Micro Characterization of Hot-Rolled Plate of Nb-Bearing Grain-Oriented Silicon Steel

Abstract

:1. Introduction

2. Materials and Experimental Procedure

3. Results

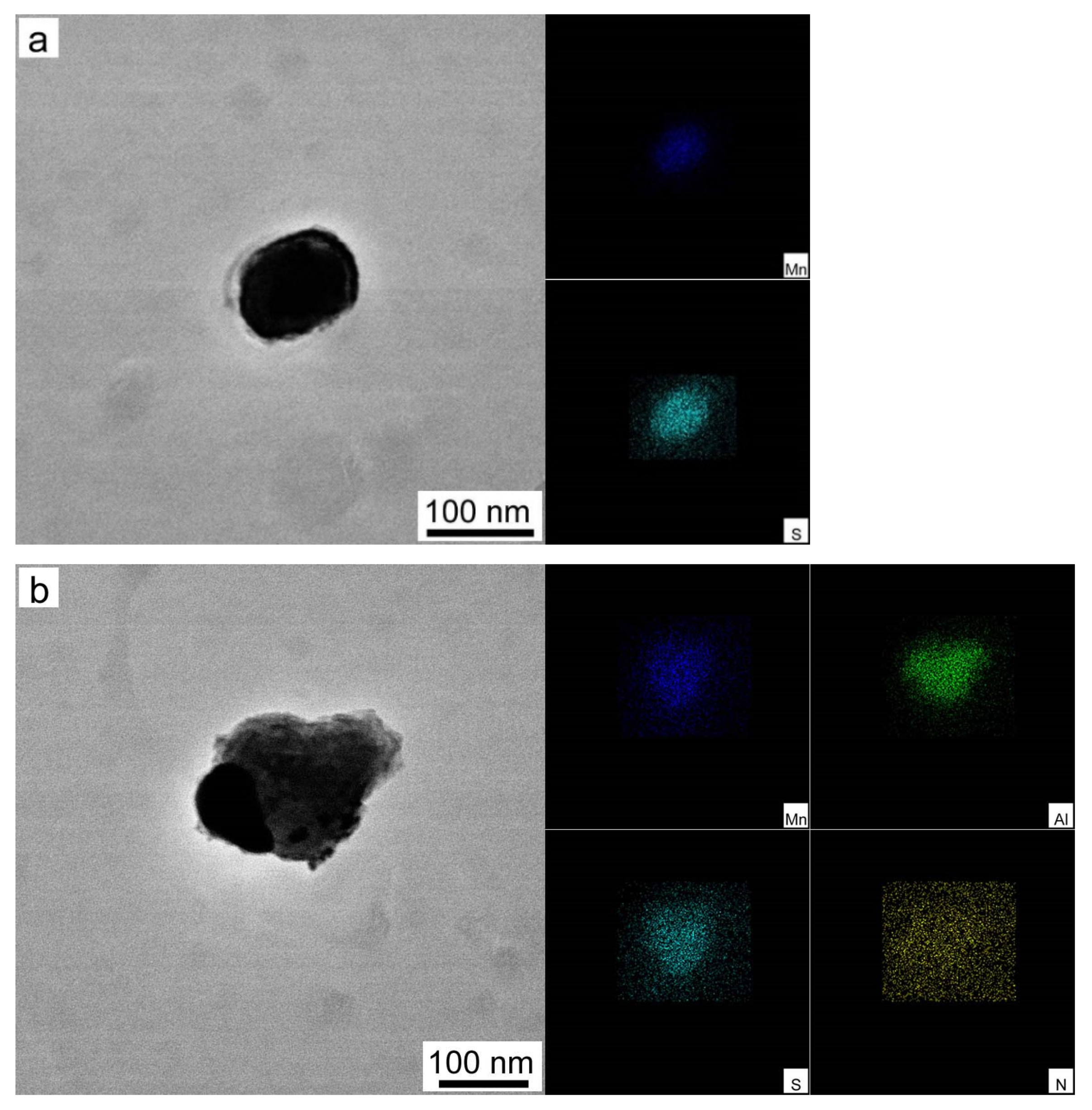

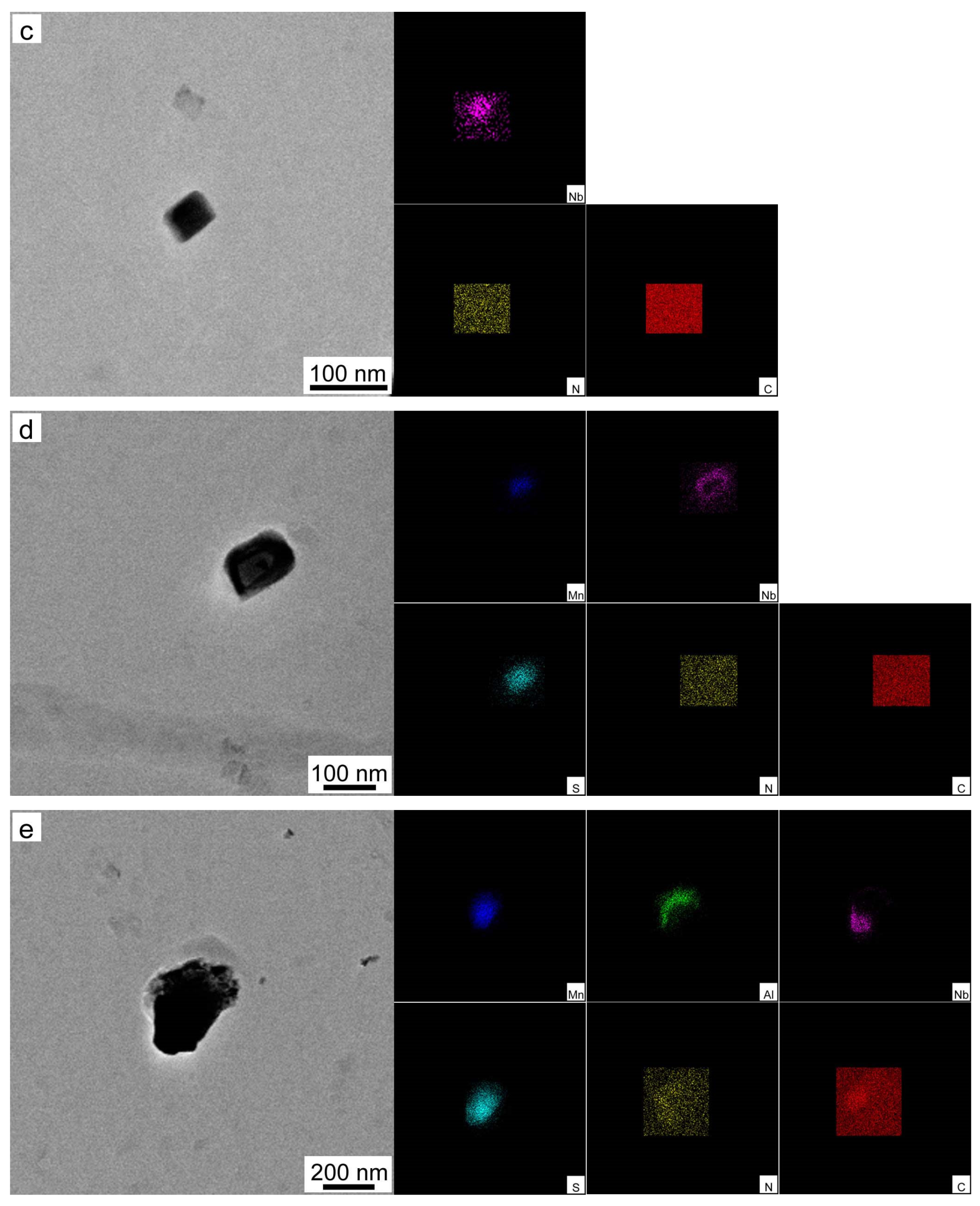

3.1. Characteristics of the Inhibitors in the Steels

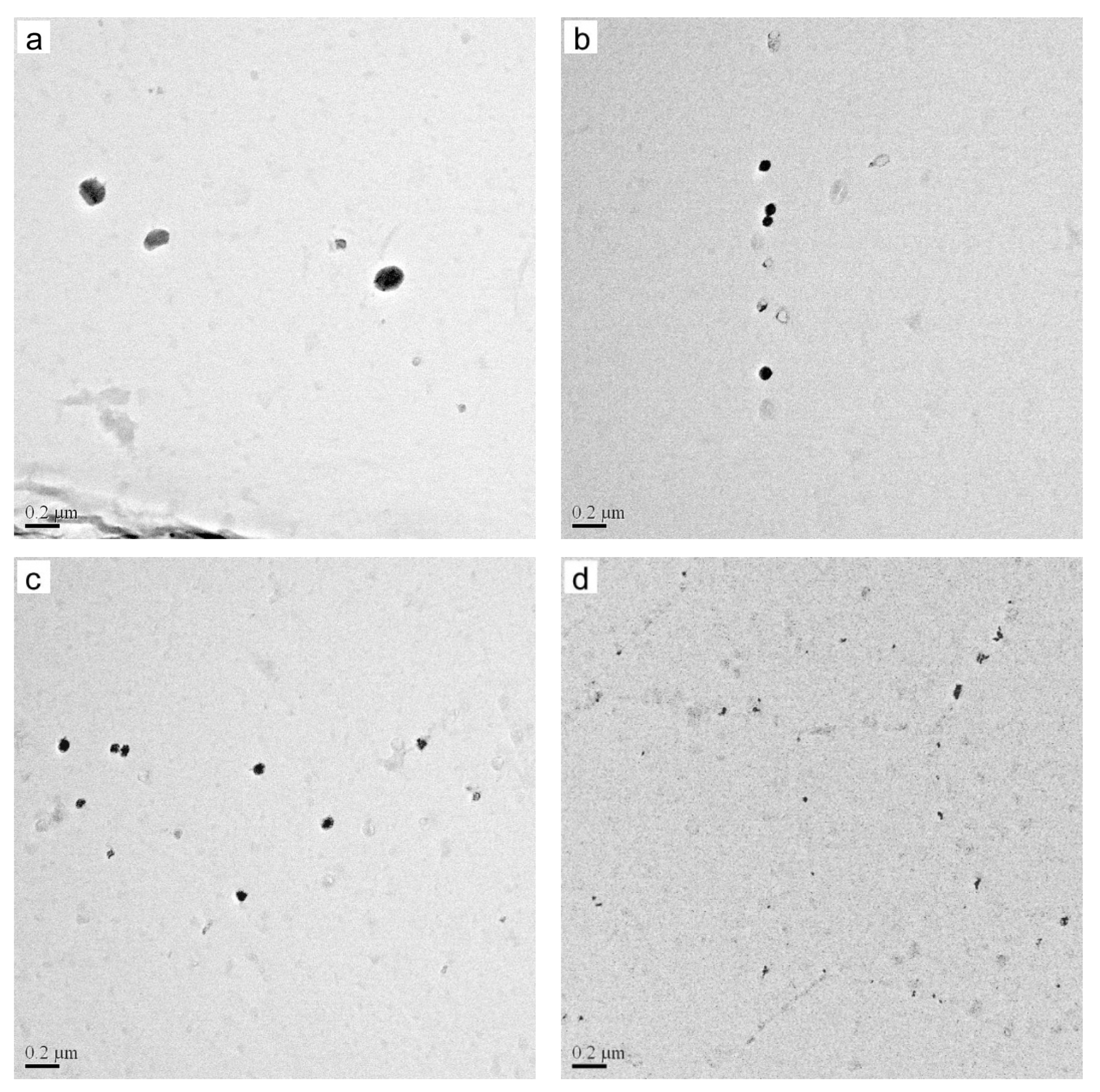

3.2. Microstructure and Texture of Hot-Rolled Bands with Different Nb Content

4. Discussion

4.1. Effect of Nb on Precipitates in Hot-Rolled Bands

4.2. Effect of Precipitates on Microstructure and Texture of Hot-Rolled Bands

5. Conclusions

- (1)

- The precipitates in hot-rolled bands were mainly single MnS and composite precipitates of MnS and AlN, and Nb(C, N) begins to precipitate after Nb is added. Meanwhile, with the increase of the Nb content, the precipitates become finer and more dispersed.

- (2)

