Study on Adhesion Property and Moisture Effect between SBS Modified Asphalt Binder and Aggregate Using Molecular Dynamics Simulation

Abstract

:1. Introduction

2. Materials and Methods

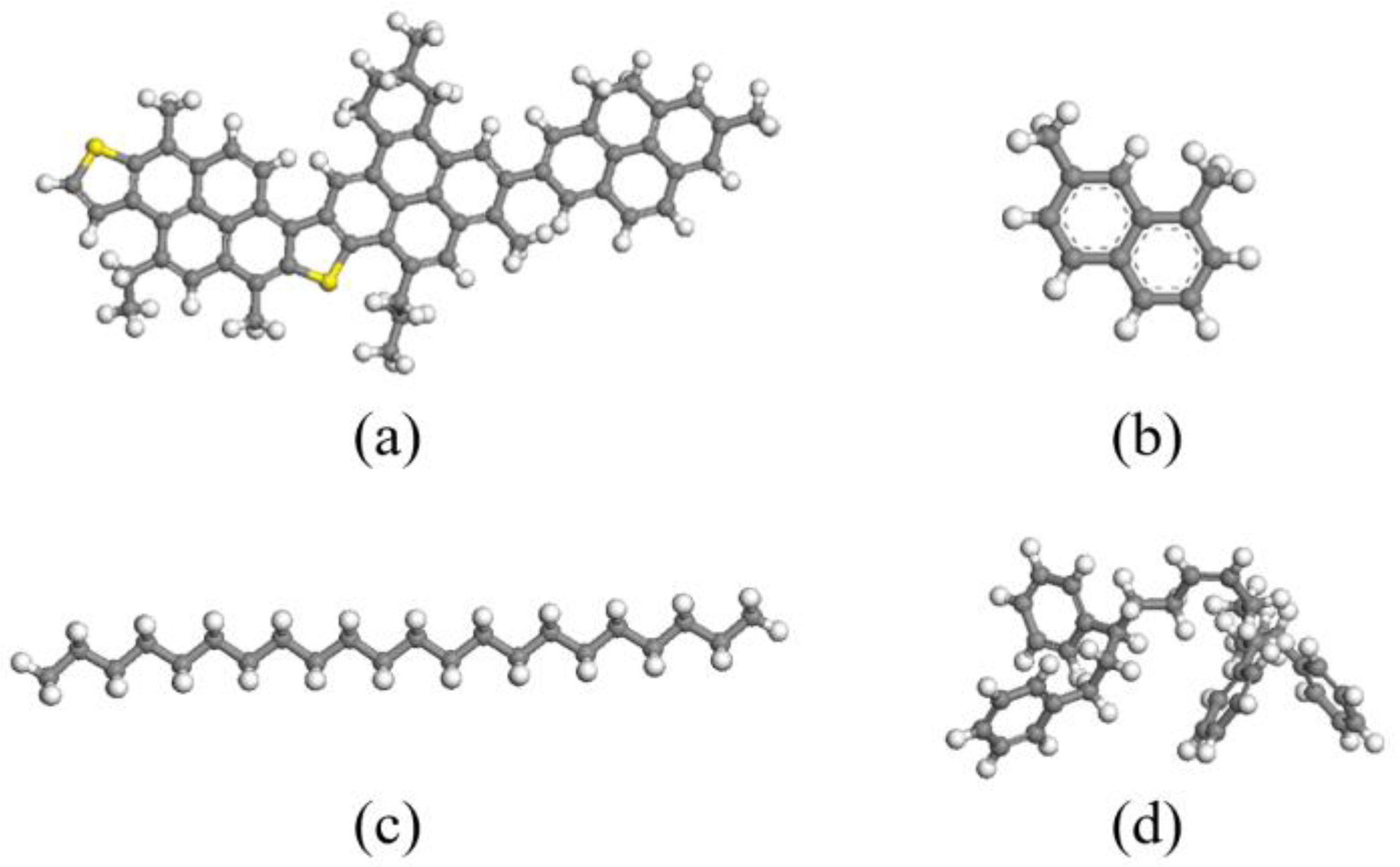

2.1. Materials

2.2. Modeling of Asphalt Binder–Aggregate Interface

2.3. Modeling of Asphalt Binder–Water–Aggregate Interface

2.4. Simulation Details and Evaluation Index

- is the work of adhesion between asphalt binder and aggregate;

