Source of Raw Materials and Its Processing for the Manufacturing of Ptolemaic Faience Bowls from Tell Atrib (Nile Delta, Egypt)

Abstract

:1. Introduction

2. Materials and Methods

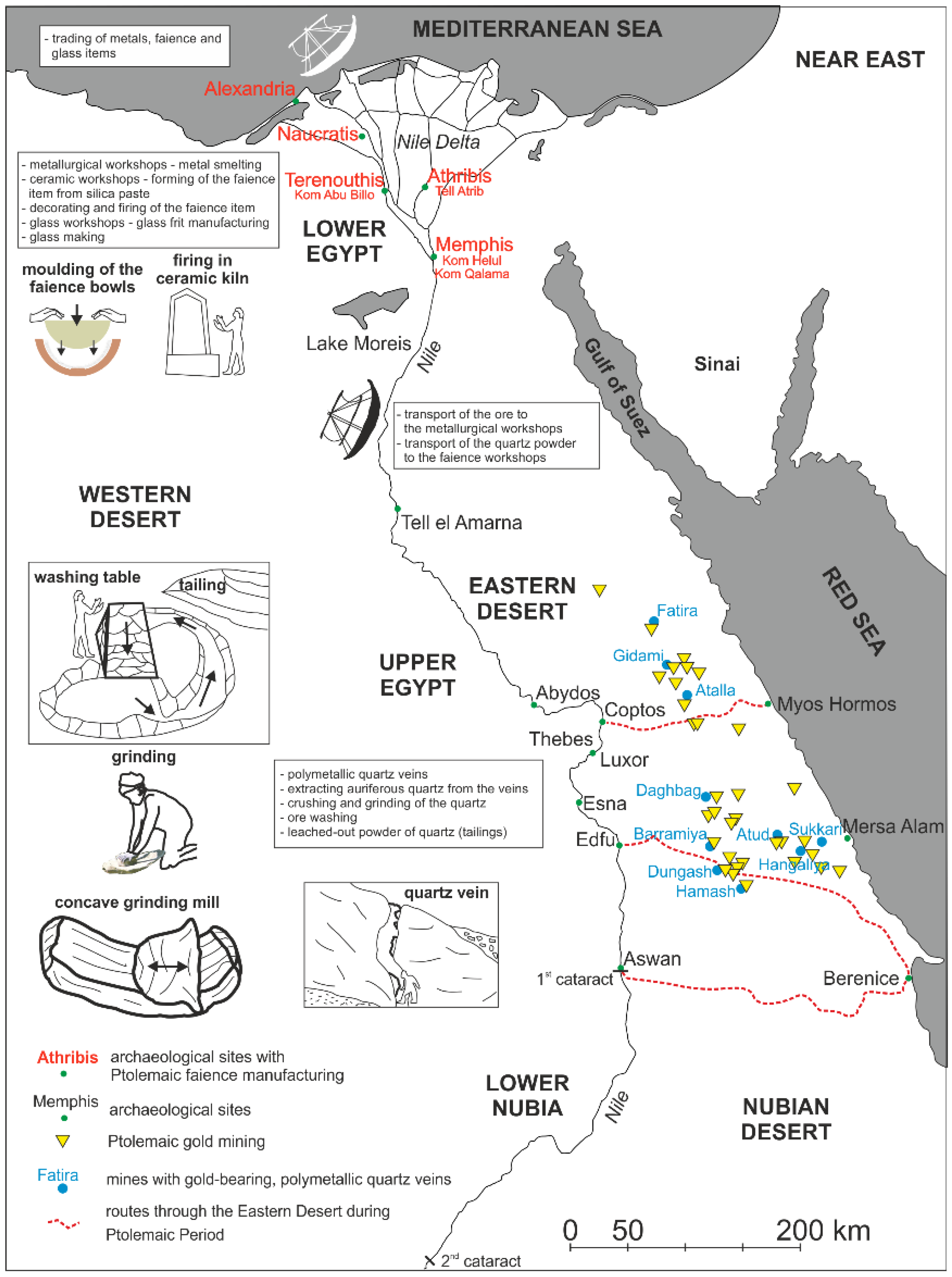

2.1. Archaeological Site

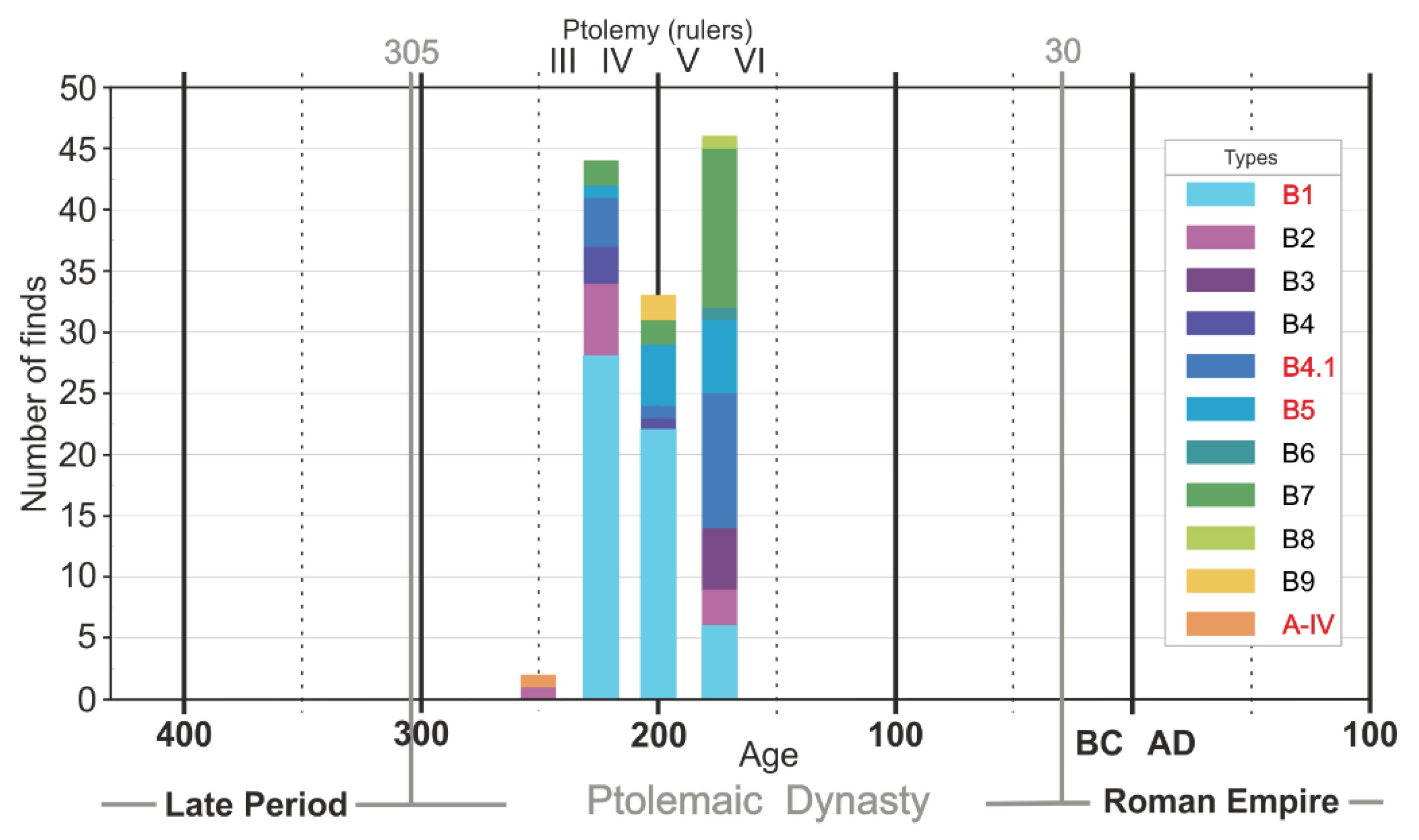

- (a)

- From the beginning of the Ptolemaic Period (sometimes also the end of the Late Period) until the first decades of the 2nd century BC,

- (b)

- The reign of Ptolemy VI and the second half of the 2nd century BC,

- (c)

- The end of the Ptolemaic Period (1st century BC) until the beginning of the Roman period (1st century BC).

