Interlayer Shear Characteristics of Bridge Deck Pavement through Experimental and Numerical Analysis

Abstract

1. Introduction

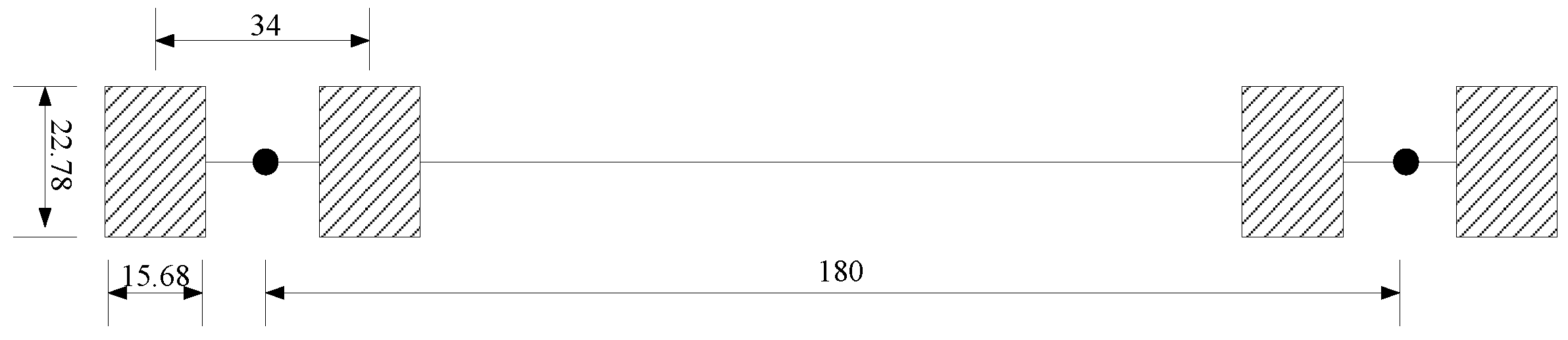

2. Numerical Simulation

