Finite Element Analysis of Self-Healing Concrete Beams Using Bacteria

Abstract

:1. Introduction

- Bacteria concentration (1%, 2% and 3%);

- Type of bacteria (Bacillus subtilis, E. coli and Pseudomonas sps.);

- Case of loading (One-point load, two-point load, and distributed load on four points).

2. Materials and Methods

2.1. Modeling Assumptions

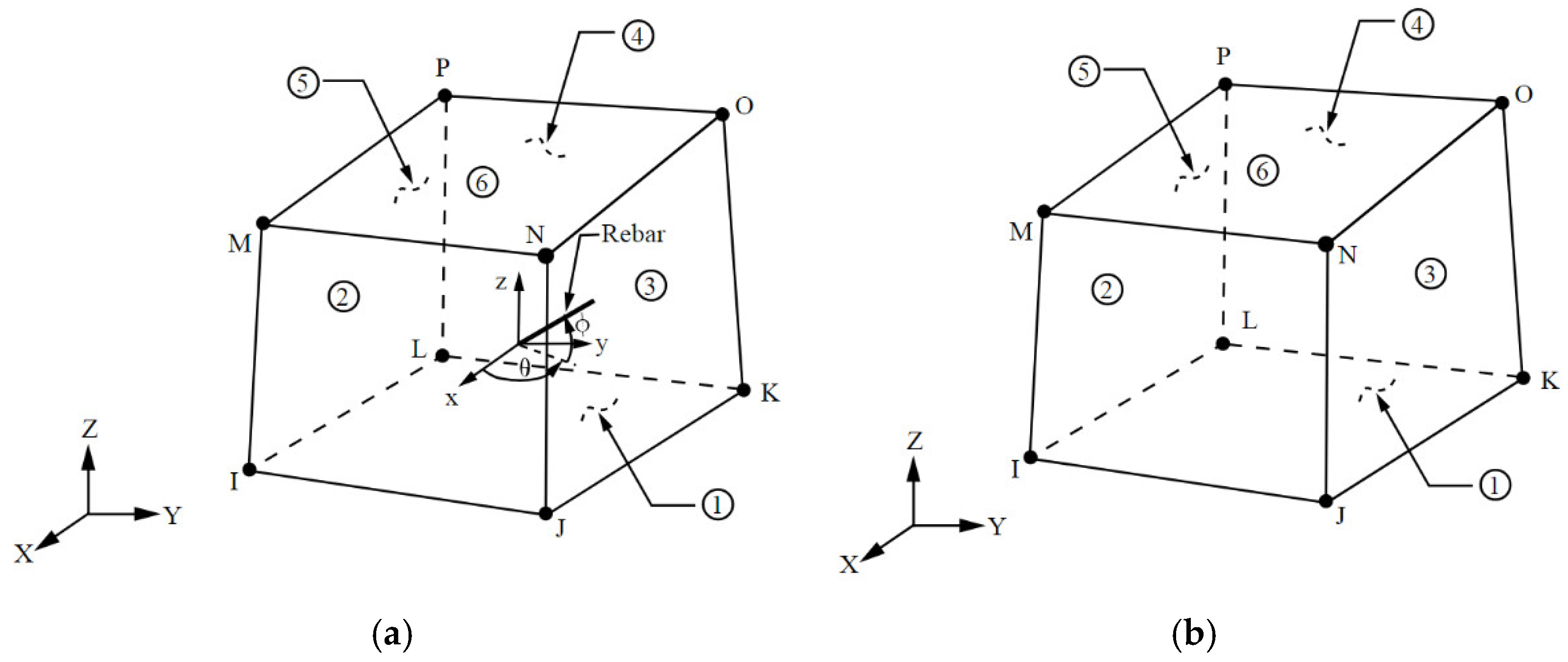

2.2. Description of Elements

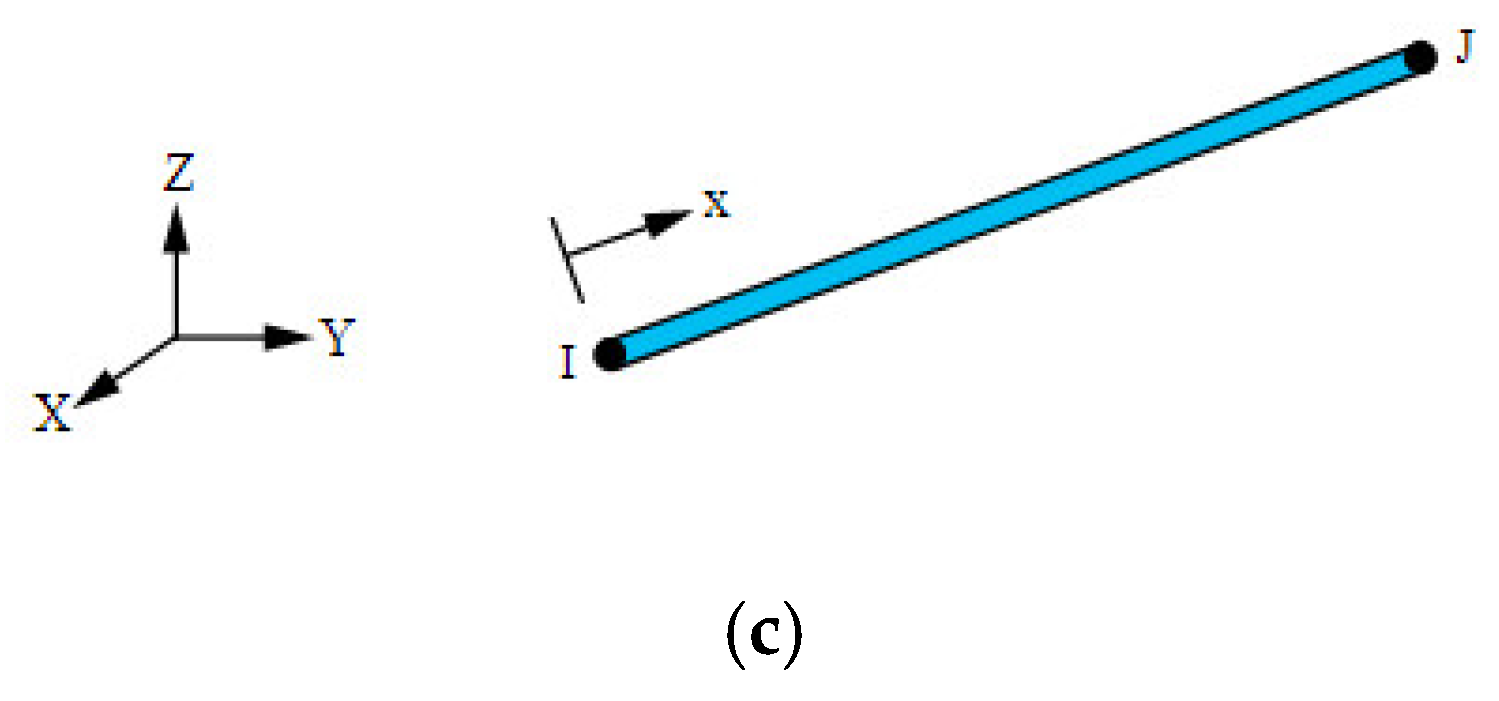

2.3. Verification Models

- Control Specimen (CS);

- Bacterial concrete beam with fly ash (BCFA).