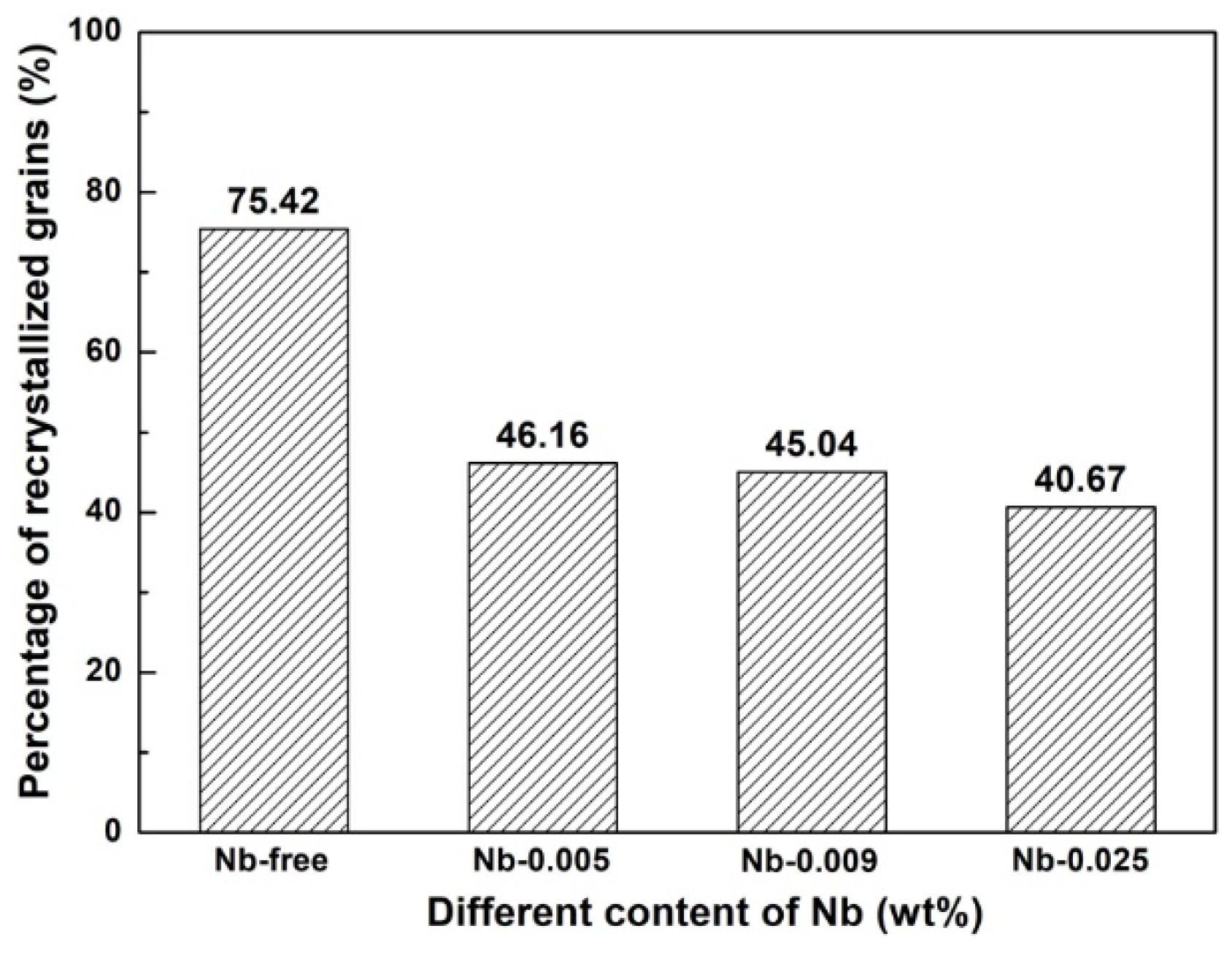

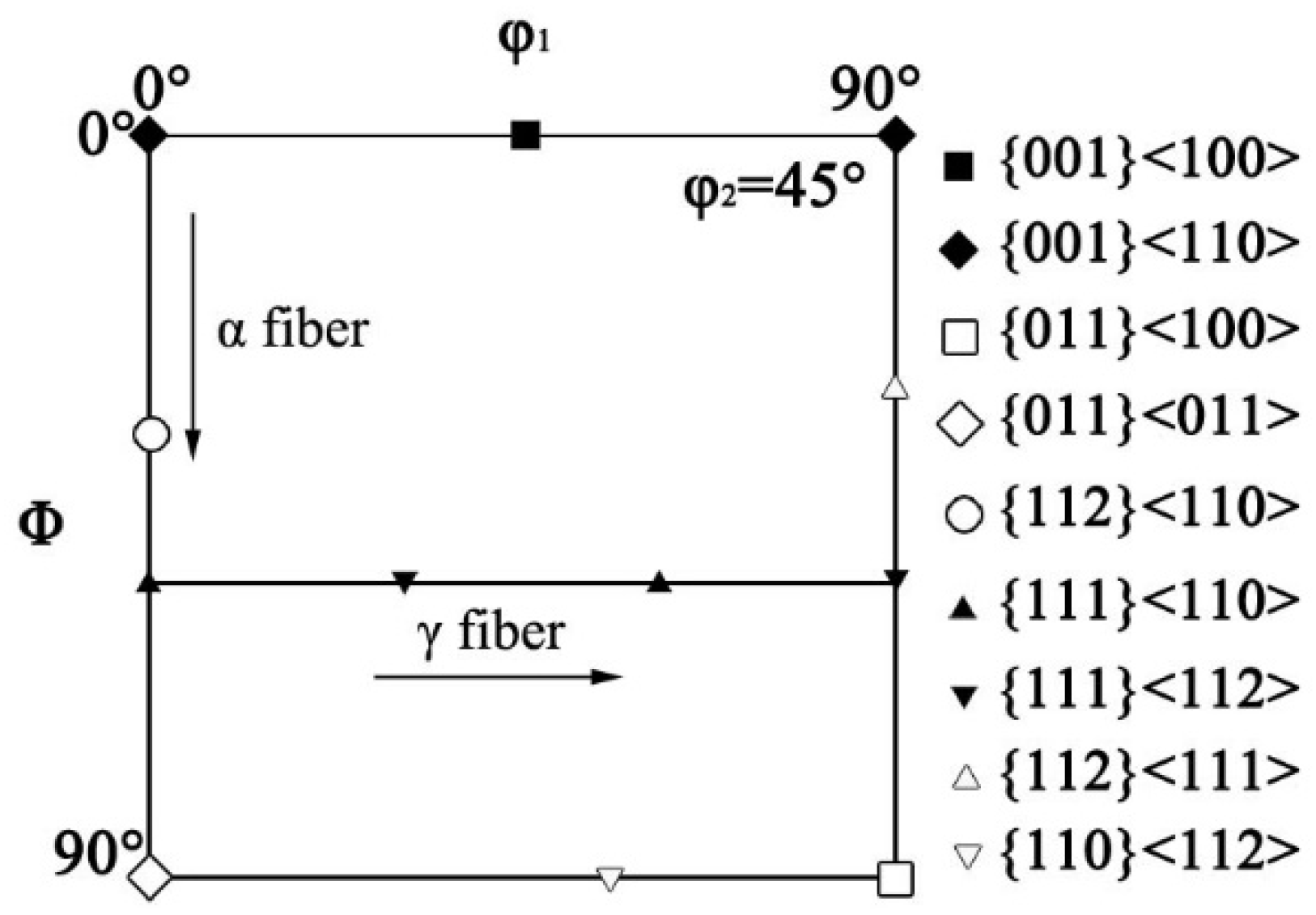

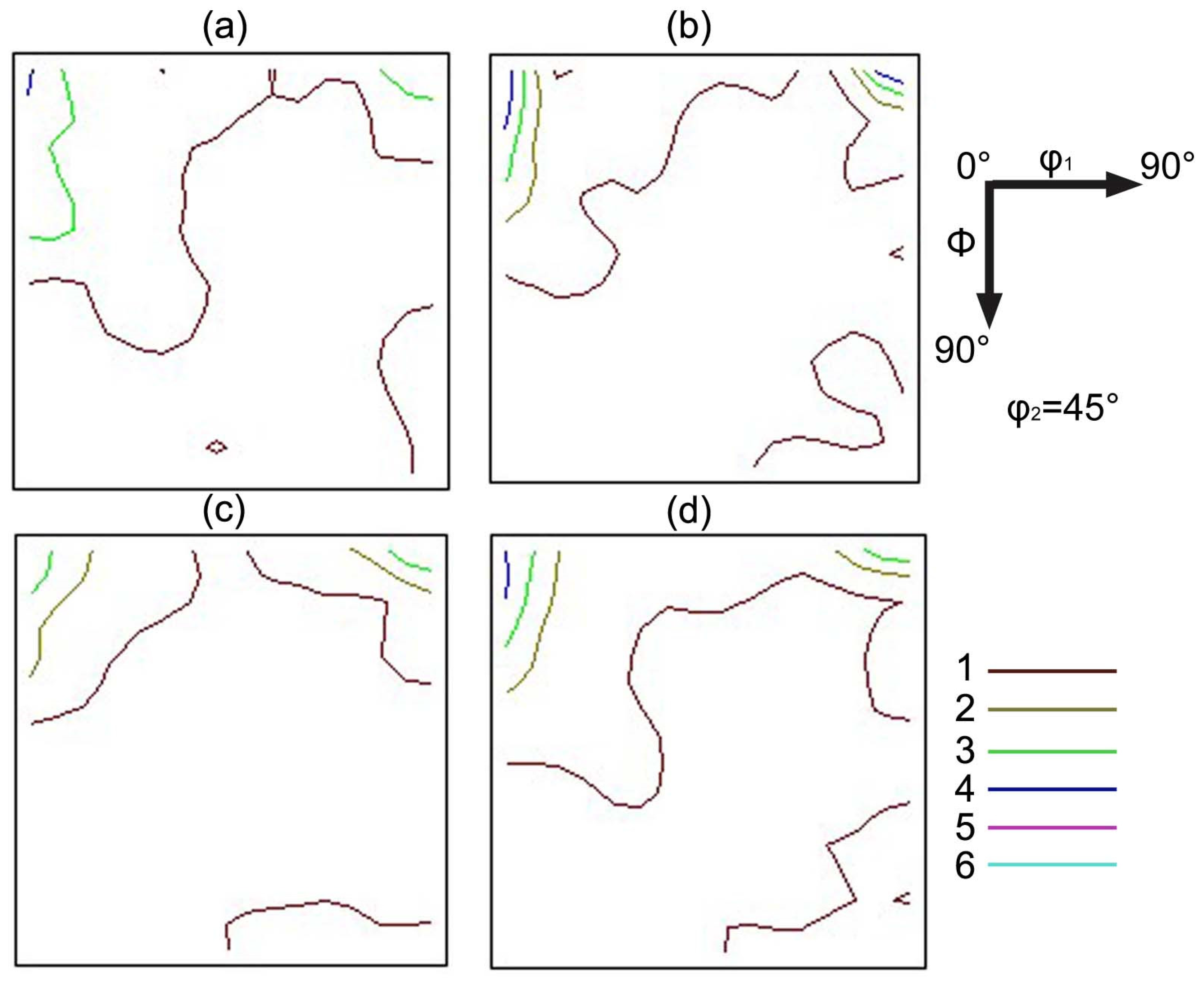

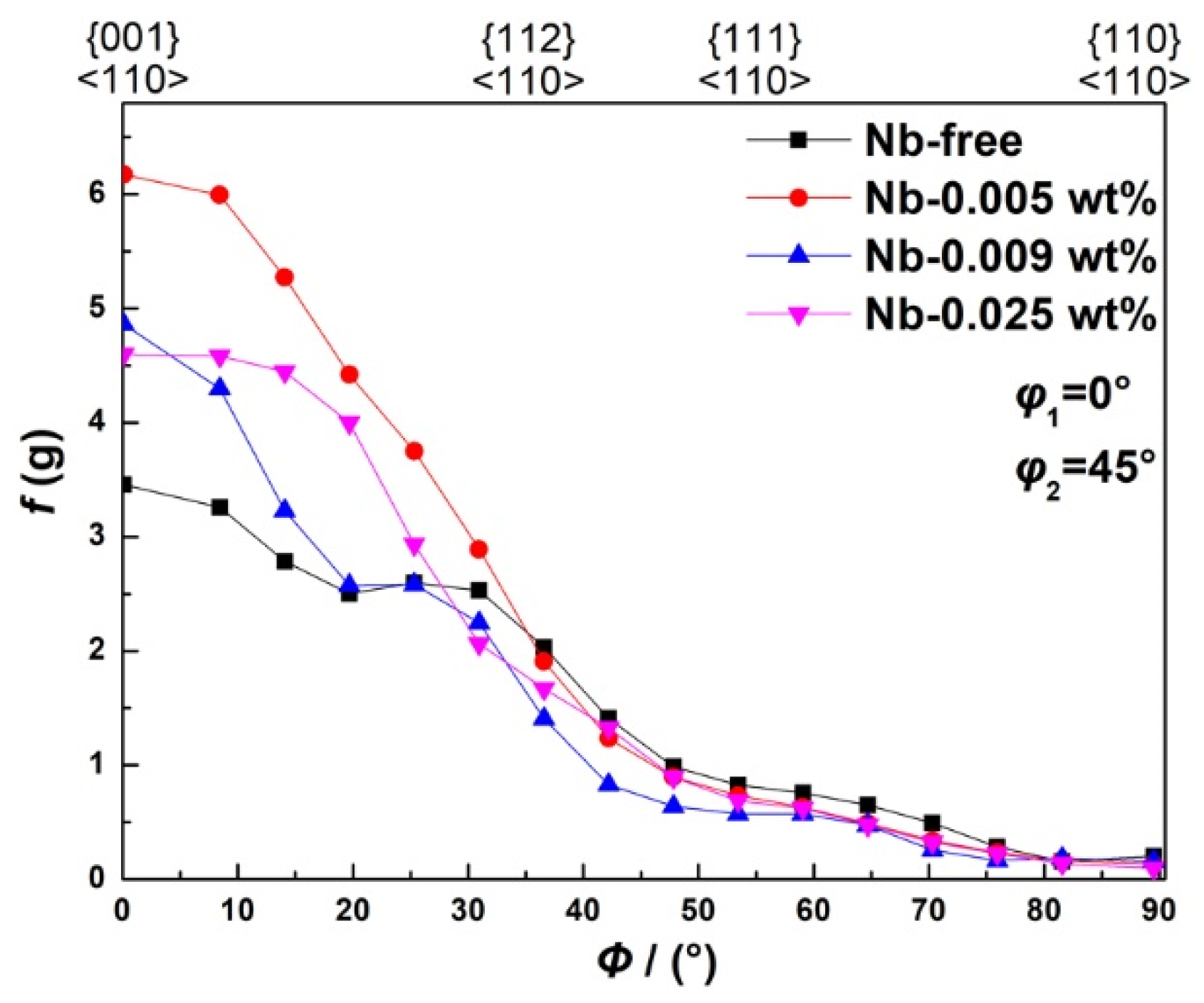

