A Comprehensive Review of Incorporating Steel Fibers of Waste Tires in Cement Composites and Its Applications

Abstract

:1. Introduction

1.1. Background

1.1.1. Tires and Global Pollution

1.1.2. Raw Steel Fiber from Waste Tires and Concrete Composites

1.1.3. Shortcomings in the Available Review Papers Related to RSF

2. Study Approach

- Collecting papers related to RSF-incorporated composites. Screening the most relevant papers using plain concrete or mortar as a reference.

- Arranging the material’s properties and strength properties of concrete and mortars separately.

- Determining the optimized content of RSF for each concrete and mortar and establishing the possible relationship between the strength properties of each of the composites with a dosage of RSF.

- Justifying the influence of RSF on a green and sustainable environment.

3. The Properties of RSF Fibers Used

4. The Properties of RSF-Incorporated Concrete

4.1. Compressive Strength of RSF Concrete

4.1.1. Compressive Strength of Concrete Containing RSF by its Volume Fraction

4.1.2. Compressive Strength of Concrete Having RSF Content by Weight

4.1.3. Compressive Strength of Concrete Using RSF Content in Kg/m3

4.2. Split Tensile Strength of RSF Concrete

4.2.1. Split Tensile Strength of Concrete Using RSF Content by Its Volume Fraction

4.2.2. Split Tensile Strength of Concrete Using RSF Content by Weight

4.2.3. Split Tensile Strength of Concrete Containing RSF Content in kg/m3

4.3. Flexure Strength of RSF Concrete

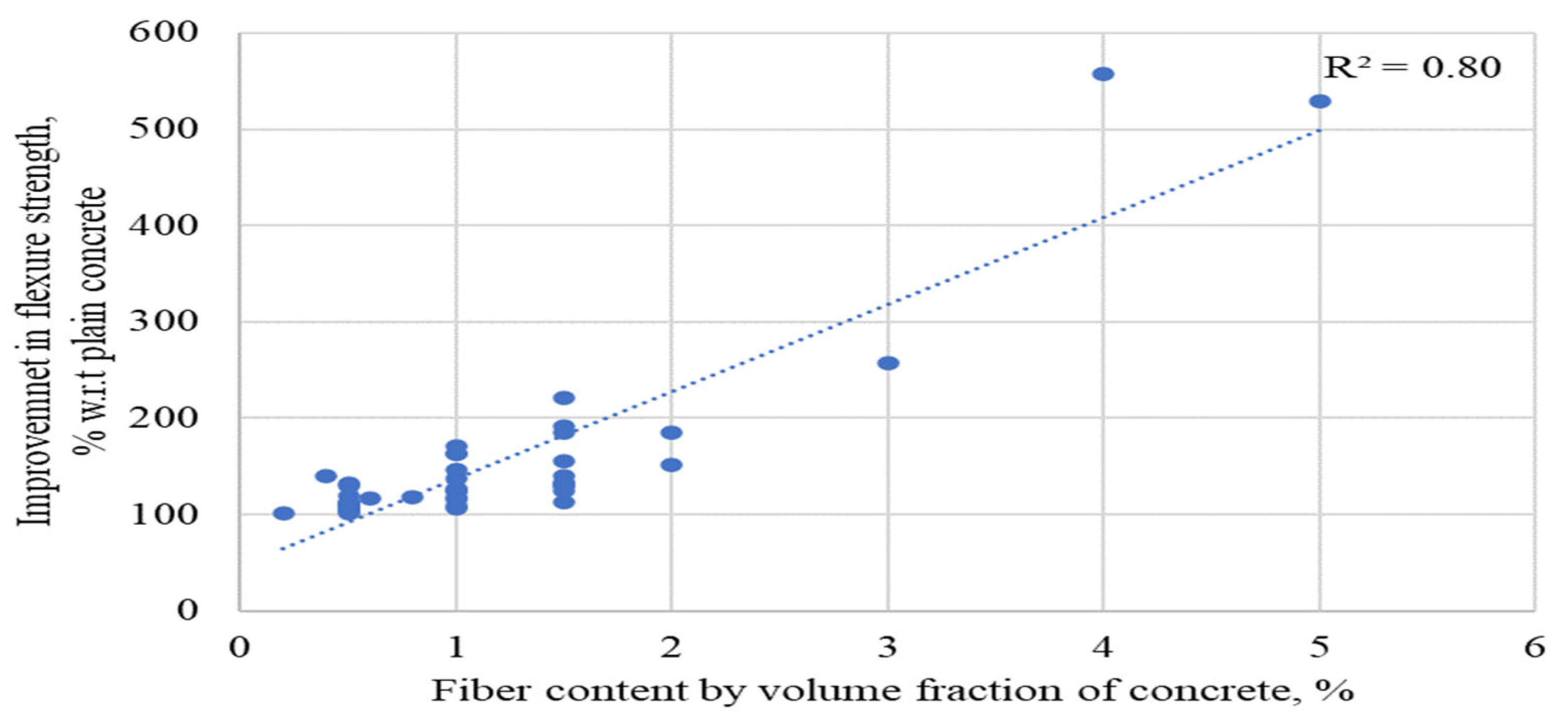

4.3.1. Flexure Strength of Concrete Using RSF Content by Its Volume Fraction

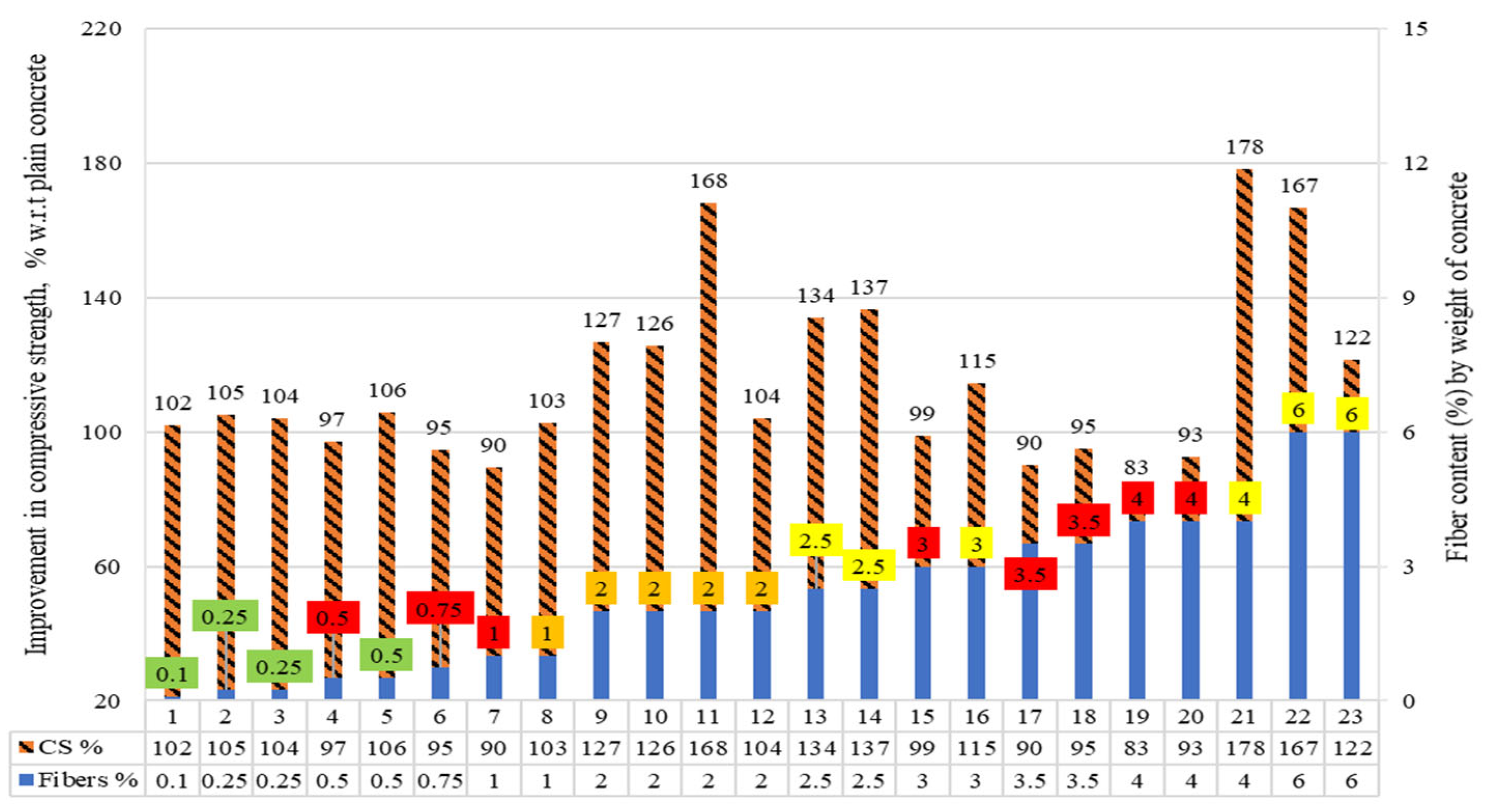

4.3.2. Flexure Strength of Concrete Using RSF Content by Weight Fraction

4.3.3. Flexure Strength of Concrete Using RSF Content in kg/m3

5. Properties of RSF-Incorporated Mortars

5.1. Compressive Strength of RSF Mortars

5.2. Split Tensile Strength of RSF Mortars

5.3. Flexure Strength of RSF Mortars

6. Correlation between Strength Properties of RSF Concrete

7. Possible Applications

7.1. Application of RSF for Rigid Pavements

7.2. Application of RSF for Hydraulic Structures

7.3. Application of RSF for Reinforced Concrete Structures

8. Conclusions and Recommendations

- A maximum enhancement of 29% was reported in compressive strength (CS) at 0.40% RSF (62 mm long and 0.80 mm thick) added by the volume fraction of concrete. A maximum enhancement of 78% in CS at 4% RSF (29 mm long and 0.20 mm thick) by weight fraction of concrete was reported. The most significant improvement in CS was reported at 50 kg/m3 RSF (17.50 mm long and 0.25 mm thick) by adding RSFs in kg/m3 to concrete.

