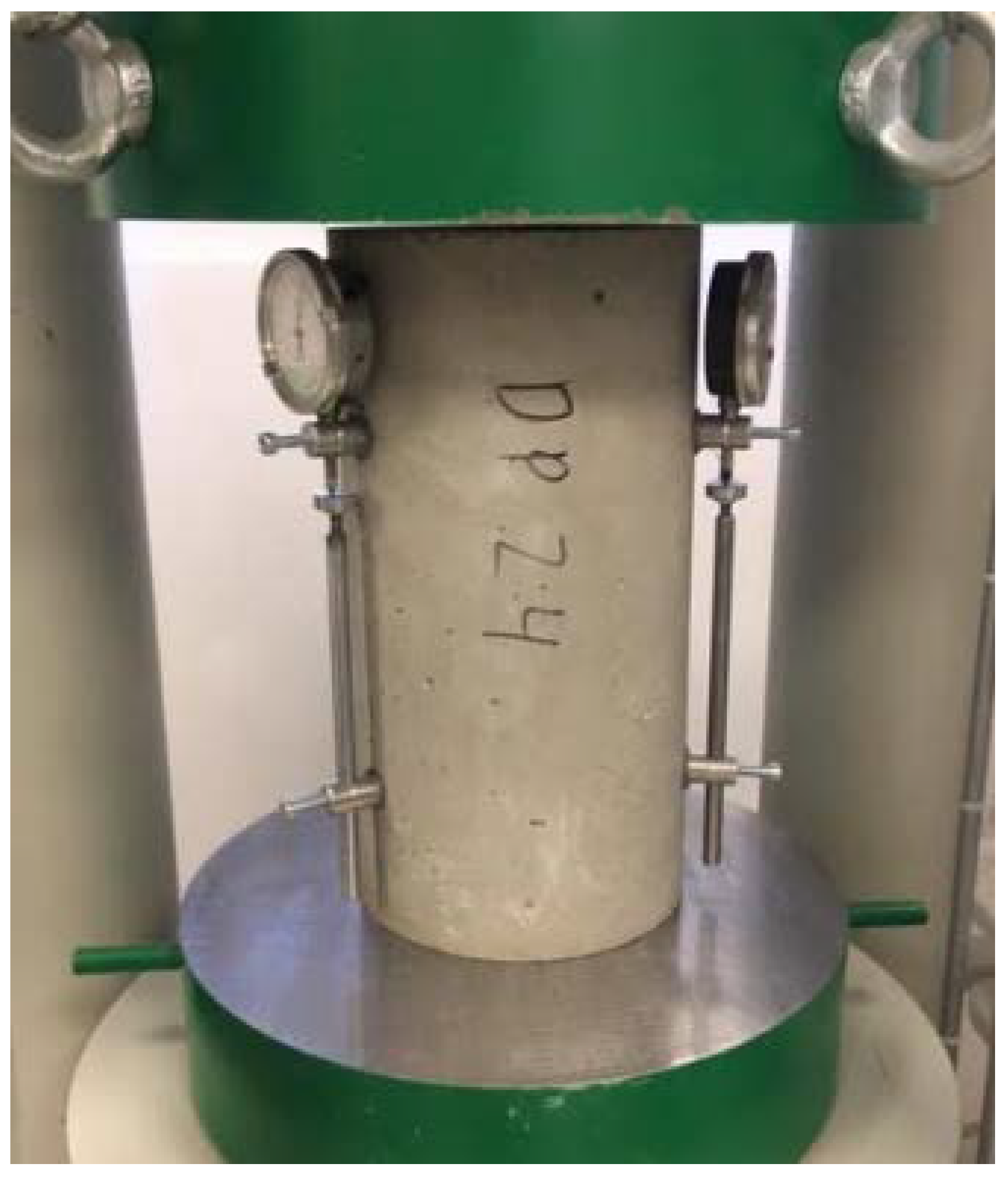

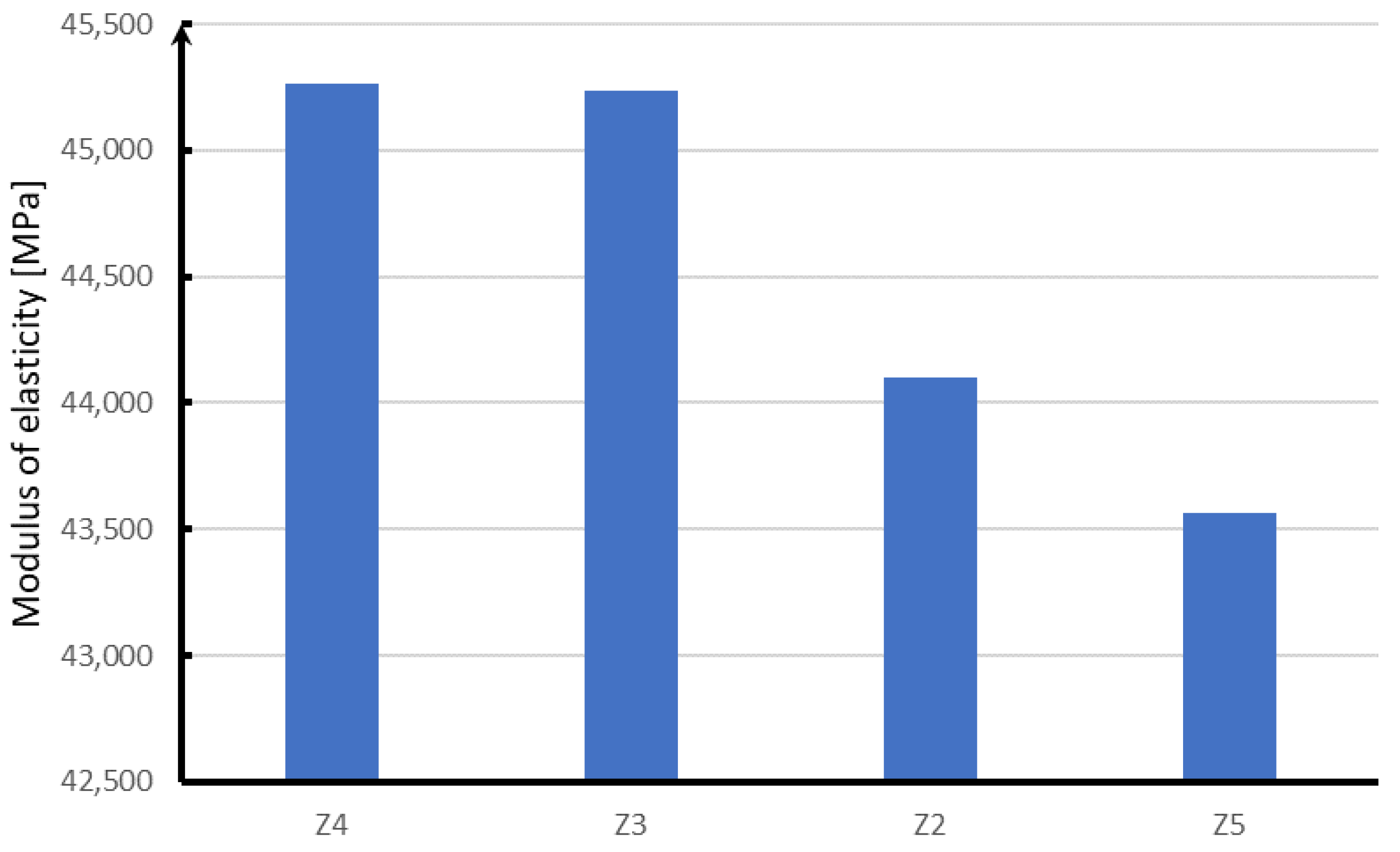

3.4. Modulus of Elasticity

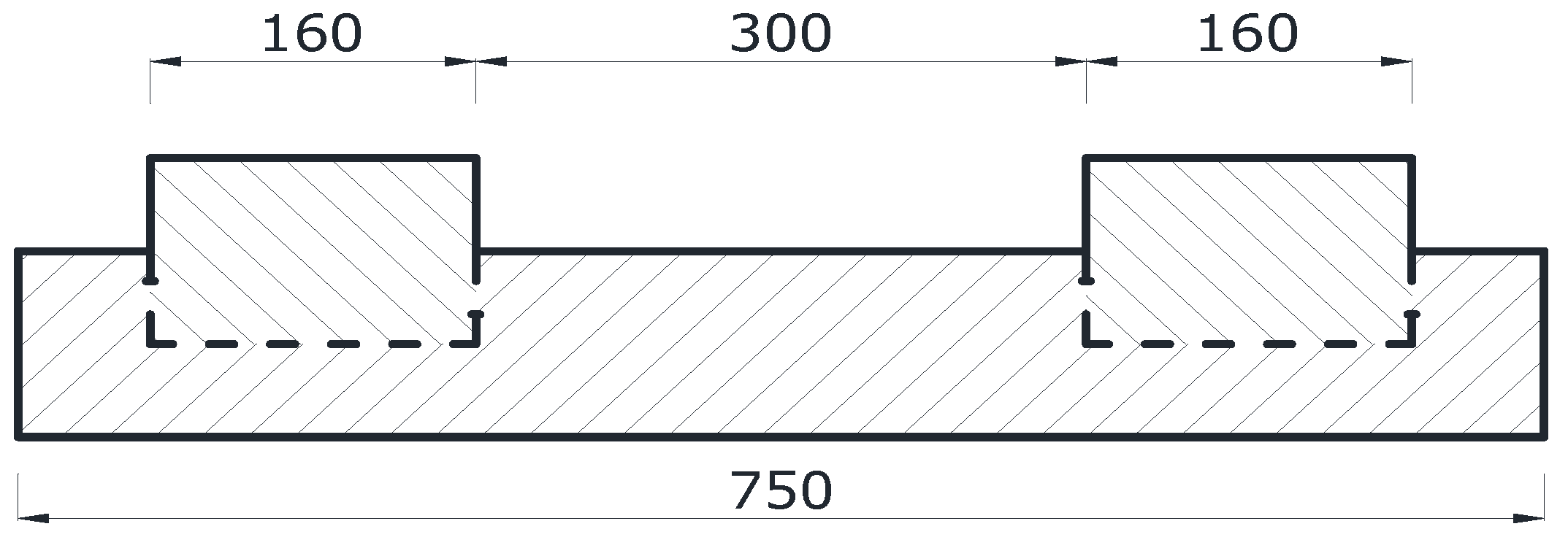

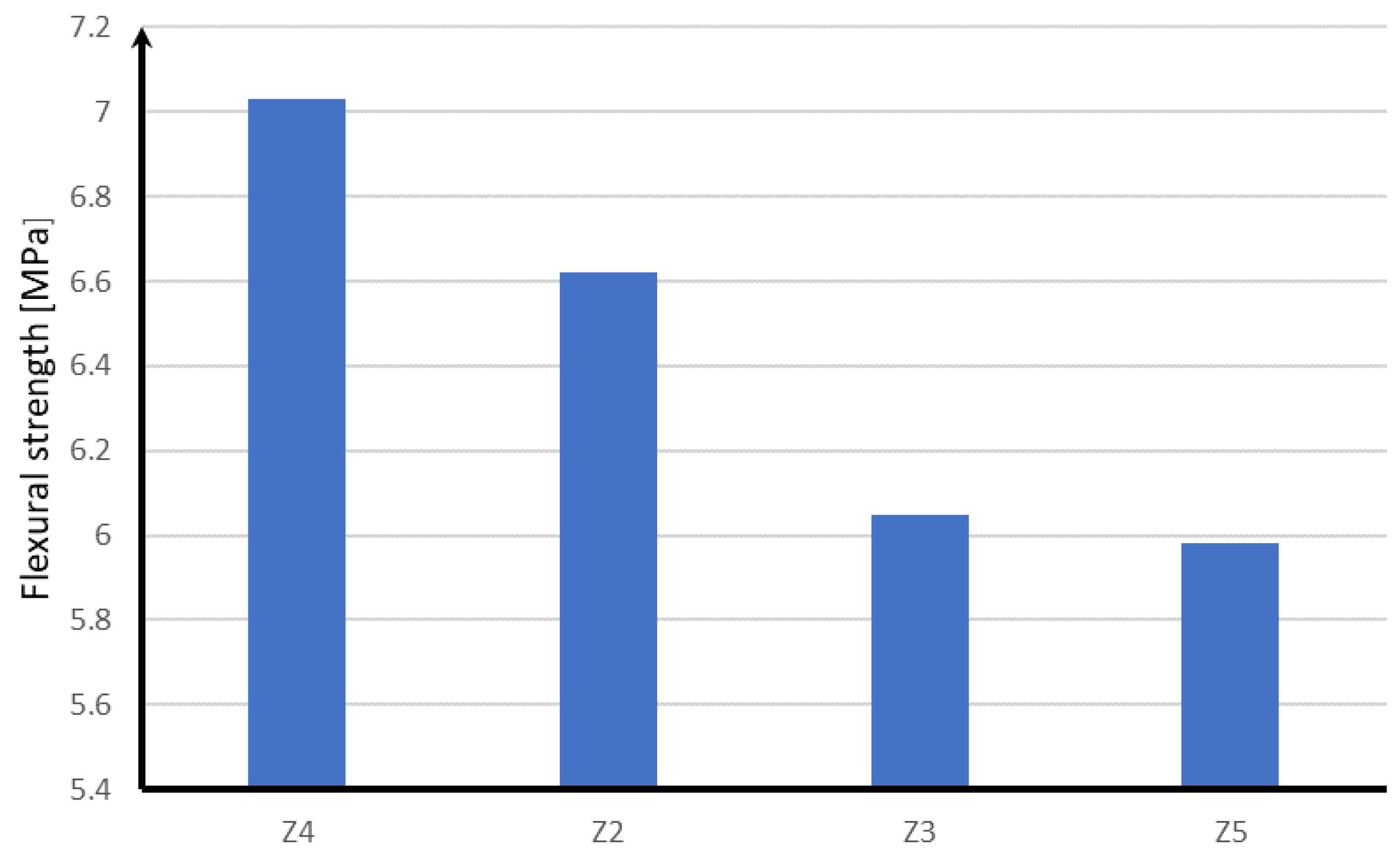

3.5. Tensile Strength of the Cross-Section of the Ballastless Railway Surface

3.6. Tensile Strength of the Longitudinal Section of the Ballastless Railway Surface

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gołaszewski, J. Domieszki do Betonu. Efekt Działania, Ocena i Badania Efektywności, Stosowanie; Wydawnictwo Politechniki: Śląskiej, Gliwice, 2016. [Google Scholar]

- Rudnicki, T. Natural and synthetic admixtures plasticize the tail and mechanisms of their interaction in the concrete mix. Mag. Autostrady 2004, 4, 22–25. [Google Scholar] [CrossRef]