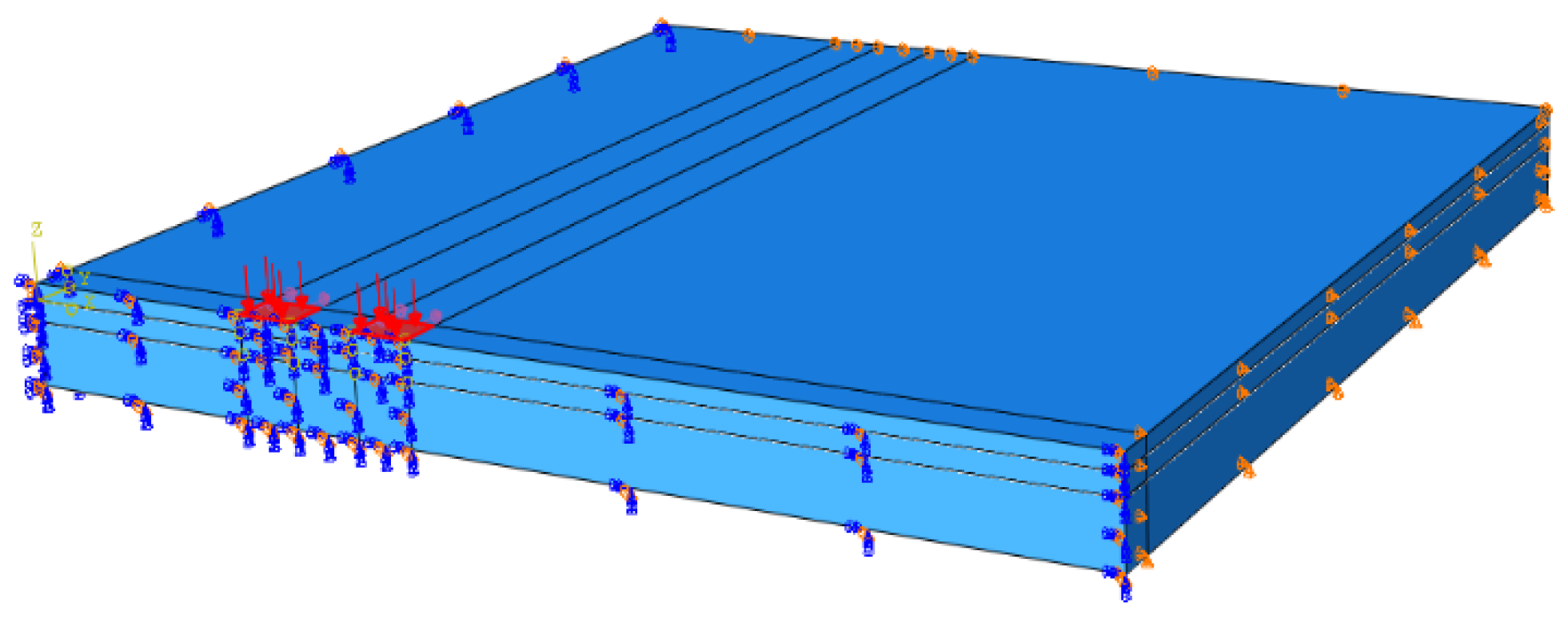

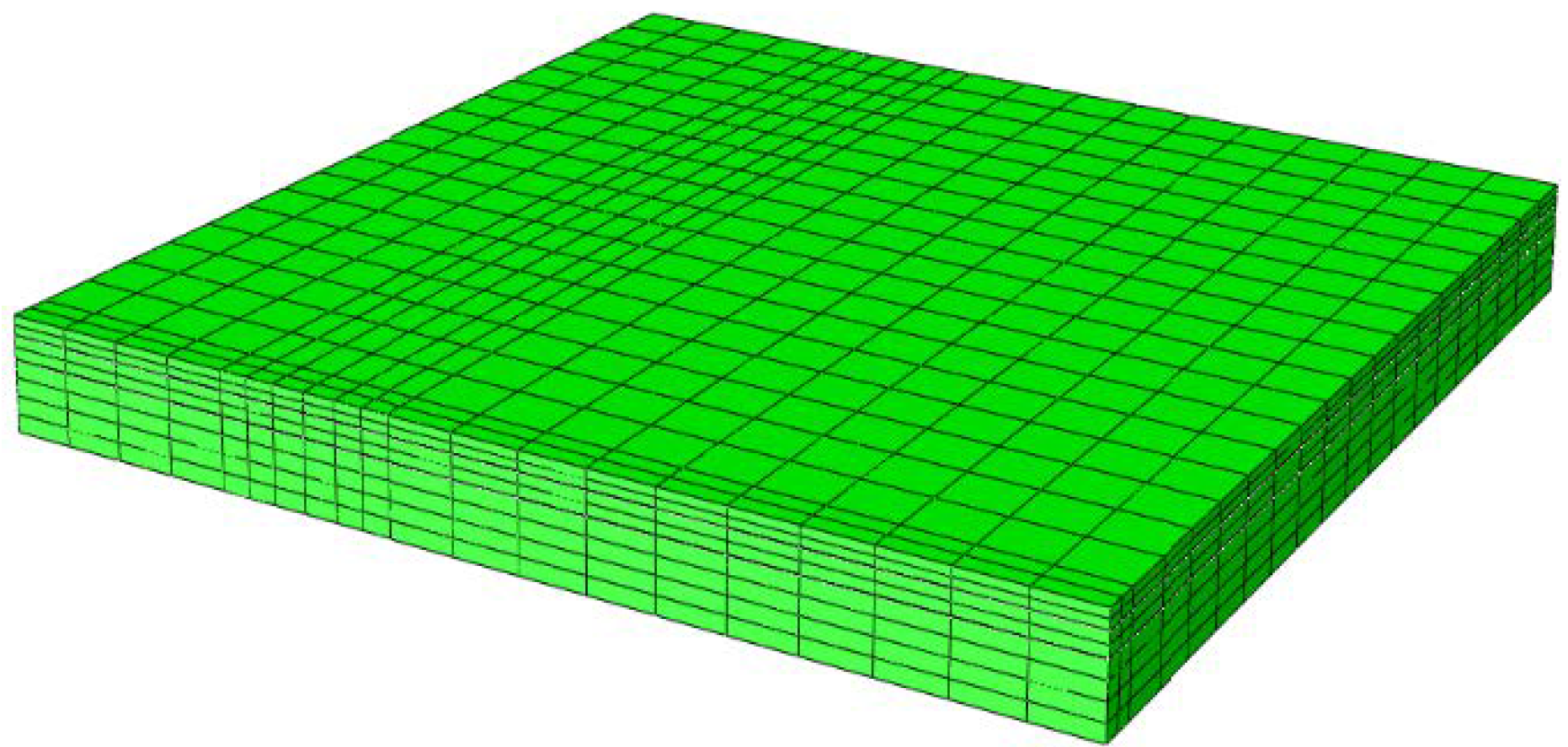

2.1. FEM Model Development

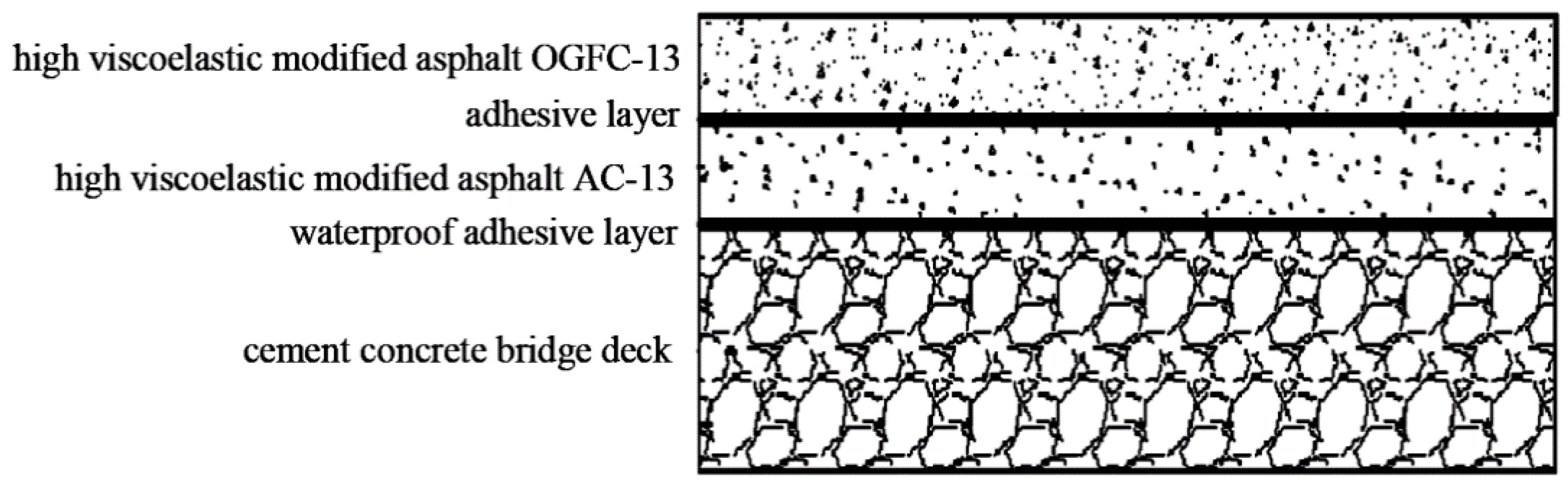

2.1.1. Model Structure