2.4. Parametric Study

3. Results and Discussion

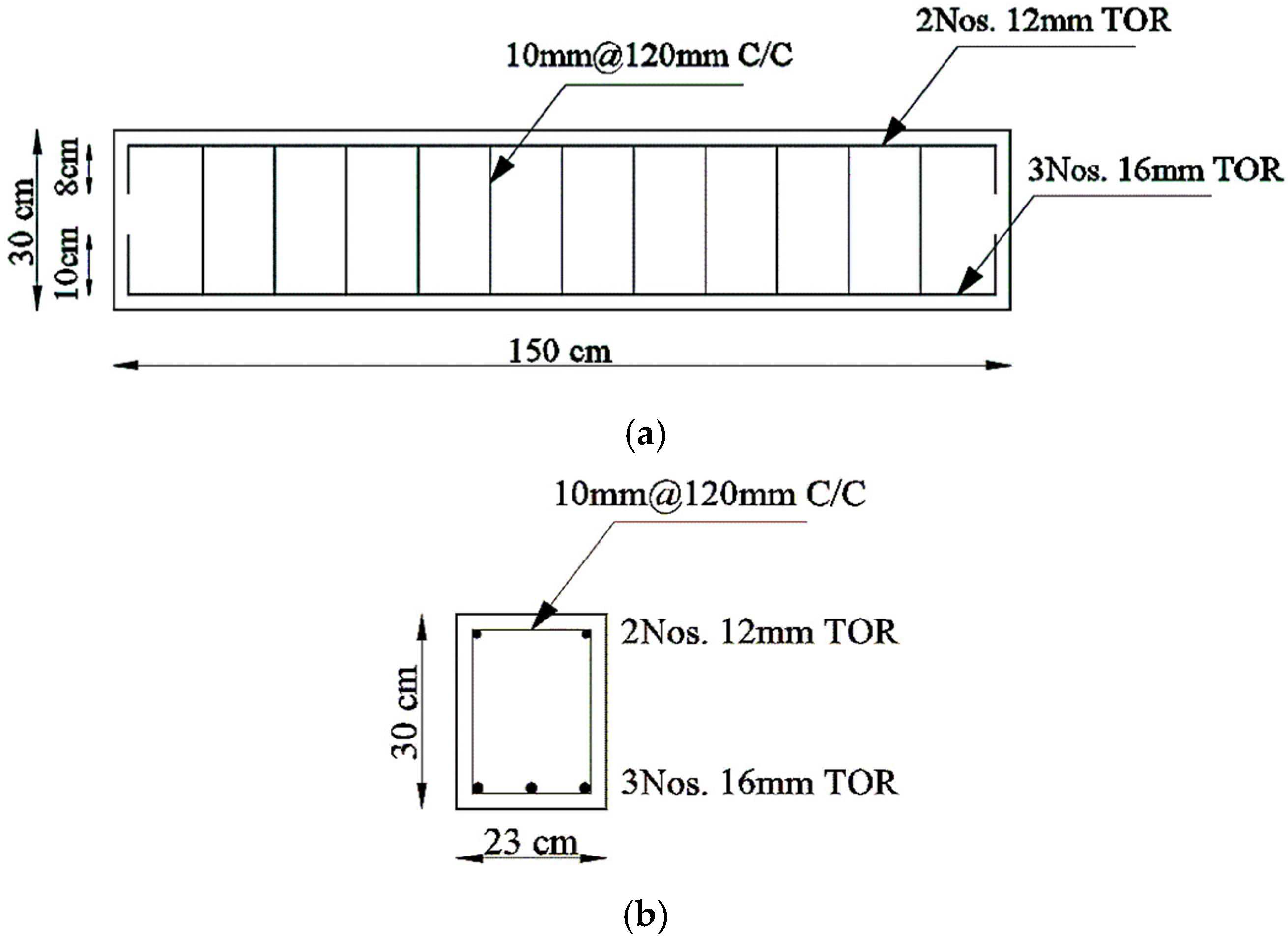

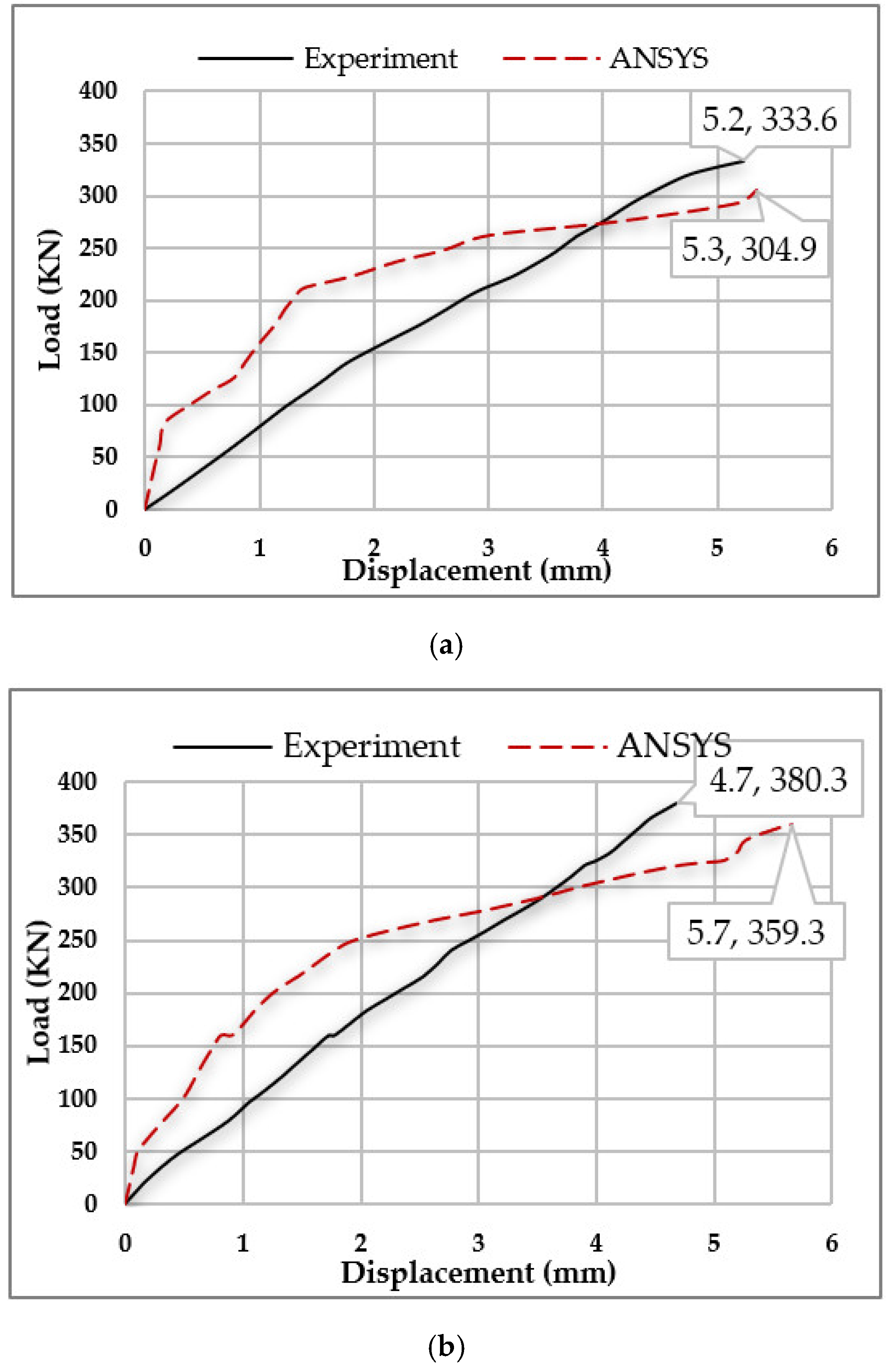

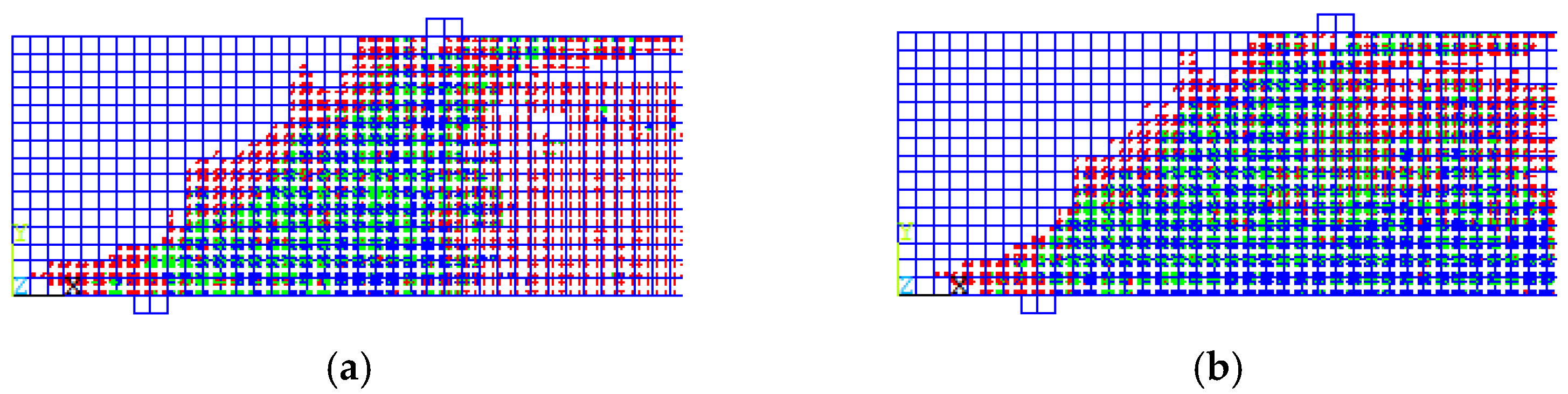

3.1. Results of the Verification Models

- (Pans)/(Pexp)% for the control specimen (CS) = 91.4%;

- (Pans)/(Pexp)% for the bacterial concrete beam with fly ash (BCFA) = 94.5%.

