Effect of Multi-Component on Crack Resistance of High-Performance Concrete on Subway Underground Station Floor

Abstract

:1. Introduction

2. Experiment Materials and Methods

2.1. Materials

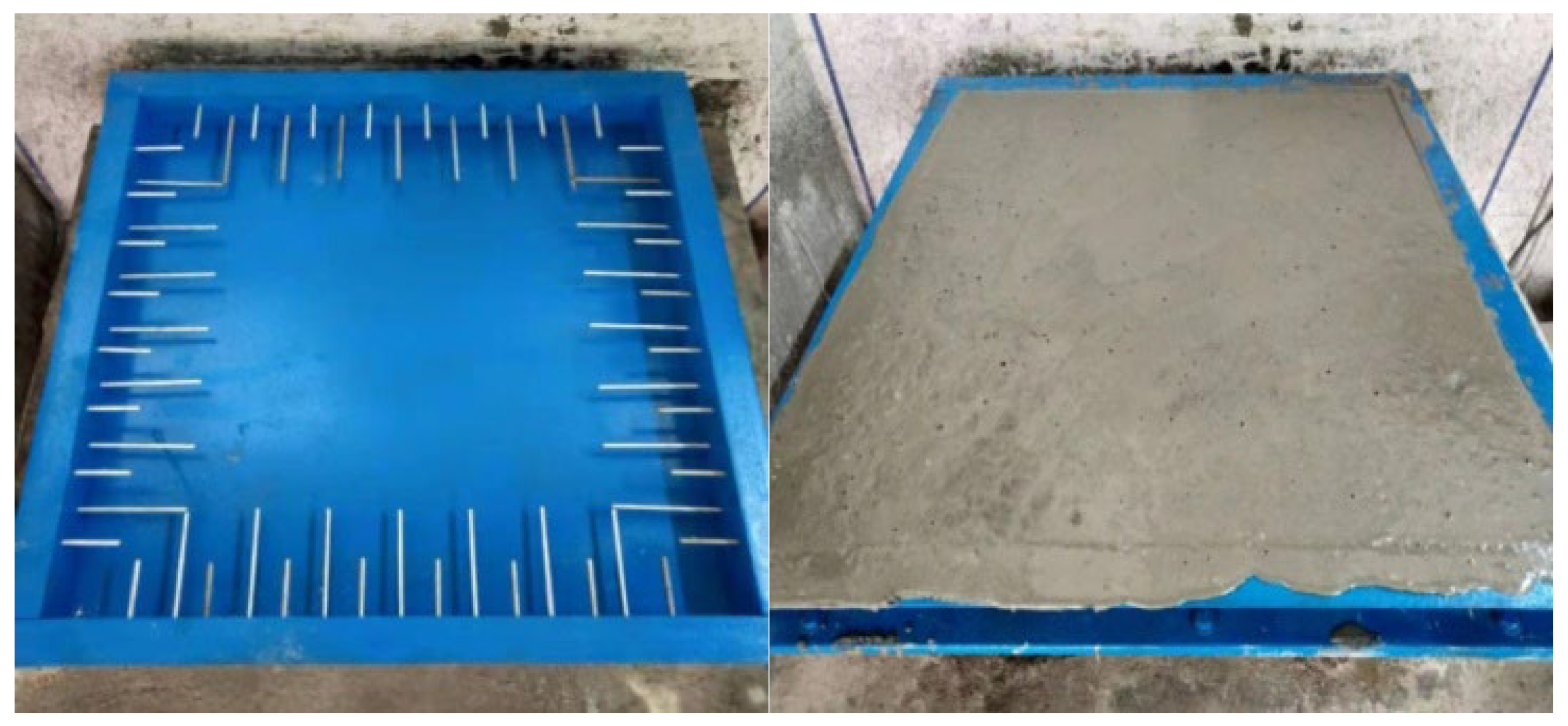

2.2. Specimens Preparation and Testing Programs

3. Results and Discussion

3.1. Effect of Material Composition on Compressive Strength of Concrete

3.2. Effect of Material Composition on the Time of Initial Crack and Through Crack of Concrete

3.3. Effect of Material Composition on Cracking Area of Concrete

3.4. Effect of Material Composition on Microstructure

3.4.1. SEM Analysis

3.4.2. XRD Analysis

3.4.3. MIP Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Yoo, D.Y.; Min, K.H.; Lee, J.H.; Yoon, Y.S. Shrinkage and cracking of restrained ultra-high-performance fiber-reinforced concrete slabs at early age. Constr. Build. Mater. 2014, 73, 357–365. [Google Scholar] [CrossRef]