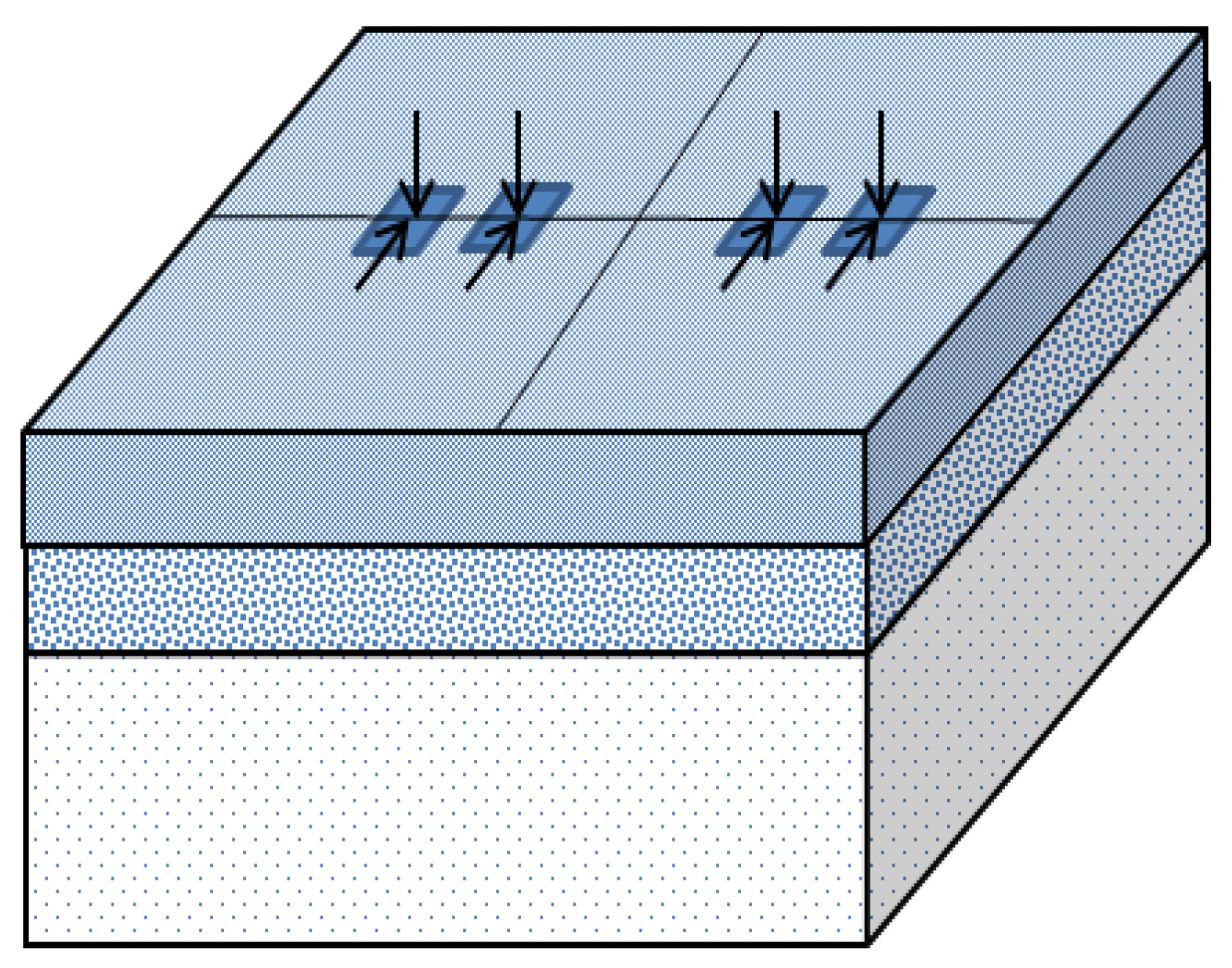

2.1.2. Loading Application

2.1.3. Interfacial Conditions

3. Experimental Program

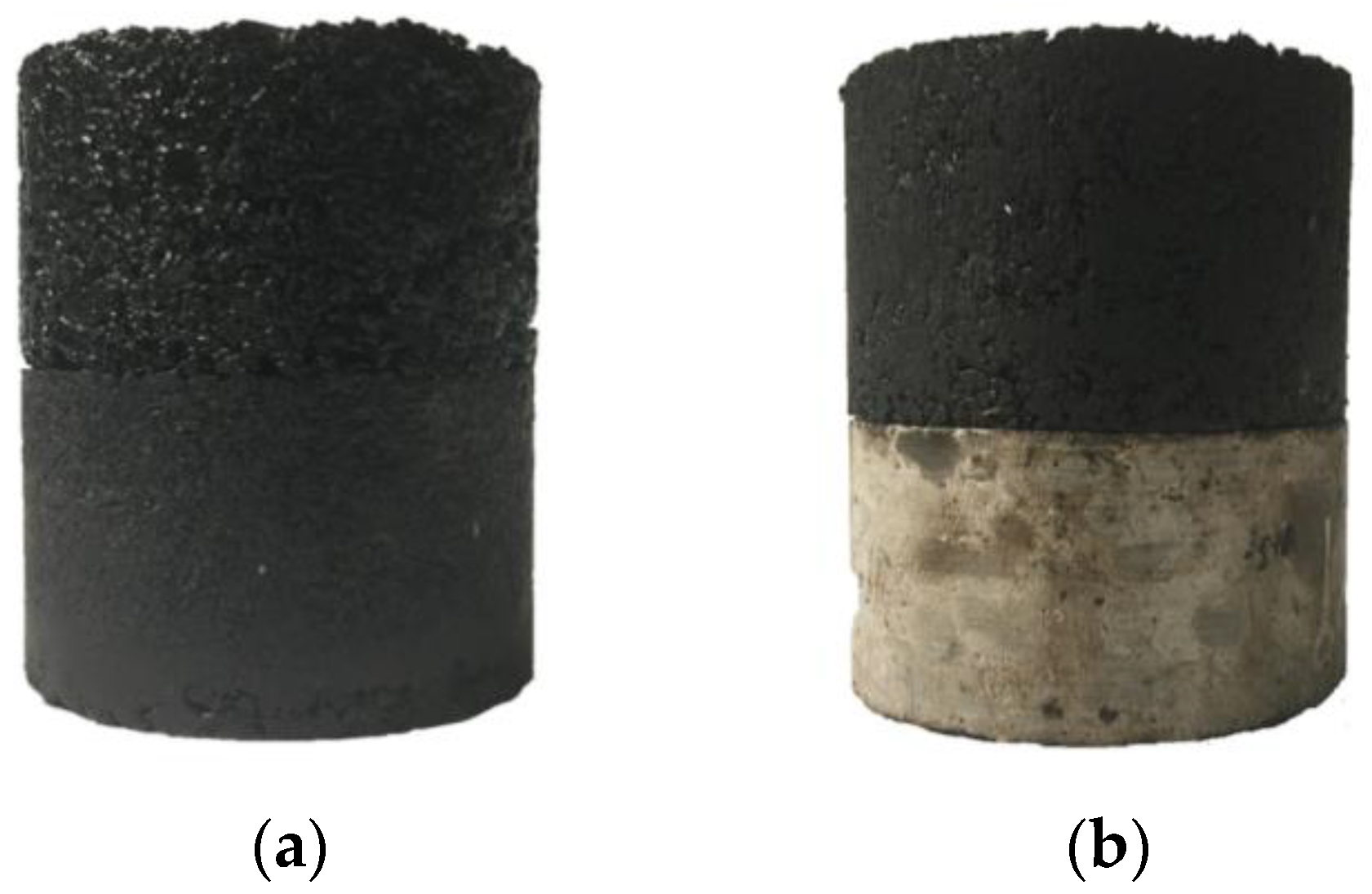

3.1. Materials

3.2. Specimen Preparation

