Wear Mechanism of Multilayer Coated Carbide Cutting Tool in the Milling Process of AISI 4340 under Cryogenic Environment

Abstract

:1. Introduction

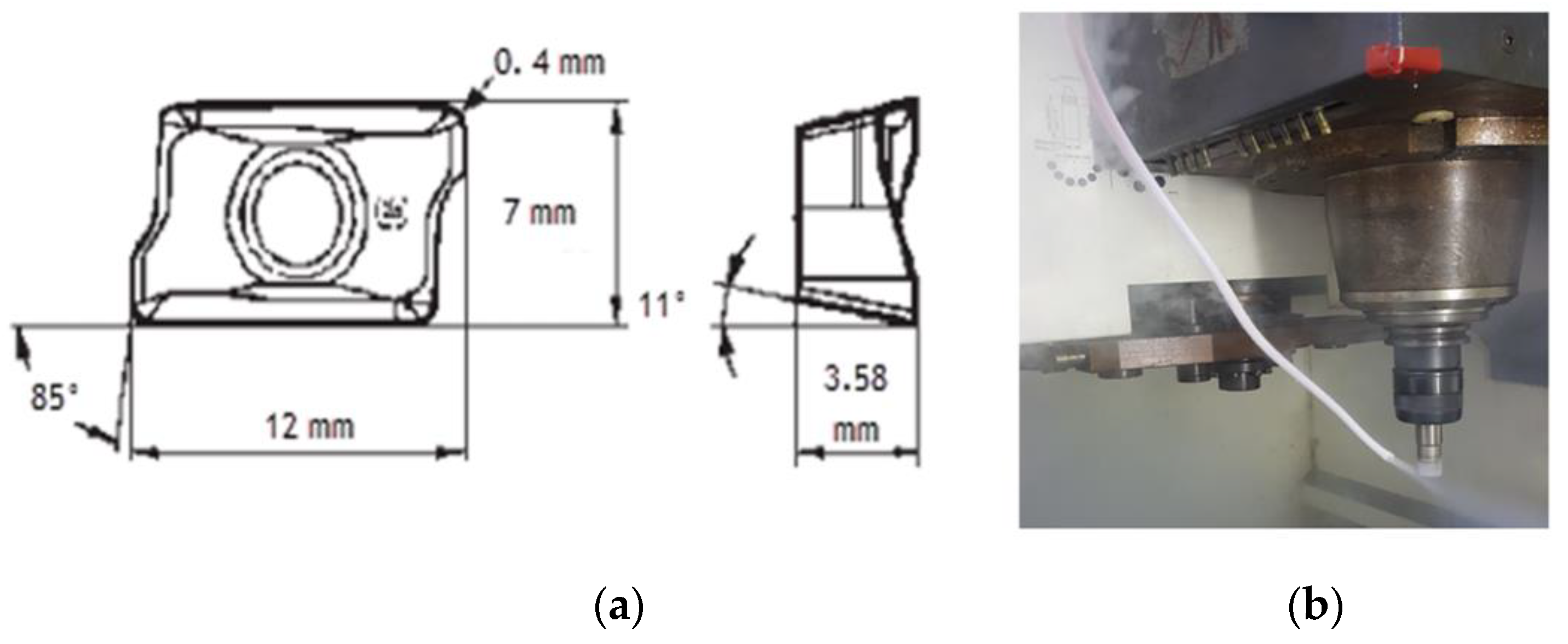

2. Materials and Methods

3. Results and Discussion

3.1. Tool Life under Cryogenic Conditions

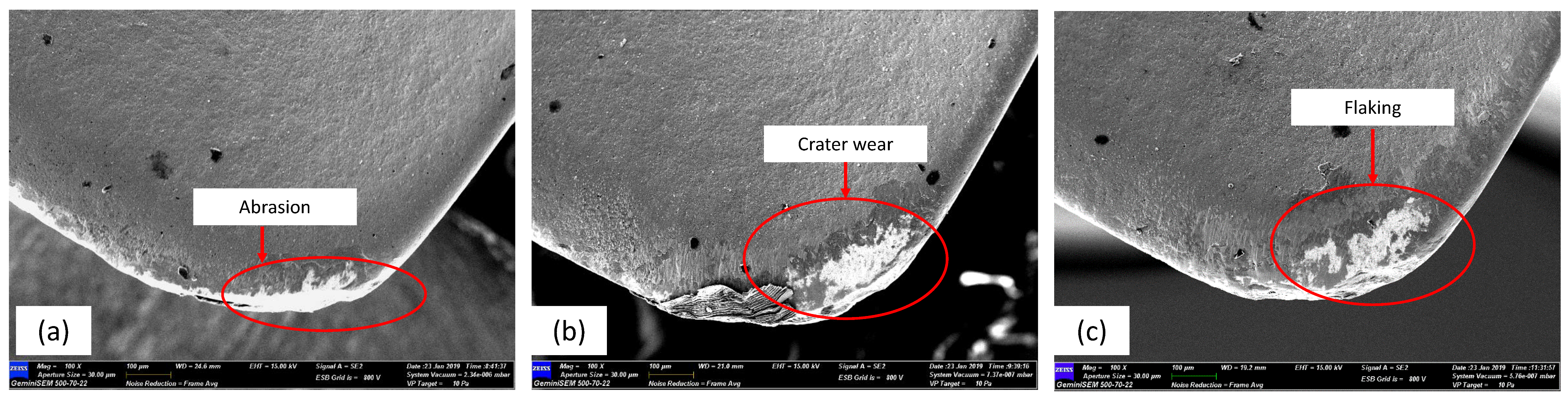

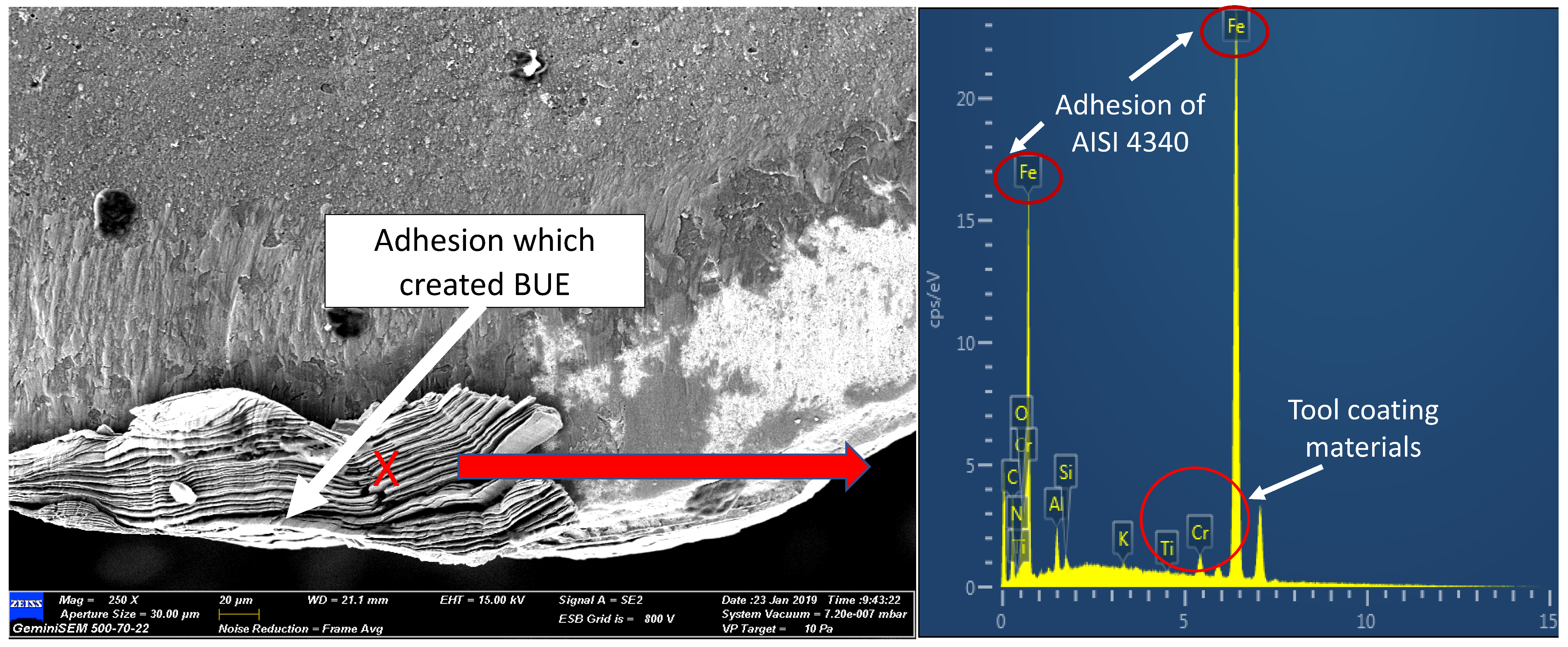

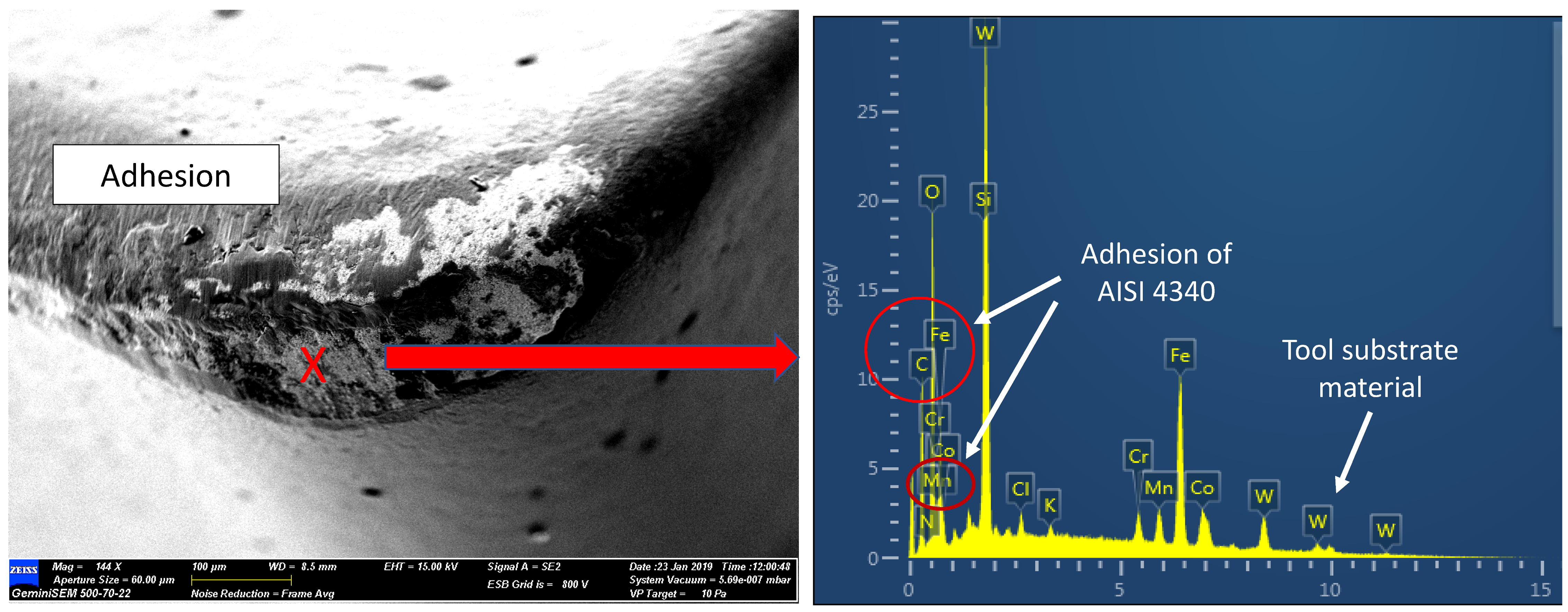

3.2. Tool Wear and Wear Mechanisms of a Multilayer Coated Carbide Cutting Tool