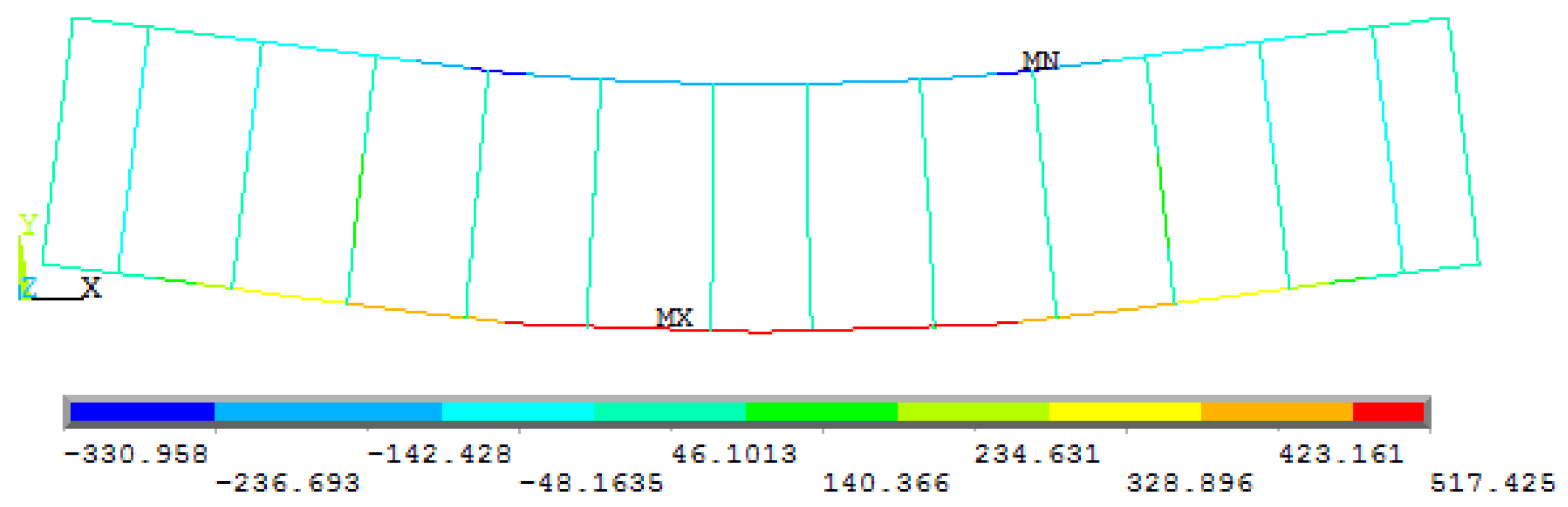

3.2. Results of the Parametric Study

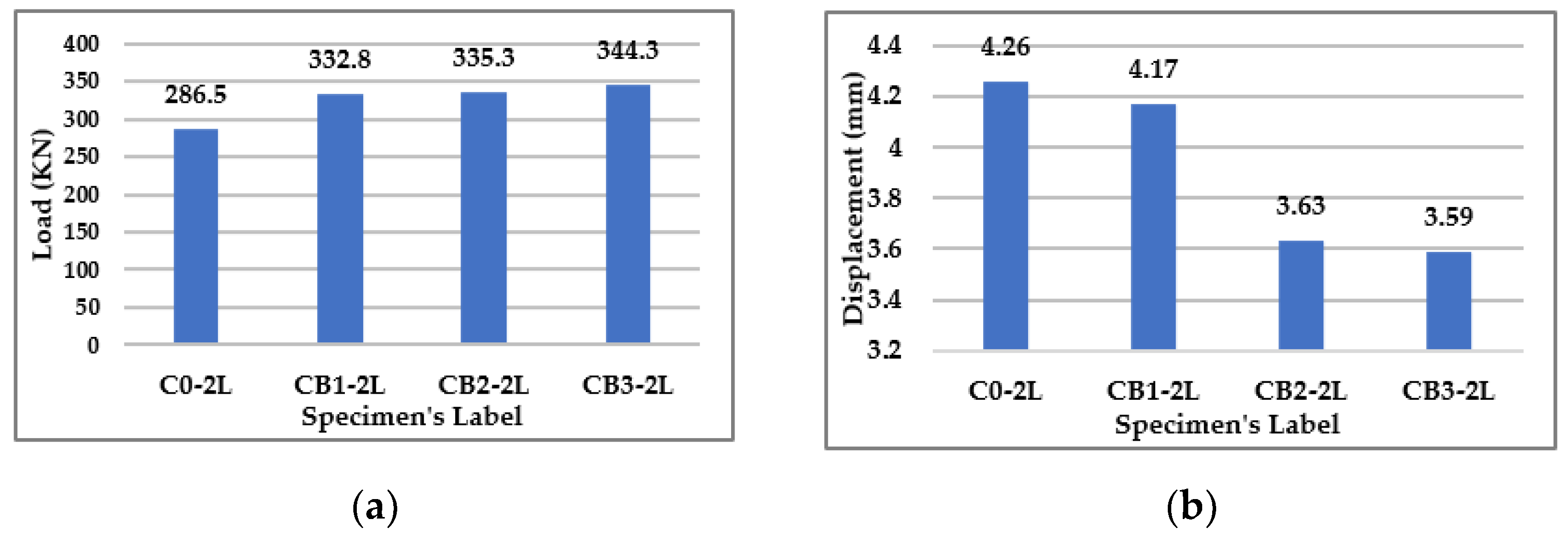

3.2.1. Concentration of Bacteria

3.2.2. Type of Bacteria

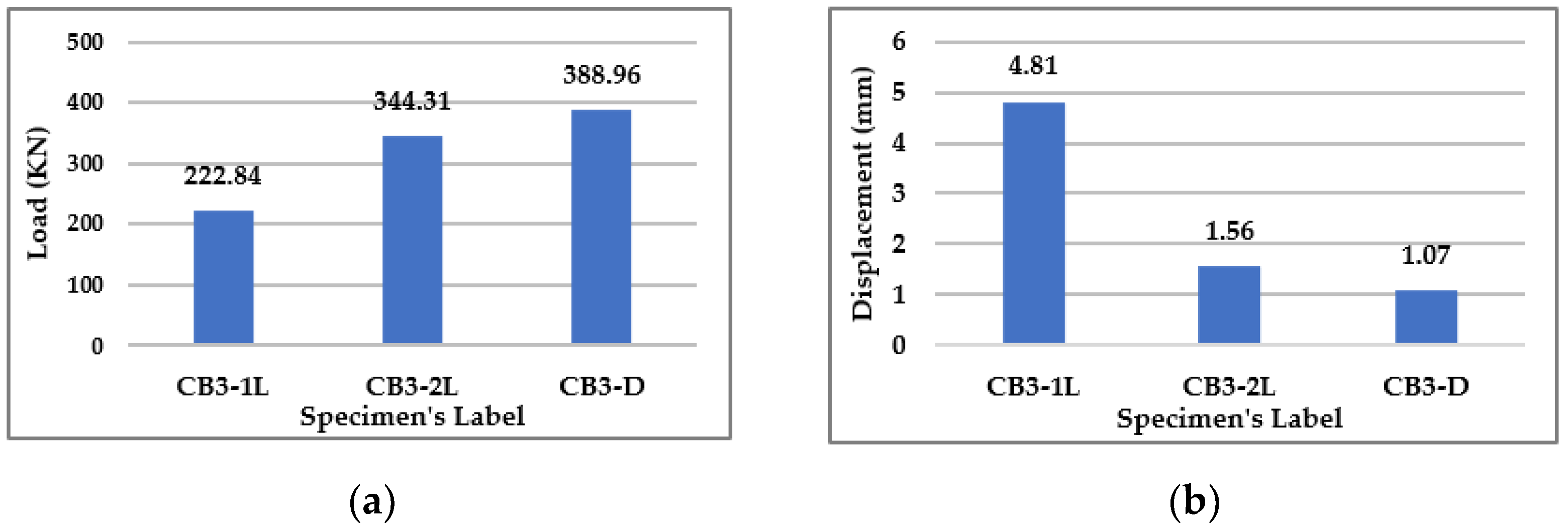

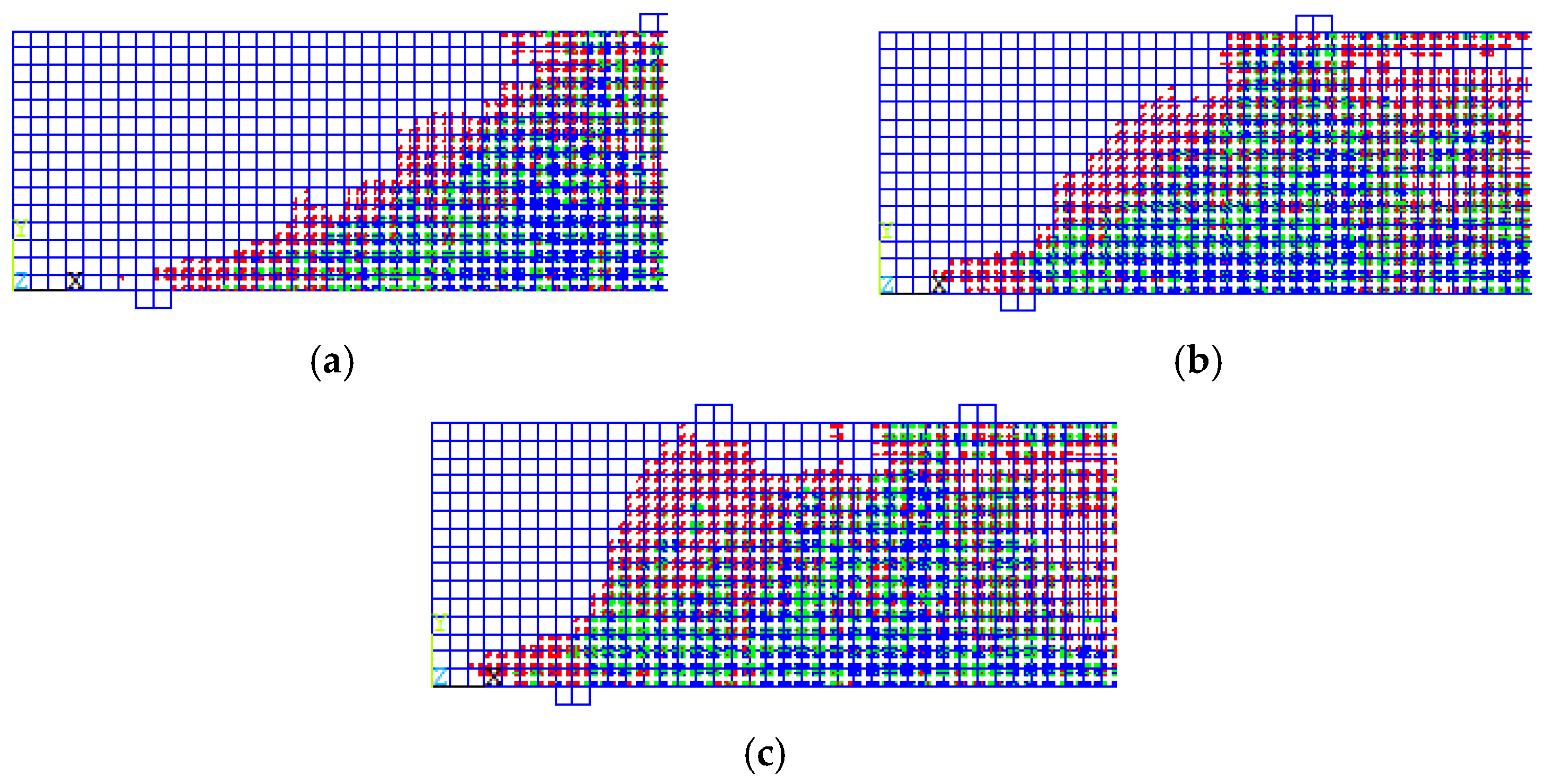

3.2.3. Loading Cases

4. Conclusions

- The ANSYS failure loads (Pans) represented 91.4% to 94.5% of the experimental failure loads (Pexp) which is good agreement with the verification models:

- a.

- (Pans)/(Pexp)% for the control specimen (CS) = 91.4%

- b.

- (Pans)/(Pexp)% for the bacterial concrete beam with fly ash (BCFA) = 94.5%;

- Adding bacteria to the reinforced concrete beams increased their capacity and decreased the deflection, depending on the bacteria type and concentration;

- The Bacillus subtilis was the optimum type of bacteria and had a higher significant effect than the E. coli and Pseudomonas sps. especially with a concentration of 3%, as it increased the capacity of the beam by 20.2% and decreased the deflection by 15.7%, compared to the control specimen without bacteria;

