Correlation between Differential Fast Scanning Calorimetry and Additive Manufacturing Results of Aluminium Alloys

Abstract

1. Introduction

| Reference | Al Alloy | Nanoparticles |

|---|---|---|

| Gu et al., 2014 [6] | AlSi10Mg | TiC |

| Martin et al., 2017 [7] | 7075 | Zr → Al3Zr |

| Tan et al., 2020 [8] | 2024 | Ti → Al3Ti |

| Zhao et al., 2020 [9] | 5024 | TiC |

| Xi et al., 2020 [10] | AlSi10Mg | TiB2 |

| Opprecht et al., 2020 [11] | 6061 | YSZ * (60 nm) → Al3Zr |

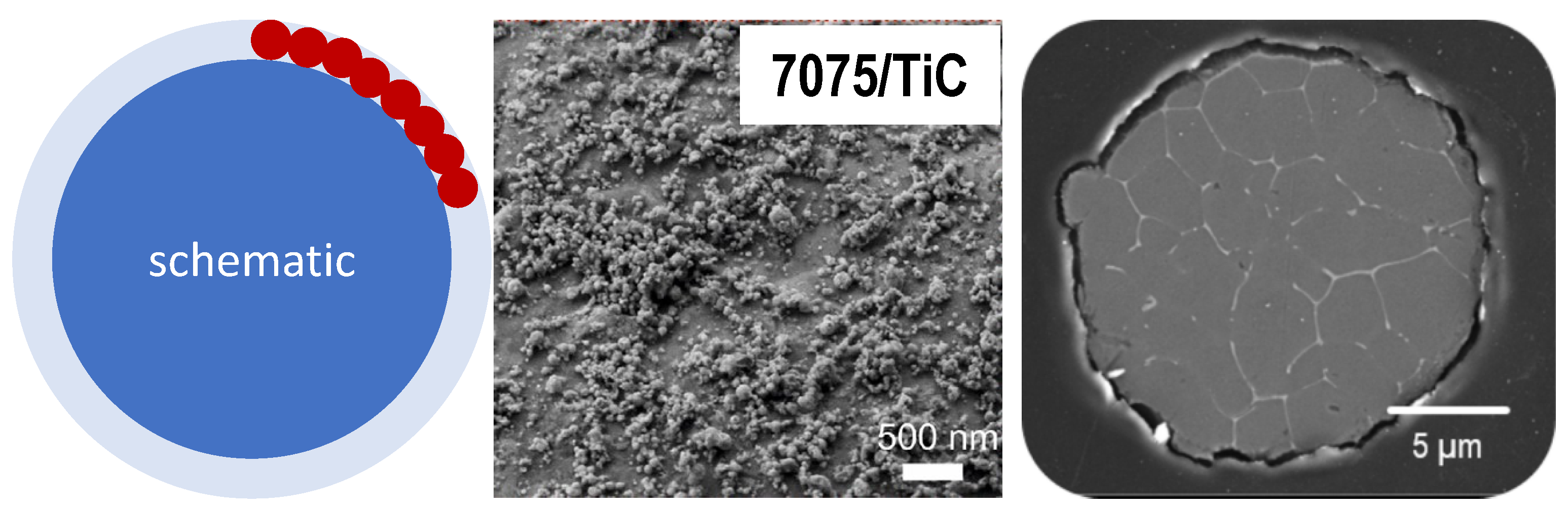

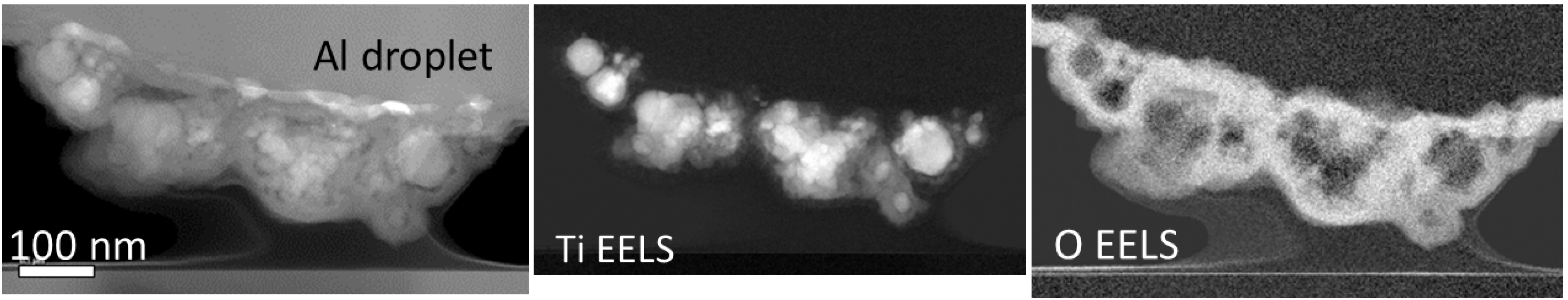

| Zhuravlev et al., 2021 [5] | 7075 | TiC (40 nm) |

| Heiland et al., 2021 [12] | 7075 | TiC (40 nm) |

