Hydration and Mechanical Properties of High-Volume Fly Ash Concrete with Nano-Silica and Silica Fume

Abstract

:1. Introduction

2. Materials and Methods

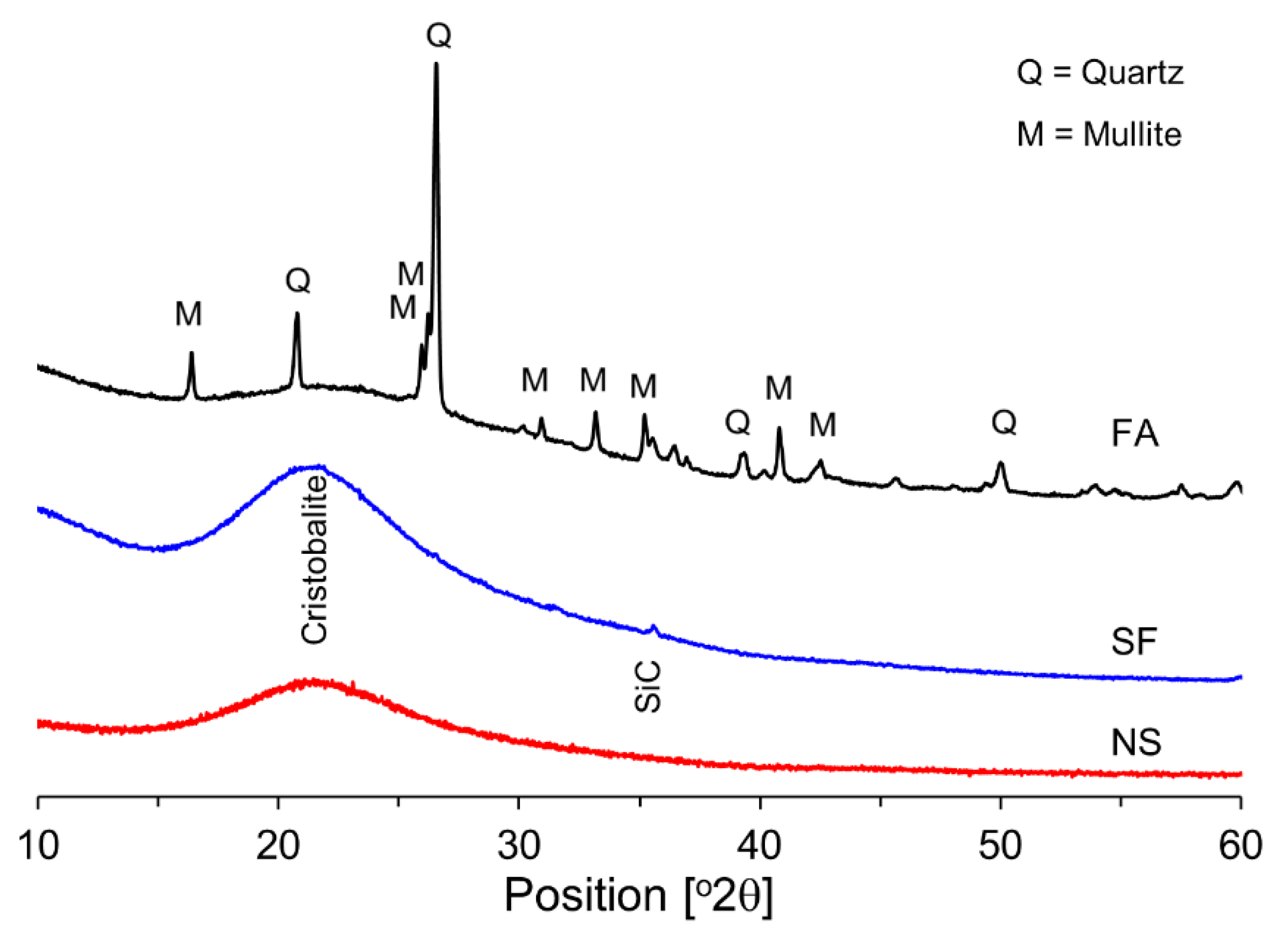

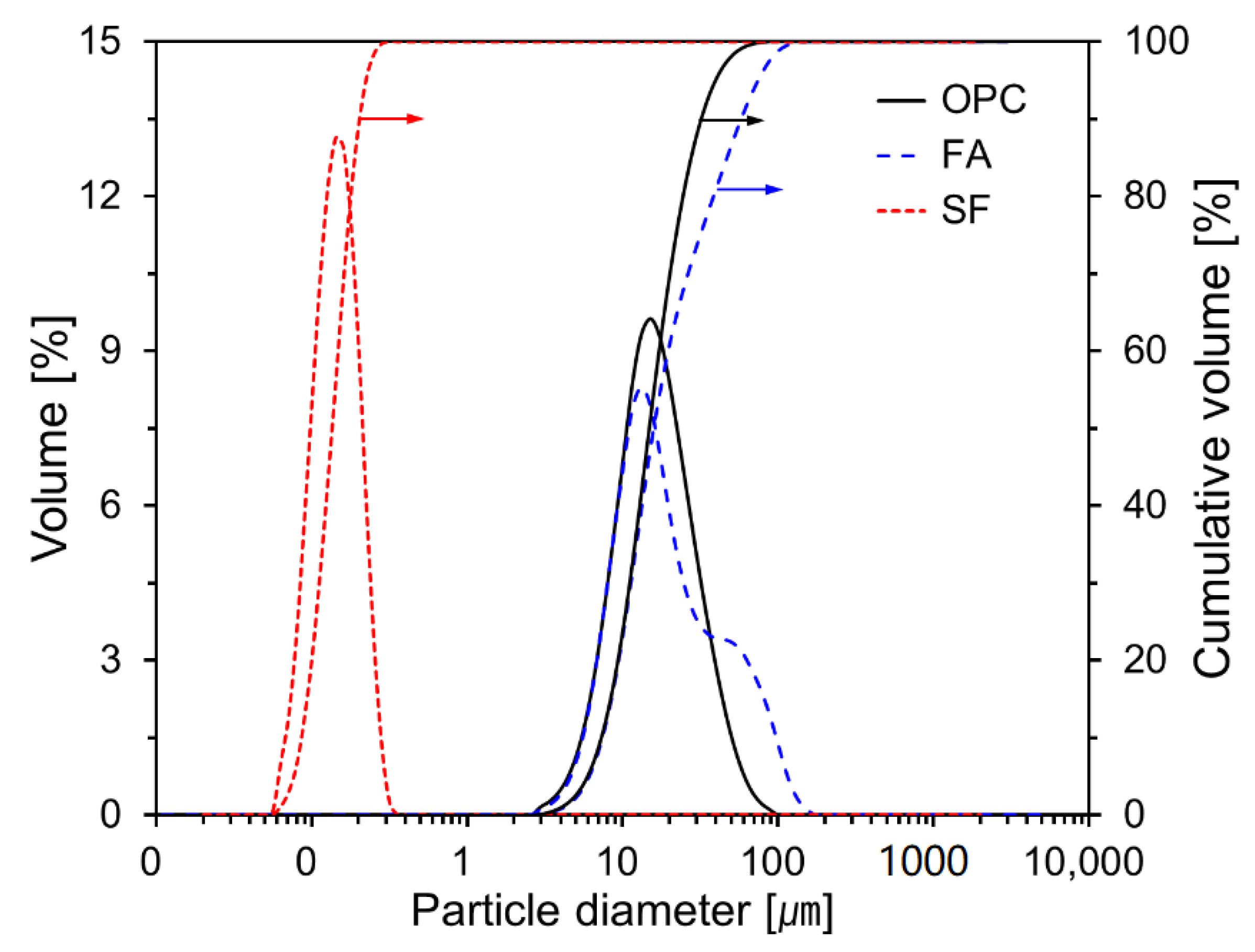

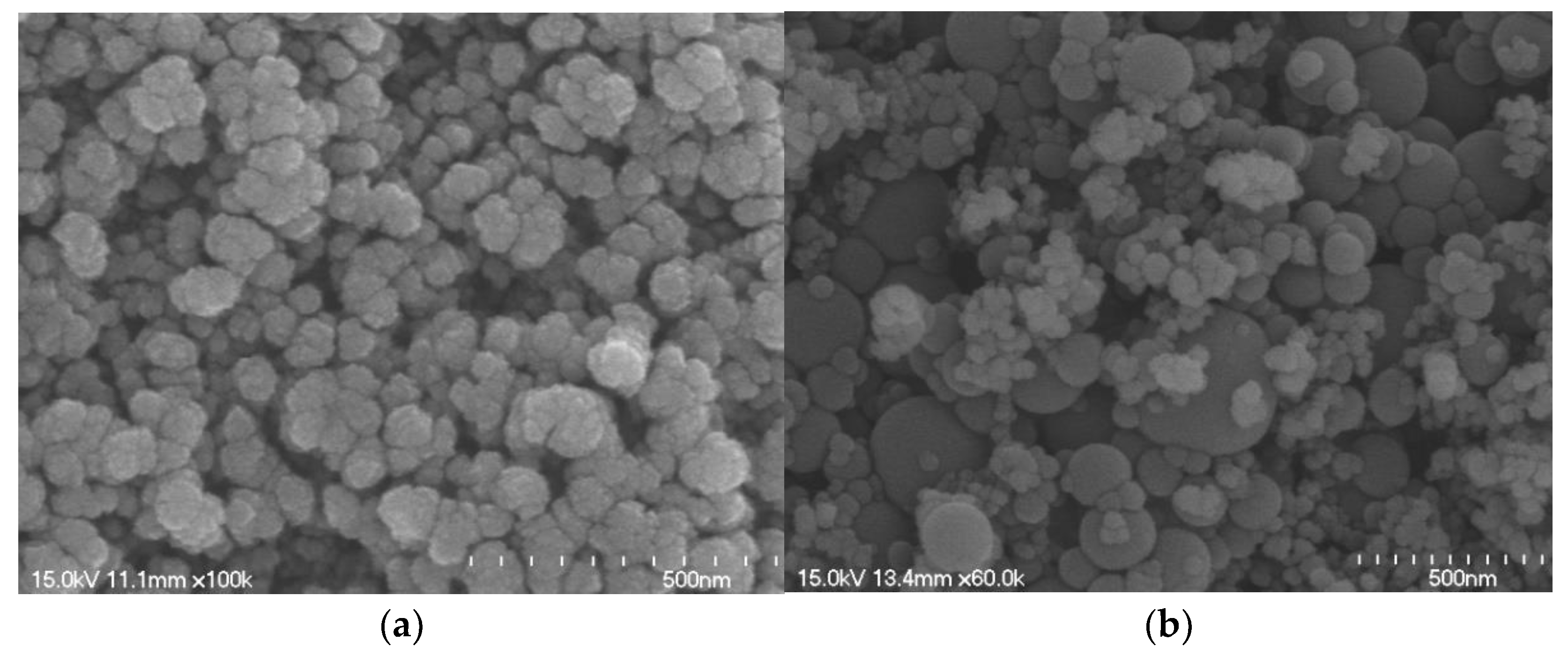

2.1. Materials

2.2. Mix Proportions and Specimen Preparation

2.3. Test Methods

3. Results and Discussion

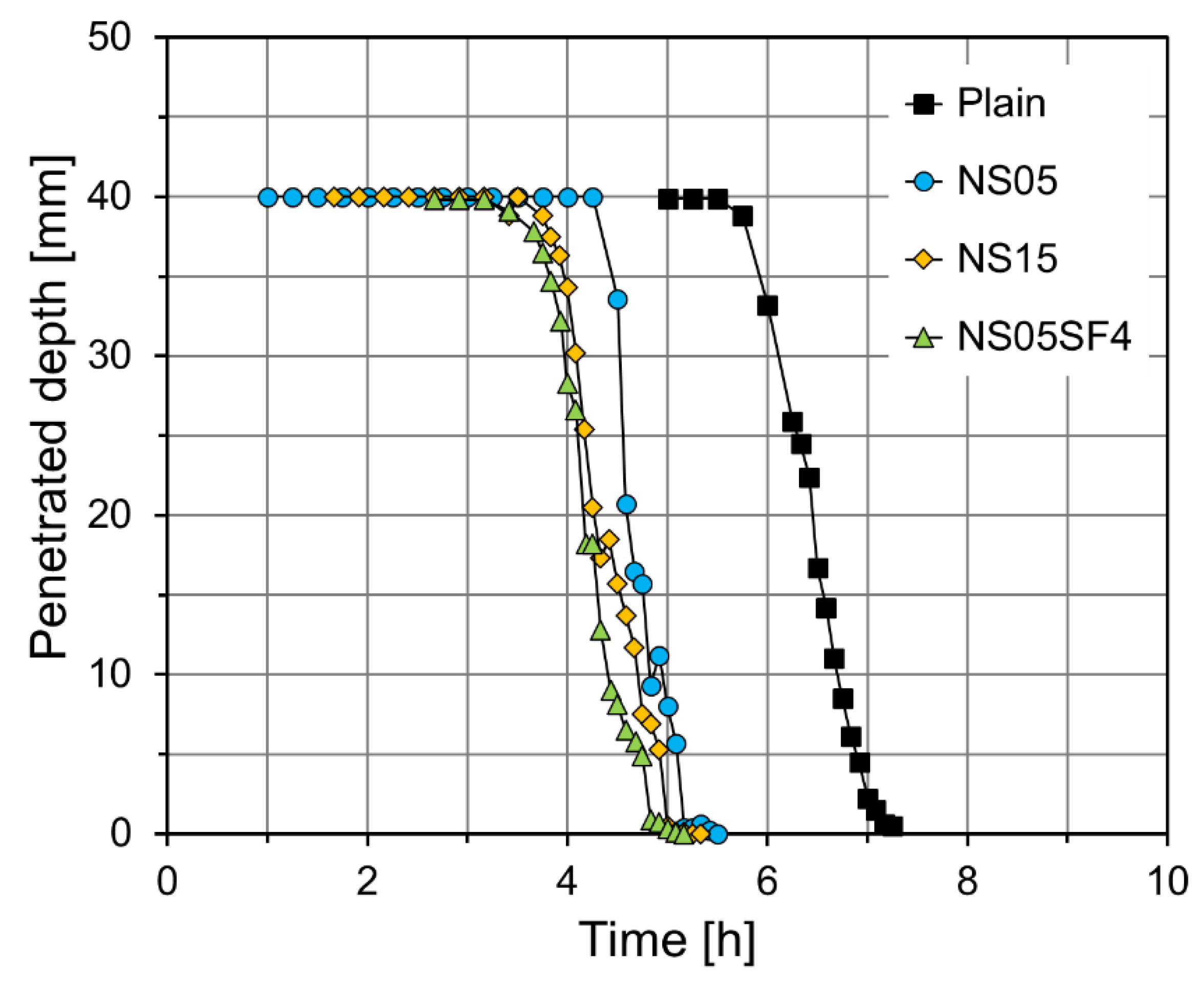