- Split tensile strength (STS) was increased maximally by up to 149% when two percent RSF (62 mm long) was added to concrete by volume fraction. The highest increase of 96% in STS at 6% RSF (29 mm in length and 0.20 mm in diameter) for RSF by weight fraction of concrete was reported. The most significant improvement of 43% in STS was reported at 50 kg/m3 RSF (17.50 mm long and 0.25 mm thick) when adding RSFs in kg/m3 to concrete.

- The maximum increase in flexure strength (FS) was up to 157% when adding 3% RSF (45 mm long and 0.245 mm thick) into the concrete by volume fraction. An increase of 457% and 429% in FS was reported at 4% and 5% of RSF. However, such a high increase in FS needs to be explored and verified by additional research. At 6% RSF (29 mm in length and 0.20 mm in diameter) added to concrete by its weight proportion, the maximum increase in FS was 162 percent. The greatest improvement in FS was 68% when adding 40 kg/m3 RSFs (50 mm long and 0.60 mm thick) to concrete.

- The size of RSFs have a significant impact on the concrete’s CS. A considerable rise in CS was observed by many researchers for the same proportion of lengthier RSFs.

- It was found that small RSFs work better than large RSFs for increasing the STS of concrete. In comparison, longer RSFs were more effective than smaller RSFs in improving the FS of concrete.

- The most significant increases of 46%, 50.6%, and 69%, were reported in CS, STS, and FS of cement mortars (zero coarse aggregate mixture), adding 1.50% RSF (50 mm long and 0.15 mm thick), 0.02% RSF (50 mm long and 0.15 mm thick), and 0.57% RSF (21 mm lengthy and 0.20 mm thick), respectively, by volume fraction of mortar.

- In mortar, the low proportion of lengthy RFs worked effectively in improving CS. It is noted that even at a low dose of RFs for mortar, a sizable increment in CS was observed. In contrast to RF mortar, the rise in CS for RF concrete was minimal. Compared to other RFs, medium-size (20 to 35 mm long) RFs performed better in improving their FS. Therefore, it is vital to introduce advanced techniques to improve the RSF mixes’ homogeneity and the dispersion of RSF within the mix of mortar and concrete.

- The increase or decrease of RSF on the concrete’s CS is mostly no more than 48%. However, opposite to the low volume of fiber concrete, if the fiber content was controlled at higher than moderate volume (1% to 2% by volume fraction of concrete), the improvement showed a slightly dropping trend with RSF. The impact of RSF on the compressive strength of various cement-based mixtures, especially mortar, is yet unknown; more research is needed to fully comprehend the fiber’s interaction with the matrix and its behavior under compressive loads. However, unlike mortar, experimental results reveal that maintaining the RSF fiber content at lower than 1% of the volume fraction of concrete slightly improves compressive strength capacity.

- For similar content of RSF, mechanical strengths can differ when using different lengths of RSF. It was observed that different authors noted variations in compressive, split tensile, and flexure strengths for the different lengths of RSF used in the same dose of RSFs. Therefore, for optimizing RSF’s content for any mix, dimensional parameters, especially the length of RSF, also need to be considered.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Revuelta, D.; Carballosa, P.; García Calvo, J.L.; Pedrosa, F. Residual strength and drying behavior of concrete reinforced with recycled steel fiber from tires. Materials 2021, 14, 6111. [Google Scholar] [CrossRef] [PubMed]

- Qin, X.; Kaewunruen, S. Environment-friendly recycled steel fibre reinforced concrete. Constr. Build. Mater. 2022, 327, 126967. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- ETRMA. European Tyre and Rubber Industry Statistics 2021; ETRMA: Brussels, Belgium, 2021. [Google Scholar]

- European Council. Council Directive 1999/31/EC of April 1999 on the Landfill of Waste. Off. J. Eur. Communities 1999, L182, 1–9. [Google Scholar]

- ETRMA. ELT-Management-Figures-2017-vf; ETRMA: Brussels, Belgium, 2019. [Google Scholar]

- Binglin, Y. Research status and prospect of waste steel fiber reinforced concrete. In Proceedings of the E3S Web of Conferences, Hangzhou, China, 13–15 August 2021; Volume 248. [Google Scholar]

- Pilakoutas, K.; Neocleous, K.; Tlemat, H. Reuse of tyre steel fibres as concrete reinforcement. Eng. Sustain. 2004, 157, 131–138. [Google Scholar] [CrossRef]

- Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact Eng. 2015, 83, 76–87. [Google Scholar] [CrossRef]

- ETRMA. ETRMA-2018. End of Life Tyres Management-Europe-Status; ETRMA: Brussels, Belgium, 2018. [Google Scholar]

- Bulei, C.; Todor, M.P.; Heput, T.; Kiss, I. Directions for material recovery of used tires and their use in the production of new products intended for the industry of civil construction and pavements. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2018, 294, 012064. [Google Scholar] [CrossRef]

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Scott, E. End-of-life Tyre REPORT, European Tyre & Rubber Manufacturers Association, 2015. Resour. Conserv. Recycl. 2015, 3. [Google Scholar]

- Evans, R. The Composition of a Tyre: Typical Components Creating Markets for Recycled Resources. Heliyon 2006, 5, e02139. [Google Scholar]

- Shannag, M.J. Characteristics of lightweight concrete containing mineral admixtures. Constr. Build. Mater. 2011, 25, 658–662. [Google Scholar] [CrossRef]

- Atoyebi, O.D.; Odeyemi, S.O.; Orama, J.A. Experimental data on the splitting tensile strength of bamboo reinforced lateritic concrete using different culm sizes. Data Br. 2018, 20, 1960–1964. [Google Scholar] [CrossRef] [PubMed]

- Zia, A.; Ali, M. Behavior of fiber reinforced concrete for controlling the rate of cracking in canal-lining. Constr. Build. Mater. 2017, 155, 726–739. [Google Scholar] [CrossRef]

- Zia, A.; Khan, A.A. Effectiveness of bagasse ash for performance improvement of asphalt concrete pavements. SN Appl. Sci. 2021, 3, 502. [Google Scholar] [CrossRef]

- Bedewi, N. Steel Fiber Reinforced Concrete Made with Fibers Extracted from Used Tyres. Master’s Thesis, Addis Ababa University, Addis Ababa, Ethiopia, 2009. [Google Scholar]

- Thomas, B.S.; Gupta, R.C.; Kalla, P.; Cseteneyi, L. Strength, abrasion and permeation characteristics of cement concrete containing discarded rubber fine aggregates. Constr. Build. Mater. 2014, 59, 204–212. [Google Scholar] [CrossRef]

- Pawelska-Mazur, M.; Kaszynska, M. Mechanical performance and environmental assessment of sustainable concrete reinforced with recycled end-of-life tyre fibres. Materials 2021, 14, 256. [Google Scholar] [CrossRef] [PubMed]

- Ayanoğlu, A.; Yumrutaş, R. Production of gasoline and diesel like fuels from waste tire oil by using catalytic pyrolysis. Energy 2016, 103, 456–468. [Google Scholar] [CrossRef]

- Golpasand, G.B.; Farzam, M.; Shishvan, S.S. Behavior of recycled steel fiber reinforced concrete under uniaxial cyclic compression and biaxial tests. Constr. Build. Mater. 2020, 263, 120664. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R.; Illikainen, M. Development of eco-efficient and cost-effective reinforced self-consolidation concretes with hybrid industrial/recycled steel fibers. Constr. Build. Mater. 2018, 166, 214–226. [Google Scholar] [CrossRef]

- Samarakoon, S.M.S.M.K.; Ruben, P.; Wie Pedersen, J.; Evangelista, L. Mechanical performance of concrete made of steel fibers from tire waste. Case Stud. Constr. Mater. 2019, 11, e00259. [Google Scholar] [CrossRef]

