Influence of the Accelerated Aging Process on the Fragment-Resistant Properties of Para-Aramid Body Armor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Tested Samples

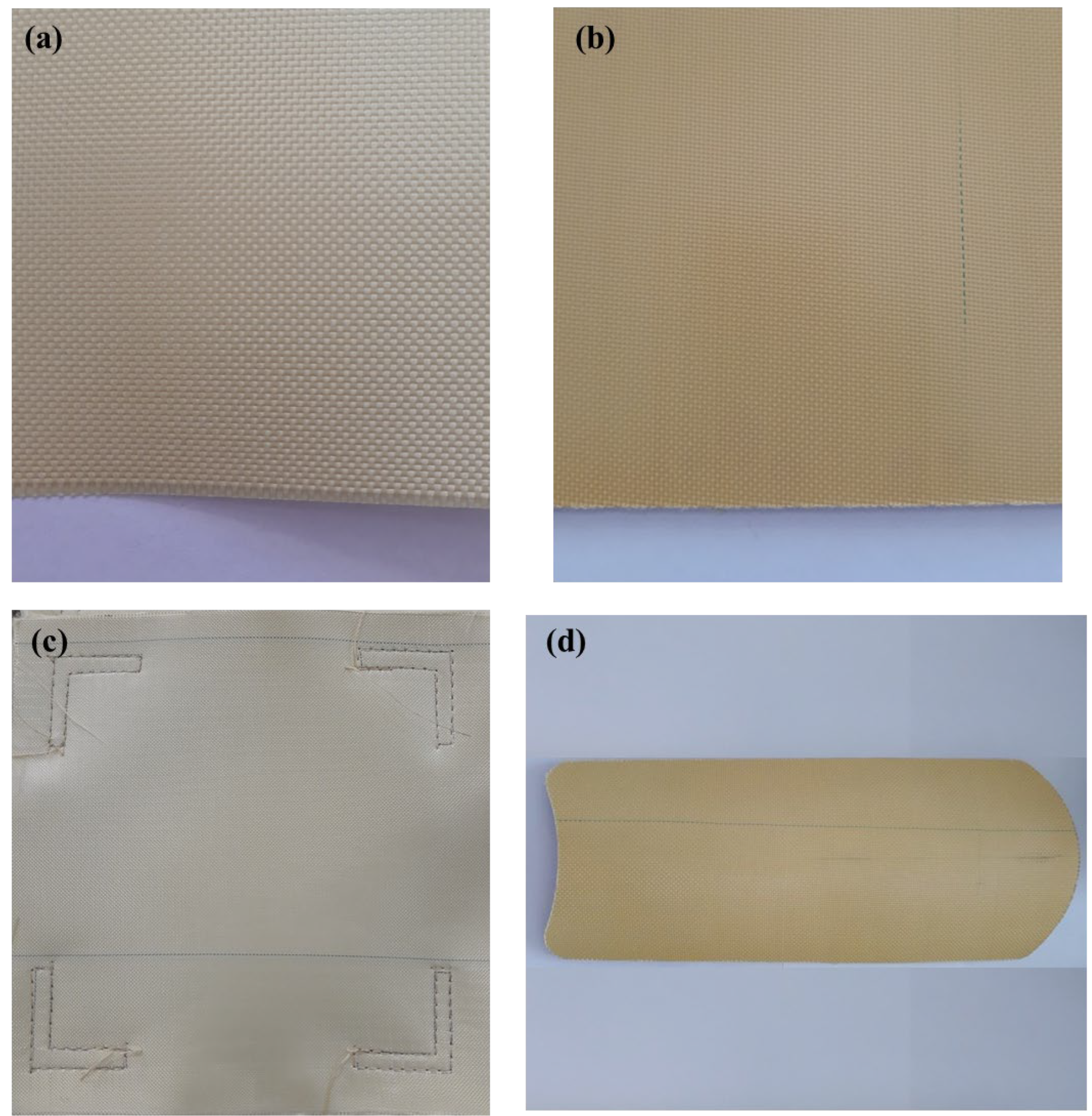

- Twaron®CT612 WRT (Teijin Aramid GmbH, Wuppertal, Germany), which is plain-woven para-aramid fabric with water repellent treatment (WRT) finishing, which was marked as sample A (Figure 1a). Twaron®CT612 WRT has 120 ± 5 g/m2 areal density, EPI (ends per inch) of 110 ± 2 per 10 cm, PPI (picks per inch) equal to 110 ± 2 per 10 cm and a linear density of its yarns of 550 and 500 dtex in the warp and weft directions, respectively.

