Surface Modification of Carbon Fibers by Low-Temperature Plasma with Runaway Electrons for Manufacturing PEEK-Based Laminates

Abstract

1. Introduction

1.1. Thermal Oxidation

1.2. Chemical Modification

1.3. Plasma Treatment

2. Materials and Methods

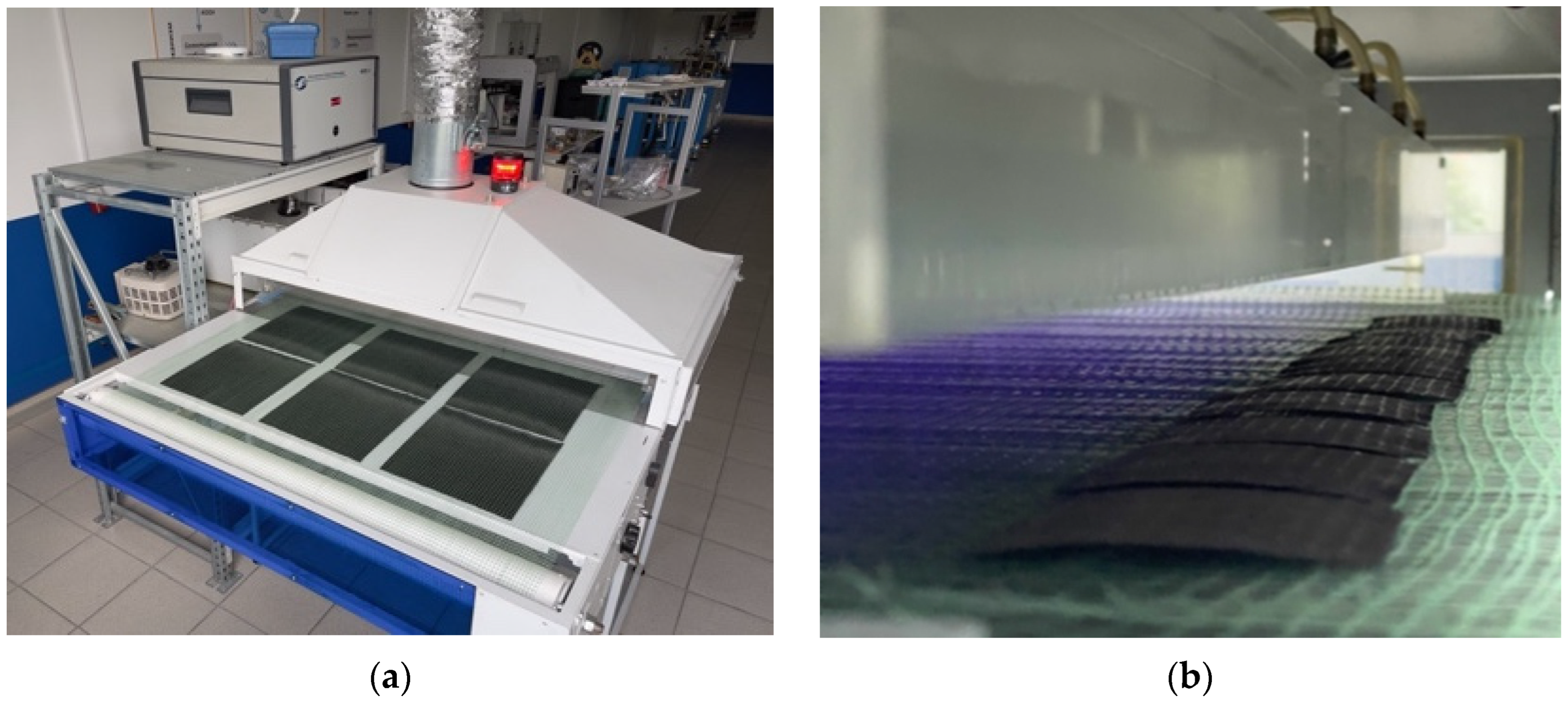

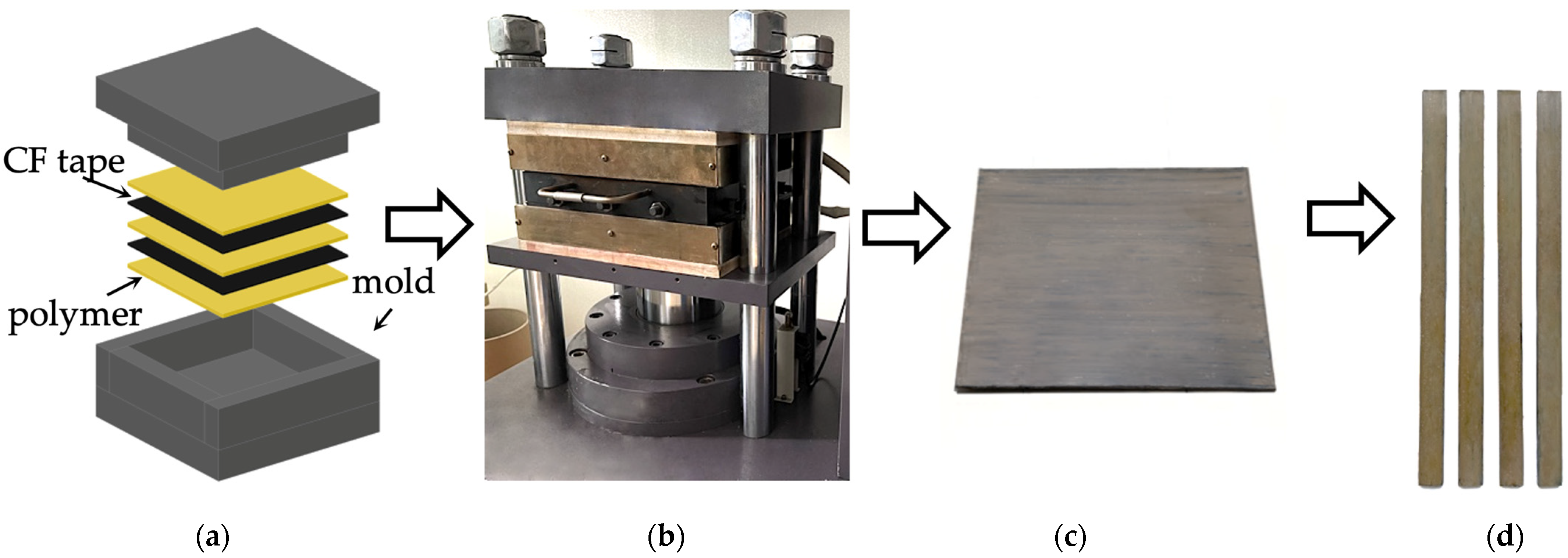

2.1. Experimental Study