| Mair et al., 2022 [13] | 2024 | CaB6 (200 nm) |

2. Materials and Methods

3. Results and Discussion

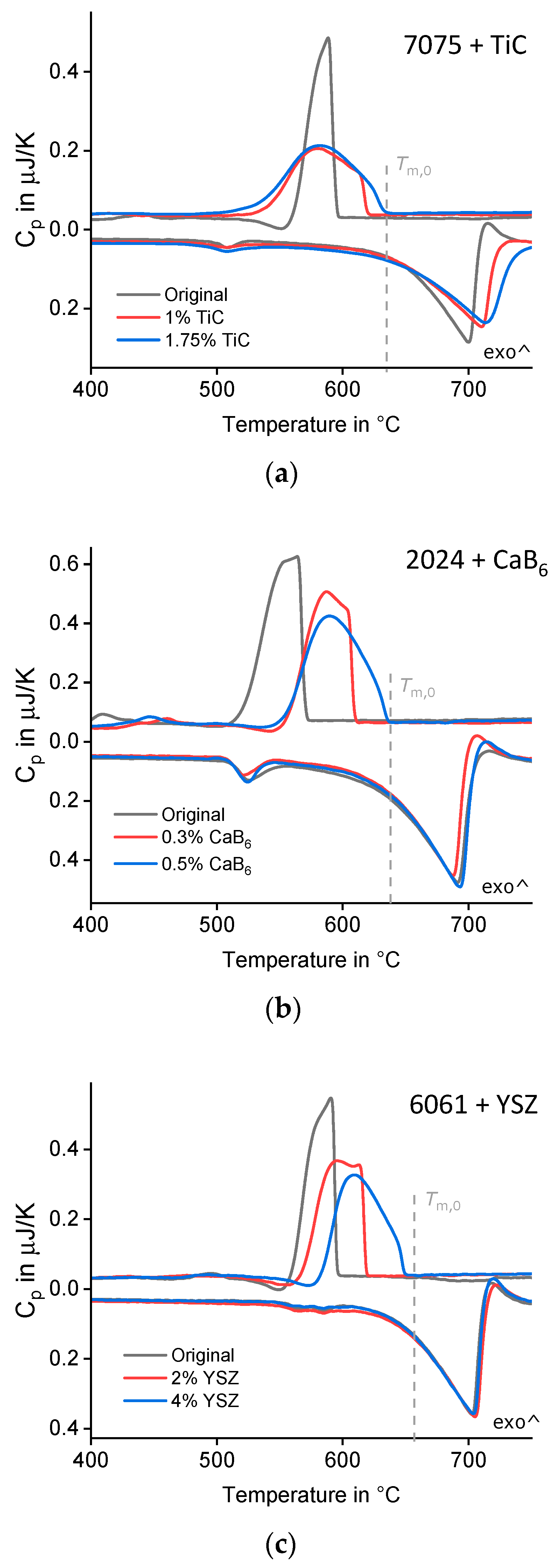

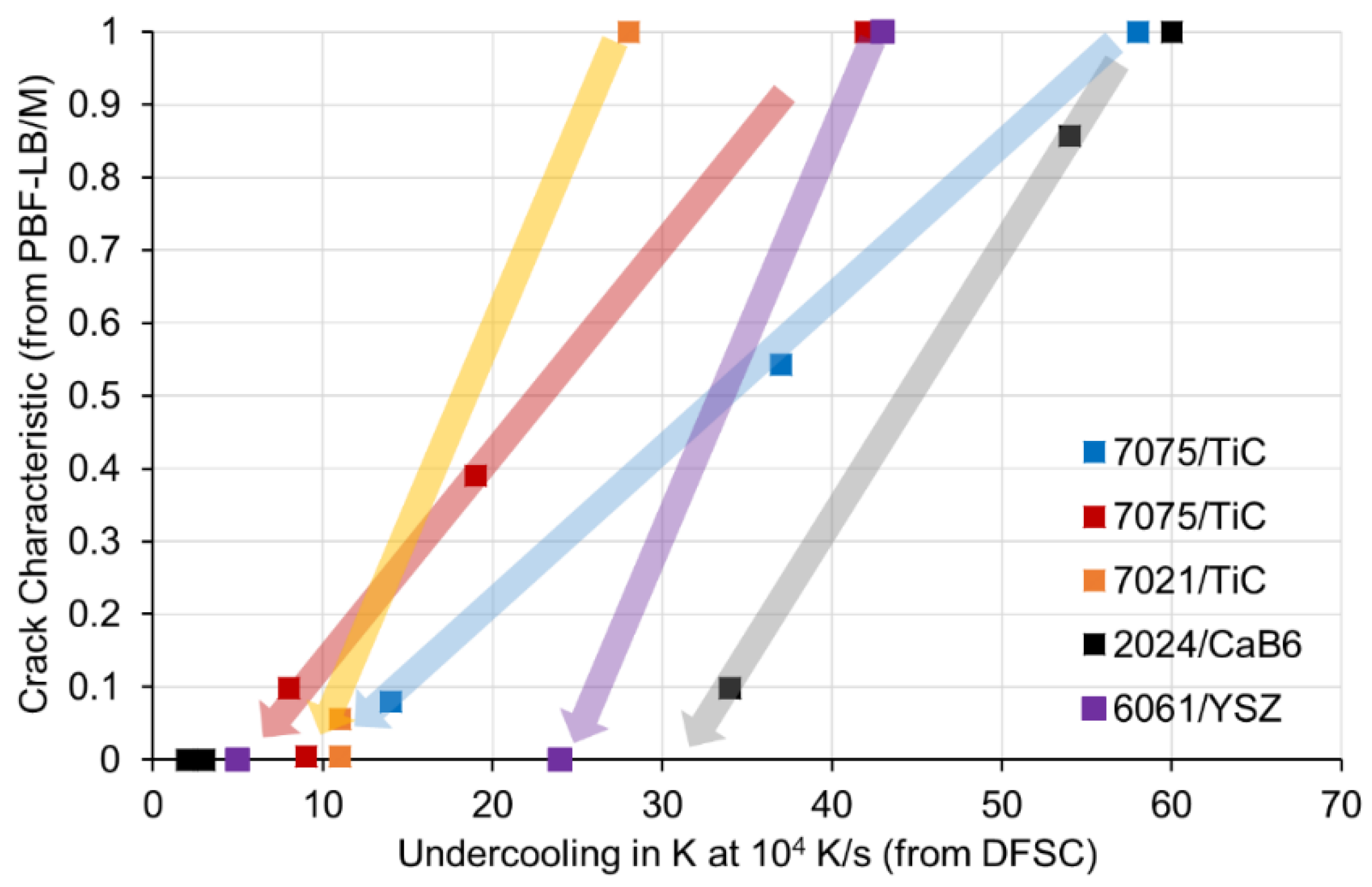

3.1. Correlation between Crack Characteristics C and Solidification Undercooling

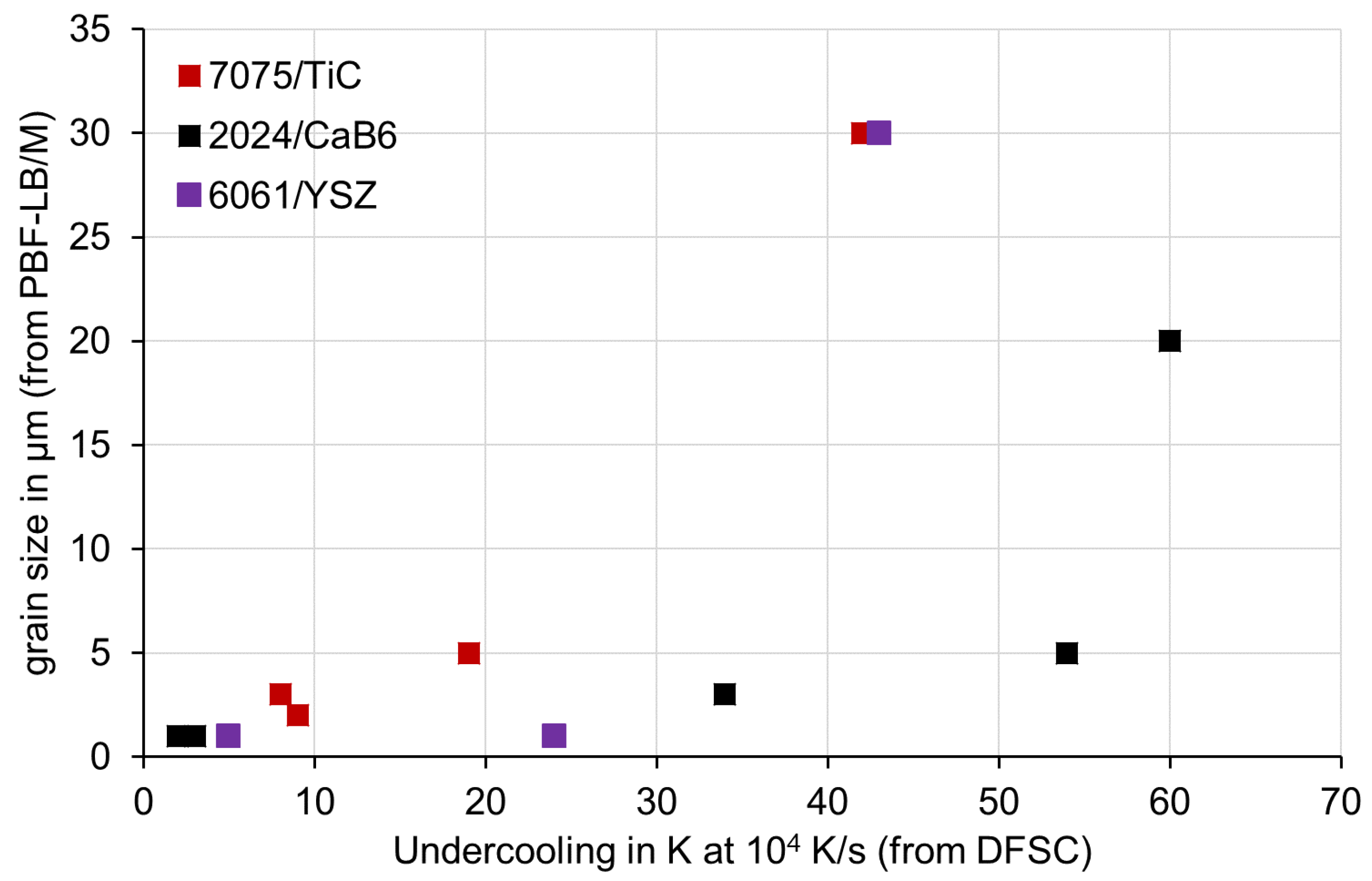

3.2. Correlation between Grain Size and Solidification Undercooling

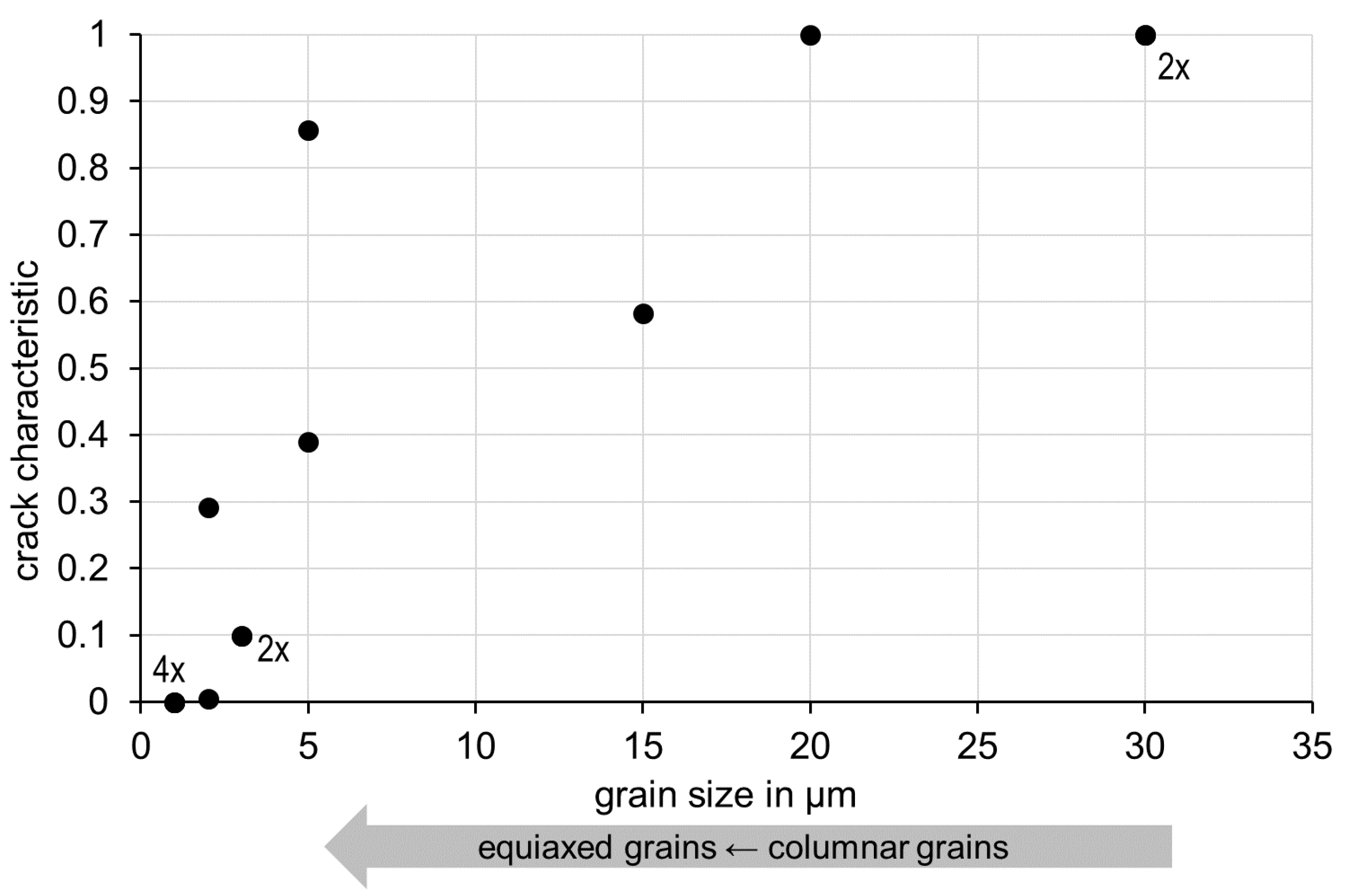

3.3. Correlation between Crack Characteristics C and Grain Size

3.4. Efficiency of Nanoparticle Inoculation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Dimitrii, A. Petrov and MSIT®. SpringerMaterials; Effenberg, G., Ed.; 10.11491.1.9; Springer-Verlag GmbH: Heidelberg, Germany, 1993. [Google Scholar]