- Twaron®CT736 (Teijin Aramid GmbH, Wuppertal, Germany), which is fabric impregnated with polyvinyl butyral (PVB) or PVB phenolic resin (resin amount declared by the manufacturer 12%), which was marked as sample B (Figure 1b). Twaron®CT736 fabric is made of 1680 dtex yarns and has a 410 ± 10 g/m2 areal density, and the EPI and PPI are equal to 127 ± 4 per 10 cm.

- The objects of the fragment-resistance study were two types of ballistic systems:

- soft ballistic inserts made of Twaron®CT612 WRT (Teijin Aramid GmbH, Wuppertal, Germany) para-aramid sheets with 300 × 300 mm dimensions and an areal density of (5.0 ± 0.5) kg/m2, which were marked as ballistic system A (Figure 1c);

- hard ballistic inserts obtained from multilayer pressed Twaron®CT736 (Teijin Aramid GmbH, Wuppertal, Germany) pre-impregnated sheets with 440 × 160 mm dimensions and an areal density of (10.6 ± 0.5) kg/m2, used in conjunction with soft ballistic inserts with the composition and areal density as above, which were marked as ballistic system B (Figure 1d).

2.2. Accelerated Aging Process

2.3. Fatigue Tests Simulating Mechanical Loads of Ballistic Inserts

- 9360 cycles, which corresponded to the estimated use of the insert once a week over 6 years;

- 28,080 cycles, which corresponded to the estimated use of the insert three times a week over 6 years;

- 46,800 cycles, which corresponded to the estimated use of the insert five times a week over 6 years.