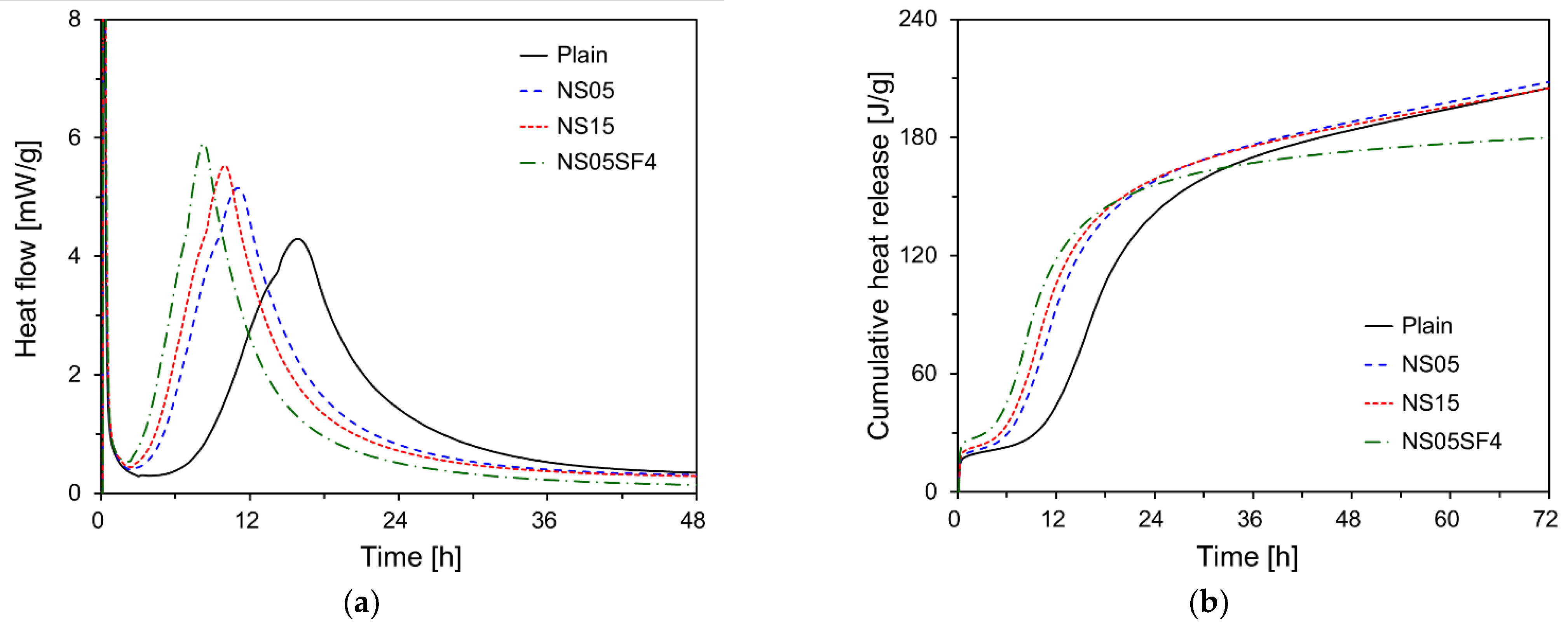

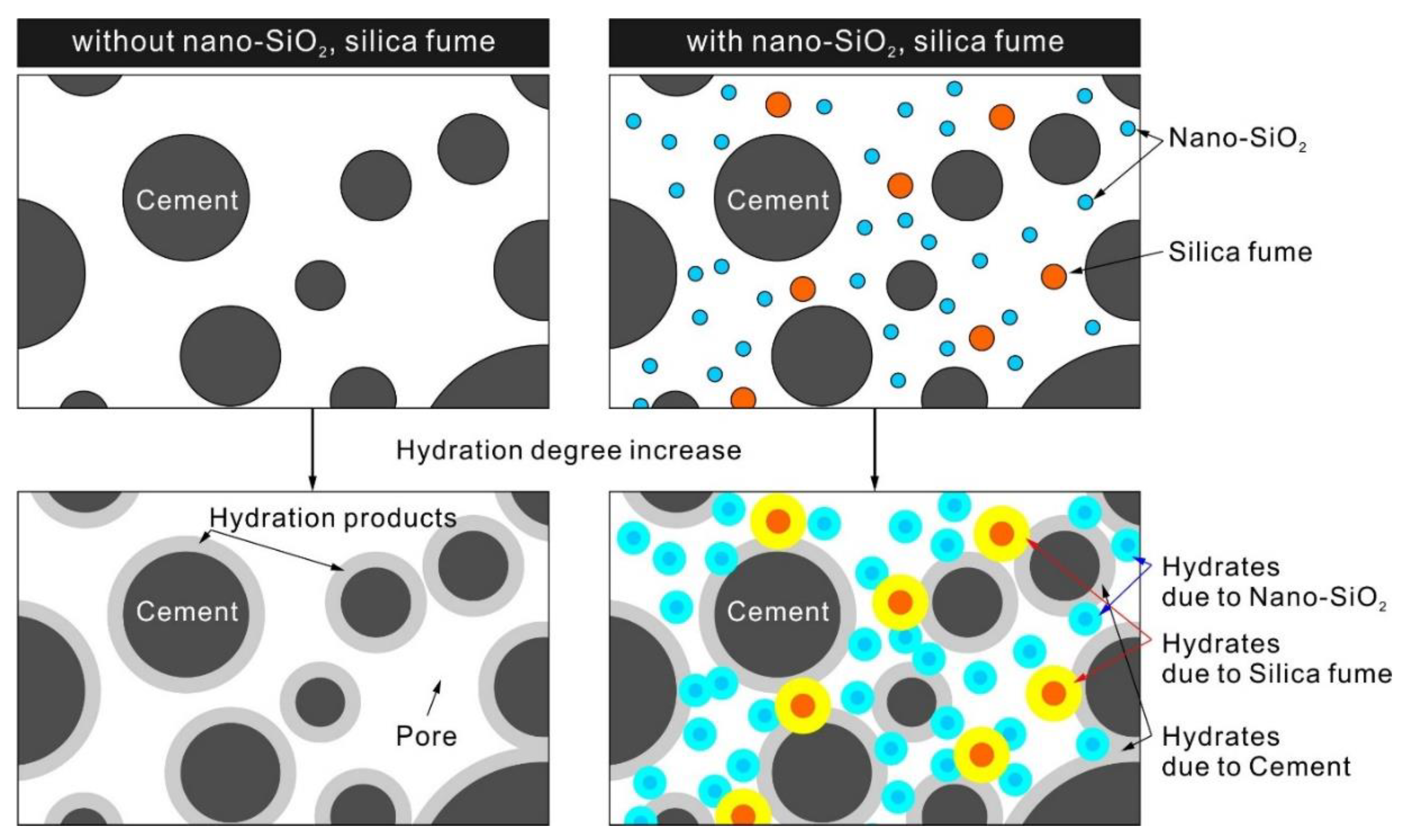

3.1. Hydration Properties

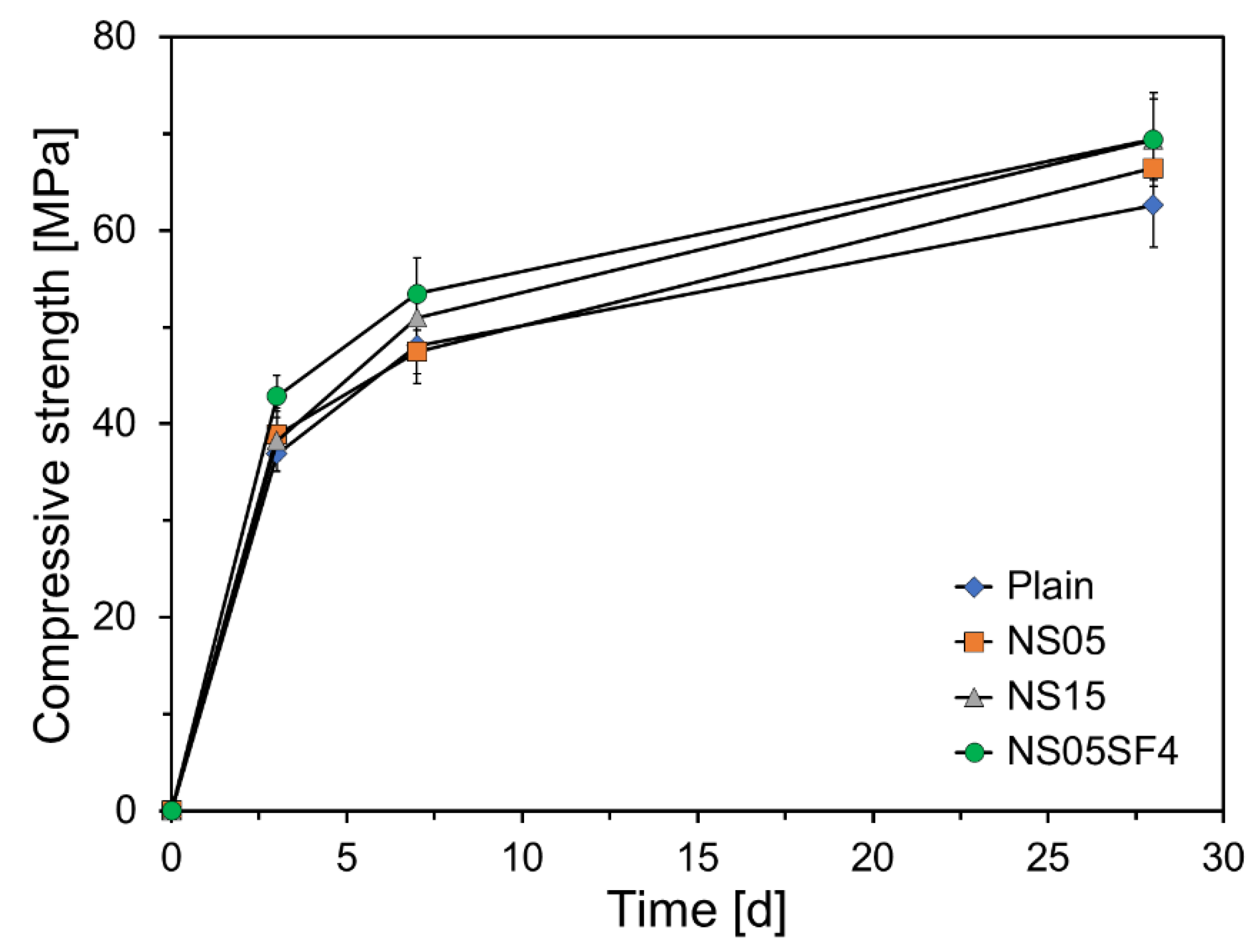

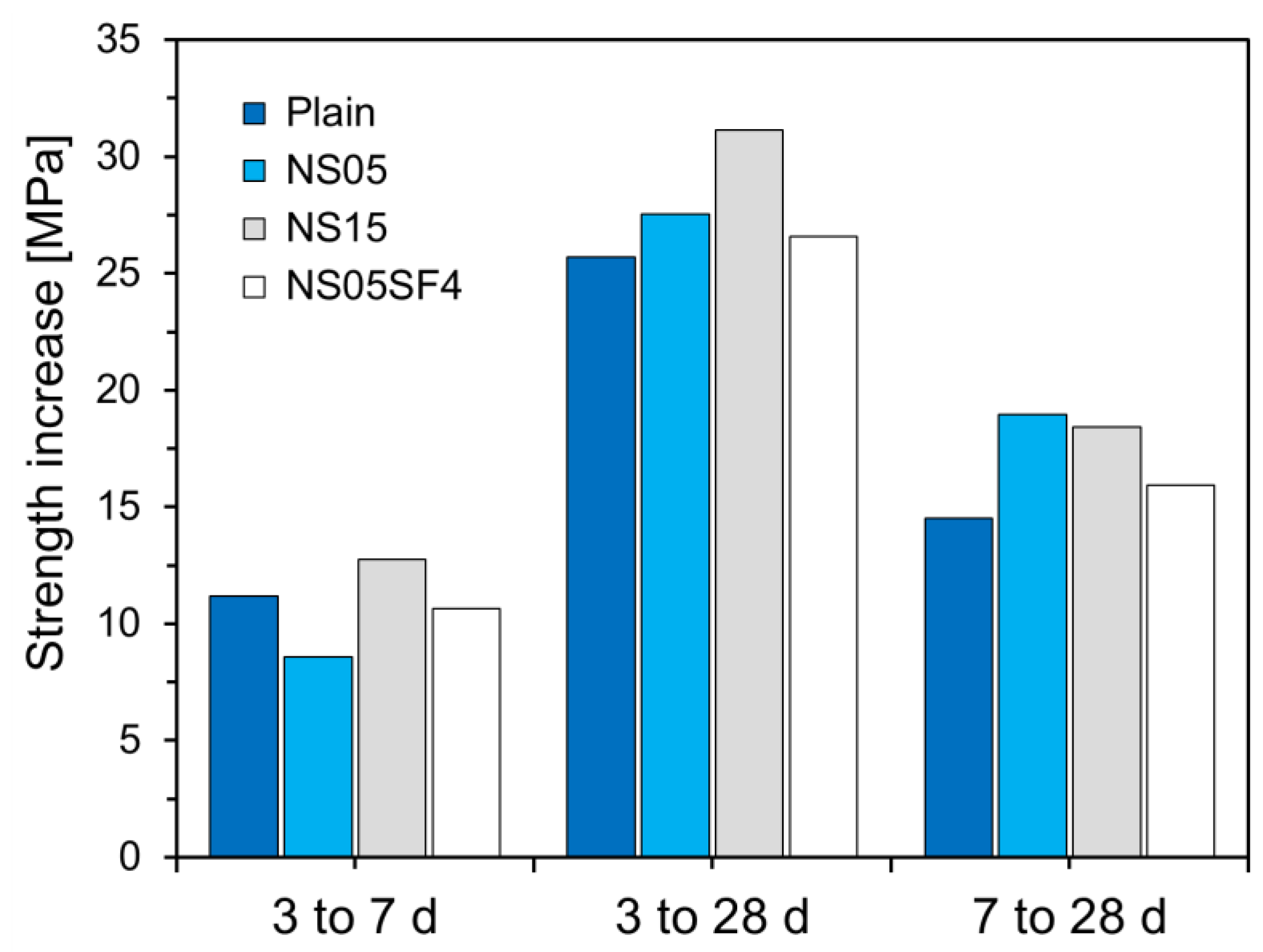

3.2. Compressive Strength

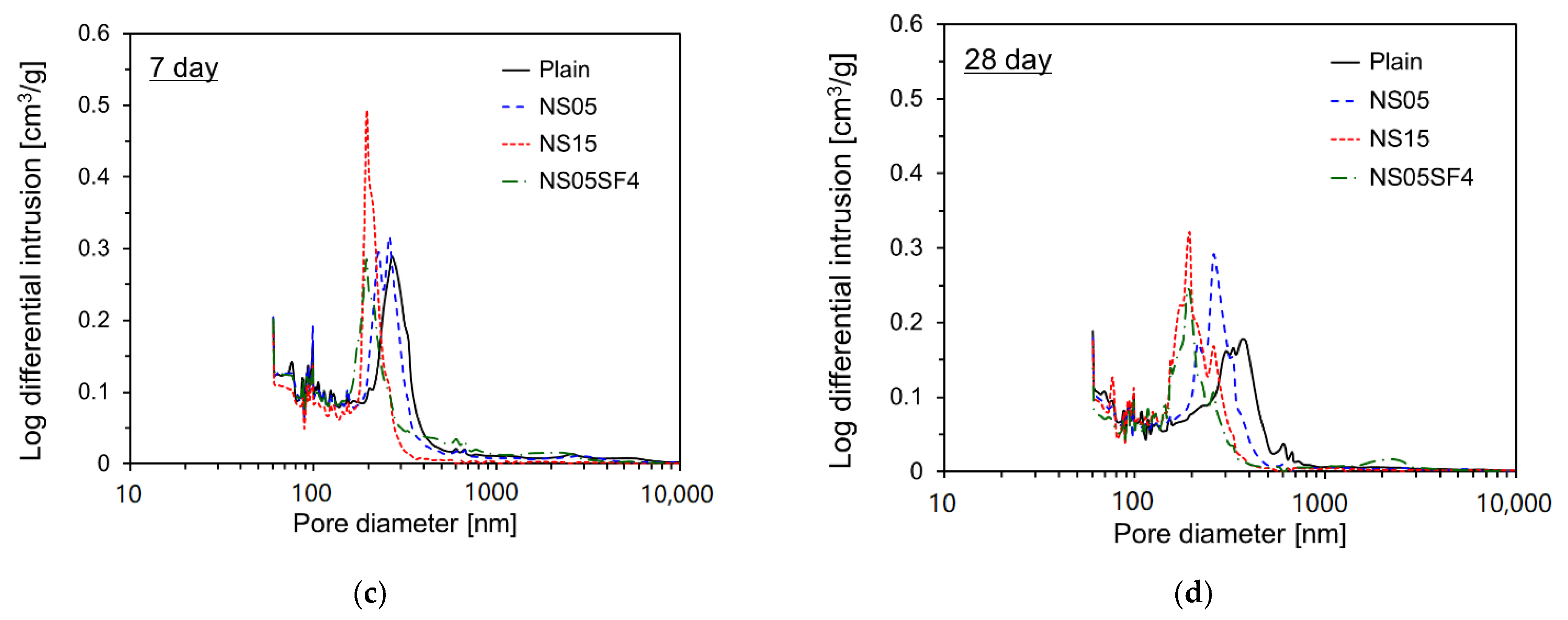

3.3. Microstructure

4. Conclusions

- The initial and final setting times of HVFC were shortened as the NS and SF particle content increased. The setting time was shorter when NS and SF were added together than when NS was used alone. In particular, in the case of the specimen containing the NSF solution with multiple particle sizes, the initial setting time was reduced by 35.5% from that of the plain specimen. This appears to be the result of the NSF solution with multiple size distribution filling the gaps between the cement particles and improving the filling rate.

- The peak occurrence time of hydration heat flow decreased and the magnitude of the peak increased as the NS content increased. The cumulative heat release of all non-plain specimens was higher than that of the plain specimen until 22 h of hydration. This appears to be because NS and SF particles acted as additional nucleation sites for cement hydrates during the initial stage of hydration. In the case of the specimen containing the NSF solution, however, the cumulative heat release became less than that for NS05 or NS15 after approximately 22 h of hydration. These results are similar to the previous studies that reported that the cumulative caloric value decreased after 1 day of age when NS and SF were added together. Therefore, future studies on optimal NS and SF content are needed.

