Synergistic Effects of La and Y on the Microstructure and Mechanical Properties of Cast Al-Si-Cu Alloys

Abstract

:1. Introduction

2. Experimental

2.1. Original Materials

2.2. Preparation of Master Alloys

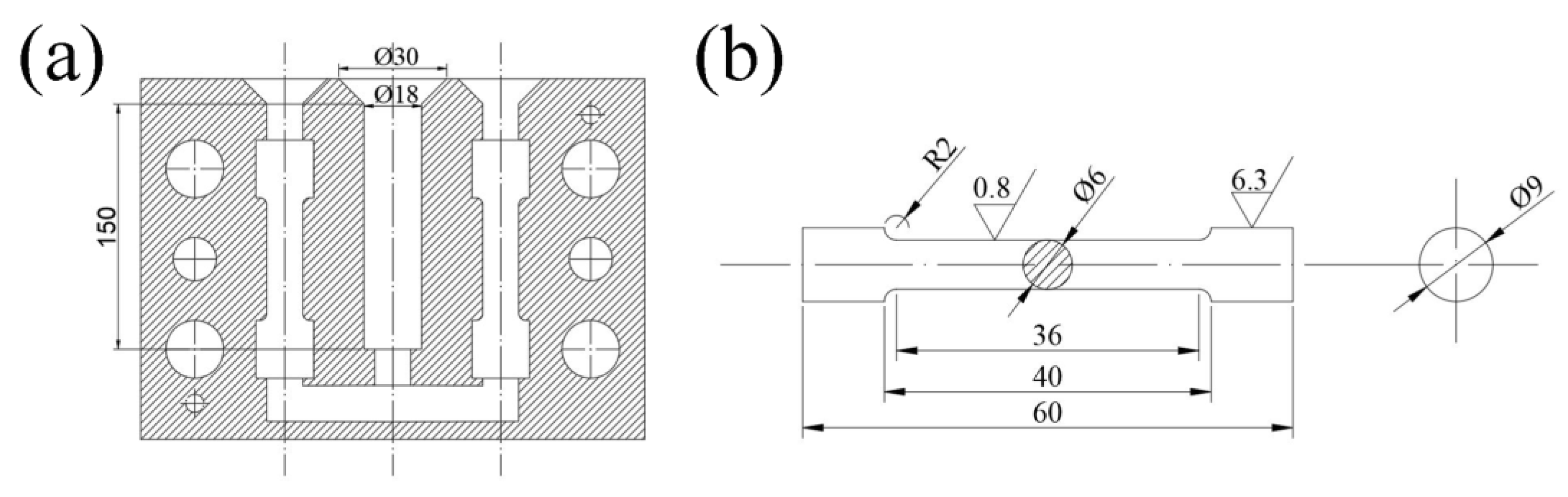

2.3. Preparation of Modified Aluminum Alloys

2.4. Microstructure Characterization

3. Results

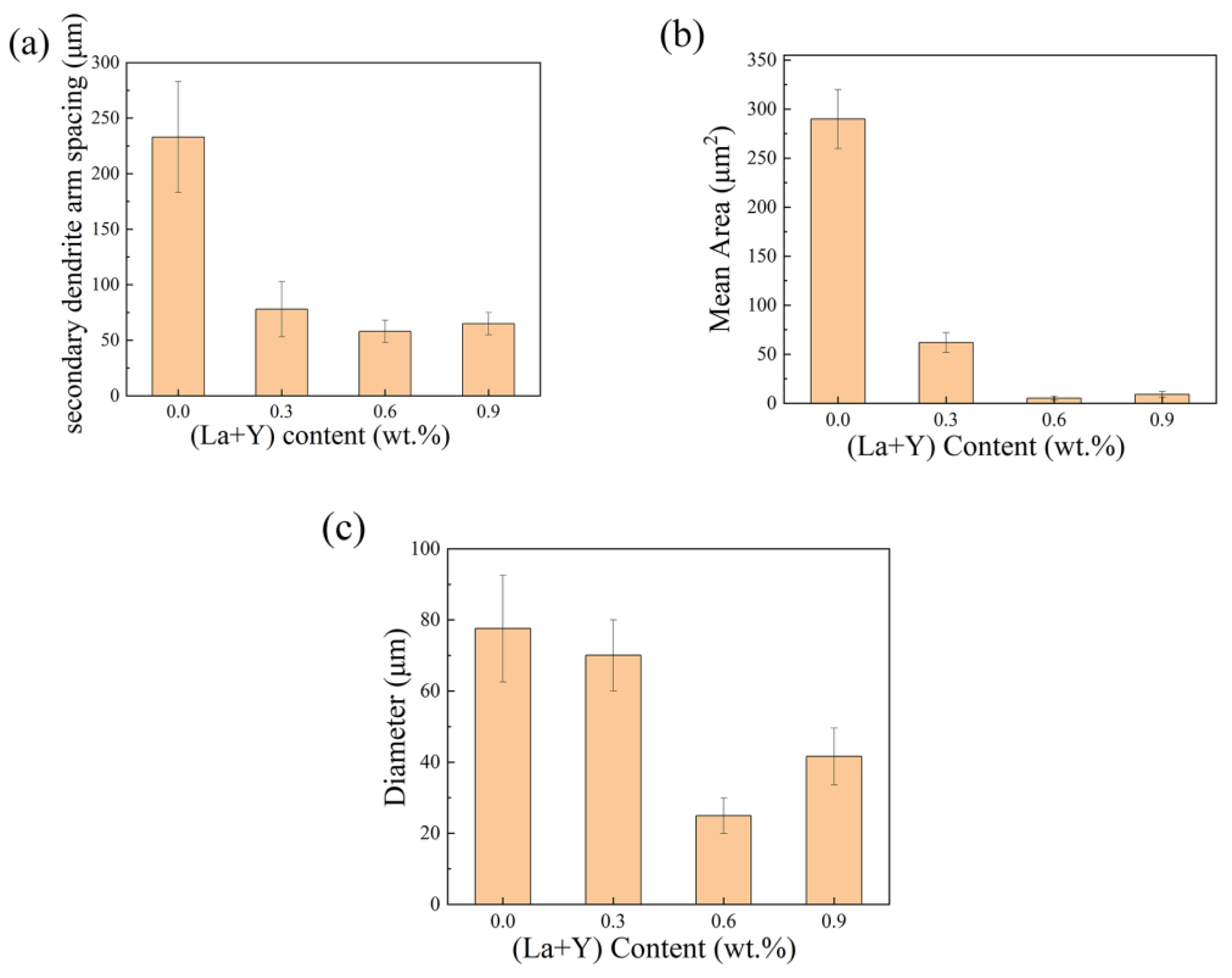

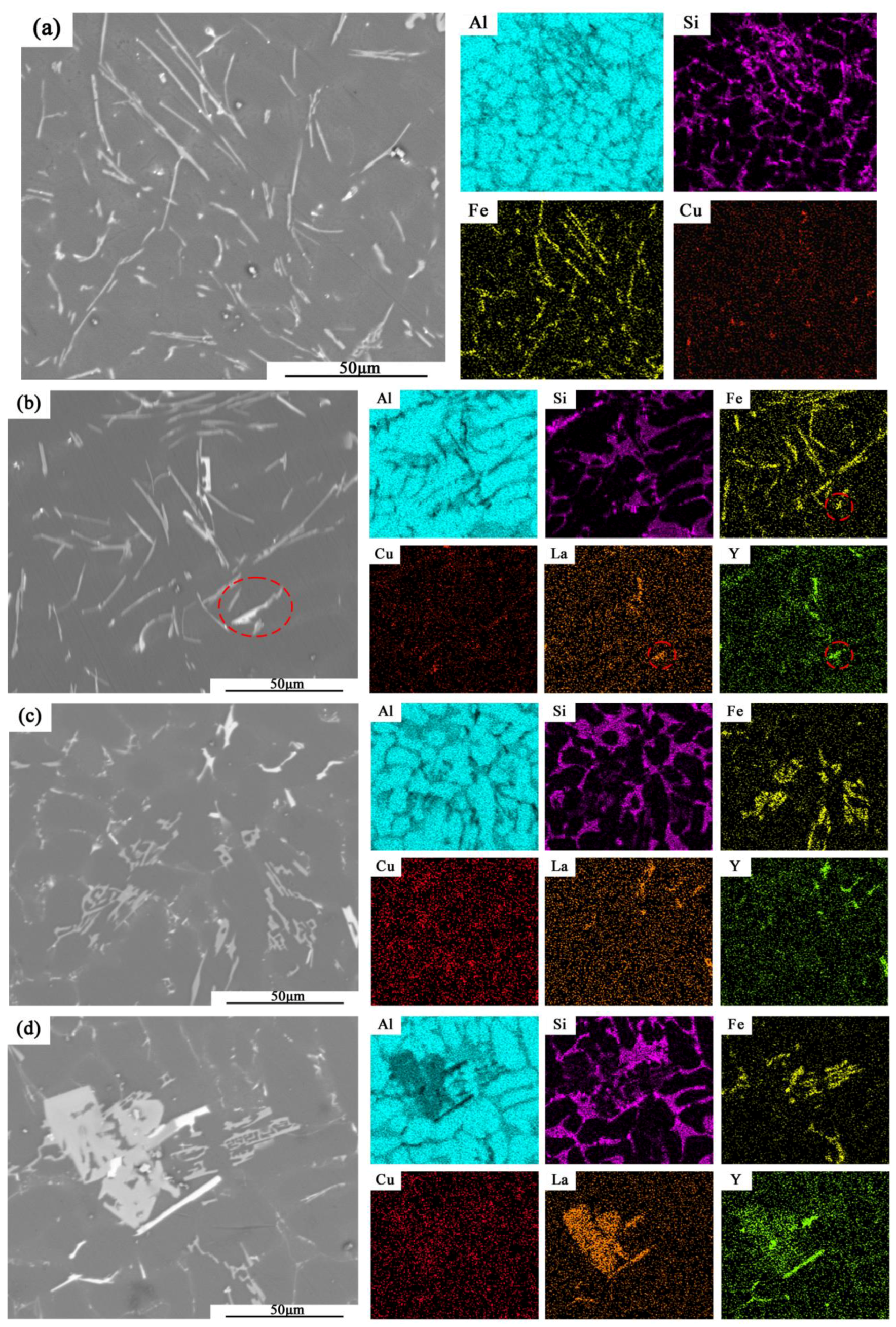

3.1. Effect of Adding La+Y on the Microstructure of the Alloy

3.2. Mechanical Properties

3.3. Fracture Analysis

4. Discussion

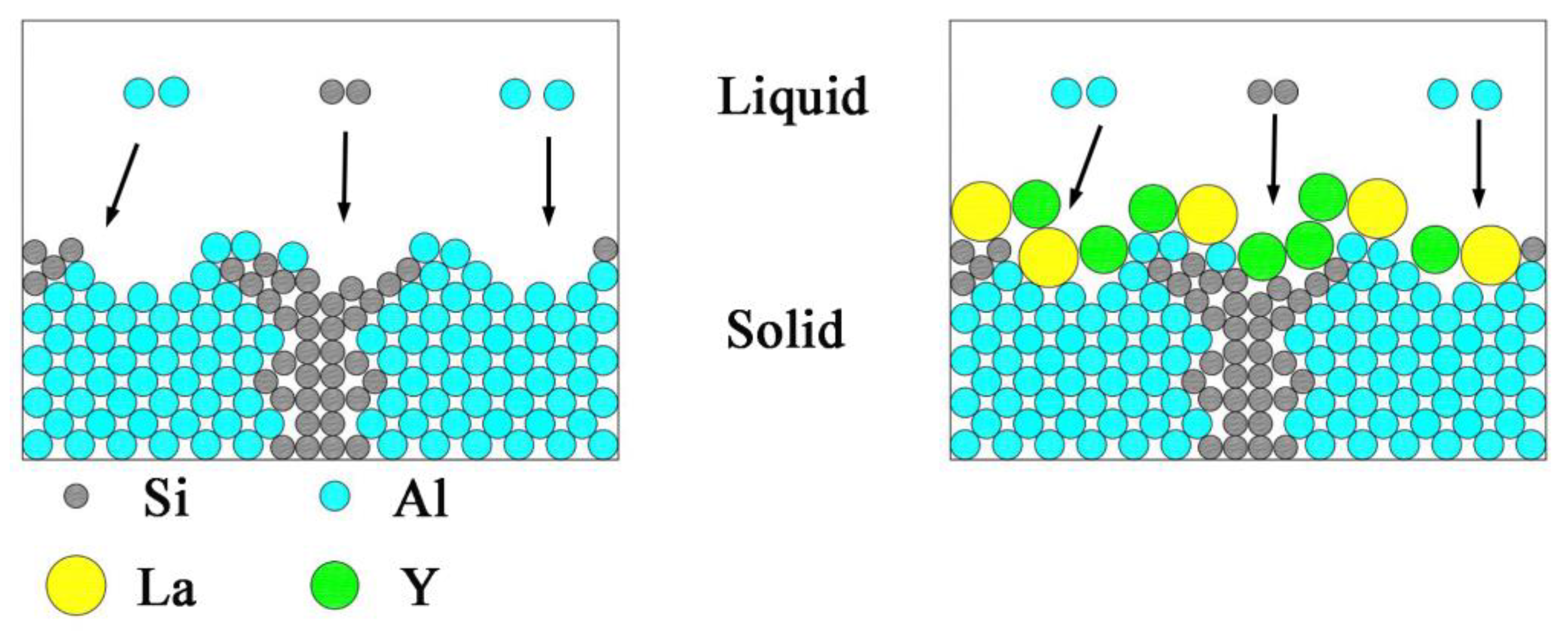

4.1. Effect of La and Y on α-Al Grains

4.2. Modification of Eutectic Si Phase by La and Y

4.3. Effect of La and Y on Fe-Rich Phase

4.4. Thermodynamic Analysis of Rare Earth Phase Generation