- Rutherford, S. Process for Recycling Vehicle Tires. U.S. Patent 5115983A, 26 May 1992. [Google Scholar]

- Bartolac, M.; Damjanovic, D.; Krolo, J.; Baricevic, A. Punching Shear Strength of Concrete Slabs Reinforced with Recycled Steel Fibres from Waste Tires. In Proceedings of the II International Conference on Concrete Sustainability ICCS16, Barselona, Spain, 13–15 June 2016. [Google Scholar]

- Peng, G.F.; Niu, X.J.; Long, Q.Q. Experimental study of strengthening and toughening for recycled steel fiber reinforced ultra-high performance concrete. Proc. Key Eng. Mater. 2015, 629–630, 104–111. [Google Scholar] [CrossRef]

- Bjegovic, D.; Baricevic, A.; Lakusic, S.; Damjanovic, D.; Duvnjak, I. Positive interaction of industrial and recycled steel fibres in fibre reinforced concrete. J. Civ. Eng. Manag. 2013, 19, S50–S60. [Google Scholar] [CrossRef] [Green Version]

- Sotoudeh, M.H.; Jalal, M. Effects of Waste Steel Fibers on Strength and Stress-strain Behavior of Concrete Incorporating Silica Nanopowder. Indian J. Sci. Technol. 2013, 6, 1–17. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Faraj, R.H.; Hilal, N.; Mohammed, A.A.; Sherwani, A.F.H. Use of recycled fibers in concrete composites: A systematic comprehensive review. Compos. Part B Eng. 2021, 215, 108769. [Google Scholar] [CrossRef]

- Al-musawi, H.; Figueiredo, F.P.; Guadagnini, M.; Pilakoutas, K. Shrinkage properties of plain and recycled steel–fibre-reinforced rapid hardening mortars for repairs. Constr. Build. Mater. 2019, 197, 369–384. [Google Scholar] [CrossRef] [Green Version]

- Dehghanpour, H.; Yılmaz, K. Mechanical and impact behavior on recycled steel Fiber reinforced cementitious mortars. Russ. J. Build. Constr. Archit. 2018, 3, 67–84. [Google Scholar]

- Awolusi, T.F.; Oke, O.L.; Atoyebi, O.D.; Akinkurolere, O.O.; Sojobi, A.O. Waste tires steel fiber in concrete: A review. Innov. Infrastruct. Solut. 2021, 6, 34. [Google Scholar] [CrossRef]

- Jean Claude, N. Effect of Recycled Tyre Steel Fibres on Structural Performance and Impact Resistance of Rubberized Concrete, Pan African University Institute for Basic Sciences, Technology and Innovation. Master’s Thesis, Pan-African University, Yaoundé, Cameroun, 2018. [Google Scholar]

- Mastali, M.; Dalvand, A. Use of silica fume and recycled steel fibers in self-compacting concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

- Rossli, S.A.; Ibrahim, I.S. Mechanical Properties of Recycled Steel Tire Fibres in Concrete; Technical Report; Universiti Teknologi Malaysia: Johor Bahru, Malaysia, 2012. [Google Scholar]

- Balea, A.; Fuente, E.; Monte, M.C.; Blanco, A.; Negro, C. Recycled fibers for sustainable hybrid fiber cement based material: A review. Materials 2021, 14, 2408. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled fibers in reinforced concrete: A systematic literature review. J. Clean. Prod. 2020, 248, 119207. [Google Scholar] [CrossRef]

- Ming, Y.; Chen, P.; Li, L.; Gan, G.; Pan, G. A comprehensive review on the utilization of recycled waste fibers in cement-based composites. Materials 2021, 14, 3643. [Google Scholar] [CrossRef] [PubMed]

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Fiber-reinforced concrete with low content of recycled steel fiber: Shear behaviour. Constr. Build. Mater. 2018, 161, 141–155. [Google Scholar] [CrossRef]

- Vistos, L.; Galladini, D.; Xargay, H.; Caggiano, A.; Folino, P.; Martinelli, E. Hybrid industrial/recycled SFRC: Experimental analysis and design. In Proceedings of Italian Concrete Days 2016. ICD 2016; Lecture Notes in Civil Engineering; Springer: Cham, Switzrland, 2018; Volume 10. [Google Scholar] [CrossRef]

- Martinelli, E.; Caggiano, A.; Xargay, H. An experimental study on the post-cracking behaviour of Hybrid Industrial/Recycled Steel Fibre-Reinforced Concrete. Constr. Build. Mater. 2015, 94, 290–298. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef] [Green Version]

- Gul, A.; Alam, B.; Iqbal, M.J.; Ahmed, W.; Shahzada, K.; Javed, M.H.; Khan, E.A. Impact of Length and Percent Dosage of Recycled Steel Fibers on the Mechanical Properties of Concrete. Civ. Eng. J. 2021, 7, 1650–1666. [Google Scholar] [CrossRef]

- Siraj, N.; Kedir, N.S. Synthesis and characterization of pyrolised recycled steel fibers for use in reinforced concrete. Int. J. Eng. Sci. Manag. Res. 2017, 4, 21–32. [Google Scholar]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of Hybrid Fiber Reinforced Concrete with Recycled and Industrial Steel Fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Sengul, O. Mechanical behavior of concretes containing waste steel fibers recovered from scrap tires. Constr. Build. Mater. 2016, 122, 649–658. [Google Scholar] [CrossRef]

- Frazão, C.; Díaz, B.; Barros, J.; Bogas, J.A.; Toptan, F. An experimental study on the corrosion susceptibility of Recycled Steel Fiber Reinforced Concrete. Cem. Concr. Compos. 2019, 96, 138–153. [Google Scholar] [CrossRef]

- Najim, K.B.; Saeb, A.; Al-Azzawi, Z. Structural behaviour and fracture energy of recycled steel fibre self-compacting reinforced concrete beams. J. Build. Eng. 2018, 17, 174–182. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Fresh and Hardened Properties of Self-Compacting Concrete Reinforced with Hybrid Recycled Steel–Polypropylene Fiber. J. Mater. Civ. Eng. 2017, 29, 04017012. [Google Scholar] [CrossRef]

- Abdul Awal, A.S.M.; Kadir, M.A.A.; Yee, L.L.; Memon, N. Strength and Deformation Behaviour of Concrete Incorporating Steel Fibre from Recycled Tyre. In CIEC 2014, Proceedings of the International Civil and Infrastructure Engineering Conference; Springer: Singapore, 2015. [Google Scholar]

- Skarżyński, Ł.; Suchorzewski, J. Mechanical and fracture properties of concrete reinforced with recycled and industrial steel fibers using Digital Image Correlation technique and X-ray micro computed tomography. Constr. Build. Mater. 2018, 183, 283–299. [Google Scholar] [CrossRef]

- Chen, M.; Si, H.; Fan, X.; Xuan, Y.; Zhang, M. Dynamic compressive behaviour of recycled tyre steel fibre reinforced concrete. Constr. Build. Mater. 2022, 316, 125896. [Google Scholar] [CrossRef]

- Dorr, B.J.; Kanali, C.L.; Onchiri, R.O. Shear Performance of Recycled Tyres Steel Fibres Reinforced Lightweight Concrete Beam using Palm Kernel Shear as Partial Replacement of Coarse Aggregate. Int. J. Eng. Res. Technol. 2019, 12, 1818–1823. [Google Scholar]

- Suleman, M.; Ahmad, N.; Ullah Khan, S.; Ahmad, T. Investigating flexural performance of waste tires steel fibers-reinforced cement-treated mixtures for sustainable composite pavements. Constr. Build. Mater. 2021, 275, 122099. [Google Scholar] [CrossRef]

- Younis, K.H. Mechanical Performance of Concrete Reinforced with Steel Fibres Extracted from Post-Consumer Tyres. In Proceedings of the 2nd Internationa Engineering Conference on Developments in Civil and Computer Applications, Erbil, Kudistan Region, Iraq, 20–21 February 2016. [Google Scholar]

- Graeff, A.G.; Pilakoutas, K.; Neocleous, K.; Peres, M.V.N.N. Fatigue resistance and cracking mechanism of concrete pavements reinforced with recycled steel fibres recovered from post-consumer tyres. Eng. Struct. 2012, 45, 385–395. [Google Scholar] [CrossRef]

- Shah, S.H.A.; Ali, B.; Ahmed, G.H.; Tirmazi, S.M.T.; El Ouni, M.H.; Hussain, I. Effect of recycled steel fibers on the mechanical strength and impact toughness of precast paving blocks. Case Stud. Constr. Mater. 2022, 16, e01025. [Google Scholar] [CrossRef]

- Akhtar, T.; Ali, B.; Ben Kahla, N.; Kurda, R.; Rizwan, M.; Mohsin Javed, M.; Raza, A. Experimental investigation of eco-friendly high strength fiber-reinforced concrete developed with combined incorporation of tyre-steel fiber and fly ash. Constr. Build. Mater. 2022, 314, 125626. [Google Scholar] [CrossRef]

