Evaluation of Surface Treatment for Enhancing Adhesion at the Metal–Composite Interface in Fibre Metal-Laminates

Abstract

:1. Introduction

2. Materials and Methods

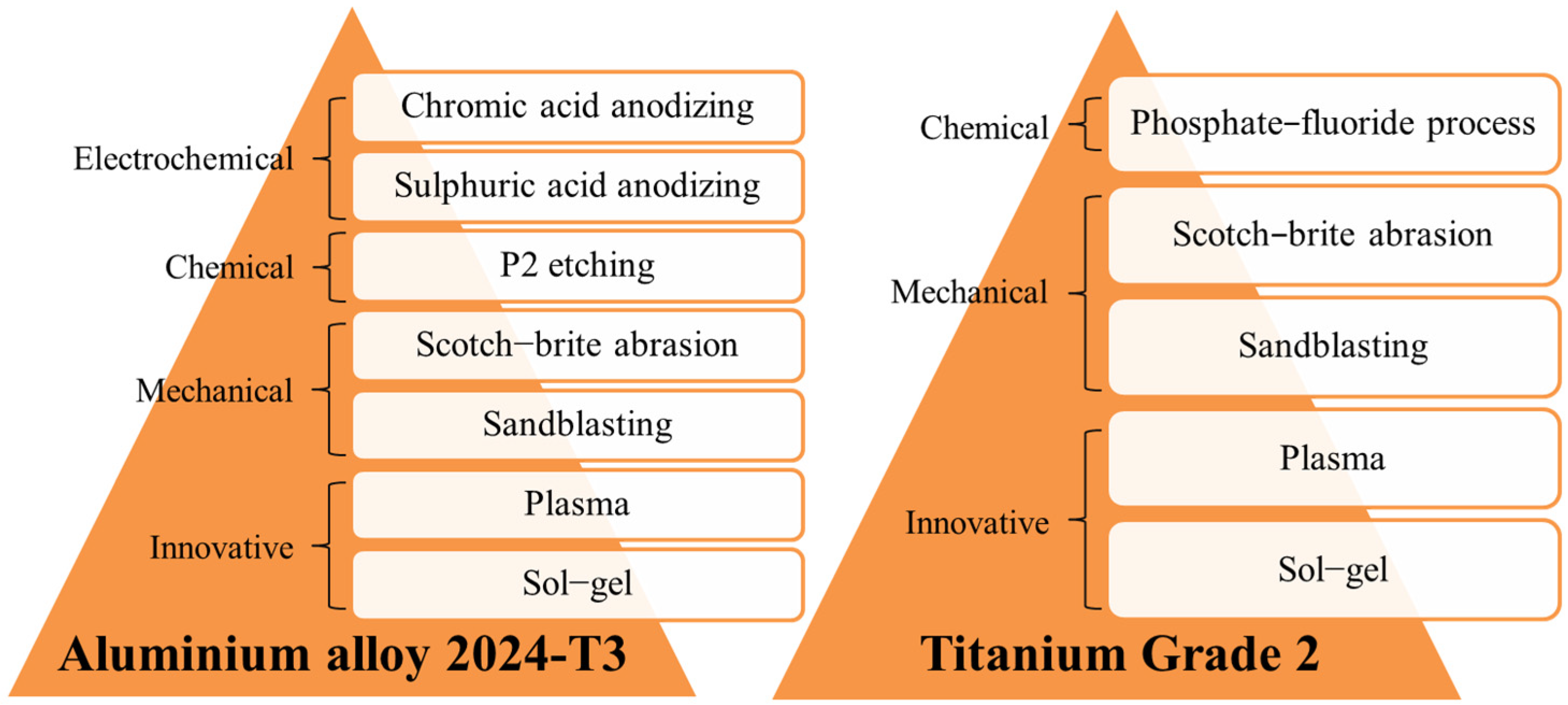

2.1. Materials and Surface Treatments

2.2. Surface Characterization

3. Results and Discussion

3.1. Roughness and Topography

3.2. Surface-Free Energy

3.3. Surface Morphology

4. Conclusions

- The applied methods of surface treatment results in a structure with specific geometric, morphological, and physicochemical characteristics.

