Remarkable Enhanced Mechanical Properties of TiAlCrNbV Medium-Entropy Alloy with Zr Additions

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

2.2. Thermomechanical Treatment

2.3. Microstructure Characterization

2.4. Mechanical Testing

3. Results

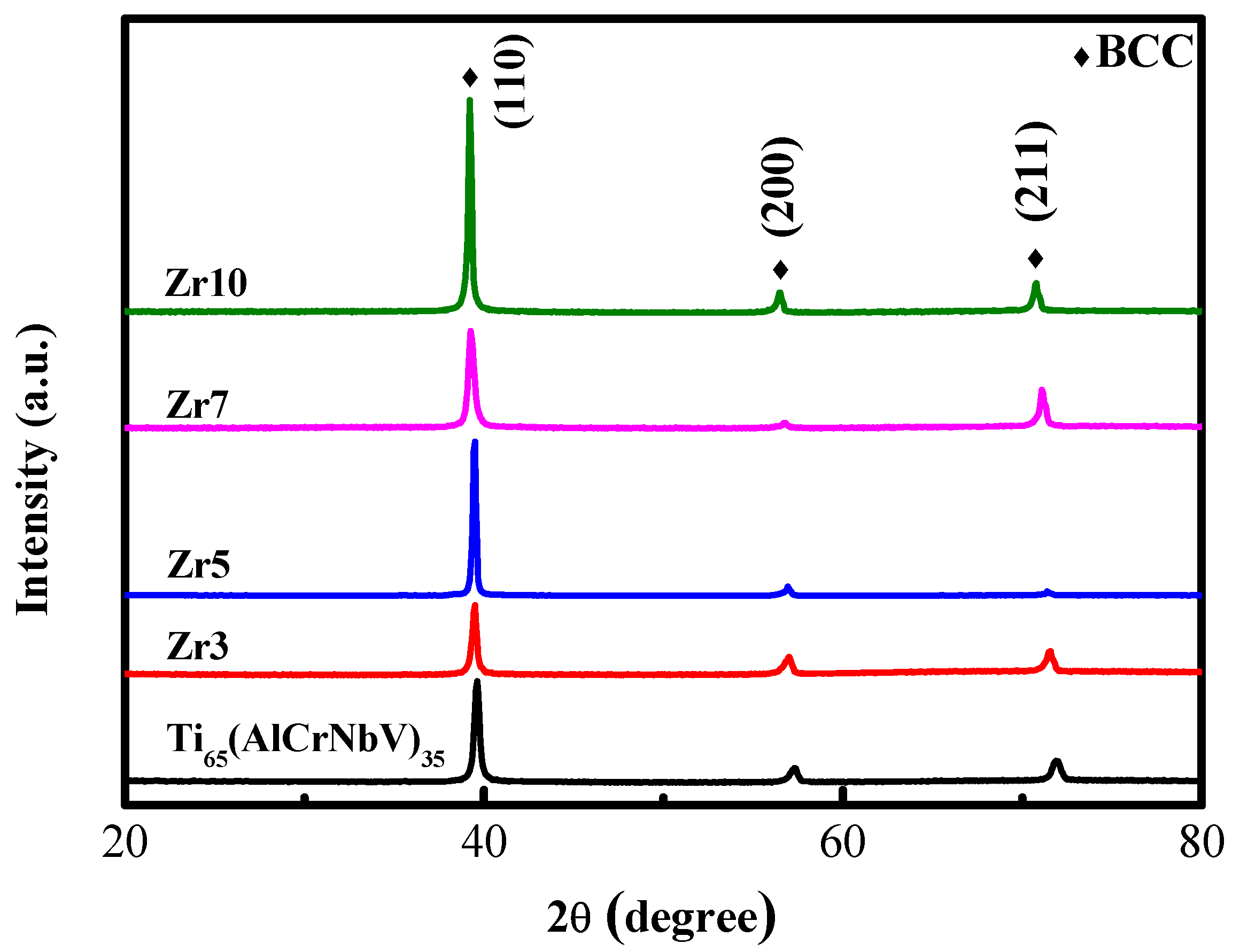

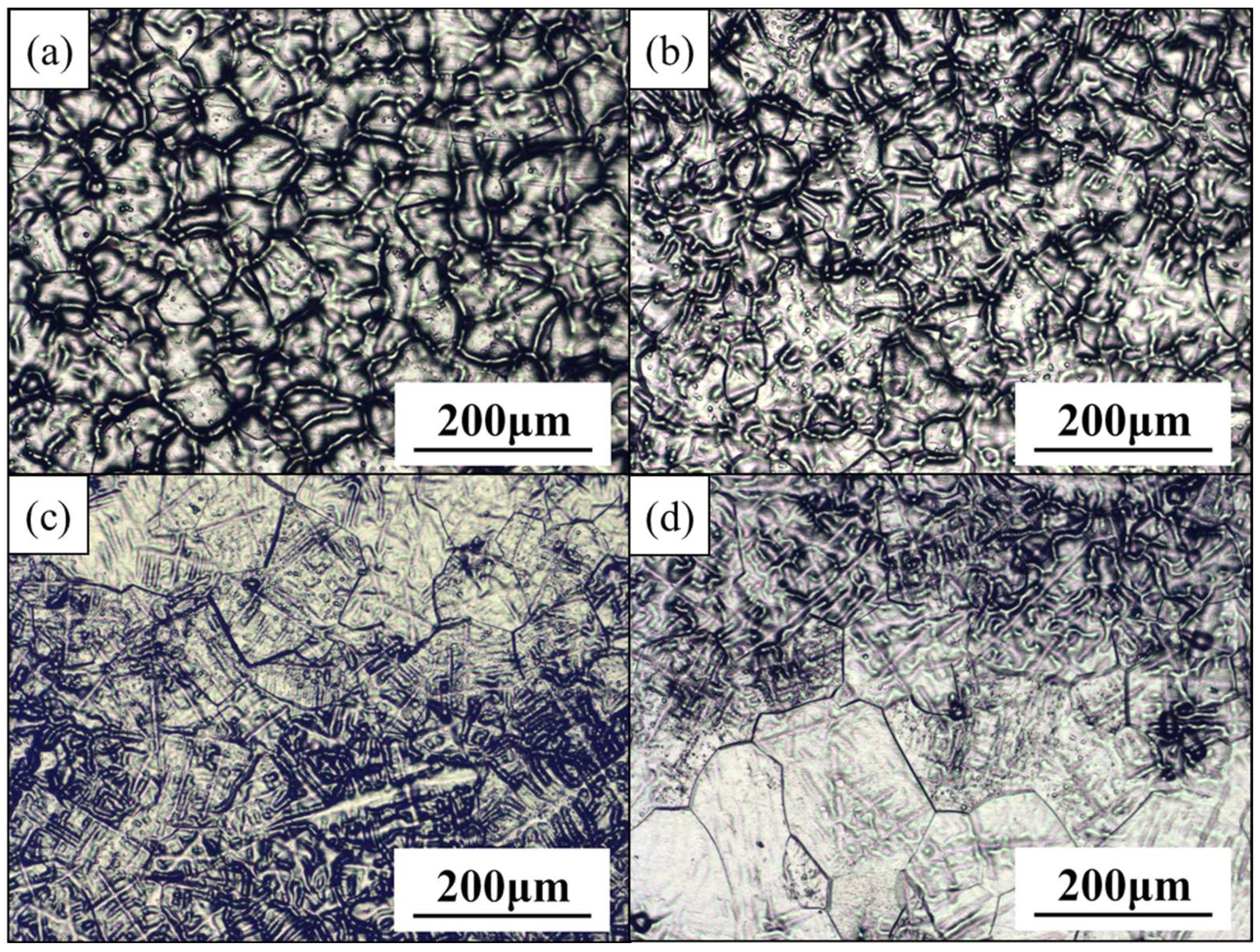

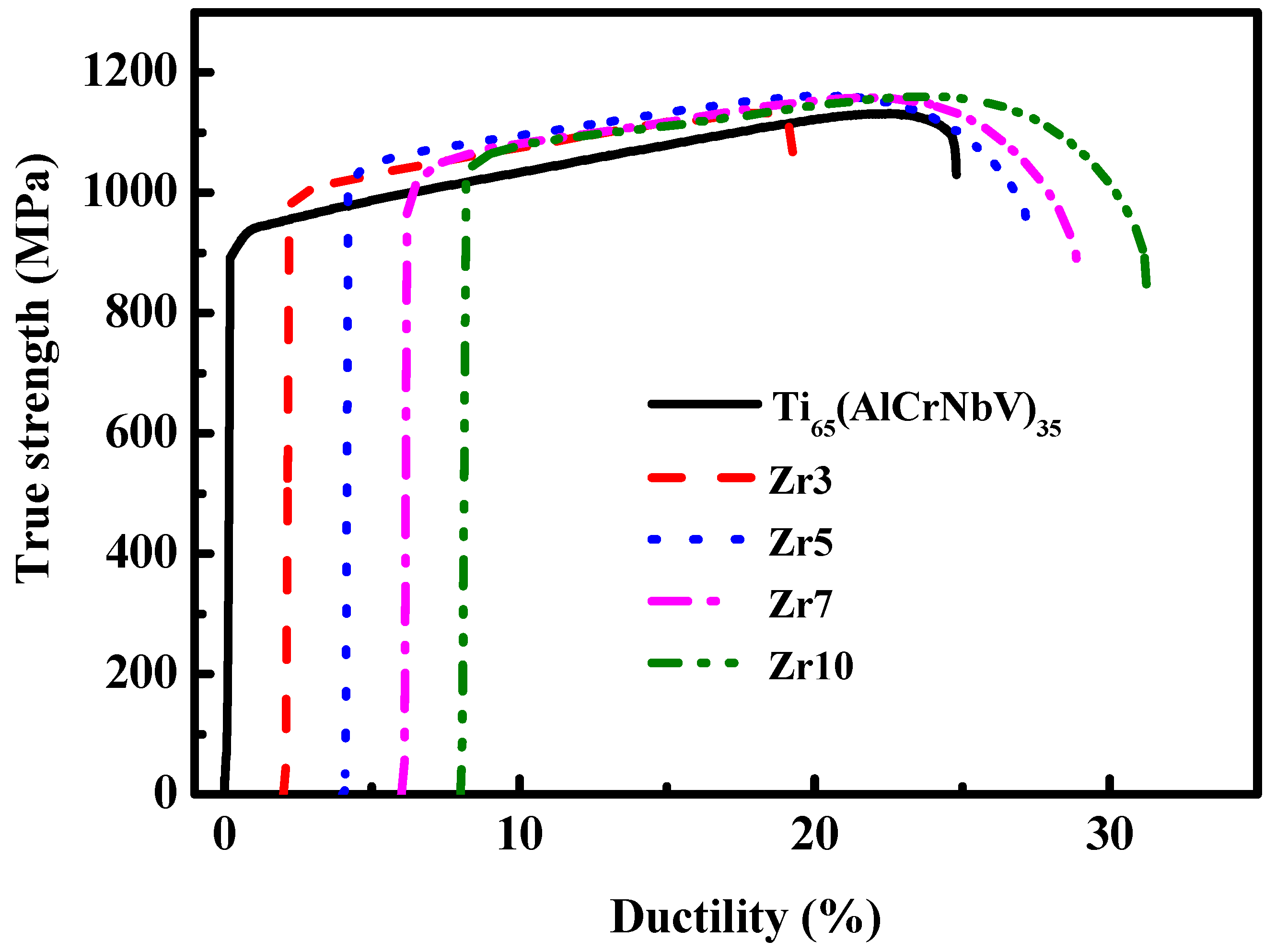

3.1. Characterization of As-Cast Ti65(AlCrNbV)35-xZrx (x = 3, 5, 7, and 10) MEAs

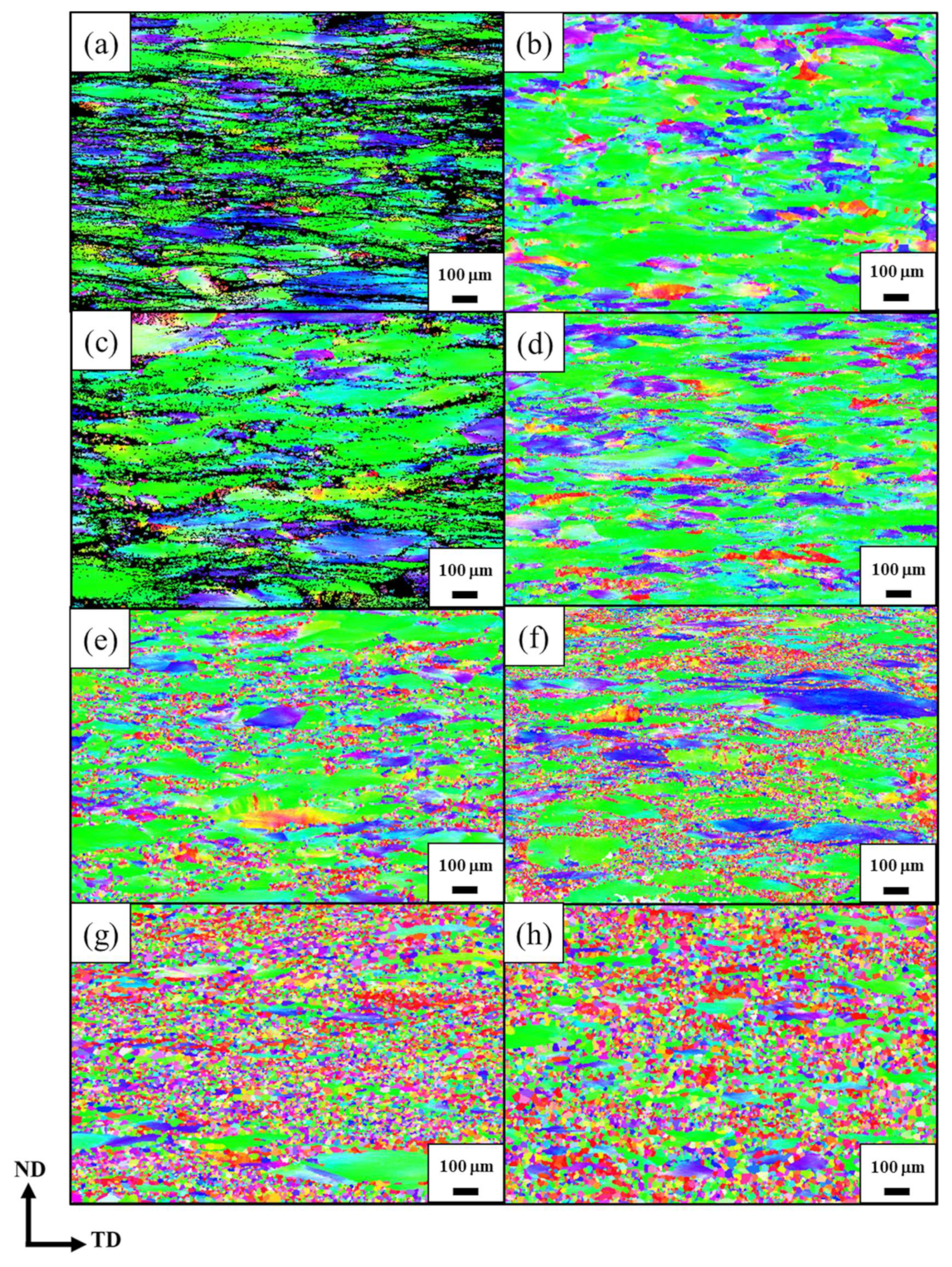

3.2. Performance of the Zr7 MEA after TMT Processing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASM International. Handbook Committee, “Properties and Selection: Irons, Steels, and High-Performance Alloys”; ASM International: Materials Park, OH, USA, 1990; Volume 1. [Google Scholar]