4.5. Effects of La and Y on the Mechanical Properties of A380 Alloys

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Okayasu, M.; Ota, K.; Takeuchi, S.; Ohfuji, H.; Shiraishi, T. Influence of microstructural characteristics on mechanical properties of ADC12 aluminum alloy. Mater. Sci. Eng. A 2014, 592, 189–200. [Google Scholar] [CrossRef]

- Shankar, S.; Apelian, D. Die soldering: Mechanism of the interface reaction between molten aluminum alloy and tool steel. Metall. Mater. Trans. B 2002, 33, 465–476. [Google Scholar] [CrossRef] [Green Version]

- Tang, P.; Li, W.; Wang, K.; Du, J.; Chen, X.; Zhao, Y.; Li, W. Effect of Al-Ti-C master alloy addition on microstructures and mechanical properties of cast eutectic Al-Si-Fe-Cu alloy. Mater. Des. 2017, 115, 147–157. [Google Scholar] [CrossRef]

- Pan, S.; Chen, X.; Zhou, X.; Wang, Z.; Chen, K.; Cao, Y.; Lu, F.; Li, S. Micro-alloying effect of Er and Zr on microstructural evolution and yield strength of Al-3Cu (wt.%) binary alloys. Mater. Sci. Eng. A 2020, 790, 139–391. [Google Scholar] [CrossRef]

- Liao, H.; Xu, H.; Hu, Y. Effect of RE addition on solidification process and high-temperature strength of Al-12%Si-4%Cu-1.6%Mn heat-resistant alloy. Trans. Nonferr. Metal. Soc. 2019, 29, 1117–1126. [Google Scholar] [CrossRef]

- Li, Z.; Yan, H.; Hu, Z.; Song, X. Fluidity of ADC12 + xLa aluminum alloys. Rare Met. 2021, 40, 1191–1197. [Google Scholar] [CrossRef]

- Mao, G.; Yan, H.; Zhu, C.; Wu, Z.; Gao, W. The varied mechanisms of yttrium (Y) modifying a hypoeutectic Al–Si alloy under conditions of different cooling rates. J. Alloys Compd. 2019, 806, 909–916. [Google Scholar] [CrossRef]

- Kang, J.; Su, R.; Wu, D.; Liu, C.; Li, T.; Wang, L.; Narayanaswamy, B. Synergistic effects of Ce and Mg on the microstructure and tensile properties of Al-7Si-0.3Mg-0.2Fe alloy. J. Alloys Compd. 2019, 796, 267–278. [Google Scholar] [CrossRef]

- Li, J.; Wang, X.; Ludwig, T.; Tsunekawa, Y.; Arnberg, L.; Jiang, J.; Schumacher, P. Modification of eutectic Si in Al-Si-Cu alloys with Eu addition. Acta Mater. 2015, 84, 153–163. [Google Scholar] [CrossRef]

- Hosseinifar, M.; Malakhov, D.V. Effect of Ce and La on microstructure and properties of a 6xxx series type aluminum alloy. J. Mater. Sci. 2008, 43, 7157–7164. [Google Scholar] [CrossRef]

