Experimental Study at the Phase Interface of a Single-Crystal Ni-Based Superalloy Using TEM

Abstract

1. Introduction

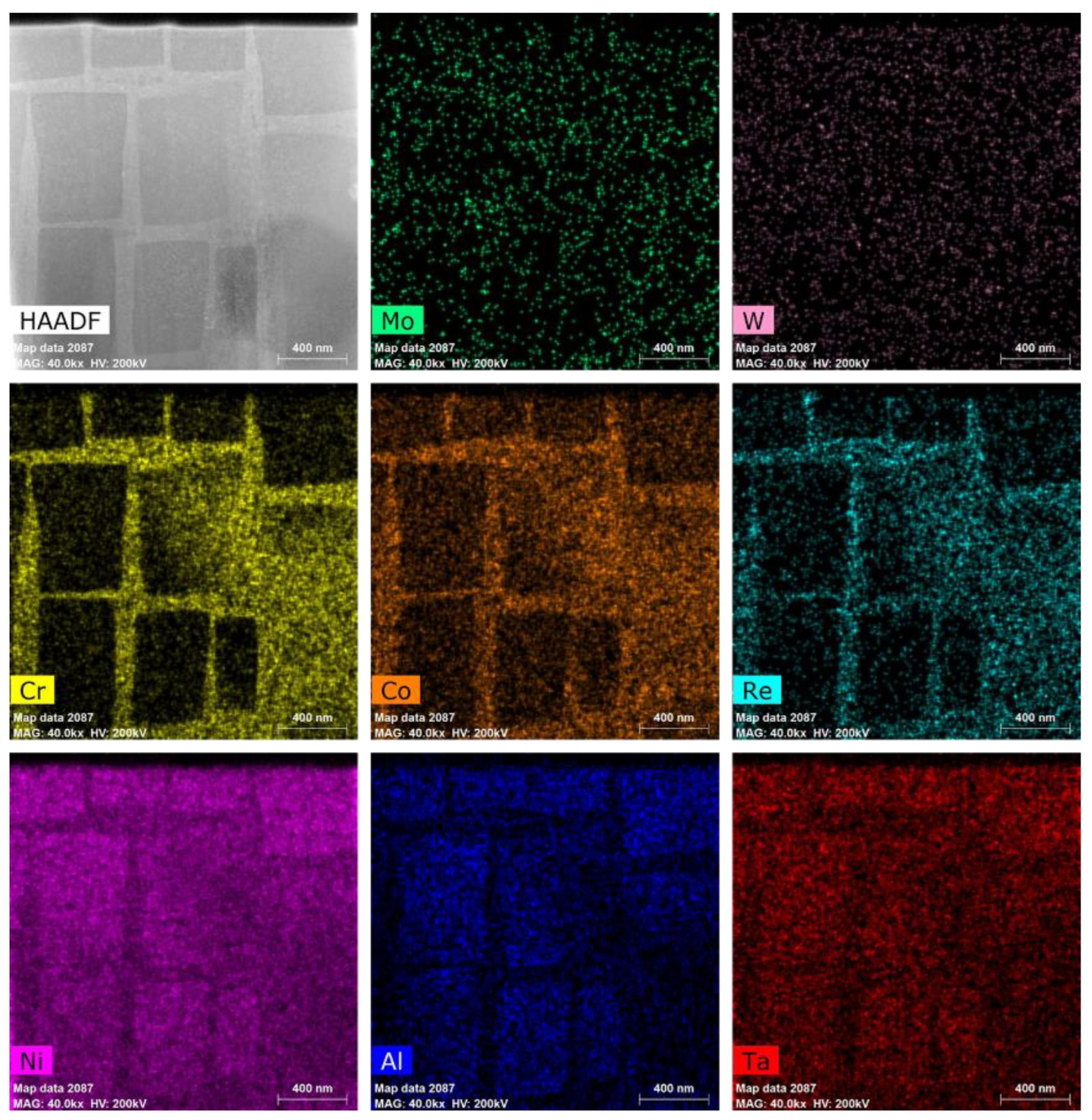

2. Experimental and Materials

3. Methods

4. Results and Discussion

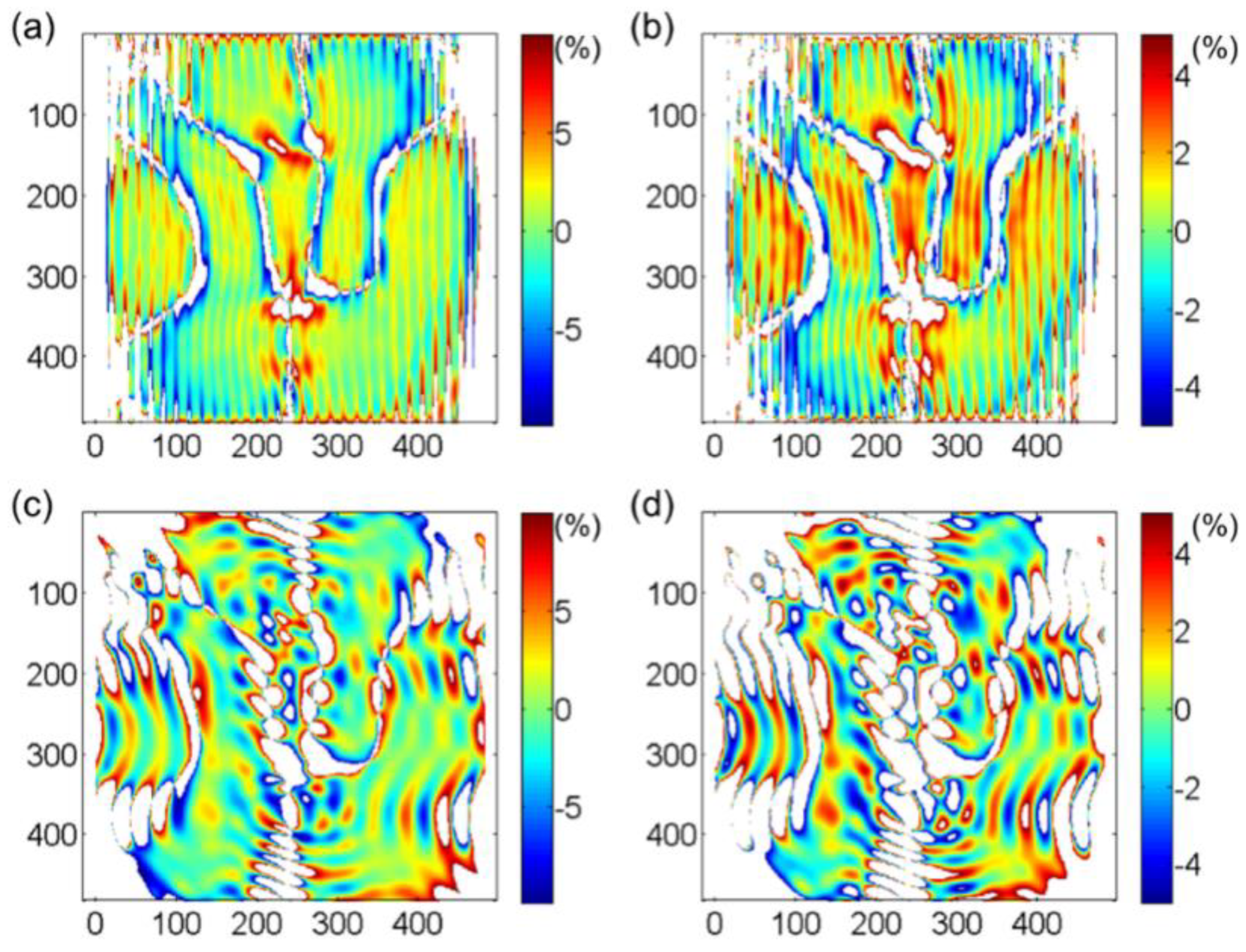

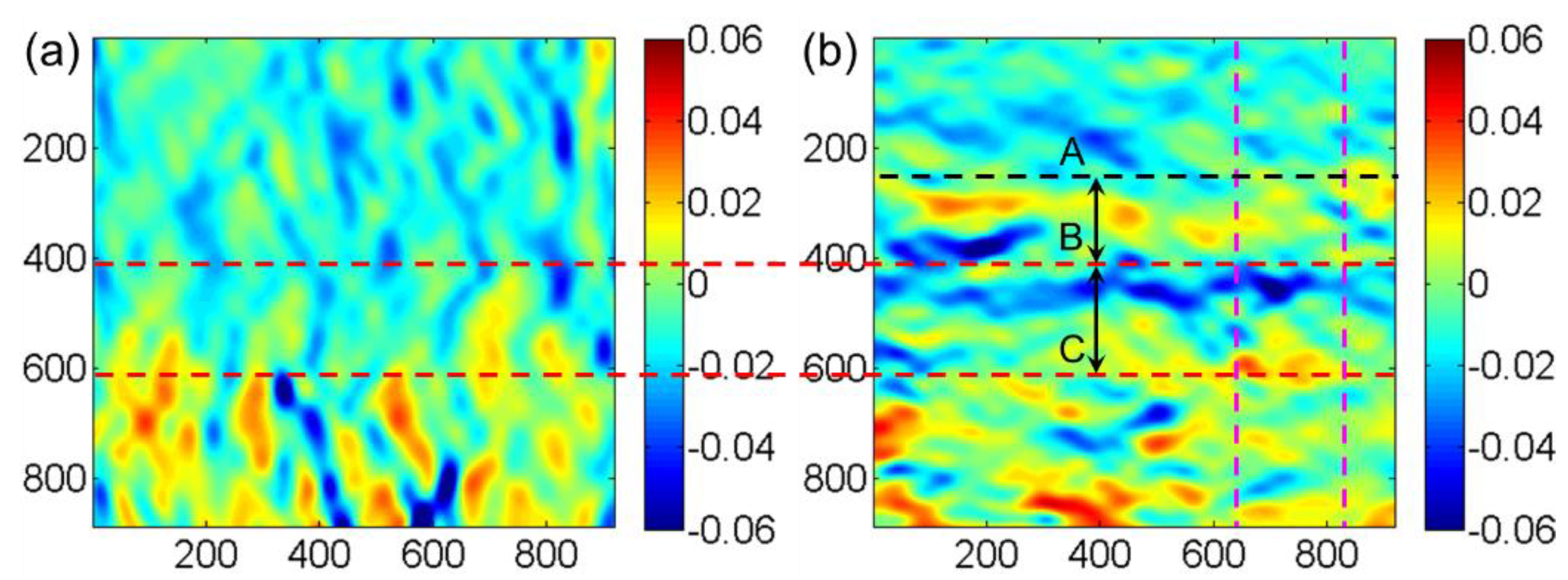

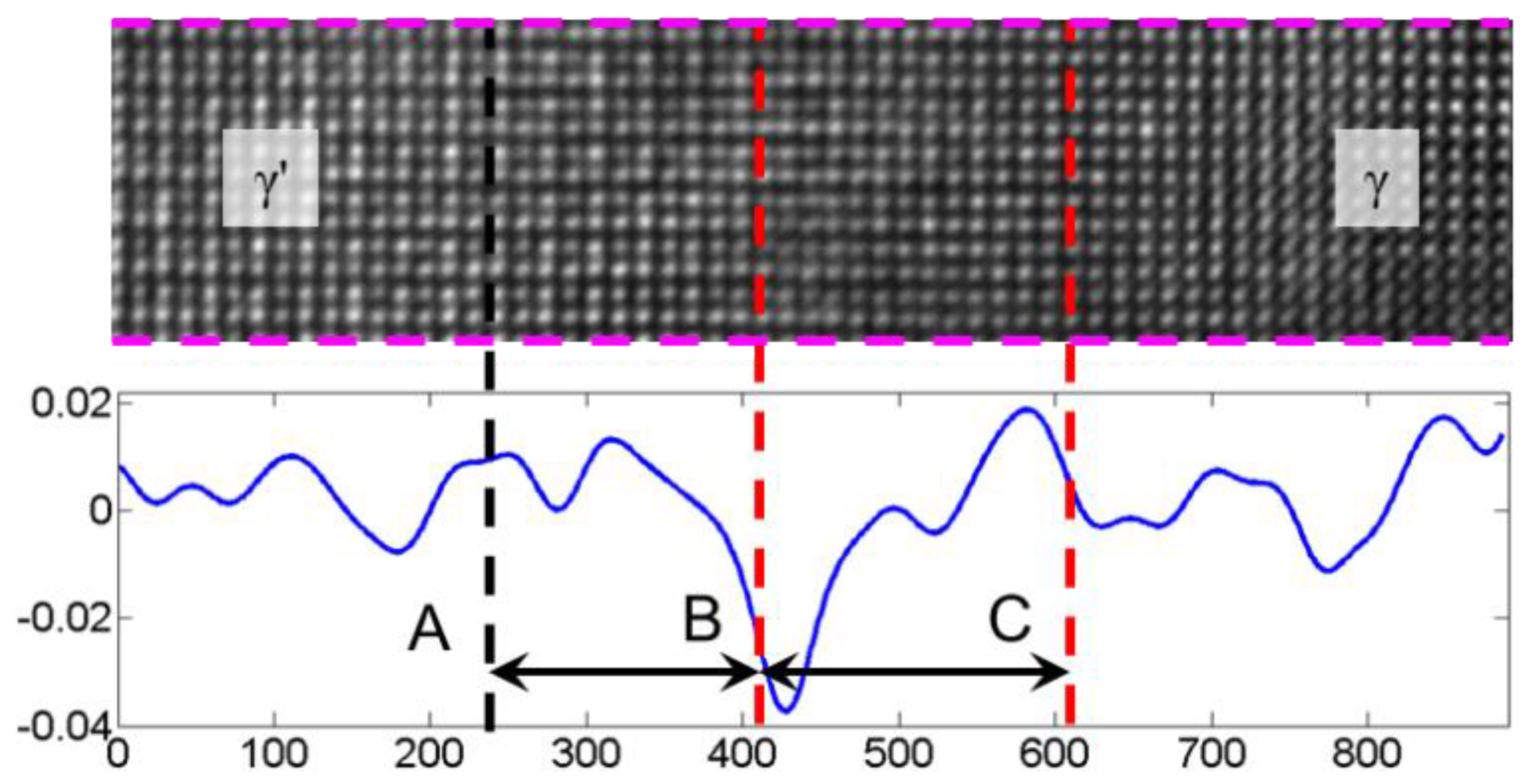

4.1. Phase Interface Width and Strain Distribution

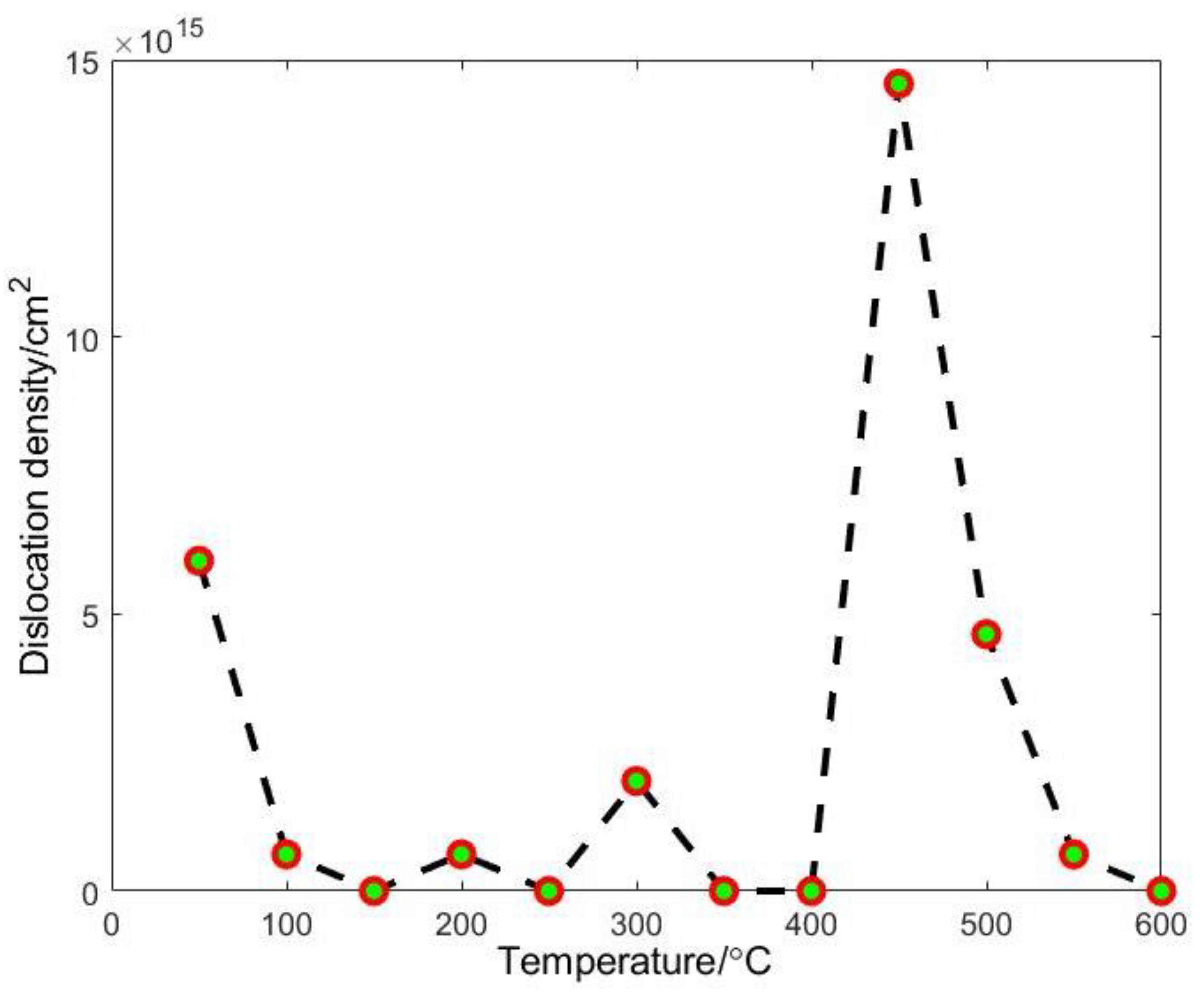

4.2. Variation of Dislocation Density and Intermediate Temperature Brittleness

5. Conclusions

- (1)

- The S-GPA method has been enhanced. The mask selection form in the GPA method is introduced, and the adaptive mask selection method is used to solve the problem of low accuracy of GPA measurement under non-uniform large deformation.