- Özbay, E.; Erdemir, M.; Durmushd, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete properties-a review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Vahid, A.; Susanto, T. Experiments on drying shrinkage and creep of high performance hybrid-fiber-reinforced concrete. Cem. Concr. Compos. 2020, 106, 103481. [Google Scholar]

- Wei, Y.; Hansen, W. Early-age strain-stress relationship and cracking behavior of slag cement mixtures subject to constant uniaxial restraint. Constr. Build. Mater. 2013, 49, 635–642. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Wang, A. Effects of MgO-based expansive additive on compensating the shrinkage of cement paste under non-wet curing conditions. Cem. Concr. Compos. 2012, 34, 377–393. [Google Scholar] [CrossRef]

- Juarez, C.A.; Fajardo, G.; Monroy, S.; Duran-Herrera, A.; Valdez, P.; Magniont, C. Comparative study between natural and PVA fibers to reduce plastic shrinkage cracking in cement-based composite. Constr. Build. Mater. 2015, 91, 164–170. [Google Scholar] [CrossRef]

- Adam, J.M.; Parisi, F.; Sagaseta, J.; Lu, X. Research and practice on progressive collapse and robustness of building structures in the 21st century. Eng. Struct. 2018, 173, 122–149. [Google Scholar] [CrossRef]

- Yasuda, N.; Tsukada, K.; Asakura, T. Elastic solutions for circular tunnel with void behind lining. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2017, 70, 274–285. [Google Scholar] [CrossRef]

- Ray, I.; Gong, Z.; Davalos, J. Shrinkage and cracking studies of high performance concrete for bridge decks. Constr. Build. Mater. 2012, 28, 244–254. [Google Scholar] [CrossRef]

- Altoubat, S.; Badran, D.; Junaid, M.T.; Leblouba, M. Restrained shrinkage behavior of self-compacting concrete containing ground-granulated blast-furnace slag. Constr. Build. Mater. 2016, 129, 98–105. [Google Scholar] [CrossRef]

- Altoubat, S.; Junaid, M.T.; Leblouba, M.; Badran, D. Effectiveness of fly ash on the restrained shrinkage cracking resistance of self-compacting concrete. Cem. Concr. Compos. 2017, 79, 9–20. [Google Scholar] [CrossRef]

- Xin, J.; Zhang, G.; Liu, Y.; Wang, Z.; Wu, Z. Effect of temperature history and restraint degree on cracking behavior of early-age concrete. Constr. Build. Mater. 2018, 192, 381–390. [Google Scholar] [CrossRef]

- Yoichi, M.; Vanissorn, V.; Itaru, H.; Isamu, Y. Tensile mechanical properties of fly ash concrete at early age for thermal stress analysis. J. Infrastruct. Preserv. Resil. 2020, 1, 14. [Google Scholar]

- Meddah, M.S.; Ismail, M.A.; El-Gamal, S.; Fitriani, H. Performances evaluation of binary concrete designed with silica fume and metakaolin. Constr. Build. Mater. 2018, 166, 400–412. [Google Scholar] [CrossRef]

- Perfilov, V.A.; Oreshkin, D.V.; Zemlyanushnov, D.Y. Concrete strength and crack resistance control. Procedia Eng. 2016, 150, 1474–1478. [Google Scholar] [CrossRef]

- Li, M.; Liu, M.; Yang, Y.; Li, Z.; Guo, X. Mechanical properties of oil well cement stone reinforced with hybrid fiber of calcium carbonate whisker and carbon fiber. Pet. Explor. Dev. 2015, 42, 104–111. [Google Scholar]

- Gao, P.; Lu, X.; Tang, M. Effects of different expansive agents on mass concrete deformation property. J. Nanjing Univ. Aeronaut. Astronaut. 2006, 38, 251–255. [Google Scholar]

- Gao, P. Shrinkage and Expansive Strain of Concrete with Fly Ash and Expansive Agent. J. Wuhan Univ. Technol. 2009, 24, 150–153. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, P.; Liu, H.; Zhang, L.; Liu, X.; Ju, X. Cracking and mechanical properties of airport concrete pavement with fiber and expansive agent. Trans. Nanjing Univ. Aeronaut. Astronaut. 2014, 31, 675–680. [Google Scholar]

- Choi, H.; Choi, H.; Lim, M.; Noguchi, T.; Kitagaki, R. Modeling of volume changes of concrete mixed with expansive additives. Constr. Build. Mater. 2015, 75, 266–274. [Google Scholar] [CrossRef]

- Mo, L.; Fang, J.; Huang, B.; Wang, A.; Deng, M. Combined effects of biochar and MgO expansive additive on the autogenous shrinkage, internal relative humidity and compressive strength of cement pastes. Constr. Build. Mater. 2019, 229, 116877. [Google Scholar] [CrossRef]

