A Review of Magnetic Flux Leakage Nondestructive Testing

Abstract

1. Introduction

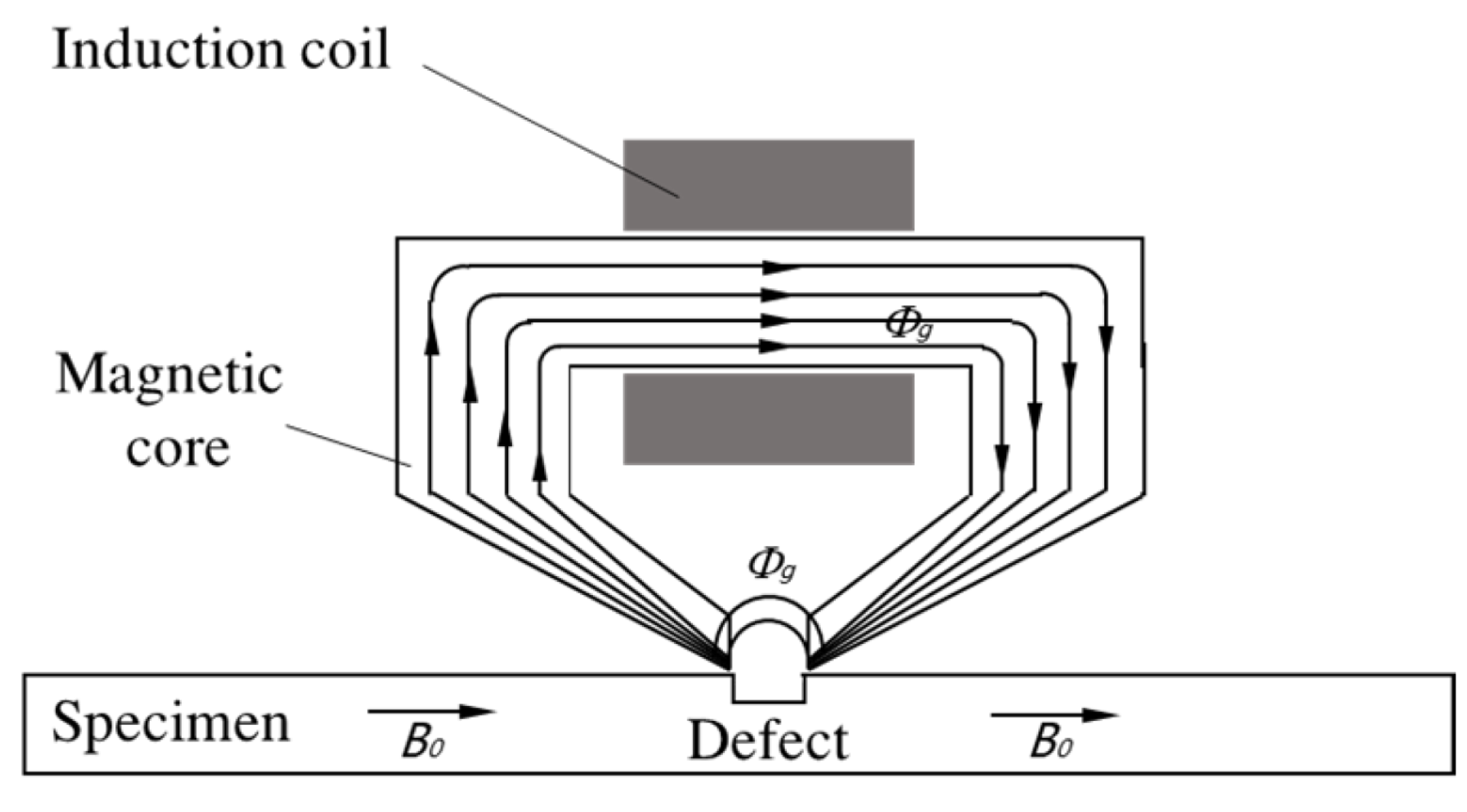

2. MFL Principle and Analytical Model

2.1. MFL Principle

2.2. Forward Problem and Magnetic Dipole Model

3. Factors Influencing MFL Signal

3.1. Defect Dimension and Orientation

3.2. Liftoff Effect

3.3. Magnetization Strength and Material Property

3.4. Velocity Effect

3.5. Other Effects

4. Excitation and Sensing Techniques in MFL Testing

4.1. Excitation Methods

4.1.1. Structures of Magnetizer

4.1.2. Excitation Signal Waveforms

4.2. Sensing Methods

5. Inverse Problem in MFL and Defect Quantification

5.1. Machine Learning-Based Defect Quantification

5.2. Iteration-Based Defect Quantification

6. Applications and Comparison with Related NDT Methods

6.1. Applications of MFL Testing

6.2. Comparison with Related NDT Methods

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shi, Y.; Zhang, C.; Li, R.; Cai, M.; Jia, G. Theory and Application of Magnetic Flux Leakage Pipeline Detection. Sensors 2015, 15, 31036–31055. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.D.; Gu, Y.; Wang, Y.S. A Review of Three Magnetic NDT Technologies. J. Magn. Magn. Mater. 2012, 324, 382–388. [Google Scholar] [CrossRef]

- Liu, S.; Sun, Y.; Gu, M.; Liu, C.; He, L.; Kang, Y. Review and Analysis of Three Representative Electromagnetic NDT Methods. Insight 2017, 59, 176–183. [Google Scholar] [CrossRef]

- Ma, Q.; Tian, G.; Zeng, Y.; Li, R.; Song, H.; Wang, Z.; Gao, B.; Zeng, K. Pipeline In-Line Inspection Method, Instrumentation and Data Management. Sensors 2021, 21, 3862. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, Y. Magnetic Mechanisms of Magnetic Flux Leakage Nondestructive Testing. Appl. Phys. Lett. 2013, 103, 184104. [Google Scholar] [CrossRef]

- Zatsepin, N.; Shcherbinin, V. Calculation of the magnetostatic field of surface defects, I. Field topography of defect models. Defektoskopiya 1966, 5, 50–59. [Google Scholar]

- Shcherbinin, V.; Pashagin, A. Influence of the extension of a defect on the magnitude of its magnetic field. Defektoskopiya 1972, 8, 74–82. [Google Scholar]

- Förster, F. New Findings in the Field of Non-Destructive Magnetic Leakage Field Inspection. NDT Int. 1986, 19, 3–14. [Google Scholar] [CrossRef]

- Edwards, C.; Palmer, S.B. The Magnetic Leakage Field of Surface-Breaking Cracks. J. Phys. D Appl. Phys. 1986, 19, 657–673. [Google Scholar] [CrossRef]