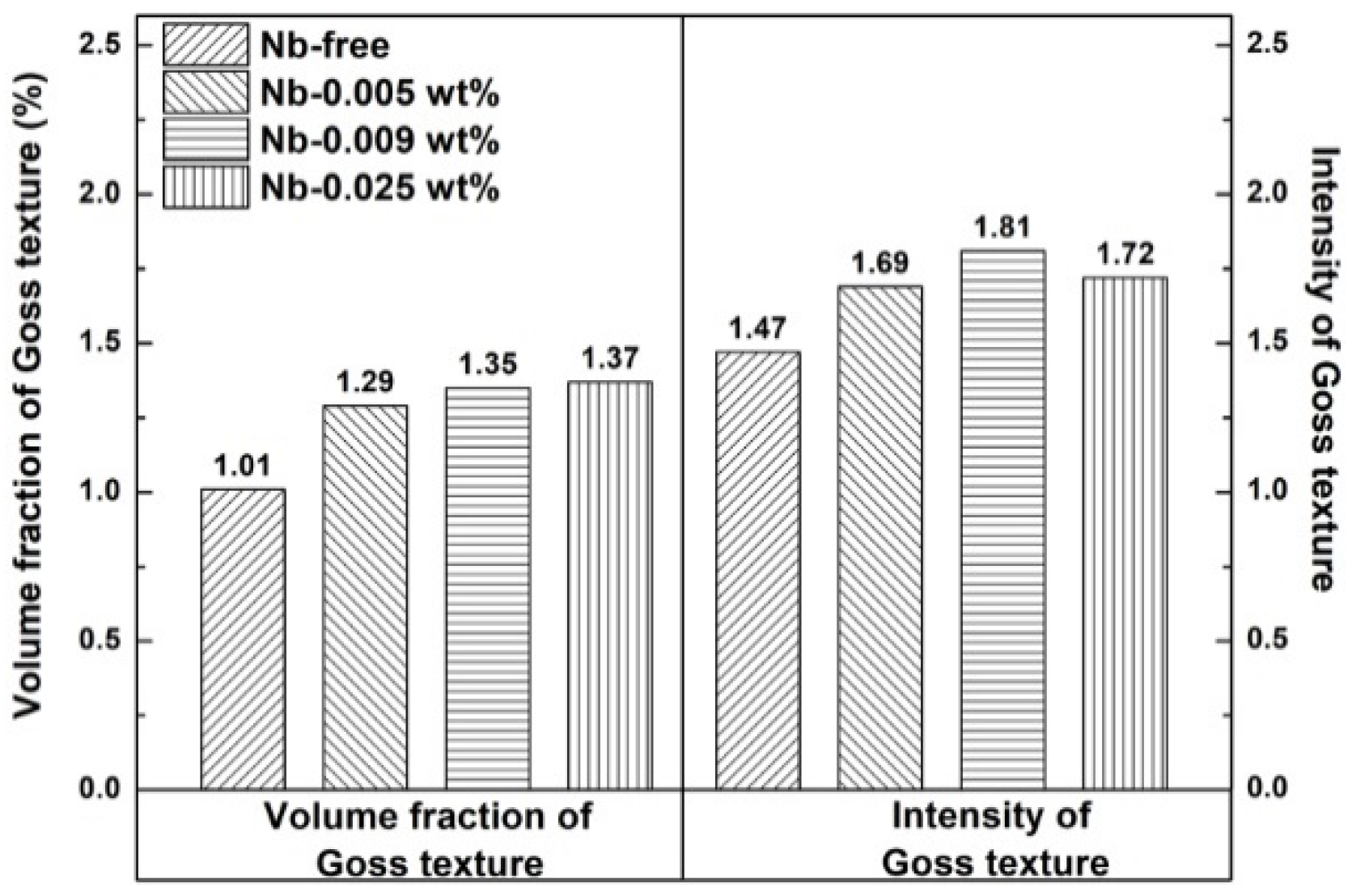

- The stronger pining force was obtained in the specimens with the Nb addition, which pinned up the deformed matrix and blocked the dynamic recrystallization during hot rolling; the structure and recrystallization fraction of the specimens with the Nb addition are finer and less, respectively. Larger volume fractions and a stronger intensity of Goss texture was formed in the specimens containing 0.025 wt% Nb, due to the finer and more dispersed precipitates.