- When NS and SF were mixed, the compressive strength of the cement composite showed a tendency to improve. The compressive strengths of all specimens were higher than that of the Plain at all ages, except for the compressive strength of NS05 at 7 days of age. In addition, the increase in the compressive strength of all non-plain specimens after 7 days was greater than that of the Plain, the largest increase being in the age interval from 7 to 28 days. This appears to be because the pozzolanic reaction was accelerated by NS and SF particles. A quantitative study on the effect of pozzolanic reaction of NS and SF on long-term compressive strength is needed in the future.

- The pore size of the specimens decreased according to NS and SF particle content. After 28 days of age, the pore diameters of the non-plain specimens were substantially less than those of the Plain. This appears to be due to the improvement in pore structure caused by the pozzolanic activity of NS and SF particles during the middle stage of hydration. In addition, the cumulative pore volumes of all specimens decreased after 7 days of age, with the greatest decrease being that at 28 days in the specimen containing the NSF solution.

- NS and SF improved the early strength of cement composites and improved the internal pore structure. In particular, the mechanical properties and pore structure of the cement composite were further improved when NS and SF were mixed together than when NS was used alone. It seems that the properties of the cement composite will vary depending on the amount of NS and SF mixed. Therefore, in order to apply nanomaterials such as NS and SF to construction products, research on the optimum mix design suitable for the characteristics of each construction product is required in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prakash, R.; Raman, S.N.; Subramanian, C.; Divyah, N. 6—Eco-friendly fiber-reinforced concretes. In Handbook of Sustainable Concrete and Industrial Waste Management; Woodhead Publishing: Sawston, UK, 2022; pp. 109–145. [Google Scholar] [CrossRef]

- Agnihotri, A.; Ramana, P.V. GGBS: Fly-Ash evaluation and mechanical properties within high strength concrete. Mater. Today Proc. 2022, 50, 2404–2410. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, R.; Liu, P.; Liu, C.; Sun, L.; Zhang, H. Effects of silica fume on the abrasion resistance of low-heat Portland cement concrete. Constr. Build. Mater. 2022, 329, 127165. [Google Scholar] [CrossRef]

- Sahoo, S.; Das, B.B.; Mustakim, S. Acid, alkali, and chloride resistance of concrete composed of low-carbonated fly ash. J. Mater. Civ. Eng. 2017, 29, 04016242. [Google Scholar] [CrossRef]

- Bagheri, A.R.; Zanganeh, H.; Moalemi, M.M. Mechanical and durability properties of ternary concretes containing silica fume and low reactivity blast furnace slag. Cem. Concr. Compos. 2012, 34, 663–670. [Google Scholar] [CrossRef]

- De Sensale, G.R. Strength development of concrete with rice husk ash. Cem. Concr. Compos. 2006, 28, 158–160. [Google Scholar] [CrossRef]

- Giner, V.T.; Ivorra, S.; Baeza, F.J.; Zornoza, E.; Ferrer, B. Silica fume admixture effect on the dynamic properties of concrete. Constr. Build. Mater. 2011, 25, 3272–3277. [Google Scholar] [CrossRef]

- Roshani, M.M.; Kargar, S.H.; Farhangi, V.; Karakouzian, M. Predicting the Effect of Fly Ash on Concrete’s Mechanical Properties by ANN. Sustainability 2021, 13, 1469. [Google Scholar] [CrossRef]

- Obla, K.H.; Hill, R.L.; Thomas, M.D.A.; Shashiprakash, S.G.; Perebatova, O. Properties of concrete containing ultra-fine fly ash. ACI Mater. J. 2003, 100, 426–433. [Google Scholar] [CrossRef]

- Dai, J.; Wang, Q.; Xie, C.; Xue, Y.; Duan, Y.; Cui, X. The effect of fineness on the hydration activity index of ground granulated blast furnace slag. Materials 2019, 12, 2984. [Google Scholar] [CrossRef] [Green Version]

- Copeland, K.D.; Obla, K.H.; Hill, R.L.; Thomas, M.D.A. Ultra Fine Fly Ash for High Performance Concrete. In Proceedings of the Construction Institute Sessions at ASCE Civil Engineering Conference 2001, Houston, TX, USA, 10–13 October 2001; pp. 166–175. [Google Scholar] [CrossRef]

- Das, B.B.; Singh, D.N.; Pandey, S.P. Rapid chloride ion permeability of OPC- and PPC-based carbonated concrete. J. Mater. Civ. Eng. 2012, 24, 606–611. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Peris-Mora, E.; Amahjour, F. Mechanical treatment of fly ashes: Part IV. Strength development of ground fly ash-cement mortars cured at different temperatures. Cem. Concr. Res. 2000, 30, 543–551. [Google Scholar] [CrossRef]

- Qian, J.; Shi, C.; Wang, Z. Activation of blended cements containing fly ash. Cem. Concr. Res. 2001, 31, 1121–1127. [Google Scholar] [CrossRef]

- Babaian, P.M.; Wang, K.; Mishulovich, A.; Bhattacharja, S.; Shah, S.P. Effect of mechanochemical activation on reactivity of cement kiln dust-fly ash systems. ACI Mater. J. 2003, 100, 55–62. [Google Scholar] [CrossRef]

- Goñi, S.; Guerrero, A.; Luxán, M.P.; Macías, A. Activation of the fly ash pozzolanic reaction by hydrothermal conditions. Cem. Concr. Res. 2003, 33, 1399–1405. [Google Scholar] [CrossRef]

- Wang, K.; Shah, S.P.; Mishulovich, A. Effects of curing temperature and NaOH addition on hydration and strength development of clinker-free CKD-fly ash binders. Cem. Concr. Res. 2004, 34, 299–309. [Google Scholar] [CrossRef]

- Yang, G.; Wu, T.; Fu, C.; Ye, H. Effects of activator dosage and silica fume on the properties of Na2SO4-activated high-volume fly ash. Constr. Build. Mater. 2021, 278, 122346. [Google Scholar] [CrossRef]

- Bondar, D.; Coakley, E. Use of gypsum and CKD to enhance early age strength of High Volume Fly Ash (HVFA) pastes. Constr. Build. Mater. 2014, 71, 93–108. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.G.; Wang, C.M.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Enhancement of barrier properties of cement mortar with graphene nanoplatelet. Cem. Concr. Res. 2015, 76, 10–19. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.; Ou, J. A study on mechanical and pressure-sensitive properties of cement mortar with nanophase materials. Cem. Concr. Res. 2004, 34, 435–438. [Google Scholar] [CrossRef]

- Silvestre, J.; Silvestre, N.; de Brito, J. Review on concrete nanotechnology. Eur. J. Environ. Civ. Eng. 2016, 20, 455–485. [Google Scholar] [CrossRef]

- Wang, Y.; Hughes, P.; Niu, H.; Fan, Y. A new method to improve the properties of recycled aggregate concrete: Composite addition of basalt fiber and nanosilica. J. Clean. Prod. 2019, 236, 117602. [Google Scholar] [CrossRef]