- Köroğlu, M.A. Behavior of composite self-compacting concrete (SCC) reinforced with steel wires from waste tires. Rev. La Constr. 2019, 17, 484–498. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Aiello, M.A. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–57. [Google Scholar] [CrossRef]

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Experimental Study on Bond Behavior in Fiber-Reinforced Concrete with Low Content of Recycled Steel Fiber. J. Mater. Civ. Eng. 2016, 28, 04016068. [Google Scholar] [CrossRef]

- Groli, G.; Pérez Caldentey, A.; Soto, A.G. Cracking performance of SCC reinforced with recycled fibres—An experimental study. Struct. Concr. 2014, 15, 136–153. [Google Scholar] [CrossRef]

- Shi, X.; Brescia-Norambuena, L.; Grasley, Z.; Hogancamp, J. Fracture Properties and Restrained Shrinkage Cracking Resistance of Cement Mortar Reinforced by Recycled Steel Fiber from Scrap Tires. Transp. Res. Rec. 2020, 2674, 581–590. [Google Scholar] [CrossRef]

- Zamanzadeh, Z.; Hosseinzadeh, F.; Bashiri, M. Cement-Based Mortar Panels Reinforced with Recycled Steel Fibers in Flexural Strengthening of Concrete Beams. Int. J. Eng. Technol. Innov. 2021, 11, 305–315. [Google Scholar] [CrossRef]

- Al-musawi, H.; Figueiredo, F.P.; Bernal, S.A.; Guadagnini, M.; Pilakoutas, K. Performance of rapid hardening recycled clean steel fibre materials. Constr. Build. Mater. 2019, 195, 483–496. [Google Scholar] [CrossRef]

- Transportation Officials. AASHTO Guide for Design of Pavement Structures; Transportation Officials: Washington, DC, USA, 1993. [Google Scholar]

- ARA Inc. AASHTOWare Pavement ME Design; ARA Inc.: Laurel, MD, USA, 2022. [Google Scholar]

- American Concrete Pavement Association (ACPA). Pavement design software, StreetPave. 2020. Available online: https://www.acpa.org/streetpave/ (accessed on 14 July 2022).

- Jiang, Y.; Darter, M.I.; Owusu-Antwi, E. Analysis of current state rigid pavement design practices in the United States. Transp. Res. Rec. 1996, 1525, 72–82. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Effectiveness of hair and wave polypropylene fibers for concrete roads. Constr. Build. Mater. 2018, 166, 581–591. [Google Scholar] [CrossRef]

- Cui, J.H.; Xie, Z.Q.; Xiao, H.J. Cause analysis on the cracks in concrete plate of canal lining. Proc. Appl. Mech. Mater. 2013, 405–408, 2596–2599. [Google Scholar] [CrossRef]

- Zia, A.; Ali, M. Effectiveness of polypropylene fiber reinforced concrete in enhancement of long-term durability of hydraulic structures. Proc. Mater. Sci. Forum 2018, 923, 125–129. [Google Scholar] [CrossRef]

- Saatcioglu, M.; Mitchell, D.; Tinawi, R.; Gardner, N.J.; Gillies, A.G.; Ghobarah, A.; Anderson, D.L.; Lau, D. The August 17, 1999, Kocaeli (Turkey) earthquake—Damage to structures. Can. J. Civ. Eng. 2001, 28, 715–737. [Google Scholar] [CrossRef]

- Bayhan, B.; Moehle, J.P.; Yavari, S.; Elwood, K.J.; Lin, S.H.; Wu, C.L.; Hwang, S.J. Seismic response of a concrete frame with weak beam-column joints. Earthq. Spectra 2015, 31, 293–315. [Google Scholar] [CrossRef]

- Zia, A.; Pu, Z.; Holly, I.; Umar, T.; Tariq, M.A.U.R. Development of an Analytical Model for the FRP Retrofitted Deficient Interior Reinforced Concrete Beam-Column Joints. Appl. Sci. 2022, 12, 2339. [Google Scholar] [CrossRef]

- Adibi, M.; Marefat, M.S.; Allahvirdizadeh, R. Nonlinear modeling of cyclic response of RC beam–column joints reinforced by plain bars. Bull. Earthq. Eng. 2018, 16, 5529–5556. [Google Scholar] [CrossRef]

- Cosgun, C.; Cömert, M.; Demir, C.; İlki, A. Seismic Retrofit of Joints of a Full-Scale 3D Reinforced Concrete Frame with FRP Composites. J. Compos. Constr. 2019, 23, 04019004. [Google Scholar] [CrossRef]

- D’Ayala, D.F.; Penford, A.; Valentini, S. Use of FRP fabric for strengthening of reinforced concrete beam-column joints. In Proceedings of the 10th International conference on structural faults and repair, London, UK, 1–3 July 2013. [Google Scholar]

- Sharma, R.; Bansal, P.P. Behavior of RC exterior beam column joint retrofitted using UHP-HFRC. Constr. Build. Mater. 2019, 195, 376–389. [Google Scholar] [CrossRef]

| Authors | Fiber Properties | ||

|---|---|---|---|

| Average Length | Average Diameter | Tensile Strength | |

| (mm) | (mm) | (MPa) | |

| Gul et al. [46] | 100.16 | 0.939 | 996.15 |

| 7.62 | 0.939 | 996.15 | |

| Rossli and Ibrahim [37] | 60 | 0.80 | - |

| Siraj and Kedir [47] | 20 | 0.89 | 970.2 |

| 40 | 0.89 | 970.2 | |

| 60 | 0.89 | 970.2 | |

| Leone et al. [41] | 13.94 | 0.25 | - |

| Caggiano et al. [48] | 26.17 | 0.25 | - |

| Pawelska-Mazur and Kaszynska [21] | 17.50 | 0.25 | 2200 |

| Sengul [49] | 50 | 0.3 | - |

| 50 | 0.6 | 1330 | |

| 50 | 1.4 | 1160 | |

| Frazão et al. [50] | 23 | 0.22 | 2570 |

| Najim et al. [51] | 50 | - | 781.3 |

| Vistos et al. [42] | 12 | 0.27 | 2235 |

| Mastali et al. [24] | 50 | 0.15 | 1150 |

| Mastali et al. [52] | 50 | 0.15 | 1150 |

| Samarakoon et al. [25] | 37 | 0.42 | 870 |

| Peng et al. [28] | 30 | 1 | 1900 |

| 35 | 1 | 1900 | |

| Abdul Awal et al. [53] | 30 | - | 1030 |

| Skarzynski and Suchorzewski [54] | 26.17 | 0.25 | - |

| Aiello et al. [44] | 26 | 0.258 | 2377 |

| Chen et al. [55] | 7.3 | 0.22 | 2165 |

| Dorr et al. [56] | 93.6 | 1.17 | 1032.35 |

| Suleman et al. [57] | 45 | 0.35 | 1300 |

| Younis [58] | 29 | 0.2 | 2000 |

| Graeff et al. [59] | 13 | 0.2 | 2000 |

| Shah et al. [60] | 31 | - | 2000 |

| Akhtar et al. [61] | 30 | 1.1 | 1900 |

| Köroğlu [62] | 45 | 0.245 | 2134 |

| Centonze et al. [63] | 31.4 | 0.24 | - |

| Leone et al. [64] | 31.4 | 0.24 | - |

| Groli et al. [65] | 21 | - | - |

| Maximum value | 7.3 | 0.15 | 781.3 |

| Minimum value | 100.16 | 1.4 | 2570 |

| Authors | Specimen Number in Figure 4 | Fiber Properties | Compressive Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| Fiber Less Than 0.30% | % a | mm | mm | MPa | % b | |

| Aiello et al. [44] | 1 (1% Sp) | 0.13 | 26.0 | 0.258 | 40.4 | 103 |

| 2 (1% Sp) | 0.15 | 26.0 | 0.258 | 32.2 | 82 | |

| 3 (1% Sp) | 0.19 | 26.0 | 0.258 | 34.9 | 89 | |

| 4 (1.20% Sp) * | 0.19 | 26.0 | 0.258 | 33.4 | 85 | |

| Rossli and Ibrahim [37] | 5 (0.002 Sp) | 0.20 | 62.00 | 0.8 | 52.0 | 113 |

| Aiello et al. [44] (Planetary mixer) | 6 (1.12%) | 0.23 | 26.0 | 0.258 | 38.5 | 120 |

| Centonze et al. [63] (Planetary mixer) | 7 | 0.23 | 31.4 | 0.24 | 39.0 | 123 |

| Aiello et al. [44] (Normal concrete mixure) | 8 (1.20% Sp) | 0.26 | 26.0 | 0.258 | 34.6 | 89 |