- Adding 1% and 2% of Bacillus subtilis to the reinforced concrete beams had approximately the same effect on the beam’s capacity, which increased by 16.2% and 17%, respectively, compared to the control specimen without bacteria;

- Adding 1% Bacillus subtilis to the reinforced concrete beam had no effect on deflection, as it decreased the deflection by 2% only;

- The use of Pseudomonas sps., even with a concentration of 3%, was unable to decrease the deflection at all;

- Distributing the load on many points enhanced the beam’s capacity to support more than a concentrated load on one or two points, as the beam with the distributed load on four points had a higher capacity by 74.5% than the one-point loaded beam, and by 13% than the two-point loaded beam. Also, the deflection decreased for the beam with a distributed load on four points by 77.8% when it was compared to the one-point loaded beam, and 67.6% when it was compared to the two-point loaded beam.

Future Directions and Limitations

- Low and high temperature;

- The structures’ scale;

- Carrying out an experimental study;

- Changing the nutrition type for bacteria;

- Using capsules to preserve bacteria inside the concrete until cracks occur;

- Adding bacteria to the marine concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hager, M.D.; Greil, P.; Leyens, C.; van der Zwaag, S.; Schubert, U.S. Self-Healing Materials. Adv. Mater. 2010, 22, 5424–5430. [Google Scholar] [CrossRef]

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. 2008, 33, 479–522. [Google Scholar] [CrossRef]

- Guimard, N.K.; Oehlenschlaeger, K.K.; Zhou, J.; Hilf, S.; Schmidt, F.G.; Barner-Kowollik, C. Current Trends in the Field of Self-Healing Materials. Macromol. Chem. Phys. 2012, 213, 131–143. [Google Scholar] [CrossRef]