- Yeşilmen, S.; Al-Najjar, Y.; Balav, M.H.; Şahmaran, M.; Yıldırım, G.; Lachemi, M. Nano-modification to improve the ductility of cementitious composites. Cem. Concr. Res. 2015, 76, 170–179. [Google Scholar] [CrossRef]

- Senff, L.; Tobaldi, D.M.; Lucas, S.; Hotza, D.; Ferreira, V.M.; Labrincha, J.A. Formulation of mortars with nano-SiO2 and nano-TiO2 for degradation of pollutants in buildings. Compos. Part B Eng. 2013, 44, 40–47. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Lim, N.H.A.S.; Huseien, G.F.; Amran, M.; Ma, C.K. Effect of the addition of nano glass powder on the compressive strength of high volume fly ash modified concrete. Mater. Today Proc. 2022, 48, 1789–1795. [Google Scholar] [CrossRef]

- Li, G. Properties of high-volume fly ash concrete incorporating nano-SiO2. Cem. Concr. Res. 2004, 34, 1043–1049. [Google Scholar] [CrossRef]

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cem. Concr. Res. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.; Yuan, J.; Ou, J. Microstructure of cement mortar with nano-particles. Compos. Part B Eng. 2004, 35, 185–189. [Google Scholar] [CrossRef]

- Jo, B.W.; Kim, C.H.; Lim, J.H. Characteristics of cement mortar with nano-SiO2 particles. ACI Mater. J. 2007, 104, 404–407. [Google Scholar] [CrossRef]

- Liu, R.; Xiao, H.; Li, H.; Sun, L.; Pi, Z.; Waqar, G.Q.; Du, T.; Yu, L. Effects of nano-SiO2 on the permeability-related properties of cement-based composites with different water/cement ratios. J. Mater. Sci. 2017, 53, 4974–4986. [Google Scholar] [CrossRef]

- Zhang, M.; Li, H. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr. Build. Mater. 2011, 25, 608–616. [Google Scholar] [CrossRef]

- Hou, P.; Cheng, X.; Qian, J.; Zhang, R.; Cao, W.; Shah, S.P. Characteristics of surface-treatment of nano-SiO2 on the transport properties of hardened cement pastes with different water-to-cement ratios. Cem. Concr. Compos. 2015, 55, 26–33. [Google Scholar] [CrossRef]

- Kong, D.; Du, X.; Wei, S.; Zhang, H.; Yang, Y.; Shah, S.P. Influence of nano-silica agglomeration on microstructure and properties of the hardened cement-based materials. Constr. Build. Mater. 2012, 37, 707–715. [Google Scholar] [CrossRef]

- Zhang, M.H.; Islam, J.; Peethamparan, S. Use of nano-silica to increase early strength and reduce setting time of concretes with high volumes of slag. Cem. Concr. Compos. 2012, 34, 650–662. [Google Scholar] [CrossRef]

- Li, X.; Chen, H.; Li, H.; Liu, L.; Lu, Z.; Zhang, T.; Duan, W.H. Integration of form-stable paraffin/nanosilica phase change material composites into vacuum insulation panels for thermal energy storage. Appl. Energy 2015, 159, 601–609. [Google Scholar] [CrossRef]

- Kawashima, S.; Hou, P.; Corr, D.J.; Shah, S.P. Modification of cement-based materials with nanoparticles. Cem. Concr. Compos. 2013, 36, 8–15. [Google Scholar] [CrossRef]

- Hou, P.; Kawashima, S.; Kong, D.; Corr, D.J.; Qian, J.; Shah, S.P. Modification effects of colloidal nanoSiO2 on cement hydration and its gel property. Compos. Part B Eng. 2013, 45, 440–448. [Google Scholar] [CrossRef]

- Hou, P.; Kawashima, S.; Wang, K.; Corr, D.J.; Qian, J.; Shah, S.P. Effects of colloidal nanosilica on rheological and mechanical properties of fly ash–cement mortar. Cem. Concr. Compos. 2013, 35, 12–22. [Google Scholar] [CrossRef] [Green Version]

- Haruehansapong, S.; Pulngern, T.; Chucheepsakul, S. Effect of the particle size of nanosilica on the compressive strength and the optimum replacement content of cement mortar containing nano-SiO2. Constr. Build. Mater. 2014, 50, 471–477. [Google Scholar] [CrossRef]

- Quercia, G.; Spiesz, P.; Hüsken, G.; Brouwers, H.J.H. SCC modification by use of amorphous nano-silica. Cem. Concr. Compos. 2014, 45, 69–81. [Google Scholar] [CrossRef]

- Du, H.; Du, S.; Liu, X. Durability performances of concrete with nano-silica. Constr. Build. Mater. 2014, 73, 705–712. [Google Scholar] [CrossRef]

- Du, H.; Du, S.; Liu, X. Effect of nano-silica on the mechanical and transport properties of lightweight concrete. Constr. Build. Mater. 2015, 82, 114–122. [Google Scholar] [CrossRef]

- Ibrahim, R.K.; Hamid, R.; Taha, M.R. Strength and microstructure of mortar containing nanosilica at high temperature. ACI Mater. J. 2014, 111, 163–170. [Google Scholar] [CrossRef]

- Yu, R.; Tang, P.; Spiesz, P.; Brouwers, H.J.H. A study of multiple effects of nanosilica and hybrid fibres on the properties of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC) incorporating waste bottom ash (WBA). Constr. Build. Mater. 2014, 60, 98–110. [Google Scholar] [CrossRef]

- Oertel, T.; Hutter, F.; Tänzer, R.; Helbig, U.; Sextl, G. Primary particle size and agglomerate size effects of amorphous silica in ultra-high performance concrete. Cem. Concr. Compos. 2013, 37, 61–67. [Google Scholar] [CrossRef]

- Oertel, T.; Helbig, U.; Hutter, F.; Kletti, H.; Sextl, G. Influence of amorphous silica on the hydration in ultra-high performance concrete. Cem. Concr. Res. 2014, 58, 121–130. [Google Scholar] [CrossRef]

- Liu, R.; Xiao, H.; Liu, J.; Guo, S.; Pei, Y. Improving the microstructure of ITZ and reducing the permeability of concrete with various water/cement ratios using nano-silica. J. Mater. Sci. 2019, 54, 444–456. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E.; Portugal, A.; Durães, L. The effect of nanosilica addition on flowability, strength and transport properties of ultra high performance concrete. Mater. Des. 2014, 59, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Effect of nano-silica on the hydration and microstructure development of Ultra-High Performance Concrete (UHPC) with a low binder amount. Constr. Build. Mater. 2014, 65, 140–150. [Google Scholar] [CrossRef]

- Rong, Z.; Sun, W.; Xiao, H.; Jiang, G. Effect of nano-SiO2 particles on the mechanical and microstructural properties of ultra-high performance cementitious composites. Cem. Concr. Compos. 2015, 56, 25–31. [Google Scholar] [CrossRef]

