Analysis of Electromagnetic Characteristics of Copper-Steel Composite Quadrupole Rail

Abstract

:1. Introduction

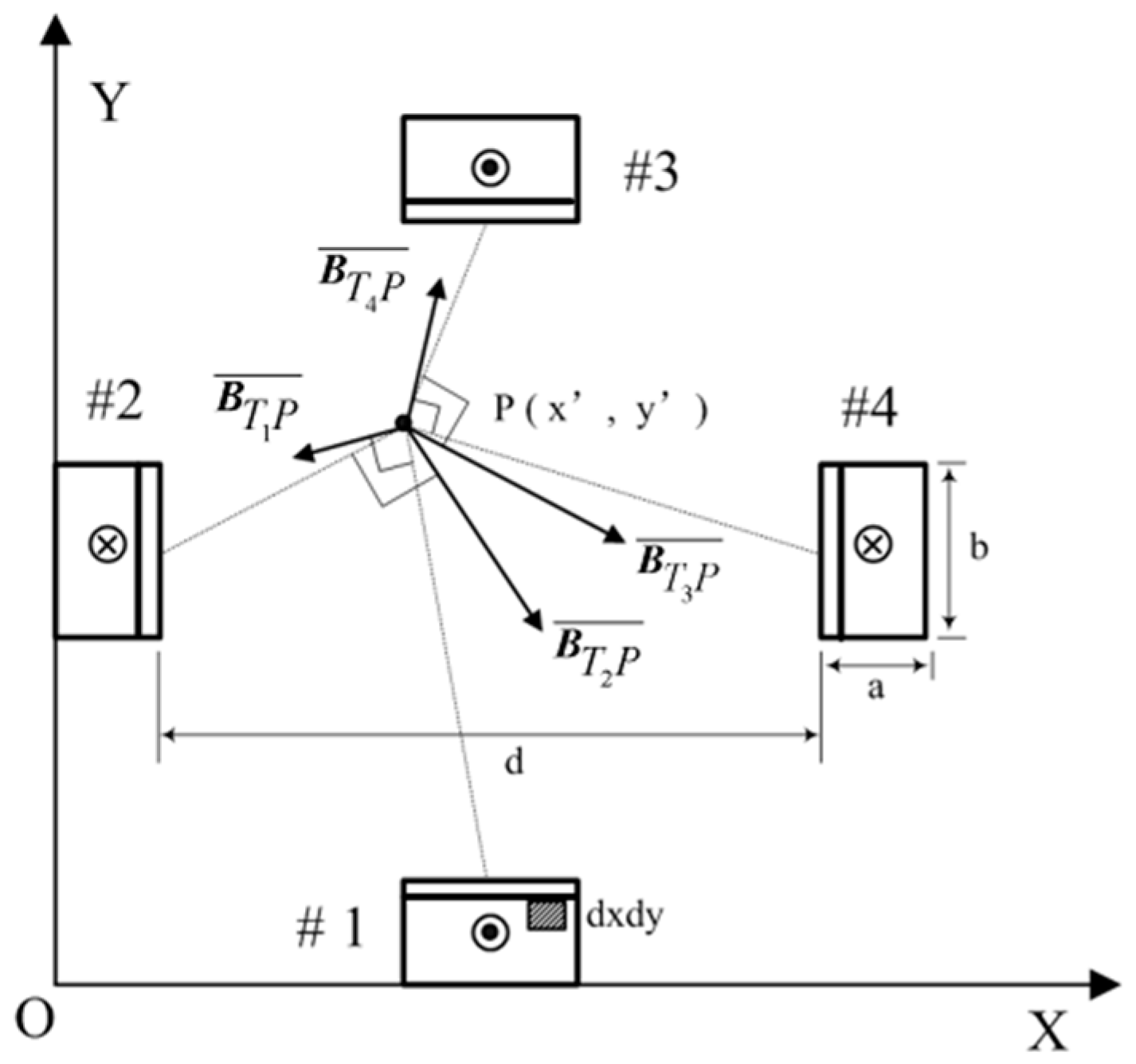

2. Quadrupole Magnetic Field Theory

3. Model Establishment and Condition Setting

3.1. Physical Model of FREL

3.2. Simulation Conditions and Method

4. Analysis of the Simulation Results

4.1. Analysis of the Current Density Distribution

4.2. Analysis of the Magnetic Field Strength Distribution

5. Effects of Composite Layer Parameters on Electromagnetic Properties

5.1. The Influence of the Composite Layer Parameters on the Current Density

5.2. The Influence of the Composite Layer Parameters on the Magnetic Field Strength

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Fair, H.D. Advances in Electromagnetic Launch Science and Technology and Its Applications. IEEE Trans. Magn. 2009, 45, 225–230. [Google Scholar] [CrossRef]