- (3)

- When the Nb content is higher than 0.009 wt%, the effect of the Nb addition on microstructure and texture is not obvious.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xia, Z.; Kang, Y.; Wang, Q. Developments in the production of grain-oriented electrical steel. J. Magn. Magn. Mater. 2008, 320, 3229–3233. [Google Scholar] [CrossRef]

- Matsuo, M. Texture control in the production of grain oriented silicon steel. ISIJ Int. 1989, 29, 809–827. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.T.; Liu, Z.Q.; Yang, P.; Mao, W.M. Correlation between primary and secondary recrystallization texture components in low-temperature reheated grain-oriented silicon steel. J. Iron. Steel. Res. Int. 2016, 23, 1234–1242. [Google Scholar] [CrossRef]

- Atake, M.; Barnett, M.; Hutchinson, B.; Ushioda, K. Warm deformation and annealing behaviour of iron–silicon–(carbon) steel sheets. Acta. Mate. 2015, 96, 410–419. [Google Scholar] [CrossRef]

- Liu, H.T.; Yao, S.J.; Sun, Y.; Song, H.Y.; Liu, G.H.; Li, L.; Geng, D.Q.; Liu, Z.Y.; Wang, G.D. Evolution of microstructure, texture and inhibitor along the processing route for grain-oriented electrical steels using strip casting. Mater. Charact. 2015, 106, 273–282. [Google Scholar] [CrossRef]

- Heo, N.H. Effects of heating rate and hydrogen flow rate on magnetic induction and final grain texture of 3 pct silicon steel. Metall. Mater. Trans. A 2005, 36, 3251–3254. [Google Scholar] [CrossRef]

- Imamura, T.; Shingaki, Y.; Hayakawa, Y. Effect of cold rolling reduction rate on secondary recrystallized texture in 3 pct Si-Fe steel. Metall. Mater. Trans. A 2013, 44, 1785–1792. [Google Scholar] [CrossRef]

- Gao, Y.; Xu, G.; Guo, X.; Li, G. Effect of Cr on secondary recrystallization behaviors in high permeability grain oriented silicon steel manufactured by low-temperature slab reheating. J. Magn. Magn. Mater. 2019, 476, 428–436. [Google Scholar] [CrossRef]

- Zhao, Y.; He, Z.Z.; Pei, D.R.; Mao, J.H.; Wang, L.F. Influence of Mo on hot rolling textures of Fe-3%Si grain-oriented silicon steels. Scripta. Metall. Mater. 1995, 32, 283–288. [Google Scholar] [CrossRef]

- Kubota, T.; Fujikura, M.; Ushigami, Y. Recent progress and future trend on grain-oriented silicon steel. J. Magn. Magn. Mater. 2000, 215, 69–73. [Google Scholar] [CrossRef]

- Obara, T.; Takeuchi, H.; Takamiya, T.; Kan, T. Control of inhibitor precipitation for producing grain-oriented silicon steel. J. Mater. Eng. Perform. 1993, 2, 205. [Google Scholar] [CrossRef]

- Takamiya, T.; Furukimi, O. Precipitation behavior and inhibition effect of MnS, MnSe and AlN in 3% Si steel. Tetsu-to-Hagane. 2014, 100, 1413–1420. [Google Scholar] [CrossRef] [Green Version]

- Sakai, T.; Shimazu, T.; Chikuma, K.; Tanino, M.; Matsuo, M. Improvement of magnetic properties by Cu addition in grian-oriented silicon steel. Tetsu-to-Hagané 1984, 70, 2049–2056. [Google Scholar] [CrossRef] [Green Version]

- Hulka, K.; Vlad, C.; Doniga, A. The role of niobium as microalloying element in electrical sheet. Steel. Res. Int. 2002, 73, 453–460. [Google Scholar] [CrossRef]

- Feng, Y.; Li, Y.; Guo, J.; Li, J.; Du, T. Effect of slab reheating temperature on recrystallization microstructure, texture and magnetic properties of Nb-containing grain-oriented silicon steel. J. Magn. Magn. Mater. 2017, 439, 135–143. [Google Scholar] [CrossRef]

- Feng, Y.; Guo, J.; Li, J.; Ning, J. Effect of Nb on solution and precipitation of inhibitors in grain-oriented silicon steel. J. Magn. Magn. Mater. 2017, 426, 89–94. [Google Scholar] [CrossRef]

- Fang, F.; Lan, M.F.; Lu, X.; Zhang, Y.X.; Wang, Y.; Yuan, G.; Wang, G.D. The impact of niobium on the microstructure, texture and magnetic properties of strip-cast grain oriented silicon steel. J. Magn. Magn. Mater. 2017, 442, 1–7. [Google Scholar] [CrossRef]

- van Dijk, N.H.; Offerman, S.E.; Bouwman, W.G.; Rekveldt, M.T.; Sietsma, J.; van der Zwaag, S.; Bodin, A.; Heenan, R.K. SANS experiments on Nb(C, N) and MnS precipitates in HSLA steel. Appl. Phys. A Mater. 2002, 74, s978–s980. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, C.; Li, G.; Liu, Y.; Zhou, B. The effect of Nb content on precipitates, microstructure and texture of grain oriented silicon steel. High. Temp. Mat. Processes 2019, 38, 628–638. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Xu, Y.B.; Zhang, Y.X.; Fang, F.; Lu, X.; Misra, R.D.K.; Wang, G.D. Effect of annealing after strip casting on texture development in grain oriented silicon steel produced by twin roll casting. Mater. Charact. 2015, 107, 79–84. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, C.; Li, G.; Liu, Y.; Liu, Y. Influence of Nb content on precipitation, grain microstructure, texture and magnetic properties of grain-oriented silicon steel. Materials 2020, 13, 5581. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Guo, X.; Wang, Y.; Liu, Y.; Zhu, C.; Li, G. Effect of Nb content on primary recrystallization microstructure, texture and magnetic properties of grain-oriented silicon steel manufactured by low-temperature slab reheating. J. Magn. Magn. Mater. 2020, 516, 167343. [Google Scholar] [CrossRef]

