A Study on the Photopolymerization Kinetics of Selected Dental Resins Using Fourier Infrared Spectroscopy (FTIR)

Abstract

1. Introduction

2. Materials and Methods

2.1. Methods

2.2. Preparation of the Sample

2.3. Calculation of the Degree of Polymerization Conversion

2.4. Statistical Analysis

3. Results

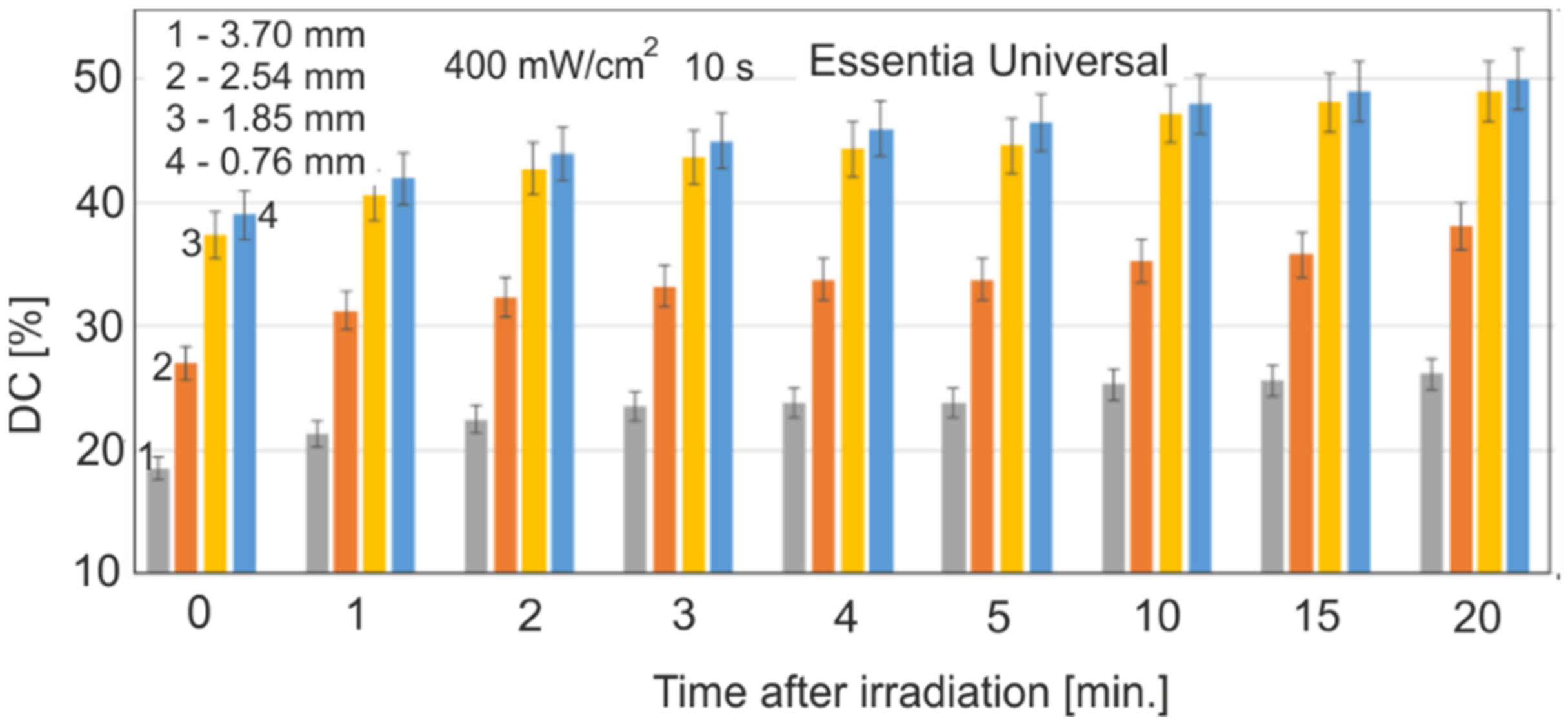

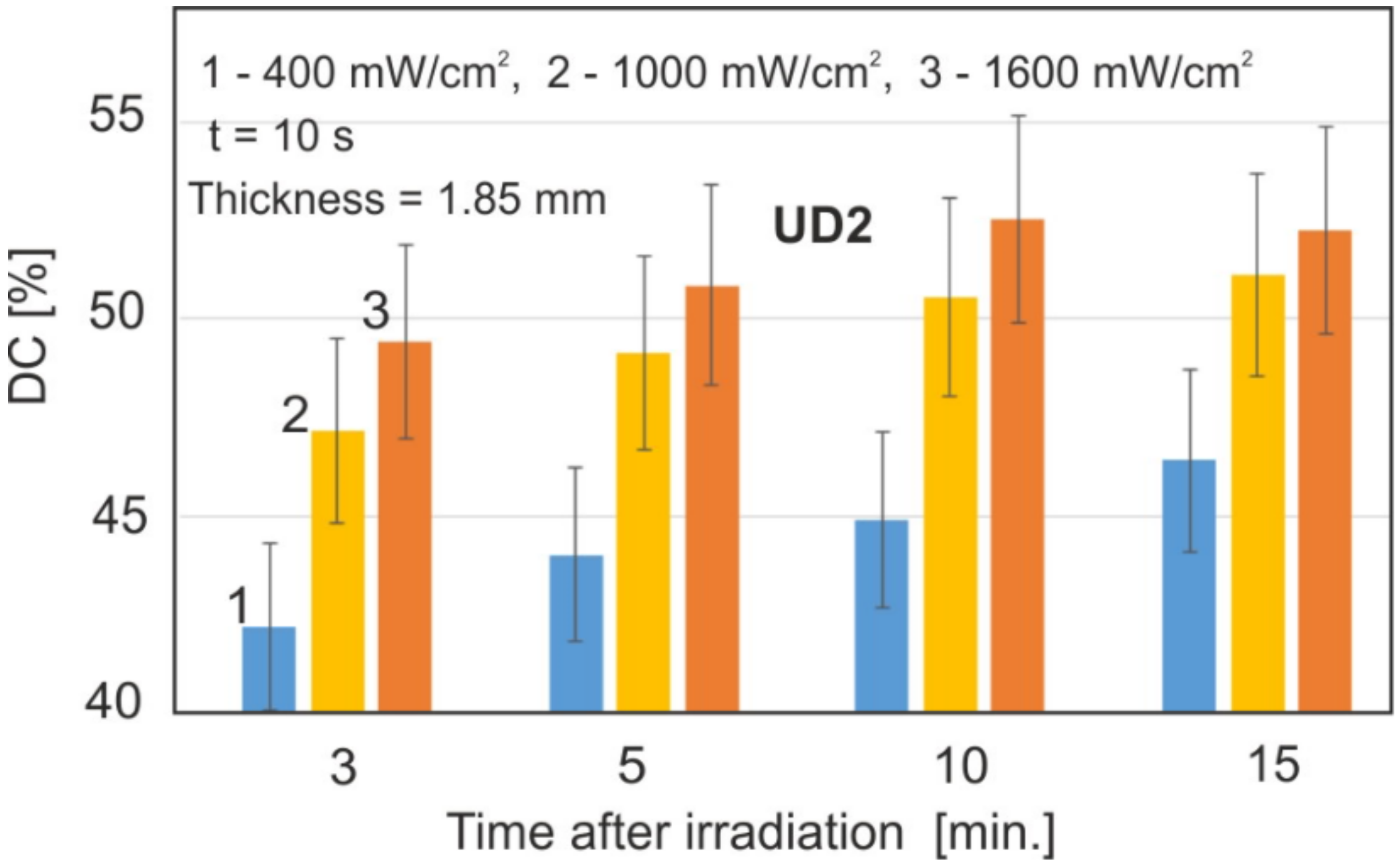

