Bond Behavior of Steel Bars in Concrete Confined with Stirrups under Freeze–Thaw Cycles

Abstract

:1. Introduction

2. Experimental Program

2.1. Specimen Design

2.2. Materials

2.3. Freeze–Thaw Test

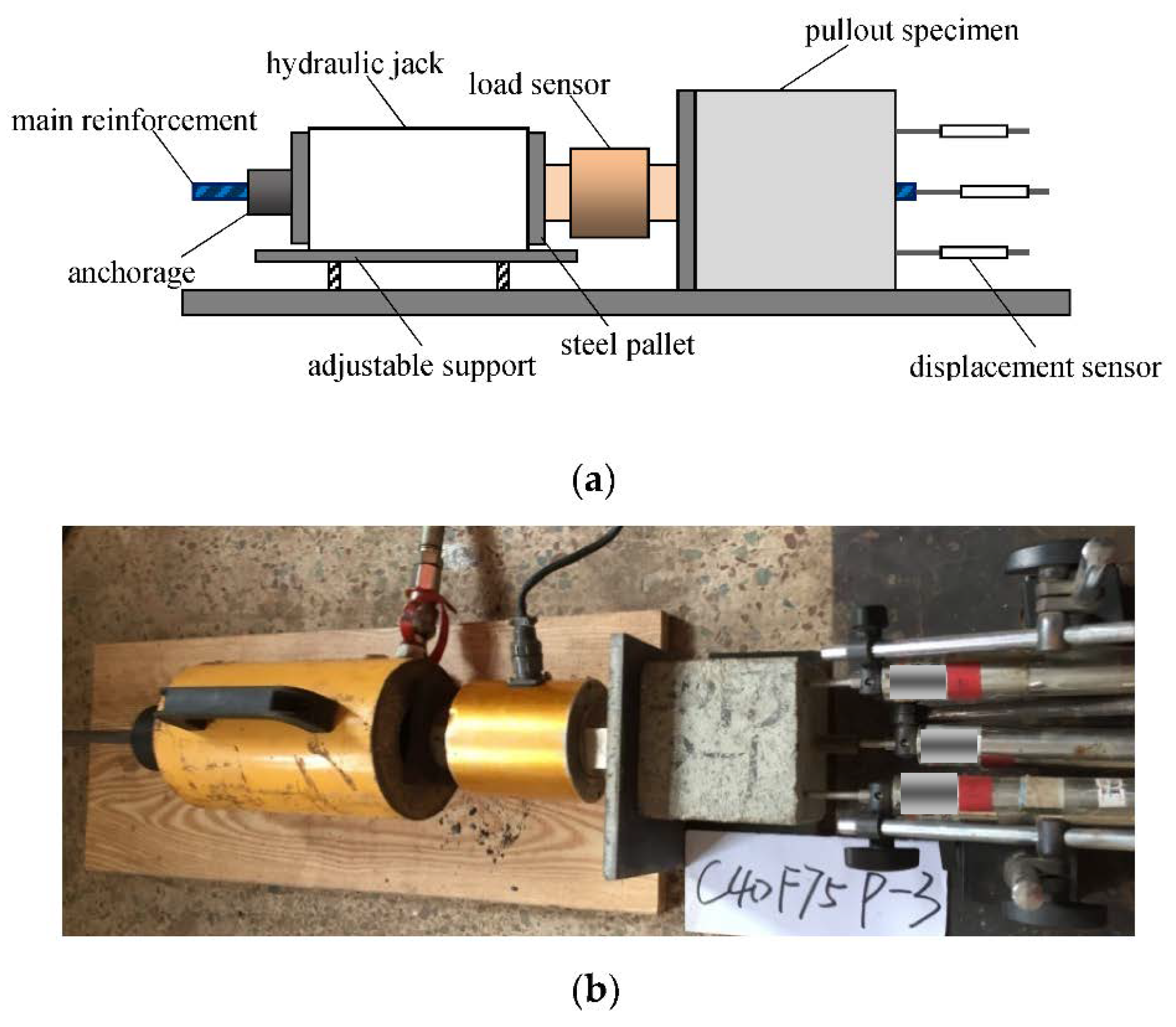

2.4. Pullout Tests

3. Results

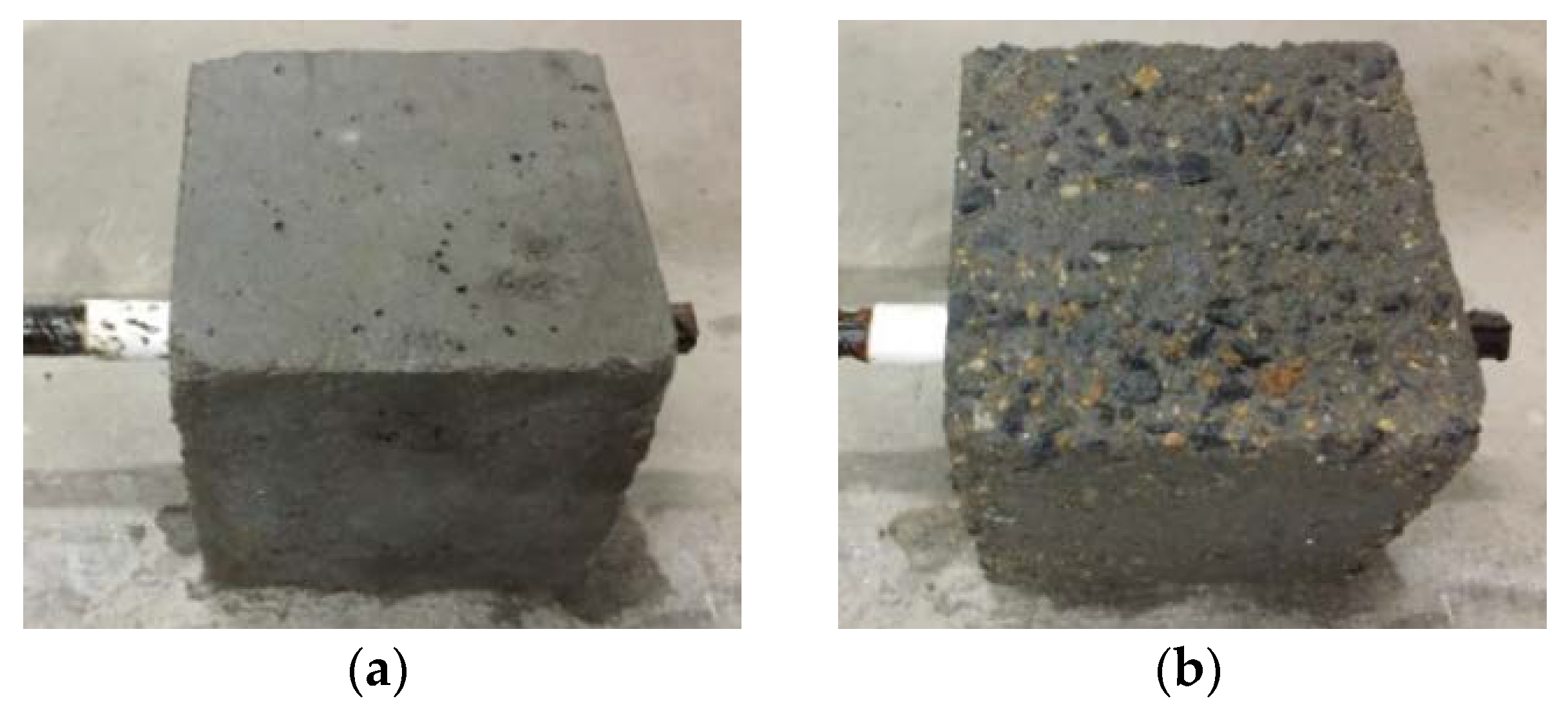

3.1. Failure Modes

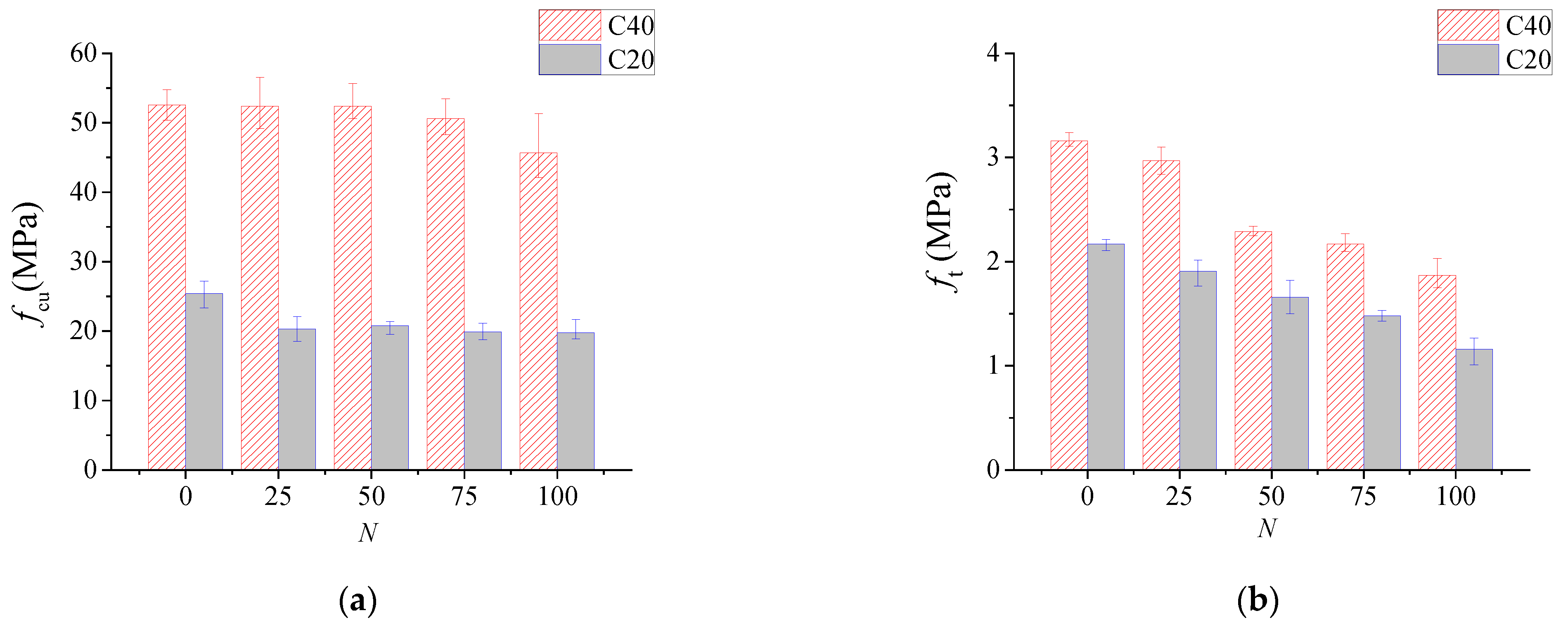

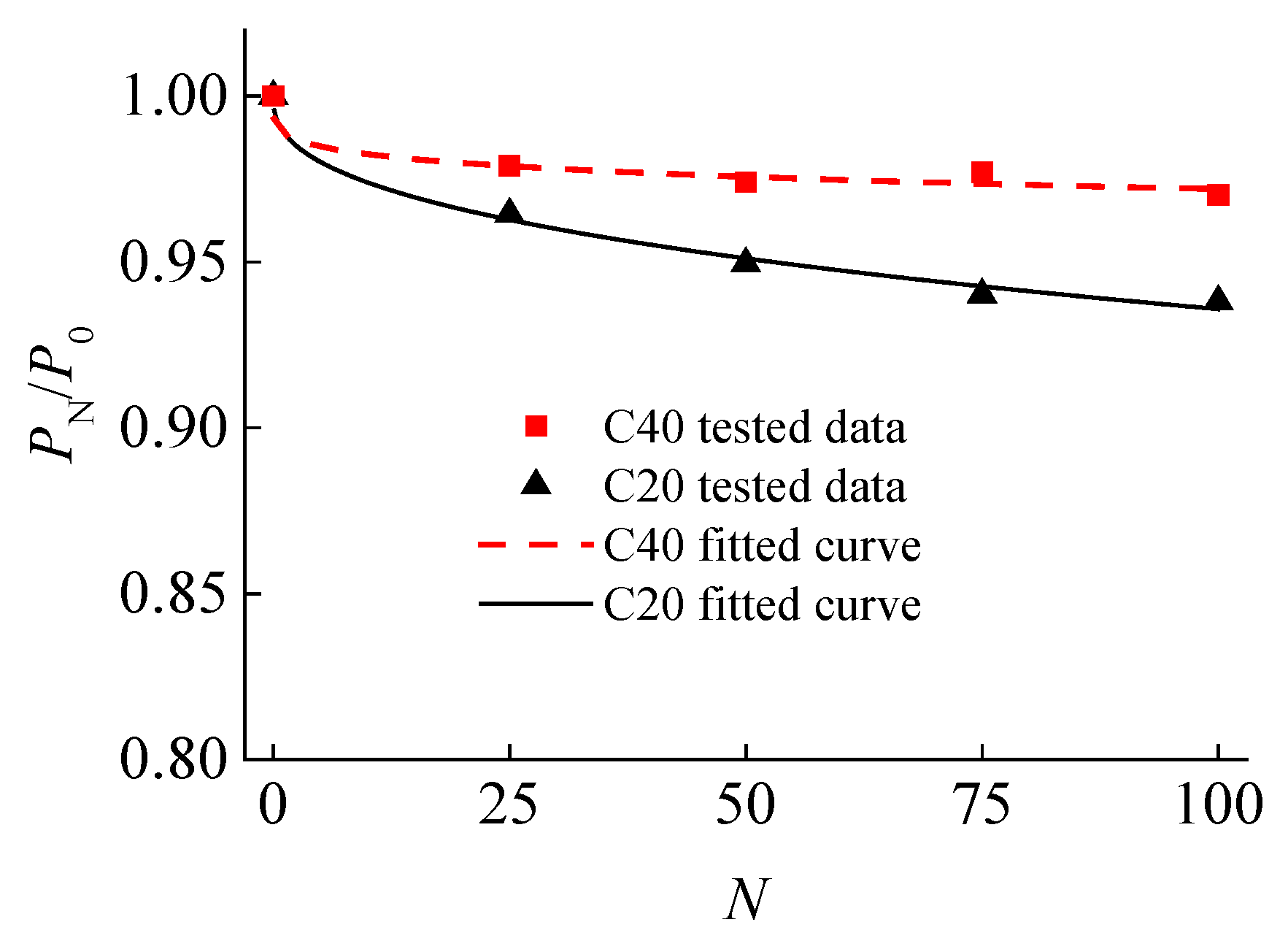

