Influence of Friction Riveting Parameters on the Dissimilar Joint Formation and Strength

Abstract

1. Introduction

2. Materials and Methods

3. Results

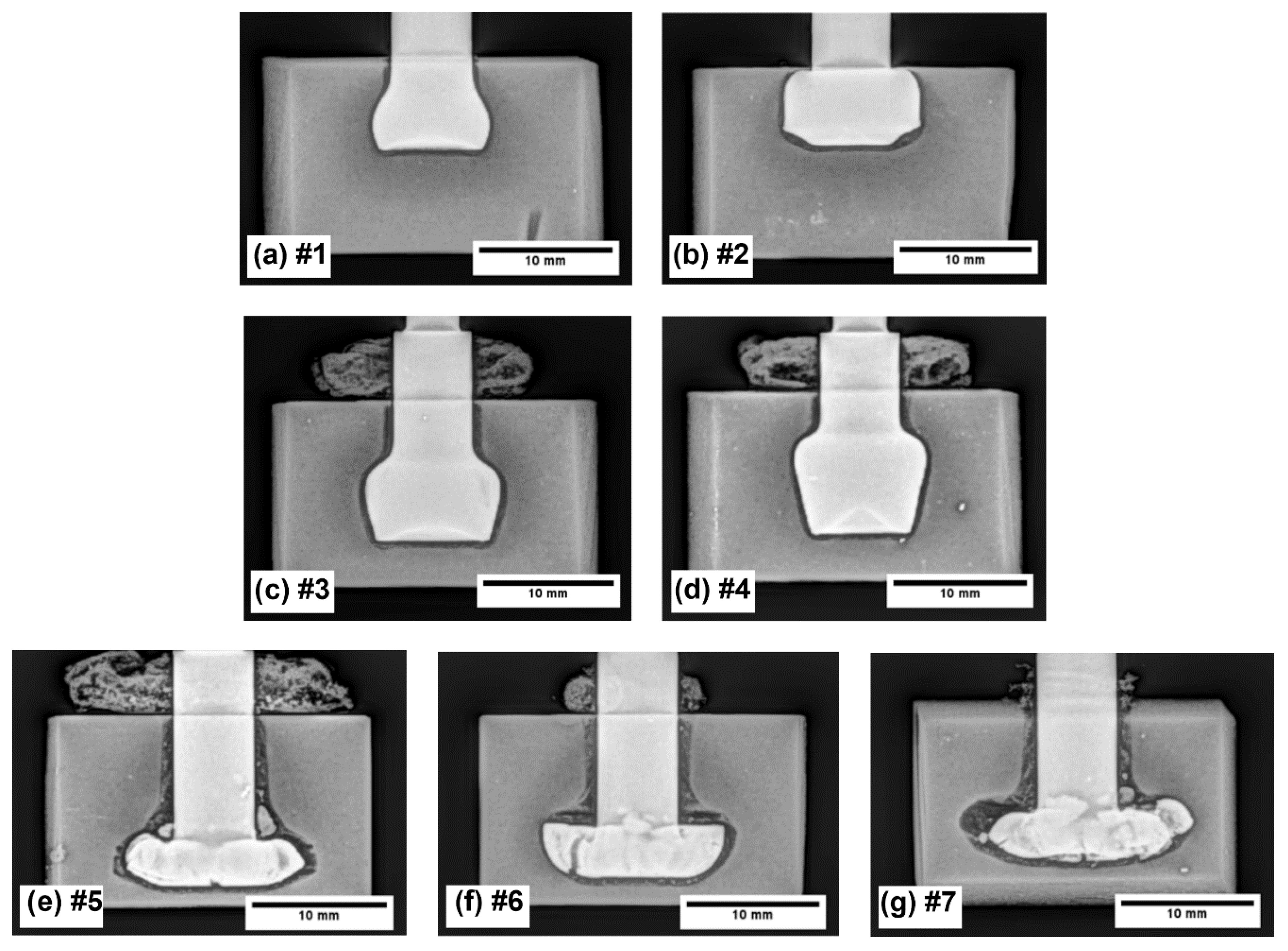

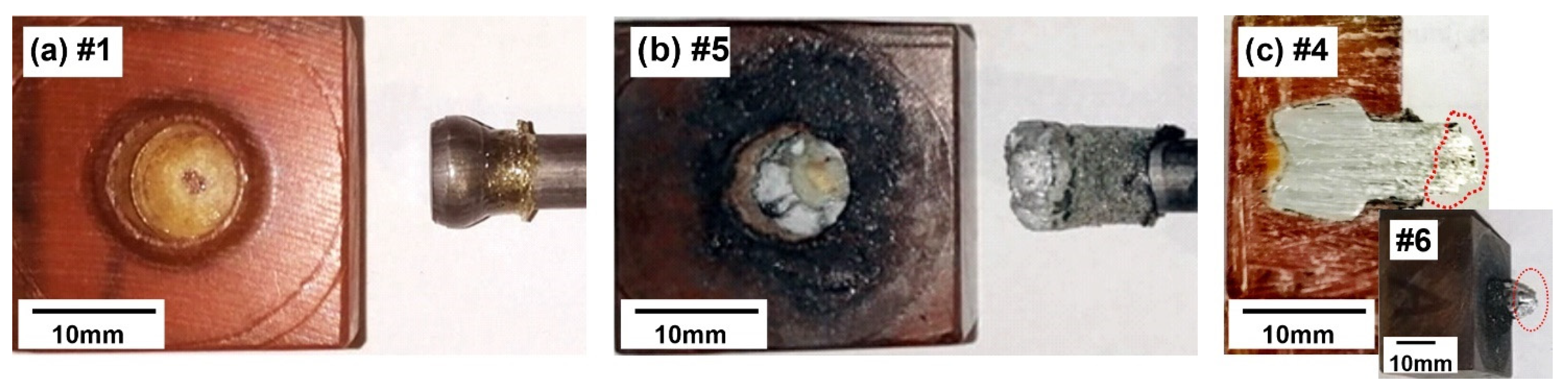

3.1. X-ray Examination and Macroscopic Observations

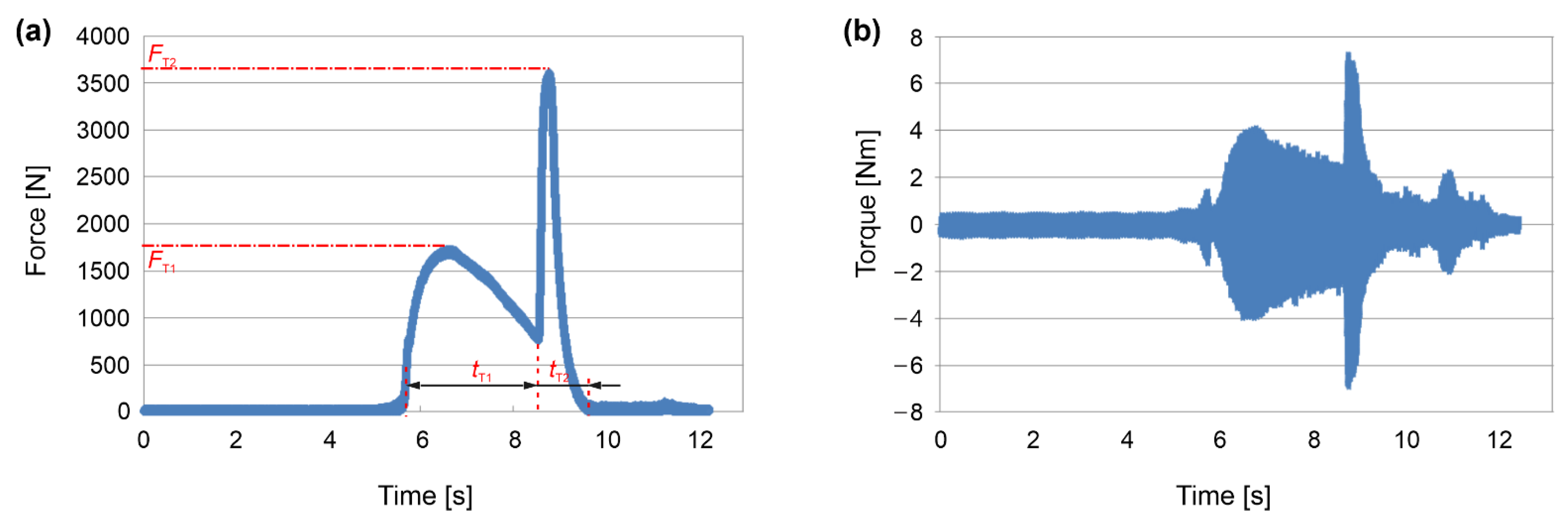

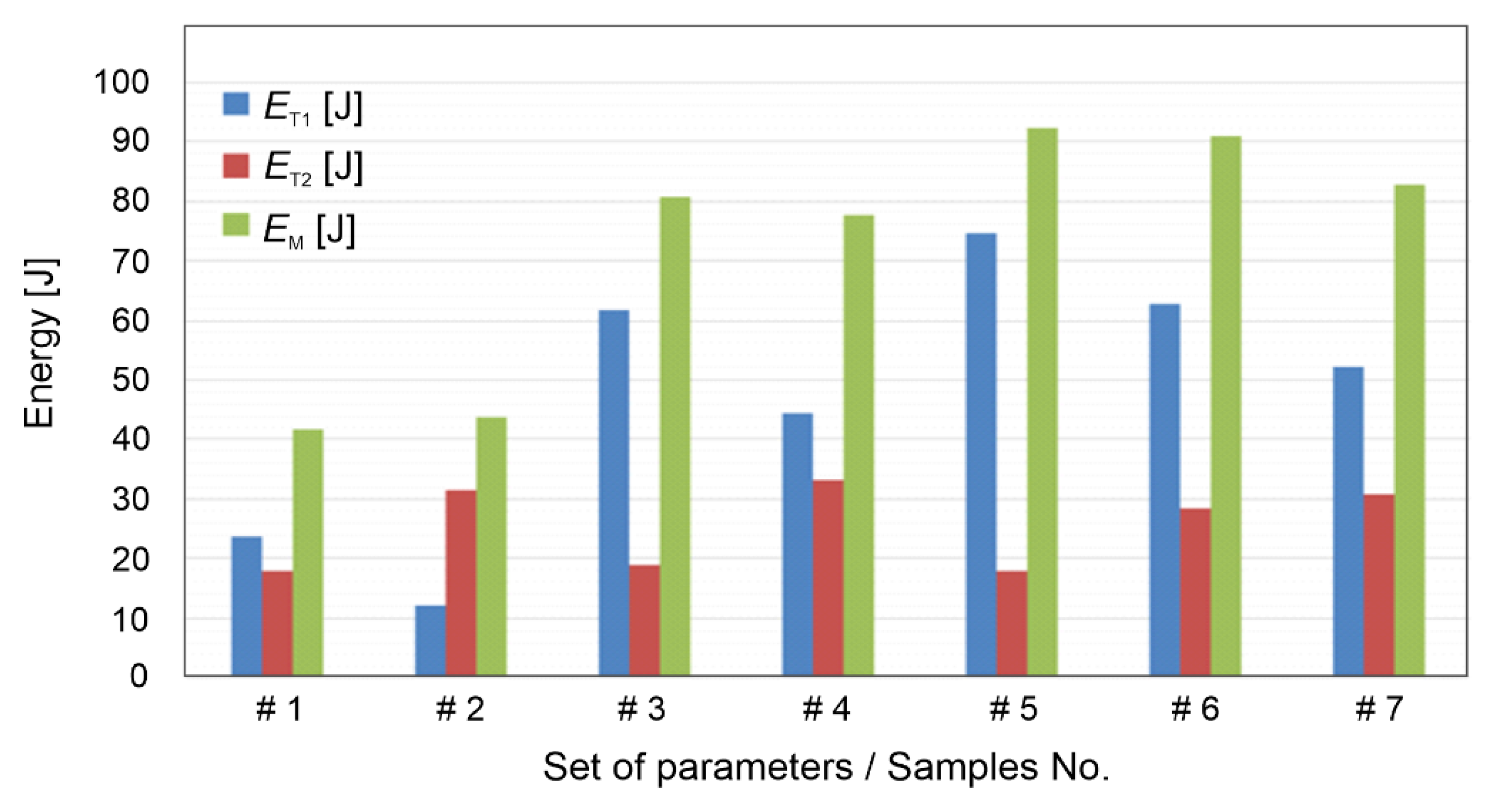

3.2. Axial Force, Torque and Heat Input

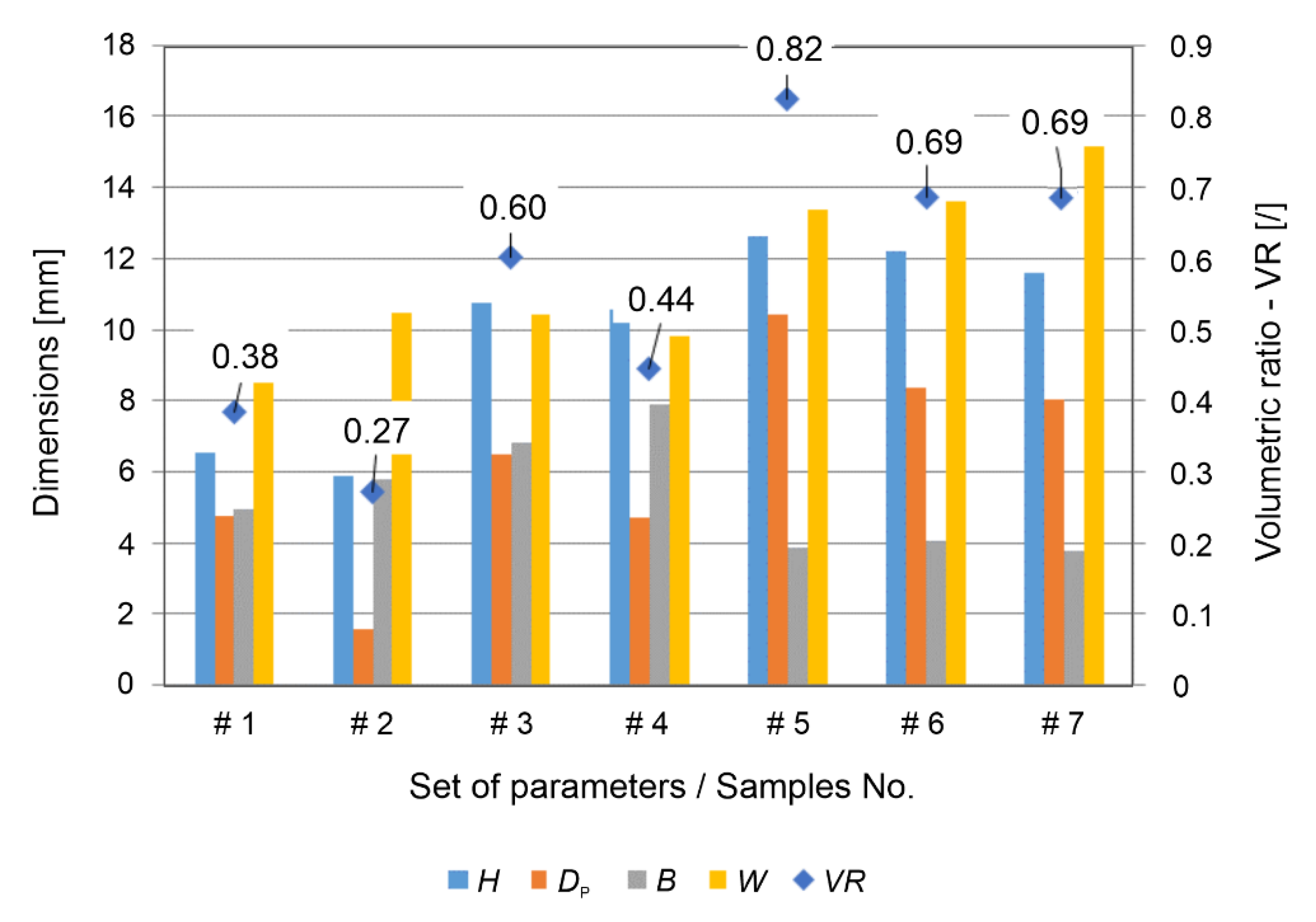

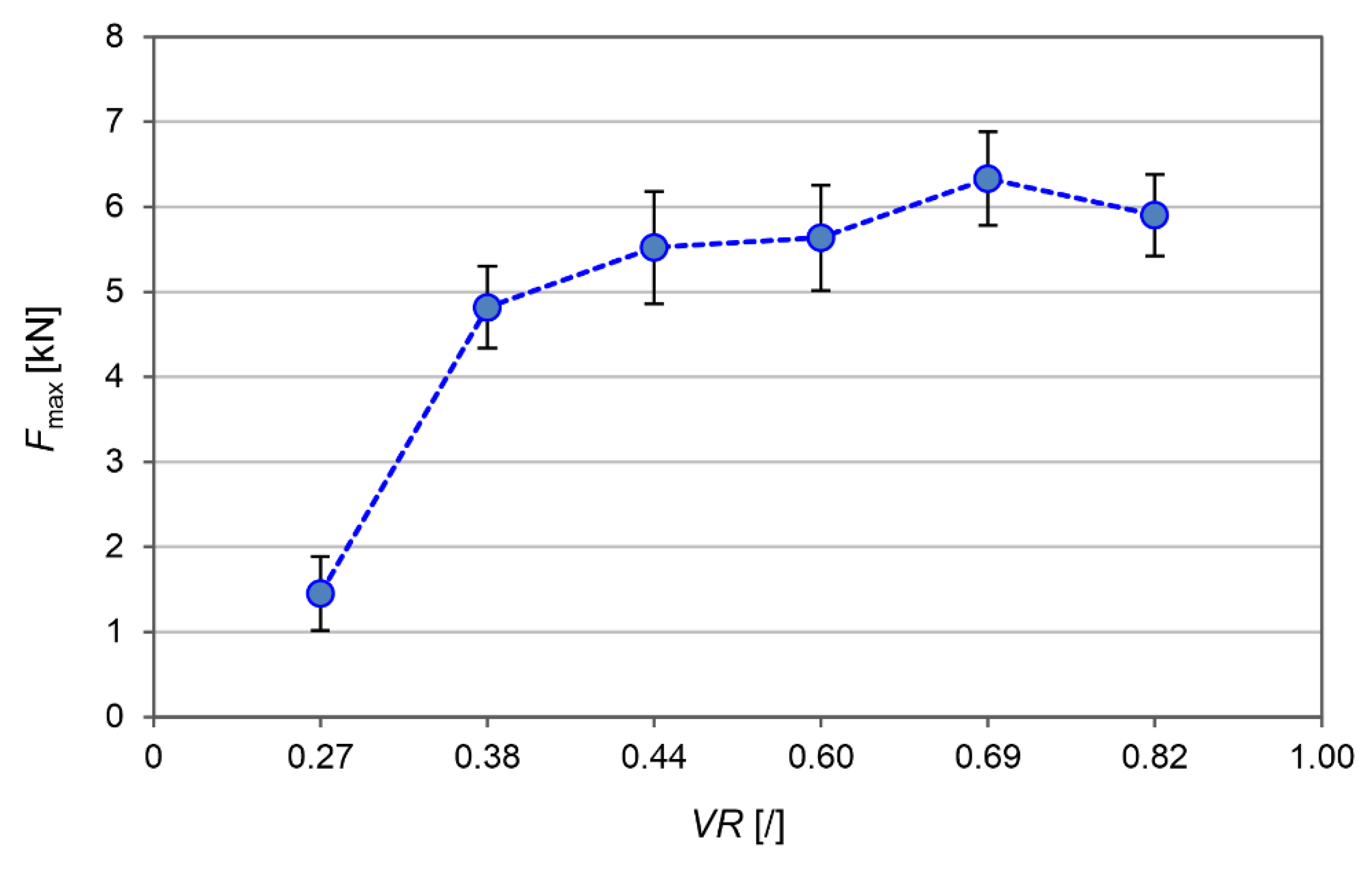

3.3. Volumetric Ratio and Pull-Out Force

4. Discussion

5. Conclusions

