Characterization on Crack Initiation and Early Propagation Region of Nickel-Based Alloys in Very High Cycle Fatigue

Abstract

:1. Introduction

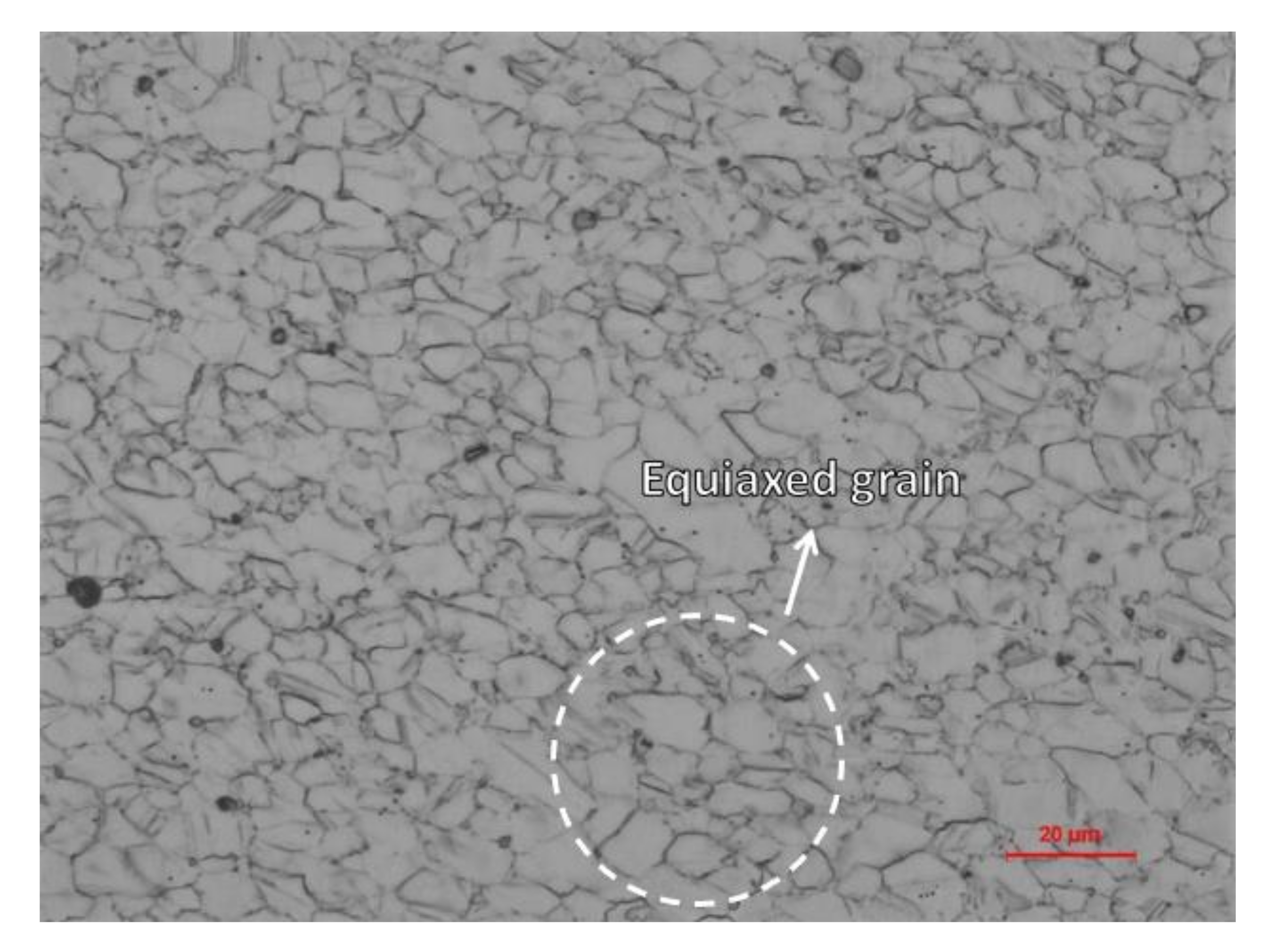

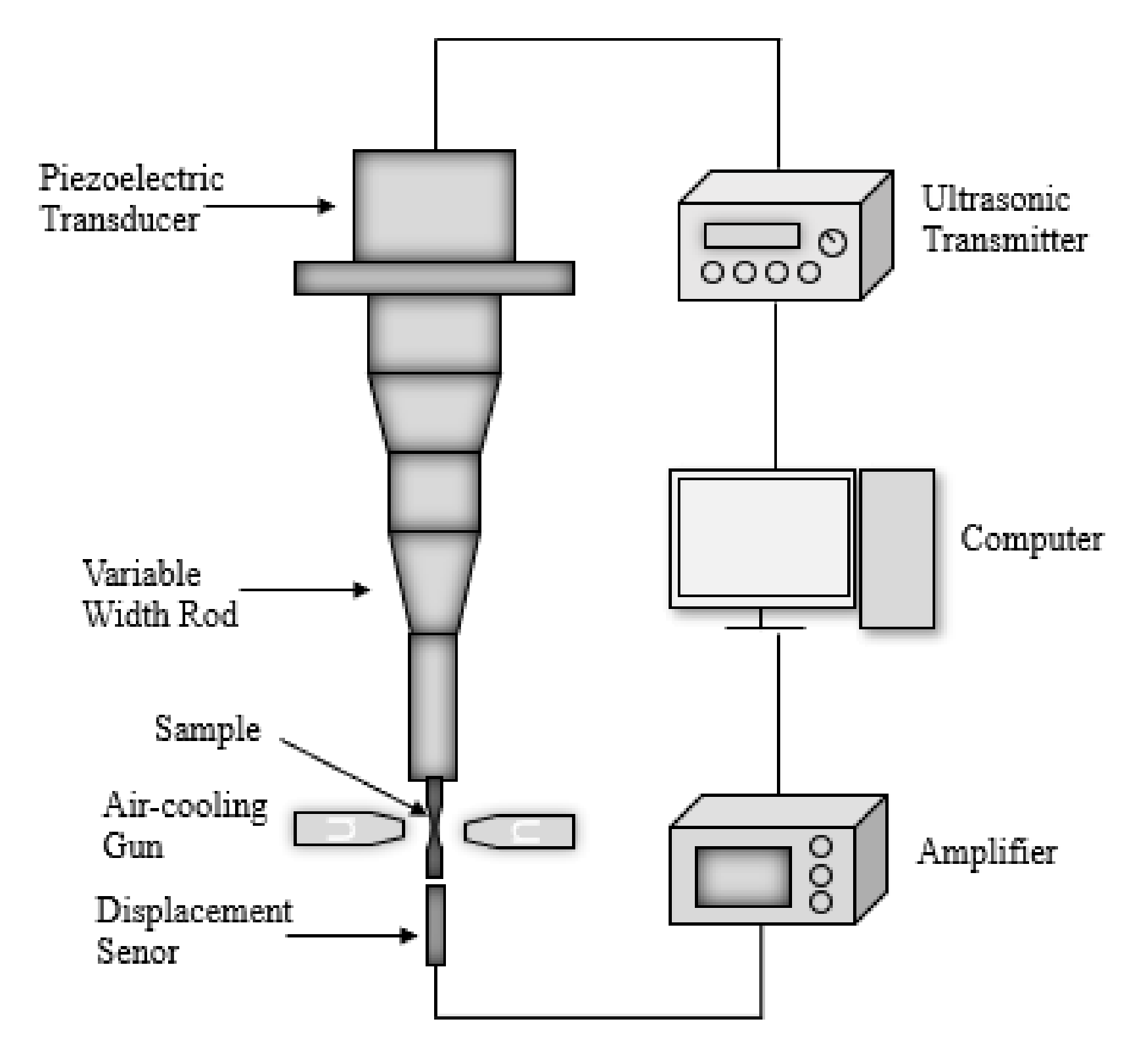

2. Materials and Methods

3. Results

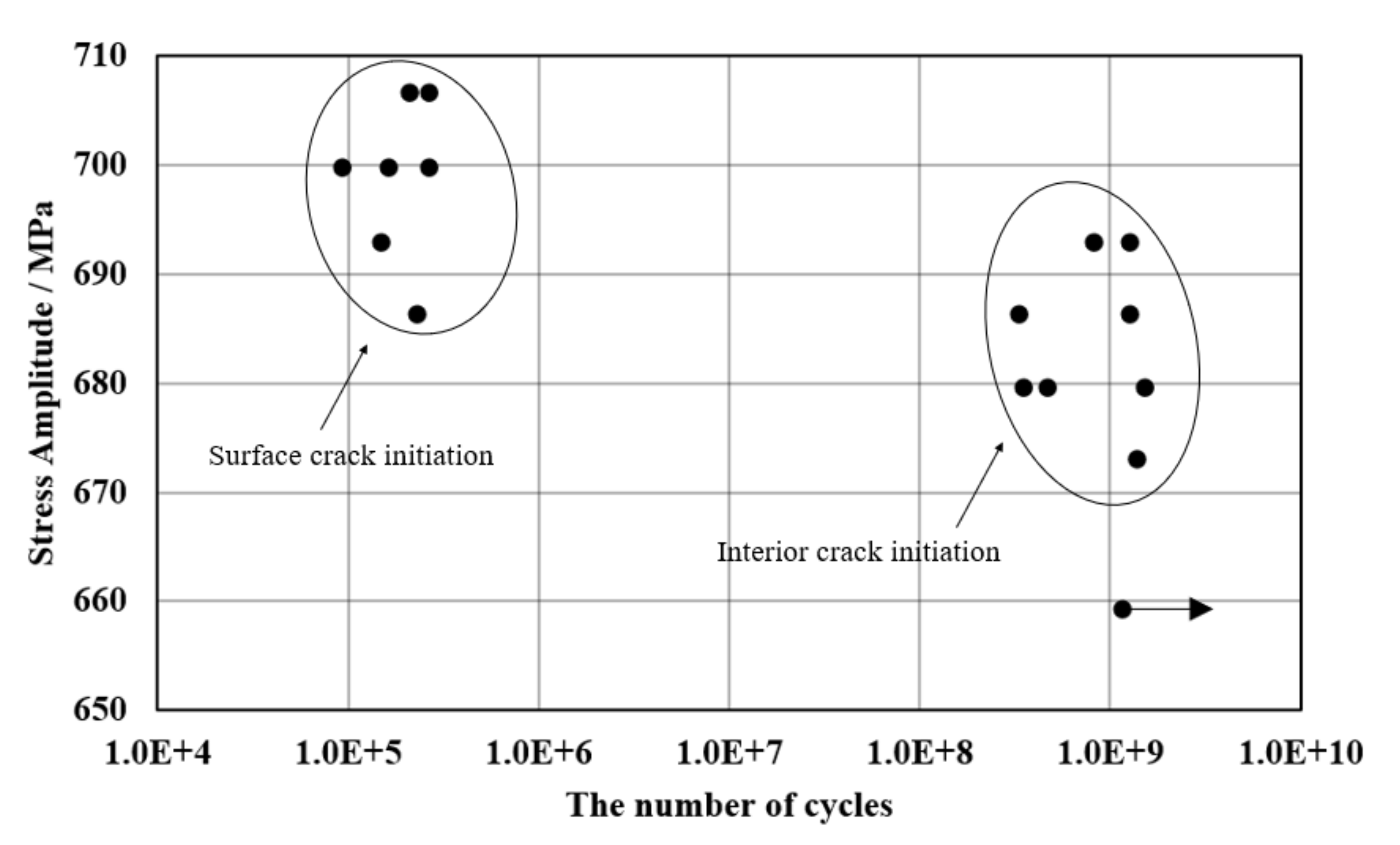

3.1. S-N Data of the Specimen

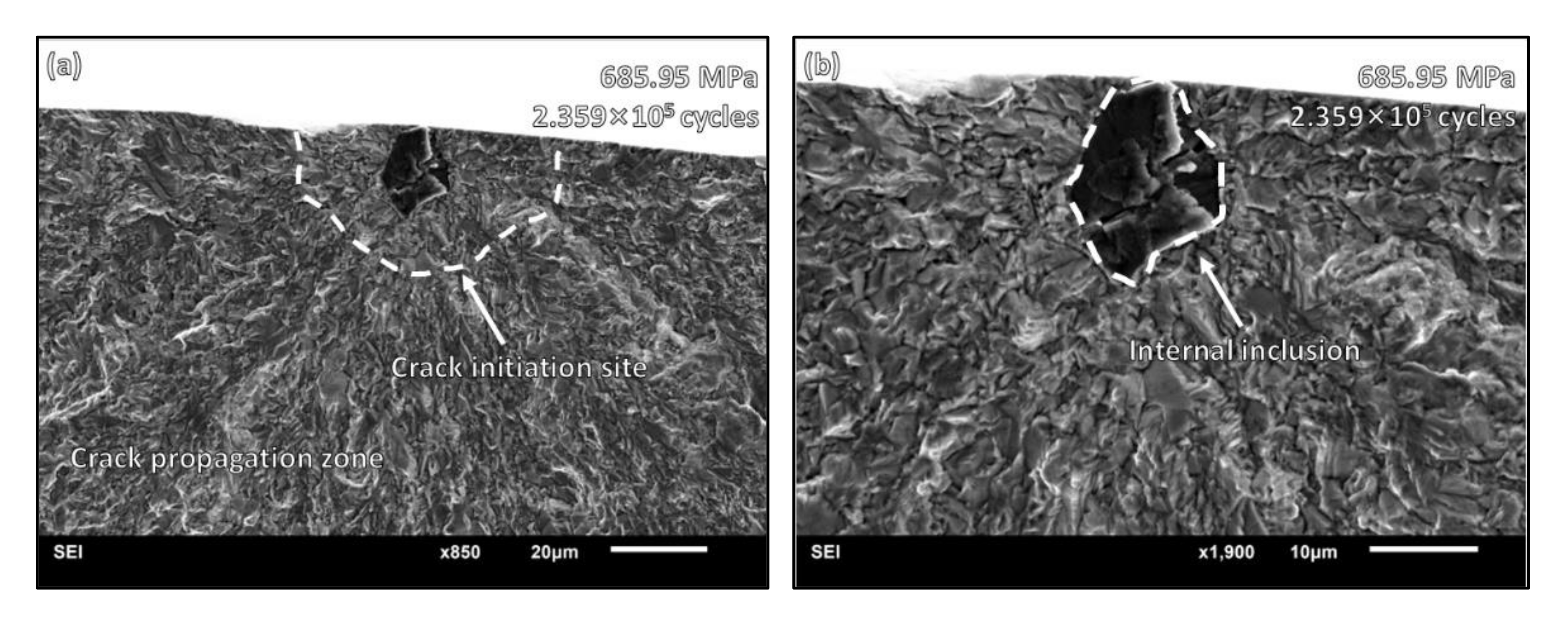

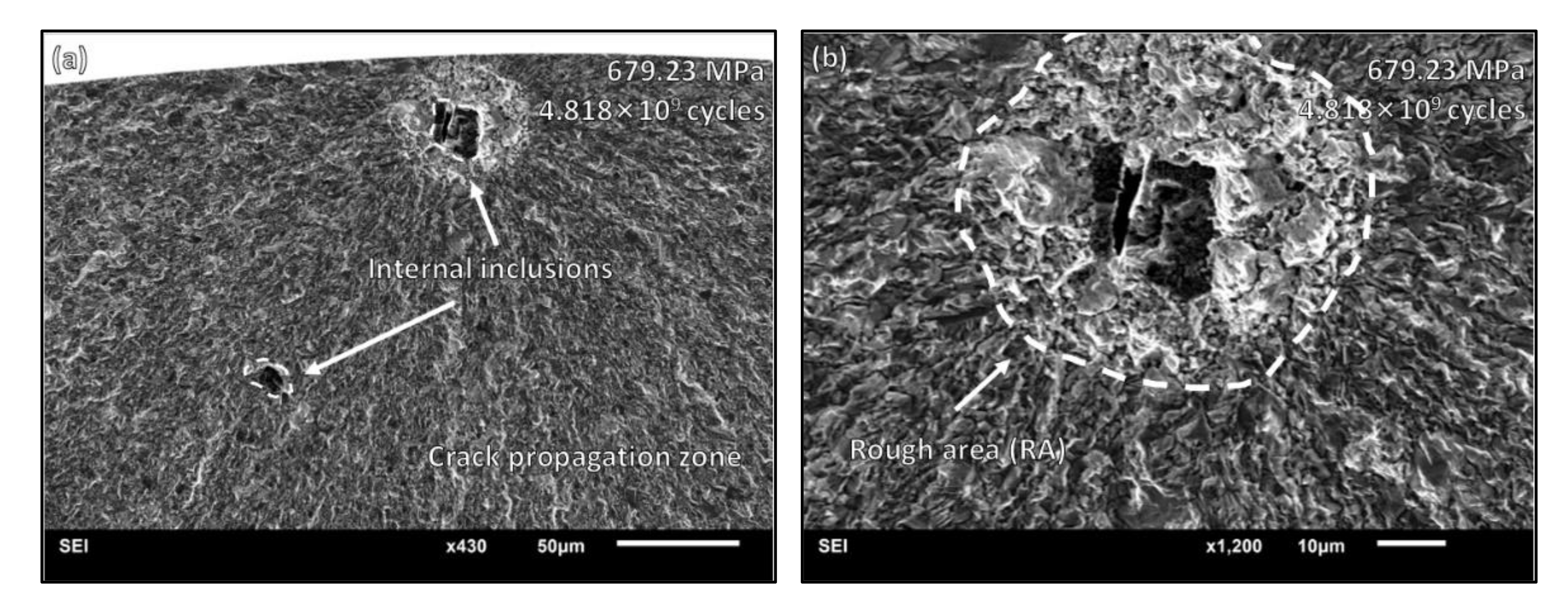

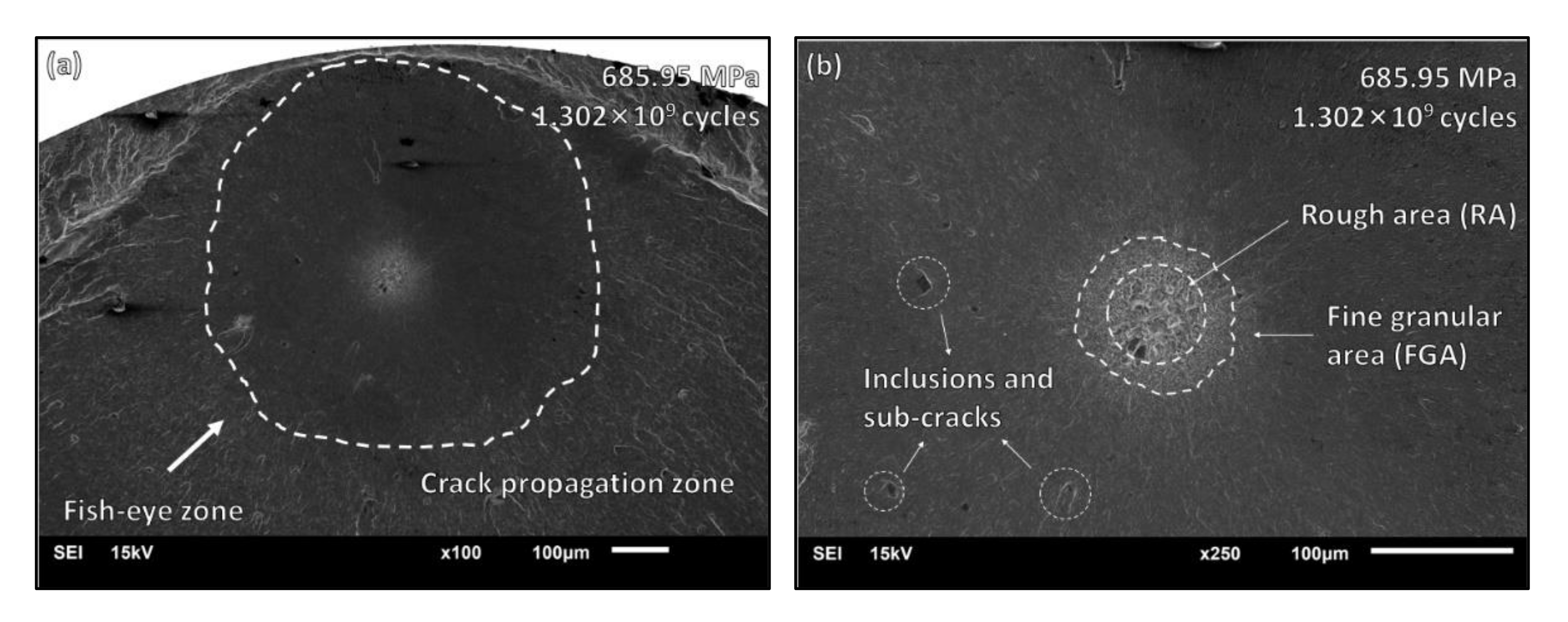

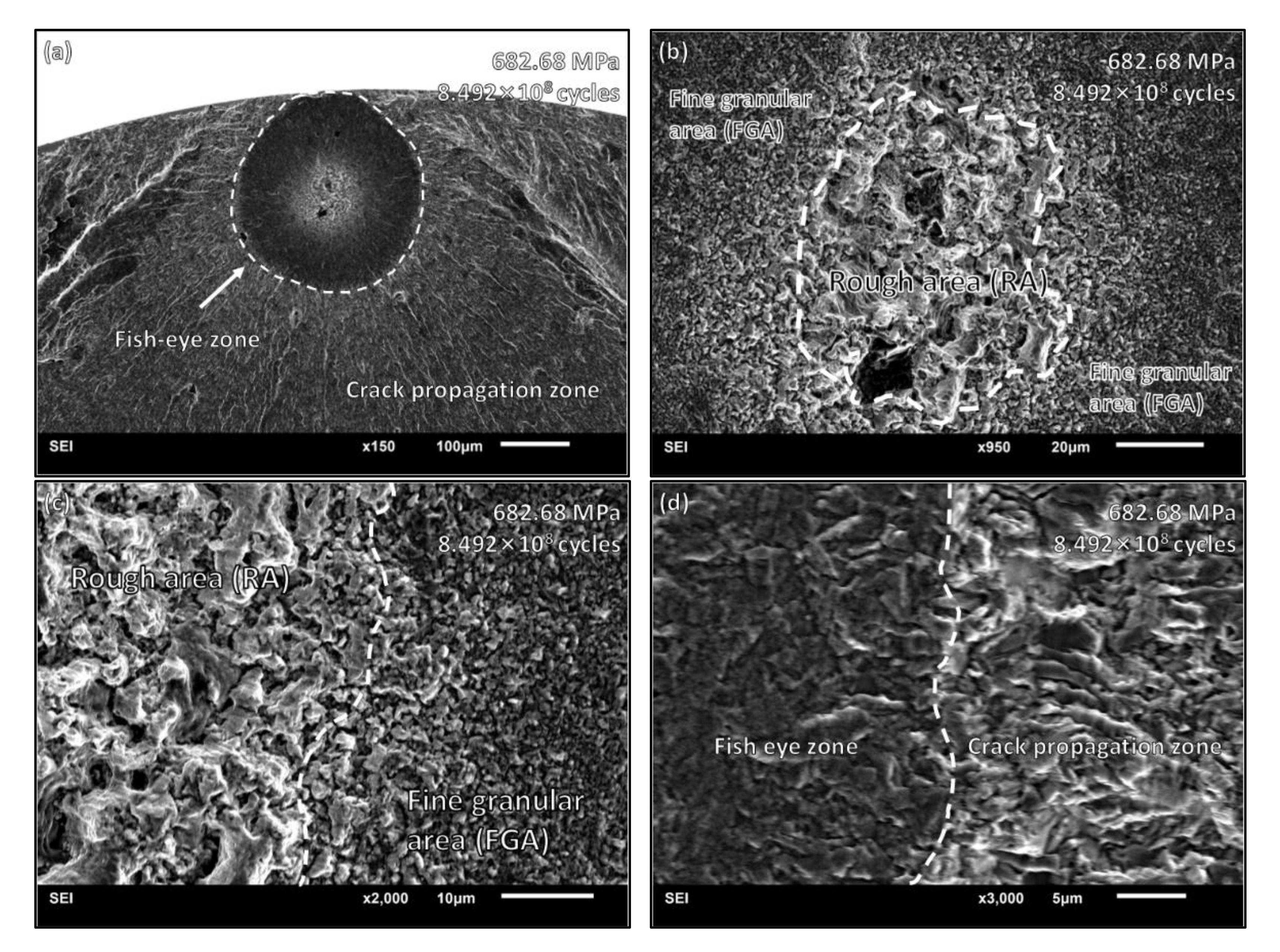

3.2. Fracture Morphology

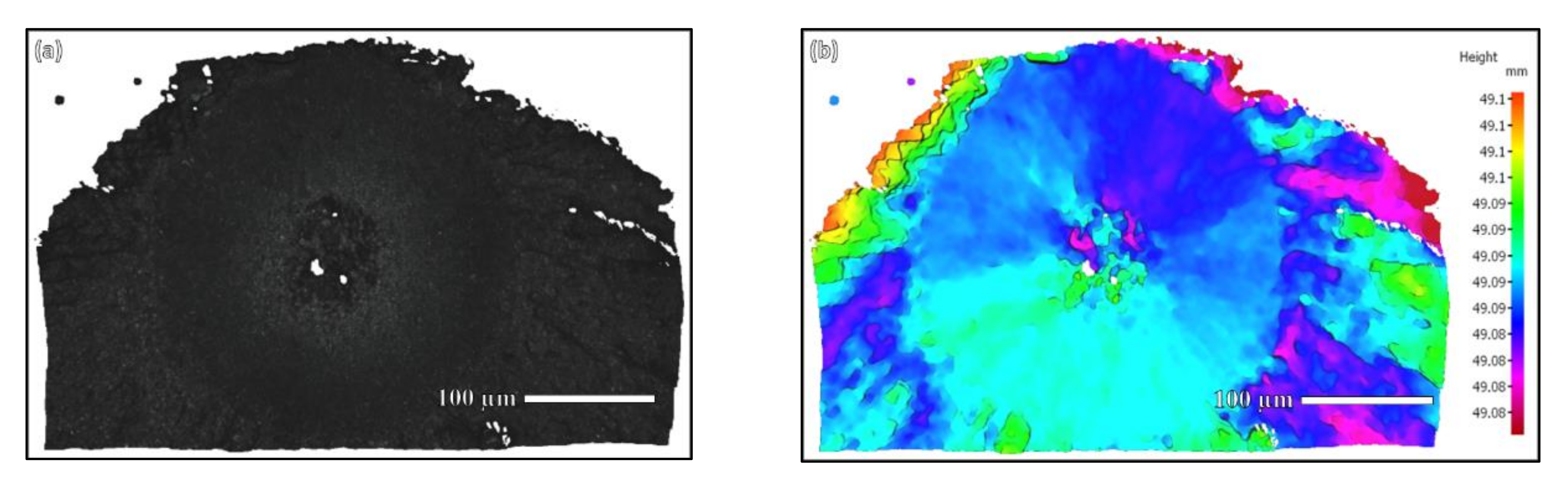

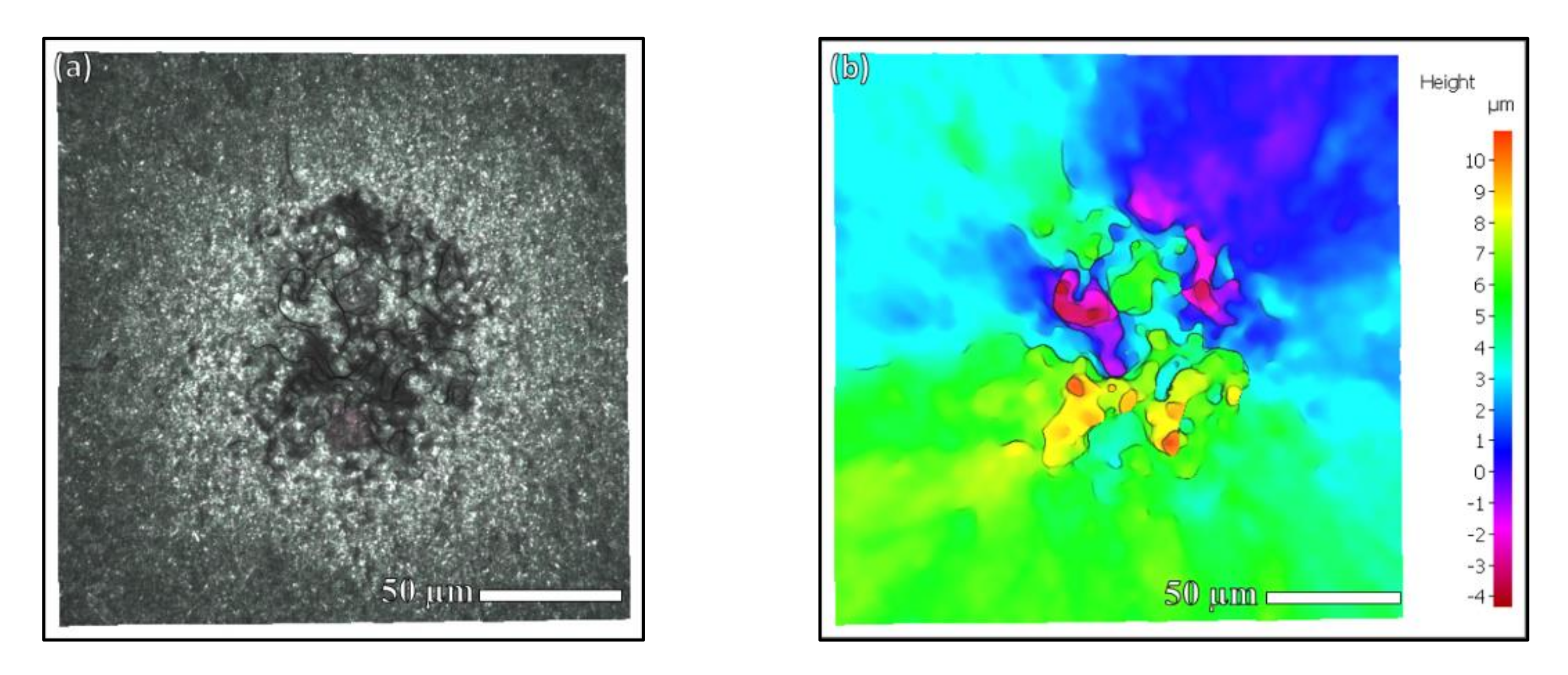

3.3. Three-Dimensional Morphology Scanning