3.2. Concrete Strength

3.3. Mass Loss and Dynamic Modulus of Elasticity

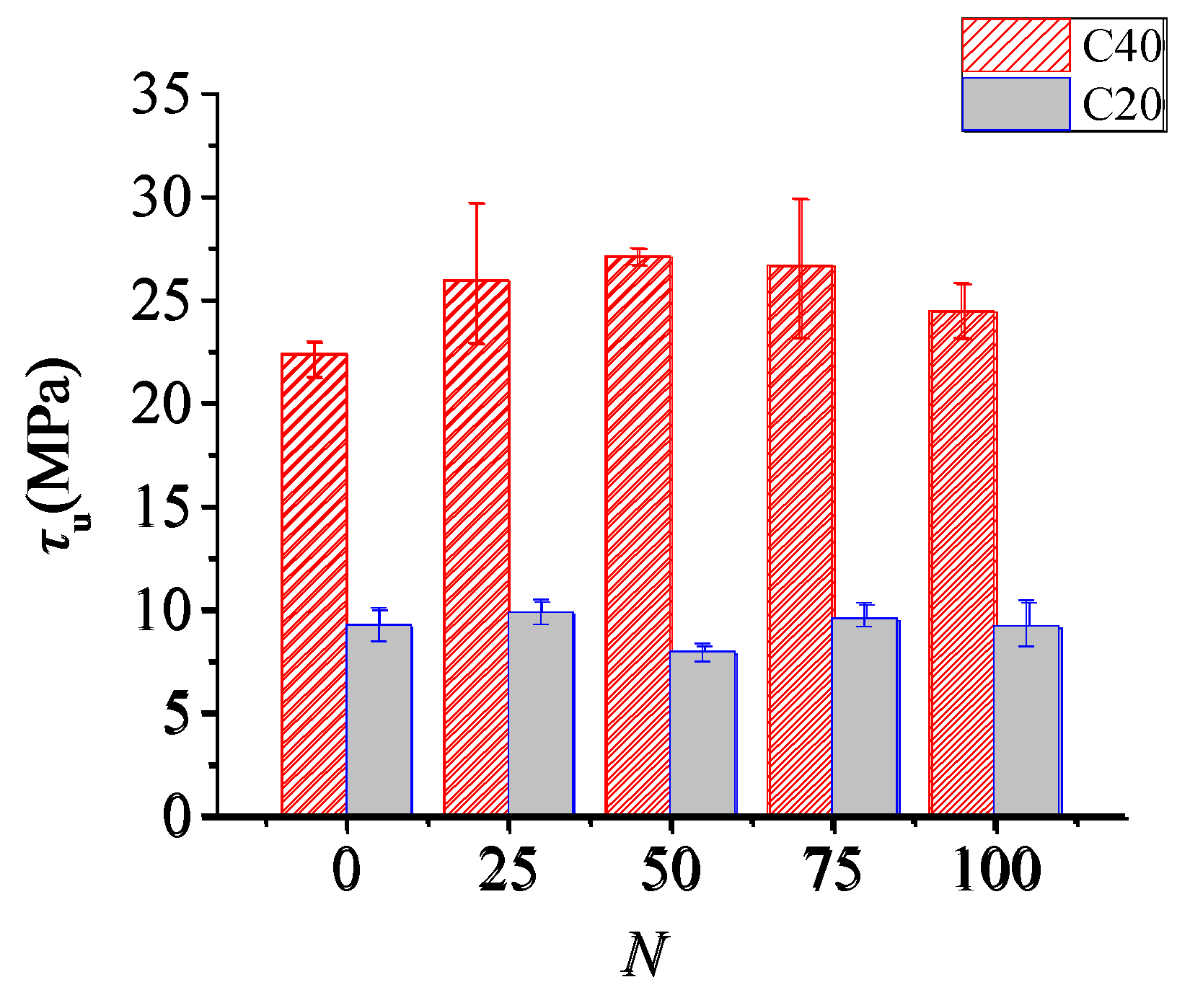

3.4. Bond Strength Calculation

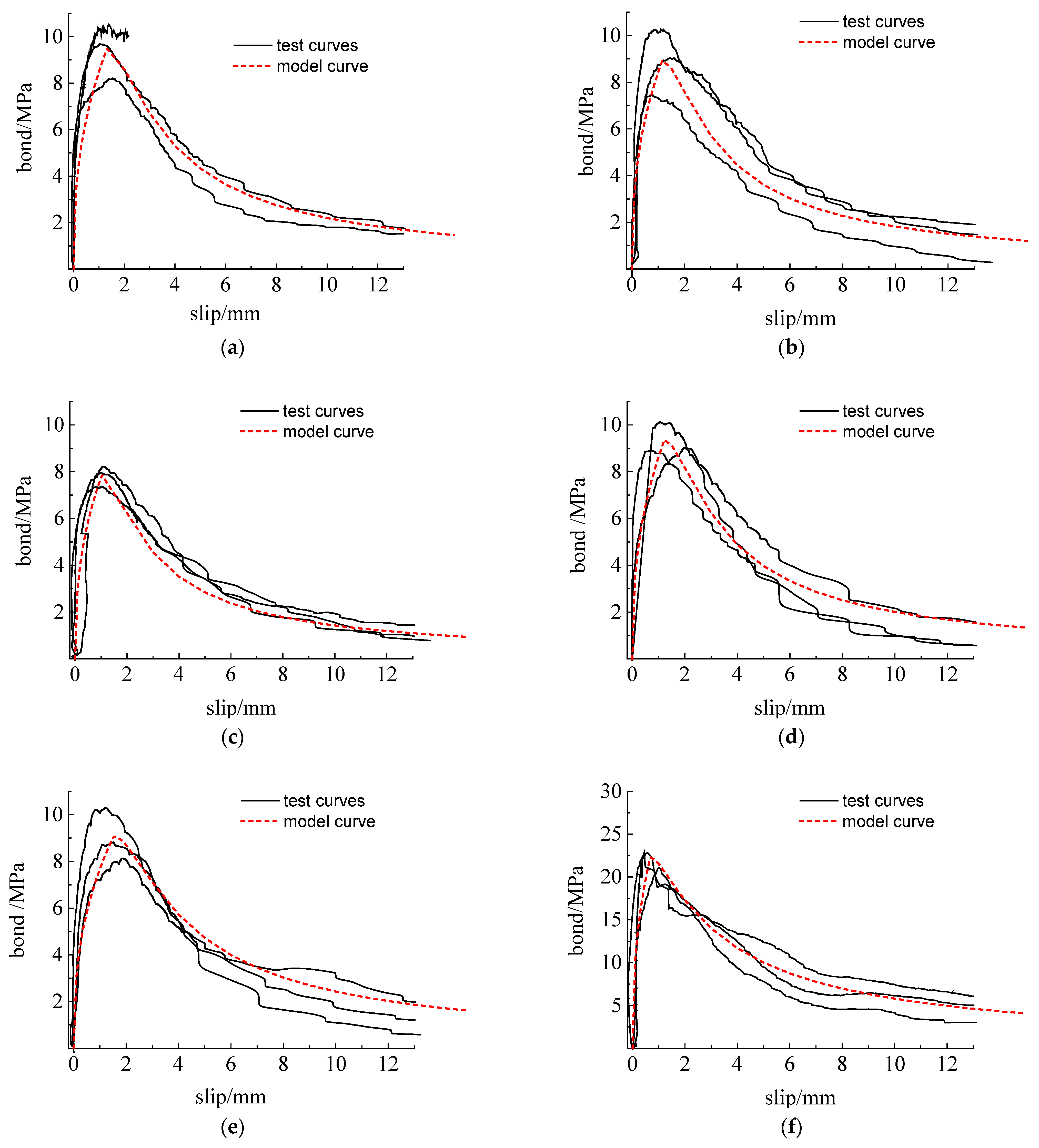

3.5. Bond–Slip Curves

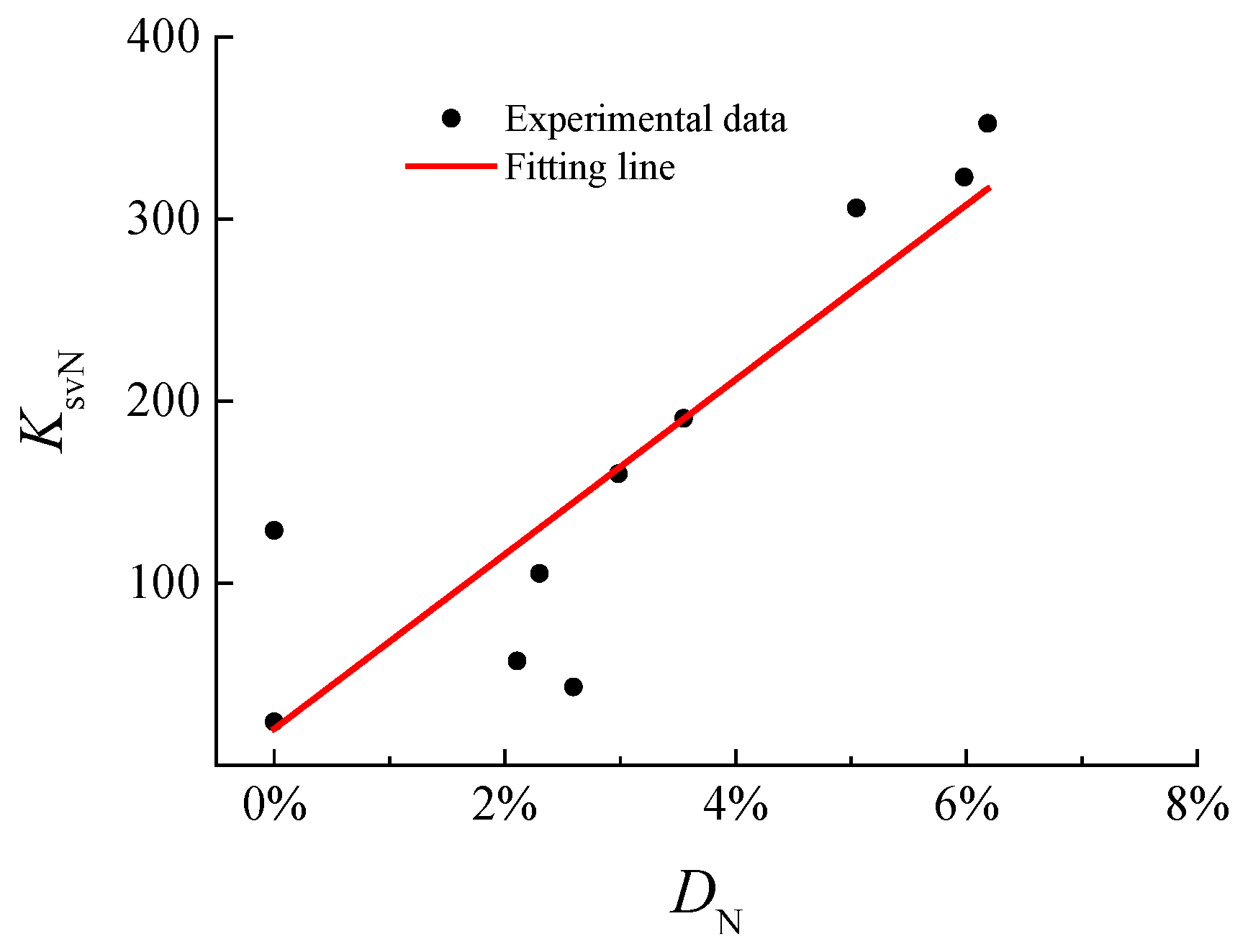

3.6. Bond–Slip Constitutive Model

4. Discussion

5. Conclusions

- (1)

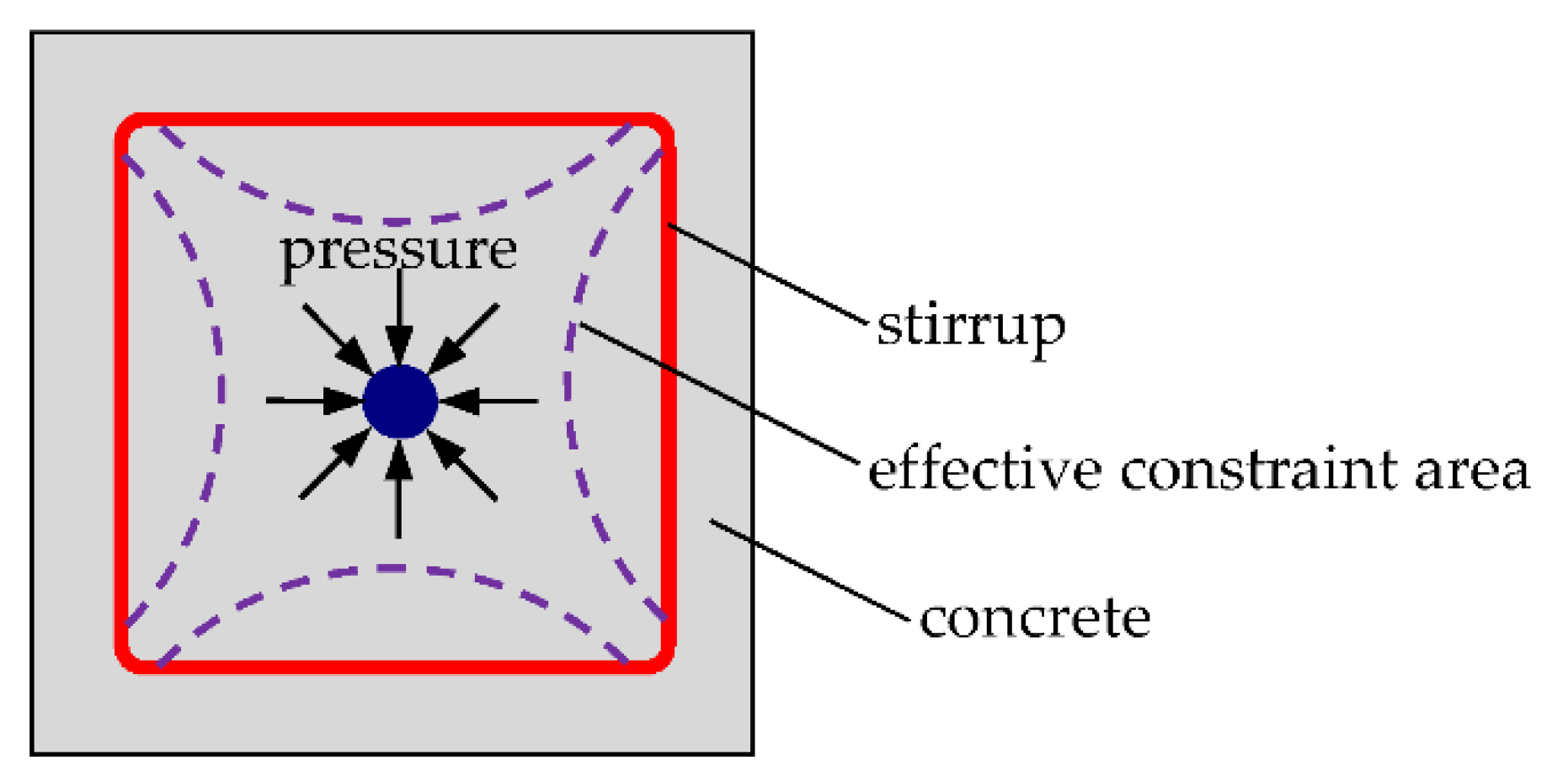

- Due to the confinement effect of transverse stirrups, the generation of cracks was effectively prevented, and steel bar pullout failure was observed for all bond specimens in this study. This is different from the splitting–pullout failure mode of specimens without stirrups. The shape of the bond–slip curve was affected by stirrups in concrete and exhibited better ductility.

- (2)

- The internal pore structure of concrete was destroyed by freeze–thaw damage, which made the compressive strength and splitting tensile strength decrease to some extent. In this experiment, the compressive strength of C20 and C40 concrete after 100 freeze–thaw cycles decreased by 22.2% and 13.1%, respectively. Furthermore, the splitting tensile strength decreased by 46.5% and 40.8%, respectively. Freeze–thaw action had greater influence on the splitting tensile strength than compressive strength of concrete.

- (3)

- Transverse stirrups could effectively improve the bond performance between steel bars and concrete. Under the action of 100 freeze–thaw cycles, the bond strength did not decrease compared with that of nonfreeze–thaw specimens. However, the bond strength had a descending trend based on the experimental data analysis.