- ASM International. Handbook Committee, “Properties and Selection: Nonferrous Alloys and Special-Purpose Materials”; ASM International: Materials Park, OH, USA, 1990; Volume 2. [Google Scholar]

- Huang, K.H.; Yeh, J.W. A Study on Multicomponent Alloy Systems containing Equal-Mole Elements. Ph.D. Thesis, National Tsing Hua University, Beijing, China, 1996. [Google Scholar]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructure High-Entropy Alloys with Multiple Principle Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Yeh, J.W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Mat. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Lilensten, L.; Couzinié, J.; Perrière, L.; Bourgon, J.; Emery, N.; Guillot, I. New structure in refractory high-entropy alloys. Mater. Lett. 2014, 132, 123–125. [Google Scholar] [CrossRef]

- Youssef, K.M.; Zaddach, A.J.; Niu, C.; Irving, D.L.; Koch, C.C. A Novel Low-Density, High-Hardness, High-entropy Alloy with Close-packed Single-phase Nanocrystalline Structures. Mater. Res. Lett. 2015, 3, 95–99. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Yurchenko, N.Y.; Skibin, D.V.; Tikhonovsky, M.A.; Salishchev, G.A. Structure and mechanical properties of the AlCrxNbTiV (x = 0, 0.5, 1, 1.5) high entropy alloys. J. Alloys Compd. 2015, 652, 266–280. [Google Scholar] [CrossRef]

- Ma, D.; Yao, M.; Pradeep, K.; Tasan, C.; Springer, H.; Raabe, D. Phase stability of non-equiatomic CoCrFeMnNi high entropy alloys. Acta Mater. 2015, 98, 288–296. [Google Scholar] [CrossRef]

- Deng, Y.; Tasan, C.C.; Pradeep, K.G.; Springer, H.; Kostka, A.; Raabe, D. Design of a twinning-induced plasticity high entropy alloy. Acta Mater. 2015, 94, 124–133. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Z.; Zhang, P.; Zhang, K.; Chena, C.L.; Shen, B.L. Influence of Al content on high temperature oxidation behavior of AlxCoCrFeNiTi0.5 high entropy alloys. Vacuum 2019, 163, 263–268. [Google Scholar]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef]

- Li, Z.; Raabe, D. Strong and Ductile Non-equiatomic High-Entropy Alloys: Design, Processing, Microstructure, and Mechanical Properties. Miner. Met. Mater. Soc. 2017, 69, 2099–2106. [Google Scholar] [CrossRef] [Green Version]