4. Discussion

4.1. Formation of RA

4.2. Effect of Vacuum on the Formation of FGA

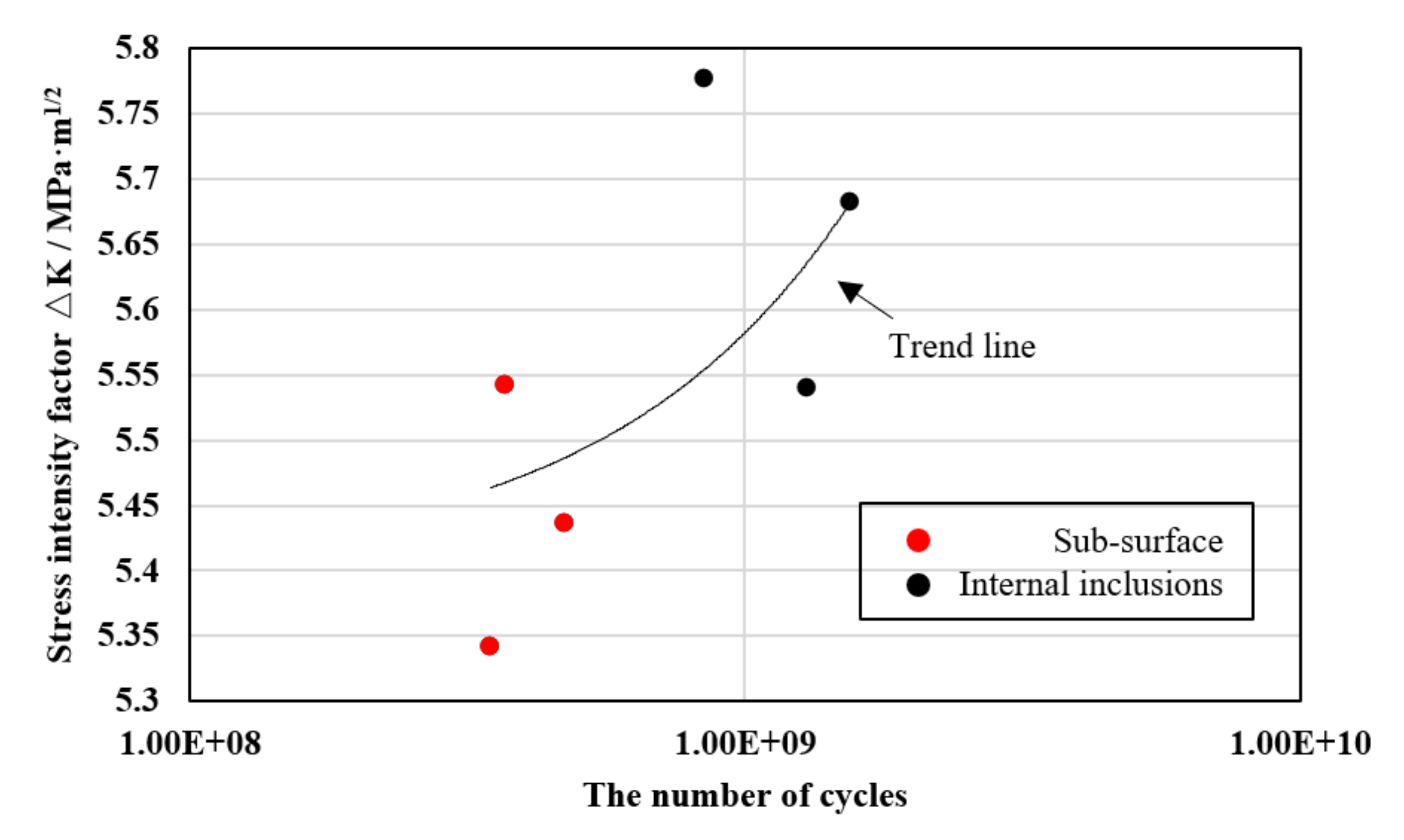

4.3. SIF and Crack Propagation Process

| No. | 4 | 5 | 6 |

|---|---|---|---|

| Fatigue life | 8.492 × 108 | 1.302 × 109 | 1.567 × 109 |

| Stress amplitude (MPa) | 692.68 | 685.95 | 679.23 |

| FGA area (µm 2) | 15,689 | 14,794 | 16,179 |

| ΔK (SIF) (MPa·m1/2) | 6.87 | 6.70 | 6.79 |

| Average | 6.79 | ||

5. Conclusions

- In a very-high-cycle fatigue regime, fatigue crack initiate from the inclusions at the subsurface or interior of the specimen, and RA surrounding the inclusions can be characterized at the crack initiation site.