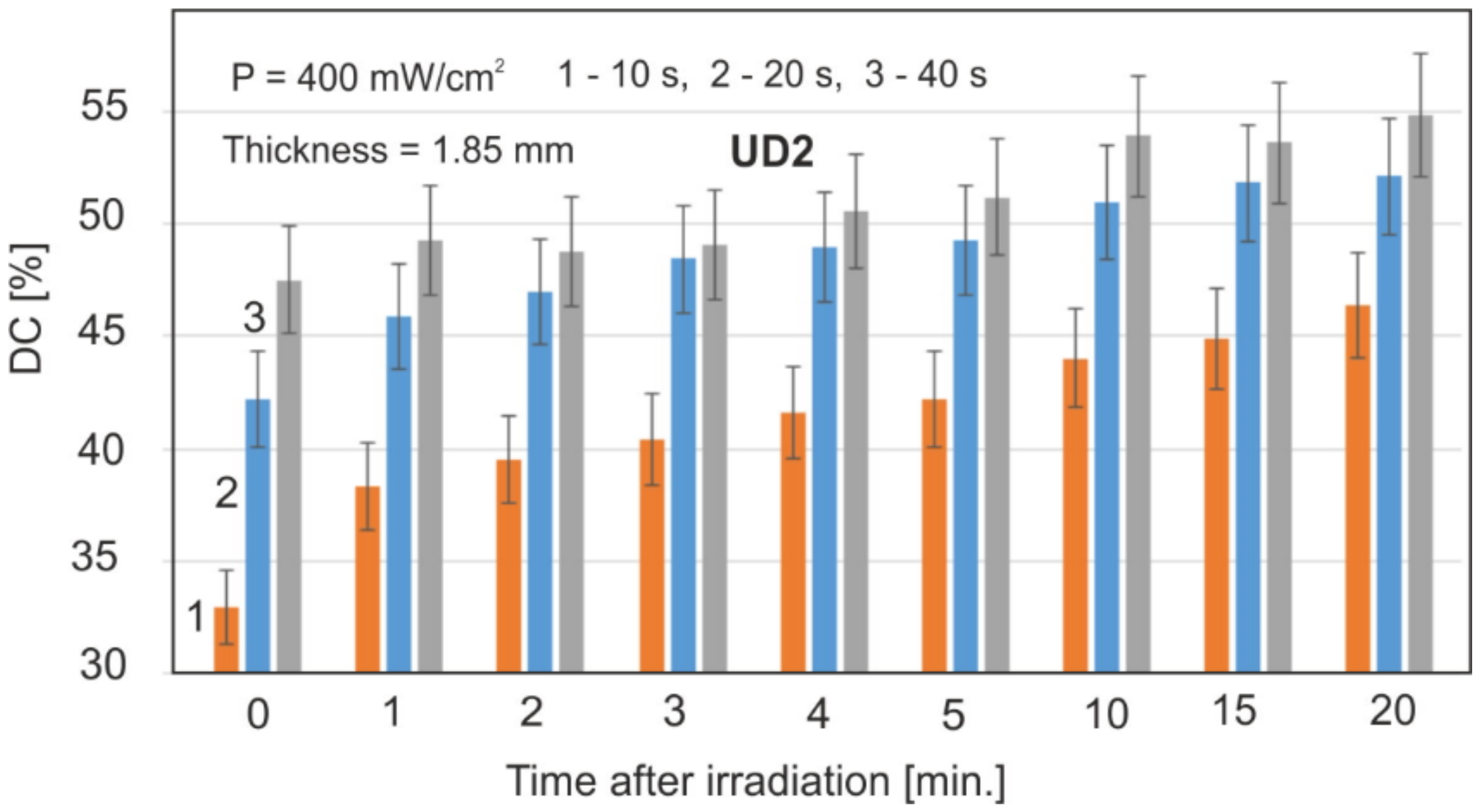

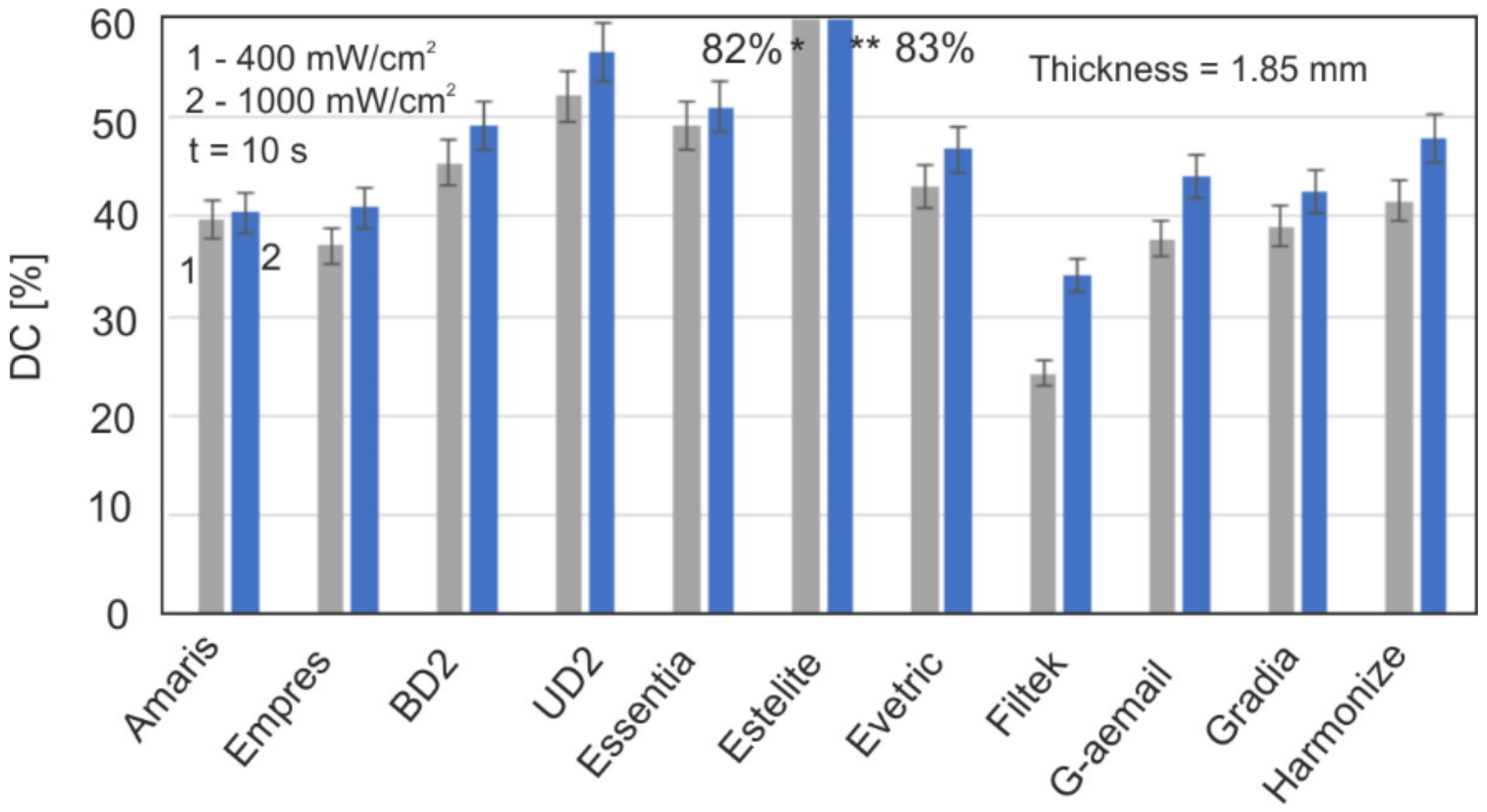

3.1. Irradiation Parameters’ Impact on DC

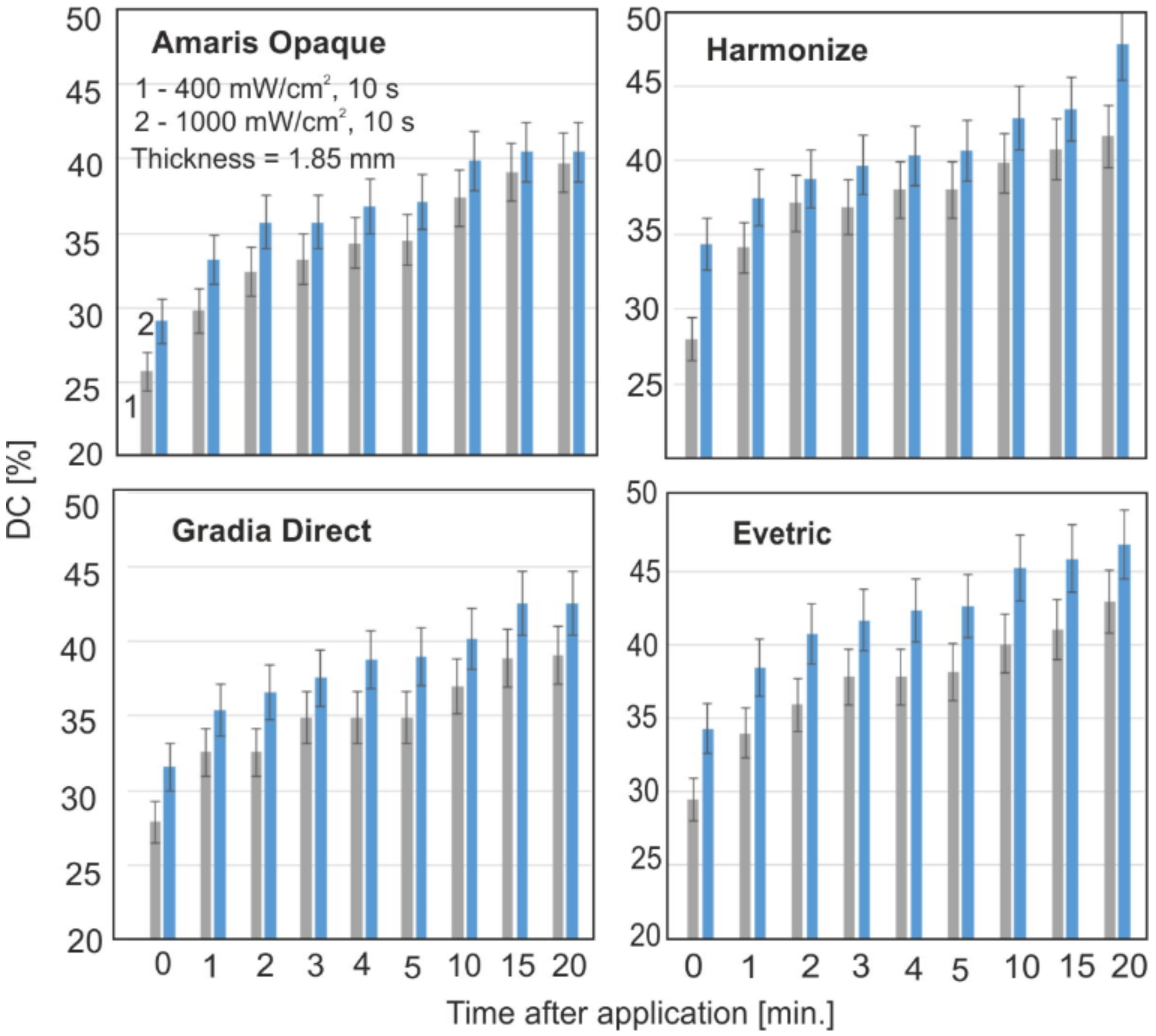