2.2. Faience Objects

2.3. Preparation of Thin Sections

2.4. Digital and Polarized Light Microscopy

2.5. X-ray Powder Diffraction (XRD)

2.6. Scanning Electron Microscopy (SEM) with Energy Dispersive Spectroscopy (EDS)

2.7. Petrographic-Mineralogical Analysis

2.8. Image and Statistical Analysis

3. Results

3.1. X-ray Powder Diffraction (XRD) Analysis of the Body Layer

3.2. Petrographic-Mineralogical Analysis of the Grains

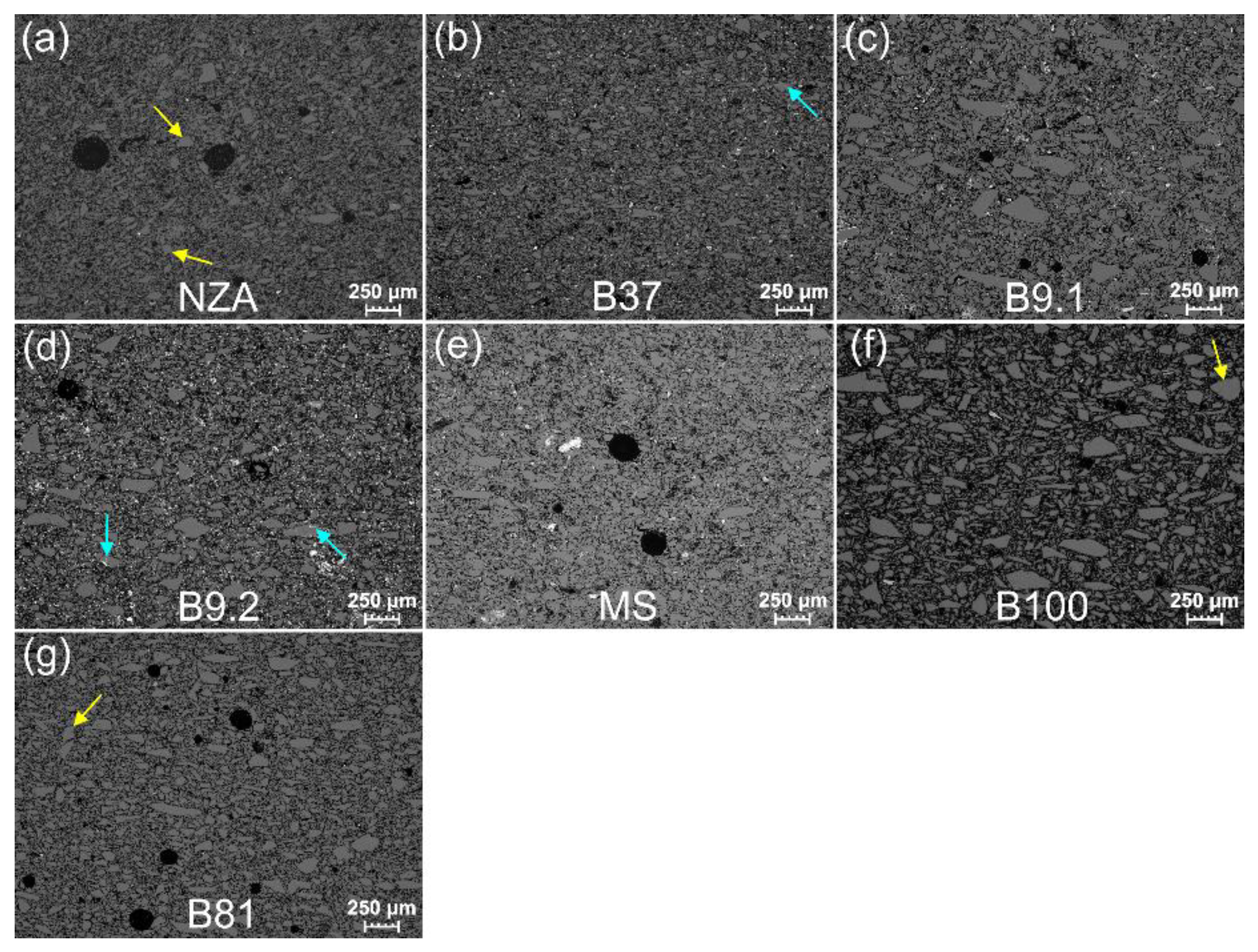

3.2.1. Quartz Grains in the Body Layer

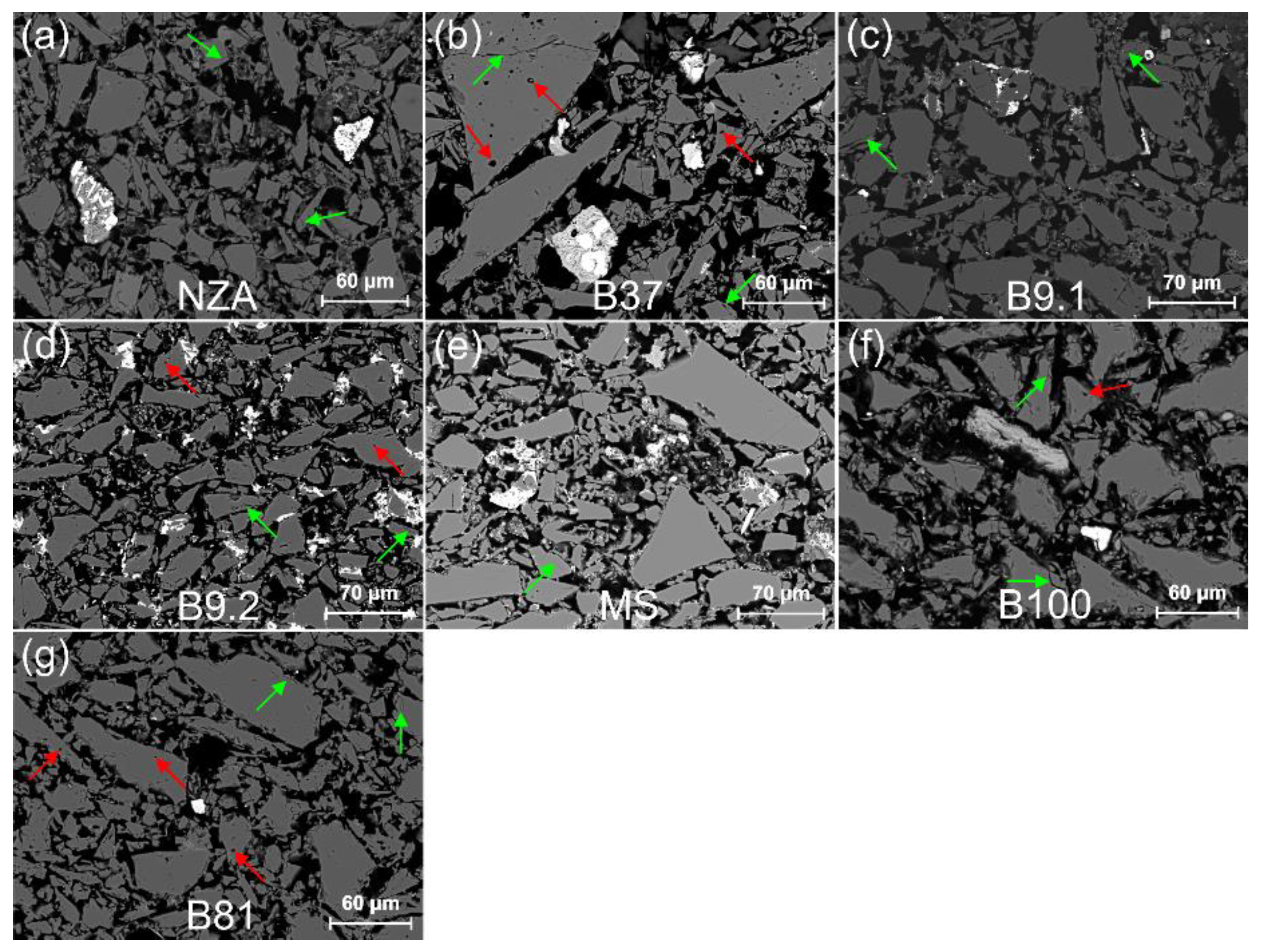

3.2.2. Accessory Grains

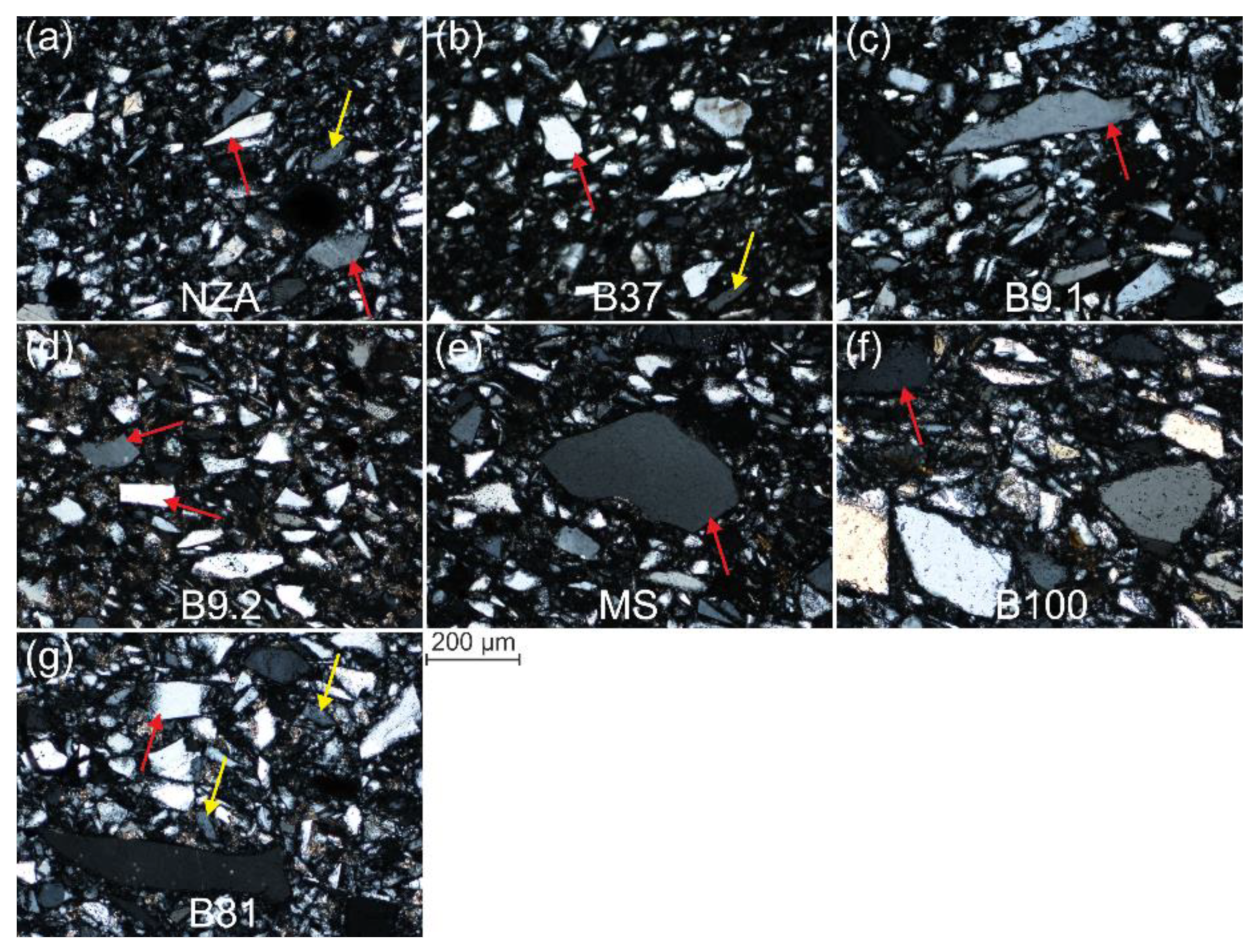

- category A—grains of accessory minerals with an unchanged texture (Figure 4). These are homogenous grains, with a structure and texture unchanged in course of firing at high temperatures. The only indication of these processes is the presence of a thin reaction zone at the boundary with grains having a different mineral composition (Figure 4c,f). The created zone plays the role of cement, a mass binding the mineral grains. The category includes grains of zircon, rutile, garnet, ilmenite, titanite, monazite, apatite, olivine, magnetite, and Na-, K- and Na-Ca-feldspars (Tables S1 and S2);

- category B—grains of rock-forming minerals, often with a partly changed texture (Figure S3). The category includes grains that contain even very small relicts of the primary mineral or those grains, in which its composition can be reconstructed based on the reaction products present. These are grains or rock-forming minerals with initial stages of melting or with large fragments of the mineral without a visible structural and textural reorganization. The transformation zone depends on the chemical composition of the mineral composing the grain and the surrounding grains/substances which have reacted with it during the firing process. The reaction area forms a coating, several to over 10 µm thick or extends within the grain along structural fractures but does not change its shape. This category includes minerals from the feldspar group with the composition of albite, sodium plagioclase, potassium feldspar, as well as biotite, epidote and amphibole (Tables S1 and S2);

- category C—grains of sulphides and oxides with an unchanged texture (Figure S4). The grains do not bear signs of structural-textural transformation on their surface or in their interior. Initial reactions with the surrounding grains (Figure S4f), colour change (changes of grey shade in BSE images), or melts on the mineral surface partly visible in the glass phase (Figure S4c) can be observed only in some grains. Some transformations are linked with the resistance of structural bonds of these minerals to high firing temperatures and the resulting high melting points. The category includes: ilmenite, cassiterite and sphalerite (Tables S1 and S2);