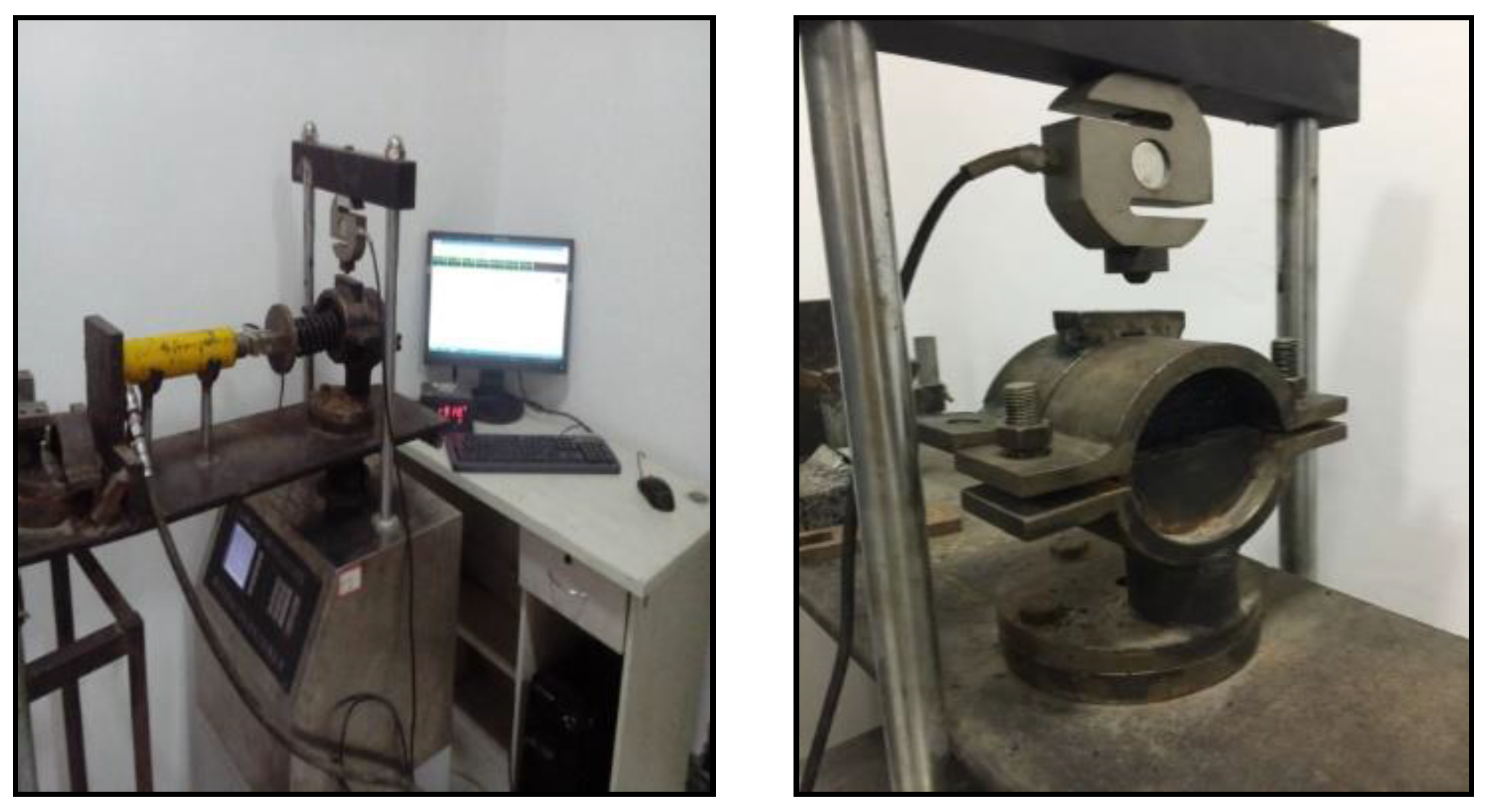

3.3. Test Device

4. Results and Discussion

4.1. Simulation Results

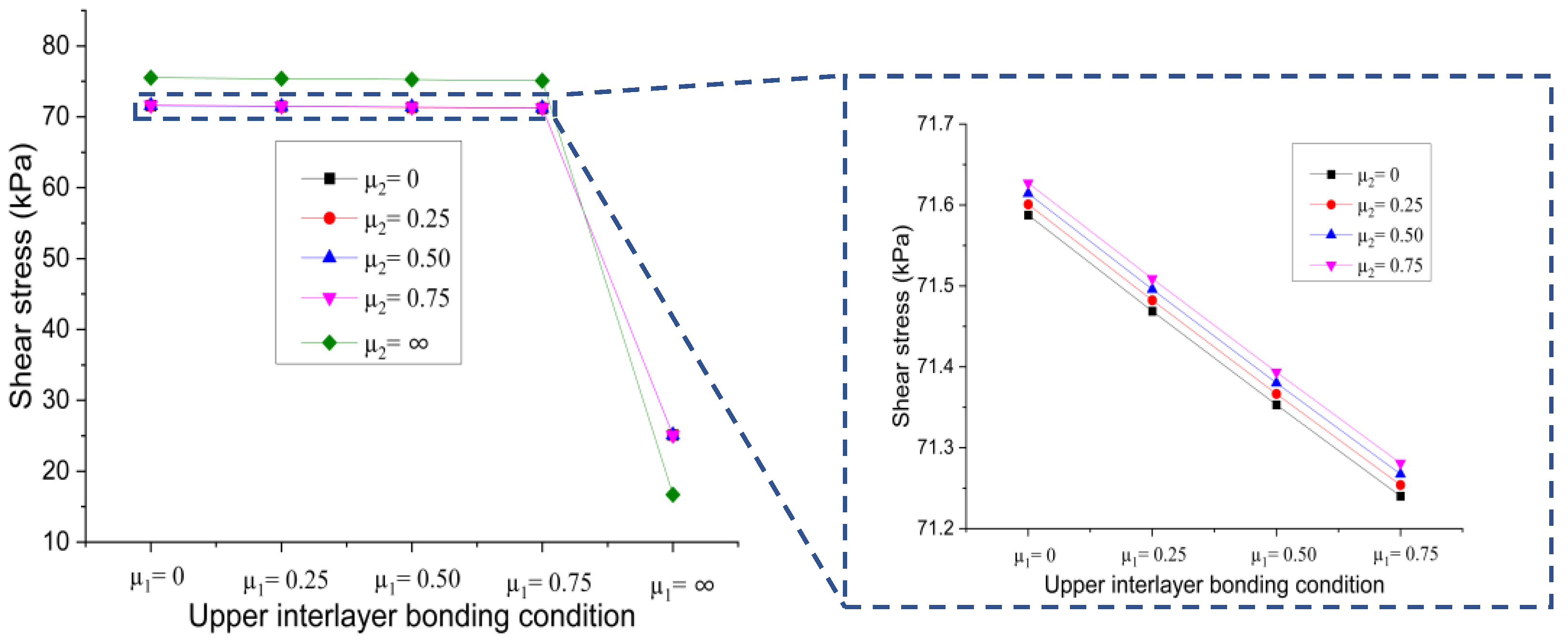

4.1.1. Shear Stress in the Upper Layer

