The Effect of Repeated Pressing on the Flexural Strength, Color Stability, Vickers Hardness, and Surface Topography of Heat-Pressed Lithium Disilicate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

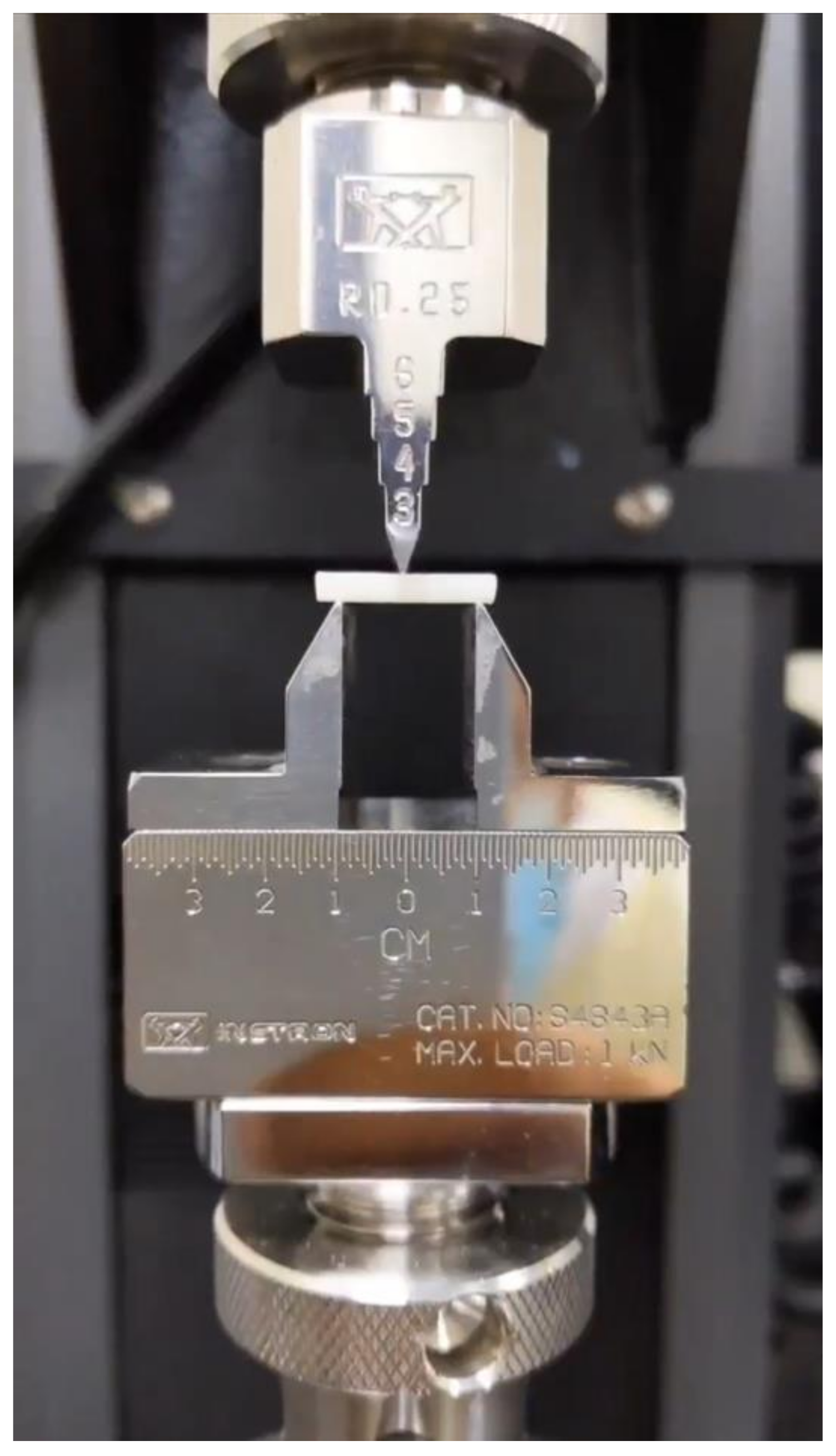

2.2. Flexural Strength Testing

2.3. Color Stability Evaluation

2.4. Vickers Hardness Test

2.5. Scanning Electron Microscopy (SEM)

2.6. Statistical Analysis

3. Results

3.1. Flexural Strength and Vickers Hardness

3.2. Color Stability (∆E)

3.3. Scanning Electron Microscopy (SEM)

4. Discussion

5. Conclusions

- There was no significant difference in the mechanical properties (flexural strength and Vickers microhardness) between the first pressed lithium disilicate group (IPS e.max Press) and the repressed groups.

- Although the repressed groups tended to be darker and more bluish, the ΔE values after two repeated pressing cycles were within the clinically acceptable range.

- The SEM images showed that the first press group presented packed interlocked crystals of lithium disilicate, while the repressed groups showed obvious larger and less closely packed crystals.

- These results may support the reuse of pressed lithium disilicate for economical purposes, but further clinical evaluation should be conducted to confirm these findings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Zhang, Y.; Kelly, J.R. Dental Ceramics for Restoration and Metal Veneering. Dent. Clin. N. Am. 2017, 61, 797–819. [Google Scholar] [CrossRef]

- Giordano, R.; McLaren, E.A. Ceramics overview: Classification by microstructure and processing methods. Compend. Contin. Educ. Dent. 2010, 31, 682–684. [Google Scholar]

- Pekkan, G.; Pekkan, K.; Bayindir, B.; Özcan, M.; Karasu, B. Factors affecting the translucency of monolithic zirconia ceramics: A review from materials science perspective. Dent. Mater. J. 2020, 39, 1–8. [Google Scholar] [CrossRef]