- category D—grains of sulphides with a partly changed texture (Figure S5). These are sulphide grains or aggregates of sulphide grains with a medium and strongly changed structure and texture, characterised by the presence of a reactive halo around the primary core of the mineral grain (Figure S5a). This zone extents for a few micrometres, which results from the impact of high firing temperatures on minerals with equally high melting points. Such textures appear around the grains of Co-Cu-Sn ore minerals (Tables S1 and S2);

- category E—grains of sulphides with a changed texture (Figure S5). These are single grains or their aggregates, which have been subject to almost complete structural and textural transformation. Oval metal oxide grains occur in the cover of a secondary silica melt (Figure S5b). The transformation includes partial or complete melting of sulphides and the appearance of drop-like accumulations of Cu, Ni and Co oxides (Tables S1 and S2);

- category F—grains of metal ores with a changed texture (Figure S6). These are ore grains with silicates or aluminosilicates, in which the primary structures and textures of mineral grains have not been preserved (Figure S6a,b) or are fragmentarily preserved (Figure S6c,d). Examples of such grains are the products of the reaction between galena and silicates and the resulting Pb silicates (Figure S6a,f) or secondary minerals belonging to Pb vanadates (Figure S6a,b, Tables S1 and S2);

- category G—lithoclast grains (Figure S7). The group includes large fragments of polymineral grains with dimensions up to 300 µm. These grains have well-preserved textures allowing for distinguishing the source rock lithology. Rock fragments with a characteristic interstitial texture are common (Figure S7a,c). Moreover, lithoclasts composed of sulphide minerals characterised by a variable grain size are quite common (Figure S7a,d). A continuous succession of sulphide grains from large lithoclasts with dimensions exceeding 300 µm to single sulphide grains with dimensions up to just over 10 µm can be observed in the analysed material. Sulphide lithoclasts are characterised by a strong degree of thermal transformations resulting from firing. An almost unchanged primary texture of the sulphide aggregates can be seen in only some larger grains (Figure S7d, Tables S1 and S2).