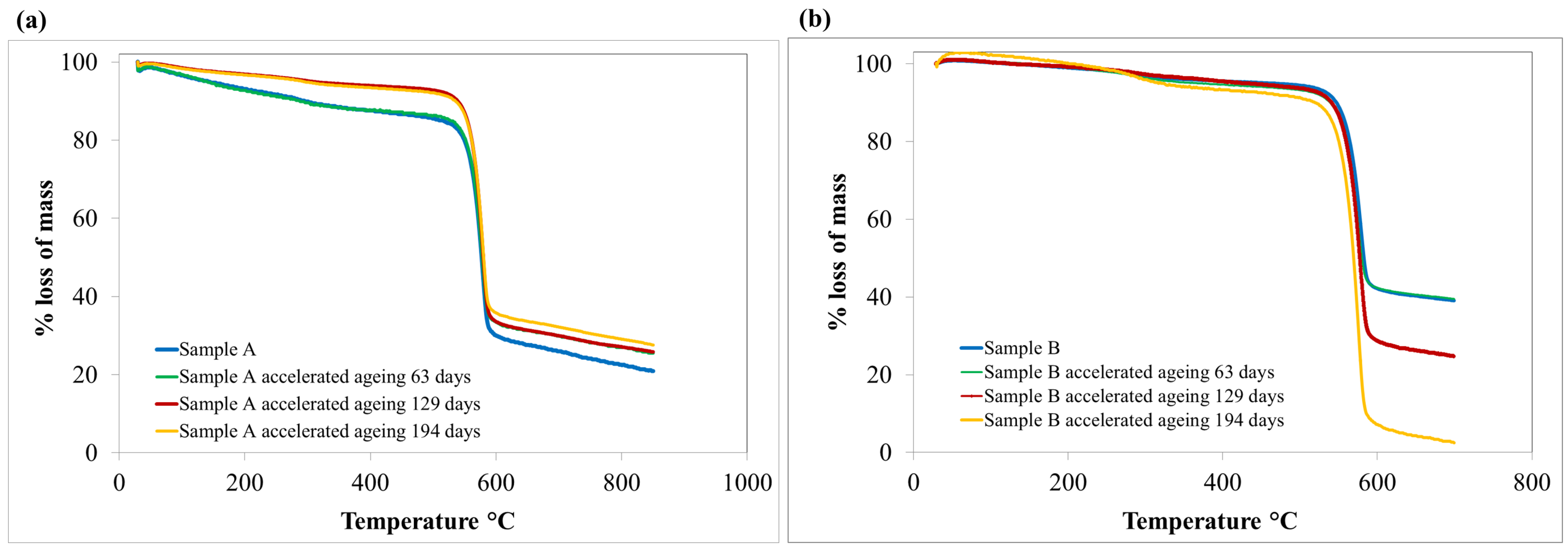

2.4. Assessment of Mechanical Properties

2.5. Analysis of Thermal Properties of Para-Aramid Materials using Thermogravimetry (TG)

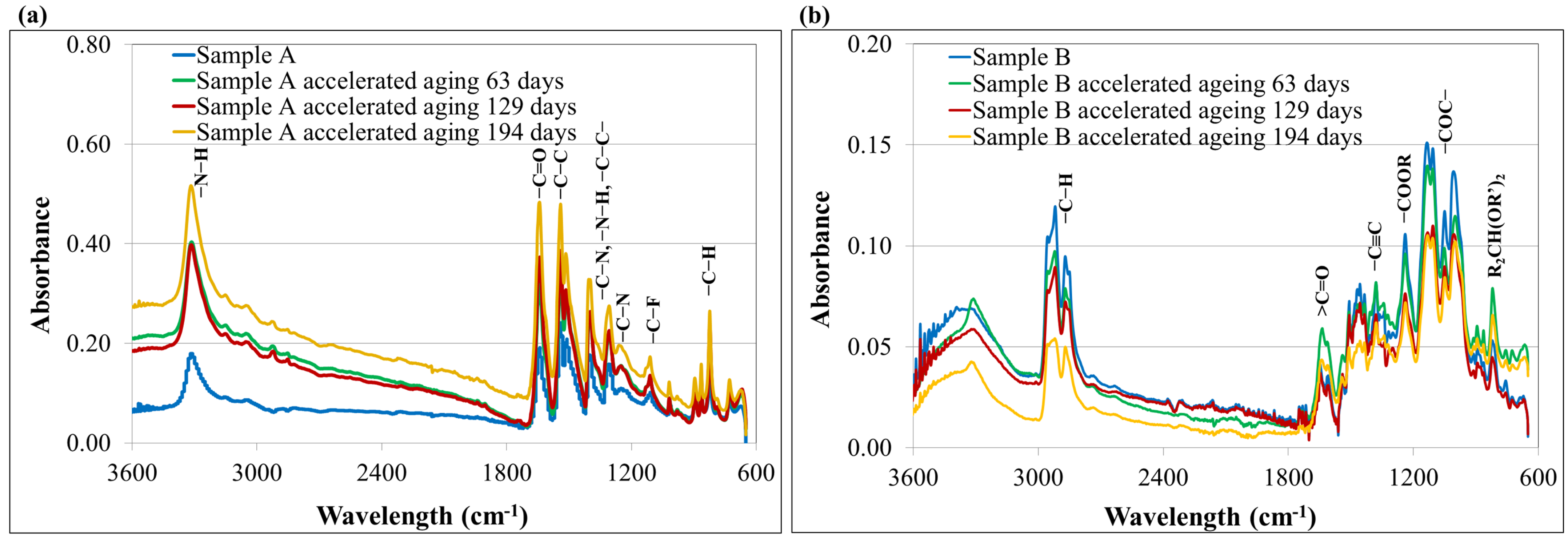

2.6. Structural Studies Performed by Infrared Spectroscopy (FT-IR)