- Uetake, I.; Saito, T. Magnetic Flux Leakage by Adjacent Parallel Surface Slots. NDT E Int. 1997, 30, 371–376. [Google Scholar] [CrossRef]

- Dutta, S.M.; Ghorbel, F.H.; Stanley, R.K. Simulation and Analysis of 3-D Magnetic Flux Leakage. IEEE Trans. Magn. 2009, 45, 1966–1972. [Google Scholar] [CrossRef]

- Dutta, S.M.; Ghorbel, F.H.; Stanley, R.K. Dipole Modeling of Magnetic Flux Leakage. IEEE Trans. Magn. 2009, 45, 1959–1965. [Google Scholar] [CrossRef]

- Mandache, C.; Clapham, L. A Model for Magnetic Flux Leakage Signal Predictions. J. Phys. D Appl. Phys. 2003, 36, 2427–2431. [Google Scholar] [CrossRef]

- Lukyanets, S.; Snarskii, A.; Shamonin, M.; Bakaev, V. Calculation of Magnetic Leakage Field from a Surface Defect in a Linear Ferromagnetic Material: An Analytical Approach. NDT E Int. 2003, 36, 51–55. [Google Scholar] [CrossRef]

- Trevino, D.A.G.; Dutta, S.M.; Ghorbel, F.H.; Karkoub, M. An Improved Dipole Model of 3-D Magnetic Flux Leakage. IEEE Trans. Magn. 2016, 52, 1–7. [Google Scholar] [CrossRef]

- Huang, X.; Wu, J.; Sun, Y.; Kang, Y. 3D Magnetic Dipole Models of Magnetic Flux Leakage for “concave” and “Bump” Defects. Int. J. Appl. Electromagn. Mech. 2019, 59, 1305–1312. [Google Scholar] [CrossRef]

- Zhang, Y.; Sekine, K.; Watanabe, S. Magnetic Leakage Field Due to Sub-Surface Defects in Ferromagnetic Specimens. NDT E Int. 1995, 28, 67–71. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.; Zhang, D.; Sun, H. Reconstruction of Magnetic Charge on Breaking Flaw Based on Two-Layers Algorithm. Int. J. Appl. Electromagn. Mech. 2016, 52, 1133–1139. [Google Scholar] [CrossRef]

- Bowler, J.R.; Bowler, N. Evaluation of the Magnetic Field near a Crack with Application to Magnetic Particle Inspection. J. Phys. D Appl. Phys. 2002, 35, 2237–2242. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, Y.; Yu, H.; Zhang, Y.; Zhang, J.; Yang, Q.; Sheng, H.; Bai, L. Solenoid Model for Visualizing Magnetic Flux Leakage Testing of Complex Defects. NDT E Int. 2018, 100, 166–174. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, Y.; Bai, L.; Zhang, J.; Yu, H.; Alimey, F.J. Solenoid Model for the Magnetic Flux Leakage Testing Based on the Molecular Current. IEEE Trans. Magn. 2018, 54, 1–14. [Google Scholar] [CrossRef]

- Huang, S.L.; Peng, L.; Wang, S.; Zhao, W. A Basic Signal Analysis Approach for Magnetic Flux Leakage Response. IEEE Trans. Magn. 2018, 54, 6201906. [Google Scholar] [CrossRef]

- Suresh, V.; Abudhair, A. Dipole Model to Predict the Rectangular Defect on Ferromagnetic Pipe. J. Magn. 2016, 21, 437–441. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Ding, S.; Dai, G.; Liu, Y.; Yang, Z.; Liu, F. Numerical Simulation and Experiment on Magnetic Flux Leakage Inspection of Cracks in Steels. In Proceedings of the 17th World Conference on Nondestructive Testing, Shanghai, China, 25–28 October 2008; pp. 1–5. [Google Scholar]

- Ji, F.; Wang, C.; Sun, S.; Wang, W. Application of 3-D FEM in the Simulation Analysis for MFL Signals. Insight Non-Destr. Test. Cond. Monit. 2009, 51, 32–35. [Google Scholar] [CrossRef]

- Pearson, N.R.; Boat, M.A.; Priewald, R.H.; Pate, M.J.; Mason, J.S.D. A Study of MFL Signals from A Spectrum of Defect Geometries. In Proceedings of the 18th World Conference on Nondestructive Testing, Durban, South Africa, 16–20 April 2012; pp. 16–20. [Google Scholar]

- Atherton, D.L.; Daly, M.G. Finite Element Calculation of Magnetic Flux Leakage Detector Signals. NDT Int. 1987, 20, 235–238. [Google Scholar] [CrossRef]

- Katragadda, G.; Si, J.T.; Lord, W.; Sun, Y.S.; Udpa, S.; Udpa, L. A Comparative Study of 3D and Axisymmetric Magnetizer Assemblies Used in Magnetic Flux Leakage Inspection of Pipelines. IEEE Trans. Magn. 1996, 32, 1573–1576. [Google Scholar] [CrossRef]

- Huang, S.; Li, L.; Yang, H.; Shi, K. Influence of Slot Defect Length on Magnetic Flux Leakage. J. Mater. Sci. Technol. 2004, 20, 231–232. [Google Scholar]

- Sun, Y.; Kang, Y. The Feasibility of MFL Inspection for Omni-Directional Defects under a Unidirectional Magnetization. Int. J. Appl. Electromagn. Mech. 2010, 33, 919–925. [Google Scholar] [CrossRef]

- Song, K.; Kang, Y.; Sun, Y.; Qiu, C.; Su, J. MFL Testing of Omni-Directional Cracks in Steel Strip Using Strong Longitudinal Magnetization. Int. J. Appl. Electromagn. Mech. 2010, 33, 1231–1236. [Google Scholar] [CrossRef]

- Wu, J.; Sun, Y.; Kang, Y.; Yang, Y. Theoretical Analyses of MFL Signal Affected by Discontinuity Orientation and Sensor-Scanning Direction. IEEE Trans. Magn. 2015, 51, 1–7. [Google Scholar] [CrossRef]

- Azizzadeh, T.; Safizadeh, M.S. Investigation of the Lift-off Effect on the Corrosion Detection Sensitivity of Three-Axis MFL Technique. J. Magn. 2018, 23, 152–159. [Google Scholar] [CrossRef]

- Wang, X.; Wu, X.; Xu, J.; Ba, H. Study on the Lift-off Effect on MFL Signals with Magnetic Circuit Model and 3D FEM. Insight Non-Destr. Test. Cond. Monit. 2012, 54, 505–510. [Google Scholar] [CrossRef]