- Albakry, M.; Guazzato, M.; Swain, M. Biaxial Flexural Strength and Microstructure Changes of Two Recycled Pressable Glass Ceramics. J. Prosthodont. 2004, 13, 141–149. [Google Scholar] [CrossRef]

- Zarone, F.; Di Mauro, M.I.; Ausiello, P.; Ruggiero, G.; Sorrentino, R. Current status on lithium disilicate and zirconia: A narrative review. BMC Oral Health 2019, 19, 134. [Google Scholar] [CrossRef]

- Rosenstiel, S.F.; Land, M.F. Contemporary Fixed Prosthodontics-E-Book; Elsevier Health Sciences: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Lien, W.; Roberts, H.W.; Platt, J.A.; Vandewalle, K.S.; Hill, T.J.; Chu, T.-M.G. Microstructural evolution and physical behavior of a lithium disilicate glass–ceramic. Dent. Mater. 2015, 31, 928–940. [Google Scholar] [CrossRef] [PubMed]

- Fabbri, G.; Zarone, F.; Dellificorelli, G.; Cannistraro, G.; De Lorenzi, M.; Mosca, A.; Sorrentino, R. Clinical Evaluation of 860 Anterior and Posterior Lithium Disilicate Restorations: Retrospective Study with a Mean Follow-up of 3 Years and a Maximum Observational Period of 6 Years. Int. J. Periodontics Restor. Dent. 2014, 34, 165–177. [Google Scholar] [CrossRef] [PubMed]

- Huettig, F.; Gehrke, U.P. Early complications and performance of 327 heat-pressed lithium disilicate crowns up to five years. J. Adv. Prosthodont. 2016, 8, 194–200. [Google Scholar] [CrossRef] [PubMed]

- Chung, K.-H.; Liao, J.-H.; Duh, J.-G.; Chan, D.C.-N. The effects of repeated heat-pressing on properties of pressable glass-ceramics. J. Oral Rehabil. 2009, 36, 132–141. [Google Scholar] [CrossRef]

- Albakry, M.; Guazzato, M.; Swain, M.V. Influence of hot pressing on the microstructure and fracture toughness of two pressable dental glass-ceramics. J. Biomed. Mater. Res. 2004, 71B, 99–107. [Google Scholar] [CrossRef]