- The profile of the RA is sensitive to the grain size of the materials. The formation of the RA is a synergistic result of multi-crack initiation from the inclusions and the local microstructural effect.

- The fine granular area only existed in the case of interior crack initiation, which is related the numerous cyclic pressing processes in a vacuum environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zongxian, S.; Hao, Q.; Zhisheng, W.; Xin, C.; Zhenjun, Z.; Ruizhe, W.; Zheng, L. Study on Ultrahigh Cycle Fatigue Performance of GH4169 Nickel-Based Alloy at 650 °C. Trans. Nanjing Univ. Aeronaut. Astronaut. 2021, 37, 970–978. [Google Scholar]

- Li, Q.; Zhang, F.; Zhao, Z. Very high cycle fatigue of nickel-based single crystal and directionally solidified superalloys: Review. Acta Aeronaut. Astronaut. Sin. 2021, 42, 524340. [Google Scholar]

- Wang, Q.; Bathias, C.; Kawagoishi, N.; Chen, Q. Effect of inclusion on subsurface crack initiation and gigacycle fatigue strength. Int. J. Fatigue 2002, 24, 1269–1274. [Google Scholar] [CrossRef]

- Cervellon, A.; Cormier, J.; Mauget, F.; Hervier, Z.; Nadot, Y. Very high cycle fatigue of Ni-based single-crystal superalloys at high temperature. Metall. Mater. Trans. 2018, 49, 3938–3950. [Google Scholar] [CrossRef]