3.2. DC Results for Individual Materials

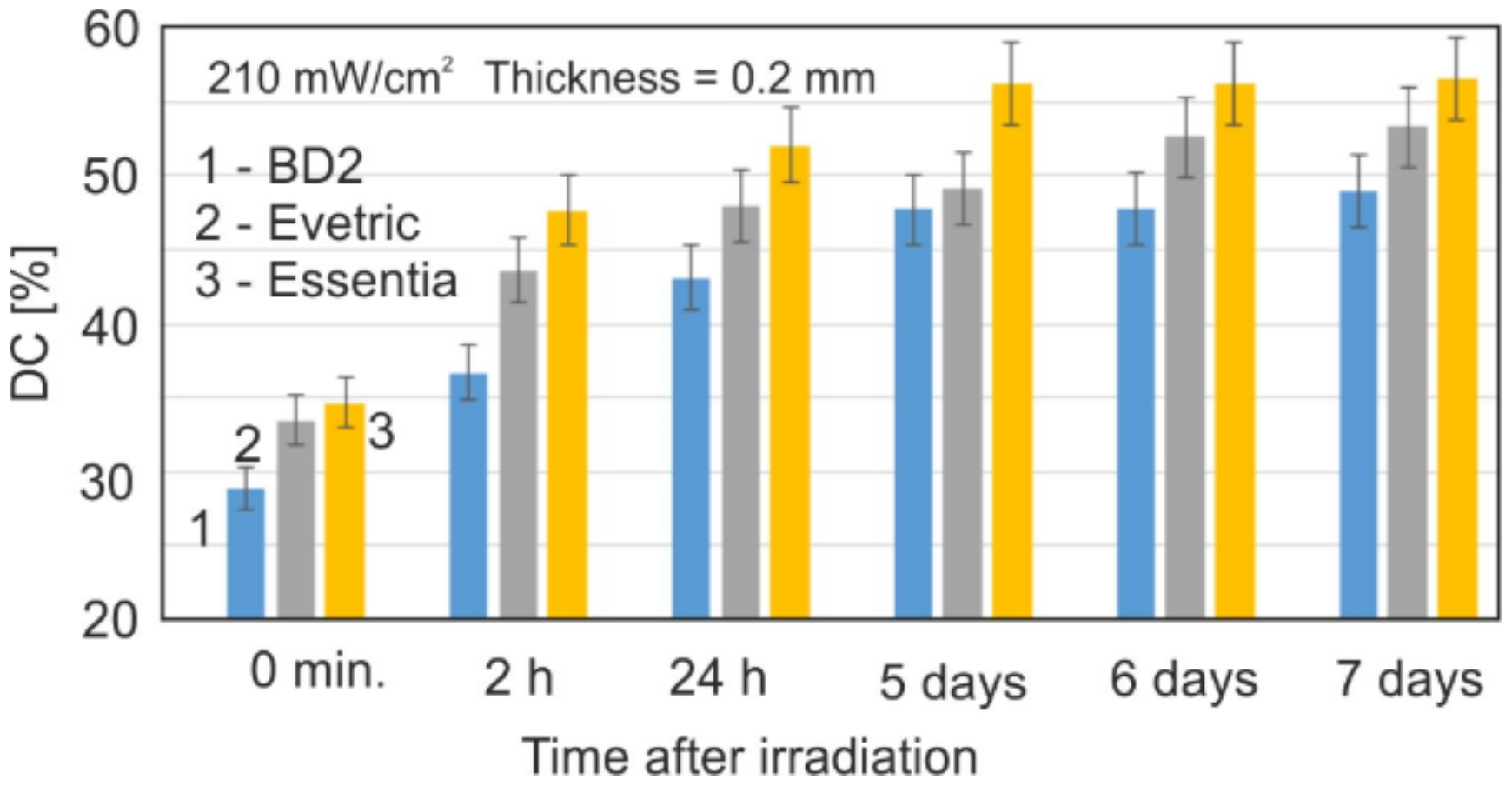

3.3. Polymerization Kinetics in the Transmission Method

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tarle, Z.; Par, M. Degree of conversion. In Dental Composite for Direct Restorations, 1st ed.; Miletic, V., Ed.; Springer: Cham, Switzerland, 2018; pp. 63–68. [Google Scholar] [CrossRef]