- (a)

- Effect of upper interlayer bonding condition

- (b)

- Effect of lower interlayer bonding condition

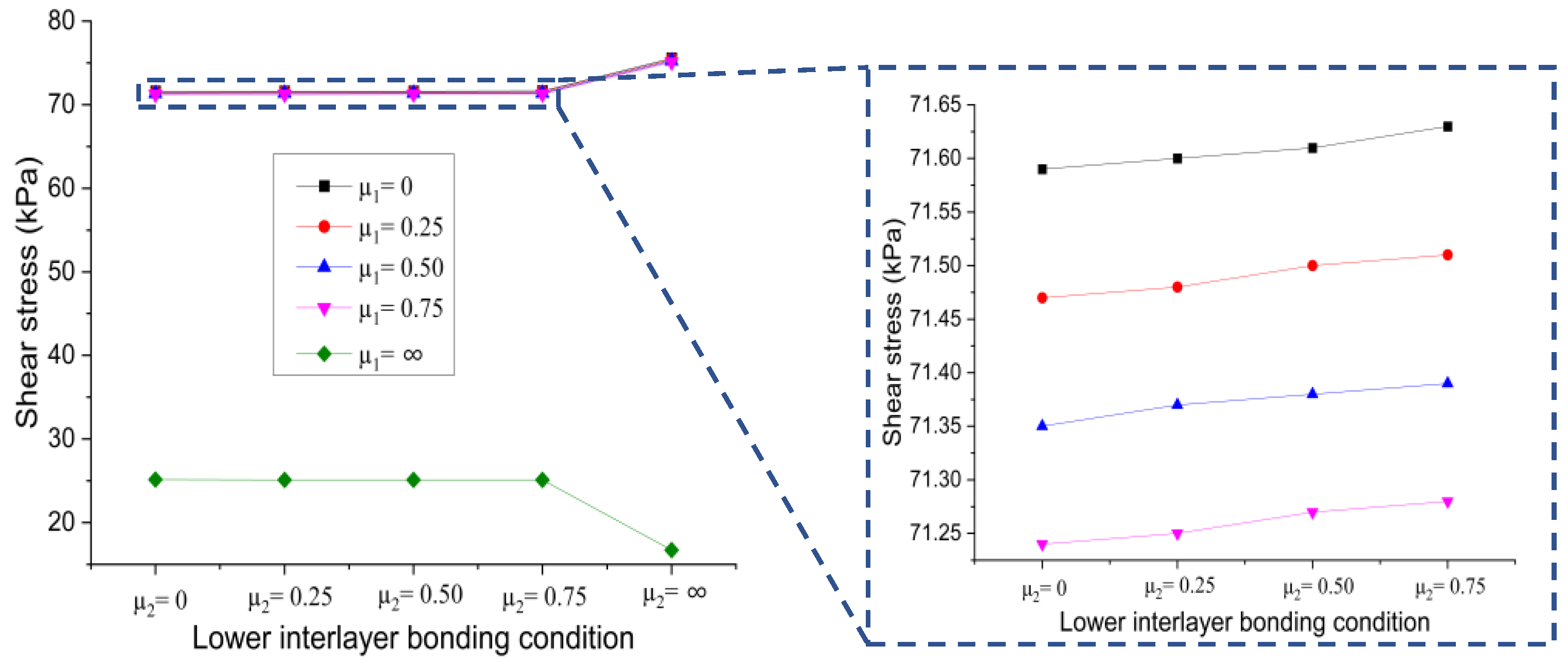

4.1.2. Shear Stress in the Lower Layer

- (a)