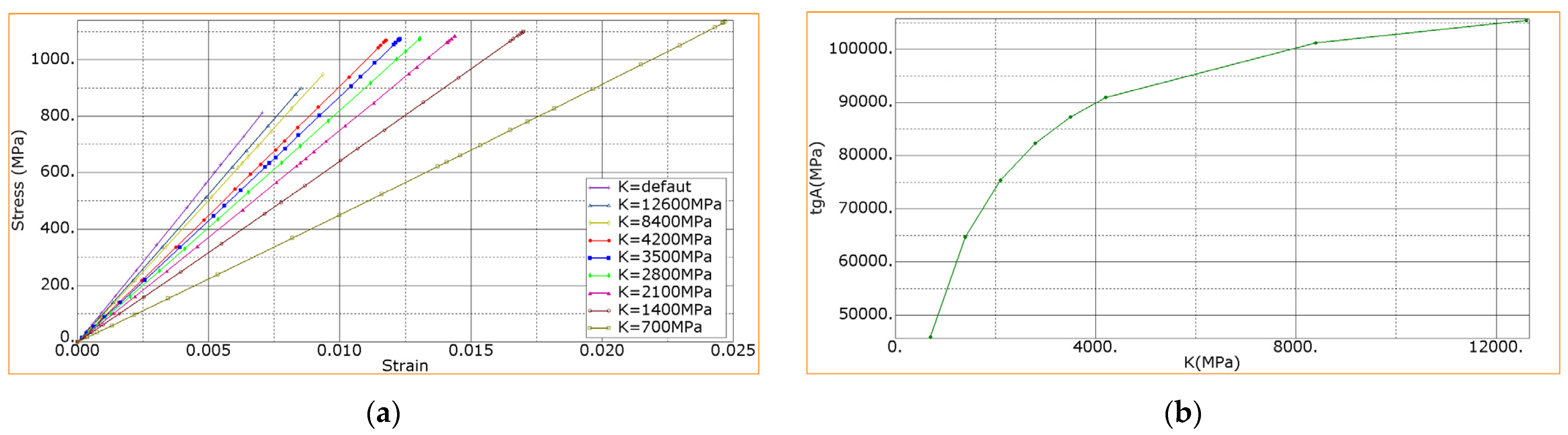

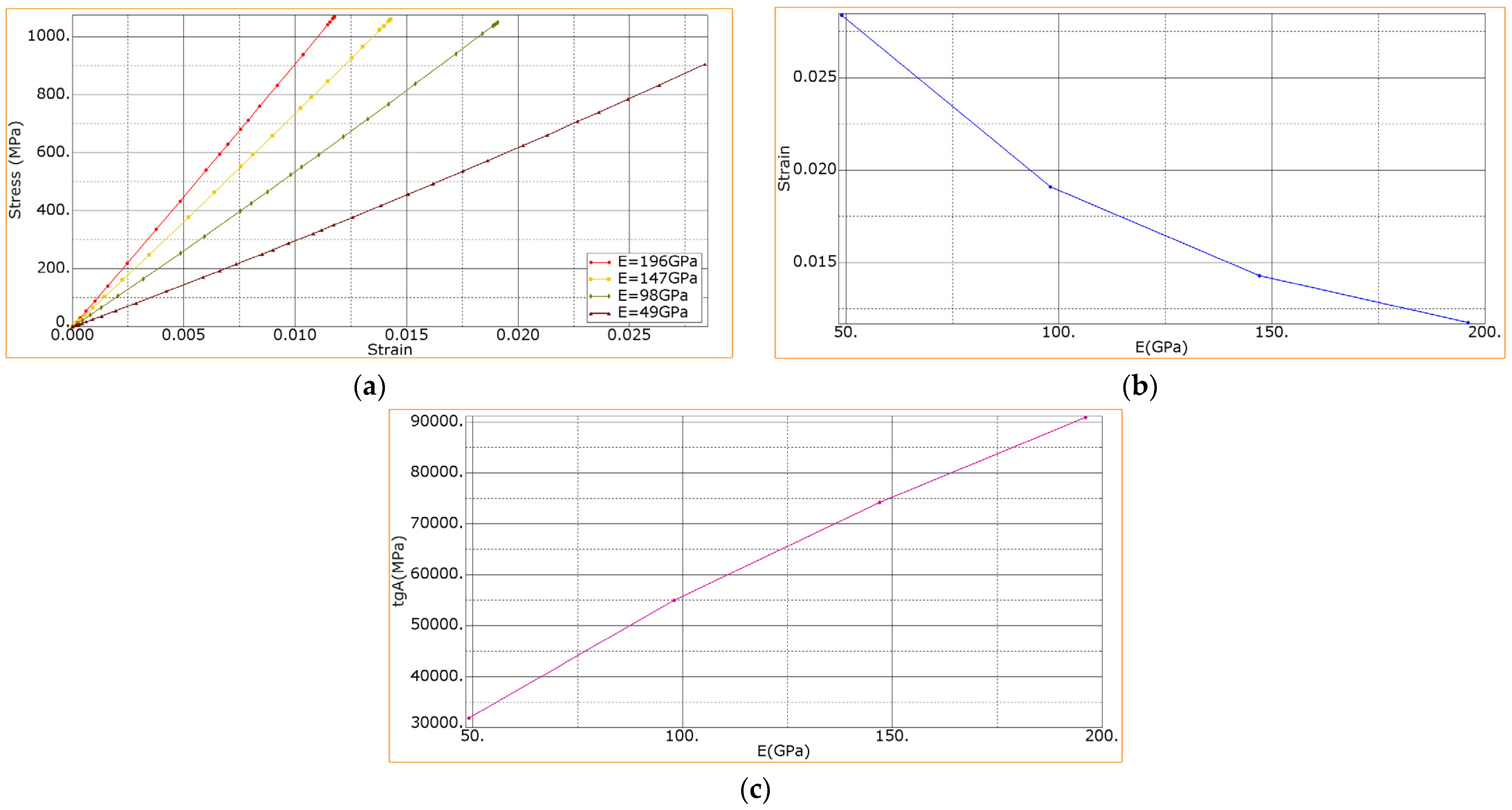

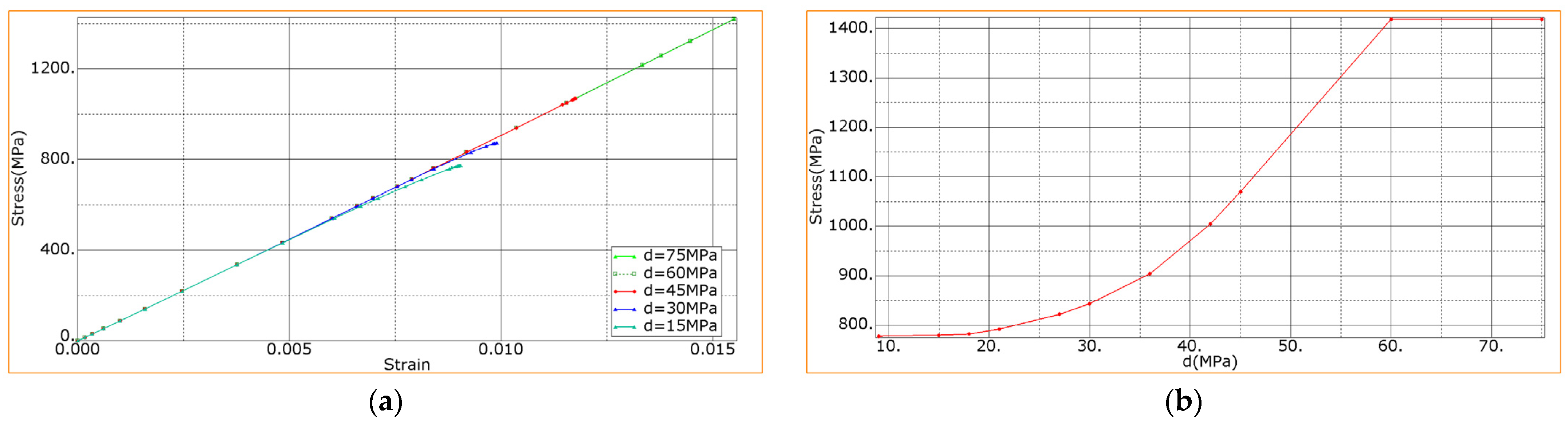

2.2. Simulation of Three-Point Bending of Laminates

- Lower supports were rigidly fixed.

- The load was applied through the loading roller (a cylinder) toward Oz direction, the roller’s displacements along other axes were prohibited.