- Etotal is the total potential energy of asphalt binder–aggregate interface model;

- Ea is the potential energy of the asphalt binder;

- Eagg is the potential energy of the aggregate;

- A is the interface contact area between the asphalt binder and aggregate surface.

- Wdebonding is the work of debonding;

- Ea_w is the interaction energy between asphalt and water;

- Eagg_w is the interaction energy between aggregate and water;

- Ea_agg is the interaction energy between aggregate and asphalt.

3. Results and Discussion

3.1. Verification of the Built MD Models

3.2. Variation in Work of Adhesion with the SBS Contents

3.3. Moisture Effect on the Interface of SBS Modified Asphalt Binder and Aggregate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cong, P.; Guo, X.; Ge, W. Effects of moisture on the bonding performance of asphalt-aggregate system. Constr. Build. Mater. 2021, 295, 123667. [Google Scholar] [CrossRef]

- Guo, F.; Pei, J.; Zhang, J.; Xue, B.; Sun, G.; Li, R. Study on the adhesion property between asphalt binder and aggregate: A state-of-the-art review. Constr. Build. Mater. 2020, 256, 119474. [Google Scholar] [CrossRef]

- Xing, C.; Jiang, W.; Li, M.; Wang, M.; Xiao, J.; Xu, Z. Application of atomic force microscopy in bitumen materials at the nanoscale: A review. Constr. Build. Mater. 2022, 342, 128059. [Google Scholar] [CrossRef]

- Zhou, L.; Huang, W.; Zhang, Y.; Lv, Q.; Yan, C.; Jiao, Y. Evaluation of the adhesion and healing properties of modified asphalt binders. Constr. Build. Mater. 2020, 251, 119026. [Google Scholar] [CrossRef]

- Júnior, J.L.L.; Babadopulos, L.F.; Soares, J.B. Moisture-induced damage resistance, stiffness and fatigue life of asphalt mixtures with different aggregate-binder adhesion properties. Constr. Build. Mater. 2019, 216, 166–175. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Xiao, F.; Hettiarachchi, C.; Abdel-Wahed, T. Bond strength in dry condition of reclaimed asphalt modified by crumb rubber modified binder. J. Adhes. 2022, 99, 1–30. [Google Scholar] [CrossRef]

- Hu, M.; Sun, D.; Lu, T.; Ma, J.; Yu, F. Laboratory investigation of the adhesion and self-healing properties of high-viscosity modified asphalt binders. Transp. Res. Rec. 2020, 2674, 307–318. [Google Scholar] [CrossRef]

- Office, J.E.; Chen, J.; Dan, H.; Ding, Y.; Gao, Y.; Guo, M.; Guo, S.; Han, B.; Hong, B.; Hou, Y.; et al. New innovations in pavement materials and engineering: A review on pavement engineering research 2021. J. Traffic Transp. Eng. 2021, 8, 815–999. [Google Scholar]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Ain Shams Eng. J. 2021, 12, 1569–1574. [Google Scholar] [CrossRef]

- Lin, P.; Huang, W.; Li, Y.; Tang, N.; Xiao, F. Investigation of influence factors on low temperature properties of SBS modified asphalt. Constr. Build. Mater. 2017, 154, 609–622. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, Z.; Zhang, K.; Huang, S.; Luo, Y. Preparation and properties of high viscosity and elasticity asphalt by styrene–butadiene–styrene/polyurethane prepolymer composite modification. J. Appl. Polym. Sci. 2020, 137, 49123. [Google Scholar] [CrossRef]