- Tsai, Y.; Chou, C.; Lee, S.; Lin, C.; Lin, J.; Lim, S. Effect of trace La addition on the microstructures and mechanical properties of A356 (Al–7Si–0.35Mg) aluminum alloys. J. Alloys Compd. 2009, 487, 157–162. [Google Scholar] [CrossRef]

- Song, X.; Yan, H.; Chen, F. Impact of rare earth element La on microstructure and hot crack resistance of ADC12 alloy. J. Wuhan Univ. Technol-Mat. Sci. Ed. 2018, 33, 193–197. [Google Scholar] [CrossRef]

- Huang, X.; Yan, H. Effect of trace La addition on the microstructure and mechanical property of as-cast ADC12 Al-Alloy. J. Wuhan Univ. Technol-Mat. Sci. Ed. 2013, 28, 202–205. [Google Scholar] [CrossRef]

- Qiu, C.; Miao, S.; Li, X.; Xia, X.; Ding, J.; Wang, Y.; Zhao, W. Synergistic effect of Sr and La on the microstructure and mechanical properties of A356.2 alloy. Mater. Des. 2017, 114, 563–571. [Google Scholar] [CrossRef]

- Cao, Y.; Chen, X.; Wang, Z.; Chen, K.; Pan, S.; Zhu, Y.; Wang, Y. Synergistic influence of La and Zr on microstructure and mechanical performance of an Al-Si-Mg alloy at casting state. J. Alloys Compd. 2022, 902, 163829. [Google Scholar] [CrossRef]

- Liu, J.; Wu, Q.; Yan, H.; Zhong, S.; Huang, Z. Effect of Trace Yttrium Addition and Heat Treatment on the Microstructure and Mechanical Properties of As-Cast ADC12 Aluminum Alloy. Appl. Sci. 2018, 9, 53. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Zhu, Y.; Zhao, S.; Lan, Y.; Zhou, H. Influences of Fe, Mn and Y additions on microstructure and mechanical properties of hypoeutectic Al–7%Si alloy. Intermetallics 2020, 120, 106768. [Google Scholar] [CrossRef]

- Wei, Z.; Lei, Y.; Yan, H.; Xu, X.; He, J. Microstructure and mechanical properties of A356 alloy with yttrium addition processed by hot extrusion. J. Rare Earths 2019, 37, 659–667. [Google Scholar] [CrossRef]

- Lakshmanan, M.; SelwinRajadurai, J.; Chakkravarthy, V.; Rajakarunakaran, S. Wear and EBSD studies on (SiC/NiTi) reinforced Al7075 composite. Mater. Lett. 2020, 272, 127879. [Google Scholar] [CrossRef]

- Liu, S.; Du, Y.; Chen, H. A thermodynamic reassessment of the Al–Y system. Calphad 2006, 30, 334–340. [Google Scholar] [CrossRef]

- Zhou, S.; Napolitano, R. Phase equilibria and thermodynamic limits for partitionless crystallization in the Al–La binary system. Acta Mater. 2006, 54, 831–840. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.; Tang, Y.; Xiao, D. Effects of the excess iron on phase and magnetocaloric property of LaFe11.6–xSi1.4 alloys. J. Rare Earths 2015, 33, 1293–1297. [Google Scholar] [CrossRef]

- Li, Q.; Xia, T.; Lan, Y.; Li, P.; Fan, L. Effects of rare earth Er addition on microstructure and mechanical properties of hypereutectic Al–20% Si alloy. Mater. Sci. Eng. A 2013, 588, 97–102. [Google Scholar] [CrossRef]

- Wu, D.; Kang, J.; Feng, Z.; Su, R.; Liu, C.; Li, T.; Wang, L. Utilizing a novel modifier to realize multi-refinement and optimized heat treatment of A356 alloy. J. Alloys Compd. 2019, 791, 628–640. [Google Scholar] [CrossRef]

- Li, L.; Li, D.; Mao, F.; Feng, J.; Zhang, Y.; Kang, Y. Effect of cooling rate on eutectic Si in Al-7.0Si-0.3Mg alloys modified by La additions. J. Alloys Compd. 2020, 826, 154–206. [Google Scholar] [CrossRef]

- Timpel, M.; Wanderka, N.; Schlesiger, R.; Yamamoto, T.; Banhart, J. The role of strontium in modifying aluminium–silicon alloys. Acta Mater. 2012, 60, 3920–3928. [Google Scholar] [CrossRef]