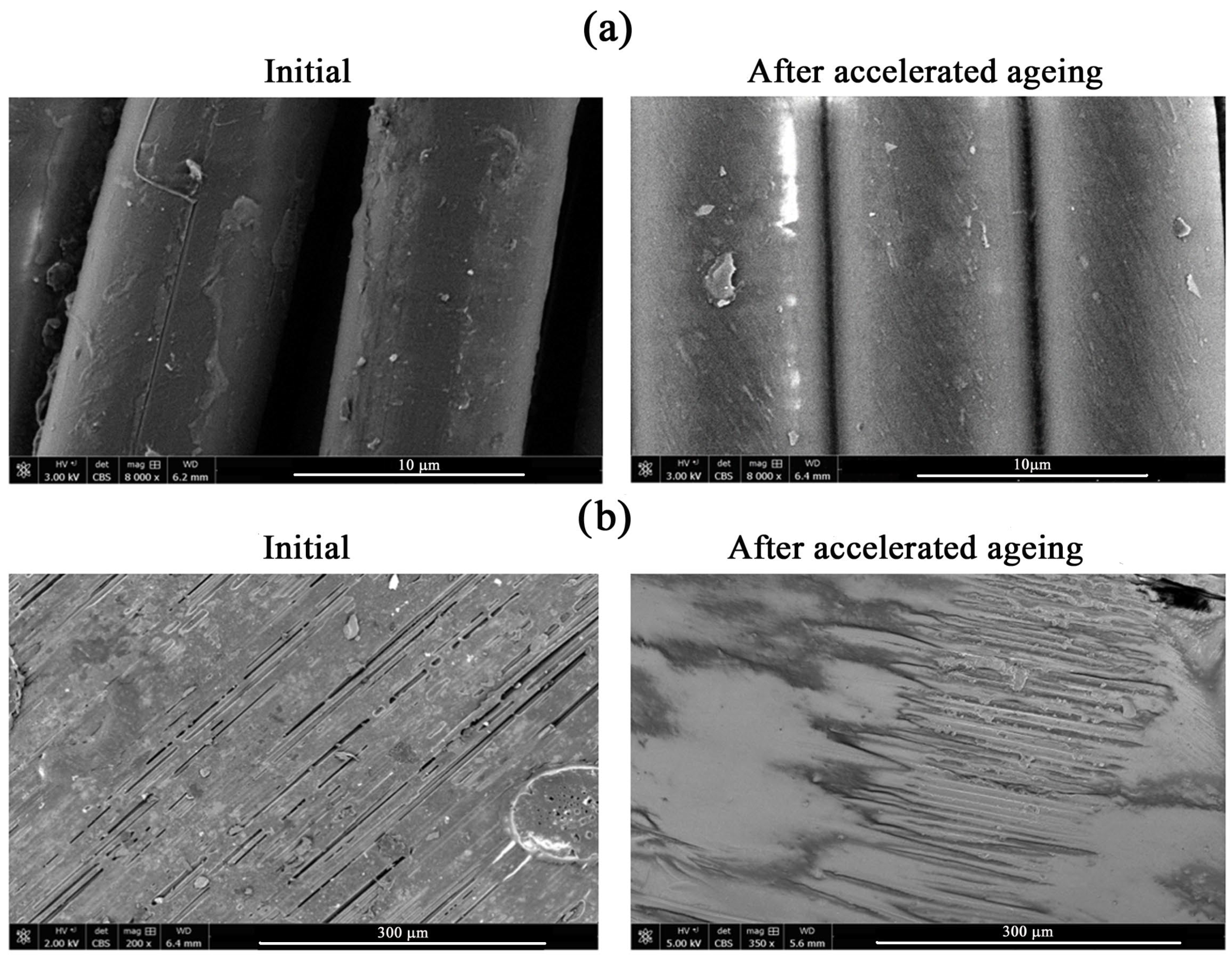

2.7. Surface Morphology Studies Using Scanning Electron Microscopy (SEM)

2.8. Fragment Resistance Measurements

3. Results

3.1. Results of Structural, Physico-Mechanical and Thermogravimetric Tests of Para-Aramid Materials Subjected to Accelerated Aging Processes