- Li, J.; Li, S.; Liu, P.; Gui, Y.; Su, N.; Dong, J.; Zhang, J.; Gao, Y.; Yuan, W.; Yan, P. Design and Testing of a 10-MJ Electromagnetic Launch Facility. IEEE Trans. Plasma Sci. 2011, 39, 1187–1191. [Google Scholar]

- Weiming, M.; Junyong, L. Electromagnetic launch technology. J. Natl. Univ. Def. Technol. 2016, 38, 1–5. [Google Scholar]

- Fair, H.D. Progress in electromagnetic launch science and technology. IEEE Trans. Magn. 2006, 43, 93–98. [Google Scholar] [CrossRef]

- Ma, W.; Lu, J. Thinking and study of electromagnetic launch technology. IEEE Trans. Plasma Sci. 2017, 45, 1071–1077. [Google Scholar] [CrossRef]

- Doerry, N.; Amy, J.; Krolick, C. History and the status of electric ship propulsion, integrated power systems, and future trends in the U.S. Navy. Proc. IEEE 2015, 103, 2243–2251. [Google Scholar] [CrossRef]

- Yingfu, Z.H.U.; Zhiguo, X.I.O.N.G.; Yulong, H.U. On the development trends of aircraft carriers. Chin. J. Ship Res. 2016, 11, 1–7. [Google Scholar]

- McNab, I.R. Large-scale pulsed power opportunities and challenges. IEEE Trans. Plasma Sci. 2014, 42, 1118–1126. [Google Scholar] [CrossRef]

- Yang, Z.; Feng, G.; Xue, X.; Shu, T. An electromagnetic rail launcher by quadrupole magnetic field for heavy intelligent projectiles. IEEE Trans. Plasma Sci. 2017, 45, 1095–1100. [Google Scholar] [CrossRef]

- Xue, X.; Shu, T.; Yang, Z.; Feng, G. A New Electromagnetic Launcher by Sextupole Rails: Electromagnetic Propulsion and Shielding Numerical Validation. IEEE Trans. Plasma Sci. 2017, 45, 2541–2545. [Google Scholar] [CrossRef]

- Chen, Q.R.; Shu, T.; Ding, R.X.; Xue, X.P.; Liu, M. Comparative Analysis on Structural Improvement and Performance Simulation of Electromagnetic Orbit Gun. J. Proj. Rocket. Missiles Guid. 2019, 39, 9–14. [Google Scholar]

- Vertelis, V.; Vincent, G.; Schneider, M.; Balevičius, S.; Stankevič, V.; Žurauskiene, N. Magnetic Field Expulsion from a Conducting Projectile in a Pulsed Serial Augmented Railgun. IEEE Trans. Plasma Sci. 2020, 3, 727–732. [Google Scholar] [CrossRef]

- Lin, Q.; Li, B. Numerical simulation of interior ballistic process of railgun based on the multi-field coupled model. Def. Technol. 2016, 12, 101–105. [Google Scholar] [CrossRef]

- Li, S.L.; Guo, X.H.; Song, K.X.; Feng, M.Q.; Wang, X. Research progress and prospect of copper matrix materials for current-carrying friction. Trans. Mater. Heat Treat. 2021, 42, 1–16. [Google Scholar]

- Cui, R.; Han, Y.; Zhu, Z.; Chen, B.; Ding, Y.; Zhang, Q.; Wang, Q.; Ma, G.; Pei, F.; Ye, Z. Investigation of the structure and properties of electrodeposited Cu/graphene composite coatings for the electrical contact materials of an ultrahigh voltage circuit breaker. J. Alloys Compd. 2019, 777, 1159–1167. [Google Scholar] [CrossRef]