- Liao, Y.C.; Chen, P.S.; Li, C.H.; Tsai, P.H.; Jang, J.S.C. Development of Novel Lightweight Dual-Phase Al-Ti-Cr-Mn-V Medium-Entropy Alloys with High Strength and Ductility. Entropy 2020, 22, 74. [Google Scholar] [CrossRef]

- Li, R.; Gao, J.; Fan, K. Study to Microstructure and Mechanical Properties of Mg Containing High Entropy Alloys. Mater. Sci. Forum 2010, 650, 265–271. [Google Scholar] [CrossRef]

- Du, X.; Wang, R.; Chen, C.; Wu, B.; Huang, J. Preparation of a Light-Weight MgCaAlLiCu High-Entropy Alloy. Key Eng. Mater. 2017, 727, 132–135. [Google Scholar] [CrossRef]

- Chang, H.; Zhang, T.W.; Ma, S.G.; Zhao, D.; Xiong, R.L.; Wang, T.; Li, Z.Q.; Wang, Z.H. Novel Si-added CrCoNi medium entropy alloys achieving the breakthrough of strength-ductility trade-off. Mater. Des. 2021, 197, 12. [Google Scholar] [CrossRef]

- Moon, J.; Tabachnikova, E.; Shumilin, S.; Hryhorova, T.; Estrin, Y.; Brechtl, J.; Liaw, P.K.; Wang, W.; Dahmen, K.A.; Kim, H.S. Unraveling the discontinuous plastic flow of a Co-Cr-Fe-Ni-Mo multiprincipal-element alloy at deep cryogenic temperatures. Phys. Rev. Mater 2021, 5, 083601. [Google Scholar]

- Shukla, S.; Mishra, R.S. Excellent high cyclic fatigue properties of a novel ultrafine-grained medium entropy alloy. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process 2020, 779, 9. [Google Scholar] [CrossRef]

- Senkov, O.N.; Semiatin, S.L. Microstructure and Properties of a Refractory High-Entropy Alloy after Cold Working. J. Alloys Compd. 2015, 649, 1110–1123. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, M.; Ma, S.; Liaw, P.K.; Zhang, Y.; Qiao, J. Strengthening in Al0.25CoCrFeNi high-entropy alloys by cold rolling. Mater. Sci. Eng. 2017, 707, 593–601. [Google Scholar] [CrossRef]

- Eleti, R.R.; Raju, V.; Veerasham, M.; Reddy, S.R.; Bhattacharjee, P.P. Influence of strain on the formation of cold-rolling and grain growth textures of an equiatomic HfZrTiTaNb refractory high entropy alloy. Mater. Charact. 2018, 136, 286–292. [Google Scholar] [CrossRef]

- Chen, S.; Tseng, K.K.; Tong, Y.; Li, W.; Tsai, C.W.; Yeh, J.W.; Liaw, P.K. Grain growth and Hall-Petch relationship in a refractory HfNbTaZrTi high-entropy alloy. J. Alloys Compd. 2019, 795, 19–26. [Google Scholar] [CrossRef]

- Huang, Y.C.; Lai, Y.C.; Lin, Y.H.; Wu, S.K. A study on the severely cold-rolled and annealed quaternary equiatomic derivatives from quinary HfNbTaTiZr refractory high entropy alloy. J. Alloys Compd. 2021, 855, 157404. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering; Wiley: Hoboken, NJ, USA, 2011; Volume 8. [Google Scholar]

- Liao, Y.C.; Li, T.H.; Tsai, P.H.; Jang, J.S.C.; Hsieh, K.C.; Chen, C.Y.; Huang, J.C.; Wu, H.J.; Lo, Y.C.; Huang, C.W.; et al. Designing novel lightweight, high-strength and high-plasticity Tix(AlCrNb)100−x medium-entropy alloys. Intermetallics 2020, 117, 106673. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Tsai, M.; Yeh, J. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

