Enhanced Strength–Ductility Synergy Properties in Selective Laser Melted 316L Stainless Steel by Strengthening Grinding Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Additive Manufacturing Procedure

2.3. Strengthening Grinding Processing Procedure

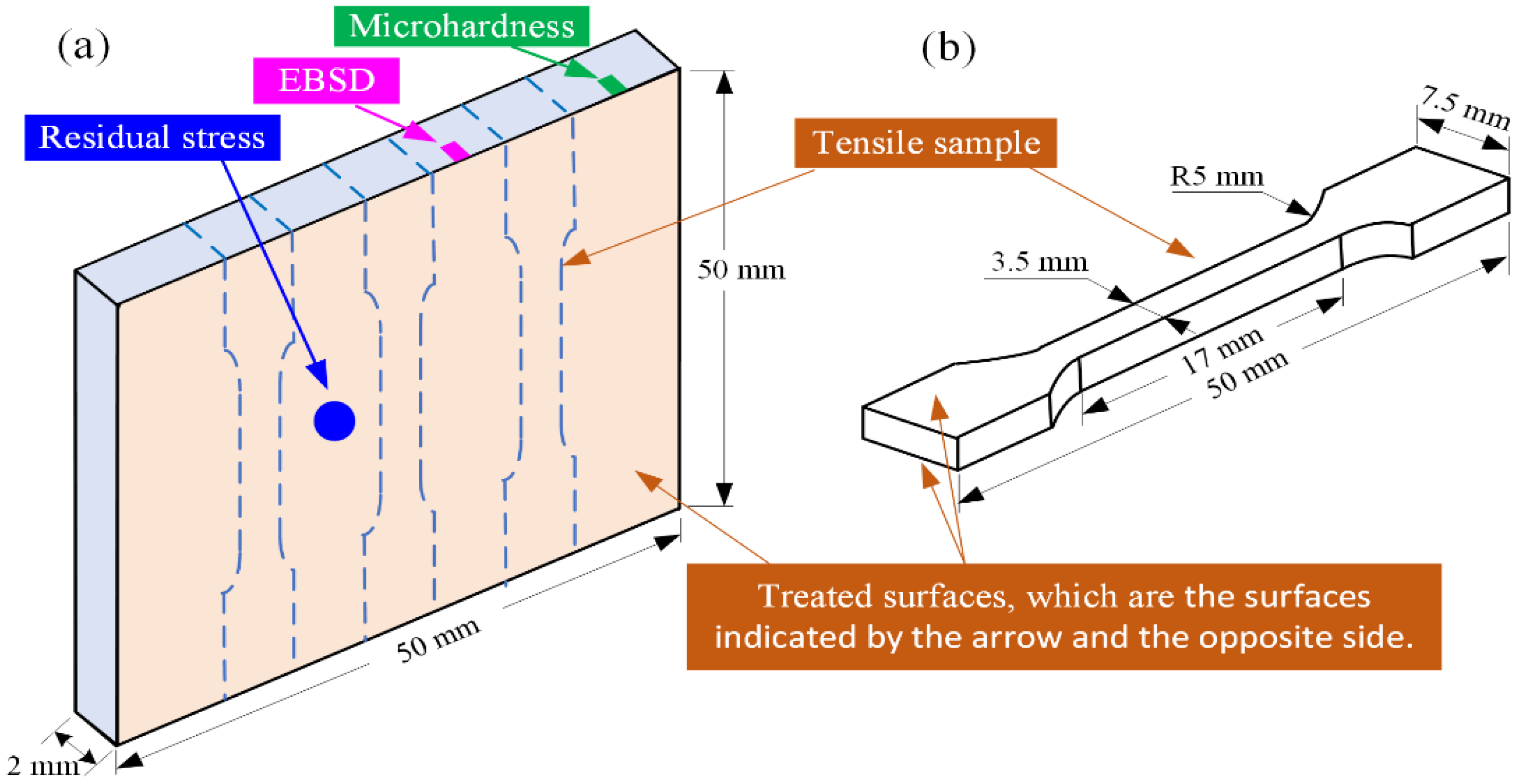

2.4. Residual Stress and Microhardness Observation

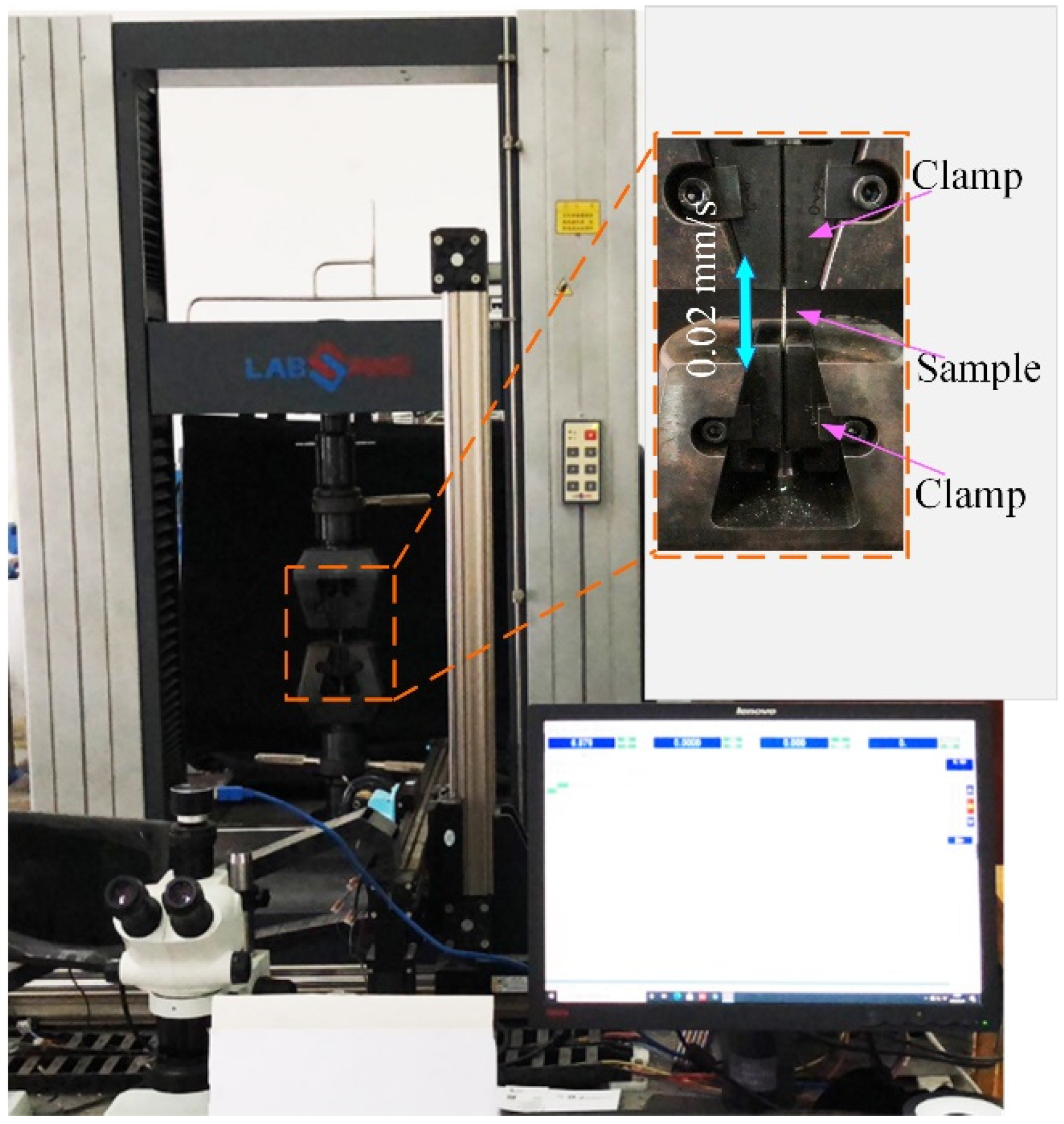

2.5. Characterization of Microstructure and Mechanical Properties

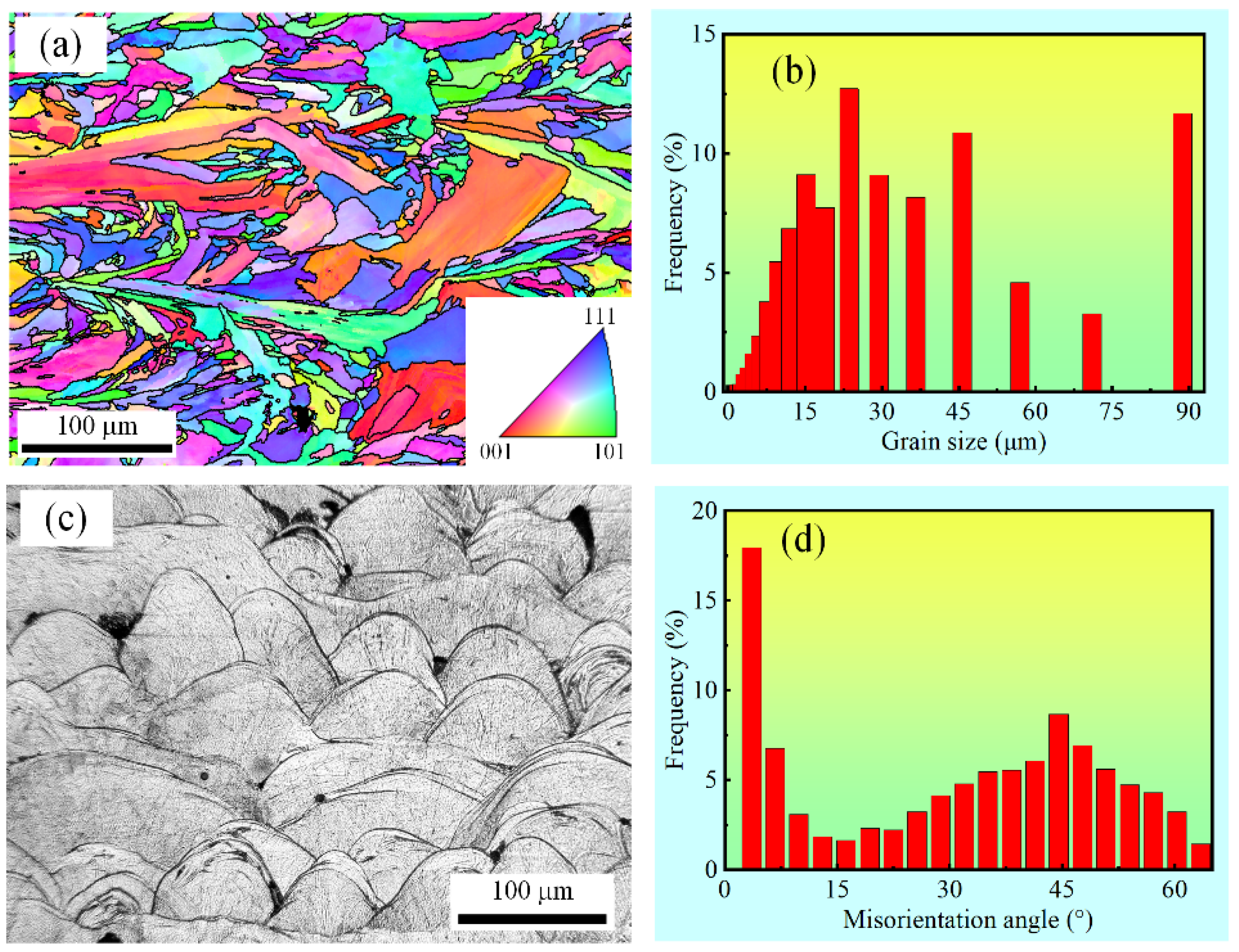

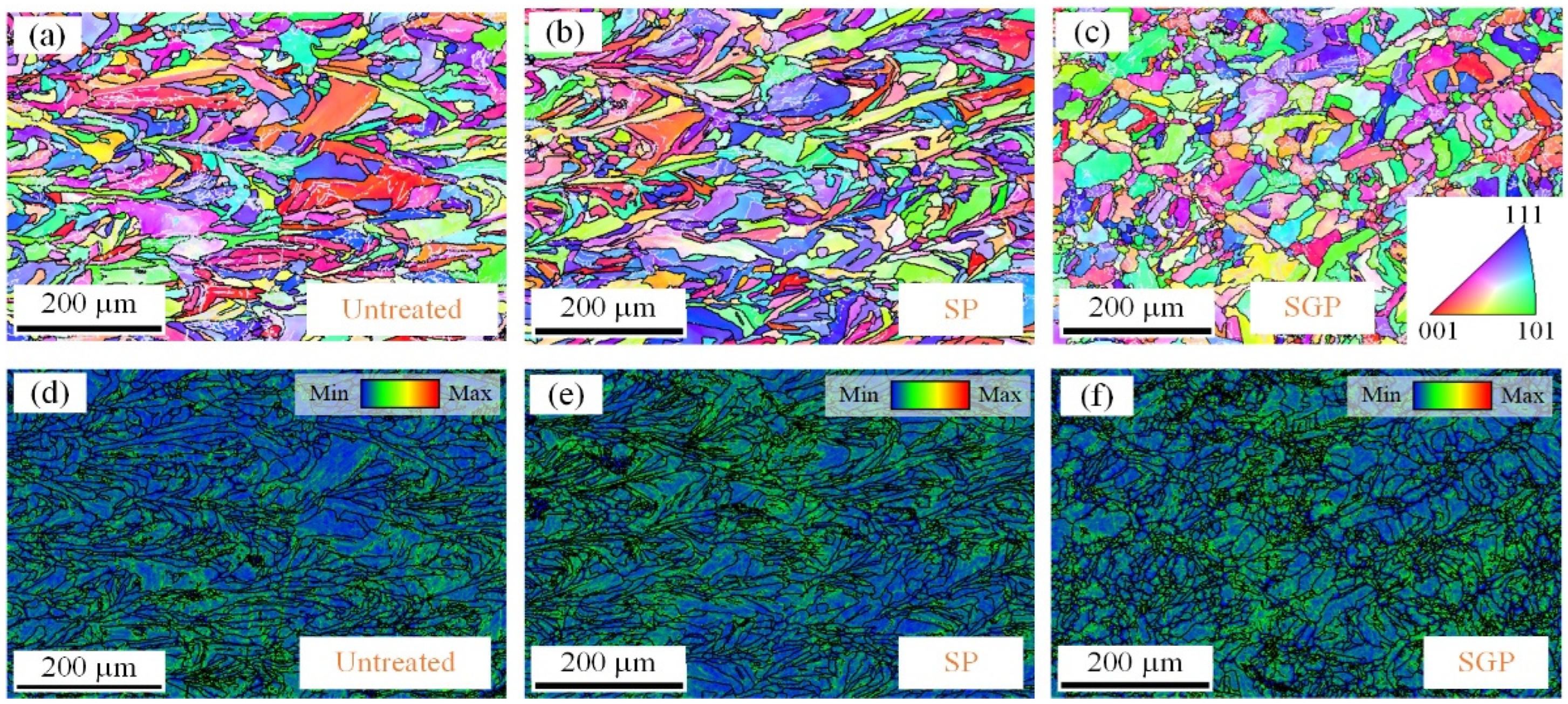

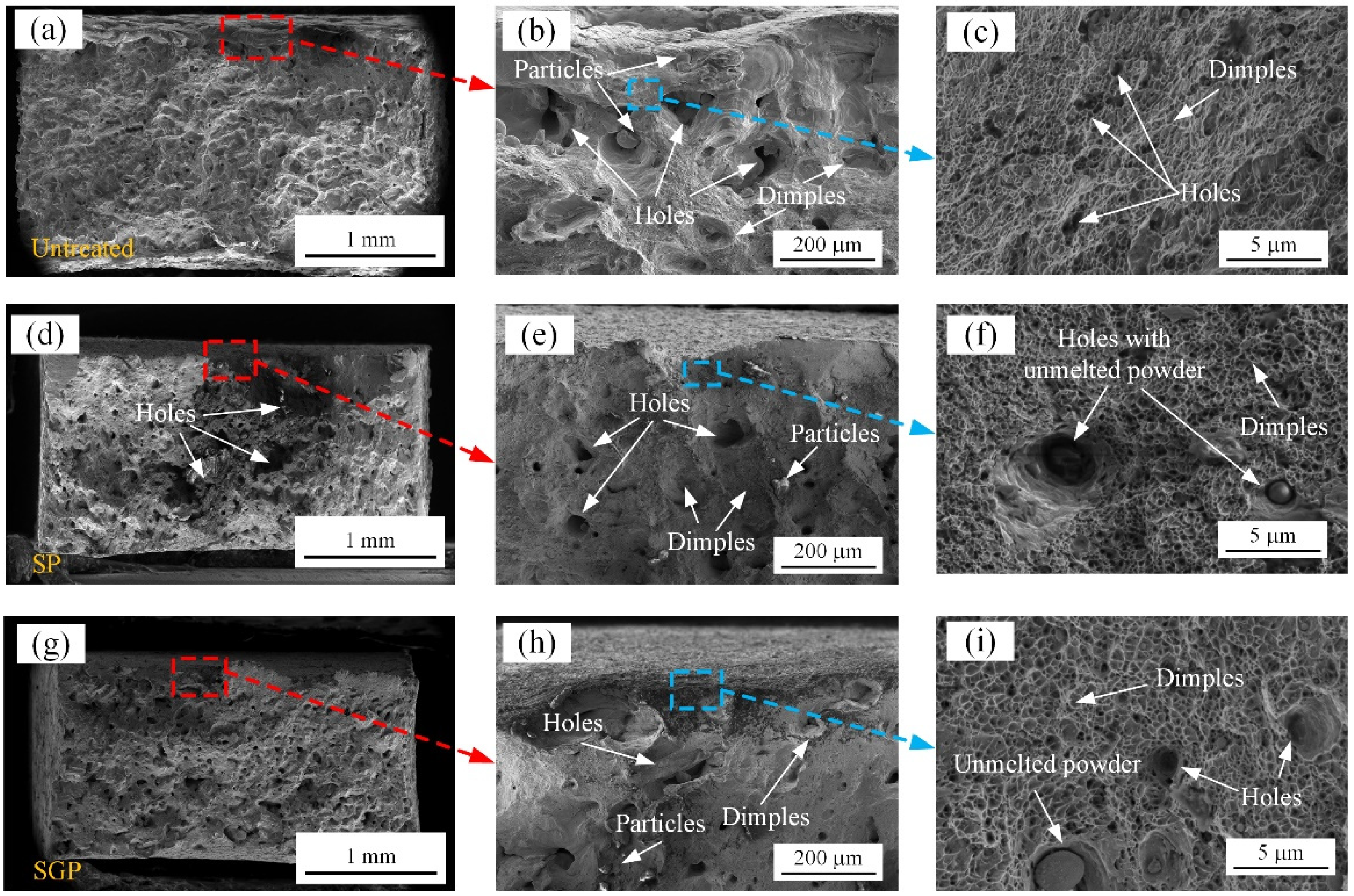

3. Results and Discussion

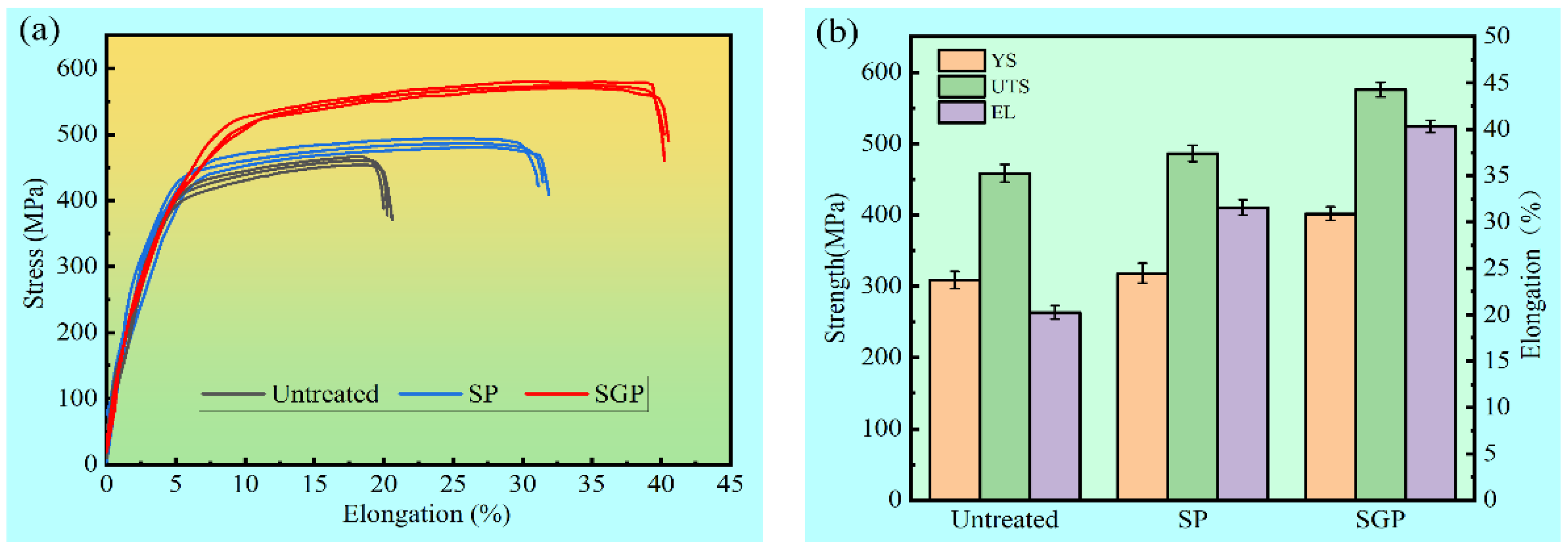

3.1. Mechanical Properties

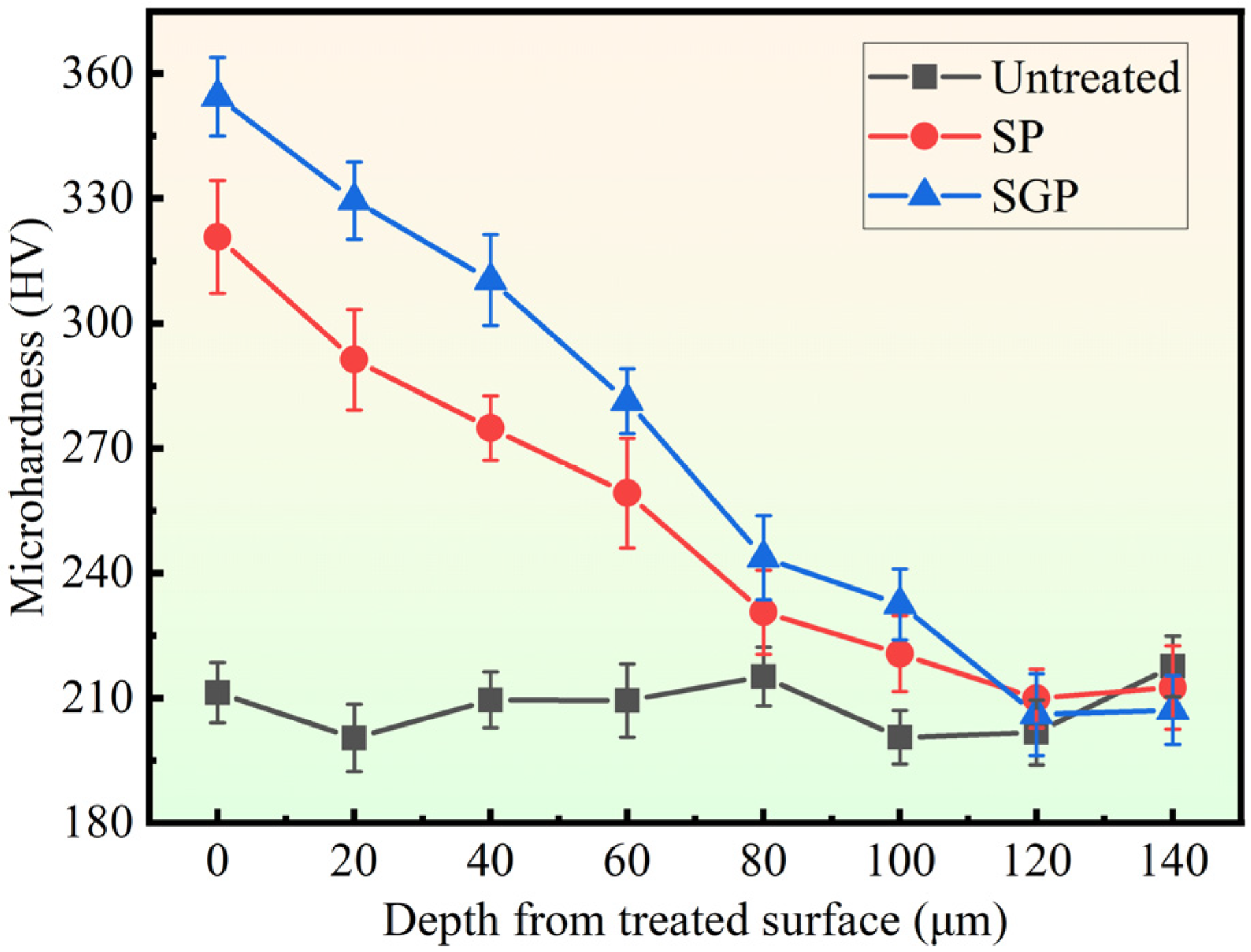