- (4)

- On the basis of the existing bond strength model for unfrozen concrete, the formula expressed by the damage coefficient was given for calculating the bond strength after freeze–thaw cycles considering the effects of concrete strength and stirrup confinement. The comparison between calculation and experiment shows that the formula used in this paper can effectively predict the bond strength confined with stirrups subject to freeze–thaw cycles.

- (5)

- The bond–slip constitutive model was developed for deformed steel bars. This model is applicable for specimens with or without stirrups under freeze–thaw action. The relevant parameter values were suggested by fitting the test curves. It was found that the model had good accuracy and could provide references for the calculation of reinforced concrete structures in cold regions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, Z.; Zhu, F.; Zhao, T. Effects of surface modification of silane coupling agent on the properties of concrete with freeze-thaw damage. KSCE J. Civ. Eng. 2018, 22, 657–669. [Google Scholar] [CrossRef]

- Mansoori, A.; Behfarnia, K. Evaluation of mechanical and durability properties of engineered cementitious composites exposed to sulfate attack and freeze–thaw cycle. Asian J. Civ. Eng. 2021, 22, 417–429. [Google Scholar] [CrossRef]

- Kessler, S.; Thiel, C.; Grosse, C.U.; Gehlen, C. Effect of freeze–thaw damage on chloride ingress into concrete. Mater. Struct. 2017, 50, 121. [Google Scholar] [CrossRef]

- Penttala, V. Surface and internal deterioration of concrete due to saline and non-saline freeze–thaw loads. Cem.Concr. Res. 2006, 36, 921–928. [Google Scholar] [CrossRef]

- Wang, R.J.; Hu, Z.Y.; Li, Y.; Wang, K.; Zhang, H. Review on the deterioration and approaches to enhance the durability of concrete in the freeze–thaw environment. Constr. Build. Mater. 2022, 321, 126371. [Google Scholar] [CrossRef]

- Chen, F.; Qiao, P. Probabilistic damage modeling and service-life prediction of concrete under freeze–thaw action. Mater. Struct. 2015, 48, 2697–2711. [Google Scholar] [CrossRef]

- Wang, Y.; An, M.Z.; Yu, Z.R.; Han, H.; Ji, W.Y. Durability of reactive powder concrete under chloride-salt freeze–thaw cycling. Mater. Struct. 2017, 50, 18. [Google Scholar] [CrossRef]

- Nili, M.; Azarioon, A.; Hosseinian, S.M. Novel internal-deterioration model of concrete exposed to freeze-thaw cycles. J. Mater. Civ. Eng. 2017, 29, 9. [Google Scholar] [CrossRef]

- Wang, Z.H.; Li, L.; Zhang, Y.X.; Wang, W.T. Bond-slip model considering freeze-thaw damage effect of concrete and its application. Eng. Struct. 2019, 201, 109831. [Google Scholar] [CrossRef]

- Powers, T.C. A working hypothesis for further studies of frost resistance of concrete. J. Am.Concr. Inst. 1945, 16, 245–272. [Google Scholar]

- Powers, T.C. Air requirement of frost-resistant concrete. In Proceedings of the Twenty-Ninth Annual Meeting of the Highway Research Board, Washington, DC, USA, 13–16 December 1949. [Google Scholar]

- Xu, Y.; Ye, H.S.; Yuan, Q.; Shi, C.J.; Gao, Y.; Fu, Q. The durability of concrete subject to mechanical load coupled with freeze–thaw cycles: A review. Arch. Civ. Mech. Eng. 2022, 22, 47. [Google Scholar] [CrossRef]

- Zhang, S.H.; Tian, B.; Chen, B.F.; Lu, X.C.; Xiong, B.B.; Shuang, N. The Influence of Freeze–Thaw Cycles and Corrosion on Reinforced Concrete and the Relationship between the Evolutions of the Microstructure and Mechanical Properties. Materials 2022, 15, 6215. [Google Scholar] [CrossRef] [PubMed]

- Yusa, S.; Yilmaz, A.; Ali, T.M. Effects of freezing conditions on the frost resistance and microstructure of concrete. Constr. Build. Mater. 2020, 270, 121458. [Google Scholar]

- Gong, F.Y.; Maekawa, K. Multi-scale simulation of freeze-thaw damage to RC column and its restoring force characteristics. Eng. Struct. 2018, 156, 522–536. [Google Scholar] [CrossRef]

- Liu, D.Y.; Tu, Y.M.; Shi, P.; Gabriel, S.; Lennart, E. Mechanical and durability properties of concrete subjected to early-age freeze–thaw cycles. Mater. Struct. 2021, 54, 211. [Google Scholar] [CrossRef]

- Lin, H.; Zhao, Y.; Ozbolt, J.; Feng, P.; Jiang, C.; Eligehausen, R. Analytical model for the bond stress-slip relationship of deformed bars in normal strength concrete. Constr. Build. Mater. 2019, 198, 570–586. [Google Scholar] [CrossRef]

- Sabău, M.; Pop, I.; Oneţ, T. Experimental study on local bond stress-slip relationship in self-compacting concrete. Mater. Struct. 2016, 49, 3693–3711. [Google Scholar] [CrossRef]

- Song, L.; Qu, F.L.; Liu, G.R.; Zhao, S.B. Bond properties of steel bar in concrete under water environment. Materials 2019, 12, 3517. [Google Scholar] [CrossRef] [Green Version]

- Alabduljabbar, H.; Alyousef, R.; Mohammadhosseini, H.; Topper, T. Bond behavior of cleaned corroded lap spliced beams repaired with carbon fiber reinforced polymer sheets and partial depth repairs. Crystals 2020, 10, 1014. [Google Scholar] [CrossRef]

- Xu, Y.L.; Shen, W.D.; Wang, H. An experimental study of bond anchorage properties of bars in concrete. J. Build. Struct. 1994, 15, 26–37. (In Chinese) [Google Scholar]

- Qu, F.L.; Yan, L.Y.; Liu, G.R.; Yu, Y.Q.; Xiao, S. Experimental study on bond performance of inhomogeneous corroded reinforcement and concrete under reciprocating load. Ind. Build. 2016, 46, 110–113. (In Chinese) [Google Scholar]

- Sun, Y.; Diao, B. Experimental study on bond degradation between reinforcement and concrete in multi-aggressive andfreeze-thaw environment. J. Build. Struct. 2007, 28, 242–246. (In Chinese) [Google Scholar]

- Kim, S.W.; Yun, H.D. Influence of recycled coarse aggregates on the bond behavior of deformed bars in concrete. Eng. Struct. 2013, 48, 133–143. [Google Scholar] [CrossRef]