3. Experimental Results

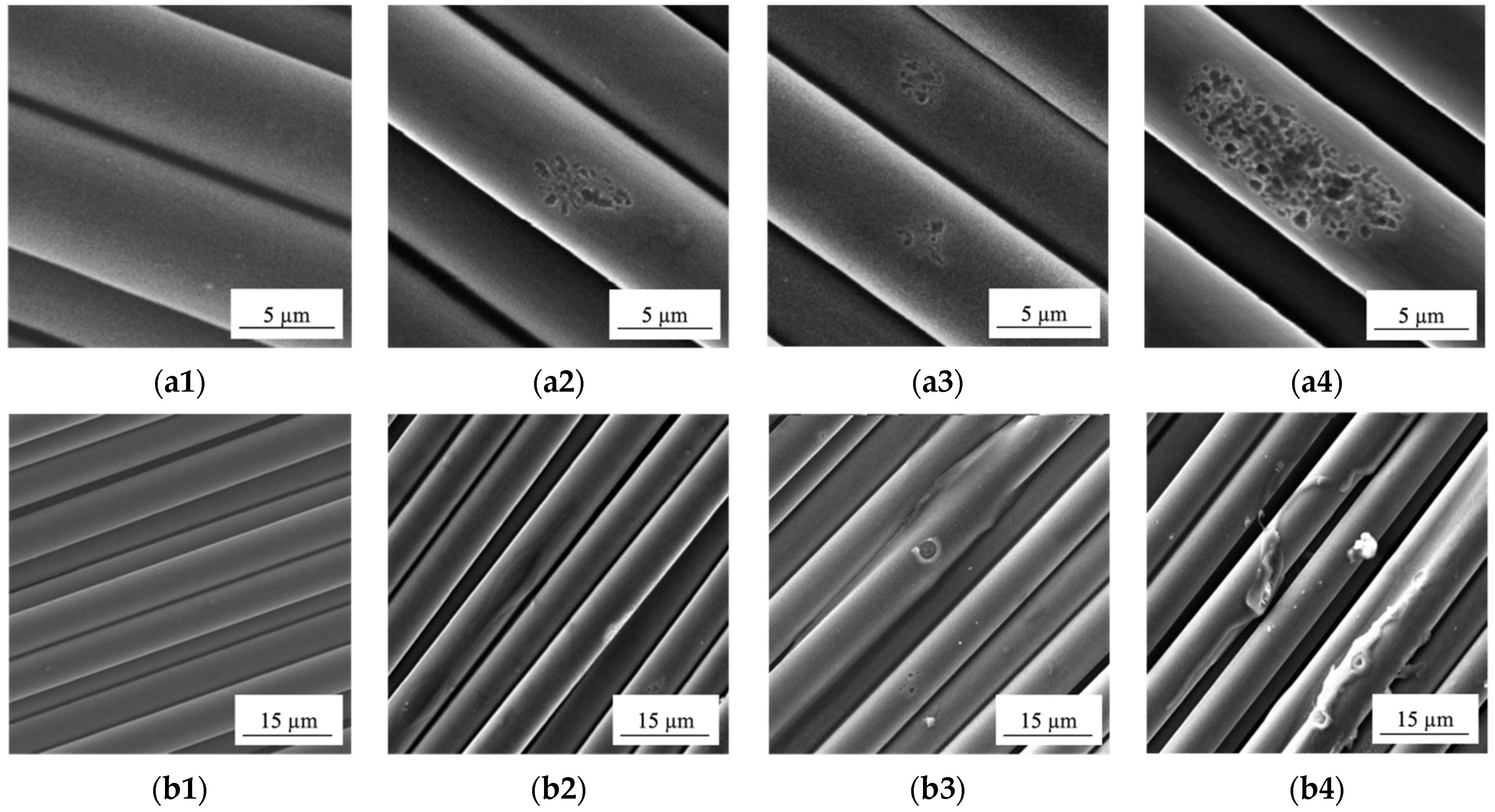

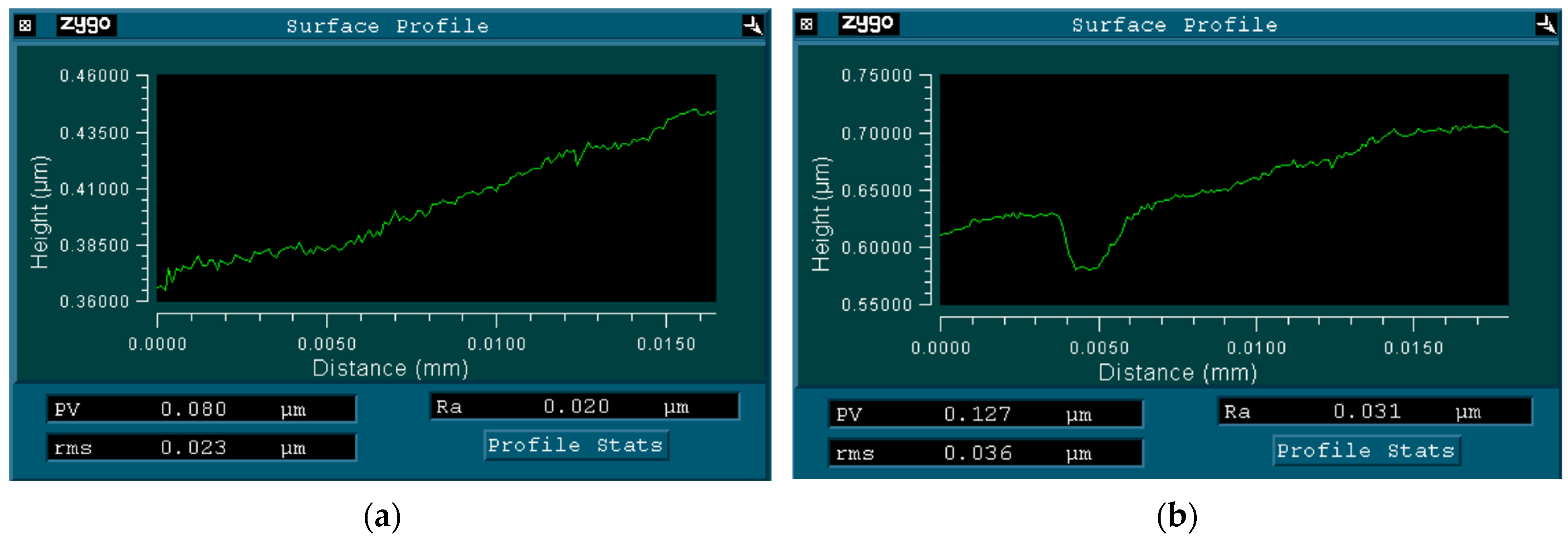

3.1. Electron Microscopy and Optical Profilometry Analysis of the CFs’ Surface

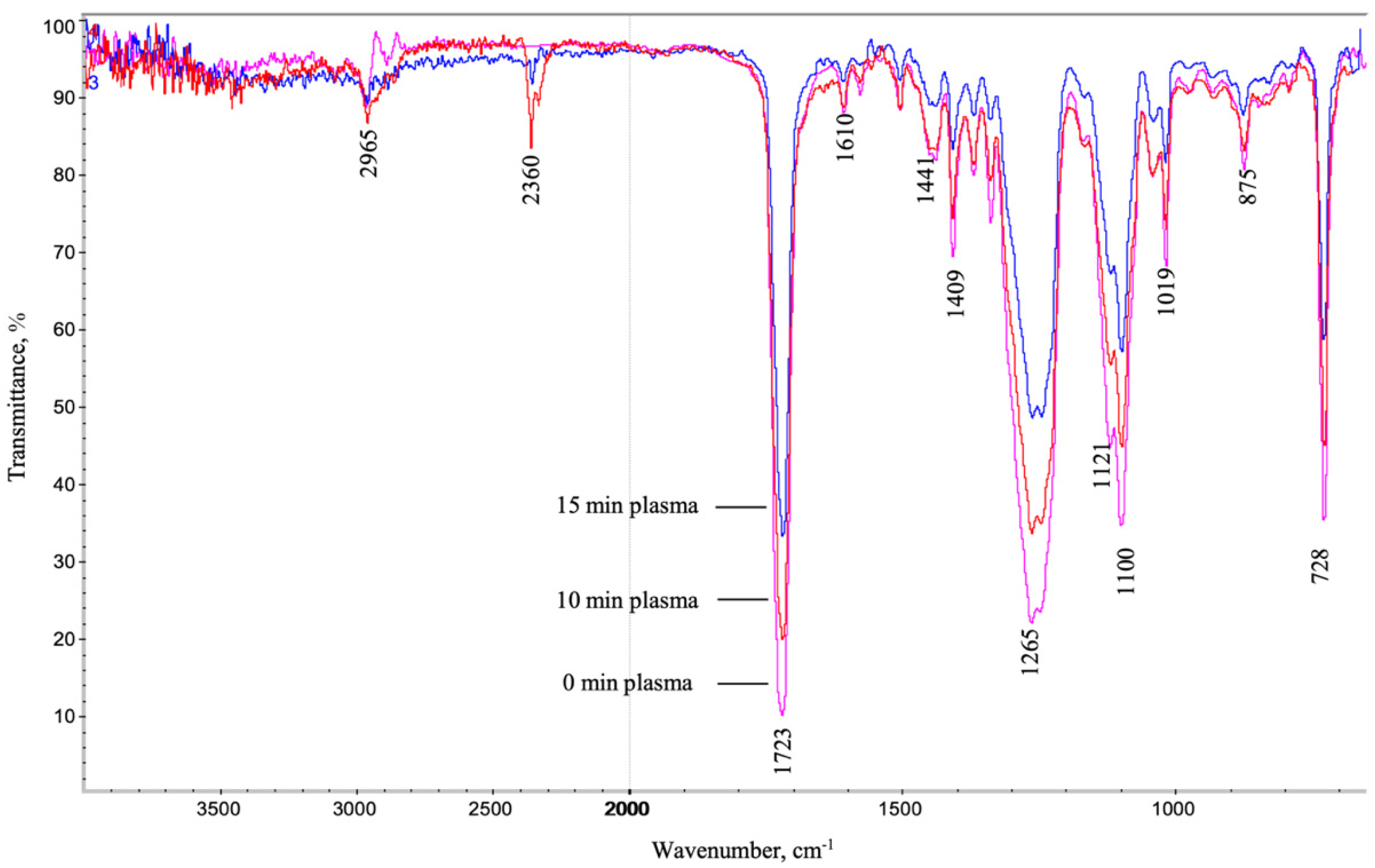

3.2. IR Analysis of Carbon Fibers