- The X-ray studies and macroscopic observations have confirmed that it is possible to achieve the desired depth and final shape of AA2024-T351 rivets in the PEI material by controlling the processing parameters.

- The results have confirmed that in the first phase of manufacturing, it is essential to ensure that there is a sufficient axial force and thus, consequently, a sufficient torque for 2.5 to 3 s to achieve the adequate penetration depth of the AA2024-T351 rivet into the PEI base material.

- Proper processing parameters lead to a higher frictional energy input due to the effects of friction and the strong heating of the rivet and the PEI material. Thus, optimal conditions were achieved with the feeding rate of 200 mm/min and a penetration depth of ~10 mm in the first phase of the friction riveting process.

- Furthermore, in the second phase of the process, the deformation energy, which depended on the axial force and the deformation speed, was crucial for the correct formation and anchoring shape of the rivet. For the dissimilar materials that were used in the current study, the optimal anchoring shape of the rivet can be achieved at a penetration depth of ~20 mm and a feed rate of 900 mm/min.

- The analyses of the volume ratio and the pull-out force results confirmed that the highest joint strength was achieved with a maximum pull-out force of up to 6.5 kN at a volume ratio of 0.69. Here, the rivet obtained an anchoring end shape and the failure occurred in the undeformed section of the rivet, which was outside of the PEI block.

- In contrast, the pull-out force decreased at a higher or lower volume ratio, indicating the “narrow” optimum technical window of the process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ayad, M.; Lapostolle, L.; Rondepierre, A.; Le Bras, C.; Ünaldi, S.; Donik, Č.; Klobčar, D.; Berthe, L.; Trdan, U. New methodology of dynamical material response of dissimilar FSWed Al alloy joint under high strain rate laser shock loading. Mater. Des. 2022, 222, 111080. [Google Scholar] [CrossRef]

- VPopov, V.V., Jr.; Katz-Demyanetz, A.; Garkun, A.; Bamberger, M. The effect of powder recycling on the mechanical properties and microstructure of electron beam melted Ti-6Al-4 V specimens. Addit. Manuf. 2018, 22, 834–843. [Google Scholar] [CrossRef]