3.2.3. Relationships of the Accessory Grains

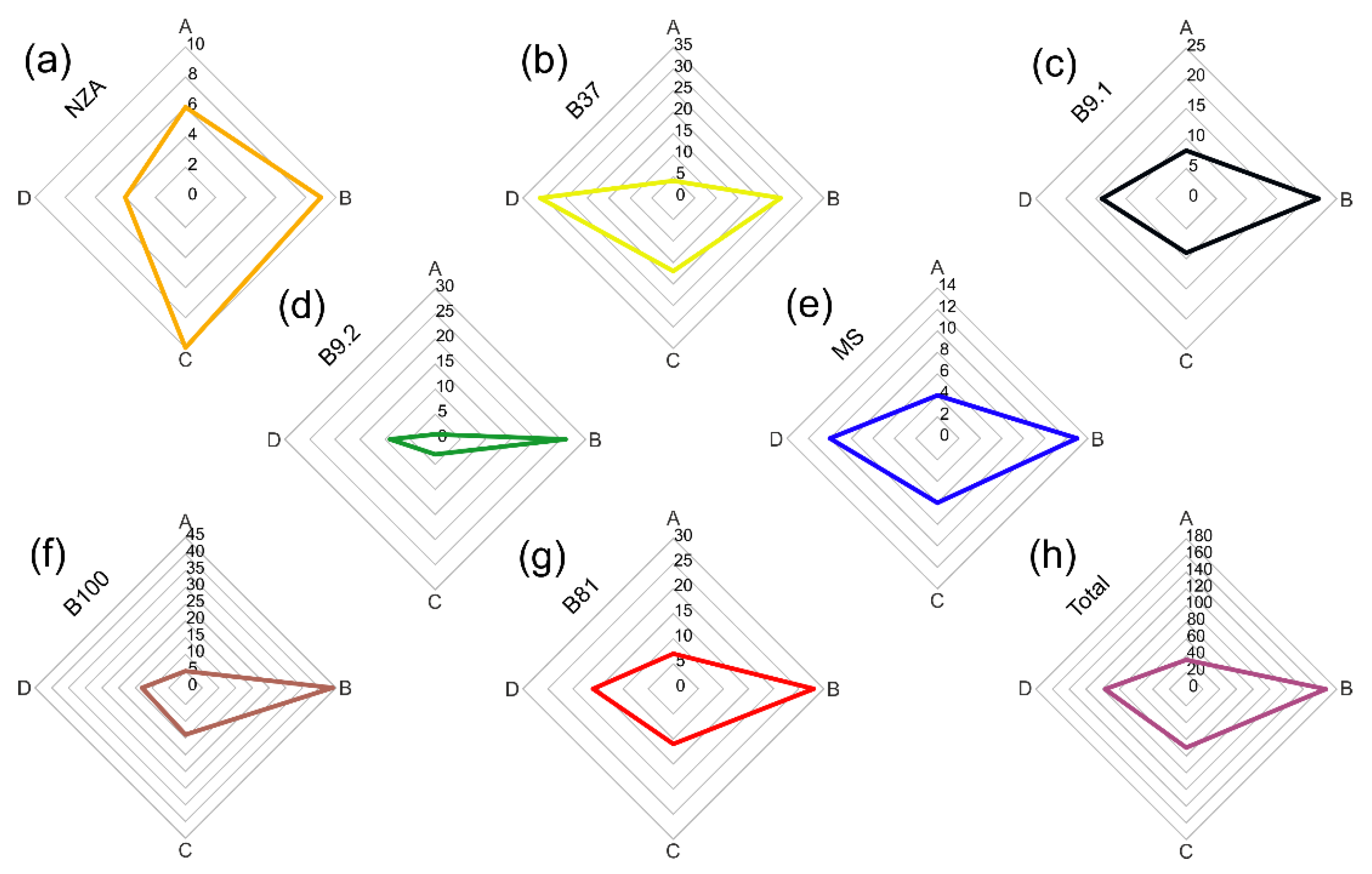

- group A—common accessory minerals represented by zircon, apatite and monazite;

- group B—common rock-forming minerals (amphibole, feldspars, epidote, titanite, garnet, olivine, biotite, pyroxene and Al2SiO5 polymorphs;

- group C—common Fe-Ti oxides: magnetite, hematite, ilmenite, and TiO2 group minerals;

- group D—sulphides representing ore minerals.

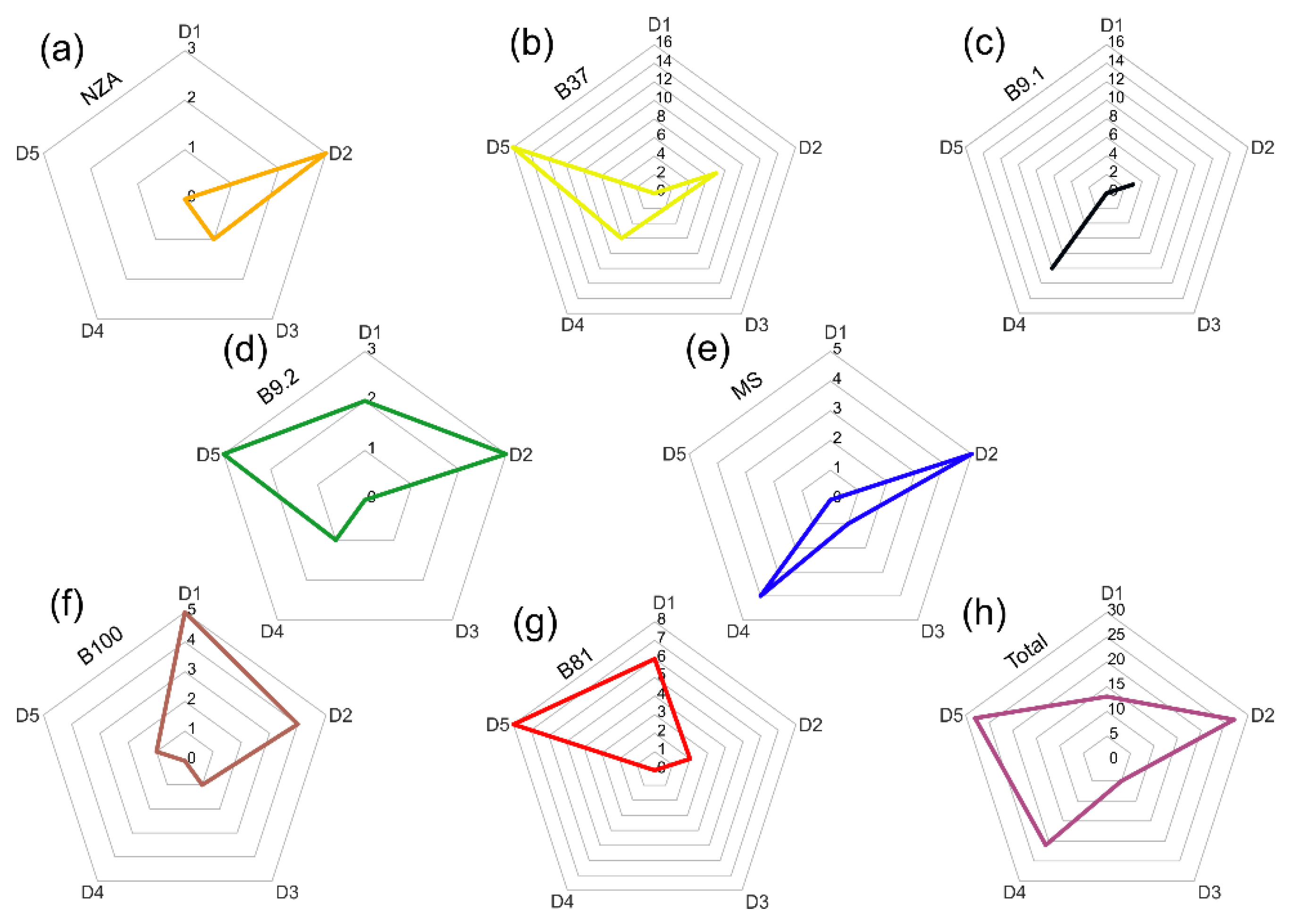

- subgroup D1—cassiterite intergrowths with ores and polymetallic Sn-Co-Cu sulphides, in which the Sn content in the products of sulphide reaction exceeds 0.5 wt.%;

- subgroup D2—polymetallic Co-Cu-Ni sulphides, in which the Sn content in the products of sulphide reaction does not exceed 0.5 wt.%;

- subgroup D3—polymetallic Cu-dominated sulphides, sometimes with a trace amount of Bi;

- subgroup D4—polymetallic Pb-Sb-As-Cu sulphides and sulfosalts;

- subgroup D5—galena, sphalerite and polymetallic Zn-Pb-dominant sulphides.