3.2. Hardness and Residual Stress Evolution of Samples

3.3. Reasons for Improvement of Strength and Ductility Synergy Properties of SGP Samples

3.4. Comparison Analysis of Strength and Ductility Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ye, F.; Zhu, T.; Mori, K.; Xu, Q.; Song, Y.; Wang, Q.; Yu, R.; Wang, B.; Cao, X. Effects of dislocations and hydrogen concentration on hydrogen embrittlement of austenitic 316 stainless steels. J. Alloy. Compd. 2021, 876, 160134. [Google Scholar] [CrossRef]

- Wang, X.; Muñiz-Lerma, J.A.; Attarian Shandiz, M.; Sanchez-Mata, O.; Brochu, M. Crystallographic-orientation-dependent tensile behaviours of stainless steel316L fabricated by laser powder bed fusion. Mater. Sci. Eng. A Struct. 2019, 766, 138395. [Google Scholar] [CrossRef]

- Lodhi, M.J.K.; Deen, K.M.; Greenlee-Wacker, M.C.; Haider, W. Additively manufactured 316L stainless steel with improved corrosion resistance and biological response for biomedical applications. Addit. Manuf. 2019, 27, 8–19. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Fredriksson, G.; Svensson, K.; Yadroitsev, I.; Yadroitsava, I.; Thuvander, M.; Peng, R. Microstructure, Solidification Texture, and Thermal Stability of 316 L Stainless Steel Manufactured by Laser Powder Bed Fusion. Metals 2018, 8, 643. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Li, M.; Wang, S.; Chi, J.; Ren, L.; Fang, M.; Zhou, C. Enhanced wear resistance and new insight into microstructure evolution of in-situ (Ti,Nb)C reinforced 316 L stainless steel matrix prepared via laser cladding. Opt. Lasers Eng. 2020, 128, 106043. [Google Scholar] [CrossRef]

- Ammarullah, M.I.; Afif, I.Y.; Maula, M.I.; Winarni, T.I.; Tauviqirrahman, M.; Jamari, J. Tresca Stress Evaluation of Metal-on-UHMWPE Total Hip Arthroplasty during Peak Loading from Normal Walking Activity. Mater. Today Proc. 2022, 63, S143–S146. [Google Scholar] [CrossRef]

- Chabak, Y.; Efremenko, B.; Petryshynets, I.; Efremenko, V.; Lekatou, A.G.; Zurnadzhy, V.; Bogomol, I.; Fedun, V.; Koval, K.; Pastukhova, T. Structural and Tribological Assessment of Biomedical 316 Stainless Steel Subjected to Pulsed-Plasma Surface Modification: Comparison of LPBF 3D Printing and Conventional Fabrication. Materials 2021, 14, 7671. [Google Scholar] [CrossRef]

- Segura-Cardenas, E.; Ramirez-Cedillo, E.G.; Sandoval-Robles, J.A.; Ruiz-Huerta, L.; Caballero-Ruiz, A.; Siller, H.R. Permeability Study of Austenitic Stainless Steel Surfaces Produced by Selective Laser Melting. Metals 2017, 7, 521. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Wu, S.; Yang, Y.; Dou, W.; Deng, S.; Wang, Z.; Li, S. The Effect of a Scanning Strategy on the Residual Stress of 316L Steel Parts Fabricated by Selective Laser Melting (SLM). Materials 2018, 11, 1821. [Google Scholar] [CrossRef] [Green Version]