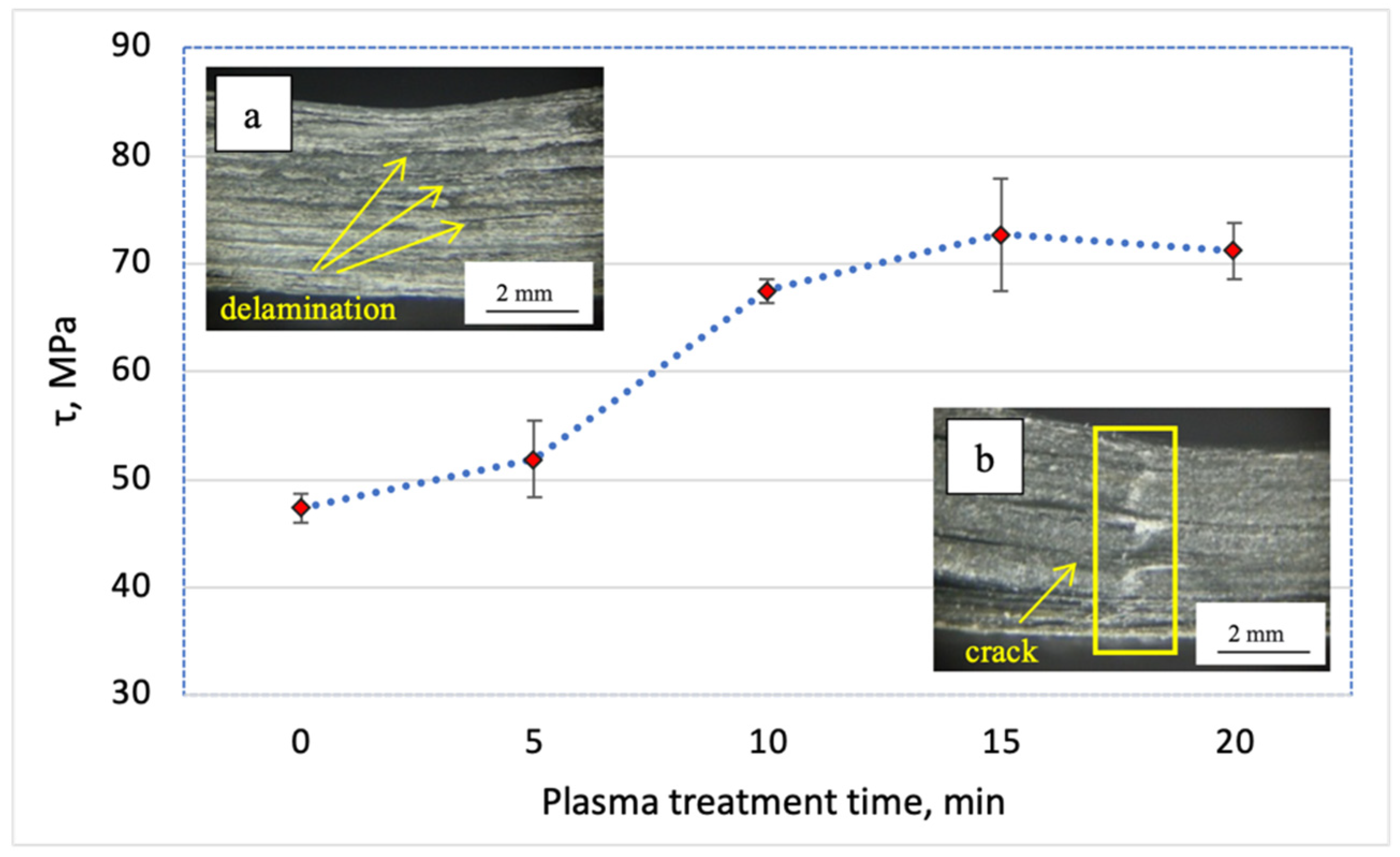

3.3. Interlayer Shear Strength (Short Beam Bending)

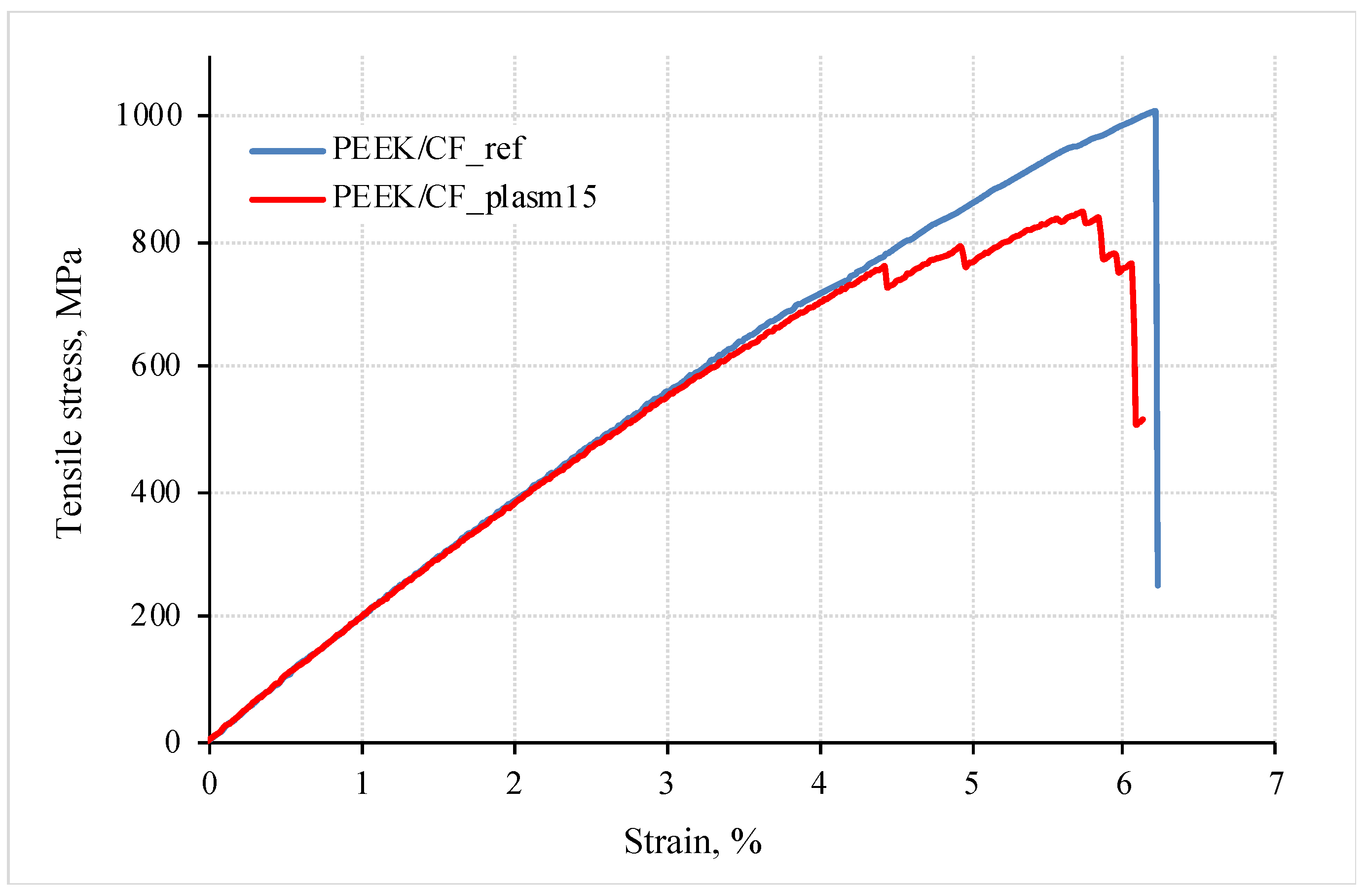

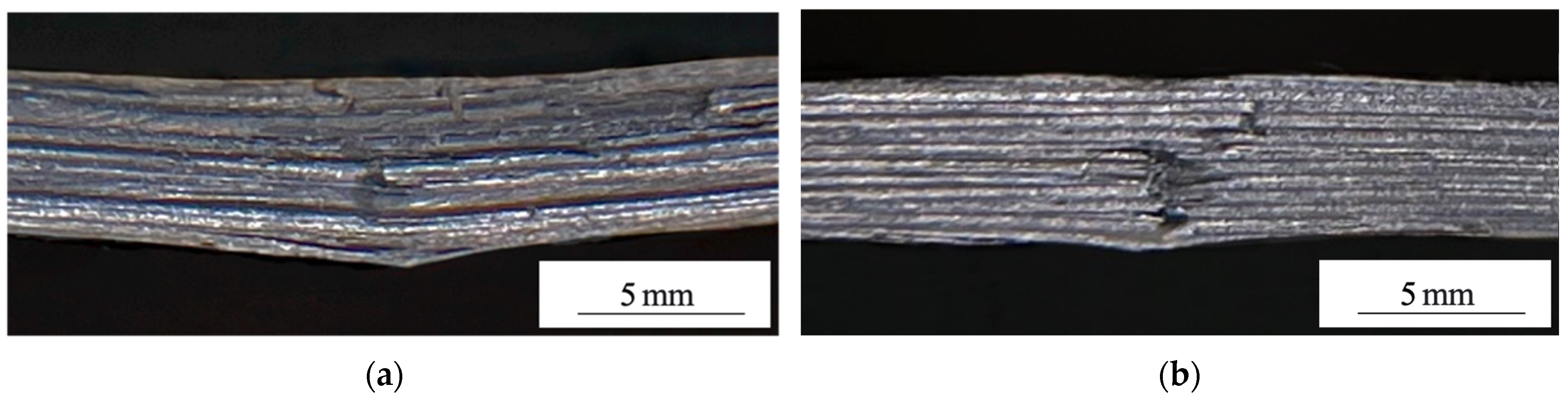

3.4. Uniaxial Tension Tests

3.5. Three-Point Bending Test

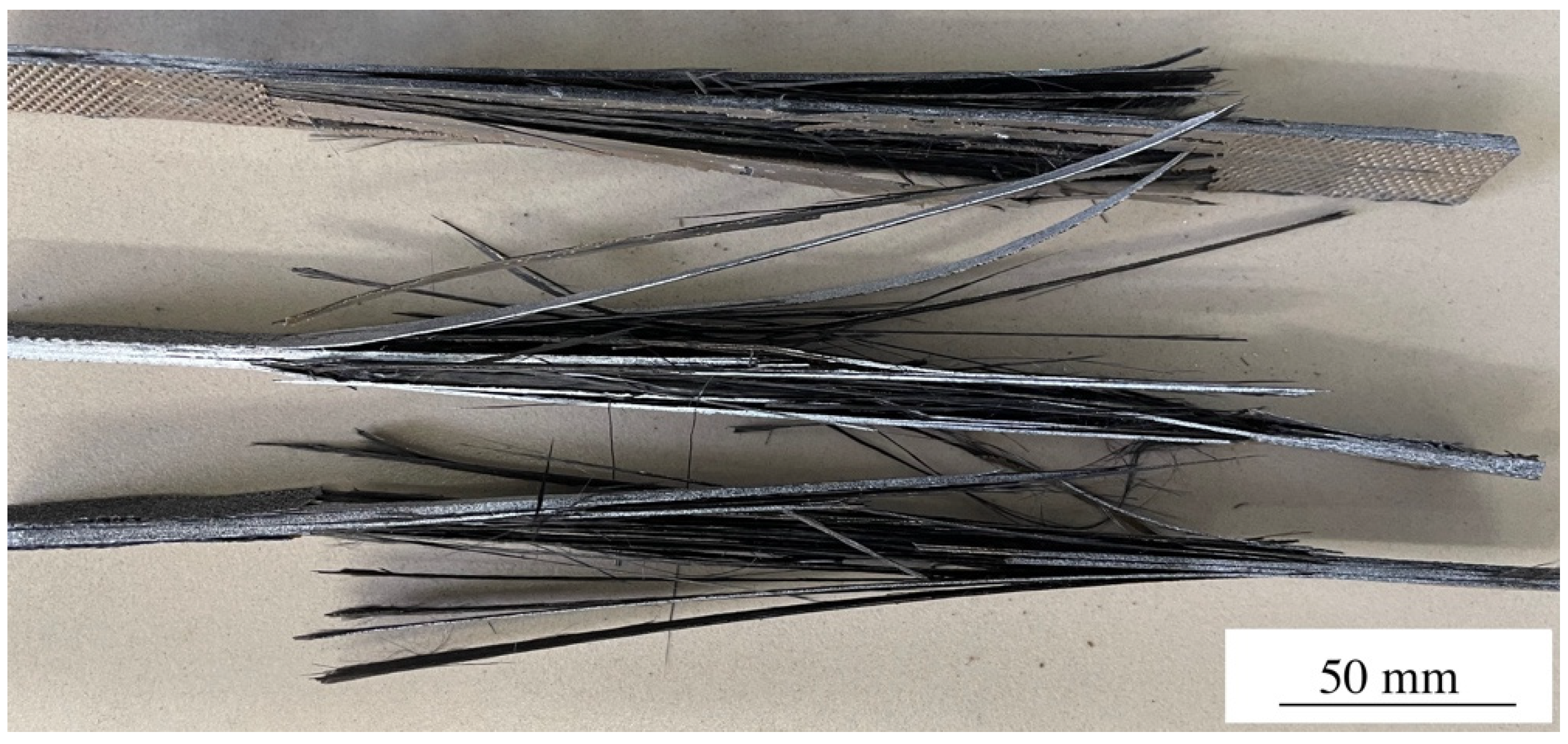

3.6. Structural Studies

4. Numerical Simulation

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, L.; Schlarb, A.K. Development and Optimization of High-performance PEEK/CF/Nanosilica Hybrid Composites. Polym. Adv. Technol. 2021, 32, 3150–3159. [Google Scholar] [CrossRef]