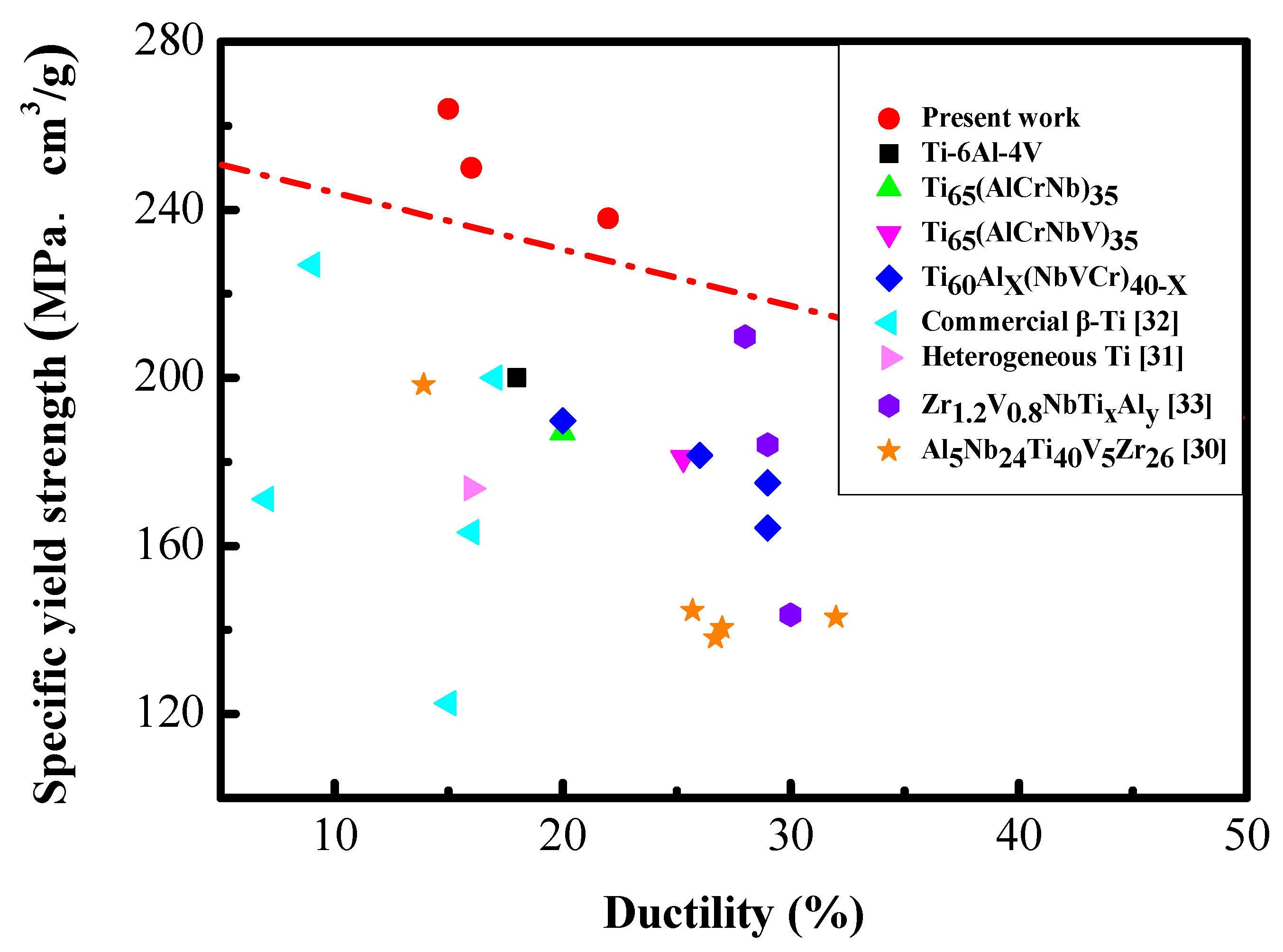

- Zherebtsov, S.; Yurchenko, N.; Panina, E.; Tikhonovsky, M.; Stepanov, N. Gum-like mechanical behavior of a partially ordered Al5Nb24Ti40V5Zr26 high entropy alloy. Intermetallics 2020, 116, 106652. [Google Scholar] [CrossRef]

- Shin, S.; Zhu, C.; Zhang, C.; Vecchio, K. Extraordinary strength-ductility synergy in a heterogeneous-structured β-Ti alloy through microstructural optimization. Mater. Res. Lett. 2019, 7, 467–473. [Google Scholar] [CrossRef] [Green Version]

- Online Materials Information Resource—MatWeb. Matweb.com. 2022. Available online: http://www.matweb.com/index.aspx (accessed on 4 January 2022).