- Ilie, N.; Hickel, R. Resin composite restorative materials. Aust. Dent. J. 2011, 56 (Suppl. 1), 59–66. [Google Scholar] [CrossRef]

- Czasch, P.; Ilie, N. In vitro comparison of mechanical properties and degree of cure of bulk fill composites. Clin. Oral Investig. 2012, 17, 227–235. [Google Scholar] [CrossRef] [PubMed]

- Leprince, J.G.; Palin, W.M.; Hadis, M.A.; Devaux, J.; Leloup, G. Progress in dimethacrylate-based dental composite technology and curing efficiency. Dent. Mater. 2013, 29, 139–156. [Google Scholar] [CrossRef] [PubMed]

- Tarle, Z.; Attin, T.; Marovic, D.; Andermatt, L.; Ristic, M.; Taubock, T.T. Influence of irradiation time on subsurface degree of conversion and microhardness of high-viscosity bulk-fill resin composites. Clin. Oral Investig. 2015, 19, 831–840. [Google Scholar] [CrossRef] [PubMed]

- Taubock, T.T.; Tarle, Z.; Marovic, D.; Attin, T. Pre-heating of high-viscosity bulk-fill resin composites: Effects on shrinkage force and monomer conversion. J. Dent. 2015, 43, 1358–1364. [Google Scholar] [CrossRef]

- Peutzfeldt, A. Resin composites in dentistry: The monomer systems. Eur. J. Oral Sci. 1997, 105, 97–116. [Google Scholar] [CrossRef] [PubMed]

- Rueggeberg, F.A. State-of-the-art: Dental photocuring—A review. Dent. Mater. 2011, 27, 39–52. [Google Scholar] [CrossRef]

- Ferracane, J.L. Resin composite—State of the art. Dent. Mater. 2011, 27, 29–38. [Google Scholar] [CrossRef]

- Kwaśny, M.; Bombalska, A.; Obroniecka, K. A reliable method of measuring the conversion degrees of methacrylate dental resins. Sensors 2022, 22, 2170. [Google Scholar] [CrossRef]

- Tuna, E.B.; Aktoren, O.; Oshida, Y.; Gencay, K. Elution of residual monomers from dental composite materials. Eur. J. Paediatr. Dent. 2010, 11, 110–114. [Google Scholar] [CrossRef]

- Halvorson, R.H.; Erickson, R.L.; Davidson, C.L. The effect of filler and silane content on the conversion of resin-based composite. Dent. Mater. 2003, 19, 327–333. [Google Scholar] [CrossRef]

- Ilie, N.; Obermaier, J.; Durner, J. Effect of modulated irradiation time on the degree of conversion and the amount of elutable substances from nano-hybrid resin-based composites. Clin. Oral Investig. 2014, 18, 97–106. [Google Scholar] [CrossRef] [PubMed]

- Frauscher, K.; Ilie, N. Degree of conversion of nano-hybrid resin-based composites with novel and conventional matrix formulation. Clin. Oral Investig. 2013, 17, 635–642. [Google Scholar] [CrossRef] [PubMed]

- Urban, V.M.; Machado, A.; Vergani, C.E.; Giampaolo, E.T.; Pavarina, A.C.; de Almeida, F.G.; Cass, Q.B. Effect of water-bath post-polymerization on the mechanical properties, degree of conversion, and leaching of residual compounds of hard chairside reline resins. Dent. Mater. 2009, 25, 662–671. [Google Scholar] [CrossRef] [PubMed]

- Grupta, S.P.; Shresta, B.K. Shear bond strength of a bracket-bonding system cured with a light-emitting diode or halogen-based light-curing at various polymerization times. Clin. Cosmet. Investig. Dent. 2018, 10, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, B.C.; Boaventura, J.M.; Brito-Goncalves, M.; Rastelli, A.N.; Bagnato, V.S.; Saad, J.R. Degree of conversion of nanofiller and microhybrid composite resins photo-activated by different generations of LEDs. J. Appl. Oral Sci. 2012, 20, 212–217. [Google Scholar] [CrossRef] [PubMed]