- Nohara, L.B.; Costa, M.L.; Alves, M.A.; Takahashi, M.F.K.; Nohara, E.L.; Rezende, M.C. Processing of High Performance Composites Based on PEEK by Aqueous Suspension Prepregging. Mater. Res. 2010, 13, 245–252. [Google Scholar] [CrossRef]

- Williams, G.; Trask, R.; Bond, I. A Self-Healing Carbon Fibre Reinforced Polymer for Aerospace Applications. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1525–1532. [Google Scholar] [CrossRef]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, Development, Outcomes, and Application Versatility of Carbon Fiber-Based Polymer Composites: A Review. Adv. Compos. Mater. Hybr. Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Pantelakis, S.; Tserpes, K. Revolutionizing Aircraft Materials and Processes, 1st ed.; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Jayan, J.S.; Appukuttan, S.; Wilson, R.; Joseph, K.; George, G.; Oksman, K. An introduction to Fiber Reinforced Composite Materials; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; ISBN 9780128210901. [Google Scholar]

- Donnet, J.B.; Ehrburger, P. Carbon Fibre in Polymer Reinforcement. Carbon 1977, 15, 143–152. [Google Scholar] [CrossRef]

- Ali, Z.; Gao, Y.; Tang, B.; Wu, X.; Wang, Y.; Li, M.; Hou, X.; Li, L.; Jiang, N.; Yu, J. Preparation, Properties and Mechanisms of Carbon Fiber/Polymer Composites for Thermal Management Applications. Polymers 2021, 13, 169. [Google Scholar] [CrossRef]

- Li, N.; Chen, J.; Liu, H.; Dong, A.; Wang, K.; Zhao, Y. Effect of Preheat Treatment on Carbon Fiber Surface Properties and Fiber/PEEK Interfacial Behavior. Polym. Compos. 2018, 40, E1407–E1415. [Google Scholar] [CrossRef]

- Kiss, P.; Glinz, J.; Stadlbauer, W.; Burgstaller, C.; Archodoulaki, V.-M. The Effect of Thermally Desized Carbon Fibre Reinforcement on the Flexural and Impact Properties of PA6, PPS and PEEK Composite Laminates: A Comparative Study. Compos. Part B Eng. 2021, 215, 108844. [Google Scholar] [CrossRef]

- Jin, Z.; Zhang, Z.; Meng, L. Effects of Ozone Method Treating Carbon Fibers on Mechanical Properties of Carbon/Carbon Composites. Mat. Chem. Phys. 2006, 97, 167–172. [Google Scholar] [CrossRef]

- Li, J. Interfacial Studies on the Ozone and Air-Oxidation-Modified Carbon Fiber Reinforced PEEK Composites. Surf. Interface Anal. 2009, 41, 310–315. [Google Scholar] [CrossRef]

- Su, Y.; Liu, P.; Jing, D.; Zhang, X.; Zhang, S. Improved Interfacial Adhesion in Carbon Fiber/Poly (Ether Ether Ketone) Composites with the Sulfonated Poly (Ether Ether Ketone) Sizing Treatment. J. Appl. Polym. Sci. 2021, 138, 51326. [Google Scholar] [CrossRef]

- Yuan, C.; Li, D.; Yuan, X.; Liu, L.; Huang, Y. Preparation of Semi-Aliphatic Polyimide for Organic-Solvent-Free Sizing Agent in CF/PEEK Composites. Compos. Sci. Technol. 2021, 201, 108490. [Google Scholar] [CrossRef]

- Lyu, H.; Jiang, N.; Li, Y.; Zhang, D. Enhancing CF/PEEK Interfacial Adhesion by Modified PEEK Grafted with Carbon Nanotubes. Compos. Sci. Technol. 2021, 210, 108831. [Google Scholar] [CrossRef]

- Wang, T.; Jiao, Y.; Mi, Z.; Wang, C.; Wang, D.; Zhao, X.; Zhou, H.; Chen, C. Improving the Interfacial Adhesion of Carbon Fiber/Polyether Ether Ketone Composites by Polyimide Coating. ChemistrySelect 2020, 5, 5507–5514. [Google Scholar] [CrossRef]

- Yan, T.; Yan, F.; Li, S.; Li, M.; Liu, Y.; Zhang, M.; Jin, L.; Shang, L.; Liu, L.; Ao, Y. Interfacial Enhancement of CF/PEEK Composites by Modifying Water-Based PEEK-NH2 Sizing Agent. Compos. Part B Eng. 2020, 199, 108258. [Google Scholar] [CrossRef]

- Donnet, J.B.; Brendle, M.; Dhami, T.L.; Bahl, O.P. Plasma Treatment Effect on the Surface Energy of Carbon and Carbon Fibers. Carbon 1986, 24, 757–770. [Google Scholar] [CrossRef]

- Mujin, S.; Baorong, H.; Yisheng, W.; Ying, T.; Weiqiu, H.; Youxian, D. The Surface of Carbon Fibres Continuously Treated by Cold Plasma. Compos. Sci. Technol. 1989, 34, 353–364. [Google Scholar] [CrossRef]

- Jones, C.; Sammann, E. The Effect of Low Power Plasmas on Carbon Fibre Surfaces. Carbon 1990, 28, 509–514. [Google Scholar] [CrossRef]

- Dilsiz, N. Plasma Surface Modification of Carbon Fibers: A Review. J. Adhes. Sci. Technol. 2000, 14, 975–987. [Google Scholar] [CrossRef]

- Mengjin, W.; Lixia, J.; Suling, L.; Zhigang, Q.; Sainan, W.; Ruosi, Y. Interfacial Performance of High-Performance Fiber-Reinforced Composites Improved by Cold Plasma Treatment: A Review. Surf. Interfaces 2021, 24, 101077. [Google Scholar] [CrossRef]

- Corujeira-Gallo, S.; Dong, H. Effect of Microstructure on the Plasma Surface Treatment of Carbon Fibres. J. Compos. Mater. 2016, 51, 3239–3256. [Google Scholar] [CrossRef]

- Huang, Y.; Yu, Q.; Li, M.; Sun, S.; Zhao, H.; Jin, S.; Fan, J.; Wang, J. An Overview of Low-temperature Plasma Surface Modification of Carbon Materials for Removal of Pollutants from Liquid and Gas Phases. Plasma Process. Polym. 2020, 18, 2000171. [Google Scholar] [CrossRef]

- Sun, X.; Bao, J.; Li, K.; Argyle, M.D.; Tan, G.; Adidharma, H.; Zhang, K.; Fan, M.; Ning, L. Advance in Using Plasma Technology for Modification or Fabrication of Carbon-Based Materials and Their Applications in Environmental, Material, and Energy Fields. Adv. Funct. Mater. 2020, 31, 2006287. [Google Scholar] [CrossRef]

- Xie, J.; Xin, D.; Cao, H.; Wang, C.; Zhao, Y.; Yao, L.; Ji, F.; Qiu, Y. Improving Carbon Fiber Adhesion to Polyimide with Atmospheric Pressure Plasma Treatment. Surf. Coat. Technol. 2011, 206, 191–201. [Google Scholar] [CrossRef]

