Strength Evaluation of Functionalized MWCNT-Reinforced Polymer Nanocomposites Synthesized Using a 3D Mixing Approach

Abstract

:1. Introduction

2. Materials and Methods

3. Specimen Preparation Procedure

3.1. The 3D Mixing Process

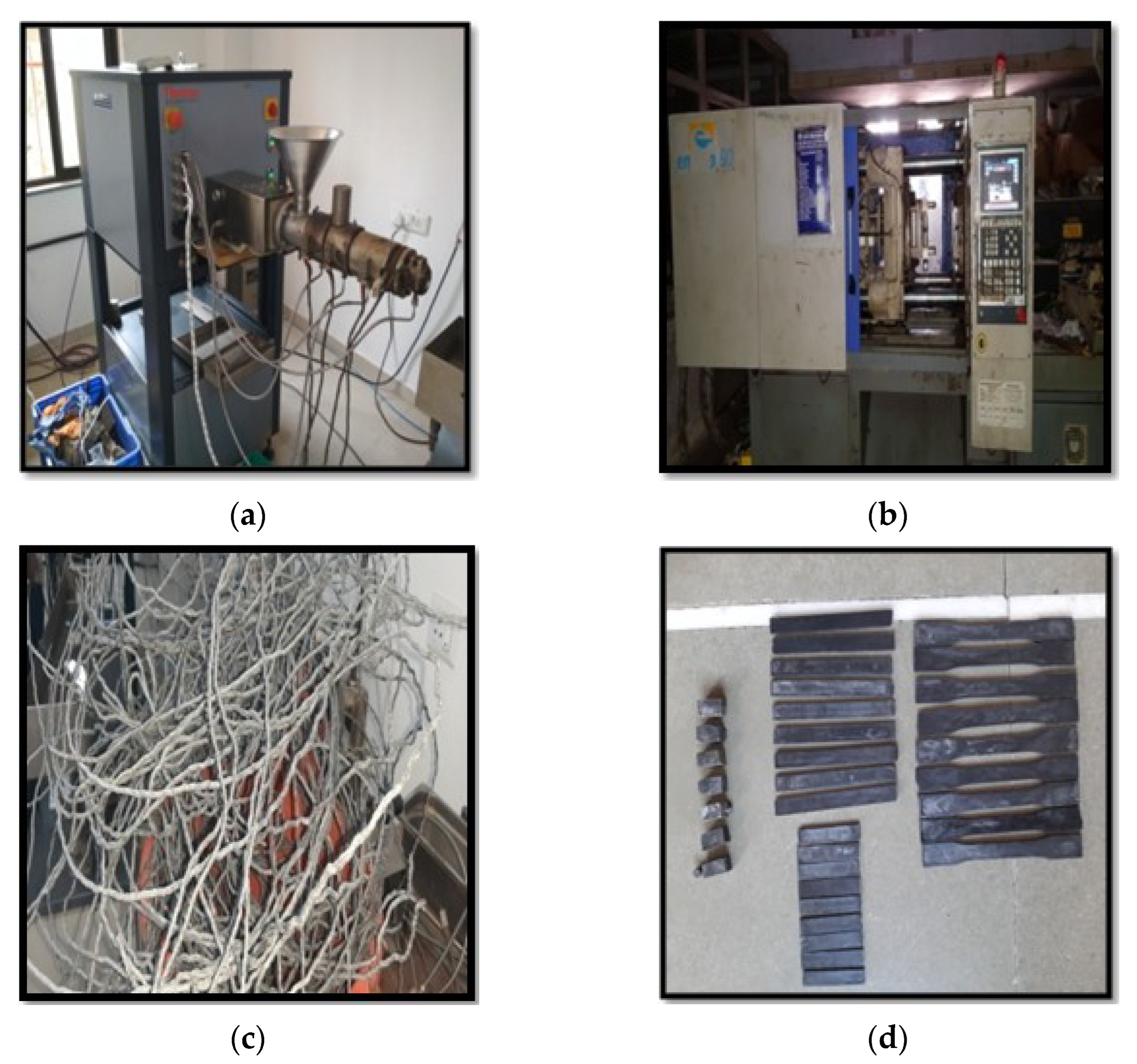

3.2. Extrusion and Injection Molding Process

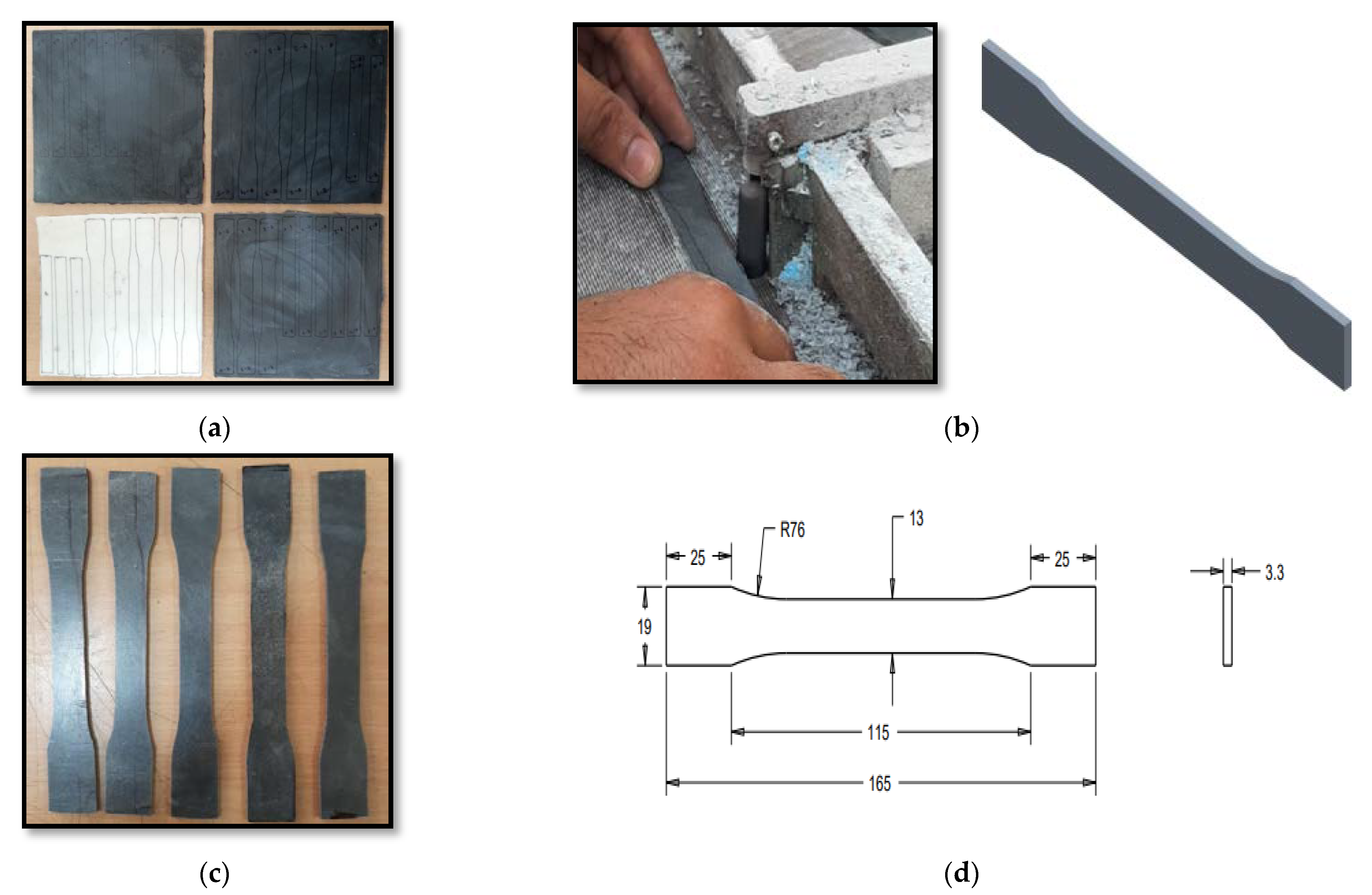

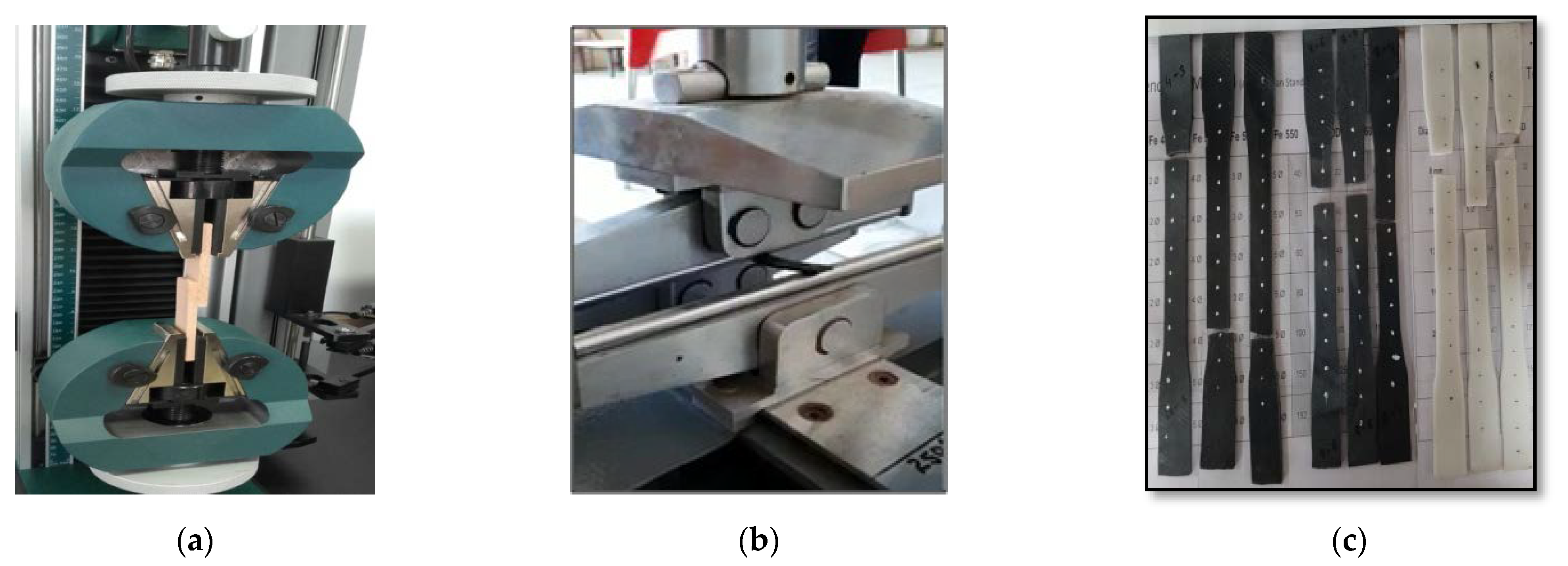

3.3. Specimen Testing and Characterization

4. Results and Discussion

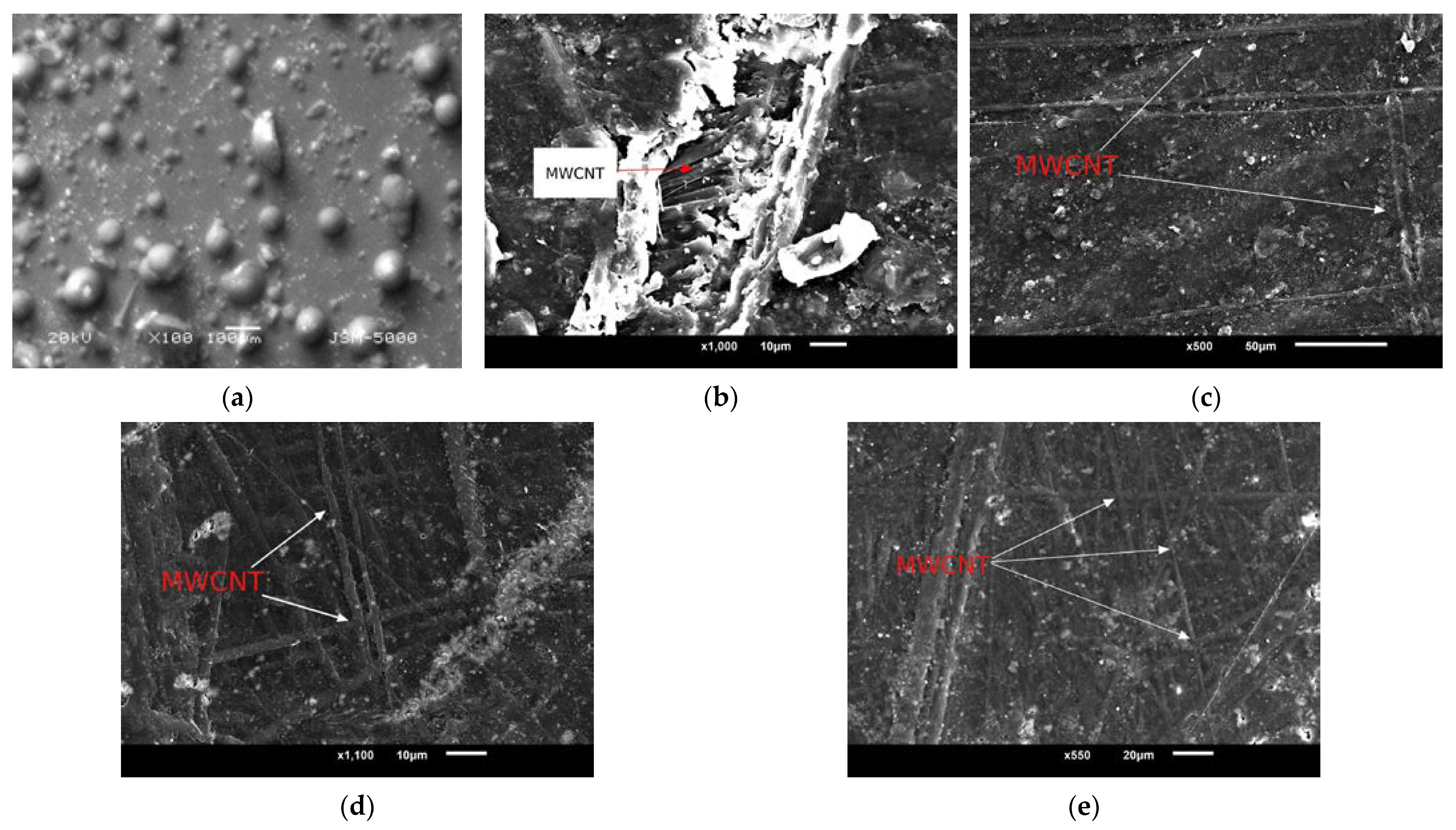

4.1. Microstructural Assessment

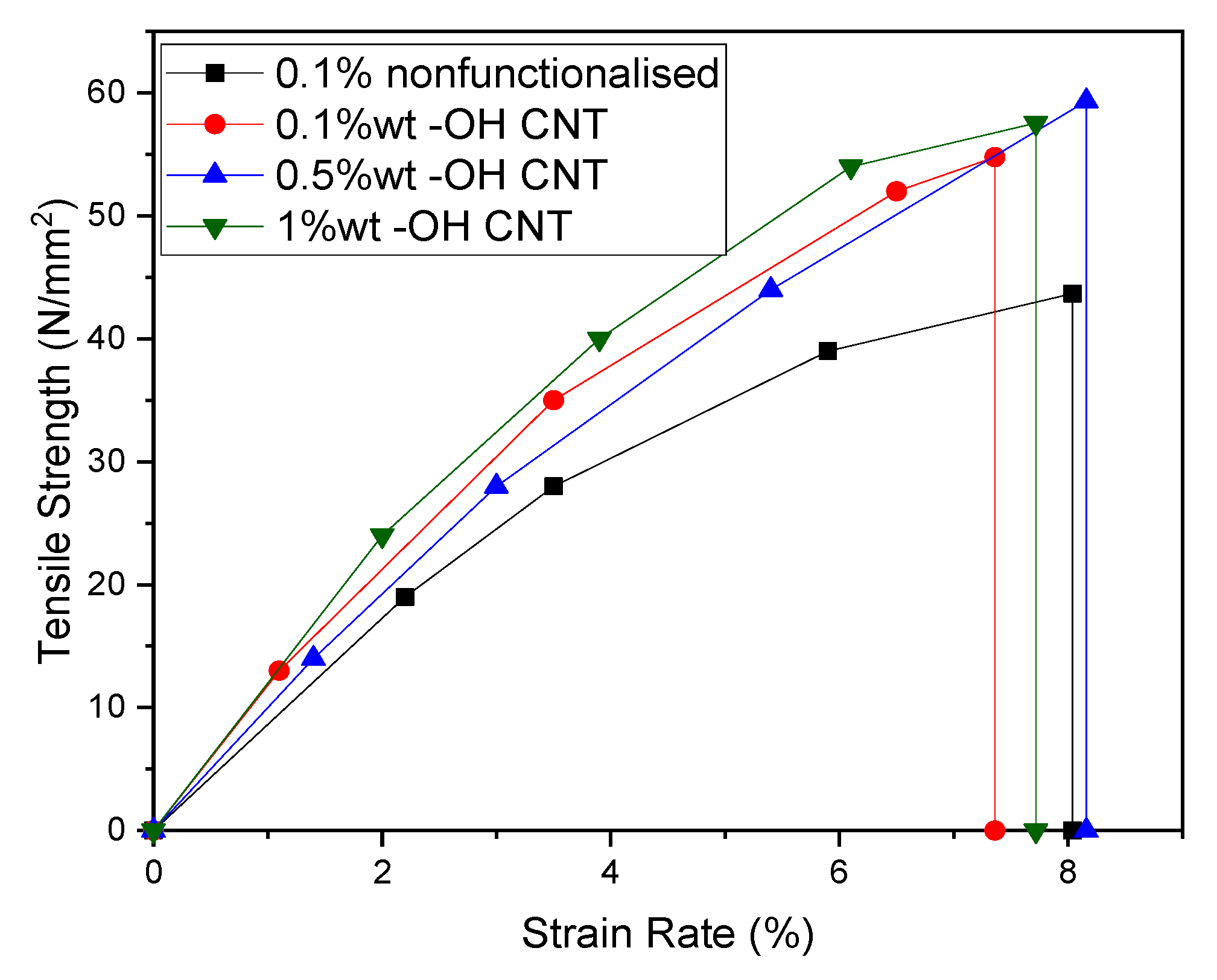

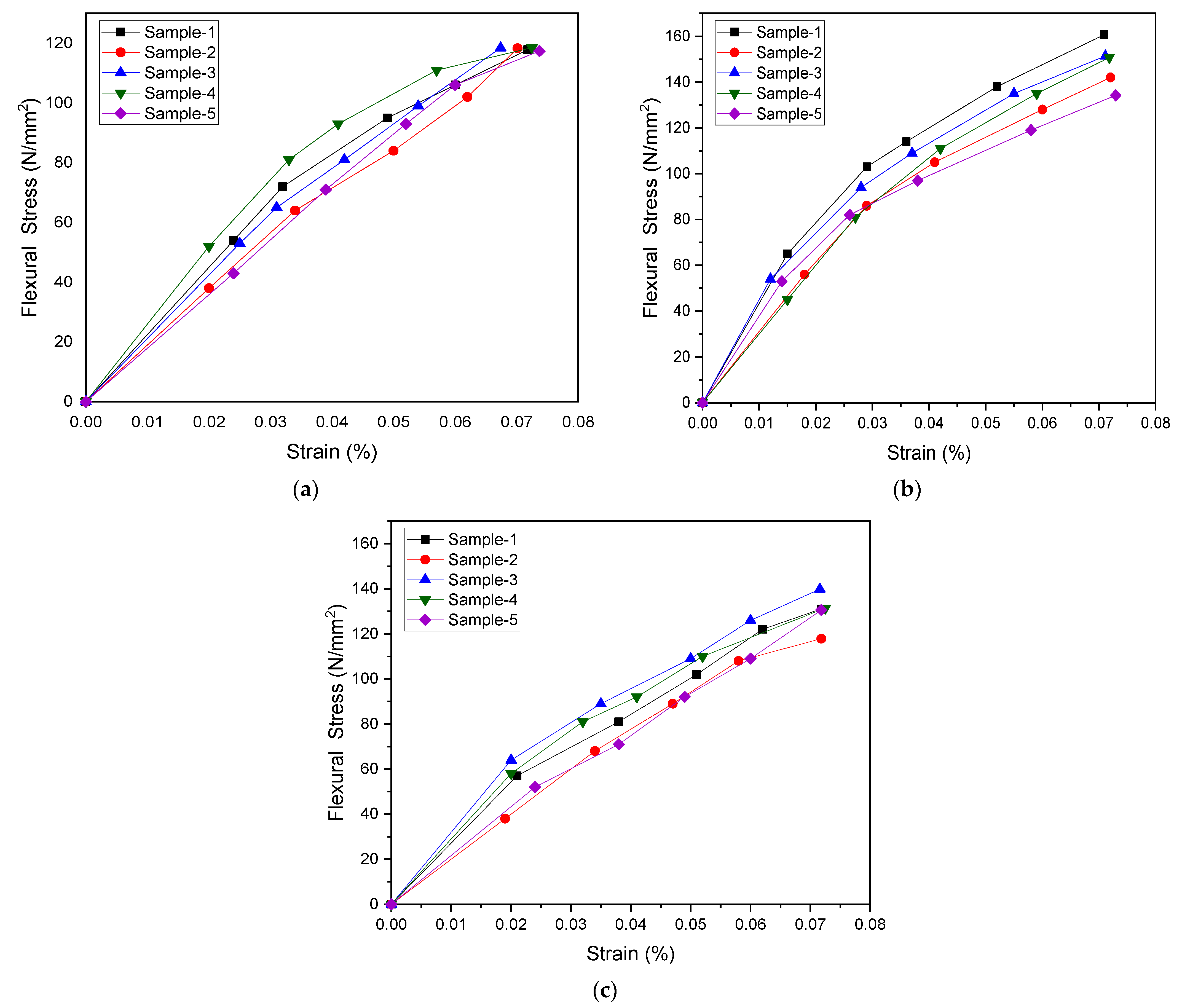

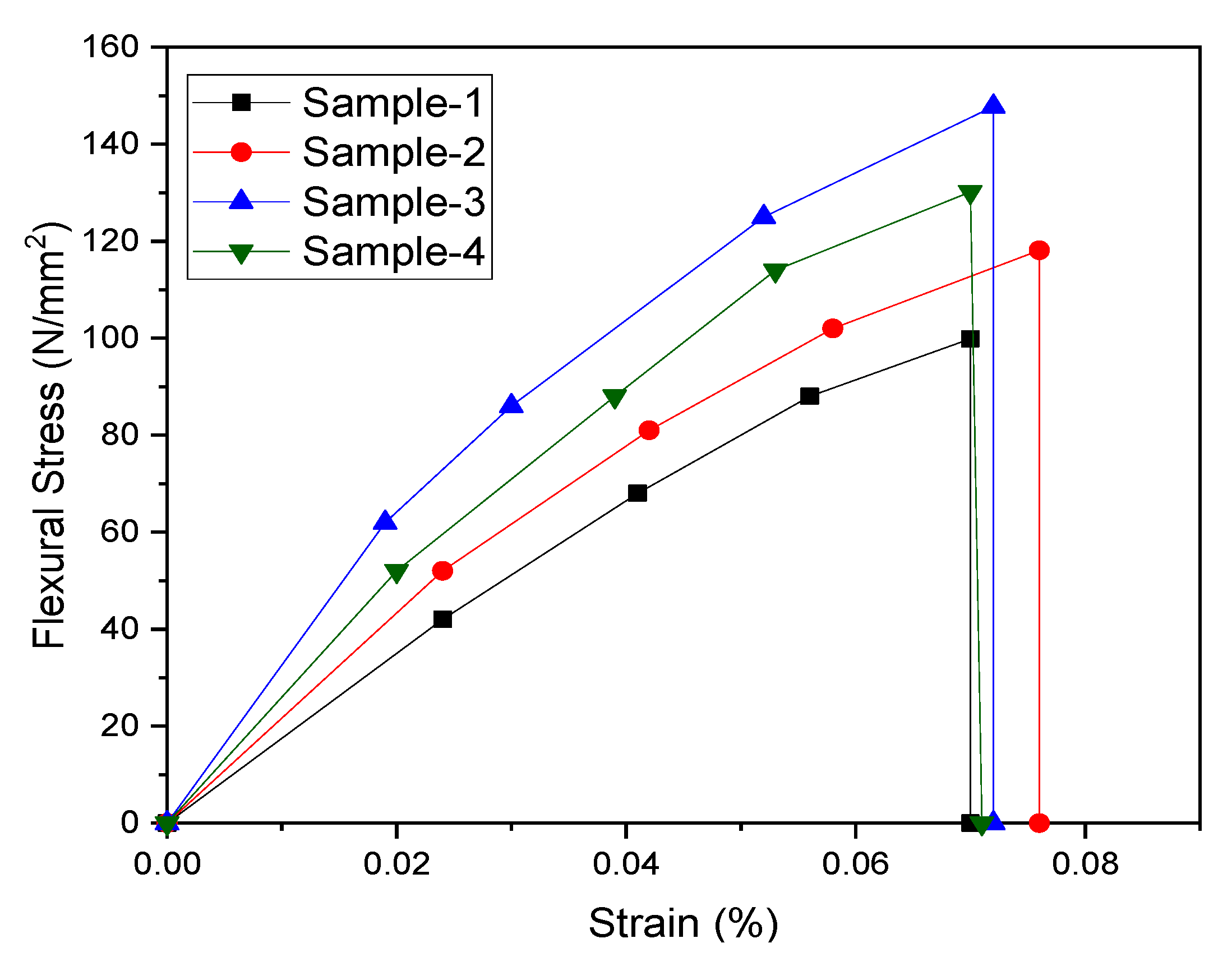

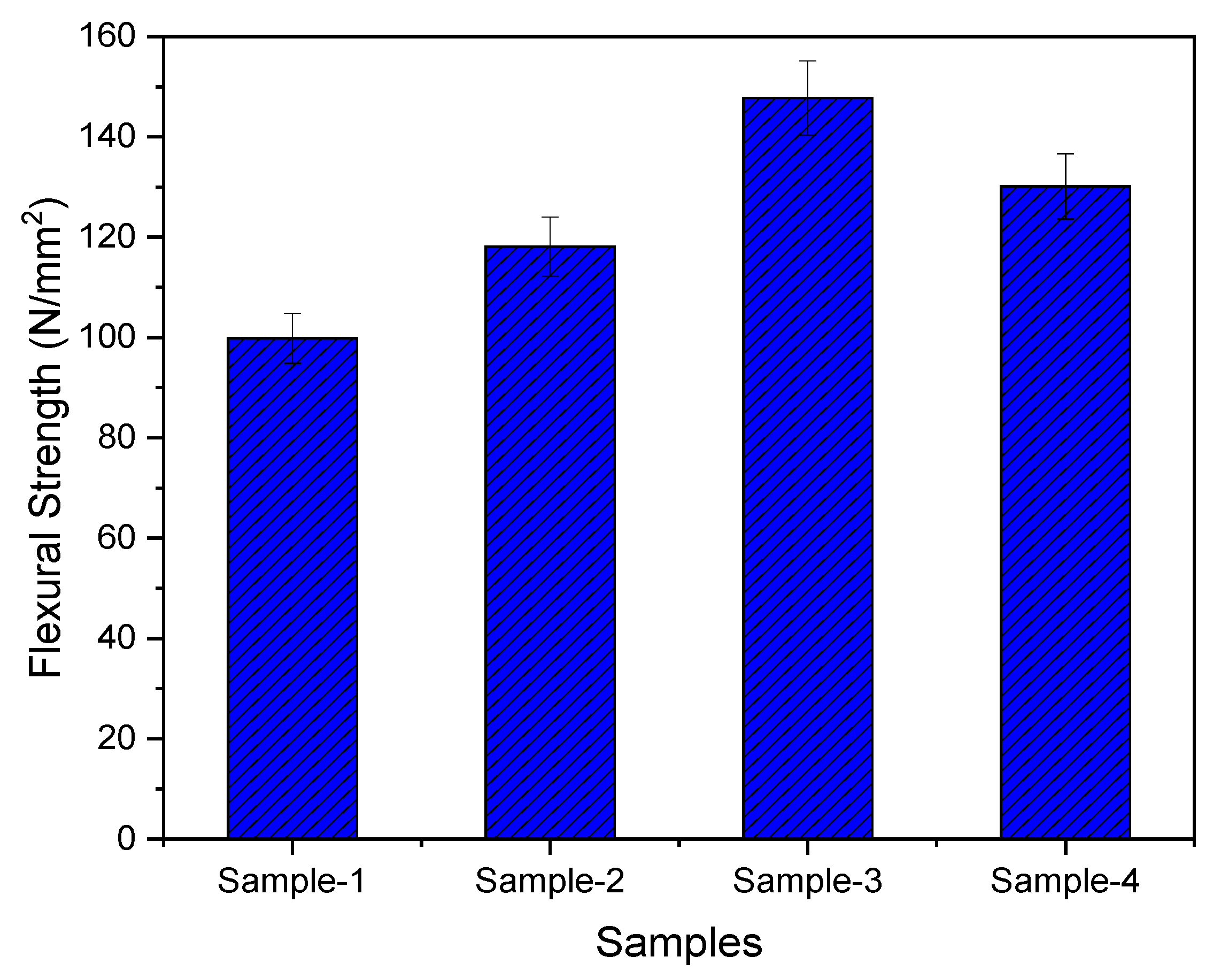