- Lunin, V.; Alexeevsky, D. Numerical Prediction of Signal for Magnetic Flux Leakage Benchmark Task. In Proceedings of the Review of Quantitative Nondestructive Evaluation, Green Bay, WI, USA, 27 July–1 August 2003; Volume 22, pp. 1830–1836. [Google Scholar]

- Jia, Y.; Lu, Y.; Xiong, L.; Zhang, Y.; Wang, P.; Zhou, H. A Filtering Method for Suppressing the Lift-Off Interference in Magnetic Flux Leakage Detection of Rail Head Surface Defect. Appl. Sci. 2022, 12, 1740. [Google Scholar] [CrossRef]

- Wu, J.; Fang, H.; Li, L.; Wang, J.; Huang, X.; Kang, Y.; Sun, Y.; Tang, C. A Lift-off-Tolerant Magnetic Flux Leakage Testing Method for Drill Pipes at Wellhead. Sensors 2017, 17, 201. [Google Scholar] [CrossRef]

- Peng, L.; Huang, S.; Wang, S.; Zhao, W. A Simplified Lift-Off Correction for Three Components of the Magnetic Flux Leakage Signal for Defect Detection. IEEE Trans. Instrum. Meas. 2021, 70, 6005109. [Google Scholar] [CrossRef]

- Wang, J.; Li, E.; Wu, J.; Xu, X. Linearization of the Lift-off Effect for Magnetic Flux Leakage Based on Fourier Transform. Meas. Sci. Technol. 2021, 32, 065012. [Google Scholar] [CrossRef]

- Altschuler, E.; Pignotti, A. Nonlinear Model of Flaw Detection in Steel Pipes by Magnetic Flux Leakage. NDT E Int. 1995, 28, 35–40. [Google Scholar] [CrossRef]

- Singh, W.S.; Rao, B.P.C.; Vaidyanathan, S.; Jayakumar, T.; Raj, B. Detection of Leakage Magnetic Flux from Near-Side and Far-Side Defects in Carbon Steel Plates Using a Giant Magneto-Resistive Sensor. Meas. Sci. Technol. 2008, 19, 015702. [Google Scholar] [CrossRef]

- Sun, Y.; Feng, B.; Ye, Z.; Liu, S.; Li, D.; Kang, Y.; Gu, M.; Liu, C. Change Trends of Magnetic Flux Leakage with Increasing Magnetic Excitation. Insight Non-Destr. Test. Cond. Monit. 2015, 57, 689–696. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, Y. Magnetic Compression Effect in Present MFL Testing Sensor. Sens. Actuators A Phys. 2010, 160, 54–59. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, Y. A New MFL Principle and Method Based on Near-Zero Background Magnetic Field. NDT E Int. 2010, 43, 348–353. [Google Scholar] [CrossRef]

- Katoh, M.; Nishio, K.; Yamaguchi, T. The Influence of Modeled B-H Curve on the Density of the Magnetic Leakage Flux Due to a Flaw Using Yoke-Magnetization. NDT E Int. 2004, 37, 603–609. [Google Scholar] [CrossRef]

- Park, G.S.; Park, S.H. Analysis of the Velocity-Induced Eddy Current in MFL Type NDT. IEEE Trans. Magn. 2004, 40, 663–666. [Google Scholar] [CrossRef]

- Gan, Z.; Chai, X. Numerical Simulation on Magnetic Flux Leakage Testing of the Steel Cable at Different Speed Title. In Proceedings of the 2011 International Conference on Electronics and Optoelectronics, Dalian, China, 29–31 July 2011; Volume 3, pp. 316–319. [Google Scholar] [CrossRef]

- Li, Y.; Tian, G.Y.; Ward, S. Numerical Simulation on Magnetic Flux Leakage Evaluation at High Speed. NDT E Int. 2006, 39, 367–373. [Google Scholar] [CrossRef]

- Antipov, A.G.; Markov, A.A. 3D Simulation and Experiment on High Speed Rail MFL Inspection. NDT E Int. 2018, 98, 177–185. [Google Scholar] [CrossRef]

- Shin, Y. Numerical Prediction of Operating Conditions for Magnetic Flux Leakage Inspection of Moving Steel Sheets. IEEE Trans. Magn. 1997, 33, 2127–2130. [Google Scholar] [CrossRef]

- Feng, B.; Deng, K.; Wang, S.; Chen, S.; Kang, Y. Theoretical Analysis on the Distribution of Eddy Current in Motion-Induced Eddy Current Testing and High-Speed MFL Testing. J. Nondestruct. Eval. 2022, 41, 59. [Google Scholar] [CrossRef]

- Du, Z.; Ruan, J.; Peng, Y.; Yu, S.; Zhang, Y.; Gan, Y.; Li, T. 3-D FEM Simulation of Velocity Effects on Magnetic Flux Leakage Testing Signals. IEEE Trans. Magn. 2008, 44, 1642–1645. [Google Scholar] [CrossRef]

- Wu, J.; Kang, Y.; Tu, J.; Sun, Y. Analysis of the Eddy-Current Effect in the Hi-Speed Axial MFL Testing for Steel Pipe. Int. J. Appl. Electromagn. Mech. 2014, 45, 193–199. [Google Scholar] [CrossRef]

- Wu, J.; Fang, H.; Wang, J.; Kang, Y. Sensitivity Difference Caused by Eddy-Current Magnetic Field in Hi-Speed MFL Testing and Its Elimination Method. Int. J. Appl. Electromagn. Mech. 2016, 52, 1007–1014. [Google Scholar] [CrossRef]

- Wu, J.; Xia, H.; Feng, B.; Li, E.; Huang, X.; Kang, Y. The Effect of Motion-Induced Eddy Current on Axial MFL Inspection for a Steel Pipe. Int. J. Appl. Electromagn. Mech. 2019, 59, 1187–1193. [Google Scholar] [CrossRef]

- Feng, B.; Kang, Y.; Sun, Y.; Yang, Y.; Yan, X. Influence of Motion Induced Eddy Current on the Magnetization of Steel Pipe and MFL Signal. Int. J. Appl. Electromagn. Mech. 2016, 52, 357–362. [Google Scholar] [CrossRef]

- Wu, J.; Xia, H.; Feng, B.; Li, E.; Huang, X.; Kang, Y. The Effect of Motion-Induced Eddy Current on Circumferential Magnetization in MFL Testing for a Steel Pipe. IEEE Trans. Magn. 2017, 53, 6201506. [Google Scholar] [CrossRef]