- Rudnicki, T. Functional Method of Designing Self-Compacting Concrete. Materials 2021, 14, 267. [Google Scholar] [CrossRef] [PubMed]

- Glinicki, M.A. Inżynieria Betonowych Nawierzchni Drogowych; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2019. [Google Scholar]

- Pasławski, J.; Rudnicki, T. Agile/Flexible and Lean Management in Ready-Mix concrete delivery. Arch. Civil Eng. 2021, 67, 689–709. [Google Scholar] [CrossRef]

- Rudnicki, T.; Jurczak, R. The impact of the addition of diabase dusts on the properties of cement pavement concrete. Arch. Civil Eng. 2022, 68, 395–411. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Influence of Polypropylene, Glass and Steel Fiber on the Thermal Properties of Concrete. Materials 2021, 14, 1888. [Google Scholar] [CrossRef] [PubMed]

- Małek, M.; Łasica, Ł.; Kadela, M.; Kluczyński, J.; Dudek, D. Physical and Mechanical Properties of Polypropylene Fibre-Reinforced Cement–Glass Composite. Materials 2021, 14, 637. [Google Scholar] [CrossRef] [PubMed]

- Foti, D. Innovative techniques for concrete reinforcement with polymers. Constr. Build. Mater. 2016, 112, 202–209. [Google Scholar] [CrossRef]

- Jurczak, R.; Szmatuła, F.; Rudnicki, T.; Korentz, J. Effect of Ground Waste Glass Addition on the Strength and Durability of Low Strength Concrete Mixes. Materials 2021, 14, 190. [Google Scholar] [CrossRef] [PubMed]

- Foti, D.; Lerna, M.; Sabbà, M.F.; Vacca, V. Mechanical characteristics and water absorption properties of blast-furnace slag concretes with fly ashes or microsilica additions. Appl. Sci. 2019, 9, 1279. [Google Scholar] [CrossRef]

- Rudnicki, T.; Jurczak, R. Recycling of a Concrete Pavement after over 80 Years in Service. Materials 2020, 13, 2262. [Google Scholar] [CrossRef] [PubMed]

- Idczak, W.; Lewandrowski, T.; Pokropski, D.; Rudnicki, T.; Trzmiel, J. Dynamic Impact of a Rail Vehicle on a Rail Infrastructure with Particular Focus on the Phenomenon of Threshold Effect. Energies 2022, 15, 2119. [Google Scholar] [CrossRef]