- Ashwath, P.; Xavior, M.A.; Batako, A.; Jeyapandiarajan, P.; Joel, J. Selective laser melting of Al–Si–10Mg alloy: Microstructural studies and mechanical properties assessment. J. Mater. Res. Technol. 2022, 17, 2249–2258. [Google Scholar] [CrossRef]

- Fu, C.; Li, J.; Bai, J.; Lei, Q.; Liu, R.; Lin, J. Evolution of helium bubbles in SLM 316L stainless steel irradiated with helium ions at different temperatures. J. Nucl. Mater. 2022, 562, 153609. [Google Scholar] [CrossRef]

- Sun, X.; Chen, F.; Huang, H.; Lin, J.; Tang, X. Effects of interfaces on the helium bubble formation and radiation hardening of an austenitic stainless steel achieved by additive manufacturing. Appl. Surf. Sci. 2019, 467–468, 1134–1139. [Google Scholar] [CrossRef]

- Deng, W.W.; Lu, H.F.; Xing, Y.H.; Luo, K.Y.; Lu, J.Z. Effect of laser shock peening on tensile properties and microstructure of selective laser melted 316L stainless steel with different build directions. Mater. Sci. Eng. A Struct. 2022, 850, 143567. [Google Scholar] [CrossRef]

- Croteau, J.R.; Griffiths, S.; Rossell, M.D.; Leinenbach, C.; Kenel, C.; Jansen, V.; Seidman, D.N.; Dunand, D.C.; Vo, N.Q. Microstructure and mechanical properties of Al-Mg-Zr alloys processed by selective laser melting. Acta Mater. 2018, 153, 35–44. [Google Scholar] [CrossRef]

- Nadammal, N.; Mishurova, T.; Fritsch, T.; Serrano-Munoz, I.; Kromm, A.; Haberland, C.; Portella, P.D.; Bruno, G. Critical role of scan strategies on the development of microstructure, texture, and residual stresses during laser powder bed fusion additive manufacturing. Addit. Manuf. 2021, 38, 101792. [Google Scholar] [CrossRef]

- Sun, S.-H.; Ishimoto, T.; Hagihara, K.; Tsutsumi, Y.; Hanawa, T.; Nakano, T. Excellent mechanical and corrosion properties of austenitic stainless steel with a unique crystallographic lamellar microstructure via selective laser melting. Scr. Mater. 2019, 159, 89–93. [Google Scholar] [CrossRef]

- Alsalla, H.; Hao, L.; Smith, C. Fracture toughness and tensile strength of 316L stainless steel cellular lattice structures manufactured using the selective laser melting technique. Mater. Sci. Eng. A Struct. 2016, 669, 1–6. [Google Scholar] [CrossRef]

- Santa-aho, S.; Kiviluoma, M.; Jokiaho, T.; Gundgire, T.; Honkanen, M.; Lindgren, M.; Vippola, M. Additive Manufactured 316L Stainless-Steel Samples: Microstructure, Residual Stress and Corrosion Characteristics after Post-Processing. Metals 2021, 11, 182. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Yan, Q.; Zhang, L.; Wang, M.; Song, B.; Shi, Y. Amorphous alloy strengthened stainless steel manufactured by selective laser melting: Enhanced strength and improved corrosion resistance. Scr. Mater. 2018, 148, 20–23. [Google Scholar] [CrossRef]

- Sugavaneswaran, M.; Jebaraj, A.V.; Kumar, M.D.B.; Lokesh, K.; Rajan, A.J. Enhancement of surface characteristics of direct metal laser sintered stainless steel 316L by shot peening. Surf. Interfaces 2018, 12, 31–40. [Google Scholar] [CrossRef]

- Sun, Y.; Bailey, R.; Moroz, A. Surface finish and properties enhancement of selective laser melted 316L stainless steel by surface mechanical attrition treatment. Surf. Coat. Technol. 2019, 378, 124993. [Google Scholar] [CrossRef]

- Lemarquis, L.; Giroux, P.F.; Maskrot, H.; Barkia, B.; Hercher, O.; Castany, P. Cold-rolling effects on the microstructure properties of 316L stainless steel parts produced by Laser Powder Bed Fusion (LPBF). J. Mater. Res. Technol. 2021, 15, 4725–4736. [Google Scholar] [CrossRef]

- Chenrayan, V.; Manivannan, C.; Shahapurkar, K.; Zewdu, G.A.; Maniselvam, N.; Alarifi, I.M.; Alblalaihid, K.; Tirth, V.; Algahtani, A. An experimental and empirical assessment of machining damage of hybrid glass-carbon FRP composite during abrasive water jet machining. J. Mater. Res. Technol. 2022, 19, 1148–1161. [Google Scholar] [CrossRef]

- Kan, W.H.; Jiang, D.; Humbert, M.; Gao, X.; Bhatia, V.K.; Proust, G.; Zhu, Y.; Hodgson, P.; Huang, A. Effect of in-situ layer-by-layer rolling on the microstructure, mechanical properties, and corrosion resistance of a directed energy deposited 316L stainless steel. Addit. Manuf. 2022, 55, 102863. [Google Scholar] [CrossRef]

- Chattopadhyay, S.; Anand, G.; Chowdhury, S.G.; Manna, I. Effect of reverse austenitic transformation on mechanical property and associated texture evolution in AISI 316 austenitic stainless steel processed by low temperature rolling and annealing. Mater. Sci. Eng. A Struct. 2018, 734, 139–148. [Google Scholar] [CrossRef]

- Liu, T.; Xia, S.; Du, D.; Bai, Q.; Zhang, L.; Lu, Y. Grain boundary engineering of large-size 316 stainless steel via warm-rolling for improving resistance to intergranular attack. Mater. Lett. 2019, 234, 201–204. [Google Scholar] [CrossRef]