- (2)

- Intensity ratio analysis was conducted for the interface width evaluation of a single-crystal Ni-based superalloy. The strain field containing the two phases was obtained by using S-GPA in the two phases by selecting a reference region, respectively. The width of the calculated two-phase interface is basically consistent with the width of the strain-irregular transition region. The determination of the two-phase interface based on HRTEM images and the calculation of the strain field near the two-phase interface can corroborate and complement each other.

- (3)

- TEM in-situ heating was conducted. The change of dislocation density in the γ phase near the two-phase interface of the single-crystal Ni-based superalloy was analyzed. The dislocation density decreases first with the increase in temperature, which is consistent with the characteristics of metal quenching, and increases sharply at 450 °C. This is closely related to the intermediate temperature brittleness of the alloy, where dislocations cause a non-equilibrium bias of solute atoms at medium temperatures, which increases the yield strength of the alloy and causes the intermediate temperature brittleness of the alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moustapha, H.; Zelesky, M.F.; Baines, N.C.; Japikse, D. Axial and Radial Turbines; Concepts NREC White River Junction: Hartford, VT, USA, 2003; Volume 2. [Google Scholar]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide; ASM International: Materials Park, OH, USA, 2002. [Google Scholar]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Dirand, L.; Cormier, J.; Jacques, A.; Chateau-Cornu, J.-P.; Schenk, T.; Ferry, O.; Bastie, P. Measurement of the effective γ/γ′ lattice mismatch during high temperature creep of Ni-based single crystal superalloy. Mater. Charact. 2013, 77, 32–46. [Google Scholar] [CrossRef]

- Sun, J.; Yang, S.; Yuan, H. Assessment of thermo-mechanical fatigue in a nickel-based single-crystal superalloy CMSX-4 accounting for temperature gradient effects. Mater. Sci. Eng. A 2021, 809, 140918. [Google Scholar] [CrossRef]

- Taheri, M.; Halvaee, A.; Kashani-Bozorg, S.F. Effect of pre-and post-weld heat treatment on microstructure and mechanical properties of GTD-111 superalloy welds. Met. Mater. Int. 2021, 27, 1173–1192. [Google Scholar] [CrossRef]

- Ge, B.; Luo, Y.; Li, J.; Zhu, J.; Tang, D.; Gui, Z. Study of γ/γ′ interfacial width in a nickel-based superalloy by scanning transmission electron microscopy. Philos. Mag. Lett. 2012, 92, 541–546. [Google Scholar] [CrossRef]

- Srinivasan, R.; Banerjee, R.; Hwang, J.; Viswanathan, G.; Tiley, J.; Dimiduk, D.; Fraser, H. Atomic scale structure and chemical composition across order-disorder interfaces. Phys. Rev. Lett. 2009, 102, 086101. [Google Scholar] [CrossRef] [PubMed]