3.2.4. Interpretation

3.3. Morphometric and Geometric Analysis of the Quartz Grains

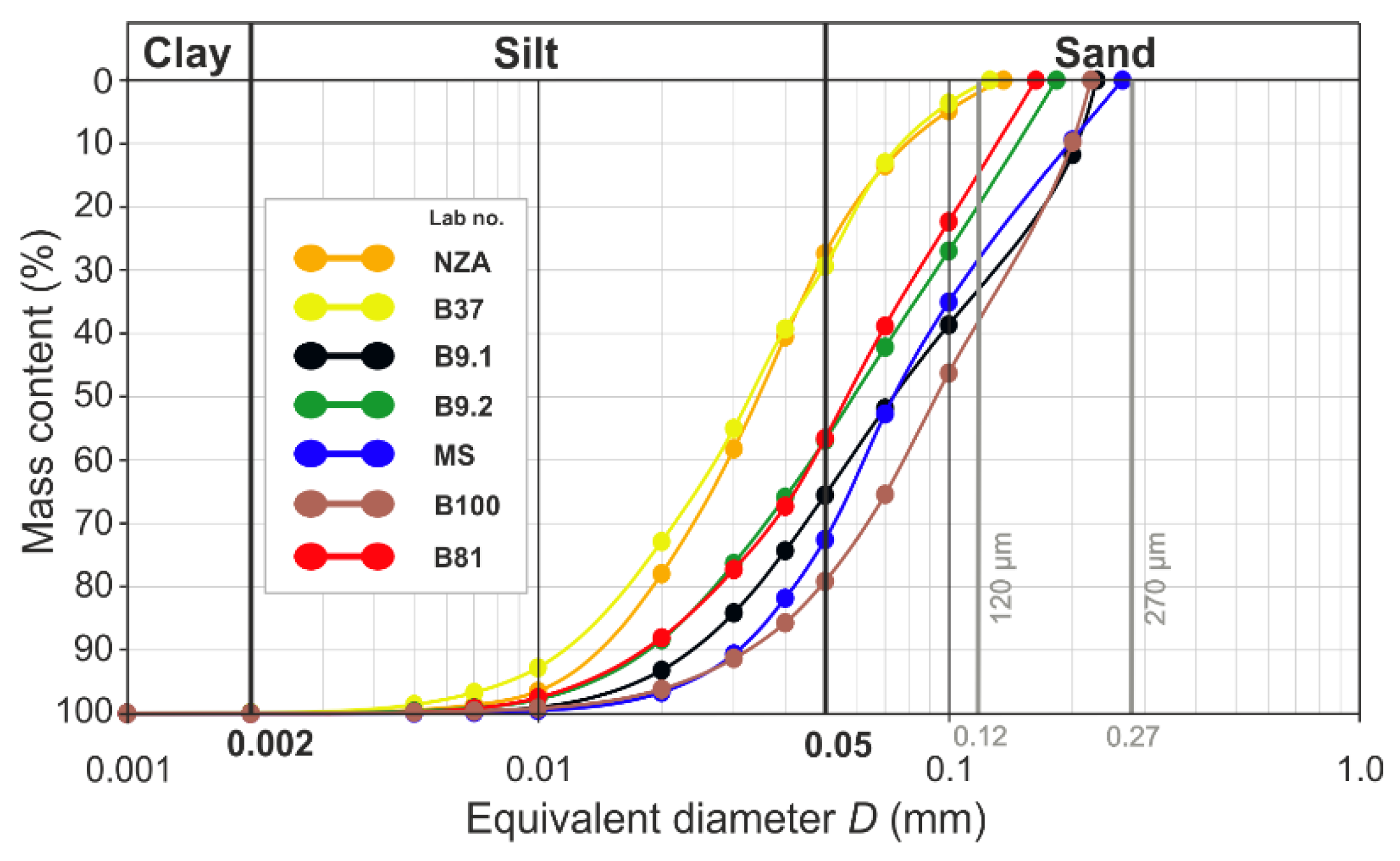

3.3.1. Grain Size Composition

3.3.2. Grain Shape Composition

3.3.3. Roundness and Sharpness

3.3.4. Cracks and Cavities

3.3.5. Microstructural and Microtextural Evidences of Quartz Grain Processing

- Grain size

- Grain shape

- Relationships of morphometric parameters

4. Discussion

4.1. Transformation of Minerals Resulting from the Firing Temperature

4.2. Origin of the Quartz

4.3. Mining and Processing of Raw Material from Quartz Veins of the Eastern Desert

4.4. From Gold Mining in the Eastern Desert to Faience Manufacturing in Tell Atrib

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nicholson, P.T. Egyptian Faience and Glass; Shire Publications Ltd.: Buckinghamshire, UK, 1993. [Google Scholar]

- Petrie, W.M.F. Tell el Amarna, 1st ed.; Methuen and Co.: London, UK, 1894; pp. 25–31. [Google Scholar]

- Petrie, W.M.F. The Arts and Crafts of Ancient Egypt, 2nd ed.; T. N. Foulis: London, UK; Edinburgh, UK, 1910; pp. 107–125. [Google Scholar]

- Friedman, F.D. Gifts of the Nile, 1st ed.; Thames & Hudson: London, UK, 1998. [Google Scholar]

- Lucas, A. Glazed Ware in Egypt, India, and Mesopotamia. JEA 1936, 22, 141–164. [Google Scholar]

- Vandiver, P. Technological change in Egyptian faience. In Archaeological Ceramics, 1st ed.; Franklin, A.D., Olin, J.S., Eds.; Smithsonian Institution Press: Washington, DC, USA, 1982; pp. 167–179. [Google Scholar]

- Vandiver, P.; Kingery, W.D. Egyptian faience: The first high-tech ceramic. In Ceramics and Civilisation; Kingery, W.D., Ed.; American Ceramic Society: Columbus, OH, USA, 1987; Volume 3, pp. 19–34. [Google Scholar]

- Sode, T.; Schnell, U. Contemporary faience makers in Qourna, Egypt. In Glass, Ceramics and Related Materials; Paterakis, A.B., Ed.; EVTEK Institute of Arts and Design: Vantaa, Finland, 1998; pp. 164–166. [Google Scholar]

- Nenna, M.D.; Seif el Din, M. Die ägyptischen Fayencewerkstätten in hellenistisch-römischer Zeit. In Türkis und Azur; Busz, R., Gercke, P., Eds.; Edition Minerva: Wolfratshausen, Germany, 1999; pp. 76–83. [Google Scholar]

- Nenna, M.D.; Seif el Din, M. La Vaisselle en Faïence D’époque Gréco-Romaine: Catalogue du Musée Grécoromain d'Alexandrie; IFAO: Cairo, Egypt, 2000. [Google Scholar]

- Mao, Y. Lead-alkaline glazed Egyptian faience: Preliminary technical investigation of Ptolemaic period faience vessels in the collection of the Walters Art Gallery. JAIC 2000, 39, 185–204. [Google Scholar] [CrossRef]

- Shortland, A.J.; Tite, M.S. Technological study of Ptolemaic-early Roman faience from Memphis, Egypt. Archaeometry 2005, 47, 31–46. [Google Scholar] [CrossRef]

- Tite, M.S.; Panagiota, M.; Shortland, A.J. A technological study of ancient faience from Egypt. J. Archaeol. Sci. 2007, 34, 1568–1583. [Google Scholar] [CrossRef]

- Nicholson, P.T. Brilliant Things for Akhenaten: The Production of Glass, Vitreous Materials and Pottery at Amarna Site O45.1; Egypt Exploration Society: London, UK, 2007. [Google Scholar]

- Nicholson, P.T. Working in Memphis: The Production of Faience at Roman Period Kom Helul; Egypt Exploration Society: London, UK, 2013; ISBN 978-0-85698-210-1. [Google Scholar]

- Welc, F. Decorated Ptolemaic faience bowl from Athribis (Tell Atrib), Nile Delta. EtTrav 2011, 24, 243–270. [Google Scholar]

- Welc, F. Tell Atrib 1985–1995 IV; Polish Centre of Mediterranean Archaeology, University of Warsaw: Warszawa, Poland, 2014. [Google Scholar]