- Cai, Y.; Xuan, D.; Poon, C.S. Effects of nano-SiO2 and glass powder on mitigating alkali-silica reaction of cement glass mortars. Constr. Build. Mater. 2019, 201, 295–302. [Google Scholar] [CrossRef]

- Durgun, M.Y.; Atahan, H.N. Strength, elastic and microstructural properties of SCCs’ with colloidal nano silica addition. Constr. Build. Mater. 2018, 158, 295–307. [Google Scholar] [CrossRef]

- Palla, R.; Karade, S.R.; Mishra, G.; Sharma, U.; Singh, L.P. High strength sustainable concrete using silica nanoparticles. Constr. Build. Mater. 2017, 138, 285–295. [Google Scholar] [CrossRef]

- Durgun, M.Y.; Atahan, H.N. Rheological and fresh properties of reduced fine content self-compacting concretes produced with different particle sizes of nano SiO2. Constr. Build. Mater. 2017, 142, 431–443. [Google Scholar] [CrossRef]

- Lavergne, F.; Belhadi, R.; Carriat, J.; Ben Fraj, A. Effect of nano-silica particles on the hydration, the rheology and the strength development of a blended cement paste. Cem. Concr. Compos. 2019, 95, 42–55. [Google Scholar] [CrossRef]

- Karakouzian, M.; Farhangi, V.; Farani, M.R.; Joshaghani, A.; Zadehmohamad, M.; Ahmadzadeh, M. Mechanical Characteristics of Cement Paste in the Presence of Carbon Nanotubes and Silica Oxide Nanoparticles: An Experimental Study. Materials 2021, 14, 1347. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Li, Q.; Ni, S.; Wang, L.; Yue, G.; Guo, Y. Effect of nano-silica dispersed at different temperatures on the properties of cement-based materials. J. Build. Eng. 2022, 46, 103750. [Google Scholar] [CrossRef]

- Kooshafar, M.; Madani, H. An investigation on the influence of nano silica morphology on the characteristics of cement composites. J. Build. Eng. 2022, 30, 101293. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. Effect of nano-SiO2 particles and curing time on development of fiber-matrix bond properties and microstructure of ultra-high strength concrete. Cem. Concr. Res. 2017, 95, 247–256. [Google Scholar] [CrossRef]

- Chithra, S.; Senthil Kumar, S.R.R.; Chinnaraju, K. The effect of colloidal nano-silica on workability, mechanical and durability properties of high-performance concrete with copper slag as partial fine aggregate. Constr. Build. Mater. 2016, 113, 794–804. [Google Scholar] [CrossRef]

- Bhatta, D.P.; Singla, S.; Garg, R. Experimental investigation on the effect of Nano-silica on the silica fume-based cement composites. Mater. Today Proc. 2022, 57, 2338–2343. [Google Scholar] [CrossRef]

- Nili, M.; Ehsani, A. Investigating the effect of the cement paste and transition zone on strength development of concrete containing nanosilica and silica fume. Mater. Des. 2015, 75, 174–183. [Google Scholar] [CrossRef]

- Xi, B.; Zhou, Y.; Yu, K.; Hu, B.; Huang, X.; Sui, L.; Xing, F. Use of nano-SiO2 to develop a high performance green lightweight engineered cementitious composites containing fly ash cenospheres. J. Clean. Prod. 2020, 262, 121274. [Google Scholar] [CrossRef]

- Wang, X.; Gong, C.; Lei, J.; Dai, J.; Lu, L.; Cheng, X. Effect of silica fume and nano-silica on hydration behavior and mechanism of high sulfate resistance Portland cement. Constr. Build. Mater. 2021, 279, 122481. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Miraldo, S.; Ding, Y.; Labrincha, J.A. Targeting HPC with the help of nanoparticles: An overview. Constr. Build. Mater. 2013, 38, 365–370. [Google Scholar] [CrossRef]

- Chekravarty, D.S.V.S.M.R.K.; Mallika, A.; Sravana, P.; Rao, S. Effect of using nano silica on mechanical properties of normal strength concrete. Mater. Today Proc. 2022, 51, 2573–2578. [Google Scholar] [CrossRef]

- Moon, G.D.; Oh, S.; Choi, Y.C. Effects of the physicochemical properties of fly ash on the compressive strength of high-volume fly ash mortar. Constr. Build. Mater. 2016, 124, 1072–1080. [Google Scholar] [CrossRef]

- Hanif, A.; Parthasarathy, P.; Ma, H.; Fan, T.; Li, Z. Properties improvement of fly ash cenosphere modified cement pastes using nano silica. Cem. Concr. Compos. 2017, 81, 35–48. [Google Scholar] [CrossRef]

- Miao, J.; Lu, L.; Jiang, J. Reinforcement of ultra-low dosage of polycarboxylate ether (PCE) grafted nano-silica sol to the mechanical and durable properties of cement mortar. J. Mater. Res. Tech. 2022, 19, 3464–3657. [Google Scholar] [CrossRef]

| Binder | Chemical Composition (wt.%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | TiO2 | K2O | Na2O | SO3 | LOI | |

| OPC | 63.2 | 20.2 | 4.1 | 3.6 | 2.7 | 0.2 | 1.0 | 0.1 | 1.4 | 0.8 |

| FA | 9.93 | 50.5 | 24.3 | 6.0 | 1.5 | 1.2 | 1.6 | 0.9 | 2.2 | 1.8 |

| SF | 0.2 | 91.6 | 0.4 | 0.9 | 1.2 | – | 1.0 | 0.8 | 0.4 | 0.6 |

| Specimen | W/B | Binder (g) | SP (wt.% by Binder) | |||

|---|---|---|---|---|---|---|

| OPC | FA | NS | SF | |||

| Plain | 0.3 | 100 | 73.42 | 0 | 0 | 0.06 |

| NS05 | 99 | 73.42 | 0.71 | 0 | 0.25 | |

| NS15 | 97 | 73.42 | 2.12 | 0 | 0.62 | |

| NS05SF4 | 91 | 73.42 | 0.71 | 5.72 | 0.30 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, B.-J.; Lee, G.-W.; Choi, Y.-C. Hydration and Mechanical Properties of High-Volume Fly Ash Concrete with Nano-Silica and Silica Fume. Materials 2022, 15, 6599. https://doi.org/10.3390/ma15196599

Kim B-J, Lee G-W, Choi Y-C. Hydration and Mechanical Properties of High-Volume Fly Ash Concrete with Nano-Silica and Silica Fume. Materials. 2022; 15(19):6599. https://doi.org/10.3390/ma15196599

Chicago/Turabian StyleKim, Byung-Jun, Geon-Wook Lee, and Young-Cheol Choi. 2022. "Hydration and Mechanical Properties of High-Volume Fly Ash Concrete with Nano-Silica and Silica Fume" Materials 15, no. 19: 6599. https://doi.org/10.3390/ma15196599