- Ganguly, S.; Mondal, S.; Das, P.; Bhawal, P.; Das, T.; Ghosh, S.; Remanan, S.; Das, N. Macromolecular research article an insight into the physico-mechanical signatures of silylated graphene oxide in poly(ethylene methyl acrylate) copolymeric thermoplastic matrix. Macromol. Res. 2019, 27, 268–281. [Google Scholar] [CrossRef]

- Bhawal, P.; Das, T.K.; Ganguly, S.; Mondal, S.; Ravindren, R.; Das, N.C. Fabrication of Light Weight Mechanically Robust Short Carbon Fiber/Ethylene Methyl Acrylate Polymeric Nanocomposite for Effective Electromagnetic Interference Shielding. J. Polym. Sci. Appl. 2017, 1, 2. [Google Scholar]

- Cao, H.Y.; Zhan, Z.J. Experimental Study on Ablation Characteristics of Electromagnetic Orbit of Copper/Diamond Composite. J. High Volt. Phys. 2016, 30, 317–322. [Google Scholar]

- Wild, B.; Schuppler, C.; Alouahabi, F.; Schneider, M.; Hoffman, R. The Influence of the Rail Material on the Multishot Performance of the Rapid Fire Railgun. IEEE Trans. Plasma Sci. 2015, 43, 2095–2099. [Google Scholar] [CrossRef]

- Tian, Z.G.; An, X.Y.; Yang, Y.; Zhao, L.K. Dynamic Stress Analysis of a Composite Electromagnetic Track. Strength Mater. 2018, 50, 743–751. [Google Scholar] [CrossRef]

- Li, T.D.; Feng, G.; Liu, S.W.; Ren, S.D.; Fan, C.L. Static analysis of four-rail electromagnetic launcher with different configurations. J. Ballist. 2021, 33, 90–96. [Google Scholar]

| Density/( ) | Conductivity/(S/m) | Relative Magnetic Permeability | |

|---|---|---|---|

| Copper rail | 8900 | 1 | |

| Steel rail | 7800 | 200 | |

| Aluminum armature | 2700 | 1 |

| The First Calculation | The Second Calculation | The Third Calculation | |

|---|---|---|---|

| Maximum grid size (mm) | 0.5 | 1 | 2 |

| maximum current density () | 7.48 | 7.28 | 6.86 |

| Copper-Steel Thickness Ratio | ||||

|---|---|---|---|---|

| 1:1 | 3:1 | 4:1 | 9:1 | |

| 3.8 | 3.6 | 3.0 | 2.25 | |

| Copper-Steel Thickness Ratio | |||||

|---|---|---|---|---|---|

| 1:1 | 3:1 | 4:1 | 9:1 | ||

| path 4 | 4.91 | 4.72 | 4.51 | 3.44 | |

| path 5 | 6.29 | 6.24 | 6.17 | 6.04 | |

| path 6 | 5.33 | 5.15 | 4.98 | 4.86 | |

| path 7 | 3.12 | 3.07 | 2.96 | 2.92 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Feng, G.; Du, C.; Zhang, P. Analysis of Electromagnetic Characteristics of Copper-Steel Composite Quadrupole Rail. Materials 2022, 15, 5851. https://doi.org/10.3390/ma15175851

Li T, Feng G, Du C, Zhang P. Analysis of Electromagnetic Characteristics of Copper-Steel Composite Quadrupole Rail. Materials. 2022; 15(17):5851. https://doi.org/10.3390/ma15175851

Chicago/Turabian StyleLi, Tengda, Gang Feng, Chong Du, and Pengxiang Zhang. 2022. "Analysis of Electromagnetic Characteristics of Copper-Steel Composite Quadrupole Rail" Materials 15, no. 17: 5851. https://doi.org/10.3390/ma15175851

APA StyleLi, T., Feng, G., Du, C., & Zhang, P. (2022). Analysis of Electromagnetic Characteristics of Copper-Steel Composite Quadrupole Rail. Materials, 15(17), 5851. https://doi.org/10.3390/ma15175851