| 9 (1.37% Sp) | 0.26 | 26.0 | 0.258 | 43.7 | 112 | |

| Leone et al. [64] | 10 | 0.3 | 31.4 | 0.24 | 35.71 | 105 |

| Average | 0.21 | 30.68 | 0.31 | 102 | ||

| 0.40% to 0.50% fiber | ||||||

| Rossli and Ibrahim [37] | 11 | 0.40 | 62.00 | 0.8 | 59.2 | 129 |

| Leone et al. [41] | 12 | 0.46 | 13.94 | 0.25 | 32.6 | 97 |

| Centonze et al. [63] (Planetary mixer) | 13 | 0.46 | 31.4 | 0.24 | 39.7 | 125 |

| Aiello et al. [44] (Planetary mixer) | 14 (1.12% Sp) | 0.46 | 26.00 | 0.258 | 37.6 | 117 |

| Groli et al. [65] | 15 | 0.5 | 21 | - | 36.4 | 97 |

| Siraj and Kedir [47] (Mix-I, C-25) | 16 | 0.50 | 20.00 | 0.89 | 28.0 | 100 |

| 17 | 0.50 | 40.00 | 0.89 | 28.2 | 101 | |

| 18 | 0.50 | 60.00 | 0.89 | 28.2 | 101 | |

| Siraj and Kedir [47] (Mix-II, C-40) | 19 | 0.50 | 20.00 | 0.89 | 40.9 | 100 |

| 20 | 0.50 | 40.00 | 0.89 | 41.5 | 101 | |

| 21 | 0.50 | 60.00 | 0.89 | 41.6 | 101 | |

| Siraj and Kedir [47] (Mix-III, C-60) | 22 | 0.50 | 20.00 | 0.89 | 59.0 | 101 |

| 23 | 0.50 | 40.00 | 0.89 | 60.5 | 104 | |

| 24 | 0.50 | 60.00 | 0.89 | 56.3 | 96 | |

| Vistos et al. [42] | 25 | 0.50 | 12.00 | 0.27 | 37.4 | 102 |

| Samarakoon et al. [25] | 26 | 0.50 | 37.00 | 0.42 | 30.6 | 105 |

| Skarżyński and Suchorzewski [54] | 27 | 0.50 | 26.17 | 0.25 | 52.4 | 122 |

| Chen et al. [55] | 28 | 0.50 | 7.30 | 0.22 | 51.6 | 103 |

| Dorr et al. [56] | 29 | 0.50 | 93.60 | 1.17 | 31.3 | 111 |

| Average | 0.49 | 36.34 | 0.66 | 106 | ||

| 0.60% to 0.80% fiber | ||||||

| Rossli and Ibrahim [37] | 30 | 0.60 | 62.00 | 0.8 | 34.5 | 75 |

| Caggiano et al. [48] | 31 | 0.75 | 26.17 | 0.25 | 22.5 | 102 |

| Chen et al. [55] | 32 | 0.75 | 7.30 | 0.22 | 57.6 | 115 |

| Rossli and Ibrahim [37] | 33 | 0.80 | 62.00 | 0.8 | 40.1 | 87 |

| Average | 0.73 | 39.37 | 0.52 | 94.92 | ||

| Authors | Specimen Number in Figure 4 | Fiber Properties | Compressive Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 1% Fiber Content | % a | mm | mm | MPa | % b | |

| Rossli and Ibrahim [37] | 34 | 1.00 | 62.00 | 0.8 | 42.3 | 92 |

| Groli et al. [65] | 35 | 1 | 21 | - | 37.5 | 100 |

| Köroğlu [62] | 36 | 1 | 45 | 0.245 | 36.26 | 99 |

| Siraj and Kedir [47] (Mix-I, C-25) | 37 | 1.00 | 20.00 | 0.89 | 27.9 | 100 |

| 38 | 1.00 | 40.00 | 0.89 | 29.1 | 104 | |

| 39 | 1.00 | 60.00 | 0.89 | 27.7 | 99 | |

| Siraj and Kedir [47] Mix-II, C-40 | 40 | 1.00 | 20.00 | 0.89 | 41.3 | 101 |

| 41 | 1.00 | 40.00 | 0.89 | 43.7 | 106 | |

| 42 | 1.00 | 60.00 | 0.89 | 41.1 | 100 | |

| Siraj and Kedir [47] Mix-III, C-60 | 43 | 1.00 | 20.00 | 0.89 | 27.9 | 100 |

| 44 | 1.00 | 40.00 | 0.89 | 29.1 | 104 | |

| 45 | 1.00 | 60.00 | 0.89 | 27.7 | 99 | |

| Samarakoon et al. [25] | 46 | 1.00 | 37.00 | 0.42 | 32.9 | 113 |

| Abdul Awal et al. [53] | 47 | 1.00 | 30.00 | - | 58.2 | 104 |

| Chen et al. [55] | 48 | 1.00 | 7.30 | 0.22 | 56.3 | 113 |

| Average | 1 | 37 | 1 | 102 | ||

| More than 1.25% Fiber | ||||||

| Chen et al. [55] | 49 | 1.25 | 7.30 | 0.22 | 52.7 | 105 |

| Siraj and Kedir [47] (Mix-I, C-25) | 50 | 1.50 | 20.00 | 0.89 | 29.0 | 103 |

| 51 | 1.50 | 40.00 | 0.89 | 31.4 | 112 | |

| 52 | 1.50 | 60.00 | 0.89 | 28.1 | 100 | |

| Siraj and Kedir [47] Mix-II, C-40 | 53 | 1.50 | 20.00 | 0.89 | 41.8 | 102 |

| 54 | 1.50 | 40.00 | 0.89 | 43.9 | 107 | |

| 55 | 1.50 | 60.00 | 0.89 | 42.0 | 102 | |

| Siraj and Kedir [47] Mix-III, C-60 | 56 | 1.50 | 20.00 | 0.89 | 62.4 | 107 |

| 57 | 1.50 | 40.00 | 0.89 | 59.2 | 101 | |

| 58 | 1.50 | 60.00 | 0.89 | 61.0 | 104 | |

| Abdul Awal et al. [53] | 59 | 1.50 | 30.00 | - | 59.0 | 106 |

| 60 | 2.00 | 30.00 | - | 58.7 | 105 | |

| Köroğlu [62] | 61 | 2 | 45 | 0.245 | 43.1 | 118 |

| 62 | 3 | 45 | 0.245 | 44.2 | 121 | |

| 63 | 4 | 45 | 0.245 | 46.2 | 127 | |

| 64 | 5 | 45 | 0.245 | 43.8 | 120 | |

| Average | 2.02 | 38 | 1 | 109 | ||

| Author | Specimen Number in Figure 6 | Fiber Properties | Compressive Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.20% to 0.75% Fiber | % a | mm | mm | MPa | % b | |

| Shah et al. [60] | 1 | 0.1 | 31.00 | - | 56.7 | 102 |

| 2 | 0.25 | 31.00 | - | 58.3 | 105 | |

| Akhtar et al. [61] | 3 | 0.25 | 30.00 | 1.10 | 78.0 | 104 |

| Shah et al. [60] | 4 | 0.5 | 31.00 | - | 54.0 | 97 |

| Akhtar et al. [61] | 5 | 0.5 | 30.00 | 1.10 | 79.5 | 106 |

| Shah et al. [60] | 6 | 0.75 | 31.00 | - | 52.5 | 95 |

| Average | 0.39 | 30.67 | 1.10 | 63.2 | 101.5 | |

| 1% to 2% Fiber | ||||||

| Shah et al. [60] | 7 | 1 | 31.00 | - | 49.7 | 90 |

| Akhtar et al. [61] | 8 | 1 | 30.00 | 1.10 | 77.0 | 103 |

| Gul et al. [46] | 9 | 2 | 100.16 | 0.94 | 35.9 | 127 |

| 10 | 2 | 7.62 | 0.94 | 35.5 | 126 | |

| Younis [58] | 11 | 2 | 29.00 | 0.20 | 47.6 | 168 |

| Graeff et al. [59] | 12 | 2 | 13.00 | 0.20 | 61.1 | 104 |

| Average | 1.67 | 35.13 | 0.68 | 51.1 | 119.5 | |

| 2.5% to 3.5% Fiber | ||||||

| Gul et al. [46] | 13 | 2.5 | 100.16 | 0.94 | 37.9 | 134 |

| 14 | 2.5 | 7.62 | 0.94 | 38.6 | 137 | |

| 15 | 3 | 100.16 | 0.94 | 27.9 | 99 | |

| 16 | 3 | 7.62 | 0.94 | 32.4 | 115 | |

| 17 | 3.5 | 100.16 | 0.94 | 25.5 | 90 | |

| 18 | 3.5 | 7.62 | 0.94 | 26.9 | 95 | |

| Average | 3.00 | 53.89 | 0.94 | 31.5 | 111.5 | |

| 4% to 6% Fiber | ||||||

| Gul et al. [46] | 19 | 4 | 100.16 | 0.94 | 23.4 | 83 |

| 20 | 4 | 7.62 | 0.94 | 26.2 | 93 | |

| Younis [58] | 21 | 4 | 29.00 | 0.20 | 50.4 | 178 |

| 22 | 6 | 29.00 | 0.20 | 47.2 | 167 | |

| Graeff et al. [59] | 23 | 6 | 13.00 | 0.20 | 71.4 | 122 |

| Average | 4.80 | 35.76 | 0.50 | 43.7 | 128.5 | |

| Author | Specimen No. in Figure 7 | Fiber Properties | Compressive Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 5 to 30 kg/m3 | kg/m3 | mm | mm | MPa | % a | |