- Ming, T.; Xue, H.; Zhang, T.; Han, Y.; Peng, Q. Improving the corrosion and stress corrosion cracking resistance of 316 L stainless steel in high temperature water by water jet cavitation peening. Surf. Coat. Technol. 2022, 438, 128420. [Google Scholar] [CrossRef]

- Zhang, P.; Yue, X.; Wang, P.; Zhai, Y. Influence of SiC pellets water jet peening on the surface integrity of 7075-T6 aluminum alloy. Vacuum 2022, 196, 110760. [Google Scholar] [CrossRef]

- Wang, C.; Luo, K.; Bu, X.; Su, Y.; Cai, J.; Zhang, Q.; Lu, J. Laser shock peening-induced surface gradient stress distribution and extension mechanism in corrosion fatigue life of AISI 420 stainless steel. Corros. Sci. 2020, 177, 109027. [Google Scholar] [CrossRef]

- Liu, D.; Shi, Y.; Liu, J.; Wen, L. Effect of laser shock peening on corrosion resistance of 316L stainless steel laser welded joint. Surf. Coat. Technol. 2019, 378, 124824. [Google Scholar] [CrossRef]

- Soyama, H.; Korsunsky, A.M. A critical comparative review of cavitation peening and other surface peening methods. J. Mater. Process. Technol. 2022, 305, 117586. [Google Scholar] [CrossRef]

- Dhakal, B.; Swaroop, S. Review: Laser shock peening as post welding treatment technique. J. Manuf. Process. 2018, 32, 721–733. [Google Scholar] [CrossRef]

- Wen, Y.; Wu, Y.; Hua, L.; Xie, L.; Wang, L.; Zhang, L.-C.; Lu, W. Effects of shot peening on microstructure evolution and mechanical properties of surface nanocrystal layer on titanium matrix composite. Mater. Des. 2021, 206, 109760. [Google Scholar] [CrossRef]

- Qu, S.; Duan, C.; Hu, X.; Jia, S.; Li, X. Effect of shot peening on microstructure and contact fatigue crack growth mechanism of shaft steel. Mater. Chem. Phys. 2021, 274, 125116. [Google Scholar] [CrossRef]

- Ghosh, S.; Bibhanshu, N.; Suwas, S.; Chatterjee, K. Surface mechanical attrition treatment of additively manufactured 316L stainless steel yields gradient nanostructure with superior strength and ductility. Mater. Sci. Eng. A Struct. 2021, 820, 141540. [Google Scholar] [CrossRef]

- Portella, Q.; Chemkhi, M.; Retraint, D. Influence of Surface Mechanical Attrition Treatment (SMAT) post-treatment on microstructural, mechanical and tensile behaviour of additive manufactured AISI 316L. Mater. Charact. 2020, 167, 110463. [Google Scholar] [CrossRef]

- Xie, X.; Guo, Z.; Zhao, Z.; Liang, Z.; Wu, J.; Liu, X.; Xiao, J. Salt-Fog Corrosion Behavior of GCr15 Steels Treated by Ultrasonic Strengthening Grinding Process. Appl. Sci. 2022, 12, 7360. [Google Scholar] [CrossRef]

- Liu, X.; Huang, J.; Liang, Z.; Huang, W.; Zhu, R.; Gao, W.; Xiao, J. Preparation and Properties of the Composite Enhancement Layer of Bearing Ring. World J. Mech. 2020, 10, 139–153. [Google Scholar] [CrossRef]

- Li, G.; Qu, S.; Xie, M.; Ren, Z.; Li, X. Effect of Multi-Pass Ultrasonic Surface Rolling on the Mechanical and Fatigue Properties of HIP Ti-6Al-4V Alloy. Materials 2017, 10, 133. [Google Scholar] [CrossRef] [Green Version]

- Xiao, X.; Tong, X.; Sun, Y.; Li, Y.; Wei, S.; Gao, G. An analytical model for predicting peening stresses with general peening coverage. J. Manuf. Process. 2019, 45, 242–254. [Google Scholar] [CrossRef]

- Xiao, J.; Zhao, Z.; Xie, X.; Liang, Z.; Liu, Z.; Liu, X.; Tang, R. Micromorphology, Microstructure, and Wear Behavior of AISI 1045 Steels Irregular Texture Fabricated by Ultrasonic Strengthening Grinding Process. Metals 2022, 12, 1027. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Mhaede, M.; Basha, M.; Wollmann, M.; Wagner, L. The effect of shot peening parameters and hydroxyapatite coating on surface properties and corrosion behavior of medical grade AISI 316L stainless steel. Surf. Coat. Technol. 2015, 280, 347–358. [Google Scholar] [CrossRef]

- Zhai, W.; Zhu, Z.; Zhou, W.; Nai, S.M.L.; Wei, J. Selective laser melting of dispersed TiC particles strengthened 316L stainless steel. Compos. Part B Eng. 2020, 199, 108291. [Google Scholar] [CrossRef]

- Oliaei, M.; Jamaati, R. Improvement of the strength-ductility-toughness balance in interstitial-free steel by gradient microstructure. Mater. Sci. Eng. A Struct. 2022, 845, 143237. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A.P. On the correlation between indentation hardness and tensile strength in friction stir processed materials. Mater. Sci. Eng. A Struct. 2020, 789, 139682. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Haghshenas, M.; Eskandari, H.; Koohbor, B. Hardness−strength relationships in fine and ultra-fine grained metals processed through constrained groove pressing. Mater. Sci. Eng. A Struct. 2015, 636, 331–339. [Google Scholar] [CrossRef]

- Sun, W.-J.; Kothari, S.; Sun, C.C. The relationship among tensile strength, Young’s modulus, and indentation hardness of pharmaceutical compacts. Powder Technol. 2018, 331, 1–6. [Google Scholar] [CrossRef]