- Duda, T.; Raghavan, L.V. 3D Metal Printing Technology. IFAC-PapersOnLine 2016, 49, 103–110. [Google Scholar] [CrossRef]

- Heide-Jørgensen, S.; de Freitas, S.T.; Budzik, M.K. On the fracture behaviour of CFRP bonded joints under mode I loading: Effect of supporting carrier and interface contamination. Compos. Sci. Technol. 2018, 160, 97–110. [Google Scholar] [CrossRef]

- de Freitas, S.T.; Sinke, J. Failure analysis of adhesively-bonded metal-skin-to-composite-stiffener: Effect of temperature and cyclic loading. Compos. Struct. 2017, 166, 27–37. [Google Scholar] [CrossRef]

- Tsiangou, E.; de Freitas, S.T.; Villegas, I.F.; Benedictus, R. Investigation on energy director-less ultrasonic welding of polyetherimide (PEI)- to epoxy-based composites. Compos. Part B Eng. 2019, 173, 107014. [Google Scholar] [CrossRef]

- Balos, S.; Dramicanin, M.; Janjatovic, P. Gas metal arc welding of metal-polymer-metal sheets. Tribol. Mater. 2022, 1, 61–69. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A.K.; Dong, Y.; Sarker, P.K.; Uddin, M.S.; Littlefair, G.; Dixit, A.R.; Chattopadhyaya, S. Joining of Carbon Fibre Reinforced Polymer (CFRP) Composites and Aluminium Alloys—A eview. Compos. Part A Appl. Sci. Manuf. 2017, 101, 1–29. [Google Scholar] [CrossRef]

- Chaturvedi, M.C. Welding and Joining of Aerospace Materials; Woodhead Publishing Limited: Sawston, UK, 2012. [Google Scholar]

- Dawei, Z.; Qi, Z.; Xiaoguang, F.; Shengdun, Z. Review on Joining Process of Carbon Fiber-Reinforced Polymer and Metal: Methods and Joining Process. Rare Met. Mater. Eng. 2018, 47, 3686–3696. [Google Scholar] [CrossRef]

- Maggiore, S.; Banea, M.D.; Stagnaro, P.; Luciano, G. A Review of Structural Adhesive Joints in Hybrid Joining Processes. Polymers 2021, 13, 3961. [Google Scholar] [CrossRef]

- Balawender, T.; Sadowski, T.; Kneć, M. Technological Problems and Experimental Investigation of Hybrid: Clinched-Adhesively Bonded Joint. Arch. Met. Mater. 2011, 56, 439–446. [Google Scholar] [CrossRef]

- Gerstmann, T.; Awiszus, B. Hybrid Joining: Numerical Process Development of Flat-Clinch-Bonding. J. Mater. Process. Technol. 2020, 277, 116421. [Google Scholar] [CrossRef]

- Zvorykina, A.; Sherepenko, O.; Neubauer, M.; Jüttner, S. Dissimilar Metal Joining of Aluminum to Steel by Hybrid Process of Adhesive Bonding and Projection Welding Using a Novel Insert Element. J. Mater. Process. Technol. 2020, 282, 116680. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Yang, C.; Gao, M. Study of Porosity Suppression in Oscillating Laser-MIG Hybrid Welding of AA6082 Aluminum Alloy. J. Mater. Process. Technol. 2021, 292, 117053. [Google Scholar] [CrossRef]

- Khan, H.A.; Li, J.; Shao, C. Analyses of Friction Stir Riveting Processes: A Review. J. Manuf. Sci. Eng. 2017, 139, 090801. [Google Scholar] [CrossRef]

- Ma, Y.; Shan, H.; Niu, S.; Li, Y.; Lin, Z.; Ma, N. A Comparative Study of Friction Self-Piercing Riveting and Self-Piercing Riveting of Aluminum Alloy AA5182-O. Engineering 2021, 7, 1741–1750. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Xie, Y.; Li, J.; Guan, M.; Wan, L.; Dong, Z.; Cao, J. Friction Self-Riveting Welding between Polymer Matrix Composites and Metals. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105624. [Google Scholar] [CrossRef]

- Lambiase, F.; Balle, F.; Blaga, L.-A.; Liu, F.; Amancio-Filho, S.T. Friction-based processes for hybrid multi-material joining. Compos. Struct. 2021, 266, 113828. [Google Scholar] [CrossRef]

- European Aluminium Association. EAA Aluminium Automotive Manual–Joining; European Aluminium Association: Brussels, Belgium, 2015; pp. 1–5. [Google Scholar]

- Hernandez, E.; Alfano, M.; Lubineau, G.; Buttner, U. Improving adhesion of copper/epoxy joints by pulsed laser ablation. Int. J. Adhes. Adhes. 2016, 64, 23–32. [Google Scholar] [CrossRef][Green Version]