4.2. Mechanical Assessment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Review article: Polymer-matrix Nanocomposites, Processing, Manufacturing, and Application: An Overview. J. Compos. Mater. 2006, 40, 1511–1575. [Google Scholar] [CrossRef]

- Hwang, T.Y.; Kim, H.J.; Ahn, Y.; Lee, J.W. Influence of twin screw extrusion processing condition on the properties of polypropylene/multi-walled carbon nanotube nanocomposites. Korea Aust. Rheol. J. 2010, 22, 141–148. [Google Scholar]

- Vaia, R.A.; Wagner, H.D. Framework for nanocomposites. Korea Aust. Rheol. J. 2004, 7, 32–37. [Google Scholar] [CrossRef]

- Joshi, U.A.; Sharma, S.C.; Harsha, S.P. Modeling and analysis of mechanical behavior of carbon nanotube reinforced composites. Proceedings of the Institution of Mechanical Engineers, Part N. J. Nanoeng. Nanosyst. 2011, 225, 23–32. [Google Scholar]

- Iijima, S. Helical microtubes of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Joshi, U.A.; Sharma, S.C.; Harsha, S.P. Effect of Carbon Nanotube orientation on the Mechanical Properties of Nano Composites. Compos. Part B Eng. 2012, 43, 2063–2071. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Grasley, Z.; Tyson, B.; Al-Rub, R.K.A. Distribution of Carbon Nanofibers and Nanotubes in Cementitious Composites. Transp. Res. Rec. 2010, 2142, 89–95. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.-P.; Liu, Y.; Li, X.-X.; You, Y.-Z. Synthesis and characteristics of poly(methyl methacrylate)/expanded graphite nanocomposites. J. Appl. Polym. Sci. 2006, 100, 1427–1431. [Google Scholar] [CrossRef]