- Billiet, S.; Hillewaere, X.K.D.; Teixeira, R.F.A.; Du Prez, F.E. Chemistry of Crosslinking Processes for Self-Healing Polymers. Macromol. Rapid Commun. 2013, 34, 290–309. [Google Scholar] [CrossRef] [PubMed]

- Banthia, N.; Biparva, A.; Mindess, S. Permeability of concrete under stress. Cem. Concr. Res. 2005, 35, 1651–1655. [Google Scholar] [CrossRef]

- Yang, Z.; Hollar, J.; He, X.; Shi, X. A self-healing cementitious composite using oil core/silica gel shell microcapsules. Cem. Concr. Compos. 2011, 33, 506–512. [Google Scholar] [CrossRef]

- Lun, H.; Lackner, R. Permeability of concrete under thermal and compressive stress influence; an experimental study. MATEC Web Conf. 2013, 6, 03007. [Google Scholar] [CrossRef]

- Picandet, V.; Khelidj, A.; Bellegou, H. Crack effects on gas and water permeability of concretes. Cem. Concr. Res. 2009, 39, 537–547. [Google Scholar] [CrossRef] [Green Version]

- Dong, B.; Fang, G.; Wang, Y.; Liu, Y.; Hong, S.; Zhang, J.; Lin, S.; Xing, F. Performance recovery concerning the permeability of concrete by means of a microcapsule based self-healing system. Cem. Concr. Compos. 2017, 78, 84–96. [Google Scholar] [CrossRef]

- Huseien, G.F.; Mirza, J.; Ismail, M.; Ghoshal, S.K.; Ariffin, M.A.M. Effect of metakaolin replaced granulated blast furnace slag on fresh and early strength properties of geopolymer mortar. Ain Shams Eng. J. 2018, 9, 1557–1566. [Google Scholar] [CrossRef]

- Li, W.; Dong, B.; Yang, Z.; Xu, J.; Chen, Q.; Li, H.; Xing, F.; Jiang, Z. Recent Advances in Intrinsic Self-Healing Cementitious Materials. Adv. Mater. 2018, 30, 1705679. [Google Scholar] [CrossRef]

- Van Breugel, K. Is there a Market for Self-Healing Cement-Based Systems in the Building Industry. In Proceedings of the First International Conference on Self Healing Materials, Noordwijk aan Zee, The Netherlands, 18–20 April 2007; pp. 1–9. [Google Scholar]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Schlangen, E.; Jonkers, H. A Two Component Bacteria-Based Self-Healing Concrete. Concrete Repair, Rehabilitation and Retrofitting II; CRC Press: Boca Raton, FL, USA, 2008; pp. 119–120. [Google Scholar]

- Jonkers, H.; Schlangen, E. Development of a Bacteria-Based Self Healing Concrete. Tailor Made Concrete Structures; CRC Press: Boca Raton, FL, USA, 2008; p. 109. [Google Scholar]

- Jonkers, H.M. Bacteria-based self-healing concrete. Heron 2011, 56, 5–16. [Google Scholar]

- Luo, M.; Qian, C.; Li, R. Factors affecting crack repairing capacity of bacteria-based self-healing concrete. Constr. Build. Mater. 2015, 87, 1–7. [Google Scholar] [CrossRef]

- Khaliq, W.; Ehsan, M.B. Crack healing in concrete using various bio influenced self-healing techniques. Constr. Build. Maters. 2016, 102, 349–357. [Google Scholar] [CrossRef]

- Lors, C.; Ducasse-Lapeyrusse, J.; Gagné, R.; Damidot, D. Microbiologically induced calcium carbonate precipitation to repair microcracks remaining after autogenous healing of mortars. Constr. Build. Mater. 2017, 141, 461–469. [Google Scholar] [CrossRef]

- Hosseini Balam, N.; Mostofinejad, D.; Eftekhar, M. Effects of bacterial remediation on compressive strength, water absorption, and chloride permeability of lightweight aggregate concrete. Constr. Build. Mater. 2017, 145, 107–116. [Google Scholar] [CrossRef]

- Achal, V.; Mukerjee, A.; Sudhakara Reddy, M. Biogenic treatment improves the durability and remediates the cracks of concrete structures. Constr. Build. Mater. 2013, 48, 1–5. [Google Scholar] [CrossRef]

- Alshalif, A.F.; Irwan, J.M.; Othman, N.; Anneza, L.H. Isolation of Sulphate Reduction Bacteria (SRB) to Improve Compress Strength and Water Penetration of Bio-Concrete. MATEC Web Conf. 2016, 47, 01016. [Google Scholar] [CrossRef] [Green Version]

- O’Connell, M.; McNally, C.; Richardson, M.G. Biochemical attack on concrete in wastewater applications: A state of the art review. Cem. Concr. Compos. 2010, 32, 479–485. [Google Scholar] [CrossRef]

- Erşan, Y.Ç.; Hernandez-Sanabria, E.; Boon, N.; de Belie, N. Enhanced crack closure performance of microbial mortar through nitrate reduction. Cem. Concr. Compos. 2016, 70, 159–170. [Google Scholar] [CrossRef]

- Erşan, Y.Ç.; Verbruggen, H.; De Graeve, I.; Verstraete, W.; De Belie, N.; Boon, N. Nitrate reducing CaCO3 precipitating bacteria survive in mortar and inhibit steel corrosion. Cem. Concr. Res. 2016, 83, 19–30. [Google Scholar] [CrossRef]