- Wang, L.; Chen, S.; Li, B.; Cao, T.; Wang, B.; Wang, L.; Ren, Y.; Liang, J.; Xue, Y. Lightweight Zr1.2V0.8NbTixAly high-entropy alloys with high tensile strength and ductility. Mater. Trans. 2015, 56, 1800–1806. [Google Scholar]

| Composition | ΔS (kJ. mol−1) | Lattice Constant (Å) | Grain Size (µm) | ||

|---|---|---|---|---|---|

| As-Cast | Homogenization | ||||

| Ti65(AlCrNb)35 | 8.58 | 4.69 | 3.226 | 81 | 124 |

| Ti65(AlCrNbV)35 | 9.42 | 4.78 | 3.213 | 92 | 134 |

| Ti65(AlCrNbV)32Zr3 | 9.92 | 5.04 | 3.227 | 48 | 100 |

| Ti65(AlCrNbV)30Zr5 | 10.03 | 5.18 | 3.230 | 55 | 352 |

| Ti65(AlCrNbV)28Zr7 | 10.07 | 5.29 | 3.243 | 70 | 416 |

| Ti65(AlCrNbV)25Zr10 | 10.01 | 5.40 | 3.253 | 76 | 485 |

| Composition | Theoretical Density (g/cm3) | Measured Density (g/cm3) |

|---|---|---|

| Ti65(AlCrNb)35 | 5.10 | 5.01 ± 1.79 |

| Ti65(AlCrNbV)35 | 5.10 | 5.09 ± 0.19 |

| Ti65(AlCrNbV)32Zr3 | 5.11 | 5.06 ± 0.98 |

| Ti65(AlCrNbV)30Zr5 | 5.12 | 5.09 ± 0.58 |

| Ti65(AlCrNbV)28Zr7 | 5.13 | 5.11 ± 0.39 |

| Ti65(AlCrNbV)25Zr10 | 5.14 | 5.13 ± 0.19 |

| Composition | Yield Strength (MPa) | Ultimate Strength (MPa) | Ductility (%) | Hardness (Hv) |