- Moraes, L.G.P.; Rocha, R.S.F.; Menegazzo, L.M.; de Araujo, E.B.; Yukimito, K.; Moraes, J.C. Infrared spectroscopy: A tool for determination of the degree of conversion in dental composites. J. Appl. Oral Sci. 2008, 16, 145–149. [Google Scholar] [CrossRef] [PubMed]

- Segreto, D.R.; Naufel, F.S.; Brandt, W.C.; Guiraldo, R.D.; Correr-Sobrinho, L.; Sinhoreti, M.A.C. Influence of photoinitiator and light-curing source on bond strength of experimental resin cement to dentin. Braz. Dent. J. 2016, 27, 83–89. [Google Scholar] [CrossRef]

- Guram, G.; Shaik, J.A. Comparison of Light-Emitting Diode-Curing Unit and Halogen-Based Light-Curing Unit for the Polymerization of Orthodontic Resins: An In-vitro Study. J. Int. Soc. Prev. Commun. Dent. 2018, 8, 409–415. [Google Scholar] [CrossRef]

- Ferracane, J.L.; Greener, E.H. Fourier transform infrared analysis of degree of polymerization in unfilled resins methods comparison. J. Dent. Res. 1984, 63, 1093–1095. [Google Scholar] [CrossRef]

- Peutzfeldt, A.; Asmussen, E. The effect of posturing on the quantity of remaining double bonds, mechanical properties, and in vitro wear of two resin composites. J. Dent. 2000, 28, 447–452. [Google Scholar] [CrossRef]

- Gauthier, M.A.; Stangel, I.; Ellis, T.H.; Zhu, X.X. A new method for quantifying the intensity of the C=C band of dimethacrylate dental monomers in their FTIR and Raman spectra. Biomaterials 2005, 26, 6440–6448. [Google Scholar] [CrossRef] [PubMed]

- Shin, W.S.; Li, X.F.; Schwartz, B.; Wunder, S.I.; Baran, G.R. Determination of the degree of cure of dental resins using Raman and FT-Raman spectroscopy. Dent. Mater. 1993, 9, 317–324. [Google Scholar] [CrossRef]

- Sustercic, D.; Cevc, P.; Funduk, N.; Pintar, M.M. Determination of curing time in visible-cured composite resins of different thickness by electron paramagnetic resonance. J. Mater. Sci. Mater. Med. 1997, 8, 507–510. [Google Scholar] [CrossRef]

- Morgan, D.R.; Kalachandra, S.; Shobla, H.K.; Gunduz, N.; Stejskal, E.O. Analysis of dimethacrylate copolymer (BisGMA and TEGDMA) network by DSC and 13C solution and solid-state NMR spectroscopy. Biomaterials 2000, 21, 1897–1903. [Google Scholar] [CrossRef]

- Imazoto, S.; McCabe, J.F.; Tarumi, H.; Ebara, A.; Ebisu, S. Degree of conversion of composites measured by DTA and FTIR. Dent. Mater. 2001, 17, 178–183. [Google Scholar] [CrossRef]

- McCabe, J.F. Cure performance of light-activated composites by differential thermal analysis (DTA). Dent. Mater. 1985, 1, 231–234. [Google Scholar] [CrossRef]

- Wang, E.; Hasheminasab, A.; Guo, Y.; Soucek, M.D.; Cakmak, M. Structure characterization of UV-curing PEG-b-PPG-b-PEG dimethacrylate cross-linked network. Polymer 2018, 153, 241–249. [Google Scholar] [CrossRef]

- Łukaszczyk, J.; Janicki, B.; Frick, A. Investigation on synthesis and properties of isosorbide based bis-GMA analogue. J. Mater. Sci. Mater. Med. 2012, 23, 1149–1155. [Google Scholar] [CrossRef][Green Version]

- Barszczewska-Rybarek, I.; Chladek, G. Studies on the curing efficiency and mechanical properties of Bis-GMA and TEGDMA nanocomposites containing silver nanoparticles. Int. J. Mol. Sci. 2018, 19, 3937. [Google Scholar] [CrossRef]

- Stencel, R.; Pakieła, W.; Barszczewska-Rybarek, I.; Zmudzki, J.; Kasperski, J.; Chladek, G. Effects of different inorganic fillers on mechanical properties and degree of conversion of dental resin composites. Arch. Metall. Mater. 2018, 63, 1361–1369. [Google Scholar] [CrossRef]

- Zhang, M.; Puska, M.A.; Botelho, M.G.; Säilynoja, E.S.; Matinlinna, J.P. Degree of conversion and leached monomers of urethane dimethacrylate-hydroxypropyl methacrylate-based dental resin systems. J. Oral Sci. 2016, 58, 15–22. [Google Scholar] [CrossRef]