- Bandelt, M.J.; Billington, S.L. Bond behavior of steel reinforcement in high-performance fiber-reinforced cementitious composite flexural members. Mater. Struct. 2016, 49, 71–86. [Google Scholar] [CrossRef]

- Shang, H.S.; Zhao, T.J.; Cao, W.Q. Bond behavior between steel bar and recycled aggregate concrete after freeze–thaw cycles. Cold Reg. Sci. Technol. 2015, 118, 38–44. [Google Scholar] [CrossRef]

- Ma, Z.M.; Zhu, F.Z.; Ba, G.Z. Effects of freeze-thaw damage on the bond behavior of concrete and enhancing measures. Constr. Build. Mater. 2019, 186, 375–385. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, J.; Wu, D.; Kang, T.; Liu, A. Bond behavior of recycled fiber recycled concrete with reinforcement after freeze-thaw cycles. Crystals 2021, 11, 1506. [Google Scholar] [CrossRef]

- Hanjari, K.Z.; Utgenannt, P.; Lundgren, K. Experimental study of the material and bond properties of frost-damaged concrete. Cem. Concr. Res. 2011, 41, 244–254. [Google Scholar] [CrossRef] [Green Version]

- Ji, X.; Song, Y.; Liu, Y. Effect of freeze-thaw cycles on bond strength between steel bars and concrete. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2008, 23, 584–588. [Google Scholar] [CrossRef]

- Tu, J.S.; Zhou, M.; Liu, Y.Z.; Chen, Y.F. Bond behavior of reinforcing steel bars in thermal insulation concrete exposed to freeze-thaw cycles. Mater. Sci. Eng. 2019, 2019, 7374964. [Google Scholar] [CrossRef] [Green Version]

- Xu, S.H.; Li, A.B.; Wang, H. Bond properties for deformed steel bar in frost-damaged concrete under monotonic and reversed cyclic loading. Constr. Build. Mater. 2017, 148, 344–358. [Google Scholar] [CrossRef]

- Fan, Y.F.; Zhang, S.Y.; Shah, S.P. Influence of nanoclay on concrete subjected to freeze-thaw cycles and bond behavior between rebar and concrete. Key Eng. Mater. 2016, 711, 256–262. [Google Scholar] [CrossRef]

- Liu, K.H.; Yan, J.C.; Meng, X.X.; Zou, C.Y. Bond behavior between deformed steel bars and recycled aggregate concrete after freeze-thaw cycles. Constr. Build. Mater. 2020, 232, 117236. [Google Scholar] [CrossRef]

- Su, T.; Wu, J.; Yang, G.X.; Zou, Z.H. Bond behavior between recycled coarse aggregate concrete and steel bar after salt-frost cycles. Constr. Build. Mater. 2019, 226, 673–685. [Google Scholar] [CrossRef]

- Li, Z.H.; Deng, Z.H.; Yang, H.F.; Wang, H.L. Bond behavior between recycled aggregate concrete and deformed rebar after Freeze-thaw damage. Constr. Build. Mater. 2020, 250, 118805. [Google Scholar] [CrossRef]

- Ren, G.H.; Shang, H.S.; Zhang, P.; Zhao, T.J. Bond behaviour of reinforced recycled concrete after rapid freezing-thawing cycles. Cold. Reg. Sci. Technol. 2019, 157, 133–138. [Google Scholar] [CrossRef]

- Zhao, J.; Luo, X.; Wang, Z.K.; Feng, S.K.; Gong, X.L.; Shumuye, E.D. Experimental study on bond performance of carbon- and glass-fiber reinforced polymer (CFRP/GFRP) bars and steel strands to concrete. Materials 2021, 14, 1268. [Google Scholar] [CrossRef]

- Zhang, J.W.; Tao, X.Y.; Li, X.Y.; Zhang, Y.Y.; Liu, Y.J. Analytical and experimental investigation of the bond behavior of confined high-strength recycled aggregate concrete. Constr. Build. Mater. 2022, 315, 125636. [Google Scholar] [CrossRef]

- Li, P.; Jin, L.; Zhang, R.B.; Du, X.L. Static bond performance between BFRP bars and concrete with stirrup confinement: A refined modelling. Eng. Struct. 2022, 262, 114379. [Google Scholar] [CrossRef]

- Yang, S.Y.; Han, M.; Chen, X.L.; Song, J.J.; Yang, J.S. Influence of sulfate crystallization on bond-slip behavior between deformed rebar and concrete subjected to combined actions of dry-wet cycle and freeze-thaw cycle. Constr. Build. Mater. 2022, 345, 128368. [Google Scholar] [CrossRef]

- Zheng, Y.; Zheng, S.S.; Yang, L.; Dong, L.G.; Zhang, Y.B. Experimental study and analytical model of the bond behavior of corroded reinforcing steel bars in concrete. Constr. Build. Mater. 2022, 327, 126991. [Google Scholar] [CrossRef]

- Feng, Q.; Wei, P.; Zhao, K.X.; Xu, R.Q. Experimental investigation of stirrup confinement effects on bond-slip responses for corner and middle bars. Constr. Build. Mater. 2022, 314, 125629. [Google Scholar] [CrossRef]

- Liu, S.; Du, M.; Tian, Y.; Wang, X.; Sun, G. Bond behavior of reinforced concrete considering freeze–thaw cycles and corrosion of stirrups. Materials 2021, 14, 4732. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.X.; Lin, H.W.; Wu, K.; Jin, W.L. Bond behaviour of normal/recycled concrete and corroded steel bars. Constr. Build. Mater. 2013, 48, 348–359. [Google Scholar] [CrossRef]

- Fang, C.Q.; Lundgren, K.; Chen, L.G.; Zhu, C.Y. Corrosion influence on bond in reinforced concrete. Cem. Concr. Res. 2004, 34, 2159–2167. [Google Scholar] [CrossRef]

- Xu, Y.L. Experimental Study of Anchorage Properties for Deformed Bars in Concrete. Ph.D. Thesis, Tsinghua University, Beijing, China, 1990. (In Chinese). [Google Scholar]

- Chinese National Standard, GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019. (In Chinese)

- Chinese National Standard, GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010. (In Chinese)

- Deng, M.K.; Pan, J.J.; Sun, H.Z. Bond behavior of steel bar embedded in Engineered Cementitious Composites under pullout load. Constr. Build. Mater. 2018, 168, 705–714. [Google Scholar] [CrossRef]