- Wang, T.; Wei, X.; Zhang, D.; Shi, H.; Cheng, Z. Evaluation for low temperature performance of SBS modified asphalt by dynamic shear rheometer method. Buildings 2021, 11, 408. [Google Scholar] [CrossRef]

- Chen, M.; Geng, J.; Xia, C.; He, L.; Liu, Z. A review of phase structure of SBS modified asphalt: Affecting factors, analytical methods, phase models and improvements. Constr. Build. Mater. 2021, 294, 123610. [Google Scholar] [CrossRef]

- Sun, D.; Lin, T.; Zhu, X.; Tian, Y.; Liu, F. Indices for self-healing performance assessments based on molecular dynamics simulation of asphalt binders. Comput. Mater. Sci. 2016, 114, 86–93. [Google Scholar] [CrossRef]

- Yao, H.; Liu, J.; Xu, M.; Ji, J.; Dai, Q.; You, Z. Discussion on molecular dynamics (MD) simulations of the asphalt materials. Adv. Colloid Interface Sci. 2022, 299, 102565. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, J.; Chen, Z.; Zhang, M.; Pei, J.; Li, R. Investigation of friction behavior between tire and pavement by molecular dynamics simulations. Constr. Build. Mater. 2021, 300, 124037. [Google Scholar] [CrossRef]

- Chen, Z.; Pei, J.; Li, R.; Xiao, F. Performance characteristics of asphalt materials based on molecular dynamics simulation–A review. Constr. Build. Mater. 2018, 189, 695–710. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Study of cohesion and adhesion properties of asphalt concrete with molecular dynamics simulation. Comput. Mater. Sci. 2016, 112, 161–169. [Google Scholar] [CrossRef]

- Luo, L.; Chu, L.; Fwa, T.F. Molecular dynamics analysis of moisture effect on asphalt-aggregate adhesion considering anisotropic mineral surfaces. Appl. Surf. Sci. 2020, 527, 146830. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Molecular dynamics study of interfacial mechanical behavior between asphalt binder and mineral aggregate. Constr. Build. Mater. 2016, 121, 246–254. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Y.; Yang, Y.; Zhang, J.; Gu, F. Molecular dynamics investigation of interfacial adhesion between oxidised bitumen and mineral surfaces. Appl. Surf. Sci. 2019, 479, 449–462. [Google Scholar] [CrossRef]

- Ding, Y.; Tang, B.; Zhang, Y.; Wei, J.; Cao, X. Molecular dynamics simulation to investigate the influence of SBS on molecular agglomeration behavior of asphalt. J. Mater. Civ. Eng. 2015, 27, C4014004. [Google Scholar] [CrossRef]

- Hossain, K.; Hossain, Z. A synthesis of computational and experimental approaches of evaluating chemical, physical, and mechanistic properties of asphalt binders. Adv. Civ. Eng. 2019, 2019. [Google Scholar] [CrossRef] [Green Version]

- Guo, F.; Zhang, J.; Pei, J.; Zhou, B.; Hu, Z. Study on the mechanical properties of rubber asphalt by molecular dynamics simulation. J. Mol. Model. 2019, 25, 365. [Google Scholar] [CrossRef]

- Zhan, Y.; Wu, H.; Song, W.; Zhu, L. Molecular dynamics study of the diffusion between virgin and aged asphalt binder. Coatings 2022, 12, 403. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Lin, P.; Gao, Y.; Erkens, S. Molecular dynamics simulation on bulk bitumen systems and its potential connections to macroscale performance: Review and discussion. Fuel 2022, 328, 125382. [Google Scholar] [CrossRef]