- Mechanical methods (sandblasting or Scotch-Brite abrasion) create a characteristic geometric structure with a high roughness, especially after sandblasting; it ranges from 0.78 to 1.18 µm and changes the surface topography. These methods increase the surface area but do not obtain the appropriate shape of the inequalities guaranteeing mechanical interlocking and adhesive anchoring. However, with good wettability at the same time, it can lead to good tangible adhesion.

- Plasma techniques accurately clean the surface, but do not change its topography. It has low roughness approx. 0.19 µm (aluminium), and 0.38 µm (titanium). Therefore, these methods will have limited application to maintain high adhesion at the metal–composite interface.

- In terms of the expected suitable adhesion properties, the most advantageous is still the aluminium treatment by creating oxide layers in the anodizing process, especially chromic acid anodizing. Then, the surface has a homogeneous structure with a high level of micro irregularities and appropriate physicochemical properties (SFE). It ranges from 84.9 mJ/m2 for CAA and 83.5 mJ/m2 for SAA.

- The beneficial structure was obtained after chemical etching. Appropriate topography and morphology was created. Particularly for aluminium after P2 etching, low roughness Ra = 0.07 µm was noted, with numerous micro-irregularities and the presence of porosity. This surface modification may be a combination of mechanical and chemical influence. In these cases, the key influence may be the specific interaction between the surface and the transition layers.

- The above modifications of the surfaces cause a synergistic interaction with the intermediate layers (primer and sol-gel). The structure of the top layer allows penetration by the primer, and particularly by the sol-gel. The porous structure with the increased interfacial surface area may favour the penetration by the primer or particularly the promising sol-gel. As a result, such modification can influence chemical and mechanical mechanisms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vlot, A. Impact loading on Fibre Metal Laminate. Int. J. Impact Eng. 1996, 18, 291–307. [Google Scholar] [CrossRef]

- Jakubczak, P.; Bieniaś, J.; Droździel, M. The collation of impact behaviour of titanium/carbon, aluminum/carbon and conventional carbon fibres laminates. Thin-Walled Struct. 2020, 155, 106952. [Google Scholar] [CrossRef]

- Sadighi, M.; Alderliesten, R.C.; Benedictus, R. Impact resistance of fiber-metal laminates: A review. Int. J. Impact Eng. 2012, 49, 77–90. [Google Scholar] [CrossRef]

- Botelho, E.C.; Silva, R.A.; Pardini, L.C.; Rezende, M.C. A review on the development and properties of continuous fiber/epoxy/aluminum hybrid composites for aircraft structures. Mater. Res. 2006, 9, 247–256. [Google Scholar] [CrossRef]

- Kalaa, K.L.; Raob, K.P. Synthesis and characterization of fabricated fiber metal laminates for aerospace applications. Mater. Today 2022, 64, 37–43. [Google Scholar] [CrossRef]

- Botelho, E.C.; Rezende, M.C.; Pardini, L.C. Hygrothermal effects evaluating using the isosipescu shear test for glare laminates. J. Braz. Soc. Mech. Sci. Eng. 2008, 30, 213–220. [Google Scholar] [CrossRef]

- Ostapiuk, M.; Surowska, B.; Bieniaś, J.; Majerski, K. Structure characteristics in glass/aluminium hybrid laminates after bending strength test. Compos. Theory Pract. 2013, 13, 237–240. [Google Scholar]

- Ostapiuk, M.; Surowska, B.; Bieniaś, J. Interface analysis of fibre metal laminates, Compos. Interfaces 2014, 21, 309–318. [Google Scholar] [CrossRef]

- Molitor, P.; Barron, V.; Young, T. Surface treatment of titanium for adhesive bonding to polymer composite: A review. Int. J. Adhes. Adhes. 2001, 21, 129–136. [Google Scholar] [CrossRef]