- Meher, S.; Viswanathan, G.; Nag, S.; Fraser, H.; Banerjee, R. Determination of the gamma prime/gamma interface width in a Co–Al–W alloy via coupled aberration-corrected scanning transmission electron microscopy and atom probe tomography. Scr. Mater. 2016, 121, 23–27. [Google Scholar] [CrossRef]

- Mishin, Y. Atomistic modeling of the γ and γ′-phases of the Ni–Al system. Acta Mater. 2004, 52, 1451–1467. [Google Scholar] [CrossRef]

- Ardell, A.J.; Ozolins, V. Trans-interface diffusion-controlled coarsening. Nat. Mater. 2005, 4, 309–316. [Google Scholar] [CrossRef] [PubMed]

- Ge, B.; Luo, Y.; Li, J.; Zhu, J. Study of γ/γ′ interfaces in nickel-based, single-crystal superalloys by scanning transmission electron microscopy. Metall. Mater. Trans. A 2011, 42, 548–552. [Google Scholar] [CrossRef]

- Ding, Q.; Shen, Z.; Xiang, S.; Tian, H.; Li, J.; Zhang, Z. In-situ environmental TEM study of γ′-γ phase transformation induced by oxidation in a nickel-based single crystal superalloy. J. Alloys Compd. 2015, 651, 255–258. [Google Scholar] [CrossRef]

- Xiang, S.; Mao, S.; Wei, H.; Liu, Y.; Zhang, J.; Shen, Z.; Long, H.; Zhang, H.; Wang, X.; Zhang, Z. Selective evolution of secondary γ′ precipitation in a Ni-based single crystal superalloy both in the γ matrix and at the dislocation nodes. Acta Mater. 2016, 116, 343–353. [Google Scholar] [CrossRef]

- Zhang, H.; Wen, H.; Liu, Z.; Zhang, Q.; Xie, H. TEM nano-Moiré evaluation for an invisible lattice structure near the grain interface. Nanoscale 2017, 9, 15923–15933. [Google Scholar] [CrossRef]

- He, R.; Zhang, H.; Liu, Z.; Wen, H.; Xie, H. Interphase interface structure and evolution of a single crystal Ni-based superalloy based on HRTEM image analysis. Appl. Opt. 2022, 61, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Guo, Y.; Wang, Y. Research progress of the directional coarsening behavor and high temperature creep mechanical properties in Ni-base superalloys. Adv. Mech. 2011, 41, 172–186. [Google Scholar]

- Sun, F. Electron Microscopic Investigations and First-Principles calculations of Interfaces in Ni-Based Single Crystal Superalloys; Shandong University: Jinan, China, 2014. [Google Scholar]

- Lv, X. Study on the Configurations and Core Structures of Dislocations during Creep Procedure in Nickel-Base Single Crystal Superalloys; Shandong University: Jinan, China, 2017. [Google Scholar]

- Giannuzzi, L.A.; Stevie, F.A. A review of focused ion beam milling techniques for TEM specimen preparation. Micron 1999, 30, 197–204. [Google Scholar] [CrossRef]

- Zhang, H.; Peng, R.; Wen, H.; Xie, H.; Liu, Z. A hybrid method for lattice image reconstruction and deformation analysis. Nanotechnology 2022, 33, 385706. [Google Scholar] [CrossRef]

- Hÿtch, M.J.; Snoeck, E.; Kilaas, R. Quantitative measurement of displacement and strain fields from HREM micrographs. Ultramicroscopy 1998, 74, 131–146. [Google Scholar] [CrossRef]

- Hÿtch, M.J.; Gandais, M. Quantitative criteria for the detection and characterization of nanocrystals from high-resolution electron microscopy images. Philos. Mag. A 1995, 72, 619–634. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Z.; Wen, H.; Xie, H.; Chao, L. Subset geometric phase analysis method for deformation evaluation of HRTEM images. Ultramicroscopy 2016, 171, 34–42. [Google Scholar] [CrossRef]

- Taraci, J.; Hÿtch, M.; Clement, T.; Peralta, P.; McCartney, M.; Drucker, J.; Picraux, S. Strain mapping in nanowires. Nanotechnology 2005, 16, 2365. [Google Scholar] [CrossRef]