- Katragadda, G.; Lord, W.; Sun, Y.S.; Udpa, S.; Udpa, L. Alternative Magnetic Flux Leakage Modalities for Pipeline Inspection. IEEE Trans. Magn. 1996, 32, 1581–1584. [Google Scholar] [CrossRef]

- Piao, G.; Li, J.; Udpa, L.; Udpa, S.; Deng, Y. The Effect of Motion-Induced Eddy Currents on Three-Axis MFL Signals for High-Speed Rail Inspection. IEEE Trans. Magn. 2021, 57, 6200211. [Google Scholar] [CrossRef]

- Piao, G.; Guo, J.; Hu, T.; Leung, H. The Effect of Motion-Induced Eddy Current on High-Speed Magnetic Flux Leakage (MFL) Inspection for Thick-Wall Steel Pipe. Res. Nondestruct. Eval. 2020, 31, 48–67. [Google Scholar] [CrossRef]

- Wang, P.; Gao, Y.; Tian, G.; Wang, H. Velocity Effect Analysis of Dynamic Magnetization in High Speed Magnetic Flux Leakage Inspection. NDT E Int. 2014, 64, 7–12. [Google Scholar] [CrossRef]

- Pullen, A.L.; Charlton, P.C.; Pearson, N.R.; Whitehead, N.J. Practical Evaluation of Velocity Effects on the Magnetic Flux Leakage Technique for Storage Tank Inspection. Insight 2020, 62, 73–80. [Google Scholar] [CrossRef]

- Pullen, A.L.; Charlton, P.C.; Pearson, N.R.; Whitehead, N.J. Magnetic Flux Leakage Scanning Velocities for Tank Floor Inspection. IEEE Trans. Magn. 2018, 54, 1–8. [Google Scholar] [CrossRef]

- Zhang, L.; Belblidia, F.; Cameron, I.; Sienz, J.; Boat, M.; Pearson, N. Influence of Specimen Velocity on the Leakage Signal in Magnetic Flux Leakage Type Nondestructive Testing. J. Nondestruct. Eval. 2015, 34, 6. [Google Scholar] [CrossRef]

- Usarek, Z.; Chmielewski, M.; Piotrowski, L. Reduction of the Velocity Impact on the Magnetic Flux Leakage Signal. J. Nondestruct. Eval. 2019, 38, 28. [Google Scholar] [CrossRef]

- Antipov, A.G.; Markov, A.A. Using a Tail Field in High-Speed Magnetic Flux Leakage Testing. J. Nondestruct. Eval. 2022, 41, 1–9. [Google Scholar] [CrossRef]

- Feng, B.; Kang, Y.; Sun, Y. Theoretical Analysis and Numerical Simulation of the Feasibility of Inspecting Nonferromagnetic Conductors by an MFL Testing Apparatus. Res. Nondestruct. Eval. 2016, 27, 100–111. [Google Scholar] [CrossRef]

- Feng, B.; Ribeiro, A.L.; Rocha, T.J.; Ramos, H.G. Comparison of Inspecting Non-Ferromagnetic and Ferromagnetic Metals Using Velocity Induced Eddy Current Probe. Sensors 2018, 18, 3199. [Google Scholar] [CrossRef]

- Rocha, T.J.; Ramos, H.G.; Lopes Ribeiro, A.; Pasadas, D.J. Magnetic Sensors Assessment in Velocity Induced Eddy Current Testing. Sens. Actuators A Phys. 2015, 228, 55–61. [Google Scholar] [CrossRef]

- Rocha, T.J.; Ramos, H.G.; Lopes Ribeiro, A.; Pasadas, D.J.; Angani, C.S. Studies to Optimize the Probe Response for Velocity Induced Eddy Current Testing in Aluminium. Measurement 2015, 67, 108–115. [Google Scholar] [CrossRef]

- Rocha, T.J.; Ramos, H.G.; Ribeiro, A.L.; Pasadas, D.J. Evaluation of Subsurface Defects Using Diffusion of Motion-Induced Eddy Currents. IEEE Trans. Instrum. Meas. 2016, 65, 1182–1187. [Google Scholar] [CrossRef]

- Yuan, F.; Yu, Y.; Li, L.; Tian, G. Investigation of DC Electromagnetic-Based Motion Induced Eddy Current on NDT for Crack Detection. IEEE Sens. J. 2021, 21, 7449–7457. [Google Scholar] [CrossRef]

- Uhlig, R.P.; Zec, M.; Brauer, H.; Thess, A. Lorentz Force Eddy Current Testing: A Prototype Model. J. Nondestruct. Eval. 2012, 31, 357–372. [Google Scholar] [CrossRef]

- Dölker, E.M.; Schmidt, R.; Gorges, S.; Otterbach, J.M.; Petković, B.; Strohmeier, D.; Eichardt, R.; Brauer, H.; Haueisen, J. Elastic Net Regularization in Lorentz Force Evaluation. NDT E Int. 2018, 99, 141–154. [Google Scholar] [CrossRef]

- Mengelkamp, J.; Carlstedt, M.; Weise, K.; Ziolkowski, M.; Brauer, H.; Haueisen, J. Current Density Reconstructions for Lorentz Force Evaluation. Res. Nondestruct. Eval. 2017, 28, 76–100. [Google Scholar] [CrossRef]

- Weise, K.; Schmidt, R.; Carlstedt, M.; Ziolkowski, M.; Brauer, H.; Toepfer, H. Optimal Magnet Design for Lorentz Force Eddy-Current Testing. IEEE Trans. Magn. 2015, 51, 1–15. [Google Scholar] [CrossRef]

- Carlstedt, M.; Porzig, K.; Uhlig, R.P.; Zec, M.; Ziolkowski, M.; Brauer, H. Application of Lorentz Force Eddy Current Testing and Eddy Current Testing on Moving Nonmagnetic Conductors. Int. J. Appl. Electromagn. Mech. 2014, 45, 519–526. [Google Scholar] [CrossRef]

- Kasai, N.; Sekine, K.; Maruyama, H. Influence of Corrosion Products on Magnetic Flux Leakage Signals in Inspection of Far-Side Metal-Loss Defects in Oil Storage Tank Bottom Floors. J. Japan Pet. Inst. 2004, 47, 19–26. [Google Scholar] [CrossRef]

- Long, Y.; Huang, S.; Peng, L.; Wang, S.; Zhao, W. A Novel Compensation Method of Probe Gesture for Magnetic Flux Leakage Testing. IEEE Sens. J. 2021, 21, 10854–10863. [Google Scholar] [CrossRef]

- Wang, Y.; Melikhov, Y.; Meydan, T.; Yang, Z.; Wu, D.; Wu, B.; He, C.; Liu, X. Stress-Dependent Magnetic Flux Leakage: Finite Element Modelling Simulations Versus Experiments. J. Nondestruct. Eval. 2020, 39, 1–9. [Google Scholar] [CrossRef]