- Song, H.; Liu, H.; Lu, H.; Li, H.; Liu, W.; Zhang, X.; Wang, G. Effect of hot rolling reduction on microstructure, texture and ductility of strip-cast grain-oriented silicon steel with different solidification structures. Mat. Sci. Eng. A 2014, 605, 260–269. [Google Scholar] [CrossRef]

- Jenkins, K.; Lindenmo, M. Precipitates in electrical steels. J. Magn. Magn. Mater. 2008, 320, 2423–2429. [Google Scholar] [CrossRef]

- Shimizu, Y.; Ito, Y.; Iida, Y. Formation of the goss orientation near the surface of 3 pct silicon steel during hot rolling. Metall. Trans. A 1986, 17, 1323–1334. [Google Scholar] [CrossRef]

- Kumano, T.; Ohata, Y.; Fujii, N.; Ushigami, Y.; Takeshita, T. Effect of nitriding on grain oriented silicon steel bearing aluminum (the second study). J. Magn. Magn. Mater. 2006, 304, e602–e607. [Google Scholar] [CrossRef]

- Iwayama, K.; Haratani, T. The dissolution and precipitation behavior of AlN and MnS in grain-oriented 3% silicon-steel with high permeability. J. Magn. Magn. Mater. 1980, 19, 15–17. [Google Scholar] [CrossRef]

- Klinkenberg, C.; Hulka, K.; Bleck, W. Niobium carbide precipitation in microalloyed steel. Steel Res. Int. 2004, 75, 744–752. [Google Scholar] [CrossRef]

- Ainslie, N.G.; Seybolt, A.U. Diffusion and solubility of sulphur in iron and silicon-iron alloys. J. Iron Steel Inst. 1960, 194, 341–350. [Google Scholar]

- Sawamura, H.; Mori, T. Thermodynamic investigation of nonmetallic inclusions in steel (I). Tetsu-to-Hagane. 1955, 41, 1082–1090. [Google Scholar] [CrossRef]

- Zhou, B.; Zhu, C.; Li, G.; Fu, Y. Effect of sulphur and acid soluble aluminium content on grain oriented silicon steel. Mate. Sci. Tech. 2015, 31, 1809–1817. [Google Scholar] [CrossRef]

- Palmiere, E.J.; Garcia, C.I.; DeArdo, A.J. The influence of niobium supersaturation in austenite on the static recrystallization behavior of low carbon microalloyed steels. Metall. Mater. Trans. A 1996, 27, 951–960. [Google Scholar] [CrossRef]

- Smith, C.S. Grains, phases, and interfaces: An introduction of microstructure. Trans. Metall. Soc. AIME 1948, 175, 15–51. [Google Scholar]

- Wu, H.; Du, L.; Liu, X. Dynamic recrystallization and precipitation behavior of Mn-Cu-V weathering steel. J. Mater. Sci. Technol. 2011, 27, 1131–1138. [Google Scholar] [CrossRef]

- Truszkowski, W.; Kr’Ol, J.; Major, B. Inhomogeneity of rolling texture in fcc metals. Metall. Trans. A 1980, 11, 749–758. [Google Scholar] [CrossRef]

- Lee, S.; Ko, H.S.; Han, K.; Kim, S.J. Role of subsurface Goss-oriented grains in abnormal grain growth in Fe-3% Si steel. Mater. Charact. 2021, 180, 111381. [Google Scholar] [CrossRef]

| Sample | C | Si | Mn | S | Als | Nb | N | Fe |

|---|---|---|---|---|---|---|---|---|

| S1 | 0.056 | 3.14 | 0.110 | 0.0068 | 0.024 | - | 0.0076 | Balance |

| S2 | 0.056 | 3.11 | 0.092 | 0.0064 | 0.026 | 0.005 | 0.0083 | Balance |

| S3 | 0.057 | 3.13 | 0.091 | 0.0079 | 0.025 | 0.009 | 0.0082 | Balance |

| S4 | 0.060 | 3.23 | 0.110 | 0.0064 | 0.026 | 0.025 | 0.0075 | Balance |

| Inhibitors | AlN | MnS | NbN | NbC |

|---|---|---|---|---|

| S1 | 1027 | 1250 | - | - |

| S2 | 1045 | 1223 | 939 | 896 |

| S3 | 1039 | 1245 | 977 | 947 |

| S4 | 1034 | 1243 | 1044 | 1048 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, G.; Zhu, C.; Liu, X.; Liu, Y.; Gao, Y.; Liu, Y. Micro Characterization of Hot-Rolled Plate of Nb-Bearing Grain-Oriented Silicon Steel. Materials 2022, 15, 429. https://doi.org/10.3390/ma15020429

Wang Y, Li G, Zhu C, Liu X, Liu Y, Gao Y, Liu Y. Micro Characterization of Hot-Rolled Plate of Nb-Bearing Grain-Oriented Silicon Steel. Materials. 2022; 15(2):429. https://doi.org/10.3390/ma15020429

Chicago/Turabian StyleWang, Yong, Guangqiang Li, Chengyi Zhu, Xinbin Liu, Yulong Liu, Yang Gao, and Yu Liu. 2022. "Micro Characterization of Hot-Rolled Plate of Nb-Bearing Grain-Oriented Silicon Steel" Materials 15, no. 2: 429. https://doi.org/10.3390/ma15020429