- Amancio Filho, S.T. Henry Granjon Prize Competition 2009 Winner Category A: ‘Joining and Fabrication Technology’ Friction Riveting: Development and Analysis of a New Joining Technique for Polymer-Metal Multi-Material Structures. Weld. World 2011, 55, 13–24. [Google Scholar] [CrossRef]

- Amancio Filho, S.T. Friction Riveting Development and Analysis of a New Joining Technique for Polymer-Metal Multi-Material Structures. Riv. Ital. Della Saldatura 2011, 63, 197–208. [Google Scholar]

- Blaga, L.; Bancilă, R.; dos Santos, J.F.; Amancio-Filho, S.T. Friction Riveting of glass-fibre-reinforced polyetherimide composite and titanium grade 2 hybrid joints. Mater. Des. 2013, 50, 825–829. [Google Scholar] [CrossRef]

- Blaga, L.; dos Santos, J.F.; Bancila, R.; Amancio-Filho, S.T. Friction Riveting (FricRiveting) as a new joining technique in GFRP lightweight bridge construction. Constr. Build. Mater. 2015, 80, 167–179. [Google Scholar] [CrossRef]

- Proenca, B.C.; Blaga, L.; Santos, J.F.D.; Canto, L.O.B.; Amancio-Filho, S.T. Force controlled friction Riveting of glass fiber reinforced polyamide 6 and aluminum alloy 6056 hybrid joints. In Proceedings of the Annual Technical Conference of Society of Plastics Engineers (ANTEC 2015); Society of Plastics Engineers: Danbury, CT, USA, 2015; pp. 1905–1912. [Google Scholar]

- De Proença, B.C.; Blaga, L.; Dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. Friction Riveting (‘FricRiveting’) of 6056 T6 Aluminium Alloy and Polyamide 6: Influence of Rotational Speed on the Formation of the Anchoring Zone and on Mechanical Performance. Weld. Int. 2017, 31, 509–518. [Google Scholar] [CrossRef]

- Cipriano, G.P.; Blaga, L.A.; dos Santos, J.F.; Vilaça, P.; Amancio-Filho, S.T. Fundamentals of force-controlled friction riveting: Part I-joint formation and heat development. Materials 2018, 11, 2294. [Google Scholar] [CrossRef]

- Cipriano, G.P.; Blaga, L.A.; Dos Santos, J.F.; Vilaça, P.; Amancio-Filho, S.T. Fundamentals of force-controlled friction riveting: Part II-Joint global mechanical performance and energy efficiency. Materials 2018, 11, 2489. [Google Scholar] [CrossRef]

- Borba, N.; Kötter, B.; Fiedler, B.; dos Santos, J.; Amancio-Filho, S. Mechanical Integrity of Friction-Riveted Joints for Aircraft Applications. Compos. Struct. 2020, 232, 111542. [Google Scholar] [CrossRef]

- Cipriano, G.P.; Ahiya, A.; dos Santos, J.F.; Vilaça, P.; Amancio-Filho, S.T. Single-Phase Friction Riveting: Metallic Rivet Deformation, Temperature Evolution, and Joint Mechanical Performance. Weld. World 2020, 64, 47–58. [Google Scholar] [CrossRef]

- dos Santos Mallmann, P.H.; Blaga, L.A.; dos Santos, J.F.; Klusemann, B. Friction Riveting of 3D Printed Polyamide 6 with AA 6056-T6. Procedia Manuf. 2020, 47, 406–412. [Google Scholar] [CrossRef]

- Feier, A.; Becheru, A.; Brîndușoiu, M.; Blaga, L. Process Transferability of Friction Riveting of AA2024-T351/Polyetherimide (PEI) Joints Using Hand-Driven, Low-Cost Drilling Equipment. Processes 2021, 9, 1376. [Google Scholar] [CrossRef]

- Cipriano, G.P.; de Carvalho, W.S.; Vilaça, P.; Amancio-Filho, S.T. Thermomechanical Modeling of the Metallic Rivet in Friction Riveting of Amorphous Thermoplastics. Weld. World 2021, 65, 855–864. [Google Scholar] [CrossRef]

- Sankaranarayanan, R.; Hynes, N.R.J.; Li, D.; Chrysanthou, A.; Amancio-Filho, S.T. Review of Research on Friction Riveting of Polymer/Metal Light Weight Multi-Material Structures. Trans. Indian Inst. Met. 2021, 74, 2541–2553. [Google Scholar] [CrossRef]

- ial Property Data. Aluminum 2024-T4; 2024-T351. Available online: http://www.matweb.com/search/DataSheet.aspx?MatGUID=67d8cd7c00a04ba29b618484f7ff7524 (accessed on 5 July 2022).