- Mandal, K.; Corey, A.; Loukas, M.E.; Weyman, P.; Eichenberger, J.; Atherton, D.L. The Effects of Defect Depth and Bending Stress on Magnetic Barkhausen Noise and Flux-Leakage Signals. J. Phys. D Appl. Phys. 1997, 30, 1976–1983. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Wu, B.; Xiao, J.; Wu, D.; He, C. Dipole Modeling of Stress-Dependent Magnetic Flux Leakage. NDT E Int. 2018, 95, 1–8. [Google Scholar] [CrossRef]

- Gao, G.; Lian, M.; Xu, Y.; Qin, Y.; Gao, L. The Effect of Variable Tensile Stress on the MFL Signal Response of Defective Wire Ropes. Insight Non-Destr. Test. Cond. Monit. 2016, 58, 135–141. [Google Scholar] [CrossRef]

- Shi, P.; Bai, P.; Chen, H.E.; Su, S.; Chen, Z. The Magneto-Elastoplastic Coupling Effect on the Magnetic Flux Leakage Signal. J. Magn. Magn. Mater. 2020, 504, 166669. [Google Scholar] [CrossRef]

- Ryu, K.S.; Atherton, D.L.; Clapham, L. Effect of Pit Geometry and Bulk Stress on Near- and Far-Side Calculated MFL Signals. J. Phys. D Appl. Phys. 2002, 35, 2693–2697. [Google Scholar] [CrossRef]

- Xiao-Meng, L.; Hong-Sheng, D.; Shi-Wu, B. Research on the Stress-Magnetism Effect of Ferromagnetic Materials Based on Three-Dimensional Magnetic Flux Leakage Testing. NDT E Int. 2014, 62, 50–54. [Google Scholar] [CrossRef]

- Van Der Horst, M.P.; Van Kreveld, S.L.; Kaminski, M.L. Effect of Stress-Induced Magnetization on Crack Monitoring by Self Magnetic Flux Leakage Method. Int. J. Appl. Electromagn. Mech. 2019, 60, 113–130. [Google Scholar] [CrossRef]

- Wu, L.; Yao, K.; Shi, P.; Zhao, B.; Wang, Y.S. Influence of Inhomogeneous Stress on Biaxial 3D Magnetic Flux Leakage Signals. NDT E Int. 2020, 109, 102178. [Google Scholar] [CrossRef]

- Babbar, V.; Bryne, J.; Clapham, L. Mechanical Damage Detection Using Magnetic Flux Leakage Tools: Modeling the Effect of Dent Geometry and Stresses. NDT E Int. 2005, 38, 471–477. [Google Scholar] [CrossRef]

- Kashefi, M.; Clapham, L.; Krause, T.W.; Underhill, P.R.; Krause, A.K. Stress-Induced Self-Magnetic Flux Leakage at Stress Concentration Zone. IEEE Trans. Magn. 2021, 57, 1–8. [Google Scholar] [CrossRef]

- Babbar, V.; Shiari, B.; Clapham, L. Mechanical Damage Detection With Magnetic Flux Leakage Tools: Modeling the Effect of Localized Residual Stresses. IEEE Trans. Magn. 2004, 40, 43–49. [Google Scholar] [CrossRef]

- Deng, Z.; Sun, Y.; Yang, Y.; Kang, Y. Effects of Surface Roughness on Magnetic Flux Leakage Testing of Micro-Cracks. Meas. Sci. Technol. 2017, 28, 045003. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L.; Deng, Z.; Kang, Y. Theoretical Analysis and Simulation of a New SNR Improvement Method for the Rough Surface Crack in MFL Detection. Int. J. Appl. Electromagn. Mech. 2016, 52, 1401–1408. [Google Scholar] [CrossRef]

- Rao, B.P.C.; Thirunavukkarasu, S.; Nand, K.K.; Jayakumar, T.; Kalyanasundaram, P.; Raj, B. Enhancement of Magnetic Flux Leakage Images of Defects in Carbon Steel Using Eigen Vector Based Approach. Nondestruct. Test. Eval. 2008, 23, 35–42. [Google Scholar] [CrossRef]

- Li, E.; Wang, J.; Wu, J.; Kang, Y. Spatial-Spectrum-Based Measurement of the Surface Roughness of Ferromagnetic Components Using Magnetic Flux Leakage Method. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Labinac, V.; Erceg, N.; Kotnik-Karuza, D. Magnetic Field of a Cylindrical Coil. Am. J. Phys. 2006, 74, 621–627. [Google Scholar] [CrossRef]

- Wang, J.; She, S.; Zhang, S. An Improved Helmholtz Coil and Analysis of Its Magnetic Field Homogeneity. Rev. Sci. Instrum. 2002, 73, 2175. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, Y. An Opening Electromagnetic Transducer. J. Appl. Phys. 2013, 114, 214904. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, J.; Feng, B.; Kang, Y. An Opening Electric-MFL Detector for the NDT of In-Service Mine Hoist Wire. IEEE Sens. J. 2014, 14, 2042–2047. [Google Scholar]

- Wang, S.; Feng, B.; Tang, J.; Chen, Y.; Kang, Y. A Novel AC-MFL Probe Based on the Parallel Cables Magnetizing Technique. J. Nondestruct. Eval. 2022, 41, 1–8. [Google Scholar] [CrossRef]

- Chang, Y.; Jiao, J.; Li, G.; Liu, X.; He, C.; Wu, B. Effects of Excitation System on the Performance of Magnetic-Flux-Leakage-Type Non-Destructive Testing. Sens. Actuators A Phys. 2017, 268, 201–212. [Google Scholar] [CrossRef]

- Parra-Raad, J.A.; Roa-Prada, S. Multi-Objective Optimization of a Magnetic Circuit for Magnetic Flux Leakage-Type Non-Destructive Testing. J. Nondestruct. Eval. 2016, 35, 1–12. [Google Scholar] [CrossRef]

- Chen, G.; Li, W.; Wang, Z. Structural Optimization of 2-D Array Probe for Alternating Current Field Measurement. NDT E Int. 2007, 40, 455–461. [Google Scholar] [CrossRef]

- Gotoh, Y.; Takahashi, N. 3-D Nonlinear Eddy-Current Analysis of Alternating Magnetic Flux Leakage Testing—Analysis of One Crack and Two Cracks. IEEE Trans. Magn. 2002, 38, 1209–1212. [Google Scholar] [CrossRef]