- Rhee, K.Y.; Park, S.J.; Hui, D.; Qiu, Y. Effect of Oxygen Plasma-Treated Carbon Fibers on the Tribological Behavior of Oil-Absorbed Carbon/Epoxy Woven Composites. Compos. Part B Eng. 2012, 43, 2395–2399. [Google Scholar] [CrossRef]

- Montes-Morán, M.A.; Martínez-Alonso, A.; Tascón, J.M.D.; Paiva, M.C.; Bernardo, C.A. Effects of Plasma Oxidation on the Surface and Interfacial Properties of Carbon Fibres/Polycarbonate Composites. Carbon 2001, 39, 1057–1068. [Google Scholar] [CrossRef]

- Cho, B.-G.; Hwang, S.-H.; Park, M.; Park, J.K.; Park, Y.-B.; Chae, H.G. The Effects of Plasma Surface Treatment on the Mechanical Properties of Polycarbonate/Carbon Nanotube/Carbon Fiber Composites. Compos. Part B Eng. 2019, 160, 436–445. [Google Scholar] [CrossRef]

- Lee, H.S.; Kim, S.; Noh, Y.J.; Kim, S.Y. Design of Microwave Plasma and Enhanced Mechanical Properties of Thermoplastic Composites Reinforced with Microwave Plasma-Treated Carbon Fiber Fabric. Compos. Part B Eng. 2014, 60, 621–626. [Google Scholar] [CrossRef]

- Tiwari, S.; Sharma, M.; Panier, S.; Mutel, B.; Mitschang, P.; Bijwe, J. Influence of Cold Remote Nitrogen Oxygen Plasma Treatment on Carbon Fabric and Its Composites with Specialty Polymers. J. Mater. Sci. 2010, 46, 964–974. [Google Scholar] [CrossRef]

- Gravis, D.; Moisan, S.; Poncin-Epaillard, F. Surface Characterization of Plasma-Modified Carbon Fiber: Correlation between Surface Chemistry and Morphology of the Single Strand. Surf. Interfaces 2020, 21, 100731. [Google Scholar] [CrossRef]

- Baghery Borooj, M.; Mousavi Shoushtari, A.; Nosratian Sabet, E.; Haji, A. Influence of Oxygen Plasma Treatment Parameters on the Properties of Carbon Fiber. J. Adhes. Sci. Technol. 2016, 30, 2372–2382. [Google Scholar] [CrossRef]

- Cioffi, M.O.H.; Voorwald, H.J.C.; Ambrogi, V.; Monetta, T.; Bellucci, F.; Nicolais, L. Tensile Strength of Radio Frequency Cold Plasma Treated PET Fibers-Part I: Influence of Environmen and Treatment Time. J. Mater. Eng. Perform. 2002, 11, 659–666. [Google Scholar] [CrossRef]

- Lu, C.; Chen, P.; Yu, Q.; Ding, Z.; Lin, Z.; Li, W. Interfacial Adhesion of Plasma-Treated Carbon Fiber/Poly(Phthalazinone Ether Sulfone Ketone) Composite. J. Appl. Polym. Sci. 2007, 106, 1733–1741. [Google Scholar] [CrossRef]

- Ma, K.; Wang, B.; Chen, P.; Zhou, X. Plasma Treatment of Carbon Fibers: Non-Equilibrium Dynamic Adsorption and Its Effect on the Mechanical Properties of RTM Fabricated Composites. Appl. Surf. Sci. 2011, 257, 3824–3830. [Google Scholar] [CrossRef]

- Santos, A.L.; Botelho, E.C.; Kostov, K.G.; Nascente, P.A.P.; da Silva, L.L.G. Atmospheric Plasma Treatment of Carbon Fibers for Enhancement of Their Adhesion Properties. IEEE Trans. Plasma Sci. 2013, 41, 319–324. [Google Scholar] [CrossRef]

- Diblíková, L.; Mašek, Z.; Král, M. The Effect of Carbon Fiber Plasma Treatment on the Wettability and Interlaminar Shear Strength of Geopolymer Composite. J. Aust. Ceram. Soc. 2019, 55, 1139–1145. [Google Scholar] [CrossRef]

- Karoly, Z.; Romanszki, L.; Weltz, G.; Mohai, M.; Moczo, J.; Klebert, S. Comparison of Dielectric Barrier Discharge and Radio-Frequency Plasma Processing of Carbon Fibers. Express Polym. Lett. 2021, 15, 1004–1017. [Google Scholar] [CrossRef]

- Khan, A.; Dragatogiannis, D.; Jagdale, P.; Rovere, M.; Rosso, C.; Tagliaferro, A.; Charitidis, C. Novel Carbon Fibres Synthesis, Plasma Functionalization, and Application to Polymer Composites. Express Polym. Lett. 2021, 15, 361–374. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, X.; Zhao, Z.; Liu, J.; Chen, Q.; Wang, X. Rapid and Continuous Atmospheric Plasma Surface Modification of PAN-Based Carbon Fibers. ACS Omega 2022, 7, 10963–10969. [Google Scholar] [CrossRef]

- Radjef, R.; Jarvis, K.L.; Fox, B.L.; McArthur, S.L. Comparing the Properties of Commercially Treated and Air Plasma Treated Carbon Fibers. Surf. Coat. Technol. 2021, 408, 126751. [Google Scholar] [CrossRef]

- Maltsev, A.N. Dense Gas Discharge with Runaway Electrons as a New Plasma Source for Surface Modification and Treatment. IEEE Trans. Plasma Sci. 2006, 34, 1166–1174. [Google Scholar] [CrossRef]

- Shao, T.; Wang, R.; Zhang, C.; Yan, P. Atmospheric-pressure Pulsed Discharges and Plasmas: Mechanism, Characteristics and Applications. High Volt. 2018, 3, 14–20. [Google Scholar] [CrossRef]

- Hassan, E.A.M.; Yang, L.; Elagib, T.H.H.; Ge, D.; Lv, X.; Zhou, J.; Yu, M.; Zhu, S. Synergistic Effect of Hydrogen Bonding and π-π Stacking in Interface of CF/PEEK Composites. Compos. Part B Eng. 2019, 171, 70–77. [Google Scholar] [CrossRef]

- Yao, C.; Qi, Z.; Chen, W.; Zhang, C. Experimental Study on CF/PEEK Thermoplastic Fastener: Effects of Fastener Matrix Crystallinity and Fibre Content on the Strength of Single-Lap Joint. Compos. Part B Eng. 2021, 213, 108737. [Google Scholar] [CrossRef]

- Kosmachev, P.V.; Alexenko, V.O.; Bochkareva, S.A.; Panin, S.V. Deformation Behavior and Fracture Patterns of Laminated PEEK- and PI-Based Composites with Various Carbon-Fiber Reinforcement. Polymers 2021, 13, 2268. [Google Scholar] [CrossRef]

- Mesyats, G.A.; Reutova, A.G.; Sharypov, K.A.; Shpak, V.G.; Shunailov, S.A.; Yalandin, M.I. On the Observed Energy of Runaway Electron Beams in Air. Laser Part. Beams 2011, 29, 425–435. [Google Scholar] [CrossRef]

- Mesyats, G.A.; Yalandin, M.I.; Zubarev, N.M.; Sadykova, A.G.; Sharypov, K.A.; Shpak, V.G.; Shunailov, S.A.; Ulmaskulov, M.R.; Zubareva, O.V.; Kozyrev, A.V.; et al. How Short Is the Runaway Electron Flow in an Air Electrode Gap? Appl. Phys. Lett. 2020, 116, 063501. [Google Scholar] [CrossRef]