- Häussler, D.; Spiecker, E.; Yang, S.; Jäger, W.; Störmer, M.; Bormann, R.; Zwicker, G. TEM characterization of La/B4C multilayer systems by the geometric phase method. Phys. Status Solidi 2005, 202, 2299–2308. [Google Scholar] [CrossRef]

- Guerrero, E.; Galindo, P.; Yáñez, A.; Ben, T.; Molina, S.I. Error quantification in strain mapping methods. Microsc. Microanal. 2007, 13, 320–328. [Google Scholar] [CrossRef] [PubMed]

- Chung, J.; Rabenberg, L. Effects of strain gradients on strain measurements using geometrical phase analysis in the transmission electron microscope. Ultramicroscopy 2008, 108, 1595–1602. [Google Scholar] [CrossRef]

- Qian, K. Two-dimensional windowed Fourier transform for fringe pattern analysis: Principles, applications and implementations. Opt. Lasers Eng. 2007, 45, 304–317. [Google Scholar]

- Wen, H.; Zhang, H.; Liu, Z.; Liu, C.; Liu, S.; Yang, X.; Liu, F.; Xie, H. Stress mapping of a strain superlattice using scanning moiré fringe imaging. Appl. Phys. Lett. 2018, 113, 031905. [Google Scholar] [CrossRef]

- Wen, H.; Zhang, H.; Liu, Z.; Liu, C.; Liu, S.; Yang, X.; Liu, F.; Xie, H. Quantitative evaluation of the interface lattice quality of a strain superlattice by strain analysis. Nanoscale 2018, 10, 17567–17575. [Google Scholar] [CrossRef]

- Li, H.; Jin, X. Dislocation density determination in nano-bainitic steels. J. Shanghai Jiaotong Univ. 2010, 44, 613–0615. [Google Scholar]

- Schmidt, M.; Kusche, R.; von Issendorff, B.; Haberland, H. Irregular variations in the melting point of size-selected atomic clusters. Nature 1998, 393, 238. [Google Scholar] [CrossRef]

- Couchman, P.; Jesser, W. Thermodynamic theory of size dependence of melting temperature in metals. Nature 1977, 269, 481. [Google Scholar] [CrossRef]

- Smirnov, W.; Kriele, A.; Yang, N.; Nebel, C. Aligned diamond nano-wires: Fabrication and characterisation for advanced applications in bio-and electrochemistry. Diam. Relat. Mater. 2010, 19, 186–189. [Google Scholar] [CrossRef]

- Sheng, L.-y.; Fang, Y.; Guo, J.-t.; Xi, T.-f. Anomalous yield and intermediate temperature brittleness behaviors of directionally solidified nickel-based superalloy. Trans. Nonferrous Met. Soc. China 2014, 24, 673–681. [Google Scholar] [CrossRef]

- Quan, D. Experimental Study of Microstructure Evolution of DD6 Single Crystal Alloy under Thermomechanical Loading; Wuhan University of Technology: Wuhan, China, 2015. [Google Scholar]

| Element | Cr | Co | W | Al | Ta | Mo | Re | Hf | Other | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| Content | 7.05 | 7.76 | 4.90 | 6.17 | 6.61 | 1.50 | 3.01 | 0.13 | <0.1 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Wen, H.; Peng, R.; He, R.; Li, M.; Feng, W.; Zhao, Y.; Liu, Z. Experimental Study at the Phase Interface of a Single-Crystal Ni-Based Superalloy Using TEM. Materials 2022, 15, 6915. https://doi.org/10.3390/ma15196915

Zhang H, Wen H, Peng R, He R, Li M, Feng W, Zhao Y, Liu Z. Experimental Study at the Phase Interface of a Single-Crystal Ni-Based Superalloy Using TEM. Materials. 2022; 15(19):6915. https://doi.org/10.3390/ma15196915

Chicago/Turabian StyleZhang, Hongye, Huihui Wen, Runlai Peng, Ruijun He, Miao Li, Wei Feng, Yao Zhao, and Zhanwei Liu. 2022. "Experimental Study at the Phase Interface of a Single-Crystal Ni-Based Superalloy Using TEM" Materials 15, no. 19: 6915. https://doi.org/10.3390/ma15196915

APA StyleZhang, H., Wen, H., Peng, R., He, R., Li, M., Feng, W., Zhao, Y., & Liu, Z. (2022). Experimental Study at the Phase Interface of a Single-Crystal Ni-Based Superalloy Using TEM. Materials, 15(19), 6915. https://doi.org/10.3390/ma15196915