- Yuan, S.; Liu, F.; He, J. Preparation and characterization of low polymerization shrinkage and Bis-GMA-free dental resin system. Adv. Polym. Technol. 2015, 34, 21503. [Google Scholar] [CrossRef]

- Al-Odayni, A.B.; Alfotawi, R.; Khan, R.; Saeed, W.S.; Al-Kahtani, A.; Aouak, T.; Alrahlah, A. Synthesis of chemically modified BisGMA analog with low viscosity and potential physical and biological properties for dental resin composite. Dent. Mater. 2019, 35, 1532–1544. [Google Scholar] [CrossRef] [PubMed]

- Moldovan, M.; Balazsi, R.; Soanca, A.; Roman, A.; Sarosi, C.; Prodan, D.; Vlassa, M.; Cojocaru, I.; Saceleanu, V.; Cristescu, I. Evaluation of the degree of conversion, residual monomers and mechanical properties of some light-cured dental resin composites. Materials 2019, 12, 2109. [Google Scholar] [CrossRef]

- Pfeifer, C.S.; Shelton, Z.R.; Braga, R.R.; Windmoller, D.; Machado, J.C.; Stansbury, J.W. Characterization of dimethacrylate polymeric networks: A study of the crosslinked structure formed by monomers used in dental composites. Eur. Polym. J. 2011, 47, 162–170. [Google Scholar] [CrossRef]

- Stansbury, J.W. Dimethacrylate network formation and polymer property evolution as determined by the selection of monomers and curing conditions. Dent. Mater. 2012, 28, 13–22. [Google Scholar] [CrossRef]

- Ogliari, F.A.; Ely, C.; Zanchi, C.H.; Fortes, C.B.; Samuel, S.M.; Demarco, F.F.; Petzhold, C.L.; Piva, E. Influence of chain extender length of aromatic dimethacrylates on polymer network development. Dent. Mater. 2007, 24, 165–171. [Google Scholar] [CrossRef]

- Scherzer, T. Real-time FTIR-ATR spectroscopy of photopolymerization reactions. Macromol. Symp. 2002, 184, 79–98. [Google Scholar] [CrossRef]

- Borges, A.F.S.; Chase, M.; Guggiar, A.L.; Gonzales, M.J.; Ribeiro, A.; Pascon, F.M.; Zanatta, A.R. A critical review on the conversion degree of resin monomers by direct analyses. Braz. Dent. Sci. 2013, 16, 18–26. [Google Scholar] [CrossRef]

| Sample Name | Manufacturer |

|---|---|

| Enamel Plus HRi (UD2) | Micerium S.p.A., Avegno, Italy |

| Enamel Plus HRi BioFunction (BD2) | Micerium S.p.A., Avegno, Italy |

| Estelite Asteria | Tokuyama Dental Corporation, Tokyo, Japan |

| FiltekTM Ultimate | 3M Oral Care, Irwindale, CA, USA |

| Essentia | GC United Kingdom Ltd., Newport Pagnell, UK |

| Gradia Direct Anterior | GC United Kingdom Ltd., Newport Pagnell, UK |

| IPS Empress Direct | Ivoclar Vivadent, Buffalo, NY, USA |

| G-aenial | GC United Kingdom Ltd., Newport Pagnell, UK |

| Evetric | Ivoclar Vivadent, Buffalo, NY, USA |

| HarmonizeTM | Kerr, Orange, CA, USA |

| Amaris | VOCO, Cuxhaven, Germany |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwaśny, M.; Polkowski, J.; Bombalska, A. A Study on the Photopolymerization Kinetics of Selected Dental Resins Using Fourier Infrared Spectroscopy (FTIR). Materials 2022, 15, 5850. https://doi.org/10.3390/ma15175850

Kwaśny M, Polkowski J, Bombalska A. A Study on the Photopolymerization Kinetics of Selected Dental Resins Using Fourier Infrared Spectroscopy (FTIR). Materials. 2022; 15(17):5850. https://doi.org/10.3390/ma15175850

Chicago/Turabian StyleKwaśny, Mirosław, Jakub Polkowski, and Aneta Bombalska. 2022. "A Study on the Photopolymerization Kinetics of Selected Dental Resins Using Fourier Infrared Spectroscopy (FTIR)" Materials 15, no. 17: 5850. https://doi.org/10.3390/ma15175850

APA StyleKwaśny, M., Polkowski, J., & Bombalska, A. (2022). A Study on the Photopolymerization Kinetics of Selected Dental Resins Using Fourier Infrared Spectroscopy (FTIR). Materials, 15(17), 5850. https://doi.org/10.3390/ma15175850