- Gonzalez-Canche, N.G.; Flores-Johnson, E.A.; Cortes, P.; Carrillo, J.G. Evaluation of surface treatments on 5052-H32 aluminum alloy for enhancing the interfacial adhesion of thermoplastic-based fiber metal laminates. Int. J. Adhes. Adhes. 2018, 82, 90–99. [Google Scholar] [CrossRef]

- Sinmazçelik, T.; Avcu, E.; Bora, M.O.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Zielecki, W.; Pawlus, P.; Perłowski, R.; Dzierwa, A. Surface topography effect on strength of lap adhesive joints after mechanical pre-treatment. Arch. Civ. Mech. Eng. 2013, 13, 175–185. [Google Scholar] [CrossRef]

- Packham, D.E. Surface energy, surface topography and adhesion. Int. J. Adhes. Adhes. 2003, 23, 437–448. [Google Scholar] [CrossRef]

- Mohamad, M.; Marzuki, H.F.A.; Ubaidillah, E.; Abidin, M.; Omar, S.; Rozi, I. Effect of surface roughness on mechanical properties of aluminium-carbon laminates composites. Adv. Mater. Res. Trans. Tech. Publ. 2014, 879, 51–57. [Google Scholar] [CrossRef]

- Critchlow, G.W.; Yendall, K.A.; Bahrani, D.; Quinn, A.; Andrews, F. Strategies for the replacement of chromic acid anodising for the structural bonding of aluminium alloys. Int. J. Adhes. Adhes. 2006, 26, 419–453. [Google Scholar] [CrossRef]

- Yao, Y.; Shi, P.; Chen, M.; Chen, G.; Gao, C.; Boisse, P.; Zhu, Y. Experimental and numerical study on Mode I and Mode II interfacial fracture toughness of co-cured steel-CFRP hybrid composites. Int. J. Adhes. Adhes. 2020, 112, 103030. [Google Scholar] [CrossRef]

- Sun, S.; Wu, G.; Sun, L.; Shan, X.; Li, M.; Ji, S. Effects of different surface treatments of aluminum alloy 5083 on interlaminar strength and anticorrosion properties of FMLs. Mater. Res. Express 2018, 5, 116506. [Google Scholar] [CrossRef]

- Lawcock, G. The effect of adhesive bonding between aluminium and composite prepreg on the mechanical properties of carbon-fibre reinforced metal laminates. Compos. Sci. Technol. 1997, 55, 35–45. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, W.J.; Choi, H.S.; Kwon, H.; Kim, S.H. Recent trends in surface treatment technologies for airframe adhesive bonding processing: A review (1995–2008). J. Adhes. 2010, 86, 192–221. [Google Scholar] [CrossRef]

- Kazemi, M.E.; Shanmugam, L.; Yang, L.; Yang, J. A review on the hybrid titanium composite laminates (HTCLs) with focuses on surface treatments, fabrications, and mechanical properties. Compos. Part A 2020, 128, 105679. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Rosario, G.; Urena, A. Effect of surface pre-treatment on the adhesive strength of epoxy-aluminium joints. Int. J. Adhes. Adhes. 2006, 26, 125–132. [Google Scholar] [CrossRef]

- Aghamohammadi, H.; Navid, S.; Abbandanak, H.; Eslami-Farsani, R.; Hossein Siadati, S.M. Effects of various aluminum surface treatments on the basalt fiber metal laminates interlaminar adhesion. Int. J. Adhes. Adhes. 2018, 84, 184–193. [Google Scholar] [CrossRef]

- Oosting, R. Toward a New Durable and Environmentally Compliant Adhesive Bonding Process for Aluminum Alloys. PhD Thesis, Delft University of Technology, Delf, The Netherlands, 1995. [Google Scholar]

- Engelkemeier, K.; Mücke, C.; Hoyer, K.P.; Schaper, M. Anodizing of electrolytically galvanized steel surfaces for improved interface properties in fiber metal laminates. Adv. Compos. Hybrid Mater. 2019, 2, 188–199. [Google Scholar] [CrossRef]