- Ding, W.W.; Tan, K.F.; Liu, L.B.; Tang, K.; Zhao, C.; He, Y. Utilisation of light calcined magnesite tailings to compensate the autogenous shrinkage of steam-cured cement paste. Adv. Cem. Res. 2016, 28, 675–686. [Google Scholar] [CrossRef]

- Cao, F.Z.; Miao, M.; Yan, P.Y. Hydration characteristics and expansive mechanism of MgO expansive agents. Constr. Build. Mater. 2018, 183, 234–242. [Google Scholar] [CrossRef]

- Babak, S.; Erfan, D.; Fattahi, A.M.; Asmael, M. Calcium carbonate nanoparticles effects on cement plast properties. Microsyst. Technol. 2021, 27, 3059–3076. [Google Scholar]

- Huang, H.L.; Qian, C.X.; Zhao, F.; Qu, J.; Guo, J.; Danzinger, M. Improvement on microstructure of concrete by polycarboxylate superplasticizer(PCE) and its influence on durability of concrete. Constr. Build. Mater. 2016, 110, 293–299. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Kong, X.M. Correlations of the dispersing capability of NSF and PCE types of superplasticizer and their impacts on cement hydration with the adsorption in fresh cement pastes. Cem. Concr. Res. 2015, 69, 1–9. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Kong, X.M.; Gao, L.; Wang, J. Rheological behaviors of fresh cement pastes with polycarboxylate superplasticizer. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2016, 31, 286–299. [Google Scholar] [CrossRef]

- Al-Amoudi, O.; Abiola, T. Effect of superplasticizer on plastic shrinkage of plain and silica fume cement concretes. Constr. Build. Mater. 2006, 20, 642–647. [Google Scholar] [CrossRef]

- Ma, B.; Wang, X.; Li, X. Influence of superplastieizers on strength and shrinkage cracking of cement mortar under drying conditions. J. Wuhan Univ. Technol. 2007, 22, 358–361. [Google Scholar] [CrossRef]

- Reza, H.; Fattahi, A.M. A micromechanical model for overlapped short platelet-reinforced composites. Mech. Based Des. Struct. Mach. 2022, 50, 2569–2581. [Google Scholar]

- Sahmani1, S.; Fattahi, A.M. Size-dependent nonlinear instability of shear deformable cylindrical nanopanels subjected to axial compression in thermal environments. Microsyst. Technol. 2017, 23, 4717–4731. [Google Scholar] [CrossRef]

- He, Z.; Li, Q.; Yu, H.; Ma, R. Double feedback control method for determining early-age restrained creep of concrete using a temperature stress testing machine. Materials 2018, 11, 1079. [Google Scholar]

- Islam, G.S.; Gupta, S.D. Evaluating plastic shrinkage and permeability of polypropylene fiber reinforced concrete. Int. J. Sustain. Built Environ. 2016, 5, 345–354. [Google Scholar] [CrossRef]

- Altoubat, S.; Rieder, K.; Junaid, M.T. Short-and long-term restrained shrinkage cracking of fiber reinforced concrete composite metal decks: An experimental study. Mater. Struct. 2017, 50, 140. [Google Scholar] [CrossRef]

- ASTM C1579-06; Standard Test Method for Evaluating Plastic Shrinkage Cracking of Restrained Fiber Reinforced Concrete (Using a Steel Form Insert). ASTM: West Conshohocken, PA, USA, 2006.

- Soroushian, P.; Ravanbaksh, S. Control of plastic shrinkage cracking with specialty cellulose fibers. ACI Mater. J. 2004, 95, 419–435. [Google Scholar]

- Harwalkar, A.; Awanti, S. Laboratory and Field Investigations on High-Volume Fly Ash Concrete for Rigid Pavement. Transp. Res. Rec. 2014, 2441, 121–127. [Google Scholar] [CrossRef]

- Dias, D.P.; Thaumaturgo, C. Fracture toughness of geopolymeric concretes reinforced with basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Xun, W.; Wu, C.; Leng, X.; Li, J.; Xin, D.; Li, Y. Effect of Functional Superplasticizers on Concrete Strength and Pore Structure. Appl. Sci. 2020, 10, 3496. [Google Scholar] [CrossRef]

- Rodrigue, A.; Duchesne, J.; Fournier, B.; Bissonnette, B. Influence of added water and fly ash content on the characteristics, properties and early-age cracking sensitivity of alkali-activated slag/fly ash concrete cured at ambient temperature. Constr. Build. Mater. 2018, 171, 929–941. [Google Scholar] [CrossRef]