- Zaremba, M.; Trzciński, J.; Rogulska, M.; Kaproń, G.; Welc, F.; Południkiewicz, A. A Multiproxy Approach to the Reconstruction of an Ancient Manufacturing Technology: A Case Study of a Faience Ptolemaic Bowl from Tell Atrib (Nile Delta). Minerals 2020, 10, 785. [Google Scholar] [CrossRef]

- Vernus, P. Athribis. In Lexikon der Ägyptischen; Otto, E., Westendorf, W., Helck, W., Eds.; Otto Harrassowitz: Wiesbaden, Germany, 1975; pp. 519–524. [Google Scholar]

- Michałowski, K. Wykopaliska archeologiczne Muzeum Narodowego w Warszawie. In Rocznik Muzeum Narodowego w Warszawie; Lorentz, S., Michałowski, K., Eds.; Państwowe Wydawnictwo Naukowe: Warsaw, Poland, 1958; pp. 7–51. [Google Scholar]

- Michałowski, K. Les Fouilles Polonaises À Tell Atrib (1957–1959). ASAE 1962, 57, 49–65. [Google Scholar]

- Michałowski, K. Fouilles Polonaises À Tell Atrib (1960). ASAE 1962, 57, 67–78. [Google Scholar]

- Michałowski, K. Les fouilles Polonaises À Tell Atrib (1961) (avec 12 planches). ASAE 1964, 58, 235–244. [Google Scholar]

- Michałowski, K. Sixième Campagne De Fouilles À Tell-Atrib (Saison 1962). ASAE 1964, 58, 245–254. [Google Scholar]

- Kołodziejczyk, K. Report of the Polish archaeological mission’s excavations at Tell Atrib in 1963. EtTrav 1972, 6, 137–145. [Google Scholar]

- Ruszczyc, B. Wykopaliska polsko-koptyjskie na Komie Sidi Youssuf w Tell Atrib. In Rocznik Muzeum Narodowego w Warszawie; Bursze, J., Ed.; Państwowe Wydawnictwo Naukowe: Warsaw, Poland, 1986; Volume 30, pp. 7–51. [Google Scholar]

- Ruszczyc, B. Wykopaliska w Tell Atrib w Roku 1984. In Rocznik Muzeum Narodowego w Warszawie; Sołtysiak, M., Ed.; Państwowe Wydawnictwo Naukowe: Warsaw, Poland, 1989–1990; Volume 33–34, pp. 673–676. [Google Scholar]

- Myśliwiec, K. Rescue Excavations at Tell Atrib in 1985–1995. In Tell Atrib 1985–1995 I; Myśliwiec, K., Sztetyłło, Z., Eds.; ZAŚ PAN & Neriton: Warsaw, Poland, 2000; pp. 9–52. [Google Scholar]

- Myśliwiec, K. In the Ptolemaic Workshops of Athribis. EA 1996, 9, 34–36. [Google Scholar]

- Myśliwiec, K.; Abu Senna, S. Polish–Egyptian excavations at Tell Atrib in 1991–1993. EtTrav 1995, 17, 205–239. [Google Scholar]

- Myśliwiec, K. Polish-Egyptian excavations at Tell Atrib in 1991. In Polish Archaeology in the Mediterranean Volume III: Reports 1991; Gawlikowski, M., Daszewski, W.A., Eds.; Polish Centre of Mediterranean Archaeology: Warsaw, Poland, 1992; Volume 3, pp. 24–28. [Google Scholar]

- Sztetyłło, Z. Pottery stamps. In Tell Atrib 1985–1995 I; Myśliwiec, K., Sztetyłło, Z., Eds.; ZAŚ PAN & Neriton: Warsaw, Poland, 2000; pp. 53–204. [Google Scholar]

- Krzyżanowska, A. Les monnaies. In Tell Atrib 1985–1995 II; Myśliwiec, K., Krzyżanowska, A., Eds.; ZAŚ PAN & Neriton: Warsaw, Poland, 2009; pp. 75–210. [Google Scholar]

- Trzciński, J. Combined SEM and computerized image analysis of clay soils microstructure: Technique & application. In Advances in Geotechnical Engineering: The Skempton Conference, Proceedings of the Three Day Conference on Advances in Geotechnical Engineering, Royal Geographical Society, London, UK, 29–31 March 2004; Jardine, R.J., Potts, D.M., Higgins, K.G., Eds.; Thomas Telford: London, UK, 2004; pp. 654–666. [Google Scholar]

- Cau Ontiveros, M.A.; Day, P.M.; Montana, G. Secondary calcite in archaeological ceramics: Evaluation of alteration and contamination processes by thin section study. In Modern Trends in Ancient Ceramics; Kilikoglou, V., Hein, A., Maniatis, Y., Eds.; British Archaeological Reports: Oxford, UK, 2002; pp. 9–18. [Google Scholar]

- Ramdohr, P. The Ore Minerals and Their Intergrowths, 2nd ed.; Pergamon Press: Oxford, UK, 1980. [Google Scholar]

- Pracejus, B. The Ore Minerals under the Microscope. An Optical Guide, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Shen, Y.J.; Zhang, Y.L.; Gao, F.; Yang, G.S.; Lai, X.P. Influence of Temperature on the Microstructure Deterioration of Sandstone. Energies 2018, 11, 1753. [Google Scholar] [CrossRef]

- Myśliwiec, K. (Institute of Mediterranean and Oriental Cultures, Polish Academy of Sciences, Warsaw, Poland). Tell Atrib. register of finds 1985. 1985. Unpublished work. [Google Scholar]

- Myśliwiec, K. (Institute of Mediterranean and Oriental Cultures, Polish Academy of Sciences, Warsaw, Poland). Personal communication. 2022. [Google Scholar]

- Ulusoy, U.; Yekeler, M.; Hiçyılmaz, C. Determination of the Shape, Morphological and Wettability Properties of Quartz and Their Correlations. Miner. Eng. 2003, 16, 951–964. [Google Scholar] [CrossRef]

- Durney, T.E.; Meloy, T.P. Particle shape effects due to crushing method and size. Int. J. Miner. Process 1986, 16, 109–123. [Google Scholar] [CrossRef]

- Ahmed, M. Effect of comminution on particle shape and surface roughness and their relation to flotation process. Int. J. Miner. Process 2010, 94, 180–191. [Google Scholar] [CrossRef]

- Nesse, T. Selective attachment processes in ancient gold ore beneficiation. Miner. Eng. 2014, 58, 52–63. [Google Scholar] [CrossRef]

- Dehghani, F.; Rezaie, B.; Sachan, A.; Ghosh, T. Effects of grinding on Particle Shape: Silica and Magnetite. In Proceedings of the SME Annual Conference & Expo and CMA 121st National Western Mining Conference: Smart Mining: Resources for a Connected World, Denver, CO, USA, 24–27 February 2019; pp. 438–441. [Google Scholar]

- Anthony, J.W.; Bideaux, R.A.; Bladh, K.A.; Monte, N.C. Handbook of Mineralogy. Silica, Silicates; Mineral Data Publishing: Tucson, AZ, USA, 2003; Volume 2, p. 165. [Google Scholar]

- Sohngen, P. Cristobalite: The Hump New Data on Silica at Cone Ten. Studio Pottery 1999, 28, 84–89. [Google Scholar]

- Kiefer, C.H.; Allibert, A. Pharaonic Blue Ceramics: The Process of Self-Glazing. Archaeology 1971, 24, 107–117. [Google Scholar]

- Gliozzo, E. Ceramic technology. How to reconstruct the firing process. Archaeol. Anthropol. Sci. 2020, 12, 260. [Google Scholar] [CrossRef]

- Botros, N.S. A new classification of the gold deposits of Egypt. Ore Geol. Rev. 2004, 25, 1–37. [Google Scholar] [CrossRef]

- Abd El Monsef, M. Ore Controls and Metallogenesis of Au-Ag Deposits at Atalla Mine, Central Eastern Desert of Egypt. Acta Geol. Sin. 2020, 94, 1451–1470. [Google Scholar] [CrossRef]

- Fawzy, K.M. Ore Mineralogical and Geochemical Studies on El-Daghbag-I Gold Deposit, Central Eastern Desert, Egypt. Open J. Geol. 2017, 7, 395–419. [Google Scholar] [CrossRef]