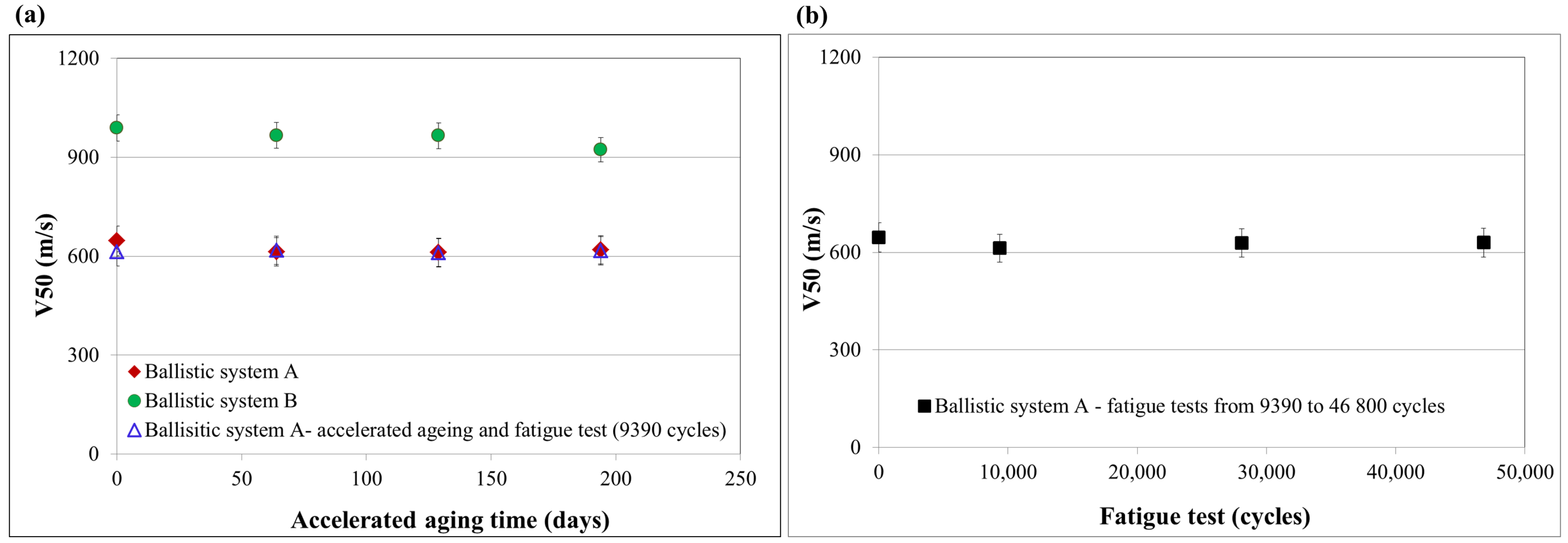

3.2. Fragment Resistance of Para-Aramid Ballistic Inserts Subjected to Accelerated Aging and Fatigue Tests

- Fatigue that simulated the use of inserts one, three and five times a week over a period of 6 years (Figure 6b),

- Fatigue simulating the use of the insert once a week (9360 fatigue cycles) and additionally accelerated aging in the period corresponding to 2–6 years of use (exposure to the temperature of 60 °C for a period of 63 to 194 days) (Figure 6a).

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zavatta, N.; Rondina, F.; Falaschetti, M.P.; Donati, L. Effect of Thermal Ageing on the Mechanical Strength of Carbon Fibre Reinforced Epoxy Composites. Polymers 2021, 13, 2006. [Google Scholar] [CrossRef] [PubMed]

- Duarte, J.P.; Guilherme, C.E.M.; Thome da Silva, A.H.M.F.; Mendonca, A.C.; Stumpf, F.T. Lifetime prediction of aramid yarns applied to offshore mooring due to purely hydrolytic degradation. Polym. Polym. Compos. 2019, 27, 518–524. [Google Scholar] [CrossRef]

- Kamocka-Bronisz, R. Tensile strength analysis of aramid fabric of firefighter’s clothing after accelerated aging and abrasion. In Proceedings of the MATEC Web of Conferences, Fire and Environmental Safety Engineering 2018 (FESE 2018), Lviv, Ukraine, 7–8 December 2018. [Google Scholar]

- Arroyo-Fernandez, O.H.; Jalbert, J.; Rodriguez-Celis, E.M.; Duchesne, S.; Morin, B.; Fofan, I. Changes in mechanical properties of impregnated Nomex papers 410 and 910 during accelerated aging. Polym. Test. 2020, 83, 106358. [Google Scholar] [CrossRef]

- Engelbrecht-Wiggans, A.; Burni, F.; Krishnamurthy, A.; Forster, A.L. Tensile testing of aged flexible unidirectional composite laminates for body armor. J. Mater. Sci. 2020, 55, 1035–1048. [Google Scholar] [CrossRef]

- Madej-Kielbik, L.; Kosla, K.; Zielinska, D.; Chmal-Fudali, E.; Maciejewska, M. Effect of accelerated ageing on the mechanical and structural properties of the material system used in protectors. Polymers 2019, 11, 1263. [Google Scholar] [CrossRef]

- Chabba, S.; Es, M.; Klinken, E.J.; Jongedijk, M.J.; Vanek, D.; Gijsman, P.; van der Waals, A.C.L.M. Accelerated aging study of ultra high molecular weight polyethylene yarn and unidirectional composites for ballistic applications. J. Mater. Sci. 2007, 42, 2891–2893. [Google Scholar] [CrossRef]

- Fejdyś, M.; Kucharska-Jastrząbek, A.; Kośla, K. Effect of Accelerated Ageing on the Ballistic Resistance of Hybrid Composite Armour with Advanced Ceramics and UHMWPE Fibres. Fibres Text. East. Eur. 2020, 28, 71–80. [Google Scholar] [CrossRef]