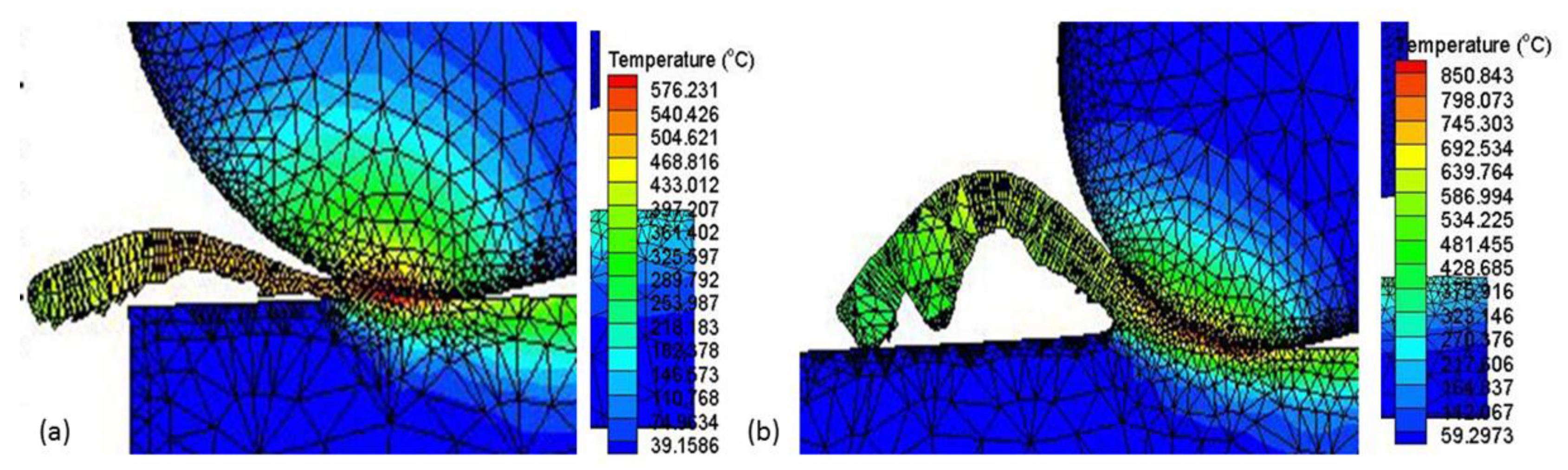

3.3. Effects of Force and Cutting Temperature on Cutting Tool Wear

4. Conclusions

- The use of a cryogenic coolant plays an important role in reducing the progress of tool wear. Consequently, milling under cryogenic conditions increases the length of cutting and prolongs the tool life.

- The main wear mechanism of the multilayer coated carbide cutting tool were abrasion, adhesion and diffusion on the rake face during cryogenic milling of AISI 4340. From the FESEM micrograph shown, the topography included adhered chip particles, grooves, BUE and rough surfaces on the cutting tools.

- The mixture of abrasion, adhesion and diffusion wear accounted for the crater wear of the carbide coated tool in Experiment 9 when compared to Experiment 1 because the cutting edge experienced higher temperatures, more friction and more tearing due to excessive cutting force.

- The application of the cryogenic technique is recommended as it leads to a sustainable manufacturing process, with only a small amount of LN2 dissipating to the atmosphere, which does not cause environmental pollution.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Roy, S.; Kumar, R.; Das, R.K.; Sahoo, A.K. A Comprehensive Review on Machinability Aspects in Hard Turning of AISI 4340 Steel. IOP Conf. Series: Mater. Sci. Eng. 2018, 390, 012009. [Google Scholar] [CrossRef]