- Majain, N.; Rahman, A.; Adnan, A. Bond behaviour of deformed steel bars in steel fibre high-strength self-compacting concrete. Constr. Build. Mater. 2022, 318, 125906. [Google Scholar] [CrossRef]

- Wu, C.L.; Chen, G.D. Unified model of local bond between deformed steel rebar andconcrete: Indentation analogy theory and validation. J. Eng. Mech. 2015, 141, 10. [Google Scholar]

- Zhao, D.; Zhou, Y.; Xing, F.; Sui, L.; Ye, Z.; Fu, H. Bond behavior and failure mechanism of fiber-reinforced polymer bar-engineered cementitious composite interface. Eng. Struct. 2021, 243, 112520. [Google Scholar] [CrossRef]

- Ma, Z.M.; Zhao, T.J.; Yang, J. Fracture Behavior of Concrete Exposed to the Freeze-Thaw Environment. J. Mater. Civ. Eng. 2017, 29, 04017071. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, B. Research on the performance of concrete materials under the condition of freeze-thaw cycles. Eur. J. Environ. Civ. Eng. 2013, 17, 860–871. [Google Scholar] [CrossRef]

- Li, W.; Liu, H.B.; Zhu, B.; Lyu, X.; Gao, X.; Liang, C.Y. Mechanical Properties and Freeze–Thaw Durability of Basalt Fiber Reactive Powder Concrete. Appl. Sci. 2020, 10, 5682. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, J.B.; Zhang, C. On relationships between the mechanical properties of recycled aggregate concrete: An overview. Mater. Struct. 2006, 39, 655–664. [Google Scholar] [CrossRef]

- Lin, H.W.; Han, Y.F.; Liang, S.M.; Gong, F.Y.; Han, S.; Shi, C.W.; Feng, P. Effects of low temperatures and cryogenic freeze-thaw cycles on concrete mechanical properties: A literature review. Constr. Build. Mater. 2022, 345, 128287. [Google Scholar] [CrossRef]

- Wang, H. An analytical study of bond strength associated with splitting of concrete cover. Eng. Struct. 2009, 31, 968–975. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Chen, X.D.; Bai, Y.; Ning, Y.J.; Zhang, W. Evaluation of fracture behavior of high-strength hydraulic concrete damaged by freeze-thaw cycle test. Constr. Build. Mater. 2022, 321, 126346. [Google Scholar] [CrossRef]

- Harajli, M.H. Development/splice strength of reinforcing bars embedded in plain and fiber reinforced concrete. ACI Struct. J. 1994, 91, 511–520. [Google Scholar]

- Guo, Z.H. Strength and Deformation of Concrete-Experimental Foundation and Constitutive Relationship; Press of Tsinghua University: Beijing, China, 1997. (In Chinese) [Google Scholar]

- Gao, D.Y.; Yan, H.H.; Yang, L.; Pang, Y.Y.; Sun, B.B. Analysis of bond performance of steel bar in steel-polypropylene hybrid fiber reinforced concrete with partially recycled coarse aggregates. J. Clean. Prod. 2022, 370, 133528. [Google Scholar] [CrossRef]

- Rabia, M.; Cashellb, K.A.; Shamassc, R.; Desnerck, P. Bond behaviour of austenitic stainless steel reinforced concrete. Eng. Struct. 2020, 221, 111027. [Google Scholar] [CrossRef]

- Chinese National Standard, GB/T 50010-2010; Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010. (In Chinese)

| Specimen Series | Water | Cement | Sand | Stone | Superplasticizer | Air-Entraining Agent |

|---|---|---|---|---|---|---|

| C20 | 210 | 350 | 755 | 1086 | 0 | 0.375 |

| C40 | 165 | 375 | 704 | 1200 | 3.375 | 0.375 |

| Steel Type | Diameter (mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Rate of Elongation (%) |

|---|---|---|---|---|

| HPB300 | 6 | 372.6 | 566.0 | 25.3 |

| HRB500 | 12 | 619.0 | 727.5 | 15.7 |

| Freeze–Thaw Cycles N | Weight Loss ΔWN/% | |

|---|---|---|

| C20 Group | C40 Group | |

| 0 | 0 | 0 |

| 25 | 0.13 | 0.25 |

| 50 | 0.38 | 0.41 |

| 75 | 0.50 | 0.36 |

| 100 | 0.11 | 0.46 |

| Group No. | DN/% | ftN/MPa | τu,test/MPa | τu,cal/MPa | τu,cal/τu,test |

|---|---|---|---|---|---|

| C20F0 | 0 | 2.17 | 9.25 | 9.03 | 0.976 |

| C20F25 | 2.11 | 1.91 | 9.86 | 13.18 | 1.337 |

| C20F50 | 2.59 | 1.66 | 7.93 | 12.52 | 1.577 |

| C20F75 | 2.30 | 1.48 | 9.55 | 10.59 | 1.110 |

| C20F100 | 2.98 | 1.16 | 9.19 | 9.34 | 1.016 |

| C40F0 | 0 | 3.16 | 22.39 | 13.14 | 0.587 |

| C40F25 | 3.55 | 2.97 | 25.96 | 26.09 | 1.005 |

| C40F50 | 5.05 | 2.29 | 27.12 | 24.58 | 0.907 |

| C40F75 | 5.98 | 2.17 | 26.69 | 25.94 | 0.972 |

| C40F100 | 6.19 | 1.87 | 24.48 | 22.85 | 0.934 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Dou, X.; Qu, F.; Shang, P.; Zhao, S. Bond Behavior of Steel Bars in Concrete Confined with Stirrups under Freeze–Thaw Cycles. Materials 2022, 15, 7152. https://doi.org/10.3390/ma15207152

Liu G, Dou X, Qu F, Shang P, Zhao S. Bond Behavior of Steel Bars in Concrete Confined with Stirrups under Freeze–Thaw Cycles. Materials. 2022; 15(20):7152. https://doi.org/10.3390/ma15207152

Chicago/Turabian StyleLiu, Guirong, Xiaoxue Dou, Fulai Qu, Pengran Shang, and Shunbo Zhao. 2022. "Bond Behavior of Steel Bars in Concrete Confined with Stirrups under Freeze–Thaw Cycles" Materials 15, no. 20: 7152. https://doi.org/10.3390/ma15207152