Microstructural Origin of the High-Energy Storage Performance in Epitaxial Lead-Free Ba(Zr0.2Ti0.8)O3 Thick Films

Abstract

:1. Introduction

2. Materials and Methods

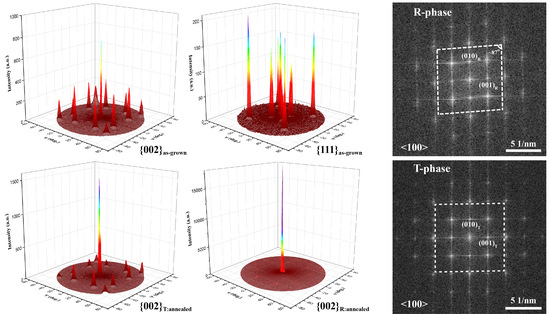

3. Results

4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shrout, T.R.; Zhang, S.J. Lead-free piezoelectric ceramics: Alternatives for PZT? J. Electroceramics 2007, 19, 113–126. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Lin, D.; Su, Y.; Zhang, L.; Liu, W. Enhanced dielectric, ferroelectric, and optical properties in rare earth elements doped PMN-PT thin films. J. Adv. Ceram. 2021, 10, 98–107. [Google Scholar] [CrossRef]

- Dash, S.; Pradhan, D.K.; Kumari, S.; Ravikant; Rahaman, M.M.; Cazorla, C.; Brajesh, K.; Kumar, A.; Thomas, R.; Rack, P.D.; et al. Enhanced ferroelectric and piezoelectric properties of BCT-BZT at the morphotropic phase boundary driven by the coexistence of phases with different symmetries. Phys. Rev. B 2021, 104, 224105. [Google Scholar] [CrossRef]

- Cui, H.; Hensleigh, R.; Yao, D.; Maurya, D.; Kumar, P.; Kang, M.G.; Priya, S.; Zheng, X.R. Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nat. Mater. 2019, 18, 234–241. [Google Scholar] [CrossRef]

- Liu, W.; Ren, X. Large piezoelectric effect in Pb-free ceramics. Phys. Rev. Lett. 2009, 103, 257602. [Google Scholar] [CrossRef]

- Fu, H.; Cohen, R.E. Polarization rotation mechanism for ultrahigh electromechanical response in single-crystal piezoelectrics. Nature 2000, 403, 281–283. [Google Scholar] [CrossRef] [PubMed]

- Roytburd, A.L.; Ouyang, J.; Artemev, A. Polydomain structures in ferroelectric and ferroelastic epitaxial films. J. Phys. Condens. Matter. 2017, 29, 163001. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Ouyang, J.; Roytburd, A.L. Effect of thickness-mediated misfit strain on the heterophase polydomain structure of epitaxial BiFeO3 films. Scr. Mater. 2012, 66, 499–502. [Google Scholar] [CrossRef]

- Kalyani, A.K.; Brajesh, K.; Senyshyn, A.; Ranjan, R. Orthorhombic-tetragonal phase coexistence and enhanced piezo-response at room temperature in Zr, Sn, and Hf modified BaTiO3. Appl. Phys. Lett. 2014, 104, 252906. [Google Scholar] [CrossRef]

- Pan, H.; Li, F.; Liu, Y.; Zhang, Q.; Wang, M.; Lan, S.; Zheng, Y.; Ma, J.; Gu, L.; Shen, Y.; et al. Ultrahigh-energy density lead-free dielectric films via polymorphic nanodomain design. Science 2019, 365, 578–582. [Google Scholar] [CrossRef] [PubMed]

- Pan, H.; Ma, J.; Ma, J.; Zhang, Q.; Liu, X.; Guan, B.; Gu, L.; Zhang, X.; Zhang, Y.-J.; Li, L.; et al. Giant energy density and high efficiency achieved in bismuth ferrite-based film capacitors via domain engineering. Nat. Commun. 2018, 9, 1813. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.X.; Xiang, B.; He, Q.; Seidel, J.; Zeches, R.J.; Yu, P.; Yang, S.Y.; Wang, C.H.; Chu, Y.H.; Martin, L.W.; et al. Large field-induced strains in a lead-free piezoelectric material. Nat. Nanotechnol. 2011, 6, 98–102. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Sun, X.; Kang, L.; Zhang, Y.; Yu, Z.; Ouyang, J.; Pan, W. Microstructural and electrical characteristics of epitaxial BiFeO3 thick films sputtered at different Ar/O2 flow ratios. Cryst. Eng. Comm. 2016, 18, 4604–4612. [Google Scholar] [CrossRef]

- Ouyang, J.; Zhang, W.; Huang, X.; Roytburd, A.L. Thermodynamics of formation of tetragonal and rhombohedral heterophase polydomains in epitaxial ferroelectric thin films. Acta Mater. 2011, 59, 3779–3791. [Google Scholar] [CrossRef]

- Fu, Z.; Yin, Z.G.; Chen, N.F.; Zhang, X.W.; Zhao, Y.J.; Bai, Y.M.; Chen, Y.; Wang, H.-H.; Zhang, X.L.; Wu, J.L. Tetragonal-tetragonal-monoclinic-rhombohedral transition: Strain relaxation of heavily compressed BiFeO3 epitaxial thin films. Appl. Phys. Lett. 2014, 104, 052908. [Google Scholar] [CrossRef]

- Zeches, R.J.; Rossell, M.D.; Zhang, J.X.; Hatt, A.J.; He, Q.; Yang, C.H.; Kumar, A.; Wang, C.H.; Melville, A.; Adamo, C.; et al. A strain-driven morphotropic phase boundary in BiFeO3. Science 2009, 326, 977–980. [Google Scholar] [CrossRef]