- Lu, S.; Hellawell, A. The mechanism of silicon modifification in aluminum–silicon alloys: Impurity-induced twinning. Metall. Mater. Trans. A 1987, 18, 1721–1733. [Google Scholar] [CrossRef]

- Moniri, S.; Xiao, X.; Shahani, A. The mechanism of eutectic modification by trace impurities. Sci. Rep. 2019, 9, 3381. [Google Scholar] [CrossRef] [Green Version]

- Saccone, A.; Cacciamani, G.; Maccio, D.; Borzone, G.; Ferro, R. Contribution to the study of the alloys and intermetallic compounds of aluminium with the rare-earth metals. Intermetallics 1998, 6, 201–215. [Google Scholar] [CrossRef]

- Rao, Y.; Yan, H.; Hu, Z. Modification of eutectic silicon and β-Al5FeSi phases in as-cast ADC12 alloys by using samarium addition. J. Rare Earths 2013, 31, 916–922. [Google Scholar] [CrossRef]

- Wan, B.; Chen, W.; Liu, L.; Cao, X.; Zhou, L.; Fu, Z. Effect of trace yttrium addition on the microstructure and tensile properties of recycled Al–7Si–0.3Mg–1.0Fe casting alloys. Mater. Sci. Eng. A 2016, 666, 165–175. [Google Scholar] [CrossRef]

- Binnewies, M.; Mike, E. Thermochemical Data of Elements and Compounds; Wiley-VCH Verlag Gmbh: Weinheim, Germany, 2002; p. 783. [Google Scholar]

- Robert Mortimer, G. Physical Chemistry; Elsevier Academic Press: Memphis, TN, USA; Amsterdam, The Netherlands, 2008; p. 173. [Google Scholar]

- Chakkravarthy, V.; Lakshmanan, M.; Manojkumar, P.; Prabhakaran, R. Crystallographic orientation and wear characteristics of TiN, SiC, Nb embedded Al7075 composite. Mater. Lett. 2022, 306, 130936. [Google Scholar] [CrossRef]

- Wyrzykowski, J.W.; Grabski, M.W. The Hall–Petch relation in aluminium and its dependence on the grain boundary structure. Philos. Mag. A 1986, 53, 505–520. [Google Scholar] [CrossRef]

- Morris, D.G.; Muñoz-Morris, M.A. High creep strength, dispersion-strengthened iron aluminide prepared by multidirectional high-strain forging. Acta Mater. 2010, 58, 6080–6089. [Google Scholar] [CrossRef]