- Raslan, M.F.; Ali, M.A. Mineral chemistry of polymetallic mineralization associated with altered granite, Hangaliya area, South Eastern Desert, Egypt. Geologija 2010, 53, 129–138. [Google Scholar] [CrossRef]

- Zoheir, B.; Lehman, B. Listvenite–lode association at the Barramiya gold mine, Eastern Desert, Egypt. Ore Geol. Rev. 2010, 39, 101–115. [Google Scholar] [CrossRef]

- Štemprok, M. Greisenization (a review). Geol. Rundsch. 1987, 76, 169–175. [Google Scholar] [CrossRef]

- Abd El Monsef, M.; Slobodník, M.; Salem, I.A. Characteristics and nature of gold-bearing fluids in Fatira area, North Eastern Desert of Egypt: Possible transition from intrusion-related to orogenic deposits. Arab. J. Geosci. 2020, 13, 1034. [Google Scholar] [CrossRef]

- Zoheir, B.; Deshesh, F.; Broman, C.; Pitcairn, I.; El-Metwally, A.; Mashaal, S. Granitoid-associated gold mineralization in Egypt: A case study from the Atalla mine. Miner. Depos. 2017, 53, 701–720. [Google Scholar] [CrossRef]

- Klemm, D.; Klemm, R.; Murr, A. Gold of the Pharaohs—6000 years of gold mining in Egypt and Nubia. J. Afr. Earth Sci. 2001, 33, 643–659. [Google Scholar] [CrossRef]

- Abd El-Rahman, Y.; Surour, A.A.; El Manawi, A.H.W.; Rifai, M.; Abdel Motelib, A.; Ali, W.K.; El Dougdoug, A.M. Ancient mining and smelting activities in the Wadi Abu Gerida Area, Central Eastern Desert, Egypt: Preliminary results. Archaeometry 2013, 55, 1067–1087. [Google Scholar] [CrossRef]

- Roubet, C. The grinding stones of site E-78-3 Wadi Kubbaniye. In The Prehistory of Wadi Kubbaniye; Wendorf, F., Ed.; Southern Methodist University Press: Dallas, TX, USA, 1989; Volume 3, pp. 473–489. [Google Scholar]

- Redon, B.; Faucher, T. Samut North: ‘heavy mineral processing plants’ are mills! EA 2016, 48, 20–22. [Google Scholar]

- Oldfather, C.H. Diodorus of Sicily: In Ten Volumes, II, Books II.35–IV.58; Harvard University Press: Cambridge, UK, 1935. [Google Scholar]

- Klemm, R.; Klemm, D. Gold and Gold Mining in Ancient Egypt and Nubia; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Faucher, T. Ptolemaic Gold: The Exploitation of Gold in the Eastern Desert. In The Eastern Desert of Egypt during the Greco-Roman Period: Archaeological Reports; Brun, J.-P., Faucher, T., Redon, B., Sidebotham, S., Eds.; Collège de France: Paris, France, 2018; pp. 1–16. [Google Scholar] [CrossRef]

- Sidebotham, S.E. Berenike and the Ancient Maritime Spice Route; University of California Press: Berkeley, CA, USA, 2011. [Google Scholar]

- Fleming, S.J. Roman Glass; Reflections on Cultural Change; University of Pennsylvania Museum of Archaeology and Anthropology: Philadelphia, PA, USA, 1999. [Google Scholar]

- Barfod, G.H.; Freestone, I.C.; Lesher, C.E.; Lichtenberger, A.; Raja, R. ‘Alexandrian’ glass confirmed by hafnium isotopes. Sci. Rep. 2020, 10, 11322. [Google Scholar] [CrossRef]

- Lewis, P.R.; Jones, G.D.B. The Dolaucothi gold mines, I: The surface evidence. Antiq. J. 1969, 49, 244–272. [Google Scholar] [CrossRef]

- Lewis, P.R.; Jones, G.D.B. Roman gold-mining in north-west Spain. J. Rom. Stud. 1970, 60, 169–185. [Google Scholar] [CrossRef]

- Allan, G.C.; Woodcock, J.T. A review of the flotation of gold and electron. Miner. Eng. 2001, 14, 931–962. [Google Scholar] [CrossRef]

- Abu-Alam, T.; Abd El Monsef, M.; Grosch, E. Shear-zone hosted gold mineralization of the Arabian–Nubian Shield: Devolatilization processes across the greenschist–amphibolite-facies transition. Geol. Soc. Spec. Publ. 2018, 478, 287–313. [Google Scholar] [CrossRef]

- Murr, A. Die Genese der Goldlagerstättenbezirke Fatira, Gidami Atalla und Hangaliya in der Ägyptischen Ostwüste; Münchner Geol. Hefte A27; Literaturhökerei Wiese: Hardegsen, Deutschland, 1999; Volume 202. [Google Scholar]

- Ogden, J.M. The So-Called ‘Platinum’ Inclusions in Egyptian Goldwork. J. Egypt Archaeol. 1976, 62, 138–144. [Google Scholar]

- Helmy, H.M.; Kaindl, R.; Fritz, H. Loizenbauer, J. The Sukari Gold Mine, Eastern Desert—Egypt: Structural setting, mineralogy and fluid inclusion study. Miner. Depos. 2004, 39, 495–511. [Google Scholar] [CrossRef]

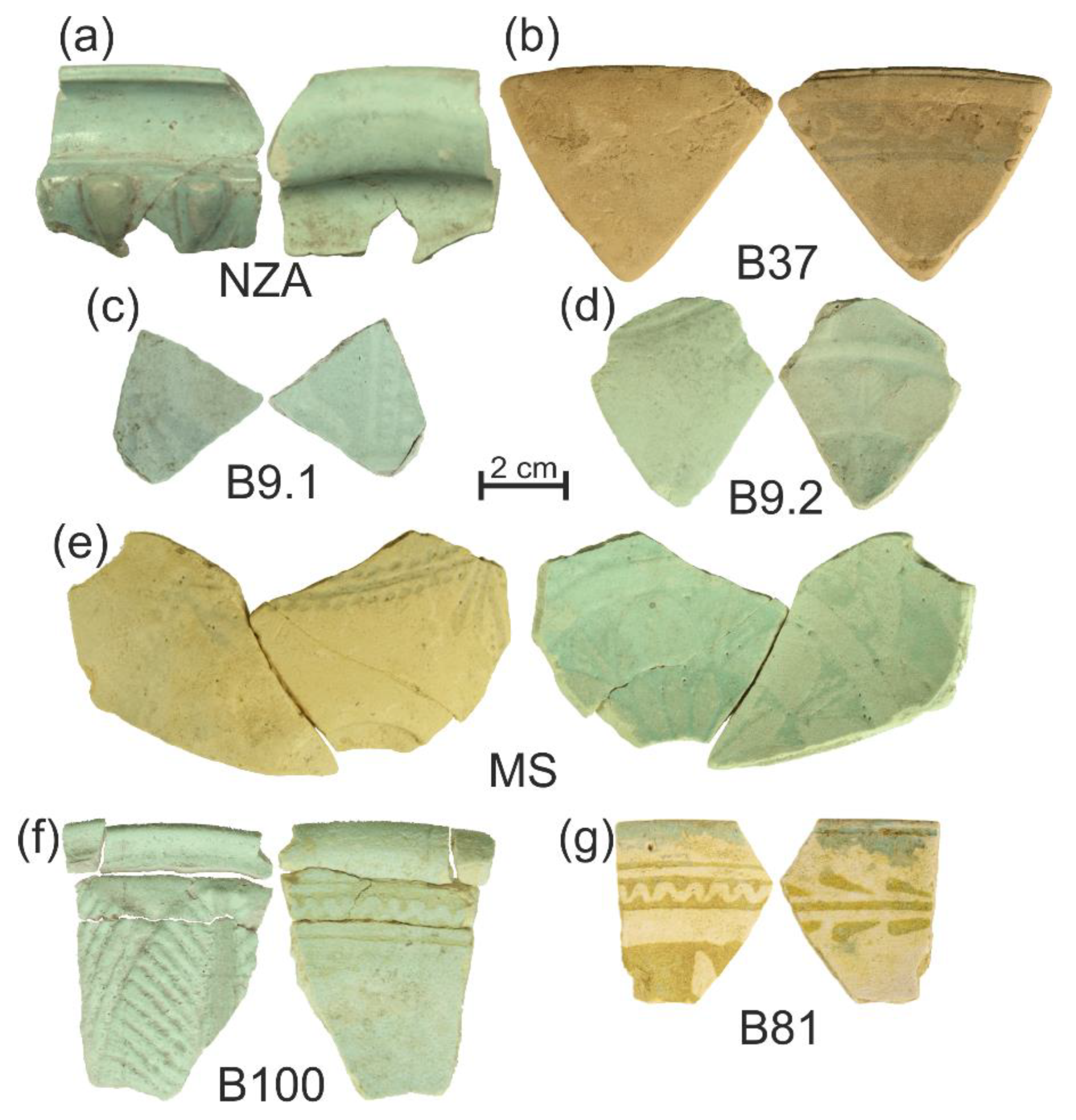

| Cat. no. a | Bowl Type | Dating a | Lab no. d | Characteristics of the Faience Fragment (Compare Figure 2 and Figure S1) | ||