- Gotoh, Y.; Takahashi, N. Study on Problems in Detecting Plural Cracks by Alternating Flux Leakage Testing Using 3-D Nonlinear Eddy Current Analysis. IEEE Trans. Magn. 2003, 39, 1527–1530. [Google Scholar] [CrossRef]

- Gotoh, Y.; Takahashi, N. Proposal of Detecting Method of Outer Side Crack by Alternating Flux Leakage Testing Using 3-D Nonlinear FEM. IEEE Trans. Magn. 2006, 42, 1415–1418. [Google Scholar] [CrossRef]

- Gotoh, Y.; Takahashi, N. Three-Dimensional FEM Analysis of Electromagnetic Inspection of Outer Side Defects on Steel Tube Using Inner Coil. IEEE Trans. Magn. 2007, 43, 1733. [Google Scholar] [CrossRef]

- Hayashi, M.; Kawakami, T.; Saito, T.; Sakai, K.; Kiwa, T.; Tsukada, K. Imaging of Defect Signal of Reinforcing Steel Bar at High Lift-Off Using a Magnetic Sensor Array by Unsaturated AC Magnetic Flux Leakage Testing. IEEE Trans. Magn. 2021, 57, 2020–2023. [Google Scholar] [CrossRef]

- Sophian, A.; Tian, G.Y.; Zairi, S. Pulsed Magnetic Flux Leakage Techniques for Crack Detection and Characterisation. Sens. Actuators A Phys. 2006, 125, 186–191. [Google Scholar] [CrossRef]

- Wilson, J.W.; Tian, G.Y. Pulsed Electromagnetic Methods for Defect Detection and Characterisation. NDT E Int. 2007, 40, 275–283. [Google Scholar] [CrossRef]

- Wilson, J.W.; Kaba, M.; Tian, G.Y.; Licciardi, S. Feature Extraction and Integration for the Quantification of PMFL Data. Nondestruct. Test. Eval. 2010, 25, 101–109. [Google Scholar] [CrossRef]

- Wang, P.; Xiong, L.; Sun, Y.; Wang, H.; Tian, G. Features Extraction of Sensor Array Based PMFL Technology for Detection of Rail Cracks. Measurement 2014, 47, 613–626. [Google Scholar] [CrossRef]

- Tang, Y.; Pan, M.C.; Luo, F.L.; Tan, X.L. Experimental and Finite Element Analysis Study of 3D Magnetic Field Sensing for Pulsed Magnetic Flux Leakage Defect Characterization. Insight 2011, 53, 497–506. [Google Scholar] [CrossRef]

- Ying, T.; Meng, P.; Feilu, C. Feature Extraction Based on the Principal Component Analysis for Pulsed Magnetic Flux Leakage Testing. In Proceedings of the 2011 International Conference on Mechatronic Science, Electric Engineering and Computer, MEC, Jilin, China, 19–22 August 2011; pp. 2563–2566. [Google Scholar]

- Wu, D.; Liu, Z.; Wang, X.; Su, L. Composite Magnetic Flux Leakage Detection Method for Pipelines Using Alternating Magnetic Field Excitation. NDT E Int. 2017, 91, 148–155. [Google Scholar] [CrossRef]

- Wang, R.; Kang, Y.; Tang, J.; Feng, B.; Deng, Y. A Novel Magnetic Flux Leakage Testing Method Based on AC and DC Composite Magnetization. J. Nondestruct. Eval. 2020, 39, 1–11. [Google Scholar] [CrossRef]

- Gotoh, Y.; Takahashi, N. Evaluation of Detecting Method with AC and DC Excitations of Opposite-Side Defect in Steel Using 3-D Nonlinear FEM Taking the Minor Loop into Account. IEEE Trans. Magn. 2008, 44, 1622–1625. [Google Scholar] [CrossRef]

- Singh, W.S.; Rao, B.P.C.; Thirunavukkarasu, S.; Jayakumar, T. Flexible GMR Sensor Array for Magnetic Flux Leakage Testing of Steel Track Ropes. J. Sens. 2012, 2012, 1–6. [Google Scholar] [CrossRef]

- Kataoka, Y.; Murayama, S.; Wakiwaka, H.; Shinoura, O. Application of GMR Line Sensor to Detect the Magnetic Flux Distribution for Nondestructive Testing. Int. J. Appl. Electromagn. Mech. 2001, 15, 47–52. [Google Scholar] [CrossRef]

- Tehranchi, M.M.; Ranjbaran, M.; Eftekhari, H. Double Core Giant Magneto-Impedance Sensors for the Inspection of Magnetic Flux Leakage from Metal Surface Cracks. Sens. Actuators A Phys. 2011, 170, 55–61. [Google Scholar] [CrossRef]

- Jin, Z.; Mohd Noor Sam, M.A.I.; Oogane, M.; Ando, Y. Serial MTJ-Based TMR Sensors in Bridge Configuration for Detection of Fractured Steel Bar in Magnetic Flux Leakage Testing. Sensors 2021, 21, 668. [Google Scholar] [CrossRef]

- Kallias, G.; Devlin, E.; Christides, C.; Niarchos, D. High Tc SQUID Sensor System for Non-Destructive Evaluation. Sens. Actuators A Phys. 2000, 85, 239–243. [Google Scholar] [CrossRef]

- Krause, H.J.; Kreutzbruck, M.V. Recent Developments in SQUID NDE. Phys. C Supercond. Its Appl. 2002, 368, 70–79. [Google Scholar] [CrossRef]

- Park, G.S.; Park, E.S. Improvement of the Sensor System in Magnetic Flux Leakage-Type Nondestructive Testing (NDT). IEEE Trans. Magn. 2002, 38, 1277–1280. [Google Scholar] [CrossRef]

- Jia, Y.; Liang, K.; Wang, P.; Ji, K.; Xu, P. Enhancement Method of Magnetic Flux Leakage Signals for Rail Track Surface Defect Detection. IET Sci. Meas. Technol. 2020, 14, 711–717. [Google Scholar] [CrossRef]

- Wu, J.; Yang, Y.; Li, E.; Deng, Z.; Kang, Y.; Tang, C.; Sunny, A.I. A High-Sensitivity MFL Method for Tiny Cracks in Bearing Rings. IEEE Trans. Magn. 2018, 54, 6201308. [Google Scholar] [CrossRef]

- Tang, J.; Wang, R.; Zhang, J.; Kang, Y. The Influence of Magnetic Head’s Pose on Magnetic Flux Leakage Detection. Int. J. Appl. Electromagn. Mech. 2020, 64, 493–500. [Google Scholar] [CrossRef]