- Hong, Y.; Liu, X.; Lei, Z.; Sun, C. The formation mechanism of characteristic region at crack initiation for very-high-cycle fatigue of high-strength steels. Int. J. Fatigue 2016, 89, 108–118. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Petit, J.; Huang, Z.; Wagner, D. Investigation of crack initiation mechanisms responsible for the fish eye formation in the Very High Cycle Fatigue regime. Int. J. Fatigue 2019, 119, 320–329. [Google Scholar] [CrossRef]

- Kim, D.; Jiang, R.; Sinclair, I.; Reed, P. Technology, Microstructural influences on fatigue crack initiation and early propagation in Ni-based superalloy. Mater. Sci. Technol. 2022, 1–14. [Google Scholar] [CrossRef]

- Hong, Y.; Lei, Z.; Sun, C.; Zhao, A. Propensities of crack interior initiation and early growth for very-high-cycle fatigue of high strength steels. Int. J. Fatigue 2014, 58, 144–151. [Google Scholar] [CrossRef] [Green Version]

- Cervellon, A.; Hémery, S.; Kürnsteiner, P.; Gault, B.; Kontis, P.; Cormier, J. Crack initiation mechanisms during very high cycle fatigue of Ni-based single crystal superalloys at high temperature. Acta Mater. 2020, 188, 131–144. [Google Scholar] [CrossRef]

- Youshi, H.; Chengqi, S.; Xiaolong, L.J. A review on mechanisms and models for very-high-cycle fatigue of metallic materials. Adv. Mech. 2018, 48, 1801. [Google Scholar]

- Kawagoishi, N.; Chen, Q.; Nisitani, H. Fatigue strength of Inconel 718 at elevated temperatures. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 209–216. [Google Scholar]

- Shanyavskiy, A.; Banov, M.; Zakharova, T.P. Principles of physical mesomechanics of nanostructural fatigue of metals. Part II. Subsurface fracture of EP741 heat-resistant alloy. Phys. Mesomech. 2010, 13, 143–151. [Google Scholar]

- Shanyavskiy, A.A. Mechanisms and modeling of subsurface fatigue cracking in metals. Eng. Fract. Mech. 2013, 110, 350–363. [Google Scholar] [CrossRef]