- Fejdyś, M.; Kośla, K.; Kucharska-Jastrząbek, A.; Łandwijt, M. Influence of ceramic properties on the ballistic performance of the hybrid ceramic–multi-layered UHMWPE composite armour. J. Aust. Ceram. Sci. 2021, 57, 149–161. [Google Scholar] [CrossRef]

- Howarter, J.A.; Liu, M.; McDonough, W.G.; Soles, C.; Holmes, G.A. Nanostructural Evidence of Mechanical Aging and Performance Loss in Ballistic Fibers. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 1711–1717. [Google Scholar] [CrossRef]

- Forster, A.L.; Leber, D.D.; Engelbrecht-Wiggans, A.; Landais, V.; Chang, A.; Guigues, E.; Messin, G.; Riley, M.A. Linking Theory to Practice: Predicting Ballistic Performance from Mechanical Properties of Aged Body Armor. J. Res. Natl. Inst. Stand. Technol. 2020, 125, 1–19. [Google Scholar] [CrossRef]

- Struszczyk, M.H.; Urbaniak-Domagała, W.; Puszkarz, A.K.; Wilbik-Hałgas, B.; Cichecka, M.; Sztajnowski, S.; Puchalski, M.; Miklas, M.; Krucinska, I. Structural Changes in the PACVD-Modified Para-Aramid, Ballistic Textiles During the Accelerated Ageing. Fibres Text. East. Eur. 2017, 25, 36–41. [Google Scholar] [CrossRef]

- Struszczyk, M.H.; Zielińska, D.; Miklas, M.; Grabowska, G.; Błaszczyk, J.; Kucińska-Król, I.; Solińska, E. Stability of the Performance and Safety of the Ballistic Body Protections Used in Humanitarian Demining. Fibres Text. East. Eur. 2017, 25, 88–92. [Google Scholar] [CrossRef]

- Engelbrecht-Wiggans, A.; Burni, F.; Guigues, E.; Jiang, S.; Huynh, T.Q.; Tsinas, Z.; Jacobs, D.; Forster, A.L. Effects of temperature and humidity on high-strength p-aramid fibers used in body armor. Text. Res. J. 2020, 90, 2428–2440. [Google Scholar] [CrossRef]

- Li, C.-S.; Huang, X.-C.; Yan, L.; Zhou, H.; Shen, Z.; Fan, X.-H. Effect of Thermal Aging on Microstructures of Aramid Composites. Polym. Compos. 2017, 38, 252–259. [Google Scholar]

- Konarzewski, V.H.C.; Spiekemann, F.L.; Campomanes Santana, R.M. Natural ageing of polyaramide fiber from ballistic armor. Polímeros 2019, 29, 1–7. [Google Scholar] [CrossRef]

- A True All-Round Para-Aramid Performer. Available online: https://www.teijinaramid.com/wp-content/uploads/2018/10/Product_brochure_Twaron.pdf (accessed on 8 September 2022).

- Twaron—A Versatile High-Performance Fiber. Available online: https://www.teijinaramid.com/wp-content/uploads/2016/07/Product-Brochure-Twaron.pdf (accessed on 8 September 2022).

- Derombise, G.; Vouyovitch Van Schoors, L.; Davies, P. Degradation of Aramid Fibers Under Alkaline and Neutral Conditions: Relations Between the Chemical Characteristics and Mechanical Properties. J. Appl. Polym. Sci. 2010, 116, 2504–2514. [Google Scholar] [CrossRef]

- Fink, J.K. High Performance Polymers, 2nd ed.; William Andrew: New York, NY, USA, 2014; pp. 301–320. [Google Scholar]

- Twaron®—FibrXL. Available online: https://fibrxl.com/fibrxl-performance/fibers/twaron/ (accessed on 8 September 2022).