- Vostroukhov, A.; Metrikine, A. Periodically supported beam on a visco-elastic layer as a model for dynamic analysis of a high-speed railway track. Int. J. Solid Struct. 2003, 2003, 5723–5752. [Google Scholar] [CrossRef]

- Szafrański, M. Wpływ Sposobu Odwzorowania Pojazdu Szynowego na Odpowiedz´ Dynamiczna˛ Przęsła Mostowego; Infrastruktura Transportu Szynowego: Gdańsk, Poland, 2019. [Google Scholar]

- Kaewunruen, S.; Lewandrowski, T.; Chamniprasart, K. Nonlinear modeling and analysis of moving train loads on interspersed railway tracks. In Proceedings of the 6th ECCOMAS Thematic Conference on Computational Methods in Structural Dynamics and Earthquake Engineering, Rhodes Island, Greece, 15–17 June 2017. [Google Scholar]

- Kaewunruen, S.; Lewandrowski, T.; Chamniprasart, K. Dynamic responses of interspersed railway tracks to moving train loads. Int. J. Struct. Stab. Dyn. 2018, 18, 1850011. [Google Scholar] [CrossRef]

- Goicolea, J.M.; Nguyen, K.; Galbadón, F.; Bermejo, M. Dynamic Analysis of High Speed Railway Traffic Loads on Ballast and Slab Tracks, Conference Paper January 2010. Available online: https://www.ctresources.info/ccp/paper.html?id=5725 (accessed on 23 June 2022).

- Skaner Laserowy ScanCONTROL 2610-50-Micro-Epsilon. Available online: http://www.micro-epsilon.pl/produkt/10115/skaner-laserowy-scancontrol-2610-50/ (accessed on 23 June 2022).

- Sołkowski, J.; Kudła, D. Analiza Niejednorodności Mechanicznych Nawierzchni i Podtorza w Obrębie Obiektu mostowego. Zeszyty Naukowo-Techniczne Stowarzyszenia Inżynierów i Techników Komunikacji Rzeczypospolitej Polskiej, Kraków. 2016. Available online: http://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-96c9ea1a-cdac-4031-85d5-243da1eb1405 (accessed on 23 June 2022).

- Sołkowski, J. Zarys analizy efektu progowego przy łączeniu nawierzchni podsypkowych z innymi typami nawierzchni. TTS Tech. Transp. Szyn. 2009, 15, 59–65. [Google Scholar]

- Sołkowski, J. Efekt Progowy w Nawierzchniach Szynowych; Politechnika Krakowska: Warszawa, Polska, 2013. [Google Scholar]

- PN-EN 206.2014 Beton. Wymagania, Właściwości, Produkcja i Zgodność. Available online: https://sklep.pkn.pl/pn-en-206-2014-04p.html (accessed on 23 June 2022).

- Specyfikacja Techniczna t.11.10.06 Bezpodsypkowa Konstrukcja Torowiska Tramwajowego w Postaci Prefabrykowanych Podkładów Dwublokowych Połączonych Konstrukcyjnie z Płytą Betonową. Available online: https://doczz.pl/doc/1998921/specyfikacja-techniczna-t.11.10.06-bezpodsypkowa-konstrukcja (accessed on 23 June 2022).

- Specyfikacja Techniczna Wykonania i Odbioru Robót Budowlanych D-04.05.01 Podbudowa z Kruszywa Stabilizowanego Cementem. Available online: https://ozimek.pl/static/img/k01/ZP%20AK_2021/obek/SPECYFIKACJE%20TECHNICZNE%20WYKONANIA%20I%20ODBIORU%20ROB%C3%93T.pdf (accessed on 23 June 2022).

- Specyfikacja Techniczna Wykonania i Odbioru Robót Budowlanych T-03.00.03. Budowa Nowej Nawierzchni Torów—Nawierzchnia Bezpodsypkowa. Gorzów Wielkopolski. Available online: https://www.gdansk.uw.gov.pl/attachments/article/1338/01_OST%20-%20WYMAGANIA%20OG%C3%93LNE.pdf (accessed on 23 June 2022).

- Warunki Techniczne Wykonania i Odbioru Podkładów i Podrozjazdnic Strunobetonowych Id—101. Warszawa, Poland. 2010. Available online: https://www.plk-sa.pl/files/public/user_upload/pdf/Akty_prawne_i_przepisy/Instrukcje/Wydruk/Id/Id-101_WCAG.pdf (accessed on 23 June 2022).