- Grad, P.; Reuscher, B.; Brodyanski, A.; Kopnarski, M.; Kerscher, E. Mechanism of fatigue crack initiation and propagation in the very high cycle fatigue regime of high-strength steels. Scr. Mater. 2012, 67, 838–841. [Google Scholar] [CrossRef]

- Sakai, T. Review and prospects for current studies on very high cycle fatigue of metallic materials for machine structural use. J. Solid Mech. Mater. Eng. 2009, 3, 425–439. [Google Scholar] [CrossRef] [Green Version]

- Oguma, H.; Nakamura, T. Fatigue crack propagation properties of Ti–6Al–4V in vacuum environments. Int. J. Fatigue 2013, 50, 89–93. [Google Scholar] [CrossRef]

- Yoshinaka, F.; Nakamura, T. Effect of vacuum environment on fatigue fracture surfaces of high strength steel. Mech. Eng. Lett. 2016, 2, 15–00730. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhang, H.; Song, W.; Pan, S.; Liu, W.; Liu, X.; Zhu, B.; Song, Y.; Zhou, W. Acceleration effect of a graphite dust environment on the fatigue crack propagation rates of Al alloy. Int. J. Fatigue 2019, 126, 20–29. [Google Scholar] [CrossRef]

- Nakamura, T.; Kaneko, M.; Kazami, S.; Noguchi, T. The effect of high vacuum environment on tensile fatigue properties of Ti-6Al-4V alloy. Zairyo 2000, 49, 1148–1154. [Google Scholar]

- Gupta, S.; Barrios, A.; England, N.; Pierron, O.N. Improved very high cycle bending fatigue behavior of Ni microbeams with Au coatings. Acta Mater. 2018, 161, 444–455. [Google Scholar] [CrossRef]

- Holper, B.; Mayer, H.; Vasudevan, A.; Stanzl-Tschegg, S.E. Near threshold fatigue crack growth in aluminium alloys at low and ultrasonic frequency: Influences of specimen thickness, strain rate, slip behaviour and air humidity. Int. J. Fatigue 2003, 25, 397–411. [Google Scholar] [CrossRef]

- Adams, J.F.; Allison, J.E.; Jones, J.W. The effects of heat treatment on very high cycle fatigue behavior in hot-rolled WE43 magnesium. Int. J. Fatigue 2016, 93, 372–386. [Google Scholar] [CrossRef] [Green Version]

- Adams, J. Investigating Microstructural Effects on Short Crack Growth and Fatigue Life Behavior of WE43 Magnesium. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2018. [Google Scholar]

- Liu, Y.; Chen, Y.; He, C.; Liu, F.; Yang, K.; Li, L.; Zhang, H.; Wang, C.; Wang, Q. Vacuum retarding and air accelerating effect on the high-cycle and very-high-cycle fatigue behavior of a ZK60 magnesium alloy. Mater. Des. 2021, 198, 109310. [Google Scholar] [CrossRef]

- Murakami, Y.; Usuki, H. Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels. II: Fatigue limit evaluation based on statistics for extreme values of inclusion size. Int. J. Fatigue 1989, 11, 299–307. [Google Scholar]

- DiMatteo, N.D. Fatigue and Fracture; ASM International: Novelty, OH, USA, 1996; Volume 19. [Google Scholar]

- Poulin, J.-R.; Brailovski, V.; Terriault, P. Long fatigue crack propagation behavior of Inconel 625 processed by laser powder bed fusion: Influence of build orientation and post-processing conditions. Int. J. Fatigue 2018, 116, 634–647. [Google Scholar] [CrossRef]

| Element | C | Cr | Fe | Mo | Nb | Mg | Al | Mn | Si | Ti | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (%) | 0.053 | 21.32 | 0.11 | 8.58 | 3.73 | 0.01 | 0.18 | 0.04 | 0.09 | 0.16 | residual |

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Fatigue life (cycles) | 3.492 × 108 | 3.734 × 108 | 4.818 × 108 | 8.492 × 108 | 1.302 × 109 | 1.567 × 109 |

| Stress amplitude (MPa) | 685.95 | 679.23 | 679.23 | 692.68 | 685.95 | 679.23 |

| Projected area (µm2) | 2081 | 2508 | 2323 | 7830 | 6883 | 7923 |

| ΔK (SIF) (MPa·m1/2) | 5.34 | 5.54 | 5.43 | 5.77 | 5.54 | 5.68 |

| Average | 5.44 | 5.66 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Dong, Z.; Liu, C.; Dai, Y.; He, C. Characterization on Crack Initiation and Early Propagation Region of Nickel-Based Alloys in Very High Cycle Fatigue. Materials 2022, 15, 5806. https://doi.org/10.3390/ma15175806

Chen Z, Dong Z, Liu C, Dai Y, He C. Characterization on Crack Initiation and Early Propagation Region of Nickel-Based Alloys in Very High Cycle Fatigue. Materials. 2022; 15(17):5806. https://doi.org/10.3390/ma15175806

Chicago/Turabian StyleChen, Zelin, Zihao Dong, Chang Liu, Yajun Dai, and Chao He. 2022. "Characterization on Crack Initiation and Early Propagation Region of Nickel-Based Alloys in Very High Cycle Fatigue" Materials 15, no. 17: 5806. https://doi.org/10.3390/ma15175806

APA StyleChen, Z., Dong, Z., Liu, C., Dai, Y., & He, C. (2022). Characterization on Crack Initiation and Early Propagation Region of Nickel-Based Alloys in Very High Cycle Fatigue. Materials, 15(17), 5806. https://doi.org/10.3390/ma15175806