- Shunailov, S.A.; Reutova, A.G.; Shpak, V.G.; Yalandin, M.I.; Mesyats, G.A. Injection Criteria and Energy Characteristics of a Runaway Electron Beam Accelerated with a Nonuniform Field in an Atmospheric Gap. J. Korean Phys. Soc. 2011, 59, 3517–3521. [Google Scholar] [CrossRef]

- Lozhkomoev, A.S.; Glazkova, E.A.; Khorobraya, E.G.; Lerner, M.I.; Maltsev, A.N.; Podkovyrov, V.G. Modification of the Polymer Fiber Surface by DRE-plasma for Adhesion of Aluminum Oxyhydroxide Particles. Russ. Phys. J. 2013, 56, 384–388. [Google Scholar] [CrossRef]

- Gibson, R.F. Principles of Composite Material Mechanics; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Li, Z.; Wu, S.; Zhao, Z.; Xu, L. Influence of Surface Properties on the Interfacial Adhesion in Carbon Fiber/Epoxy Composites. Surf. Interface Anal. 2013, 46, 16–23. [Google Scholar] [CrossRef]

- Giraud, I.; Franceschi-Messant, S.; Perez, E.; Lacabanne, C.; Dantras, E. Preparation of Aqueous Dispersion of Thermoplastic Sizing Agent for Carbon Fiber by Emulsion/Solvent Evaporation. Appl. Surf. Sci. 2013, 266, 94–99. [Google Scholar] [CrossRef]

- Stepashkin, A.A.; Chukov, D.I.; Senatov, F.S.; Salimon, A.I.; Korsunsky, A.M.; Kaloshkin, S.D. 3D-Printed PEEK-Carbon Fiber (CF) Composites: Structure and Thermal Properties. Compos. Sci. Technol. 2018, 164, 319–326. [Google Scholar] [CrossRef]

| PEEK/CF Composite Type | Ultimate Shear Strength, MPa | Increase, % |

|---|---|---|

| without treatment | 47.5 ± 1.4 | - |

| tplasm = 5 min | 51.9 ± 3.6 | +10 |

| tplasm = 10 min | 67.5 ± 1.1 | +43 |

| tplasm = 15 min | 72.7 ± 5.2 | +54 |

| tplasm = 20 min | 71.2 ± 2.7 | +51 |

| Sample | Tensile Modulus, GPa | Ultimate Tensile Strength, MPa | Ultimate Tensile Strain, mm/mm |

|---|---|---|---|

| PEEK/CFref | 18.5 ± 1.7 | 1016 ± 106 | 0.063 ± 0.003 |

| PEEK/CFplasm15 | 18.8 ± 1.1 | 834 ± 52 | 0.062 ± 0.004 |

| Sample | Flexural Modulus, GPa | Ultimate Flexural Strength, MPa | Ultimate Flexural Strain, mm/mm |

|---|---|---|---|

| PEEK/CFref | 82.6 ± 2.4 | 770 ± 63 | 0.012 ± 0.01 |

| PEEK/CFplasm15 | 92.6 ± 2.3 | 893 ± 41 | 0.011 ± 0.02 |

| Composite | Treatment Parameters | Variation of Mechanical Properties after Plasma Treatment | Reference |

|---|---|---|---|

| CF/epoxy | Vacuum 0.1–0.001 mm Hg, RF–plasma, 0–300 W, 20 MHz | ILSS: +67% Tensile strength of single CF: −1.6% | Mujin1989 [19] |

| CF/PC | Low-pressure (100 Pa), oxygen microwave plasma, 2450 MHz, 75 W, 3 min | Tensile strength of single CF: +280% (ultra-high modulus CF), +12% (high strength CF) | Montes-Morán 2001 [28] |

| CF/PPESK | Air (60–80 cm3/min) Inductively coupled plasma (ICP), 250 W, 5/10/15/20 min | ILSS: +14% (15 min) | Lu 2007 [35] |

| CF/PES, CF/PEI, CF/PEEK | N2 or N2 + O2 (33 m3/h flow rate) microwave plasma 2450 MHz, 1200 W | ILSS up to: +55% (CF/PES), +32% (CF/PEI), +7.5% (CF/PEEK) | Tiwary 2010 [31] |

| CF/epoxy | Vacuum 15 Pa, oxygen (flow rate 6–8 sccm) RF–plasma, 13.56 MHz, 300 W, 3/5/7 min | ILSS: +23% (7 min) Flexural strength: +3% (7 min) | Ma 2011 [36] |

| CF/PI | He (20 L/min) + O2 (0.4 L/min) RF–plasma, 13.56 MHz, 100 W, 2.5 mm/s, 60 °C, 16/32/64 s | IFSS: +20% (32 s) Tensile strength of single CF: −2% (64 s) | Xie 2011 [26] |

| CF/PP | Air DBD plasma, 2/5/10 min | ILSS: +67% (5 min) | Santos 2013 [37] |

| CF/epoxy | Oxygen (flow rate of 100 sccm) RF–plasma 125 W, 1 min | ILSS: +28% Tensile strength of single CF: +/−0 | Baghery Borooj 2016 [33] |

| CF/geopolymer | Ar/Ar + N2/Ar + O2/Ar + water vapor (50 L/min Ar, 0.5 L/min admixture), RF–plasma,13.56 MHz, 150 W, 2 m/min | ILSS: +24% (Ar) | Diblíková 2019 [38] |

| CF/epoxy | Low-pressure (<1 × 104 Pa) RF–plasma, 13.56 MHz, 100 W, (airflow < 5 cm3/min STP), 180/300 s. Air DBD–plasma, 300 W, 10–20 kHz, 20 kV, 10/60 s | IFSS: +360% (RF), +620% (DBD) Tensile strength of single CF: preserved (RF, 300 s), −10 ca.% (DBD, 60 s) | Karoly 2021 [39] |

| CF/epoxy | Low-pressure (40 Pa), oxygen plasma, 13.56 MHz, 100/200 W, 5 min | Tensile strength of single CF: +23% Tribology +33%Surface hardness +11% | Khan 2021 [40] |

| CF/epoxy | Air RF–plasma, 13.56 MHz, 5–100 W, 5 min | IFSS: +394% (20 W) | Radjef 2021 [42] |

| CF/epoxy | Air (0.7 MPa, 2.5 L/min) DBD–plasma, 600 W, 7.5/15/30 s. | ILSS: +23% (60 s) | Xiao 2022 [41] |

| CF/PEEK | Air DRE–plasma, 56 kV, pulse front duration of 10 ns, pulse duration at half-height of 40 ns, 5/10/15/20 min | ILSS: +54% (15 min) Tensile strength: −17% (15 min) Flexural strength: +16% (15 min) | [Current study] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosmachev, P.V.; Panin, S.V.; Panov, I.L.; Bochkareva, S.A. Surface Modification of Carbon Fibers by Low-Temperature Plasma with Runaway Electrons for Manufacturing PEEK-Based Laminates. Materials 2022, 15, 7625. https://doi.org/10.3390/ma15217625

Kosmachev PV, Panin SV, Panov IL, Bochkareva SA. Surface Modification of Carbon Fibers by Low-Temperature Plasma with Runaway Electrons for Manufacturing PEEK-Based Laminates. Materials. 2022; 15(21):7625. https://doi.org/10.3390/ma15217625

Chicago/Turabian StyleKosmachev, Pavel V., Sergey V. Panin, Iliya L. Panov, and Svetlana A. Bochkareva. 2022. "Surface Modification of Carbon Fibers by Low-Temperature Plasma with Runaway Electrons for Manufacturing PEEK-Based Laminates" Materials 15, no. 21: 7625. https://doi.org/10.3390/ma15217625

APA StyleKosmachev, P. V., Panin, S. V., Panov, I. L., & Bochkareva, S. A. (2022). Surface Modification of Carbon Fibers by Low-Temperature Plasma with Runaway Electrons for Manufacturing PEEK-Based Laminates. Materials, 15(21), 7625. https://doi.org/10.3390/ma15217625