| Sengul [49] | 1 | 5 | 52.00 | 0.30 | 69.50 | 100 |

| 2 | 10 | 52.00 | 0.30 | 65.80 | 95 | |

| 3 | 10 | 50.00 | 0.60 | 64.10 | 92 | |

| 4 | 15 | 52.00 | 0.30 | 70.60 | 102 | |

| 5 | 20 | 50.00 | 0.60 | 64.70 | 93 | |

| 6 | 20 | 50.00 | 1.40 | 68.70 | 99 | |

| 7 | 30 | 50.00 | 0.60 | 71.50 | 103 | |

| Average | 15.71 | 50.86 | 0.59 | 98 | ||

| 40 to 60 kg/m3 | ||||||

| Sengul [49] | 8 | 40 | 50.00 | 0.60 | 75.30 | 109 |

| 9 | 40 | 50.00 | 1.40 | 69.10 | 100 | |

| Pawelska-Mazur and Kaszynska [21] | 10 | 50 | 17.50 | 0.25 | 52.40 | 122 |

| Sengul [49] | 11 | 60 | 50.00 | 1.40 | 63.60 | 92 |

| Peng et al. [28] | 12 | 60 | 30.00 | 1.00 | 154.30 | 114 |

| 13 | 60 | 35.00 | 1.00 | 141.30 | 105 | |

| Average | 51.67 | 38.75 | 0.94 | - | 107 | |

| Author | Specimen No. in Figure 8 | Fiber Properties | Split Tensile Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.20% to 0.80% Fiber Content | % a | mm | mm | MPa | % b | |

| Rossli and Ibrahim [37] | 1 | 0.20 | 62.00 | 0.8 | 3.39 | 87 |

| Aiello et al. [44] | 2 | 0.23 | 26.00 | 0.258 | 2.70 | 116 |

| Leone et al. [64] | 3 | 0.30 | 31.40 | 0.24 | 4.73 | 104 |

| Rossli and Ibrahim [37] | 4 | 0.40 | 62.00 | 0.8 | 3.99 | 103 |

| Leone et al. [41] | 5 | 0.46 | 13.94 | 0.25 | 4.55 | 90 |

| Aiello et al. [44] | 6 | 0.46 | 26.00 | 0.258 | 2.54 | 109 |

| Samarakoon et al. [25] | 7 | 0.50 | 37.00 | 0.42 | 2.58 | 118 |

| Skarżyński and Suchorzewski [54] | 8 | 0.50 | 26.17 | 0.25 | 3.87 | 143 |

| Dorr et al. [56] | 9 | 0.50 | 93.60 | 1.17 | 1.80 | 86 |

| Groli et al. [65] | 10 | 0.50 | 21.00 | - | 3.1 | 74 |

| Rossli and Ibrahim [37] | 11 | 0.60 | 62.00 | 0.8 | 3.90 | 100 |

| 12 | 0.80 | 62.00 | 0.8 | 3.50 | 90 | |

| Average | 0.45 | 43.59 | 0.55 | 102 | ||

| 1% to 2% Fiber Content | ||||||

| Groli et al. [65] | 13 | 1 | 21.00 | - | 3.3 | 79 |

| Köroğlu [62] | 14 | 1 | 45.00 | 0.245 | 3.14 | 116 |

| Rossli and Ibrahim [37] | 15 | 1 | 62.00 | 0.8 | 4.44 | 114 |

| Samarakoon et al. [25] | 16 | 1 | 37.00 | 0.42 | 2.49 | 114 |

| Abdul Awal et al. [53] | 17 | 1 | 30.00 | - | 7.10 | 187 |

| 18 | 1.5 | 30.00 | - | 8.15 | 214 | |

| 19 | 2 | 30.00 | - | 9.45 | 249 | |

| Köroğlu [62] | 20 | 2 | 45.00 | 0.245 | 3.82 | 141 |

| 21 | 3 | 45.00 | 0.245 | 4.16 | 154 | |

| 22 | 4 | 45.00 | 0.245 | 4.84 | 178.6 | |

| 23 | 5 | 45.00 | 0.245 | 4.86 | 179.3 | |

| Average | 2.05 | 39.55 | 0.35 | 5.07 | 157 | |

| Author | Specimen Number In Figure 10 | Fiber Properties | Split Tensile Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.25% to 1% Fiber Content | % a | mm | mm | MPa | % b | |

| Akhtar et al. [61] | 1 | 0.25 | 30 | 1.1 | 6.10 | 135.6 |

| 2 | 0.5 | 30 | 1.1 | 6.80 | 151.1 | |

| 3 | 1 | 30 | 1.1 | 7.20 | 160.0 | |

| Average | 0.58 | 30.00 | 1.10 | 148.89 | ||

| 2% to 3.5% Fiber Content | ||||||

| Gul et al. [46] | 4 | 2 | 100.16 | 0.94 | 3.45 | 147.1 |

| 5 | 2 | 7.62 | 0.94 | 3.38 | 144.1 | |

| Younis [58] | 6 | 2 | 29.00 | 0.20 | 4.20 | 179.1 |

| Gul et al. [46] | 7 | 2.5 | 100.16 | 0.94 | 3.52 | 150.0 |

| 8 | 2.5 | 7.62 | 0.94 | 3.45 | 147.1 | |

| 9 | 3 | 100.16 | 0.94 | 3.59 | 152.9 | |

| 10 | 3 | 7.62 | 0.94 | 3.52 | 150.0 | |

| 11 | 3.5 | 100.16 | 0.94 | 3.99 | 170.3 | |

| 12 | 3.5 | 7.62 | 0.94 | 3.70 | 157.9 | |

| Average | 2.67 | 51.12 | 0.86 | 155.39 | ||

| 4% to 6% Fiber Content | ||||||

| Gul et al. [46] | 13 | 4 | 100.16 | 0.94 | 2.90 | 123.5 |

| 14 | 4 | 7.62 | 0.94 | 2.55 | 108.8 | |

| Younis [58] | 15 | 4 | 29.00 | 0.20 | 4.60 | 196.2 |

| 16 | 6 | 29.00 | 0.20 | 4.60 | 196.2 | |

| Average | 4.50 | 41.45 | 0.57 | - | 156.18 | |

| Author | Specimen No. in Figure 11 | Fiber Properties | Split Tensile Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 5 to 20 kg/m3 | kg/m3 | mm | mm | MPa | % a | |

| Sengul [49] | 1 | 5 | 52.00 | 0.30 | 5.60 | 84 |

| 2 | 10 | 52.00 | 0.30 | 6.50 | 97 | |

| 3 | 10 | 50.00 | 0.60 | 6.00 | 90 | |

| 4 | 15 | 52.00 | 0.30 | 6.60 | 99 | |

| 5 | 20 | 50.00 | 0.60 | 7.20 | 107 | |

| 6 | 20 | 50.00 | 1.40 | 6.80 | 101 | |

| 7 | 30 | 50.00 | 0.60 | 7.90 | 118 | |

| Average | 15.71 | 50.86 | 0.59 | - | 99 | |

| 20 to 60 kg/m3 | ||||||

| Sengul [49] | 8 | 40 | 50.00 | 0.60 | 9.00 | 134 |

| 9 | 40 | 50.00 | 1.40 | 7.20 | 107 | |

| Pawelska-Mazur and Kaszynska [21] | 10 | 50 | 17.50 | 0.25 | 3.87 | 143 |

| Sengul [49] | 11 | 60 | 50.00 | 1.40 | 7.00 | 104 |

| Peng et al. [28] | 12 | 60 | 30.00 | 1.00 | 8.75 | 127 |

| 13 | 60 | 35.00 | 1.00 | 9.39 | 136 | |

| Average | 51.67 | 38.75 | 0.94 | - | 125 | |

| Author | Specimen Number in Figure 12 | Fiber Properties | Flexure Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.20% to 0.80% Fiber Content | % a | mm | mm | MPa | % b | |