- Shalaby, M.; Veldhuis, S. New Observations on High-Speed Machining of Hardened AISI 4340 Steel Using Alumina-Based Ceramic Tools. J. Manuf. Mater. Process. 2018, 2, 27. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Zheng, G.; Zhang, X.; Cheng, X.; Yang, X.; Xu, R. Cutting force, tool wear and surface roughness in high-speed milling of high-strength steel with coated tools. J. Mech. Sci. Technol. 2019, 33, 5393–5398. [Google Scholar] [CrossRef]

- Zheng, G.; Cheng, X.; Dong, Y.; Liu, H.; Yu, Y. Surface integrity evaluation of high-strength steel with a TiCN-NbC composite coated tool by dry milling. Measurement 2020, 166, 108204. [Google Scholar] [CrossRef]

- Bag, R.; Panda, A.; Sahoo, A.K.; Kumar, R. Cutting tools characteristics and coating depositions for hard part turning of AISI 4340 martensitic steel: A review study. Mater. Today Proc. 2020, 26, 2073–2078. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S. Investigations on machinability aspects of hardened AISI 4340 steel at different levels of hardness using coated carbide tools. Int. J. Refract. Met. Hard Mater. 2013, 38, 124–133. [Google Scholar] [CrossRef]

- Boing, D.; de Oliveira, A.J.; Schroeter, R.B. Evaluation of wear mechanisms of PVD and CVD coatings deposited on cemented carbide substrates applied to hard turning. Int. J. Adv. Manuf. Technol. 2020, 106, 5441–5451. [Google Scholar] [CrossRef]

- Ghosh, S.; Rao, P.V. Application of sustainable techniques in metal cutting for enhanced machinability: A review. J. Clean. Prod. 2015, 100, 17–34. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Pusavec, F.; Kramar, D.; Krajnik, P.; Kopac, J. Transitioning to sustainable production—part II: Evaluation of sustainable machining technologies. J. Clean. Prod. 2010, 18, 1211–1221. [Google Scholar] [CrossRef]

- Ghosh, S.; Rao, P.V. Comparison between sustainable cryogenic techniques and nano-MQL cooling mode in turning of nickel-based alloy. J. Clean. Prod. 2019, 231, 1036–1049. [Google Scholar] [CrossRef]

- Sutherland, J.; Richter, J.; Hutchins, M.J.; Dornfeld, D.; Dzombak, R.; Mangold, J.; Robinson, S.; Hauschild, M.Z.; Bonou, A.; Schönsleben, P.; et al. The role of manufacturing in affecting the social dimension of sustainability. CIRP Ann. 2016, 65, 689–712. [Google Scholar] [CrossRef] [Green Version]

- Liew, P.J.; Shaaroni, A.; Sidik, N.A.C.; Yan, J. An overview of current status of cutting fluids and cooling techniques of turning hard steel. Int. J. Heat Mass Transf. 2017, 114, 380–394. [Google Scholar] [CrossRef]

- Natasha, A.R.; Ghani, J.A.; Haron, C.H.C. Temperature at the Tool-Chip Interface in Cryogenic and Dry Turning of AISI 4340 Using Carbide Tool. Int. J. Simul. Model. 2016, 15, 201–212. [Google Scholar] [CrossRef]

- Halim, N.; Haron, C.; Ghani, J.; Azhar, M. Tool wear and chip morphology in high-speed milling of hardened Inconel 718 under dry and cryogenic CO2 conditions. Wear 2019, 426–427, 1683–1690. [Google Scholar] [CrossRef]

- Musfirah, A.; Ghani, J.; Haron, C.C. Tool wear and surface integrity of inconel 718 in dry and cryogenic coolant at high cutting speed. Wear 2017, 376-377, 125–133. [Google Scholar] [CrossRef]

- Boakye-Yiadom, S.; Bassim, N. Effect of heat treatment on stability of impact-induced adiabatic shear bands in 4340 steel. Mater. Sci. Eng. A 2012, 546, 223–232. [Google Scholar] [CrossRef]

- Sumitomo, Sumitomo High Performance Cutting Tools General Catalog 2017/2018. 2017. Available online: https://www.sumitool.com/en/downloads/cutting-tools/general-catalog/ (accessed on 1 December 2021).