- Khan, W.; Sharma, R.; Saini, P. Carbon Nanotube-Based Polymer Composites: Synthesis, Properties and Applications. In Carbon Nanotubes-Current Progress of their Polymer Composites; Berber, M.R., Hafez, I.H., Eds.; IntechOpen: London, UK, 2016. [Google Scholar]

- Poornima, C.; Sheshadri, C.P.; Mallik, U.S. Effect of PP and PP/MWCNT-COOH Nanocomposites on Mechanical Properties. Proc. AIP Conf. 2020, 2204, 040018. [Google Scholar]

- Hamit, A. Effects of particle reinforcement on the bending and compressive behaviors of composite pipes. Mater. Test. 2019, 61, 1072–1076. [Google Scholar]

- Kalaitzidou, K.; Fukushima, H.; Drzal, L.T. A new compounding method for exfoliated graphite-polypropylene nanocomposites with enhanced flexural properties and lower percolation threshold. Compos. Sci. Technol. 2007, 67, 2045–2051. [Google Scholar] [CrossRef]

- Hamit, A.D.İ.N.; Seven, B.; Çakar, F.; YILDIRIM, H.; İsa, A.T.A.Ş. Experimental determination of the mechanical properties of composite materials produced with particle reinforced adhesives. Eur. J. Tech. (EJT) 2017, 7, 158–164. [Google Scholar]

- Jindal, P.; Goyal, M.; Kumar, N. Mechanical characterization of multiwalled carbon nanotubes-polycarbonate composites. Mater. Des. 2014, 54, 864–868. [Google Scholar] [CrossRef]

- Mathur, R.; Pande, S.; Singh, B.; Dhami, T. Electrical and mechanical properties of multi-walled carbon nanotubes reinforced PMMA and PS composites. Polym. Compos. 2008, 29, 717–727. [Google Scholar] [CrossRef]

- Oliveira, M.; Machado, A.V. Preparation of polymer-based nanocomposites by different routes. In Nanocomposites: Synthesis, Characterization and Applications; Kravchenko, T.A., Khorolskaya, S.V., Eds.; Nova Science Publishers: Hauppauge, NY, USA, 2013; pp. 1–22. [Google Scholar]

- de Oliveira, A.D.; Beatrice, C.A.G. Polymer Nanocomposites with Different Types of Nanofiller. In Nanocomposites-Recent Evolutions; Sivasankaran, S., Ed.; IntechOpen: London, UK, 2019; pp. 104–127. [Google Scholar]

- Jin, Z.; Pramoda, K.; Xu, G.; Goh, S.H. Dynamic mechanical behavior of melt-processed multi-walled carbon nanotube/poly(methyl methacrylate) composites. Chem. Phys. Lett. 2001, 337, 43–47. [Google Scholar] [CrossRef]

- Adin, M.Ş.; Kılıçkap, E. Strength of double-reinforced adhesive joints. Mater. Test. 2021, 63, 176–181. [Google Scholar] [CrossRef]