- Kurz, W.; Fisher, D.J. Fundamentals of Solidification; Trans Tech Publications Ltd.: Wollerau, Switzerland, 1998. [Google Scholar]

- Coniglio, N.; Cross, C.E. Initiation and growth mechanisms for weld solidification cracking. Int. Mater. Rev. 2013, 58, 375–397. [Google Scholar] [CrossRef]

- Rappaz, M.; Drezet, J.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A 1999, 30, 449–455. [Google Scholar] [CrossRef]

- Zhuravlev, E.; Milkereit, B.; Yang, B.; Heiland, S.; Vieth, P.; Voigt, M.; Schaper, M.; Grundmeier, G.; Schick, C.; Kessler, O. Assessment of AlZnMgCu alloy powder modification for crack-free laser powder bed fusion by differential fast scanning calorimetry. Mater. Des. 2021, 204, 109677. [Google Scholar] [CrossRef]

- Gu, D.; Wang, H.; Chang, F.; Dai, D.; Yuan, P.; Hagedorn, Y.-C.; Meiners, W. Selective laser melting additive manufacturing of TiC/AlSi10Mg bulk-form nanocomposites with tailored microstructures and properties. Phys. Procedia 2014, 56, 108–116. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Tan, Q.; Zhang, J.; Sun, Q.; Fan, Z.; Li, G.; Yin, Y.; Liu, Y.; Zhang, M.-X. Inoculation treatment of an additively manufactured 2024 aluminium alloy with titanium nanoparticles. Acta Mater. 2020, 196, 1–16. [Google Scholar] [CrossRef]