- Fang, R.; Deng, N.; Zhang, H.; Wang, G.; Su, Y.; Zhou, H.; Gao, K.; Gu, L. Effect of selective laser melting process parameters on the microstructure and properties of a precipitation hardening stainless steel. Mater. Des. 2021, 212, 110265. [Google Scholar] [CrossRef]

- Su, Y.; Chen, B.; Tan, C.; Song, X.; Feng, J. Influence of composition gradient variation on the microstructure and mechanical properties of 316 L/Inconel718 functionally graded material fabricated by laser additive manufacturing. J. Mater. Process. Technol. 2020, 283, 116702. [Google Scholar] [CrossRef]

- Rostami, M.; Miresmaeili, R.; Heydari Astaraee, A. Investigation of Surface Nanostructuring, Mechanical Performance and Deformation Mechanisms of AISI 316L Stainless Steel Treated by Surface Mechanical Impact Treatment. Met. Mater. Int. 2022, 28, 12866. [Google Scholar] [CrossRef]

- Lu, H.-H.; Guo, H.-K.; Liang, W.; Shen, X.-Q. The precipitation behavior and its effect on mechanical properties of cold-rolled super-ferritic stainless steels during high-temperature annealing. J. Mater. Res. Technol. 2021, 12, 1171–1183. [Google Scholar] [CrossRef]

- Cho, H.-J.; Cho, Y.; Gwon, H.; Lee, S.; Sohn, S.S.; Kim, S.-J. Effects of Ni/Cu replacement on improvement of tensile and hydrogen-embrittlement properties in austenitic stainless steels. Acta Mater. 2022, 235, 118093. [Google Scholar] [CrossRef]

- Wu, B.; Guo, K.; Yang, X.; Gao, Y.; Jin, Y.; Gao, Y.; Wang, Q.; Zhang, F. Effect of carbon content of substrate on the microstructure changes and tensile behavior of clad layer of stainless steel composites. Mater. Sci. Eng. A Struct. 2022, 831, 142201. [Google Scholar] [CrossRef]

| Cr | Ni | Mo | Mn | Si | C | P | S | O | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 16.84 | 10.51 | 2.84 | 1.03 | 0.55 | 0.016 | 0.013 | 0.07 | 0.048 | Bal. |

| Parameters | Value |

|---|---|

| Laser power (W) | 500 |

| Printing speed (mm/s) | 14.3 |

| Preheating temperature (°C) | 45 |

| Interlayer temperature (°C) | ≤100 |

| Dry extension (mm) | 12–16 |

| Inter-channel offset (mm) | 3.5 |

| Parameters | Value |

|---|---|

| Diameter of zirconia ceramic ball (mm) | 1.5 |

| Grain size of brown corundum (μm) | 15 |

| Jet pressure (MPa) | 0.6 |

| Processing time (s) | 60 |

| Jet angle (°) | 45 |

| Jet distance (mm) | 50 |

| Abrasive flow rate (Kg/min) | 10 |

| Processing a | YS (MPa) | UTS (MPa) | EL (%) | Refs. |

|---|---|---|---|---|

| SLM + SGP 1 min | 401.7 | 575.6 | 40.3 | Present work |

| SLM + SP 1 min | 318.5 | 486.2 | 31.6 | Present work |

| SLM | 309 | 458.5 | 20.3 | Present work |

| SLM (BD 0) | 582 | 632 | 7.7 | [13] |

| SLM (BD 0) & LSP | 584 | 658 | 5.7 | [13] |

| SLM (BD 45) & LSP | 646 | 739 | 8.4 | [13] |

| SLM (BD 90) & LSP | 679 | 771 | 9.5 | [13] |

| SLM & SMAT 10 min | 599 | 669 | 22 | [36] |

| SLM & SMAT 30 min | 624 | 676 | 16 | [36] |

| HR + 850 °C/1 h/AN | 730 | 790 | 2.1 | [49] |

| SLM & SMIT 60 min | 470 | 680 | 15 | [50] |

| SLM & SMIT 120 min | 650 | 740 | 16 | [50] |

| LMD | 262.3 | 443.4 | 19.4 | [51] |

| HR & PR-0.20C | 337 | 546 | 17 | [52] |

| HR & PR-0.06C | 309 | 519 | 24 | [52] |

| HR & 1000 °C/AN & 700 °C/1 h/AG | 153 | 492 | 69.5 | [53] |

| HR & 1000 °C/AN-2Cu | 155 | 494 | 75.7 | [53] |

| HR & 1000 °C/AN-4Cu | 169 | 492 | 66.9 | [53] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, J.; Zou, T.; Zhang, Y.; Zhao, Z.; Tang, G.; Xie, X.; Liang, Z.; Liu, X. Enhanced Strength–Ductility Synergy Properties in Selective Laser Melted 316L Stainless Steel by Strengthening Grinding Process. Materials 2022, 15, 7227. https://doi.org/10.3390/ma15207227

Xiao J, Zou T, Zhang Y, Zhao Z, Tang G, Xie X, Liang Z, Liu X. Enhanced Strength–Ductility Synergy Properties in Selective Laser Melted 316L Stainless Steel by Strengthening Grinding Process. Materials. 2022; 15(20):7227. https://doi.org/10.3390/ma15207227

Chicago/Turabian StyleXiao, Jinrui, Tao Zou, Yiteng Zhang, Zhuan Zhao, Gongbin Tang, Xincheng Xie, Zhongwei Liang, and Xiaochu Liu. 2022. "Enhanced Strength–Ductility Synergy Properties in Selective Laser Melted 316L Stainless Steel by Strengthening Grinding Process" Materials 15, no. 20: 7227. https://doi.org/10.3390/ma15207227

APA StyleXiao, J., Zou, T., Zhang, Y., Zhao, Z., Tang, G., Xie, X., Liang, Z., & Liu, X. (2022). Enhanced Strength–Ductility Synergy Properties in Selective Laser Melted 316L Stainless Steel by Strengthening Grinding Process. Materials, 15(20), 7227. https://doi.org/10.3390/ma15207227