- MatWeb Material Property Data. Overview of Materials for Polyethermide (PEI). Available online: http://www.matweb.com/search/DataSheet.aspx?MatGUID=65baf7a4f90c4a54a6ace03e16b1125b&ckck=1 (accessed on 7 July 2022).

| Parameters/ Sample | Phase 1 | Phase 2 | ||

|---|---|---|---|---|

| z [mm] | Vf [mm/min] | z [mm] | Vf [mm/min] | |

| #1 | 5 | 100 | 10 | 1200 |

| #2 | 5 | 200 | 15 | 2000 |

| #3 | 10 | 200 | 20 | 1200 |

| #4 | 10 | 200 | 20 | 1800 |

| #5 | 10 | 200 | 20 | 900 |

| #6 | 9 | 200 | 20 | 900 |

| #7 | 9 | 200 | 19 | 900 |

| Cu | Mg | Mn | Si | Fe | Zn | Ti | Cr | Al |

|---|---|---|---|---|---|---|---|---|

| 3.8–4.9 | 1.2–1.8 | 0.3–0.9 | ≤0.5 | ≤0.5 | ≤0.25 | ≤0.15 | ≤0.1 | Bal. |

| Property | Value |

|---|---|

| Rm [MPa] | 425 |

| Rp0.2 [MPa] | 310 |

| E [GPa] | 73.1 |

| Melting temperature [°C] | 502–638 |

| Heat treatment temperature [°C] | 493 |

| Tempering temperature [°C] | 413 |

| Heat conductivity [W/mK] | 121 |

| Property | Value |

|---|---|

| Rm [MPa] | 1–281 |

| E [GPa] | 39.4 |

| μtr | 0.18–0.42 |

| Tg [°C] | 168–220 |

| Heat conductivity [W/mK] | 0.036–11 |

| Melting temperature [°C] | 171–238 |

| Density [g/cm3] | 0.05–1.78 |

| Curing temperature [°C] | 82.2–150 |

| Parameters/ Sample | Rev [min−1] | FT1 [N] | tT1 [s] | FT2 [N] | tT2 [s] | M1 [Nmm] | M2 [Nmm] |

|---|---|---|---|---|---|---|---|

| #1 | 19,000 | 1694.16 | 2.95 | 3556.63 | 1.25 | 4.02 | 7.22 |

| #2 | 19,000 | 3337.65 | 1.39 | 10,317.32 | 0.76 | 4.36 | 20.91 |

| #3 | 19,000 | 3794.90 | 3.43 | 5741.10 | 0.92 | 9.06 | 10.37 |

| #4 | 19,000 | 3499.12 | 2.93 | 9242,00 | 0.82 | 7.62 | 20.27 |

| #5 | 19,000 | 3893.49 | 2.96 | 4387.70 | 1.11 | 12.65 | 8.05 |

| #6 | 19,000 | 3615.41 | 2.63 | 4906.56 | 1.09 | 11.96 | 13.07 |

| #7 | 19,000 | 3997.13 | 2.64 | 4518.52 | 1.05 | 9.92 | 14.73 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klobčar, D.; Pušavec, F.; Bračun, D.; Garašić, I.; Kožuh, Z.; Vencl, A.; Trdan, U. Influence of Friction Riveting Parameters on the Dissimilar Joint Formation and Strength. Materials 2022, 15, 6812. https://doi.org/10.3390/ma15196812

Klobčar D, Pušavec F, Bračun D, Garašić I, Kožuh Z, Vencl A, Trdan U. Influence of Friction Riveting Parameters on the Dissimilar Joint Formation and Strength. Materials. 2022; 15(19):6812. https://doi.org/10.3390/ma15196812

Chicago/Turabian StyleKlobčar, Damjan, Franci Pušavec, Drago Bračun, Ivica Garašić, Zoran Kožuh, Aleksandar Vencl, and Uroš Trdan. 2022. "Influence of Friction Riveting Parameters on the Dissimilar Joint Formation and Strength" Materials 15, no. 19: 6812. https://doi.org/10.3390/ma15196812

APA StyleKlobčar, D., Pušavec, F., Bračun, D., Garašić, I., Kožuh, Z., Vencl, A., & Trdan, U. (2022). Influence of Friction Riveting Parameters on the Dissimilar Joint Formation and Strength. Materials, 15(19), 6812. https://doi.org/10.3390/ma15196812