- Charnley, J. Anchorage of the Femoral Head Prosthesis to the Shaft of the Femur. J. Bone Jt. Surgery. Br. Vol. 1960, 42-B, 28–30. [Google Scholar] [CrossRef] [Green Version]

- Shundo, A.; Hori, K.; Penaloza, D.P.; Yoshihiro, K.; Annaka, M.; Tanaka, K. Nonsolvents-induced swelling of poly(methyl methacrylate) nanoparticles. Phys. Chem. Chem. Phys. 2013, 15, 16574–16578. [Google Scholar] [CrossRef]

- Zafar, M.S. Prosthodontic Applications of Polymethyl Methacrylate (PMMA): An Update. Polymers 2020, 12, 2299. [Google Scholar] [CrossRef]

- Radha, G.; Balakumar, S.; Venkatesan, B.; Vellaichamy, E. A novel nano-hydroxyapatite—PMMA hybrid scaffolds adopted by conjugated thermal induced phase separation (TIPS) and wet-chemical approach: Analysis of its mechanical and biological properties. Mater. Sci. Eng. C 2017, 75, 221–228. [Google Scholar]

- Vallittu, P.K. A Review of Methods Used to Reinforce Polymethyl Methacrylate Resin. J. Prosthodont. 1995, 4, 183–187. [Google Scholar] [CrossRef]

- Panyayong, W.; Oshida, Y.; Andres, C.J.; Barco, T.M.; Brown, D.T.; Hovijitra, S. Reinforcement of acrylic resins for provisional fixed restorations. Part III: Effects of addition of titania and zirconia mixtures on some mechanical and physical properties. Biomed. Mater. Eng. 2002, 12, 353–366. [Google Scholar]

- Gad, M.M.; Fouda, S.M.; Al-Harbi, F.A.; Näpänkangas, R.; Raustia, A. PMMA denture base material enhancement: A review of fiber, filler, and nanofiller addition. Int. J. Nanomed. 2017, 12, 3801–3812. [Google Scholar] [CrossRef] [Green Version]

- Rashahmadi, S.; Hasanzadeh, R.; Mosalman, S. Improving the mechanical properties of polymethylmethacrylate nanocomposites for dentistry applications reinforced with different nanoparticles. Polym. Plastics Technol. Eng. 2017, 56, 1730–1740. [Google Scholar] [CrossRef]

- Vardharajula, S.; Ali, S.Z.; Tiwari, P.M.; Eroğlu, E.; Vig, K.; Dennis, V.A.; Singh, S.R. Functionalized carbon nanotubes: Biomedical applications. Int. J. Nanomed. 2012, 7, 5361–5374. [Google Scholar]

- Ma, J.; Nan, X.; Larsen, R.M.; Huang, X.; Yu, B. Mechanical properties and biocompatibility of functionalized carbon nanotubes/polypropylene composites. J. Biomater. Sci. Polym. Ed. 2016, 27, 1003–1016. [Google Scholar] [CrossRef]

- Hamit, A.; Şukru, A.M. Effect of particles on tensile and bending properties of jute epoxy composites. Mater. Test. 2022, 64, 401–411. [Google Scholar]

- Adin, M.; Okumuş, M. Investigation of Microstructural and Mechanical Properties of Dissimilar Metal Weld between AISI 420 and AISI 1018 STEELS. Arab. J. Sci. Eng. 2021, 47, 8341–8350. [Google Scholar] [CrossRef]

- Prasad, V.V.S.; Satish, G.; Ramji, K. Manufacturing and characterization of CNT based polymer composites. Math. Model. Eng. 2017, 3, 89–97. [Google Scholar]

- Rouway, M.; Nachtane, M.; Tarfaoui, M.; Chakhchaoui, N.; Omari, L.E.H.; Fraija, F.; Cherkaoui, O. Mechanical Properties of a Biocomposite Based on Carbon Nanotube and Graphene Nanoplatelet Reinforced Polymers: Analytical and Numerical Study. J. Compos. Sci. 2021, 5, 234. [Google Scholar] [CrossRef]

- Parnian, P.; D’Amore, A. Fabrication of High-Performance CNT Reinforced Polymer Composite for Additive Manufacturing by Phase Inversion Technique. Polymers 2021, 13, 4007. [Google Scholar] [CrossRef]

- Kumar, M.; Arun, S.; Upadhyaya, P.; Pugazhenthi, G. Properties of PMMA/clay nanocomposites prepared using various compatibilizers. Int. J. Mech. Mater. Eng. 2015, 10, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Eren, O.; Ucar, N.; Onen, A.; Karacan, I. Effect of differently functionalized carbon nanotubes on the properties of composite nanofibers. Indian J. Fibre Textile Res. 2016, 41, 138–144. [Google Scholar]

- Dubey, R.; Dutta, D.; Sarkar, A.; Chattopadhyay, P. Functionalized carbon nanotubes: Synthesis, properties and applications in water purification, drug delivery, and material and biomedical sciences. Nanoscale Adv. 2021, 3, 5722–5744. [Google Scholar] [CrossRef]

- Camargo, P.H.C.; Satyanarayana, K.G.; Wypych, F. Nanocomposites: Synthesis, structure, properties and new application opportunities. Mater. Res. 2009, 12, 1–39. [Google Scholar] [CrossRef] [Green Version]

- Park, C.H.; Lee, W.I. Compression Molding in Polymer Matrix Composites. In Composites Science and Engineering, Manufacturing Techniques for Polymer Matrix Composites (PMCs); Advani, S.G., Hsiao, K.T., Eds.; Woodhead Publishing: Sawston, UK, 2012; pp. 47–94. [Google Scholar]

- Quadrini, F.; Bellisario, D.; Santo, L.; Stan, F.; Catalin, F. Compression Moulding of Thermoplastic Nanocomposites Filled with MWCNT. Polym. Polym. Compos. 2017, 25, 611–620. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-00; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM D7264/D7264M-15; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. American Society of Testing Materials: West Conshohocken, PA, USA, 2015.