- Zhang, L.; Greenfield, M.L. Analyzing properties of model asphalts using molecular simulation. Energy Fuels 2007, 21, 1712–1716. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, J.; Pei, J.; Zhou, B.; Cannone Falchetto, A.; Hu, Z. Investigating the interaction behavior between asphalt binder and rubber in rubber asphalt by molecular dynamics simulation. Constr. Build. Mater. 2020, 252, 118956. [Google Scholar] [CrossRef]

- Hu, D.; Gu, X.; Cui, B.; Pei, J.; Zhang, Q. Modeling the oxidative aging kinetics and pathways of asphalt: A ReaxFF molecular dynamics study. Energy Fuels 2020, 34, 3601–3613. [Google Scholar] [CrossRef]

- Xu, S.; Xiao, F.; Amirkhanian, S.; Singh, D. Moisture characteristics of mixtures with warm mix asphalt technologies–A review. Constr. Build. Mater. 2017, 142, 148–161. [Google Scholar] [CrossRef]

- Sun, H.; Jin, Z.; Yang, C.; Akkermans, R.L.; Robertson, S.H.; Spenley, N.A.; Miller, S.; Todd, S.M. COMPASS II: Extended coverage for polymer and drug-like molecule databases. J. Mol. Model. 2016, 22, 47. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Zhang, Y.; Gu, F.; Xu, T.; Wang, H. Impact of minerals and water on bitumen-mineral adhesion and debonding behaviours using molecular dynamics simulations. Constr. Build. Mater. 2018, 171, 214–222. [Google Scholar] [CrossRef] [Green Version]

- Dong, Z.; Liu, Z.; Wang, P.; Gong, X. Nanostructure characterization of asphalt-aggregate interface through molecular dynamics simulation and atomic force microscopy. Fuel 2017, 189, 155–163. [Google Scholar] [CrossRef]

- Long, Z.; You, L.; Tang, X.; Ma, W.; Ding, Y.; Xu, F. Analysis of interfacial adhesion properties of nano-silica modified asphalt mixtures using molecular dynamics simulation. Constr. Build. Mater. 2020, 255, 119354. [Google Scholar] [CrossRef]

- Cui, B.; Wang, H. Molecular interaction of Asphalt-Aggregate interface modified by silane coupling agents at dry and wet conditions. Appl. Surf. Sci. 2022, 572, 151365. [Google Scholar] [CrossRef]

- Hu, D.; Pei, J.; Li, R.; Zhang, J.; Jia, Y.; Fan, Z. Using thermodynamic parameters to study self-healing and interface properties of crumb rubber modified asphalt based on molecular dynamics simulation. Front. Struct. Civ. Eng. 2020, 14, 109–122. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, F.; Pei, J.; Zhang, J.; Li, R.; Liu, P.; Wang, D. Study on Adhesion Property and Moisture Effect between SBS Modified Asphalt Binder and Aggregate Using Molecular Dynamics Simulation. Materials 2022, 15, 6912. https://doi.org/10.3390/ma15196912

Guo F, Pei J, Zhang J, Li R, Liu P, Wang D. Study on Adhesion Property and Moisture Effect between SBS Modified Asphalt Binder and Aggregate Using Molecular Dynamics Simulation. Materials. 2022; 15(19):6912. https://doi.org/10.3390/ma15196912

Chicago/Turabian StyleGuo, Fucheng, Jianzhong Pei, Jiupeng Zhang, Rui Li, Pengfei Liu, and Di Wang. 2022. "Study on Adhesion Property and Moisture Effect between SBS Modified Asphalt Binder and Aggregate Using Molecular Dynamics Simulation" Materials 15, no. 19: 6912. https://doi.org/10.3390/ma15196912

APA StyleGuo, F., Pei, J., Zhang, J., Li, R., Liu, P., & Wang, D. (2022). Study on Adhesion Property and Moisture Effect between SBS Modified Asphalt Binder and Aggregate Using Molecular Dynamics Simulation. Materials, 15(19), 6912. https://doi.org/10.3390/ma15196912