| Elements | Si | Cu | Mg | Zn | Fe | Mn | Al |

|---|---|---|---|---|---|---|---|

| (wt.%) | 10.22 | 2.40 | 0.86 | 0.23 | 1.21 | 0.27 | Bal. |

| Alloys | Si | Cu | Mg | Fe | La | Y | Al |

|---|---|---|---|---|---|---|---|

| A380 + 0 La/Y | 10.22 | 2.40 | 0.86 | 1.21 | 0 | 0 | Bal. |

| A380 + 0.3 La/Y | 10.14 | 2.39 | 0.82 | 1.22 | 0.16 | 0.14 | Bal. |

| A380 + 0.6 La/Y | 10.09 | 2.39 | 0.83 | 1.18 | 0.33 | 0.31 | Bal. |

| A380 + 0.9 La/Y | 10.01 | 2.38 | 0.84 | 1.17 | 0.42 | 0.46 | Bal. |

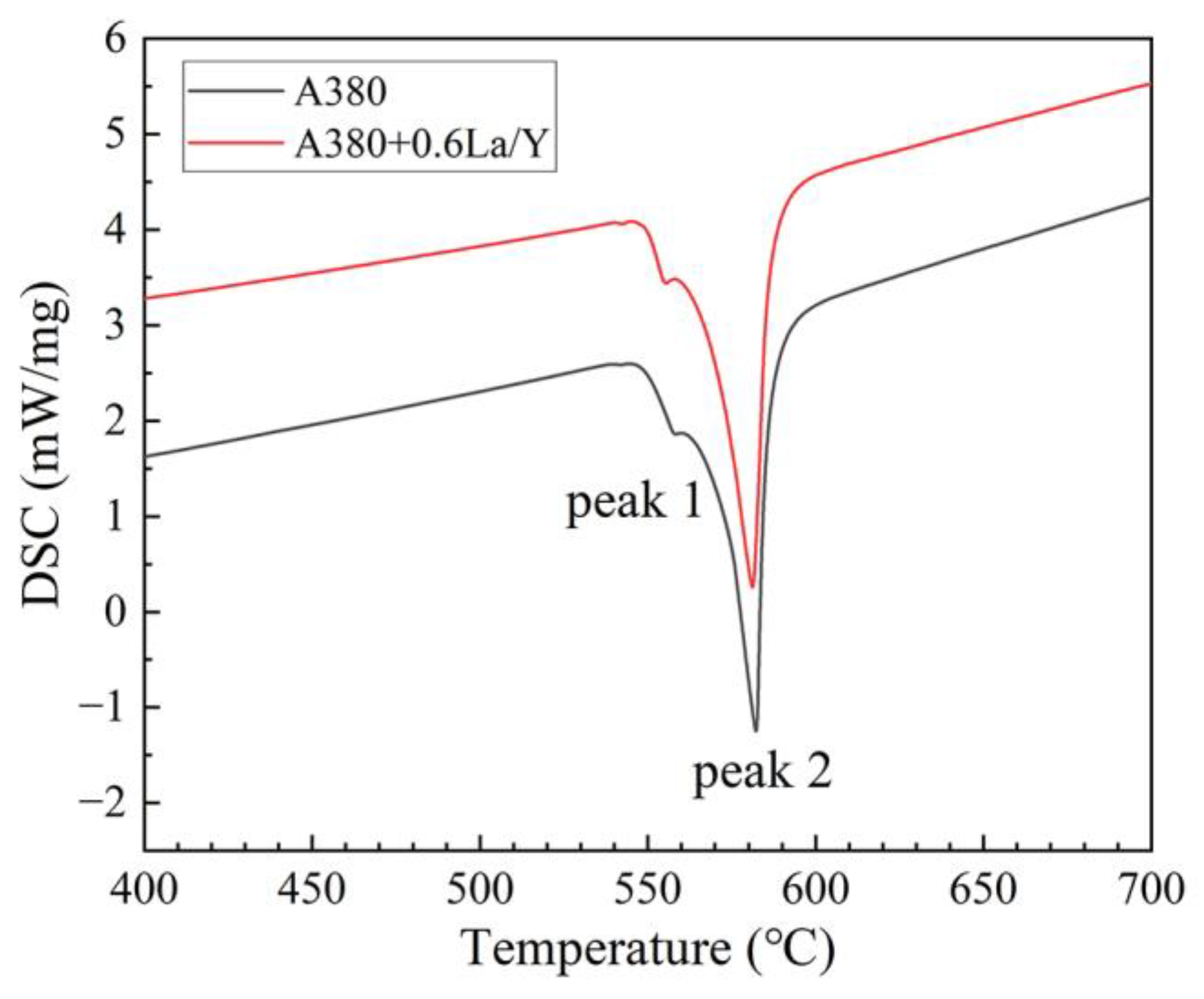

| No. | Eutectic Si | Primary α-Al | ||

|---|---|---|---|---|

| Peak 1 (°C) | ΔT1 (°C) | Peak 2 (°C) | ΔT2 (°C) | |

| A380 | 556.50 | 47.30 | 582.25 | 21.55 |

| A380 + 0.6 La/Y | 555.43 | 50.97 | 581.14 | 25.26 |

| Reaction | 3Al + Y = Al3Y | 11Al + 3La = Al11La3 |

|---|---|---|

| (J∙mol−1) | −185,600 + 83.89 T | −574,001 + 64.313 T |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shuai, L.; Zou, X.; Rao, Y.; Lu, X.; Yan, H. Synergistic Effects of La and Y on the Microstructure and Mechanical Properties of Cast Al-Si-Cu Alloys. Materials 2022, 15, 7283. https://doi.org/10.3390/ma15207283

Shuai L, Zou X, Rao Y, Lu X, Yan H. Synergistic Effects of La and Y on the Microstructure and Mechanical Properties of Cast Al-Si-Cu Alloys. Materials. 2022; 15(20):7283. https://doi.org/10.3390/ma15207283

Chicago/Turabian StyleShuai, Luming, Xiuliang Zou, Yuqiang Rao, Xiaobin Lu, and Hong Yan. 2022. "Synergistic Effects of La and Y on the Microstructure and Mechanical Properties of Cast Al-Si-Cu Alloys" Materials 15, no. 20: 7283. https://doi.org/10.3390/ma15207283