Carburization Kinetics of Zircalloy-4 and Its Implication for Small Modular Reactor Performance

Abstract

:1. Introduction

2. Materials and Methods

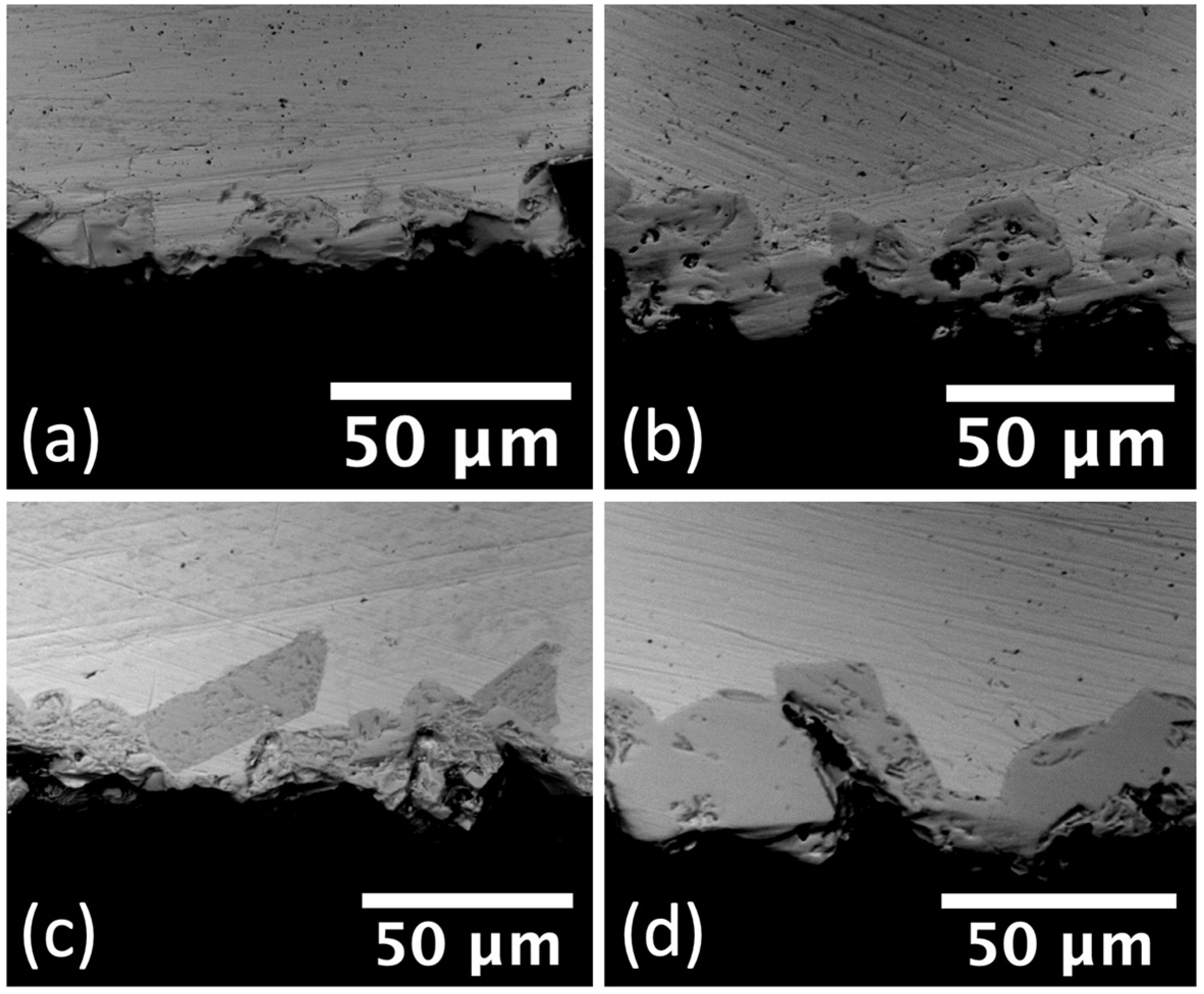

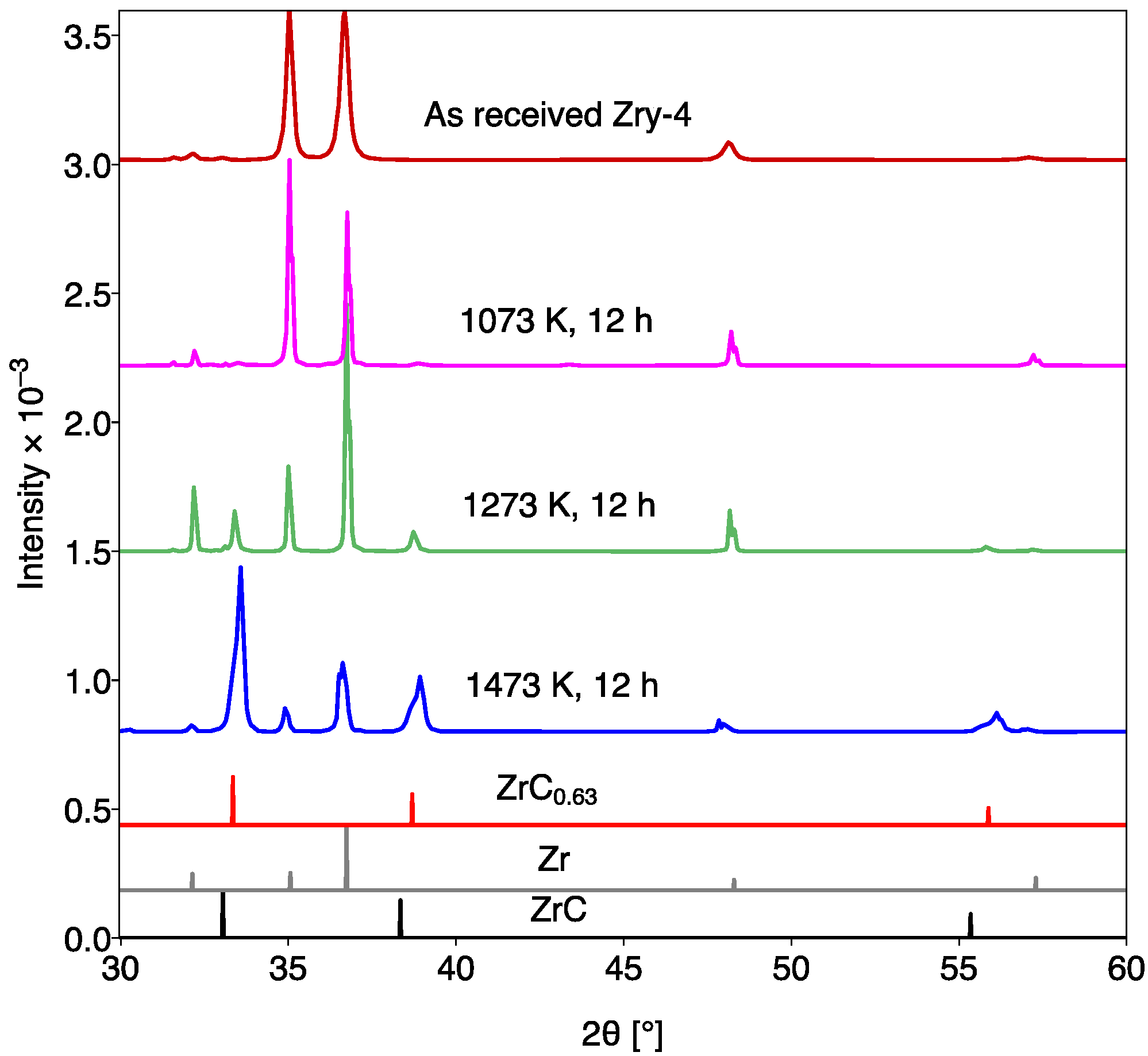