- Zhao, T.; Dahmen, M.; Cai, W.; Alkhayat, M.; Schaible, J.; Albus, P.; Zhong, C.; Hong, C.; Biermann, T.; Zhang, H.; et al. Laser metal deposition for additive manufacturing of AA5024 and nanoparticulate TiC modified AA5024 alloy composites prepared with balling milling process. Opt. Laser Technol. 2020, 131, 106438. [Google Scholar] [CrossRef]

- Xi, L.; Gu, D.; Guo, S.; Wang, R.; Ding, K.; Prashanth, K.G. Grain refinement in laser manufactured Al-based composites with TiB2 ceramic. J. Mater. Res. Technol. 2020, 9, 2611–2622. [Google Scholar] [CrossRef]

- Opprecht, M.; Garandet, J.-P.; Roux, G.; Flament, C.; Soulier, M. A solution to the hot cracking problem for aluminium alloys manufactured by laser beam melting. Acta Mater. 2020, 197, 40–53. [Google Scholar] [CrossRef]

- Heiland, S.; Milkereit, B.; Hoyer, K.-P.; Zhuravlev, E.; Kessler, O.; Schaper, M. Requirements for successfully processing high-strength AlZnMgCu alloys with PBF-LB/M. Materials 2021, 14, 7190. [Google Scholar] [CrossRef] [PubMed]

- Mair, P.; Kaserer, L.; Braun, J.; Stajkovic, J.; Klein, C.; Schimbäck, D.; Perfler, L.; Zhuravlev, E.; Kessler, O.; Leichtfried, G. Dependence of mechanical properties and microstructure on solidification onset temperature for varying Al2024/CaB6 mixtures processed using laser powder bed fusion. Mater. Sci. Eng. A 2022, 833, 142552. [Google Scholar] [CrossRef]