- Li, E.; Kang, Y.; Tang, J.; Wu, J. A New Micro Magnetic Bridge Probe in Magnetic Flux Leakage for Detecting Micro-Cracks. J. Nondestruct. Eval. 2018, 37, 1–9. [Google Scholar] [CrossRef]

- Li, E.; Chen, X.; Wu, J.; Zhu, J.; Kang, Y. A Spatial Broadband Magnetic Flux Leakage Method for Trans-Scale Defect Detection. J. Nondestruct. Eval. 2022, 41, 1–12. [Google Scholar] [CrossRef]

- Liu, S.; Sun, Y.; He, L.; Kang, Y. Magnetic Focusing Method and Sensor in Surface Topography Testing for Ferromagnetic Materials. Sens. Actuators A Phys. 2019, 285, 531–542. [Google Scholar] [CrossRef]

- Dehui, W.; Lingxin, S.; Xiaohong, W.; Zhitian, L. A Novel Non-Destructive Testing Method by Measuring the Change Rate of Magnetic Flux Leakage. J. Nondestruct. Eval. 2017, 36, 1–11. [Google Scholar] [CrossRef]

- Tang, J.; Wang, R.; Liu, B.; Kang, Y. A Novel Magnetic Flux Leakage Method Based on the Ferromagnetic Lift-off Layer with through Groove. Sens. Actuators A Phys. 2021, 332, 113091. [Google Scholar] [CrossRef]

- Nara, T.; Takanashi, Y.; Mizuide, M. A Sensor Measuring the Fourier Coefficients of the Magnetic Flux Density for Pipe Crack Detection Using the Magnetic Flux Leakage Method. J. Appl. Phys. 2011, 109, 07E305. [Google Scholar] [CrossRef]

- Philip, J.; Rao, C.B.; Jayakumar, T.; Raj, B. New Optical Technique for Detection of Defects in Ferromagnetic Materials and Components. NDT E Int. 2000, 33, 289–295. [Google Scholar] [CrossRef]

- Mahendran, V.; Philip, J. Nanofluid Based Optical Sensor for Rapid Visual Inspection of Defects in Ferromagnetic Materials. Appl. Phys. Lett. 2012, 100, 1–4. [Google Scholar] [CrossRef]

- Mahendran, V.; Philip, J. Naked Eye Visualization of Defects in Ferromagnetic Materials and Components. NDT E Int. 2013, 60, 100–109. [Google Scholar] [CrossRef]

- Lee, J.; Wang, R.; Shoji, T.; Hong, S. Non-Destructive Testing in the High-Temperature Regime by Using a Magneto-Optical Film. NDT E Int. 2008, 41, 420–426. [Google Scholar] [CrossRef]

- Tehranchi, M.M.; Hamidi, S.M.; Eftekhari, H.; Karbaschi, M.; Ranjbaran, M. The Inspection of Magnetic Flux Leakage from Metal Surface Cracks by Magneto-Optical Sensors. Sens. Actuators A Phys. 2011, 172, 365–368. [Google Scholar] [CrossRef]

- Carvalho, A.A.; Rebello, J.M.A.; Sagrilo, L.V.S.; Camerini, C.S.; Miranda, I.V.J. MFL Signals and Artificial Neural Networks Applied to Detection and Classification of Pipe Weld Defects. NDT E Int. 2006, 39, 661–667. [Google Scholar] [CrossRef]

- Hwang, K.; Mandayam, S.; Udpa, S.S.; Udpa, L.; Lord, W.; Atzal, M. Characterization of Gas Pipeline Inspection Signals Using Wavelet Basis Function Neural Networks. NDT E Int. 2000, 33, 531–545. [Google Scholar] [CrossRef]

- Khodayari-Rostamabad, A.; Reilly, J.P.; Nikolova, N.K.; Hare, J.R.; Pasha, S. Machine Learning Techniques for the Analysis of Magnetic Flux Leakage Images in Pipeline Inspection. IEEE Trans. Magn. 2009, 45, 3073–3084. [Google Scholar] [CrossRef]

- Kandroodi, M.R.; Araabi, B.N.; Bassiri, M.M.; Ahmadabadi, M.N. Estimation of Depth and Length of Defects from Magnetic Flux Leakage Measurements: Verification with Simulations, Experiments, and Pigging Data. IEEE Trans. Magn. 2017, 53, 1–10. [Google Scholar] [CrossRef]

- Feng, J.; Li, F.; Lu, S.; Liu, J.; Ma, D. Injurious or Noninjurious Defect Identification from MFL Images in Pipeline Inspection Using Convolutional Neural Network. IEEE Trans. Instrum. Meas. 2017, 66, 1883–1892. [Google Scholar] [CrossRef]

- Lu, S.; Feng, J.; Zhang, H.; Liu, J.; Wu, Z. An Estimation Method of Defect Size from MFL Image Using Visual Transformation Convolutional Neural Network. IEEE Trans. Ind. Inform. 2019, 15, 213–224. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, Y.; Liu, J.; Wang, L. A Reinforcement Learning-Based Reconstruction Method for Complex Defect Profiles in MFL Inspection. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Sun, H.; Peng, L.; Huang, S.; Li, S.; Long, Y.; Wang, S.; Zhao, W. Development of a Physics-Informed Doubly Fed Cross-Residual Deep Neural Network for High-Precision Magnetic Flux Leakage Defect Size Estimation. IEEE Trans. Ind. Inform. 2022, 18, 1629–1640. [Google Scholar] [CrossRef]

- Yan, M.; Udpa, S.; Mandayam, S.; Sun, Y.; Sacks, P.; Lord, W. Solution of Inverse Problems in Electromagnetic NDE Using Finite Element Methods. IEEE Trans. Magn. 1998, 34, 2920–2923. [Google Scholar] [CrossRef]

- Chen, Z.; Preda, G.; Mihalache, O.; Miya, K. Reconstruction of Crack Shapes from the MFLT Signals by Using a Rapid Forward Solver and an Optimization Approach. IEEE Trans. Magn. 2002, 38, 1025–1028. [Google Scholar] [CrossRef]

- Ramuhalli, P.; Udpa, L.; Udpa, S.S. Neural Network-Based Inversion Algorithms in Magnetic Flux Leakage Nondestructive Evaluation. J. Appl. Phys. 2003, 93, 8274–8276. [Google Scholar] [CrossRef]

- Amineh, R.K.; Koziel, S.; Nikolova, N.K.; Bandler, J.W.; Reilly, J.P. A Space Mapping Methodology for Defect Characterization from Magnetic Flux Leakage Measurements. IEEE Trans. Magn. 2008, 44, 2058–2065. [Google Scholar] [CrossRef]