|---|---|---|---|---|

| Ti65(AlCrNb)35 | 954 ± 19 | 1136 ± 26 | 20.0 ± 1.6 | 323 ± 5 |

| Ti65(AlCrNbV)35 | 921 ± 11 | 1159 ± 14 | 25.3 ± 1.4 | 317 ± 3 |

| Ti65(AlCrNbV)32Zr3 | 976 ± 27 | 1134 ± 26 | 17.3 ± 2.6 | 337 ± 5 |

| Ti65(AlCrNbV)30Zr5 | 1010 ± 13 | 1154 ± 25 | 20.1 ± 2.5 | 335 ± 4 |

| Ti65(AlCrNbV)28Zr7 | 1015 ± 26 | 1170 ± 14 | 22.2 ± 2.2 | 331 ± 4 |

| Ti65(AlCrNbV)25Zr10 | 1020 ± 9 | 1165 ± 22 | 23.9 ± 2.0 | 336 ± 3 |

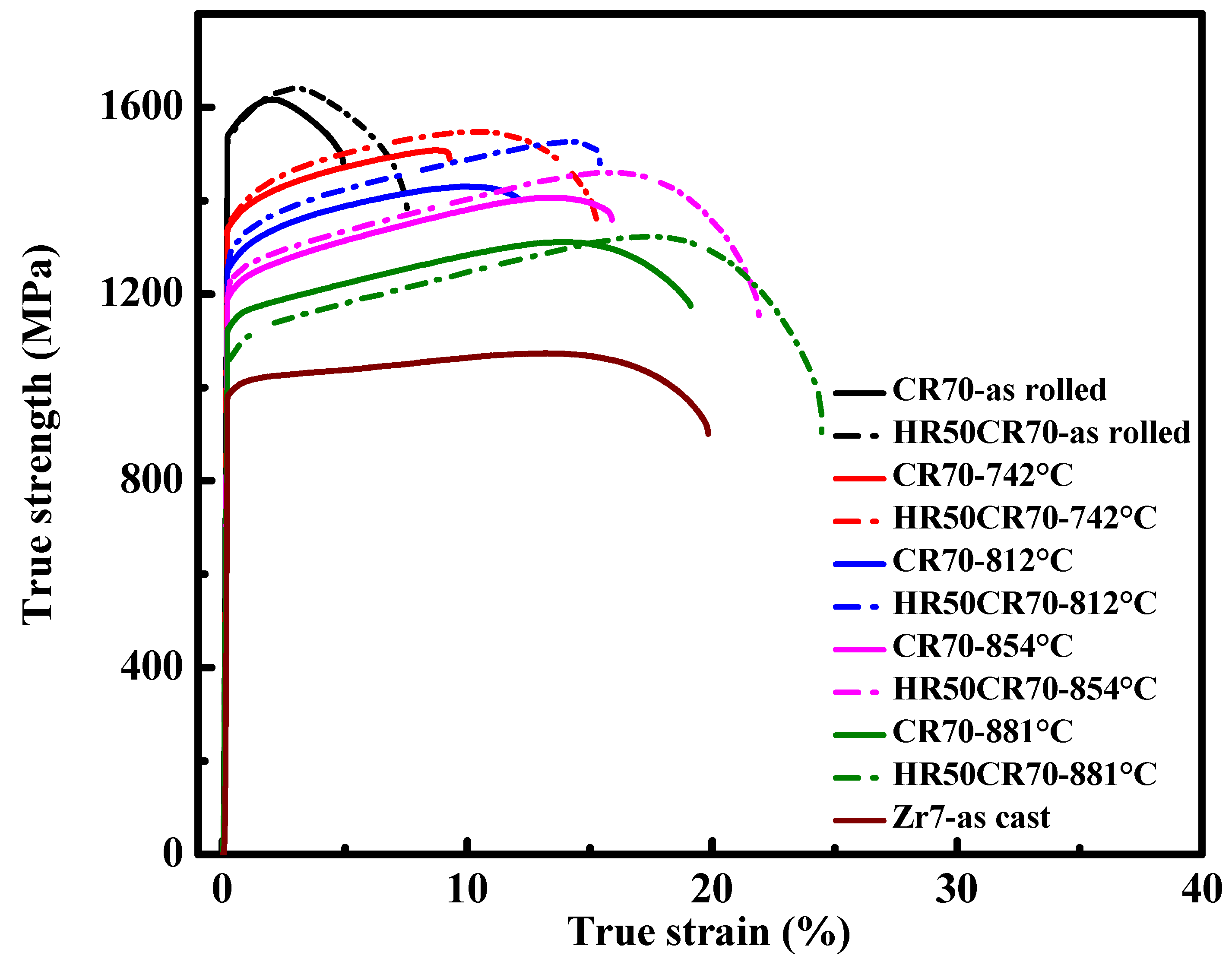

| Processing | CR70 | HR50CR70 | ||||

|---|---|---|---|---|---|---|

| Mechanical Properties | Yield Strength (MPa) | Ultimate Strength (MPa) | Ductility (%) | Yield Strength (MPa) | Ultimate Strength (MPa) | Ductility (%) |

| As-rolled | 1538 ± 23 | 1617 ± 19 | 5.0 ± 1.7 | 1528 ± 24 | 1640 ± 17 | 7.5 ± 1.7 |

| 742 °C | 1334 ± 14 | 1508 ± 9 | 9.3 ± 2.1 | 1351 ± 11 | 1548 ± 5 | 15.3 ± 2.0 |

| 812 °C | 1255 ± 8 | 1431 ± 11 | 12.2 ± 2.3 | 1279 ± 13 | 1527 ± 12 | 15.5 ± 1.3 |

| 854 °C | 1192 ± 7 | 1407 ± 5 | 15.9 ± 2.7 | 1217 ± 17 | 1461 ± 8 | 21.9 ± 1.4 |

| 881 °C | 1120 ± 14 | 1312 ± 6 | 19.2 ± 2.6 | 1052 ± 14 | 1324 ± 17 | 24.5 ± 2.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.-S.; Shiu, S.-J.; Tsai, P.-H.; Liao, Y.-C.; Jang, J.S.-C.; Wu, H.-J.; Chang, S.-Y.; Chen, C.-Y.; Tsao, I.-Y. Remarkable Enhanced Mechanical Properties of TiAlCrNbV Medium-Entropy Alloy with Zr Additions. Materials 2022, 15, 6324. https://doi.org/10.3390/ma15186324

Chen P-S, Shiu S-J, Tsai P-H, Liao Y-C, Jang JS-C, Wu H-J, Chang S-Y, Chen C-Y, Tsao I-Y. Remarkable Enhanced Mechanical Properties of TiAlCrNbV Medium-Entropy Alloy with Zr Additions. Materials. 2022; 15(18):6324. https://doi.org/10.3390/ma15186324

Chicago/Turabian StyleChen, Po-Sung, Sheng-Jia Shiu, Pei-Hua Tsai, Yu-Chin Liao, Jason Shian-Ching Jang, Hsin-Jay Wu, Shou-Yi Chang, Chih-Yen Chen, and I-Yu Tsao. 2022. "Remarkable Enhanced Mechanical Properties of TiAlCrNbV Medium-Entropy Alloy with Zr Additions" Materials 15, no. 18: 6324. https://doi.org/10.3390/ma15186324

APA StyleChen, P.-S., Shiu, S.-J., Tsai, P.-H., Liao, Y.-C., Jang, J. S.-C., Wu, H.-J., Chang, S.-Y., Chen, C.-Y., & Tsao, I.-Y. (2022). Remarkable Enhanced Mechanical Properties of TiAlCrNbV Medium-Entropy Alloy with Zr Additions. Materials, 15(18), 6324. https://doi.org/10.3390/ma15186324