- Effect of upper interlayer bonding condition

- (b)

- Effect of lower interlayer bonding condition

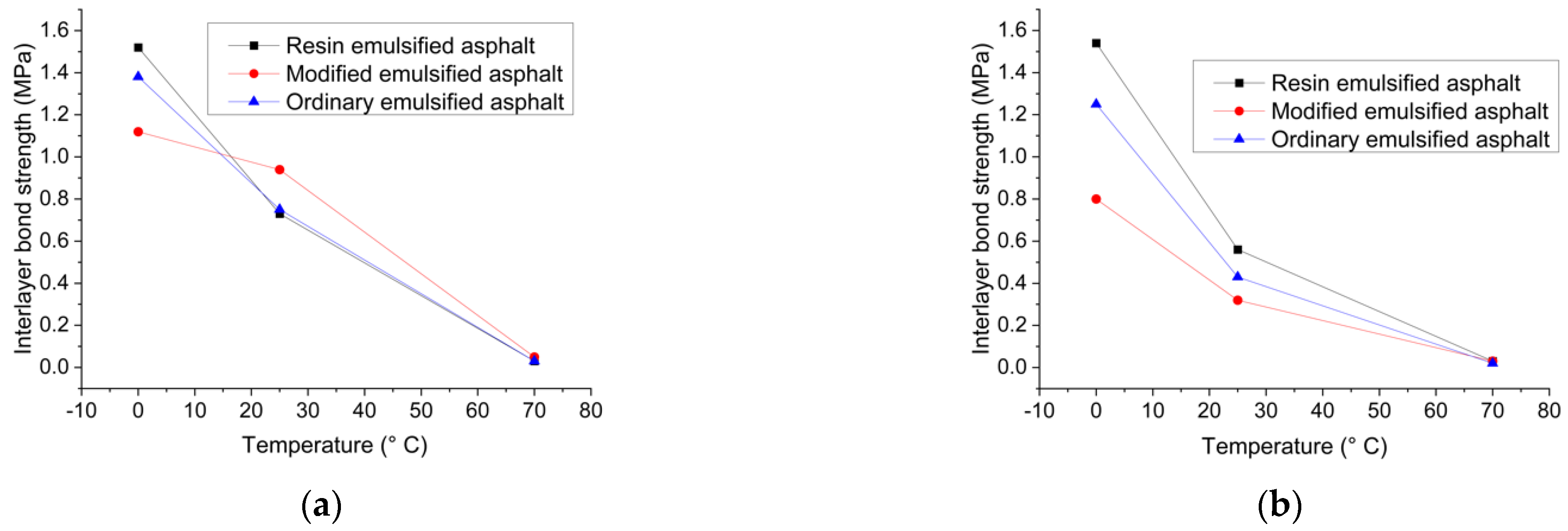

4.2. Experimental Results

4.2.1. Effect of Bonding Material

4.2.2. Effect of Structure Type

4.2.3. Analysis of Variance

5. Conclusions

- (1)

- Regardless of the bonding condition of the lower interlayer, the shear stress at the bottom of the upper layer gradually decreased with the increase of the friction coefficient of the upper layer, and the bonding condition of the lower interlayer had an insignificant effect on the produced shear stress. Only when the friction coefficient of the upper interlayer was large was the increase of the friction coefficient of the lower interlayer conducive to reducing the shear stress at the bottom of the upper layer.

- (2)

- Different bonding conditions of the upper interlayer produced different effects on the shear stress at the bottom of the lower layer. Only when the lower interlayer was in a full slip or partial bonding state was increasing the friction coefficient of the upper interlayer conducive to reducing the shear stress at the bottom of the lower layer.

- (3)

- Regardless of the bonding condition of the upper interlayer, with the increase of the friction coefficient of the lower interlayer, the shear stress at the bottom of the lower layer reduced first and then increased.

- (4)

- When a bonding material is selected for interlayer treatment, interlayer bonding performance and the influence of temperature dependency of interlayer treatment should be considered concurrently. The bridge deck pavement structure is prone to delamination, rutting, and other distresses in high-temperature areas in summer. Therefore, when a bonding material is selected for interlayer treatment, not only the adhesive ability of the material but also the stability of the interfacial bonding performance is equally important.

- (5)

- When the bonding performance of certain adhesive material in different pavement structures is compared, the evaluation of performance under various working conditions should be considered rather than comparing the performance for example at a certain temperature. In practical engineering, it is imperative to select the appropriate bonding material according to the specific pavement structure, not necessarily the one with the strongest bonding strength.

- (6)

- Results of statistical analysis revealed that all factors, including structure type, type of adhesive material, and temperature statistically have a significant effect on interlayer bonding strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.; Sun, J.; Huang, Z.; Wang, F.; Jia, M.; Lv, W.; Ye, J. A laboratory study of epoxy/polyurethane modified asphalt binders and mixtures suitable for flexible bridge deck pavement. Constr. Build. Mater. 2020, 274, 122084. [Google Scholar] [CrossRef]

- Qian, Z.-D.; Liu, Y.; Liu, C.-B.; Zheng, D. Design and skid resistance evaluation of skeleton-dense epoxy asphalt mixture for steel bridge deck pavement. Constr. Build. Mater. 2016, 114, 851–863. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.; Shi, X.; Zhang, Y.; Ren, H. Developing cold-mixed epoxy resin-based ultra-thin antiskid surface layer for steel bridge deck pavement. Constr. Build. Mater. 2021, 291, 123366. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Han, F.; Zhang, Z.; Lv, W. A lab study to develop a bridge deck pavement using bisphenol A unsaturated polyester resin modified asphalt mixture. Constr. Build. Mater. 2018, 159, 83–98. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Liu, T.; Lv, W. Study on the micro-mechanism and structure of unsaturated polyester resin modified concrete for bridge deck pavement. Constr. Build. Mater. 2021, 289, 123174. [Google Scholar] [CrossRef]