- Venables, J.; McNamara, D.; Chen, J.; Sun, T.; Hopping, R. Oxide morphologies on aluminum prepared for adhesive bonding. Appl. Surf. Sci. 1979, 3, 88–98. [Google Scholar] [CrossRef]

- He, P.; Chen, K.; Yang, J. Surface modifications of Ti alloy with tunable hierarchical structures and chemistry for improved metal-polymer interface used in deepwater composite riser. Appl. Surf. Sci. 2015, 328, 614–622. [Google Scholar] [CrossRef]

- Xu, Y.; Li, H.; Shen, Y.; Liu, S.; Wang, W.; Tao, J. Improvement of adhesion performance between aluminum alloy sheet and epoxy based on anodizing technique. Int. J. Adhes. Adhes. 2016, 70, 74–80. [Google Scholar] [CrossRef]

- Santos, A.L.; Nakazato, R.Z.; Schmeer, S.; Botelho, E.C. Influence of anodization of aluminum 2024 T3 for application in aluminum/cf/epoxy laminate. Compos. Part B Eng. 2020, 184, 107718. [Google Scholar] [CrossRef]

- Carrino, L.; Napolitano, G.; Sorrentino, L. Wettability improving of 2024 aluminium alloy by oxygen cold plasma treatment. Int. J. Adv. Manuf. Technol. 2006, 31, 465–473. [Google Scholar] [CrossRef]

- Wang, X.; Lin, J.; Min, J.; Wang, P.C.; Sun, C. Effect of atmospheric pressure plasma treatment on strength of adhesive-bonded aluminum AA5052. J. Adhes. 2018, 94, 701–722. [Google Scholar] [CrossRef]

- Liu, J.; Chaudhury, M.K.; Berry, D.H.; Seebergh, J.E.; Osborne, J.H.; Blohowiak, K.Y. Effect of surface morphology on crack growth at a sol-gel reinforced epoxy/aluminum interface. J. Adhes. 2006, 82, 487–516. [Google Scholar] [CrossRef]

- Varma, P.C.R.; Colreavy, J.; Cassidy, J.; Oubaha, M.; Duffy, B.; McDonagh, C. Effect of organic chelates on the performance of hybrid sol-gel coated AA 2024-T3 aluminium alloys. Prog. Org. Coat. 2009, 66, 406–411. [Google Scholar] [CrossRef] [Green Version]

- Ardila-Rodríguez, L.A.; Boshuizen, B.; Rans, C.; Poulis, J.A. The influence of grit blasting and UV/Ozone treatments on Ti-Ti adhesive bonds and their durability after sol-gel and primer application. Int. J. Adhes. Adhes. 2021, 104, 102750. [Google Scholar] [CrossRef]

- Williams, T.; Yu, H.; Hicks, R. Atmospheric pressure plasma activation as a surface pre-treatment for the adhesive bonding of aluminum 2024. J. Adhes. Sci. Technol. 2014, 28, 653–674. [Google Scholar] [CrossRef]

- Williams, T.; Yu, H.; Yeh, P.; Yang, J.; Hicks, R. Atmospheric pressure plasma effects on the adhesive bonding properties of stainless steel and epoxy composites. J. Compos. Mater. 2014, 48, 219–233. [Google Scholar] [CrossRef]

- Mui, T.S.M.; Silva, L.L.G.; Prysiazhnyi, V.; Kostov, K.G. Surface modification of aluminium alloys by atmospheric pressure plasma treatments for enhancement of their adhesion properties. Surf. Coat. 2017, 312, 32–36. [Google Scholar] [CrossRef]

- Lin, Y.; Li, H.; Wang, Q.; Gong, Z.; Tao, J. Effect of plasma surface treatment of aluminum alloy sheet on the properties of Al/Gf/PP laminates. Appl. Surf. Sci. 2020, 507, 145062. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, W.J. Investigation on the effectiveness of silane-based field level surface treatments of aluminum substrates for on-aircraft bonded repairs. Int. J. Adhes. Adhes. 2019, 95, 102414. [Google Scholar] [CrossRef]