- ISO 8688-2. 1989. Available online: https://www.evs.ee/preview/iso-8688-2-1989-en.pdf (accessed on 13 October 2017).

- Strano, M.; Chiappini, E.; Tirelli, S.; Albertelli, P.; Monno, M. Comparison of Ti6Al4V machining forces and tool life for cryogenic versus conventional cooling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 1403–1408. [Google Scholar] [CrossRef]

- Kaynak, Y.; Gharibi, A. Progressive Tool Wear in Cryogenic Machining: The Effect of Liquid Nitrogen and Carbon Dioxide. J. Manuf. Mater. Process. 2018, 2, 31. [Google Scholar] [CrossRef] [Green Version]

- Leadebal, W.V., Jr.; De Melo, A.C.A.; De Oliveira, A.J.; Castro, N.A. Tool wear and chip analysis after the hard turning of AISI D6 steel assisted by LN2. Mach. Sci. Technol. 2019, 23, 886–905. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Newman, S.; Imani-Asrai, R. An Initial Study of the Effect of Using Liquid Nitrogen Coolant on the Surface Roughness of Inconel 718 Nickel-Based Alloy in CNC Milling. Procedia CIRP 2012, 3, 121–125. [Google Scholar] [CrossRef] [Green Version]

- Jebaraj, M.; Kumar, M.P. End milling of DIN 1.2714 die steel with cryogenic CO2 cooling. J. Mech. Sci. Technol. 2019, 33, 2407–2416. [Google Scholar] [CrossRef]

- Tang, L.; Sun, Y.; Li, B.; Shen, J.; Meng, G. Wear performance and mechanisms of PCBN tool in dry hard turning of AISI D2 hardened steel. Tribol. Int. 2019, 132, 228–236. [Google Scholar] [CrossRef]

- Xue, C.; Chen, W. Adhering layer formation and its effect on the wear of coated carbide tools during turning of a nickel-based alloy. Wear 2011, 270, 895–902. [Google Scholar] [CrossRef]

- Das, S.R.; Panda, A.; Dhupal, D. Experimental investigation of surface roughness, flank wear, chip morphology and cost estimation during machining of hardened AISI 4340 steel with coated carbide insert. Mech. Adv. Mater. Mod. Process. 2017, 3, 305. [Google Scholar] [CrossRef] [Green Version]

- Chinchanikar, S.; Choudhury, S.K. Predictive modeling for flank wear progression of coated carbide tool in turning hardened steel under practical machining conditions. Int. J. Adv. Manuf. Technol. 2014, 76, 1185–1201. [Google Scholar] [CrossRef]

- Tascioglu, E.; Gharibi, A.; Kaynak, Y. High speed machining of near-beta titanium Ti-5553 alloy under various cooling and lubrication conditions. Int. J. Adv. Manuf. Technol. 2019, 102, 4257–4271. [Google Scholar] [CrossRef]

- Raof, N.A.; Ghani, J.A.; Haron, C.H.C. Machining-induced grain refinement of AISI 4340 alloy steel under dry and cryogenic conditions. J. Mater. Res. Technol. 2019, 8, 4347–4353. [Google Scholar] [CrossRef]

- Varghese, V.; Ramesh, M.R.; Chakradhar, D. Experimental investigation of cryogenic end milling on maraging steel using cryogenically treated tungsten carbide-cobalt inserts. Int. J. Adv. Manuf. Technol. 2019, 105, 2001–2019. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S. Machining of hardened steel—Experimental investigations, performance modeling and cooling techniques: A review. Int. J. Mach. Tools Manuf. 2015, 89, 95–109. [Google Scholar] [CrossRef]

- Kaynak, Y.; Gharibi, A. Cryogenic Machining of Titanium Ti-5553 Alloy. J. Manuf. Sci. Eng. 2019, 141, 1–23. [Google Scholar] [CrossRef]