- Gorman, C.M.; Horgan, K.; Dollard, R.P.; Stanton, K.T. Effects of repeated processing on the strength and microstructure of a heat-pressed dental ceramic. J. Prosthet. Dent. 2014, 112, 1370–1376. [Google Scholar] [CrossRef]

- Tang, X.; Tang, C.; Su, H.; Luo, H.; Nakamura, T.; Yatani, H. The effects of repeated heat-pressing on the mechanical properties and microstructure of IPS e.max Press. J. Mech. Behav. Biomed. Mater. 2014, 40, 390–396. [Google Scholar] [CrossRef]

- Salem, S.K.; Shalaby, M.M. Fracture strength and marginal gap of re-Pressed ips e.max press crowns with different concentrations. Egypt. Dent. J. 2019, 65, 1939–1948. [Google Scholar] [CrossRef]

- Della Bona, A.; Mecholsky, J.J., Jr.; Anusavice, K.J. Fracture behavior of lithia disilicate- and leucite-based ceramics. Dent. Mater. 2004, 20, 956–962. [Google Scholar] [CrossRef]

- Guazzato, M.; Albakry, M.; Ringer, S.P.; Swain, M.V. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part I. Pressable and alumina glass-infiltrated ceramics. Dent. Mater. 2004, 20, 441–448. [Google Scholar] [CrossRef]

- Al-Thobity, A.M.; Alsalman, A. Flexural properties of three lithium disilicate materials: An in vitro evaluation. Saudi Dent. J. 2021, 33, 620–627. [Google Scholar] [CrossRef]

- Fonzar, R.F.; Carrabba, M.; Sedda, M.; Ferrari, M.; Goracci, C.; Vichi, A. Flexural resistance of heat-pressed and CAD-CAM lithium disilicate with different translucencies. Dent. Mater. 2017, 33, 63–70. [Google Scholar] [CrossRef]

- Albakry, M.; Guazzato, M.; Swain, M. Biaxial flexural strength, elastic moduli, and X-ray diffraction characterization of three pressable all-ceramic materials. J. Prosthet. Dent. 2003, 89, 374–380. [Google Scholar] [CrossRef]

- Denry, I.L.; Holloway, J.A. Effect of post-processing heat treatment on the fracture strength of a heat-pressed dental ceramic. J. Biomed. Mater. Res. B Appl. Biomater. 2004, 68, 174–179. [Google Scholar] [CrossRef]

- Wang, F.; Chai, Z.; Deng, Z.; Gao, J.; Wang, H.; Chen, J. Effect of heat-pressing temperature and holding time on the microstructure and flexural strength of lithium disilicate glass-ceramics. PLoS ONE 2015, 10, e0126896. [Google Scholar]

- Höland, W.; Schweiger, M.; Frank, M.; Rheinberger, V. A comparison of the microstructure and properties of the IPS Empress 2 and the IPS Empress glass-ceramics. J. Biomed. Mater. Res. 2000, 53, 297–303. [Google Scholar] [CrossRef]

- Vivadent, I. IPS e.max the Future of All-Ceramic Dentistry. 2009. Available online: https://www.thaidentalcenter.com/img/treatments/veneers/EmaxMaterialScience.pdf (accessed on 1 March 2020).

- Martin, J.W.; Doherty, R.D.; Cantor, B. Stability of Microstructure in Metallic Systems; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar] [CrossRef]

- Bühler-Zemp, P.; Völkel, T.; Fischer, K. Scientific Documentation IPS e. max® Press; Ivoclar Vivadent: Schaan, Liechtenstein, 2011; pp. 1–40. [Google Scholar]

- Aurélio, I.L.; Dorneles, L.S.; May, L.G. Extended glaze firing on ceramics for hard machining: Crack healing, residual stresses, optical and microstructural aspects. Dent. Mater. 2017, 33, 226–240. [Google Scholar] [CrossRef]

- Ragain, J.C., Jr.; Johnston, W.M. Color acceptance of direct dental restorative materials by human observers. Color Res. Appl. 2000, 25, 278–285. [Google Scholar] [CrossRef]