- Xiong, J.B.; Li, P.P.; Wang, S.N. Influence of mineral admixtures on chloride diffusion coefficient of self-compacting concrete. Appl. Mech. Mater. 2013, 405–408, 2876–2880. [Google Scholar]

| Materials | CaO | SiO2 | Al2O3 | Fe2O3 | L.O.I | ∑ |

|---|---|---|---|---|---|---|

| Expander | 90.14 | 6.34 | 0.91 | 1.24 | 1.35 | 99.98 |

| Length/mm | Filament Diameter/μm | Density/kg·m−3 | Tensile Strength/MPa | Elastic Modulus/GPa | Elongation /% | Fiberizing Temperature/°C | Max Temperature/°C | Softening Point /°C |

|---|---|---|---|---|---|---|---|---|

| 12 | 16 | 2650 | 4150 | 100 | 3.2 | 1430 | 650 | 960 |

| NO. | Fly Ash | Basalt Fiber | Expander | Water Reducer |

|---|---|---|---|---|

| 1 | 15% | 0.1% | 4% | 1.0% |

| 2 | 20% | 0.2% | 6% | 1.1% |

| 3 | 25% | 0.3% | 8% | 1.2% |

| 4 | 30% | 0.4% | 10% | 1.3% |

| NO. | Cement | Fly Ash | Silica Fume | Slag | Sand | Gravel | Water | Basalt Fiber | Expander | Water Reducer |

|---|---|---|---|---|---|---|---|---|---|---|

| H1 | 245 | 75 | 30 | 150 | 646 | 1054 | 160 | 2.65 | 20 | 5 |

| H2 | 245 | 75 | 30 | 150 | 646 | 1054 | 160 | 5.30 | 30 | 5.5 |

| H3 | 245 | 75 | 30 | 150 | 646 | 1054 | 160 | 7.95 | 40 | 6 |

| H4 | 245 | 75 | 30 | 150 | 646 | 1054 | 160 | 10.60 | 50 | 6.5 |

| H5 | 220 | 100 | 30 | 150 | 646 | 1054 | 160 | 2.65 | 40 | 5.5 |

| H6 | 220 | 100 | 30 | 150 | 646 | 1054 | 160 | 5.30 | 50 | 5 |

| H7 | 220 | 100 | 30 | 150 | 646 | 1054 | 160 | 7.95 | 20 | 6.5 |

| H8 | 220 | 100 | 30 | 150 | 646 | 1054 | 160 | 10.60 | 30 | 6 |

| H9 | 195 | 125 | 30 | 150 | 646 | 1054 | 160 | 2.65 | 50 | 6 |

| H10 | 195 | 125 | 30 | 150 | 646 | 1054 | 160 | 5.30 | 40 | 6.5 |

| H11 | 195 | 125 | 30 | 150 | 646 | 1054 | 160 | 7.95 | 30 | 5 |

| H12 | 195 | 125 | 30 | 150 | 646 | 1054 | 160 | 10.60 | 20 | 5.5 |

| H13 | 170 | 150 | 30 | 150 | 646 | 1054 | 160 | 2.65 | 30 | 6.5 |

| H14 | 170 | 150 | 30 | 150 | 646 | 1054 | 160 | 5.30 | 20 | 6 |

| H15 | 170 | 150 | 30 | 150 | 646 | 1054 | 160 | 7.95 | 50 | 5.5 |

| H16 | 170 | 150 | 30 | 150 | 646 | 1054 | 160 | 10.60 | 40 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Gao, P.; Huang, L.; Chen, L.; Cen, F.; Zhao, Z.; Tian, Y. Effect of Multi-Component on Crack Resistance of High-Performance Concrete on Subway Underground Station Floor. Materials 2022, 15, 5868. https://doi.org/10.3390/ma15175868

Xu S, Gao P, Huang L, Chen L, Cen F, Zhao Z, Tian Y. Effect of Multi-Component on Crack Resistance of High-Performance Concrete on Subway Underground Station Floor. Materials. 2022; 15(17):5868. https://doi.org/10.3390/ma15175868

Chicago/Turabian StyleXu, Shaoyun, Peiwei Gao, Lingling Huang, Lifeng Chen, Feng Cen, Zhiqing Zhao, and Yilang Tian. 2022. "Effect of Multi-Component on Crack Resistance of High-Performance Concrete on Subway Underground Station Floor" Materials 15, no. 17: 5868. https://doi.org/10.3390/ma15175868

APA StyleXu, S., Gao, P., Huang, L., Chen, L., Cen, F., Zhao, Z., & Tian, Y. (2022). Effect of Multi-Component on Crack Resistance of High-Performance Concrete on Subway Underground Station Floor. Materials, 15(17), 5868. https://doi.org/10.3390/ma15175868