| Rossli and Ibrahim [37] | 1 | 0.2 | 62 | 0.80 | 5.45 | 102 |

| 2 | 0.4 | 62 | 0.80 | 7.49 | 140 | |

| Siraj and Kedir [47] Mix-I, C-25 | 3 | 0.5 | 20 | 0.89 | 6.84 | 111 |

| 4 | 0.5 | 40 | 0.89 | 6.96 | 113 | |

| 5 | 0.5 | 60 | 0.89 | 8.19 | 133 | |

| Siraj and Kedir [47] Mix-I, C-40 | 6 | 0.5 | 20 | 0.89 | 8.34 | 108 |

| 7 | 0.5 | 40 | 0.89 | 8.64 | 112 | |

| 8 | 0.5 | 60 | 0.89 | 9.24 | 120 | |

| Siraj and Kedir [47] Mix-I, C-60 | 9 | 0.5 | 20 | 0.89 | 8.85 | 101 |

| 10 | 0.5 | 40 | 0.89 | 9.09 | 104 | |

| 11 | 0.5 | 60 | 0.89 | 9.21 | 105 | |

| Skarżyński and Suchorzewski [54] | 12 | 0.5 | 26.17 | 0.25 | 4.67 | 130 |

| Rossli and Ibrahim [37] | 13 | 0.60 | 62 | 0.80 | 6.24 | 117 |

| 14 | 0.80 | 62 | 0.80 | 6.36 | 119 | |

| Average | 0.50 | 45.30 | 0.82 | 115.24 | ||

| 1% to 2% Fiber Content | ||||||

| Rossli and Ibrahim [37] | 15 | 1 | 62 | 0.80 | 6.321 | 118 |

| Köroğlu [62] | 16 | 1 | 45 | 0.245 | 3.60 | 171 |

| Siraj and Kedir [47] Mix-I, C-25 | 17 | 1 | 20 | 0.89 | 7.17 | 116 |

| 18 | 1 | 40 | 0.89 | 7.89 | 128 | |

| 19 | 1 | 60 | 0.89 | 10.08 | 163 | |

| Siraj and Kedir [47] Mix-I, C-40 | 20 | 1 | 20 | 0.89 | 8.46 | 110 |

| 21 | 1 | 40 | 0.89 | 9.60 | 124 | |

| 22 | 1 | 60 | 0.89 | 12.57 | 163 | |

| Siraj and Kedir [47] Mix-I, C-60 | 23 | 1 | 20 | 0.89 | 9.30 | 107 |

| 24 | 1 | 40 | 0.89 | 12.00 | 138 | |

| 25 | 1 | 60 | 0.89 | 12.84 | 147 | |

| Abdul Awal et al. [53] | 26 | 1 | 30 | - | 5.75 | 125 |

| Siraj and Kedir [47] Mix-I, C-25 | 27 | 1.5 | 20 | 0.89 | 8.07 | 131 |

| 28 | 1.5 | 40 | 0.89 | 8.64 | 140 | |

| 29 | 1.5 | 60 | 0.89 | 13.71 | 222 | |

| Siraj and Kedir [47] Mix-I, C-40 | 30 | 1.5 | 20 | 0.89 | 8.7 | 113 |

| 31 | 1.5 | 40 | 0.89 | 9.60 | 124 | |

| 32 | 1.5 | 60 | 0.89 | 14.79 | 192 | |

| Siraj and Kedir [47] Mix-I, C-60 | 33 | 1.5 | 20 | 0.89 | 11.37 | 130 |

| 34 | 1.5 | 40 | 0.89 | 13.53 | 155 | |

| 35 | 1.5 | 60 | 0.89 | 16.14 | 185 | |

| Abdul Awal et al. [53] | 36 | 1.5 | 30 | - | 6.15 | 134 |

| 37 | 2 | 30 | - | 6.95 | 151 | |

| Köroğlu [62] | 38 | 2 | 45 | 0.245 | 3.90 | 186 |

| Köroğlu [62] | 39 | 3 | 45 | 0.245 | 5.40 | 257 |

| Köroğlu [62] | 40 | 4 | 45 | 0.245 | 11.70 | 557 |

| Köroğlu [62] | 41 | 5 | 45 | 0.245 | 11.10 | 529 |

| Average | 1.59 | 41 | 0.75 | 178 | ||

| Author | Specimen Number in Figure 14 | Fiber Properties | Flexure Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.25% to 1% Fiber Content | % a | mm | mm | MPa | % b | |

| Shah et al. [60] | 1 | 0.10 | 31.00 | - | 5.23 | 116 |

| 2 | 0.25 | 31.00 | - | 5.7 | 127 | |

| Akhtar et al. [61] | 3 | 0.25 | 30.00 | 1.10 | 9.3 | 124 |

| Shah et al. [60] | 4 | 0.50 | 31.00 | - | 6.41 | 142 |

| Akhtar et al. [61] | 5 | 0.50 | 30.00 | 1.10 | 11.8 | 157 |

| Shah et al. [60] | 6 | 0.75 | 31.00 | - | 5.63 | 125 |

| 7 | 1 | 31.00 | - | 5.53 | 123 | |

| Akhtar et al. [61] | 8 | 1 | 30.00 | 1.10 | 12.8 | 171 |

| Average | 0.54 | 30.63 | 1.10 | 136 | ||

| 2% to 3.5% Fiber Content | ||||||

| Akhtar et al. [46] | 9 | 2 | 100.16 | 0.94 | 7.17 | 179 |

| 10 | 2 | 7.62 | 0.94 | 6.34 | 159 | |

| Younis [58] | 11 | 2 | 29.00 | 0.20 | 4.60 | 100 |

| Graeff et al. [59] | 12 | 2 | 13.00 | 0.20 | 6.47 | 135 |

| Gul et al. [46] | 13 | 2.5 | 100.16 | 0.94 | 7.72 | 193 |

| 14 | 2.5 | 7.62 | 0.94 | 6.62 | 166 | |

| 15 | 3 | 100.16 | 0.94 | 8.97 | 224 | |

| 16 | 3 | 7.62 | 0.94 | 7.45 | 186 | |

| 17 | 3.5 | 100.16 | 0.94 | 10.5 | 262 | |

| 18 | 3.5 | 7.62 | 0.94 | 8.14 | 203 | |

| Average | 2.60 | 47.31 | 0.79 | 181 | ||

| 4% to 6% Fiber Content | ||||||

| Gul et al. [46] | 19 | 4 | 100.16 | 0.94 | 9.1 | 228 |

| 20 | 4 | 7.62 | 0.94 | 8.9 | 222 | |

| Younis [58] | 21 | 4 | 29.00 | 0.20 | 5 | 109 |

| 22 | 6 | 29.00 | 0.20 | 4.8 | 104 | |

| Graeff et al. [59] | 23 | 6 | 13 | 0.2 | 7.11 | 148 |

| Average | 4.80 | 35.76 | 0.50 | 162 | ||

| Author | Specimen Number in Figure 15 | Fiber Properties | Flexure Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 5 to 20 kg/m3 | kg/m3 | mm | mm | MPa | % a | |

| Sengul [49] | 1 | 5 | 52.00 | 0.30 | 7.40 | 132 |

| 2 | 10 | 52.00 | 0.30 | 5.10 | 91 | |

| 3 | 10 | 50.00 | 0.60 | 5.70 | 102 | |

| 4 | 15 | 52.00 | 0.30 | 7.20 | 129 | |

| 5 | 20 | 50.00 | 0.60 | 5.40 | 96 | |

| 6 | 20 | 50.00 | 1.40 | 6.80 | 121 | |

| Average | - | 13.33 | 51.00 | 0.58 | - | 112 |

| 30 to 60 kg/m3 | ||||||

| Sengul [49] | 7 | 30 | 50.00 | 0.60 | 7.70 | 138 |

| 8 | 40 | 50.00 | 0.60 | 9.40 | 168 | |

| 9 | 40 | 50.00 | 1.40 | 6.70 | 120 | |

| 10 | 60 | 50.00 | 1.40 | 6.70 | 120 | |

| Average | - | 42.5 | 50.00 | 1.00 | - | 136 |

| Author | Specimen Number in Figure 16 | Fiber Properties | Compressive Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.10% b to 1% b Fiber | % b | mm | mm | MPa | % c | |

| Shi et al. [66] | 1 | 0.01 | 14.9 | 0.32 | 44.1 | 99.3 |

| 2 | 0.02 | 14.9 | 0.32 | 48.9 | 110.3 | |

| Mastali and Dalvand [52] | 3 | 0.35 | 50 | 0.15 | 57.3 | 109.0 |

| Al-musawi et al. [32] (0.21 Sp) d | 4 | 0.57 | 21 | 0.20 | 43.0 | 111.7 |

| Al-musawi et al. [32] (0.60 Sp) d | 5 | 0.57 | 21 | 0.20 | 47.0 | 135.1 |

| Mastali and Dalvand [52] | 6 | 0.70 | 50 | 0.15 | 61.7 | 117.4 |

| Average | 0.37 | 28.63 | 0.22 | 113.8 | ||

| 1% b to 3% b Fiber | ||||||

| Dehghanpour and Yılmaz [33] | 7 | 1.00 | 25.00 | 0.26 | 62.7 | 109.8 |

| Mastali and Dalvand [52] | 8 | 1.05 | 50.00 | 0.15 | 65.8 | 125.2 |

| Dehghanpour and Yılmaz [33] | 9 | 1.50 | 25.00 | 0.26 | 66.6 | 116.6 |

| Zamanzadeh et al. [67] | 10 | 1.50 | 31.70 | 0.92 | 21.2 | 95.5 |

| Mastali et al. [24] | 11 | 1.50 | 50.00 | 0.15 | 73.0 | 146.0 |

| Dehghanpour and Yılmaz [33] | 12 | 2.00 | 25.00 | 0.26 | 70.5 | 123.3 |

| 13 | 2.50 | 25.00 | 0.26 | 64.6 | 112.9 | |

| Zamanzadeh et al. [67] | 14 | 3.00 | 31.70 | 0.92 | 22.1 | 99.5 |

| Average | 1.76 | 32.93 | 0.40 | 116.1 | ||

| Author | Specimen Number in Figure 18 | Fiber Properties | Flexure Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.35% b to 0.70% b Fiber | % b | mm | mm | MPa | % c | |