- PN-EN 14889-1:2007—Włókna do Betonu—Część 1: Włókna Stalowe—Definicje Wymagania i Zgodność. Available online: https://infostore.saiglobal.com/en-us/Standards/PN-EN-14889-1-2007-933809_SAIG_PKN_PKN_2200615/ (accessed on 23 June 2022).

- Available online: www.siatpol-zbrojenia.pl (accessed on 23 June 2022).

- PN-EN 14889—Włókna do Betonu. Available online: https://sklep.pkn.pl/pn-en-14889-1-2007p.html (accessed on 23 June 2022).

- PN-EN 12350-2:2011 Badania Mieszanki Betonowej—Część 2: Badanie Konsystencji Metodą Opadu Stożka. Available online: https://sklep.pkn.pl/pn-en-12350-2-2011p.html (accessed on 23 June 2022).

- PN-EN 12390-3:2019-08 Badania Betonu—Część 3: Wytrzymałość na Ściskanie Próbek do Badań. Available online: https://sklep.pkn.pl/pn-en-12390-3-2019-07p.html (accessed on 23 June 2022).

- PN-88/B-06250 Beton Zwykły. Available online: https://sklep.pkn.pl/pn-b-06250-1988p.html (accessed on 23 June 2022).

- PN-EN 12390-13-2014-02 Badania Betonu. Część 13: Wyznaczanie Siecznego Modułu Sprężystości Przy Ściskaniu. Available online: https://sklep.pkn.pl/pn-en-12390-13-2014-02e.html (accessed on 23 June 2022).