- Amineh, R.K.; Nikolova, N.K.; Reilly, J.P.; Hare, J.R. Characterization of Surface-Breaking Cracks Using One Tangential Component of Magnetic Leakage Field Measurements. IEEE Trans. Magn. 2008, 44, 516–524. [Google Scholar] [CrossRef]

- Liu, X.; Deng, Y.; Zeng, Z.; Udpa, L.; Udpa, S.S. Model-Based Inversion Technique Using Element-Free Galerkin Method and State Space Search. IEEE Trans. Magn. 2009, 45, 1486–1489. [Google Scholar] [CrossRef]

- Priewald, R.H.; Magele, C.; Ledger, P.D.; Pearson, N.R.; Mason, J.S.D. Fast Magnetic Flux Leakage Signal Inversion for the Reconstruction of Arbitrary Defect Profiles in Steel Using Finite Elements. IEEE Trans. Magn. 2013, 49, 506–516. [Google Scholar] [CrossRef]

- Chen, J.; Huang, S.; Zhao, W. Three-Dimensional Defect Inversion from Magnetic Flux Leakage Signals Using Iterative Neural Network. IET Sci. Meas. Technol. 2015, 9, 418–426. [Google Scholar] [CrossRef]

- Feng, J.; Li, F.; Lu, S.; Liu, J. Fast Reconstruction of Defect Profiles from Magnetic Flux Leakage Measurements Using a RBFNN Based Error Adjustment Methodology. IET Sci. Meas. Technol. 2017, 11, 262–269. [Google Scholar] [CrossRef]

- Li, F.; Feng, J.; Zhang, H.; Liu, J.; Lu, S.; Ma, D. Quick Reconstruction of Arbitrary Pipeline Defect Profiles from MFL Measurements Employing Modified Harmony Search Algorithm. IEEE Trans. Instrum. Meas. 2018, 67, 2200–2213. [Google Scholar] [CrossRef]

- Yu, G.; Liu, J.; Zhang, H.; Liu, C. An Iterative Stacking Method for Pipeline Defect Inversion with Complex MFL Signals. IEEE Trans. Instrum. Meas. 2020, 69, 3780–3788. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, Y.; Wang, L. A Pinning Actor-Critic Structure-Based Algorithm for Sizing Complex-Shaped Depth Profiles in MFL Inspection with High Degree of Freedom. Complexity 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Wang, J.; Zuo, F.; Wang, J.; Liu, J. A Pipeline Defect Inversion Method with Erratic MFL Signals Based on Cascading Abstract Features. IEEE Trans. Instrum. Meas. 2022, 71, 3506711. [Google Scholar] [CrossRef]

- Ramuhalli, P.; Udpa, L.; Udpa, S.S. Electromagnetic NDE Signal Inversion by Function-Approximation Neural Networks. IEEE Trans. Magn. 2002, 38, 3633–3642. [Google Scholar] [CrossRef]

- Xu, C.; Wang, C.; Ji, F.; Yuan, X. Finite-Element Neural Network-Based Solving 3-D Differential Equations in Mfl. IEEE Trans. Magn. 2012, 48, 4747–4756. [Google Scholar] [CrossRef]

- Hari, K.C.; Nabi, M.; Kulkarni, S.V. Improved FEM model for defect-shape construction from MFL signal by using genetic algorithm. IET Sci. Meas. Technol. 2007, 14, 196–200. [Google Scholar] [CrossRef]

- Han, W.; Wu, Z.; Zhou, M.; Hou, E.; Su, X.; Wang, P.; Tian, G. Magnetic Flux Leakage Signal Inversion Based on Improved Efficient Population Utilization Strategy for Particle Swarm Optimization. Russ. J. Nondestruct. Test. 2017, 53, 862–873. [Google Scholar] [CrossRef]

- Han, W.; Xu, J.; Wang, P.; Tian, G. Defect Profile Estimation from Magnetic Flux Leakage Signal via Efficient Managing Particle Swarm Optimization. Sensors 2014, 14, 10361–10380. [Google Scholar] [CrossRef]

- Zhang, Y.; Ye, Z.; Wang, C. A Fast Method for Rectangular Crack Sizes Reconstruction in Magnetic Flux Leakage Testing. NDT E Int. 2009, 42, 369–375. [Google Scholar] [CrossRef]

- Han, W.; Xu, J.; Zhou, M.; Tian, G.; Wang, P.; Shen, X.; Hou, E. Cuckoo Search and Particle Filter-Based Inversing Approach to Estimating Defects via Magnetic Flux Leakage Signals. IEEE Trans. Magn. 2016, 52, 1–11. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, C.; Fei, J. Defect Reconstruction from Magnetic Flux Leakage Measurements Employing Modified Cuckoo Search Algorithm. Math. Biosci. Eng. 2021, 18, 1898–1925. [Google Scholar] [CrossRef] [PubMed]

- Vértesy, G.; Gasparics, A.; Tomáš, I. Inspection of Local Wall Thinning by Different Magnetic Methods. J. Nondestruct. Eval. 2018, 37, 1–8. [Google Scholar] [CrossRef]

- Deng, Z.; Li, T.; Zhang, J.; Song, X.; Kang, Y. A Magnetic Permeability Perturbation Testing Methodology and Experimental Research for Deeply Buried Defect in Ferromagnetic Materials. NDT E Int. 2022, 131, 102694. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, Y.; Qiu, C. A New NDT Method Based on Permanent Magnetic Field Perturbation. NDT E Int. 2011, 44, 1–7. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, Y.; Qiu, C. A Permanent Magnetic Perturbation Testing Sensor. Sens. Actuators A Phys. 2009, 155, 226–232. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, B.; Wu, J.; Tu, H.; Tang, J.; Kang, Y. A Review of Magnetic Flux Leakage Nondestructive Testing. Materials 2022, 15, 7362. https://doi.org/10.3390/ma15207362

Feng B, Wu J, Tu H, Tang J, Kang Y. A Review of Magnetic Flux Leakage Nondestructive Testing. Materials. 2022; 15(20):7362. https://doi.org/10.3390/ma15207362

Chicago/Turabian StyleFeng, Bo, Jianbo Wu, Hongming Tu, Jian Tang, and Yihua Kang. 2022. "A Review of Magnetic Flux Leakage Nondestructive Testing" Materials 15, no. 20: 7362. https://doi.org/10.3390/ma15207362

APA StyleFeng, B., Wu, J., Tu, H., Tang, J., & Kang, Y. (2022). A Review of Magnetic Flux Leakage Nondestructive Testing. Materials, 15(20), 7362. https://doi.org/10.3390/ma15207362