- Yang, F.; Cong, L.; Li, Z.; Yuan, J.; Guo, G.; Tan, L. Study on preparation and performance of a thermosetting polyurethane modified asphalt binder for bridge deck pavements. Constr. Build. Mater. 2022, 326, 126784. [Google Scholar] [CrossRef]

- Cheng, Y.; Shi, Z. Experimental Study on Nano-SiO2 Improving Concrete Durability of Bridge Deck Pavement in Cold Regions. Adv. Civ. Eng. 2019, 2019, 5284913. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Tang, C.; Yang, J.; You, Y.; Lv, Z. A lab study to develop polyurethane concrete for bridge deck pavement. Int. J. Pavement Eng. 2022, 23, 1404–1412. [Google Scholar] [CrossRef]

- Wang, L.; Hou, Y.; Zhang, L.; Liu, G. A combined static-and-dynamics mechanics analysis on the bridge deck pavement. J. Clean. Prod. 2017, 166, 209–220. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, C.; Lu, Y.; Zheng, T.; Dong, Z.; Tian, Y.; Jia, Y. In-situ recognition of moisture damage in bridge deck asphalt pavement with time-frequency features of GPR signal. Constr. Build. Mater. 2020, 244, 118295. [Google Scholar] [CrossRef]

- Chun, S.; Kim, K.; Greene, J.; Choubane, B. Evaluation of interlayer bonding condition on structural response characteristics of asphalt pavement using finite element analysis and full-scale field tests. Constr. Build. Mater. 2015, 96, 307–318. [Google Scholar] [CrossRef]

- Wu, S.; Chen, H.; Zhang, J.; Zhang, Z. Effects of interlayer bonding conditions between semi-rigid base layer and asphalt layer on mechanical responses of asphalt pavement structure. Int. J. Pavement Res. Technol. 2017, 10, 274–281. [Google Scholar] [CrossRef]

- Wang, X.; Ma, X. Responses of Semi-Rigid Base Asphalt Pavement with Interlayer Contact Bonding Model. Adv. Civ. Eng. 2020, 2020, 8841139. [Google Scholar] [CrossRef]

- Li, S.; Tang, L.; Yao, K. Comparison of Two Typical Professional Programs for Mechanical Analysis of Interlayer Bonding of Asphalt Pavement Structure. Adv. Mater. Sci. Eng. 2020, 2020, 5850627. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Feng, J.; Wang, H.; Hong, S.; Zheng, S. Stress Regression Analysis of Asphalt Concrete Deck Pavement Based on Orthogonal Experimental Design and Interlayer Contact. IOP Conf. Ser. Mater. Sci. Eng. 2018, 322, 042026. [Google Scholar] [CrossRef]

- He, C.; Hu, J.; Zhu, Y.; Lu, H. Mechanical Analysis for Asphalt Paving on Steel Bridge Using Different Interlayer Contact Condition. In ICCTP 2011: Towards Sustainable Transportation System; ASCE: Reston, VA, USA, 2011. [Google Scholar]

- Liu, Y.; Qian, Z.; Yin, Y.; Ren, H. Investigation on Interlayer Behaviors of a Double-Layered Heterogeneous Asphalt Pavement Structure for Steel Bridge Deck. J. Mater. Civ. Eng. 2022, 34, 04022062. [Google Scholar] [CrossRef]

- Jin, W.; Zhao, Y.; Wang, W.; He, F. Performance Evaluation and Optimization of Waterproof Adhesive Layer for Concrete Bridge Deck in Seasonal Frozen Region Using AHP. Adv. Mater. Sci. Eng. 2021, 2021, 5555535. [Google Scholar] [CrossRef]

- Fu, J.; Shen, A.; Yuan, Z. Properties of Different Waterproof Bonding Layer Systems for Cement Concrete Bridge Deck Pavement. Coatings 2022, 12, 308. [Google Scholar] [CrossRef]

- Zhang, M.; Hao, P.; Men, G.; Liu, N.; Yuan, G. Research on the compatibility of waterproof layer materials and asphalt mixture for steel bridge deck. Constr. Build. Mater. 2020, 269, 121346. [Google Scholar] [CrossRef]

- Xu, Y.; Lv, X.; Ma, C.; Liang, F.; Qi, J.; Chou, Z.; Xu, S. Shear Fatigue Performance of Epoxy Resin Waterproof Adhesive Layer on Steel Bridge Deck Pavement. Front. Mater. 2021, 7, 618073. [Google Scholar] [CrossRef]

- Cao, M.M.; Huang, W.Q.; Lu, Y.; Tan, Q.Q. Test and Evaluation Method of lnterlaminar Shear Performance of Composite Pavement. J. Highway Transp. Res. Dev. 2018, 12, 33–43. (In English) [Google Scholar] [CrossRef]

- Liu, Y.; Wu, J.; Chen, J. Mechanical properties of a waterproofing adhesive layer used on concrete bridges under heavy traffic and temperature loading. Int. J. Adhes. Adhes. 2014, 48, 102–109. [Google Scholar] [CrossRef]

- Ai, C.; Huang, H.; Rahman, A.; An, S. Establishment of a new approach to optimized selection of steel bridge deck waterproof bonding materials composite system. Constr. Build. Mater. 2020, 264, 120269. [Google Scholar] [CrossRef]

- Liu, H.; Wu, S.; Han, J. Research on shear strength and fatigue characteristics of bridge deck pavement bonding layers. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering, Wuhan, China, 26–28 June 2010; pp. 970–972. [Google Scholar]