|---|---|---|---|---|---|---|

| Cat. a | Others | Fragment | Material | |||

| 195 | A-IV | T5.2 b | mid-3rd century BC | NZA | rim and upper body | Body: 3–6 mm thick, yellow, 2.5 Y 9/2 f Glaze: ~0.3 mm thick, smooth, blue-green, 2.5 BG 8/2 |

| 37 | B.1 | T1 c | 2nd half of 3rd century BC | B37 | rim and upper body | Body: 5–6 mm thick, yellow, 2.5 Y 9/3 Glaze: ~0.1 mm thick, worn, blue-green, 10 BG 9/2 |

| 9 | B.1 | T1 c | end (?) of 3rd century BC | B9.1 e | lower body | Body: 3–4 mm thick, yellow-red, 10 Y 9/1 Glaze: ~0.15 mm thick, glossy, blue, 2.5 B 8/2 |

| 9 | B.1 | T1 c | end (?) of 3rd century BC | B9.2 e | lower body | Body: 3–6 mm thick, yellow, 5 Y 9/1 Glaze: 0.2–0.4 mm thick, glossy, blue-green, 5 BG 9/2 |

| 4 | B.1 | T1 c | end (?) of 3rd century BC | MS | base and lower body | Body: 5–6 mm thick, yellow, 2.5 Y 9/2 Glaze: ~0.3 mm thick, glossy, smooth, blue-green, 2.5 BG 9/2 |

| 100 | B.5 | T2.1c | end of 3rd century BC or 1st half of 2nd century BC | B100 | rim and upper body | Body: 5–7 mm thick, yellow-red, 10 YR 9/3 Glaze: 0.15–0.2 mm thick, matt, blue-green, 7.5 BG 9/2 |

| 81 | B.4.1 | T2.3d c | 1st half of 2nd century BC | B81 | rim and upper body | Body: 3–5 mm of thick, yellow-red, 10 YR 9/1 Glaze: ~0.1 mm thick, worn, blue-green, 10 BG 9/2 |

| Grains Parameters | Lab No. | ||||||

|---|---|---|---|---|---|---|---|

| NZA | B37 | B9.1 | B9.2 | MS | B100 | B81 | |

| Relative area s (%) | 55.0 | 60.9 | 62.8 | 64.0 | 63.2 | 55.7 | 66.2 |

| Number Ns × 103 (−) | 51 | 111 | 42 | 65 | 18 | 37 | 42 |

| Total area St × 103 (µm2) | 3638 | 3937 | 4141 | 4199 | 4233 | 3674 | 4418 |

| Average area Sav (µm2) | 71 | 35 | 99 | 65 | 237 | 101 | 106 |

| Total perimeter Pt × 103 (µm) | 1889 | 2608 | 1700 | 2020 | 1332 | 1341 | 1863 |

| Average perimeter Pav (µm) | 37 | 24 | 41 | 31 | 75 | 37 | 45 |

| Average diameter Dav (µm) | 6.1 | 4.3 | 6.0 | 5.2 | 10.0 | 5.6 | 7.5 |

| Sand Ø > 50 µm (%) | 27.4 | 29.4 | 65.5 | 56.9 | 72.6 | 79.1 | 56.6 |

| Silt 2 < Ø < 50 µm (%) | 72.6 | 70.5 | 34.5 | 43.1 | 27.4 | 20.9 | 43.4 |

| Clay Ø < 2 µm (%) | 0 | 0.1 | 0 | 0 | 0 | 0 | 0 |

| Average form index Kfav (−) | 0.477 | 0.456 | 0.481 | 0.475 | 0.488 | 0.468 | 0.477 |

| Elongated grains (%) | 1.0 | 2.1 | 1.0 | 1.5 | 0.7 | 1.4 | 1.4 |

| Anisometric grains (%) | 81.6 | 82.2 | 80.8 | 80.7 | 80.7 | 82.0 | 80.4 |

| Isometric grains (%) | 17.4 | 15.7 | 18.2 | 17.8 | 18.6 | 16.6 | 18.2 |

| Accessory Grains | Primary Mineral, Rock | Degree, Character of Transformation | Secondary Mineral, Alloy | Indicator of Raw Materials Provenance | Firing Temperature Indicators [°C] | |

|---|---|---|---|---|---|---|

| Category | Change in Texture | |||||

| A accessory minerals | unchanged | zircon, rutile, garnet, ilmenite, titanite, monazite, apatite, olivine, magnetite, Na-, K- and Na-Ca feldspars | very low, thick layer of reaction | - | Host rocks: granodiorite, monzogranite, porphyry | - |

| B rock-forming minerals | partially changed | albite, Na plagioclase, K feldspar, biotite, epidote, amphibole | low, initial melted | - | Host rocks, contact zone of hydrothermal vein: granodiorite, monzogranite, | Formation of perthites |

| C sulphurs and oxides | unchanged | ilmenite, cassiterite, sphalerite | very low, without change | - | High and mid-temperature hydrothermal veins | - |

| D sulphurs | partially changed | Co-Cu-Sn ores | low, thick layer of reaction (halo) | - | High and mid-temperature hydrothermal veins | ? |

| E sulphurs | changed | sulphurs | medium and high,partially or completely melted | drops of Cu, Ni, Co oxides in silica alloy | High and mid-temperature hydrothermal vein | Exsolution textures: chalcopyrite in sphalerite ca. 550 °C |

| F ores and sulfosalts | changed | Pb ores (galena), sulfosalts Pb-Sb-S with silicates or aluminosilicates | High, completely melted | Pb silicates | Low-temperature hydrothermal vein | PbS-SiO2 alloy forming at 775 °C |

| G lithoclasts (lithic fragments) | unchanged, change, intersertal, porphyry | igneous and dolerite rocks, volcanic effusive rocks, sulphurs | medium and high,partially or completely melted | polymineral sulphurs alloy, Pb-P alloy Fe oxides | Surrounding rocks—source for stone tools | Dolerite rock melting starts at ca. 800 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trzciński, J.; Zaremba, M.; Nejbert, K.; Kaproń, G. Source of Raw Materials and Its Processing for the Manufacturing of Ptolemaic Faience Bowls from Tell Atrib (Nile Delta, Egypt). Materials 2022, 15, 6251. https://doi.org/10.3390/ma15186251

Trzciński J, Zaremba M, Nejbert K, Kaproń G. Source of Raw Materials and Its Processing for the Manufacturing of Ptolemaic Faience Bowls from Tell Atrib (Nile Delta, Egypt). Materials. 2022; 15(18):6251. https://doi.org/10.3390/ma15186251

Chicago/Turabian StyleTrzciński, Jerzy, Małgorzata Zaremba, Krzysztof Nejbert, and Grzegorz Kaproń. 2022. "Source of Raw Materials and Its Processing for the Manufacturing of Ptolemaic Faience Bowls from Tell Atrib (Nile Delta, Egypt)" Materials 15, no. 18: 6251. https://doi.org/10.3390/ma15186251

APA StyleTrzciński, J., Zaremba, M., Nejbert, K., & Kaproń, G. (2022). Source of Raw Materials and Its Processing for the Manufacturing of Ptolemaic Faience Bowls from Tell Atrib (Nile Delta, Egypt). Materials, 15(18), 6251. https://doi.org/10.3390/ma15186251