- Peng, Q.; Yang, B.; Milkereit, B.; Liu, D.; Springer, A.; Rettenmayr, M.; Schick, C.; Keßler, O. Nucleation Behavior of a Single Al-20Si Particle Rapidly Solidified in a Fast Scanning Calorimeter. Materials 2021, 14, 2920. [Google Scholar] [CrossRef] [PubMed]

- Milkereit, B.; Meißner, Y.; Ladewig, C.; Osten, J.; Peng, Q.; Yang, B.; Springer, A.; Keßler, O. Metallographic Preparation of Single Powder Particles. Pract. Metallogr. 2021, 58, 129–139. [Google Scholar] [CrossRef]

- Hengsbach, F.; Hoyer, K.-P.; Schaper, M.; Andreiev, A. Isotropic, Crack-Free Steel Design Using an Additive Manufacturing Method. Patent WO 2021/180777 A1, 16 September 2021. [Google Scholar]

| Reference | Al-Alloy | Nanoparticles, Amount | NP Deposition | DFSC Rate |

|---|---|---|---|---|

| Zhuravlev et al., 2021 [5] | 7075 | TiC 40nm 0–0.5 mass % | ball milling wet deposition | 104 K/s |

| Heiland et al., 2021 [12] | 7075 | TiC 40 nm 0–2.5 mass % | ball milling | 104 K/s |

| this work | 7021 | TiC 40 nm 0–1.75 mass % | ball milling | 104 K/s |

| this work | 7021 | TiB2 50 nm 0–1.75 mass % | ball milling | 104 K/s |

| Mair et al., 2022 [13] | 2024 | CaB6 200 nm 0–2 mass % | ball milling | 104 K/s |

| Opprecht et al., 2020 [11] | 6061 | YSZ 60 nm 0–4 volume % * | ball milling | 103 K/s |

| Alloy/Nanoparticles | Numbers of Analysed Particles | Numbers of Repetitions per Particle | Numbers of Evaluated DFSC Experiments |

|---|---|---|---|

| 7075/TiC | at least 5 | about 60 | about 300 |

| 2024/CaB6 | at least 3 | about 75 | about 225 |

| 6061/YSZ | at least 15 | about 10 | about 150 |

| Reference | Alloy/Nanoparticles | Necessary Amount of Nanoparticles |

|---|---|---|

| this work | 7075/TiC | 1.75 mass % |

| this work | 7021/TiC | 1 mass % |

| Mair et al., 2022 [13] | 2024/CaB6 | 0.5 mass % |

| Opprecht et al., 2020 [11] | 6061/YSZ | 2 volume % * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kessler, O.; Zhuravlev, E.; Wenner, S.; Heiland, S.; Schaper, M. Correlation between Differential Fast Scanning Calorimetry and Additive Manufacturing Results of Aluminium Alloys. Materials 2022, 15, 7195. https://doi.org/10.3390/ma15207195

Kessler O, Zhuravlev E, Wenner S, Heiland S, Schaper M. Correlation between Differential Fast Scanning Calorimetry and Additive Manufacturing Results of Aluminium Alloys. Materials. 2022; 15(20):7195. https://doi.org/10.3390/ma15207195

Chicago/Turabian StyleKessler, Olaf, Evgeny Zhuravlev, Sigurd Wenner, Steffen Heiland, and Mirko Schaper. 2022. "Correlation between Differential Fast Scanning Calorimetry and Additive Manufacturing Results of Aluminium Alloys" Materials 15, no. 20: 7195. https://doi.org/10.3390/ma15207195

APA StyleKessler, O., Zhuravlev, E., Wenner, S., Heiland, S., & Schaper, M. (2022). Correlation between Differential Fast Scanning Calorimetry and Additive Manufacturing Results of Aluminium Alloys. Materials, 15(20), 7195. https://doi.org/10.3390/ma15207195