- Kawahara, Y.; Ujimoto, K.; Yoshimura, T.; Fujimura, N. Control of Crystal Structure of BiFeO3 Epitaxial Thin Films by Adjusting Growth Conditions and Piezoelectric Properties. Jpn. J. Appl. Phys. 2012, 51, 09LB04. [Google Scholar] [CrossRef]

- Kobayashi, S.; Inoue, K.; Kato, T.; Ikuhara, Y.; Yamamoto, T. Multiphase nanodomains in a strained BaTiO3 film on a GdScO3 substrate. J. Appl. Phys. 2018, 123, 064102. [Google Scholar] [CrossRef]

- Sheng, G.; Zhang, J.X.; Li, Y.L.; Choudhury, S.; Jia, Q.X.; Liu, Z.K.; Chen, L.Q. Misfit strain–misfit strain diagram of epitaxial BaTiO3 thin films: Thermodynamic calculations and phase-field simulations. Appl. Phys. Lett. 2008, 93, 23290. [Google Scholar] [CrossRef] [Green Version]

- Peng, W.; Zorn, J.A.; Mun, J.; Sheeraz, M.; Roh, C.J.; Pan, J.; Wang, B.; Guo, K.; Ahn, C.W.; Zhang, Y.; et al. Constructing Polymorphic Nanodomains in BaTiO3 Films via Epitaxial Symmetry Engineering. Adv. Funct. Mater. 2020, 30, 1910569. [Google Scholar] [CrossRef]

- Yokoyama, S.; Honda, Y.; Morioka, H.; Oikawa, T.; Funakubo, H.; Iijima, T.; Matsuda, H.; Saito, K. Large piezoelectric response in (111)-oriented epitaxial Pb(Zr,Ti)O3 films consisting of mixed phases with rhombohedral and tetragonal symmetry. Appl. Phys. Lett. 2003, 83, 2408–2410. [Google Scholar] [CrossRef]

- Li, F.; Lin, D.; Chen, Z.; Cheng, Z.; Wang, J.; Li, C.; Xu, Z.; Huang, Q.; Liao, X.; Chen, L.-Q.; et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 2018, 17, 349–354. [Google Scholar] [CrossRef]

- Cheng, H.; Ouyang, J.; Zhang, Y.X.; Ascienzo, D.; Li, Y.; Zhao, Y.Y.; Ren, Y. Demonstration of ultra-high recyclable energy densities in domain-engineered ferroelectric films. Nat. Commun. 2017, 8, 1999. [Google Scholar] [CrossRef]

- Dong, L.; Stone, D.S.; Lakes, R.S. Enhanced dielectric and piezoelectric properties of xBaZrO3-(1−x)BaTiO3 ceramics. J. Appl. Phys. 2012, 111, 084107. [Google Scholar] [CrossRef]

- Wang, J.-J.; Su, Y.-J.; Wang, B.; Ouyang, J.; Ren, Y.-H.; Chen, L.-Q. Strain engineering of dischargeable energy density of ferroelectric thin-film capacitors. Nano Energy 2020, 72, 104665. [Google Scholar] [CrossRef]

- Ren, Y.; Cheng, H.; Ouyang, J.; Kurt, O.; Wang, J.; Zhang, Q.; Zhao, Y.; Gu, L.; Chen, L.-Q. Bimodal polymorphic nanodomains in ferroelectric films for giant energy storage. Energy Storage Mater. 2022, 48, 306–313. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, J.; Cheng, H.; Chen, N.; Yan, P.; Ouyang, J. Low thermal budget lead zirconate titanate thick films integrated on Si for piezo-MEMS applications. Microelectron. Eng. 2020, 219, 111145. [Google Scholar] [CrossRef]

- Nagarajan, V.; Roytburd, A.; Stanishevsky, A.; Prasertchoung, S.; Zhao, T.; Chen, L.; Melngailis, J.; Auciello, O.; Ramesh, R. Dynamics of ferroelastic domains in ferroelectric thin films. Nat. Mater. 2003, 2, 43–47. [Google Scholar] [CrossRef]

- Ren, Y.; Kurt, O.; Cheng, H.; Le, T.; Greenbaum, S.; Ouyang, J. Electrical Field Driven Structural Evolutions of Polymorphic Nanodomains in Ferroelectric Ba(Zr,Ti)O3 Films. Adv. Electron. Mater. 2022, 2200465. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouyang, J.; Wang, X.; Shao, C.; Cheng, H.; Zhu, H.; Ren, Y. Microstructural Origin of the High-Energy Storage Performance in Epitaxial Lead-Free Ba(Zr0.2Ti0.8)O3 Thick Films. Materials 2022, 15, 6778. https://doi.org/10.3390/ma15196778

Ouyang J, Wang X, Shao C, Cheng H, Zhu H, Ren Y. Microstructural Origin of the High-Energy Storage Performance in Epitaxial Lead-Free Ba(Zr0.2Ti0.8)O3 Thick Films. Materials. 2022; 15(19):6778. https://doi.org/10.3390/ma15196778

Chicago/Turabian StyleOuyang, Jun, Xianke Wang, Changtao Shao, Hongbo Cheng, Hanfei Zhu, and Yuhang Ren. 2022. "Microstructural Origin of the High-Energy Storage Performance in Epitaxial Lead-Free Ba(Zr0.2Ti0.8)O3 Thick Films" Materials 15, no. 19: 6778. https://doi.org/10.3390/ma15196778

APA StyleOuyang, J., Wang, X., Shao, C., Cheng, H., Zhu, H., & Ren, Y. (2022). Microstructural Origin of the High-Energy Storage Performance in Epitaxial Lead-Free Ba(Zr0.2Ti0.8)O3 Thick Films. Materials, 15(19), 6778. https://doi.org/10.3390/ma15196778