- Kośla, K.; Kubiak, P.; Łandwijt, M.; Urbaniak, W.; Kucharska-Jastrząbek, A. Fragment-Resistant Property Optimization within Ballistic Inserts Obtained on the Basis of Para-Aramid Materials. Materials 2022, 15, 2314. [Google Scholar] [CrossRef]

- Fejdyś, M.; Cichecka, M.; Łandwijt, M.; Struszczyk, M.H. Prediction of the Durability of Composite Soft Ballistic Inserts. Fibres Text. East. Eur. 2014, 22, 81–89. [Google Scholar]

- Shebanov, S.M.; Novikov, I.K.; Pavlikov, A.V.; Anan′in, O.B.; Gerasimov, I.A. IR and Raman Spectra of modern aramid fibres. Fibre Chem. 2016, 48, 158–164. [Google Scholar] [CrossRef]

- Pate, P.L. The preparation of and Upper Atmospheric Effects on Kevlar Films. Master Thesis, The Faculty of the Department of Chemistry, The College of William and Mary in Virginia, Williamsburg, VA, USA, 1990. [Google Scholar]

- Carlsson, D.J.; Gan, L.H.; Wiles, D.M. Photodegradation of aramids. II. Irradiation in air. J. Polym. Sci. A. Polym. Chem. 1978, 16, 2365–2376. [Google Scholar] [CrossRef]

- Arrieta, C.; David, É.; Dolez, P.; Vu-Khanh, T. Hydrolytic and photochemical aging studies of a Kevlar®-PBI blend. Polym. Degrad. Stab. 2011, 96, 1411–1419. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar, D.; Khan, N. Polivinyl butyral (PVB), versatile template for designing nanocomposite/ composite materials: A Review. Green Chem. Technol. Lett. 2016, 2, 185–194. [Google Scholar] [CrossRef] [Green Version]

- Carrot, C.; Bendaould, A.; Pillon, C. Polyvinyl Butyral. In Handbook of Thermoplastic, 2nd ed.; Olabisi, O., Adewale, K., Eds.; CRC Press: London, UK, 2015; ISBN 9781466577220. [Google Scholar]

- Ivanova, V.B.; Zavodchikova, A.A.; Popova, E.I.; Lazareva, O.L.; Belova, O.A.; Kryuchkov, I.A.; Bykov, E.V. Accelerated testing of thermo-oxidative degradation of polyvinylbutyral. Thermochim. Acta 2014, 589, 70–75. [Google Scholar] [CrossRef]

- Bottger, C.; Hartert, R.; Stolze, K.; Jager, J.; Ven, H.; Akker, P. Method for Producing a Hydrophobically Finished Aramid Fabric and Use Thereof. US Patent No. US20040142617A1, 7 November 2006. [Google Scholar]

- Li, X.G.; Huang, M.R. Thermal degradation of Kevlar fiber by high-resolution thermogravimetry. J. Appl. Polym. Sci. 1999, 71, 565–571. [Google Scholar] [CrossRef]

- Perepelkin, K.E.; Andreeva, I.V.; Pakshver, E.A.; Yu Morgoeva, I. Thermal characteristics of para-aramid fibres. Fibre Chem. 2003, 35, 265–269. [Google Scholar] [CrossRef]

| No. | Tested Sample | Parameter | Before Ageing | Accelerated Ageing 63 Days | Accelerated Ageing 129 Days | Accelerated Ageing 194 Days |

|---|---|---|---|---|---|---|

| 1 | Sample A | T5 [°C] | 355 | 351 | 309 | 294 |

| 2 | T50 [°C] | 576 | 578 | 580 | 580 | |

| 3 | Sample B | T5 [°C] | 459 | 425 | 367 | 317 |

| 4 | T50 [°C] | 583 | 576 | 581 | 569 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kośla, K.; Łandwijt, M.; Miklas, M.; Fejdyś, M. Influence of the Accelerated Aging Process on the Fragment-Resistant Properties of Para-Aramid Body Armor. Materials 2022, 15, 6492. https://doi.org/10.3390/ma15186492

Kośla K, Łandwijt M, Miklas M, Fejdyś M. Influence of the Accelerated Aging Process on the Fragment-Resistant Properties of Para-Aramid Body Armor. Materials. 2022; 15(18):6492. https://doi.org/10.3390/ma15186492

Chicago/Turabian StyleKośla, Katarzyna, Marcin Łandwijt, Michał Miklas, and Marzena Fejdyś. 2022. "Influence of the Accelerated Aging Process on the Fragment-Resistant Properties of Para-Aramid Body Armor" Materials 15, no. 18: 6492. https://doi.org/10.3390/ma15186492

APA StyleKośla, K., Łandwijt, M., Miklas, M., & Fejdyś, M. (2022). Influence of the Accelerated Aging Process on the Fragment-Resistant Properties of Para-Aramid Body Armor. Materials, 15(18), 6492. https://doi.org/10.3390/ma15186492