- Surowska, B.; Ostapiuk, M.; Jakubczak, P.; Droździel, M. The Durability of an Organic-Inorganic Sol-Gel Interlayer in Al-GFRP-CFRP Laminates in a Saline Environment. Materials 2019, 12, 2362. [Google Scholar] [CrossRef]

- Liu, J.; Chaudhury, M.K.; Berry, D.H.; Seebergh, J.E.; Osborne, J.H.; Blohowiak, K.Y. Fracture behavior of an epoxy/aluminum interface reinforced by sol-gel coatings. J. Adhes. Sci. Technol. 2006, 20, 277–305. [Google Scholar] [CrossRef]

- Cobb, T.Q.; Johnson, W.S.; Lowther, S.E.; St Clair, T.L. Optimization of surface treatment and adhesive selection for bond durability in Ti-15-3 laminates. J. Adhes. 1999, 71, 115–141. [Google Scholar] [CrossRef]

- May, M.; Wang, H.; Akid, R. Bond strength of hybrid sol-gel coatings with different additives. J. Coat. Technol. Res. 2013, 10, 407–413. [Google Scholar] [CrossRef]

- Jarkko Aakkula, J.; Saarela, O. Silane based field level surface treatment methods for aluminium, titanium and steel bonding. Int. J. Adhes. Adhes. 2014, 48, 268–279. [Google Scholar] [CrossRef]

- Critchlow, G.W.; Brewis, D.M. Review of surface pretreatments for titanium alloys. Int. J. Adhes. Adhes. 1995, 15, 161–172. [Google Scholar] [CrossRef]

- Ijaola, A.O.; Bamidele, E.A.; Akisin, C.J.; Bello, I.T.; Oyatobo, A.T.; Abdulkareem, A.; Farayibi, P.K.; Asmatulu, E. Wettability Transition for Laser Textured Surfaces: A Comprehensive Review. J. Build. Eng. 2020, 21, 100802. [Google Scholar] [CrossRef]

- Harris, A.F.; Beevers, A. The effects of grit–blasting on surface properties for adhesion. Int. J. Adhes. Adhes. 1999, 19, 445–452. [Google Scholar] [CrossRef]

- Wang, X.L.; Qu, Z.G.; Lai, T.; Ren, G.F.; Wang, W.K. Enhancing water transport performance of gas diffusion layers through coupling manipulation of pore structure and hydrophobicity. J. Power Sources 2022, 525, 231121. [Google Scholar] [CrossRef]

- Kinloch, A.J. Adhesion and Adhesives: Science and Technology; Springer: Berlin/Heidelberg, Germany, 1987. [Google Scholar]

- Kim, W.S.; Yun, I.H.; Lee, J.J.; Jung, H.T. Evaluation of mechanical interlock effect on adhesion strength of polymer-metal interfaces using micro-patterned surface topography. Int. J. Adhes. Adhes. 2010, 30, 408–441. [Google Scholar] [CrossRef]

- Boutar, Y.; Naimi, S.; Mezlini, S.; Sik Ali, M.B. Effect of surface treatment on the shear strength of aluminium adhesive single-lap joints for automotive applications. Int. J. Adhes. Adhes. 2016, 70, 74–80. [Google Scholar] [CrossRef]

- Safari, A.; Farahani, M.; Ghabezi, P. Experimental study on the influences of differentsurface treatment processes and adhesive type on the aluminum adhesive-bonded joint strength. Mech. Based Des. Struct. Mach. 2020, 19, 9530–9542. [Google Scholar] [CrossRef]

- Kwon, D.J.; Kim, J.H.; Kim, Y.J.; Kim, J.J.; Park, S.M.; Kwon, I.J.; Shin, P.S.; DeVries, L.K.; Park, J.M. Comparison of interfacial adhesion of hybrid materials of aluminum/carbon fiber reinforced epoxy composites with different surface roughness. Compos. Part B 2019, 170, 11–18. [Google Scholar] [CrossRef]