- Ruyter, I.; Nilner, K.; Möller, B. Color stability of dental composite resin materials for crown and bridge veneers. Dent. Mater. 1987, 3, 246–251. [Google Scholar] [CrossRef]

- Şahin, V.; Gülgezen Aydın, H.; Akyel, A.; Uludağ, B.C. The effect of repetitive firings on the color of an alumina ceramic system with varying ceramic shade and thickness. J. Esthet. Restor. Dent. 2019, 31, 471–477. [Google Scholar] [CrossRef]

- ElNaggar, Y.M.; Hammad, I.A.; Azer, A.S. Effect of additional pressing on the color and translucency of pressable ceramic materials: An in vitro study. J. Prosthet. Dent. 2021, 126, 588.e1–588.e5. [Google Scholar] [CrossRef]

| 1st Press | 2nd Press | 3rd Press | p-Value | |

|---|---|---|---|---|

| Flexural Strength (MPa) | 269.85 ± 30.48 | 266.66 ± 27.12 | 253.16 ± 22.18 | 0.283 |

| Vickers Hardness (HV) | 570.07 ± 20.63 | 563.32 ± 19.08 | 554.97 ± 15.74 | 0.220 |

| Coordinate | 1st Press | 2nd Press | 3rd Press |

|---|---|---|---|

| L | 66.10 ± 0.50 * | 63.96 ± 0.77 | 64.0 ± 0.42 |

| a | −1.72 ± 0.05 * | −1.58 ± 0.11 | −1.58 ± 0.06 |

| b | 2.50 ± 0.22 * | 1.83 ± 0.25 | 2.16 ± 0.16 |

| Pair | t-Value | Degree of Freedom | T Critical Value | p-Value |

|---|---|---|---|---|

| L1–L2 | 5.24 | 7 | 2.37 | 0.001 |

| L1–L3 | 7.19 | 8 | 2.30 | <0.001 |

| L2–L3 | −0.11 | 6 | 2.45 | 0.907 |

| a1–a2 | −2.52 | 6 | 2.45 | 0.048 |

| a1–a3 | −3.75 | 8 | 2.30 | 0.006 |

| a2–a3 | 0.00 | 6 | 2.45 | 1.000 |

| b1–b2 | 4.58 | 8 | 2.30 | 0.002 |

| b1–b2 | 3.23 | 7 | 2.37 | 0.014 |

| b2–b3 | −2.17 | 7 | 2.37 | 0.06 |

| 1st Press–2nd Press | 1st Press–3rd Press | t-Value | Degree of Freedom | p-Value | |

|---|---|---|---|---|---|

| ∆E | 2.04 ± 1.27 | 2.14 ± 0.77 | −0.15 | 8 | 0.887 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

AbuHaimed, T.S.; Alzahrani, S.J.; Farsi, S.A.; AL-Turki, L.E.; Hajjaj, M.S. The Effect of Repeated Pressing on the Flexural Strength, Color Stability, Vickers Hardness, and Surface Topography of Heat-Pressed Lithium Disilicate. Materials 2022, 15, 6787. https://doi.org/10.3390/ma15196787

AbuHaimed TS, Alzahrani SJ, Farsi SA, AL-Turki LE, Hajjaj MS. The Effect of Repeated Pressing on the Flexural Strength, Color Stability, Vickers Hardness, and Surface Topography of Heat-Pressed Lithium Disilicate. Materials. 2022; 15(19):6787. https://doi.org/10.3390/ma15196787

Chicago/Turabian StyleAbuHaimed, Tariq S., Saeed J. Alzahrani, Sami A. Farsi, Lulwa E. AL-Turki, and Maher S. Hajjaj. 2022. "The Effect of Repeated Pressing on the Flexural Strength, Color Stability, Vickers Hardness, and Surface Topography of Heat-Pressed Lithium Disilicate" Materials 15, no. 19: 6787. https://doi.org/10.3390/ma15196787