- Yin, Y. Research on Interlayer Adhesion Performance of “EA+SMA” Steel Deck Pavement Structure; Southeastern University: Lakeland, FL, USA, 2020. [Google Scholar]

- He, Q.; Zhang, H.; Li, J.; Duan, H. Performance evaluation of polyurethane/epoxy resin modified asphalt as adhesive layer material for steel-UHPC composite bridge deck pavements. Constr. Build. Mater. 2021, 291, 123364. [Google Scholar] [CrossRef]

- Guo, L.; Zeng, G. Study on mechanical properties of typical steel bridge deck pavement waterproof bonding system. J. Phys. Conf. Ser. 2021, 1802, 22018. [Google Scholar] [CrossRef]

- Qian, G.; Li, S.; Yu, H.; Gong, X. Interlaminar Bonding Properties on Cement Concrete Deck and Phosphorous Slag Asphalt Pavement. Materials 2019, 12, 1427. [Google Scholar] [CrossRef]

- Qiu, Y.; An, S.; Rahman, A.; Ai, C. Evaluation and optimization of bridge deck waterproof bonding system using multi-objective grey target decision method. Road Mater. Pavement Des. 2019, 21, 1844–1858. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, W.; Zhao, J.; An, L.; Wang, F.; Du, Z.; Chen, Q. Experimental Study of the Factors Influencing the Performance of the Bonding Interface between Epoxy Asphalt Concrete Pavement and a Steel Bridge Deck. Buildings 2022, 12, 477. [Google Scholar] [CrossRef]

- Kim, T.W.; Baek, J.; Lee, H.J.; Lee, S.Y. Effect of pavement design parameters on the behaviors of orthotropic steel bridge deck pavements under traffic loading. Int. J. Pavement Eng. 2014, 15, 471–482. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, C.; Sun, R. Response analysis of orthotropic steel deck pavement based on interlayer contact bonding condition. Sci. Rep. 2021, 11, 23692. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Zhou, Q.; Medina, C.; Chang, G.K.; Rozycki, D.K. Experimental and numerical analysis of a waterproofing adhesive layer used on concrete-bridge decks. Int. J. Adhes. Adhes. 2009, 29, 525–534. [Google Scholar] [CrossRef]

- Logan, D.L.; Chaudhry, K.K.; Singh, P. A First Course in the Finite Element Method, 4th ed.; Cengage Learning: Stamford, CT, USA, 2011; 798p. [Google Scholar]

- Yang, H.H. Pavement Analysis and Design, 2nd ed.; Pearson Education International: Upper Saddle River, NJ, USA, 2012. [Google Scholar]

- Liu, Y.; Qian, Z.; Gong, M.; Huang, Q.; Ren, H. Interlayer residual stress analysis of steel bridge deck pavement during gussasphalt pavement paving. Constr. Build. Mater. 2022, 324, 126624. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, D.; Li, X.; Gao, Z.; Chen, Q.; Wang, C. Overview: Application of Resin Waterproof Adhesive Materials in Bridge Deck Pavement in China. Adv. Civ. Eng. 2022, 2022, 2320374. [Google Scholar] [CrossRef]

| Material | Thickness (cm) | Elastic Modulus (MPa) | Density (g·cm−3) | Poisson Ratio |

|---|---|---|---|---|

| Upper layer | 4 | 2000 | 2.20 | 0.3 |

| Lower layer | 5 | 3000 | 2.20 | 0.3 |

| Concrete | 15 | 31,000 | 2.40 | 0.15 |

| Passing Percentage (%) | Mineral Powder | Fiber (%) * | Asphalt Binder (%) * | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sieve Size (mm) | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |||

| OGFC-10 | 0 | 3 | 5 | 53 | 7 | 7 | 7 | 4 | 4 | 10 | 0.3 | 6.2 |

| AC-13 | 5 | 33 | 35 | 7 | 1 | 3 | 3 | 1 | 2 | 10 | 0.3 | 5.8 |

| System Type | Adhesive Material | Temperature (°C) | ||

|---|---|---|---|---|

| 0 | 25 | 70 | ||

| Type I | Resin emulsified asphalt | 1.52 | 0.73 | 0.03 |

| Modified emulsified asphalt | 1.12 | 0.94 | 0.05 | |

| Ordinary emulsified asphalt | 1.38 | 0.75 | 0.03 | |

| Type II | Resin emulsified asphalt | 1.54 | 0.56 | 0.03 |

| Modified emulsified asphalt | 0.8 | 0.32 | 0.03 | |

| Ordinary emulsified asphalt | 1.25 | 0.43 | 0.02 | |

| Factor | DF a | SS b | MS c | F-Value d | p-Value e |

|---|---|---|---|---|---|

| System type | 1 | 0.399 | 0.399 | 93.042 | ≤0.001 |

| Adhesive material | 2 | 0.353 | 0.176 | 41.123 | ≤0.001 |

| Temperature | 2 | 13.860 | 6.930 | 1616.517 | ≤0.001 |

| Error | 36 | 0.154 | 0.004 | ||

| Total | 53 | 15.932 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Hui, B.; Rahman, A. Interlayer Shear Characteristics of Bridge Deck Pavement through Experimental and Numerical Analysis. Materials 2022, 15, 7001. https://doi.org/10.3390/ma15197001

Chen W, Hui B, Rahman A. Interlayer Shear Characteristics of Bridge Deck Pavement through Experimental and Numerical Analysis. Materials. 2022; 15(19):7001. https://doi.org/10.3390/ma15197001

Chicago/Turabian StyleChen, Weidong, Bing Hui, and Ali Rahman. 2022. "Interlayer Shear Characteristics of Bridge Deck Pavement through Experimental and Numerical Analysis" Materials 15, no. 19: 7001. https://doi.org/10.3390/ma15197001

APA StyleChen, W., Hui, B., & Rahman, A. (2022). Interlayer Shear Characteristics of Bridge Deck Pavement through Experimental and Numerical Analysis. Materials, 15(19), 7001. https://doi.org/10.3390/ma15197001