- Talati, J. Nine things you should know when considering a 3d shaker mixer. Indian Pharm. 2017, 15, 5–6. [Google Scholar]

- Choudhary, V.; Gupta, A. Polymer/Carbon Nanotube Nanocomposites. In Carbon Nanotubes-Polymer Nanocomposites; IntechOpen: London, UK, 2011. [Google Scholar]

- Nurazzi, N.M.; Sabaruddin, F.A.; Harussani, M.M.; Kamarudin, S.H.; Rayung, M.; Asyraf, M.R.M.; Aisyah, H.A.; Norrrahim, M.N.F.; Ilyas, R.A.; Abdullah, N.; et al. Mechanical Performance and Applications of CNTs Reinforced Polymer Composites—A Review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef]

- Garg, P.; Singh, B.P.; Kumar, G.; Gupta, T.K.; Pandey, I.; Seth, R.K.; Tandon, R.P.; Mathur, R.B. Effect of dispersion conditions on the mechanical properties of multi-walled carbon nanotubes based epoxy resin composites. J. Polym. Res. 2011, 18, 1397–1407. [Google Scholar] [CrossRef]

- Hossain, M.K. Scanning Electron Microscopy Study of Fiber Reinforced Polymeric Nanocomposites. In Scanning Electron Microscopy; Kazmiruk, V., Ed.; IntechOpen: London, UK, 2012. [Google Scholar]

- Patel, V.; Joshi, U.; Joshi, A. Investigating the mechanical properties of nonfunctionalized MWCNT reinforced polymer nanocomposites. International Conference on Nanoelectronics, Nanophotonics, Nanomaterials, NanobioscienceNanotechnology, India. Mater. Today Proc. 2021, 43, 3511–3515. [Google Scholar] [CrossRef]

- Ismail, N.M.; Aziz, A.; Jaafar, M. Mechanical properties of multi-walled carbon nanotube (MWCNT)/polymethylmethacrylate (PMMA) nanocomposite prepared via the coagulation method. In 2nd Asian-Apctp Workshop on Advanced Materials Science and Nanotechnology; American Institute of Physics: College Park, AR, USA, 2012; Volume 1455, pp. 208–211. [Google Scholar]

- Mallick, A.; Mishra, P.; Swain, S.K. The Effect of Functionalized MWCNTon Mechanical and Electrical Properties of PMMA Nanocomposites. In Nanoelectronic Materials, and Devices; Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Liu, L.Q.; Wagner, H.D. A comparison of the mechanical strength and stiffness of MWNT-PMMA and MWNT-epoxy nanocomposites. Compos. Interfaces 2007, 14, 285–297. [Google Scholar] [CrossRef]

- Deep, N.; Mishra, P. Evaluation of mechanical properties of functionalized carbon nanotube reinforced PMMA polymer nanocomposite. Karbala Int. J. Mod. Sci. 2018, 4, 207–215. [Google Scholar] [CrossRef]

| Properties | Description |

|---|---|

| Color | White |

| Particle size | 48 micron |

| Tensile strength | 45 MPa |

| Young Modulus | 2855 MPa |

| Density | 1.18 g/cm3 |

| Properties | Description |

|---|---|

| Color | Black |

| Length | 0.5–5 μm |

| Diameter | 10–20 nm |

| Purity | >98 wt.% |

| Density | 2.60 g/cm3 |

| Aspect Ratio (L/D) | 183 |

| Trial | Factor Changed | Direction (Forward-F; Reverse-R) | Mixing Ratio (%wt.) | Speed (RPM) | Time (Minutes) | Visual Mixing Quality |

|---|---|---|---|---|---|---|

| 1 | Time | F & R | 0.1 | 25 | 10 | 0 |

| 2 | F & R | 0.1 | 25 | 20 | 0 | |

| 3 | F & R | 0.1 | 25 | 30 | 0 | |

| 1 | Speed | F | 0.1 | 25 | 30 | 1 |

| 2 | F | 0.1 | 35 | 30 | 2 | |

| 3 | F | 0.1 | 45 | 30 | 3 | |

| 1 | Time and Speed | R | 0.1 | 35 | 10 | 1 |

| 2 | R | 0.1 | 35 | 20 | 1 | |

| 3 | R | 0.1 | 45 | 30 | 3 |

| Parameter | Description |

|---|---|

| Volume | 270 cm3 |

| Quantity of charge (mass) | 102.6 cm3 |

| Pressure of the molding process | 700 kPa |

| Mold temperature: temperature range | 260–285 °C |

| Cure time variables | 6 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, V.; Joshi, U.; Joshi, A.; Oza, A.D.; Prakash, C.; Linul, E.; Campilho, R.D.S.G.; Kumar, S.; Saxena, K.K. Strength Evaluation of Functionalized MWCNT-Reinforced Polymer Nanocomposites Synthesized Using a 3D Mixing Approach. Materials 2022, 15, 7263. https://doi.org/10.3390/ma15207263

Patel V, Joshi U, Joshi A, Oza AD, Prakash C, Linul E, Campilho RDSG, Kumar S, Saxena KK. Strength Evaluation of Functionalized MWCNT-Reinforced Polymer Nanocomposites Synthesized Using a 3D Mixing Approach. Materials. 2022; 15(20):7263. https://doi.org/10.3390/ma15207263

Chicago/Turabian StylePatel, Vijay, Unnati Joshi, Anand Joshi, Ankit D. Oza, Chander Prakash, Emanoil Linul, Raul Duarte Salgueiral Gomes Campilho, Sandeep Kumar, and Kuldeep Kumar Saxena. 2022. "Strength Evaluation of Functionalized MWCNT-Reinforced Polymer Nanocomposites Synthesized Using a 3D Mixing Approach" Materials 15, no. 20: 7263. https://doi.org/10.3390/ma15207263