| Parameter | Unit | CEM I 42.5 N/NA WARTA | CEM I 42.5 R CEMEX |

|---|---|---|---|

| Compressive strength | |||

| after 2 days | MPa | 17.9 | 25.6 |

| after 28 days | MPa | 50.5 | 54.3 |

| Bending strength | |||

| after 2 days | MPa | 3.7 | - |

| after 28 days | MPa | 8.3 | - |

| Setting time: | |||

| beginning | min | 200 | 187 |

| the end | min | 280 | 248 |

| Specific surface | cm2/g | 3207 | 3746 |

| Cement shrinkage | mm/m | 0.46 | - |

| Loss of roasting | % | 3.80 | 3.24 |

| Chemical composition: | |||

| CaO | % | 63.69 | - |

| MgO | % | 1.07 | - |

| SiO2 | % | 20.19 | - |

| Al2O3 | % | 4.49 | - |

| Fe2O3 | % | 2.78 | - |

| SO3 | % | 2.36 | 2.98 |

| Na2Oeq | % | 0.54 | 0.60 |

| Cl | % | 0.032 | 0.079 |

| Parameter | Concrete for Track Slab | Concrete for Block Supports |

|---|---|---|

| Compressive strength class | C35/45 | C50/60 |

| Exposure class to carbonation corrosion | XC4 | XC4 |

| Frost aggression exposure class | XF1 | XF1 |

| Degree of frost resistance | F150 | F125 |

| Required cement grade | CEM 42.5 | CEM 42.5 |

| Maximum cement content [kg] | 400 | 450 |

| Required consistency | S3 | S2 |

| Maximum absorbability of concrete | 5% | 4% |

| Water-cement indicator w/c | <0.5 | <0.45 |

| Ingredient | Content [kg] |

|---|---|

| Cement CEM I 42.5 N/NA from WARTA company | 390 |

| Fine aggregate Sand 0/2 from Żabiny company | 517 |

| Coarse aggregate 1 Granite 2/8 from Graniczna company | 497 |

| Coarse aggregate 2 Granit 8/16 from Graniczna company | 919 |

| Water | 148 |

| Plasticizer Version of Viscocrete | 3.1 |

| Aerator Sica AerPro 3 | 0.6 |

| Ingredient | Content [kg] |

|---|---|

| Cement CEM I 42.5 R from CEMEX company | 420 |

| Fine aggregate Sand 0/2 from Żabiny company | 486 |

| Coarse aggregate 1 Granite 2/8 from Graniczna company | 523 |

| Coarse aggregate 2 Granit 8/16 from Graniczna company | 860 |

| Water | 155 |

| Plasticizer Version of Viscocrete | 3.3 |

| Aerator Sica AerPro 3 | 0.7 |

| Parameter | Steel Fibers | Polymer Fibers | Glass Fibers |

|---|---|---|---|

| Diameter | 1.0 mm ± 10% | 0.6 mm | 0.01 mm |

| Length | 50 mm ± 10% | 25 mm ± 10% | 36 mm ± 10% |

| Dosage | 25–35 kg/m3 | 3–9 kg/m3 | 0.5–2 kg/m3 |

| Tensile strength | 1100 MPa | 550–650 MPa | 2500 MPa |

| Concrete Type | Cone Fall [mm] | Consistency Class |

|---|---|---|

| Z1 | 140 | S3 |

| Z2 | 80 | S2 |

| Z3 | 70 | S2 |

| Z4 | 60 | S2 |

| Z5 | 80 | S2 |

| Concrete Type | Compressive Strength [MPa] | Standard Deviation [MPa] |

|---|---|---|

| Z1 | 59.80 | 2.12 |

| Z2 | 71.67 | 3.26 |

| Z3 | 72.87 | 1.14 |

| Z4 | 76.98 | 1.52 |

| Z5 | 68.50 | 2.14 |

| Concrete Type | Average Weight Loss (%) | Compressive Strength of the Comparative Samples (MPa) | Compressive Strength of Samples after Frost Resistance Test (MPa) | Average Strength Decrease (%) |

|---|---|---|---|---|

| Z1 | 0.21 | 59.8 | 58.2 | 2.67 |

| Z2 | 0.25 | 73.3 | 72.0 | 1.77 |

| Z3 | 0.28 | 73.1 | 71.4 | 2.34 |

| Z4 | 0.32 | 76.3 | 74.9 | 1.97 |

| Z5 | 0.34 | 71.3 | 69.0 | 3.23 |

| Concrete Type | Medium Modulus of Elasticity (MPa) | Standard Deviation (MPa) |

|---|---|---|

| Z1 | 40,467 | 550.8 |

| Z2 | 45,433 | 115.5 |

| Z3 | 46,667 | 288.7 |

| Z4 | 46,933 | 208.2 |

| Z5 | 44,800 | 300.0 |

| Concrete Type | Medium Modulus of Elasticity (MPa) | Standard Deviation (MPa) |

|---|---|---|

| Z1 | 38,567 | 472.6 |

| Z2 | 44,100 | 264.6 |

| Z3 | 45,233 | 416.3 |

| Z4 | 45,267 | 321.5 |

| Z5 | 43,567 | 321.5 |

| Concrete Type | Average Tensile Strength (MPa) | Standard Deviation (MPa) |

|---|---|---|

| Z2 | 6.62 | 0.42 |

| Z3 | 6.05 | 0.10 |

| Z4 | 7.03 | 0.34 |

| Z5 | 5.98 | 0.16 |

| Concrete Type | Average Tensil Strength (MPa) | Standard Deviation (MPa) |

|---|---|---|

| Z2 | 7.82 | 0.36 |

| Z3 | 7.85 | 0.27 |

| Z4 | 7.93 | 0.39 |

| Z5 | 7.30 | 0.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Idczak, W.; Lewandrowski, T.; Pokropski, D.; Rogojsz, G.; Rudnicki, T. The Influence of the Type of Fibers on the Reduction of the Threshold Effect in the Transition Zone of a Railway Track. Materials 2022, 15, 5730. https://doi.org/10.3390/ma15165730

Idczak W, Lewandrowski T, Pokropski D, Rogojsz G, Rudnicki T. The Influence of the Type of Fibers on the Reduction of the Threshold Effect in the Transition Zone of a Railway Track. Materials. 2022; 15(16):5730. https://doi.org/10.3390/ma15165730

Chicago/Turabian StyleIdczak, Włodzimierz, Tomasz Lewandrowski, Dominik Pokropski, Grzegorz Rogojsz, and Tomasz Rudnicki. 2022. "The Influence of the Type of Fibers on the Reduction of the Threshold Effect in the Transition Zone of a Railway Track" Materials 15, no. 16: 5730. https://doi.org/10.3390/ma15165730

APA StyleIdczak, W., Lewandrowski, T., Pokropski, D., Rogojsz, G., & Rudnicki, T. (2022). The Influence of the Type of Fibers on the Reduction of the Threshold Effect in the Transition Zone of a Railway Track. Materials, 15(16), 5730. https://doi.org/10.3390/ma15165730