| Mastali and Dalvand [52] | 1 | 0.35 | 50 | 0.15 | 4.75 | 110 |

| Al-musawi et al. [68] | 2 | 0.57 | 21 | 0.20 | 8.60 | 169 |

| 3 | 0.57 | 21 | 0.20 | 5.50 | 131 | |

| Mastali and Dalvand [52] | 4 | 0.70 | 50 | 0.15 | 4.85 | 113 |

| Average | 0.55 | 35.50 | 0.18 | 131 | ||

| 1% b to 3% b Fiber | ||||||

| Dehghanpour and Yılmaz [33] | 5 | 1.00 | 25.00 | 0.26 | 6.83 | 131 |

| Mastali and Dalvand [52] | 6 | 1.05 | 50.00 | 0.15 | 5.15 | 119 |

| Dehghanpour and Yılmaz [33] | 7 | 1.50 | 25.00 | 0.26 | 7.34 | 141 |

| Zamanzadeh et al. [67] | 8 | 1.50 | 31.70 | 0.92 | 8.43 | 141 |

| Mastali et al. [24] | 9 | 1.50 | 50.00 | 0.15 | 8.20 | 125 |

| Dehghanpour and Yılmaz [33] | 10 | 2.00 | 25.00 | 0.26 | 8.09 | 155 |

| 11 | 2.50 | 25.00 | 0.26 | 8.19 | 157 | |

| Zamanzadeh et al. [67] | 12 | 3.00 | 31.70 | 0.92 | 8.88 | 148 |

| Average | 1.76 | 32.93 | 0.40 | 140 | ||

| Author | Fiber | fc′ | √fc′ | STS | STS/√(fc′) |

|---|---|---|---|---|---|

| % a | MPa | MPa | |||

| Rossli and Ibrahim [37] | 0.20 | 51.99 | 7.21 | 3.39 | 0.47 |

| 0.40 | 59.17 | 7.69 | 3.99 | 0.52 | |

| 0.60 | 34.50 | 5.87 | 3.90 | 0.66 | |

| 0.80 | 40.13 | 6.33 | 3.50 | 0.55 | |

| 1.00 | 28.05 | 5.30 | 4.44 | 0.84 | |

| M. Leone et al. [41] | 0.46 | 22.00 | 4.69 | 4.55 | 0.97 |

| Samarakoon et al. [25] | 0.50 | 30.60 | 5.53 | 2.58 | 0.47 |

| 1.00 | 55.85 | 7.47 | 2.49 | 0.33 | |

| Abdul Awal et al. [53] | 1.00 | 58.20 | 7.63 | 7.10 | 0.93 |

| 1.50 | 59.00 | 7.68 | 8.15 | 1.06 | |

| 2.00 | 42.91 | 6.55 | 9.45 | 1.44 | |

| Skarżyński and Suchorzewski [54] | 0.50 | 39.08 | 6.25 | 3.87 | 0.62 |

| Aiello et al. [44] | 0.23 | 38.47 | 6.20 | 2.70 | 0.44 |

| 0.46 | 50.03 | 7.07 | 2.54 | 0.36 | |

| Dorr et al. [56] | 0.50 | 31.30 | 5.59 | 1.80 | 0.32 |

| Average | 0.67 |

| Author | Fiber | fc′ | √fc′ | FS | FS | FS/√(fc′) |

|---|---|---|---|---|---|---|

| % a | MPa | - | MPa | % b | - | |

| Rossli and Ibrahim [37] | 0.20 | 51.99 | 7.21 | 5.45 | 101.76 | 0.76 |

| 0.40 | 59.17 | 7.69 | 7.49 | 139.79 | 0.97 | |

| 0.60 | 34.50 | 5.87 | 6.24 | 116.58 | 1.06 | |

| 0.80 | 40.13 | 6.33 | 6.36 | 118.73 | 1.00 | |

| 1.00 | 28.05 | 5.30 | 6.32 | 118.04 | 1.19 | |

| Siraj and Kedir [47] (Mix-I, C-25) | 0.50 | 27.97 | 5.29 | 6.84 | 111 | 1.29 |

| 0.50 | 28.20 | 5.31 | 6.96 | 113 | 1.31 | |

| 0.50 | 28.23 | 5.31 | 8.19 | 133 | 1.54 | |

| 1.00 | 27.94 | 5.29 | 7.17 | 116 | 1.36 | |

| 1.00 | 29.09 | 5.39 | 7.89 | 128 | 1.46 | |

| 1.00 | 27.72 | 5.26 | 10.08 | 163 | 1.91 | |

| 1.50 | 28.95 | 5.38 | 8.07 | 131 | 1.50 | |

| 1.50 | 31.35 | 5.60 | 8.64 | 140 | 1.54 | |

| 1.50 | 41.03 | 6.41 | 13.71 | 222 | 2.14 | |

| Siraj and Kedir [47] (Mix-II, C-40) | 0.50 | 40.92 | 6.40 | 8.34 | 108 | 1.30 |

| 0.50 | 41.51 | 6.44 | 8.64 | 112 | 1.34 | |

| 0.50 | 41.58 | 6.45 | 9.24 | 120 | 1.43 | |

| 1.00 | 41.32 | 6.43 | 8.46 | 110 | 1.32 | |

| 1.00 | 43.66 | 6.61 | 9.60 | 124 | 1.45 | |

| 1.00 | 41.06 | 6.41 | 12.57 | 163 | 1.96 | |

| 1.50 | 41.78 | 6.46 | 8.70 | 113 | 1.35 | |

| 1.50 | 43.94 | 6.63 | 9.60 | 124 | 1.45 | |

| 1.50 | 58.40 | 7.64 | 14.79 | 192 | 1.94 | |

| Siraj and Kedir [47] (Mix-III, C-60) | 0.50 | 58.98 | 7.68 | 8.85 | 101 | 1.15 |

| 0.50 | 60.45 | 7.77 | 9.09 | 104 | 1.17 | |

| 0.50 | 56.25 | 7.50 | 9.21 | 105 | 1.23 | |

| 1.00 | 60.56 | 7.78 | 9.30 | 107 | 1.20 | |

| 1.00 | 60.52 | 7.78 | 12.00 | 137 | 1.54 | |

| 1.00 | 59.50 | 7.71 | 12.84 | 147 | 1.66 | |

| 1.50 | 62.41 | 7.90 | 11.37 | 130 | 1.44 | |

| 1.50 | 59.17 | 7.69 | 13.53 | 155 | 1.76 | |

| 1.50 | 33.61 | 5.80 | 16.14 | 185 | 2.78 | |

| Abdul Awal et al. [53] | 1.00 | 58.20 | 7.63 | 5.75 | 125 | 0.75 |

| 1.50 | 59.00 | 7.68 | 6.15 | 134 | 0.80 | |

| 2.00 | 42.91 | 6.55 | 6.95 | 151 | 1.06 | |

| Skarżyński and Suchorzewski [54] | 0.50 | 39.08 | 6.25 | 4.67 | 130 | 0.75 |

| Average | 1.39 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zia, A.; Pu, Z.; Holly, I.; Umar, T.; Tariq, M.A.U.R.; Sufian, M. A Comprehensive Review of Incorporating Steel Fibers of Waste Tires in Cement Composites and Its Applications. Materials 2022, 15, 7420. https://doi.org/10.3390/ma15217420

Zia A, Pu Z, Holly I, Umar T, Tariq MAUR, Sufian M. A Comprehensive Review of Incorporating Steel Fibers of Waste Tires in Cement Composites and Its Applications. Materials. 2022; 15(21):7420. https://doi.org/10.3390/ma15217420

Chicago/Turabian StyleZia, Asad, Zhang Pu, Ivan Holly, Tariq Umar, Muhammad Atiq Ur Rehman Tariq, and Muhammad Sufian. 2022. "A Comprehensive Review of Incorporating Steel Fibers of Waste Tires in Cement Composites and Its Applications" Materials 15, no. 21: 7420. https://doi.org/10.3390/ma15217420