- Boutar, Y.; Naimi, S.; Mezlini, S.; Carbas, R.J.C.; da Silva, L.F.M.; Ben Sik Ali, M. Fatigue resistance of an aluminium one-component polyurethane adhesive joint for the automotive industry: Effect of surface rough-ness and adhesive thickness. Int. J. Adhes. Adhes 2018, 83, 143–152. [Google Scholar] [CrossRef]

- Wu, X.; Zhan, L.; Zhao, X.; Wang, X.; Chang, T. Effects of surface pre-treatment and adhesive quantity on interface characteristics of fiber metal laminates. Compos. Interfaces 2020, 27, 829–843. [Google Scholar] [CrossRef]

- Zheng, X.; Zhao, Z.; Chu, Z.; Yin, H.; Wang, W. Effect of surface treatment methods on the interfacial behavior of fiber metal laminate based on WE43 magnesium alloy. Int. J. Adhes. Adhes. 2021, 110, 102957. [Google Scholar] [CrossRef]

- Zhan, X.; Chen, J.; Cheng, G.; Peng, Q.; Chen, J.; Wei, Y. Study on effects of pre-treatment and surface roughness on tensile-shear strength of 2060 Al-Li alloy adhesive joints. J. Adhes. 2017, 93, 613–625. [Google Scholar] [CrossRef]

| Surface Treatment | Acronym | Parameters Description |

|---|---|---|

| Scotch-Brite abrasion | SC | The process was conducted manually using an abrasive Scotch-Brite disc pad 07447+ (3M, Saint Paul, MN, USA). The process was relayed on the moving Scotch-Brite pad from side-to-side and then changed the direction by 90 degrees until a cross coat was obtained. Then, the surface was precisely degreased with acetone using lint-free tissue. |

| Sandblasting | S/B | The sandblasting process was conducted with alumina (Al2O3) powder. The powder was 180 µm grits. Then, the surface was precisely degreased with acetone using lint-free tissue. |

| P2 etching | E | The process was carried out according to Russell and Garnis, the etchant contained concentrated sulphuric acid, ferric sulphate, and sufficient water. The aluminium surface was etched for 11 min at a temperature from 63 °C to 65 °C, then rinsed in a water tank and after that drained. |

| Phosphate-Fluoride process | PF | The process included degreasing, rinsing, as well as digestion with hydro-fluoric acid, nitric acid and sodium sulphate for 2–3 min at room temperature 24 °C. In addition, phosphate-fluoride treatment with sodium phosphate, potassium fluoride, and hydrofluoric acid was carried out for 1.5–2.5 min. The process temperature was 24 °C. |

| Chromic acid anodizing | CAA | The process included the following stages: alkaline degreasing, rinsing, and etching in a sulphochrome bath. Chromic acid anodizing was prepared using chromic acid anhydride CrO3. The process temperature was 38–42 °C, voltage: 20 V, time: 45 min. |

| Sulphuric acid anodizing | SAA | The process included etching with sodium hydroxide NaOH, rinsing, brightening with nitric acid HNO3, filling with potassium dichromate K2Cr3O7, or drying. The sulphuric acid anodizing was performed in sulphuric acid H2SO4, process temperature was 10–15 °C, voltage: 13–24 V, time: 24 min. |

| Plasma | K | The plasma process was conducted under the following conditions: power: 140 W, He flow: 30 L/min, O2 striking flow: 0.1 L/min. The plasma activation was per-formed using the Atomflo 500 plasma systems (Surfx Technologies). |

| Sol-gel coating | SG | The sol-gel coatings were produced using the 3M™ Surface Pre-Treatment AC 130-2 (3M™) two-component formulation. Two components were mixed and left on induction time of 30 min. Then, the mixture was applied to the surface using lint-free tissue, it was left to drain for 10 min and after that, the coated surface was left for drying at room temperature for 60 min. |