- Ghani, J.A.; Haron, C.H.C.; Kasim, M.S.; Sulaiman, M.A.; Tomadi, S.H. Wear mechanism of coated and uncoated carbide cutting tool in machining process. J. Mater. Res. 2016, 31, 1873–1879. [Google Scholar] [CrossRef] [Green Version]

- Jebaraj, M.; Pradeep, K.M.; Anburaj, R. Effect of LN2 and CO2 coolants in milling of 55NiCrMoV7 steel. J. Manuf. Process. 2020, 53, 318–327. [Google Scholar] [CrossRef]

- Yıldırım Çağrı, V. Investigation of hard turning performance of eco-friendly cooling strategies: Cryogenic cooling and nanofluid based MQL. Tribol. Int. 2020, 144, 106127. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Cr | Mo | Ni |

| Minimum (%) | 0.37 | 0.10 | 0.55 | 0.00 | 0.00 | 0.65 | 0.2 | 1.55 |

| Maximum (%) | 0.44 | 0.35 | 0.90 | 0.04 | 0.04 | 0.95 | 0.35 | 2.00 |

| Items | Value |

| Number of inserts | 3 |

| Tool diameter | 20 mm |

| Rake angle | 28° |

| Clearance angle | 11° |

| Coating material | TiAlN /AlCrN |

| Machine centre | DMC 635 V Eco |

| Workpiece material | AISI 4340 |

| Cutting speed, Vc (m/ min) | 200, 250, 300 |

| Feed rate, fz (mm/tooth) | 0.15, 0.20, 0.30 |

| Axial depth of cut, ap (mm) | 0.3, 0.4, 0.5 |

| Radial depth of cut, ae (mm) | 0.20, 0.35, 0.50 |

| Cutting configuration | Down milling |

| Lubricant | Cryogenic LN2 with flow rate of 1.159 × 10−3 m3/s |

| Exp. No. | vc (m/min) | fz (mm/tooth) | ap (mm) | ae (mm) |

| 1 | 200 | 0.15 | 0.3 | 0.20 |

| 2 | 200 | 0.20 | 0.4 | 0.35 |

| 3 | 200 | 0.30 | 0.5 | 0.50 |

| 4 | 250 | 0.15 | 0.5 | 0.35 |

| 5 | 250 | 0.20 | 0.3 | 0.50 |

| 6 | 250 | 0.30 | 0.4 | 0.20 |

| 7 | 300 | 0.15 | 0.4 | 0.50 |

| 8 | 300 | 0.20 | 0.5 | 0.20 |

| 9 | 300 | 0.30 | 0.3 | 0.35 |

| Experiment | Tool Life (mins) | Cutting Length (m) |

|---|---|---|

| 1 | 45.0 | 22.28 |

| 2 | 28.3 | 18.98 |

| 3 | 29.8 | 28.05 |

| 4 | 36.8 | 21.45 |

| 5 | 30.0 | 24.75 |

| 6 | 21.0 | 24.75 |

| 7 | 37.3 | 26.40 |

| 8 | 29.6 | 28.05 |

| 9 | 21.0 | 29.70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhamad, S.S.; Ghani, J.A.; Che Haron, C.H.; Yazid, H. Wear Mechanism of Multilayer Coated Carbide Cutting Tool in the Milling Process of AISI 4340 under Cryogenic Environment. Materials 2022, 15, 524. https://doi.org/10.3390/ma15020524

Muhamad SS, Ghani JA, Che Haron CH, Yazid H. Wear Mechanism of Multilayer Coated Carbide Cutting Tool in the Milling Process of AISI 4340 under Cryogenic Environment. Materials. 2022; 15(2):524. https://doi.org/10.3390/ma15020524

Chicago/Turabian StyleMuhamad, Shalina Sheik, Jaharah A. Ghani, Che Hassan Che Haron, and Hafizal Yazid. 2022. "Wear Mechanism of Multilayer Coated Carbide Cutting Tool in the Milling Process of AISI 4340 under Cryogenic Environment" Materials 15, no. 2: 524. https://doi.org/10.3390/ma15020524