- Wiktor, V.; Jonkers, H.M. Quantification of crack-healing in novel bacteria-based self-healing concrete. Cem. Concr. Compos. 2011, 33, 763–770. [Google Scholar] [CrossRef]

- Mirshahmohammad, M.; Rahmani, H.; Maleki-Kakelar, M.; Bahari, A. Effect of sustained service loads on the self-healing and corrosion of bacterial concretes. Constr. Build. Mater. 2022, 322, 126423. [Google Scholar] [CrossRef]

- Shashank, B.S.; Nagaraja, P.S. Fracture behavior study of self-healing bacterial concrete. Mater. Today Proc. 2022, 60, 267–274. [Google Scholar] [CrossRef]

- Rohini, I.; Padmapriya, R.; Anusuya, R.; Sudarsan, J.S.; Nithiyanantham, S. Valuation of characteristics strength by utilizing Construction and Demolition (C&D) waste as Recycled Aggregates (RA) in concrete. J. Build. Pathol. Rehabil. 2021, 6, 27. [Google Scholar]

- Aliko-Benítez, A.; Doblaré, M.; Sanz-Herrera, J.A. Chemical-diffusive modeling of the self-healing behavior in concrete. Int. J. Solids Struct. 2015, 69–70, 392–402. [Google Scholar] [CrossRef]

- Zemskov, S.V.; Jonkers, H.M.; Vermolen, F.J. A mathematical model for bacterial self-healing of cracks in concrete. J. Intell. Mater. Syst. Struct. 2014, 25, 4–12. [Google Scholar] [CrossRef]

- Milan, J.; Sneha, M.V. Experimental Study on Strength Characteristics of Self—Healing Concrete with Fly Ash. IJERT 2018, 6, 1–4. [Google Scholar]

- Sundravel, K.V.; Ramesh, S.; Jegatheeswaran, D. Design and formulation of microbially induced self-healing concrete for building structure strength enhancement. Mater. Express. 2021, 11, 1753–1765. [Google Scholar] [CrossRef]

| Specimen Label | Specimen Details | Compressive Strength MPa | Tensile Strength MPa |

|---|---|---|---|

| CS | Control specimen | 31.11 | 3.53 |

| BCFA | Bacterial concrete with fly ash | 36.44 | 3.89 |

| Group No. | Specimen’s Label | Specimen’s Detail | Type of Bacteria | Bacteria’s Concentration | Case of Loading |

|---|---|---|---|---|---|

| 1 | C0-2L | Control | - | - | Two-Point Loads |

| CB1-2L | Bacterial Concrete | Bacillus subtilis | 1% | Two-Point Loads | |

| CB2-2L | Bacterial Concrete | Bacillus subtilis | 2% | Two-Point Loads | |

| CB3-2L | Bacterial Concrete | Bacillus subtilis | 3% | Two-Point Loads | |

| 2 | C0-2L | Control | - | - | Two-Point Loads |

| CB3-2L | Bacterial Concrete | Bacillus subtilis | 3% | Two-Point Loads | |

| CE3-2L | Bacterial Concrete | E. coli | 3% | Two-Point Loads | |

| CP3-2L | Bacterial Concrete | Pseudomonas sps. | 3% | Two-Point Loads | |

| 3 | CB3-1L | Bacterial Concrete | Bacillus subtilis | 3% | One-Point Load |

| CB3-2L | Bacterial Concrete | Bacillus subtilis | 3% | Two-Point Loads | |

| CB3-D | Bacterial Concrete | Bacillus subtilis | 3% | Distributed |

| Type of Bacteria | Bacteria’s Concentration | Compressive Strength MPa | Tensile Strength MPa |

|---|---|---|---|

| Control | - | 30 | 4 |

| Bacillus subtilis | 1% | 33.6 | 4.09 |

| Bacillus subtilis | 2% | 36.58 | 4.22 |

| Bacillus subtilis | 3% | 38.95 | 4.3 |

| E. coli | 3% | 34.67 | 4.17 |

| Pseudomonas sps. | 3% | 33.74 | 4.13 |

| Specimen’s Label | Experimental Failure Load (Pexp) (KN) | Experimental Displacement (mm) | ANSYS Failure Load (Pans) (KN) | ANSYS Displacement (mm) | Pans/Pexp% |

|---|---|---|---|---|---|

| CS | 333.6 | 5.2 | 304.9 | 5.3 | 91.4% |

| BCFA | 380.3 | 4.7 | 359.3 | 5.7 | 94.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salem, G.G.; Galishnikova, V.V.; Elroba, S.M.; Vatin, N.I.; Kharun, M. Finite Element Analysis of Self-Healing Concrete Beams Using Bacteria. Materials 2022, 15, 7506. https://doi.org/10.3390/ma15217506

Salem GG, Galishnikova VV, Elroba SM, Vatin NI, Kharun M. Finite Element Analysis of Self-Healing Concrete Beams Using Bacteria. Materials. 2022; 15(21):7506. https://doi.org/10.3390/ma15217506

Chicago/Turabian StyleSalem, Ghada G., Vera V. Galishnikova, S. M. Elroba, Nikolai I. Vatin, and Makhmud Kharun. 2022. "Finite Element Analysis of Self-Healing Concrete Beams Using Bacteria" Materials 15, no. 21: 7506. https://doi.org/10.3390/ma15217506