| Primer | P | The aluminium surface was coated with EC-3924B corrosion-inhibiting structural adhesive primer (3M™ Scotch-Weld™). The titanium surface was coated with EC-3960 (3M™ Scotch-Weld™). The process consists of applying a thin layer of a primer using the spray method. |

| Surface Treatment | Roughness Parameters [µm] | |||||

|---|---|---|---|---|---|---|

| Ra | Rq | Rt | Rz | Rv | Rp | |

| Sandblasting | 0.78 (±0.09) | 0.98 (±0.10) | 4.97 (±0.16) | 4.96 (±0.16) | 2.26 (±0.44) | 2.70 (±0.28) |

| Sulphuric acid anodizing | 0.39 (±0.03) | 0.51 (±0.06) | 3.01 (±0.69) | 2.83 (±0.44) | 1.89 (±0.37) | 0.95 (±0.06) |

| Aluminium degreased | 0.21 (±0.00) | 0.24 (±0.01) | 1.11 (±0.21) | 1.08 (±0.19) | 0.63 (±0.12) | 0.46 (±0.07) |

| Chromic acid anodizing | 0.19 (±0.01) | 0.24 (±0.01) | 1.43 (±0.06) | 1.43 (±0.06) | 0.86 (±0.11) | 0.57 (±0.17) |

| Scotch-Brite abrasion | 0.19 (±0.00) | 0.23 (±0.01) | 1.22 (±0.12) | 1.20 (±0.09) | 0.67 (±0.09) | 0.52 (±0.00) |

| Plasma | 0.17 (±0.01) | 0.31 (±0.00) | 2.84 (±0.23) | 2.69 (±0.03) | 1.48 (±1.13) | 1.21 (±1.17) |

| P2 etching | 0.07 (±0.04) | 0.13 (±0.10) | 1.45 (±0.71) | 1.32 (±0.89) | 1.63 (±0.11) | 0.19 (±0.06) |

| Surface Treatment | Roughness Parameters [µm] | |||||

|---|---|---|---|---|---|---|

| Ra | Rq | Rt | Rz | Rv | Rp | |

| Sandblasting | 1.14 (±0.18) | 1.45 (±0.18) | 7.54 (±0.55) | 3.31 (±1.06) | 4.23 (±0.52) | 7.54 (±0.55) |

| Phosphate–fluoride process | 0.98 (±0.08) | 1.24 (±0.08) | 6.44 (±0.51) | 3.27 (±0.66) | 3.16 (±0.58) | 6.43 (±0.52) |

| Plasma | 0.38 (±0.04) | 0.54 (±0.06) | 3.53 (±0.28) | 0.95 (±0.01) | 2.58 (±0.29) | 3.53 (±0.28) |

| Titanium degreased | 0.32 (±0.01) | 0.43 (±0.04) | 2.99 (±0.16) | 1.02 (±0.11) | 1.71 (±0.53) | 2.73 (±0.42) |

| Scotch-Brite abrasion | 0.28 (±0.03) | 0.38 (±0.07) | 2.24 (±0.69) | 0.60 (±0.02) | 1.64 (±0.66) | 2.24 (±0.69) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Droździel-Jurkiewicz, M.; Bieniaś, J. Evaluation of Surface Treatment for Enhancing Adhesion at the Metal–Composite Interface in Fibre Metal-Laminates. Materials 2022, 15, 6118. https://doi.org/10.3390/ma15176118

Droździel-Jurkiewicz M, Bieniaś J. Evaluation of Surface Treatment for Enhancing Adhesion at the Metal–Composite Interface in Fibre Metal-Laminates. Materials. 2022; 15(17):6118. https://doi.org/10.3390/ma15176118

Chicago/Turabian StyleDroździel-Jurkiewicz, Magda, and Jarosław Bieniaś. 2022. "Evaluation of Surface Treatment for Enhancing Adhesion at the Metal–Composite Interface in Fibre Metal-Laminates" Materials 15, no. 17: 6118. https://doi.org/10.3390/ma15176118