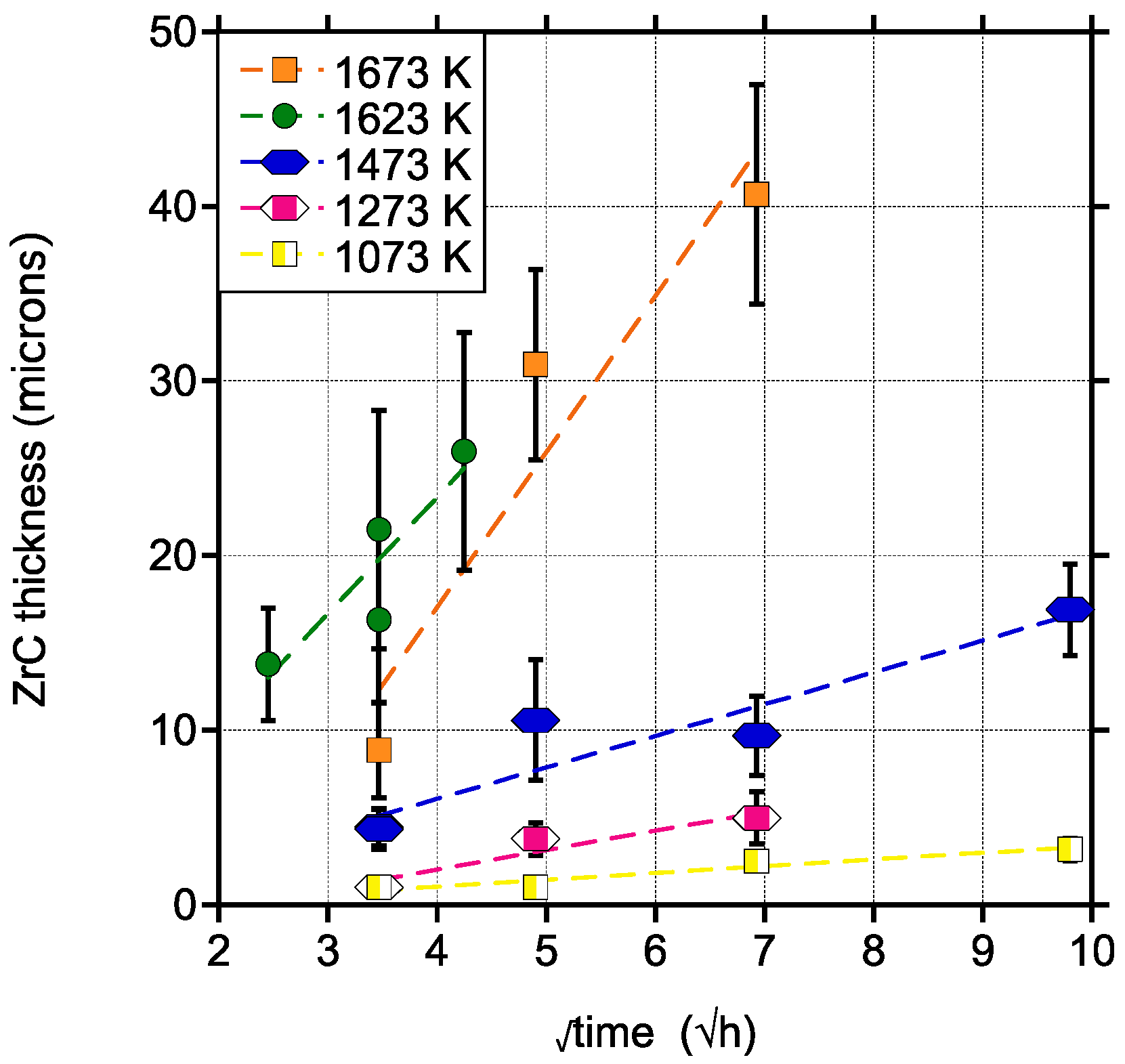

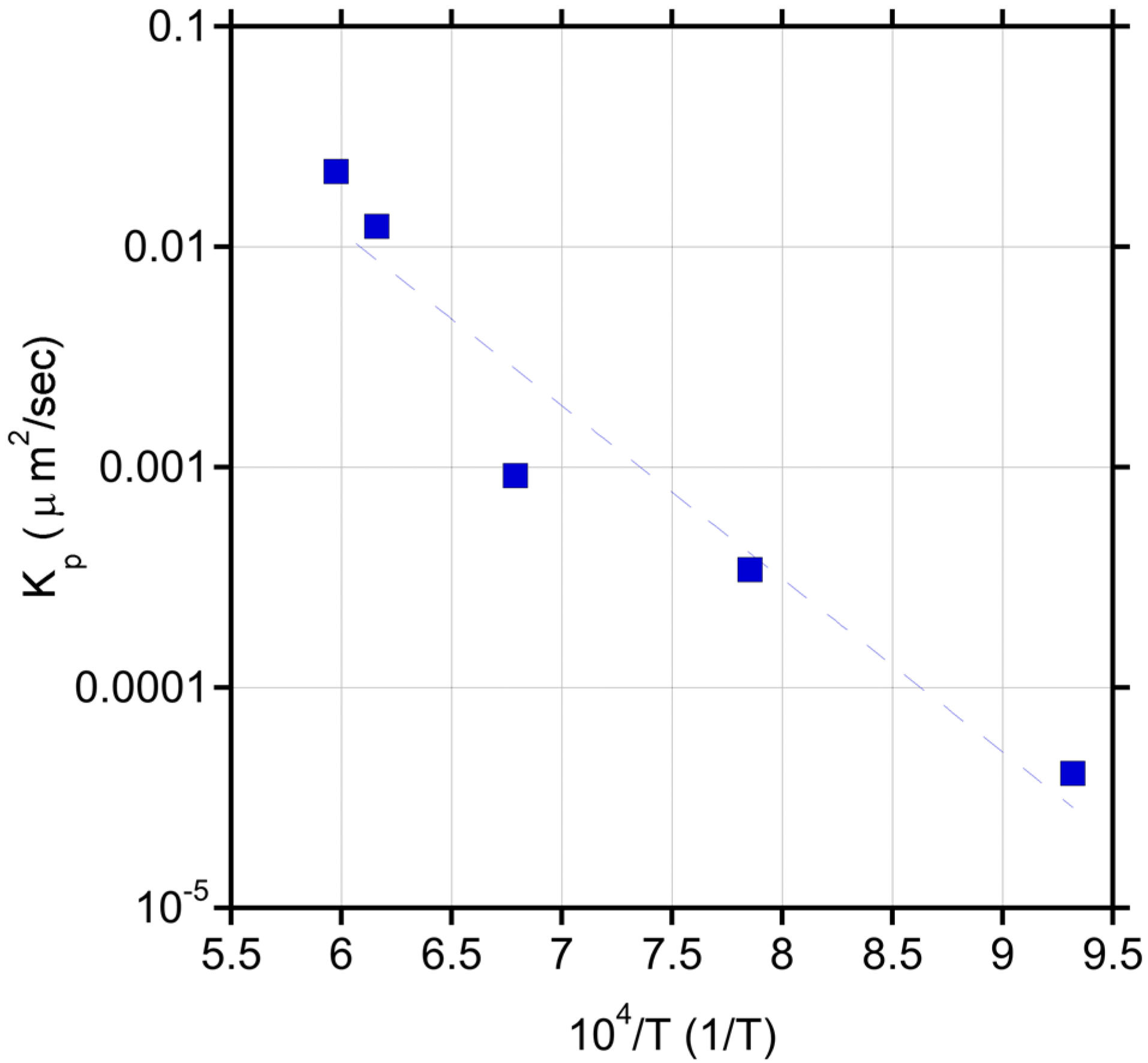

3. Results

4. Discussion

5. Conclusions

- In all cases a parabolic growth was established.

- Assessments of the resulting ZrC thicknesses as a function of time and temperature led to the development of an equation for parabolic constant Kp as a function of temperature.

- In-situ ZrC growth was shown to be sluggish at nominal SMR operating temperatures (e.g., below 1173 K) and, therefore, it is not expected that the ZrC layer will impact the thermal conductivity or the mechanical integrity of the cladding.

- XRD results revealed a sub-stoichiometric ZrC layer, which in reactor operation could act as a sink for C diffusion, limiting the ingress of C in the Zry-4 bulk.

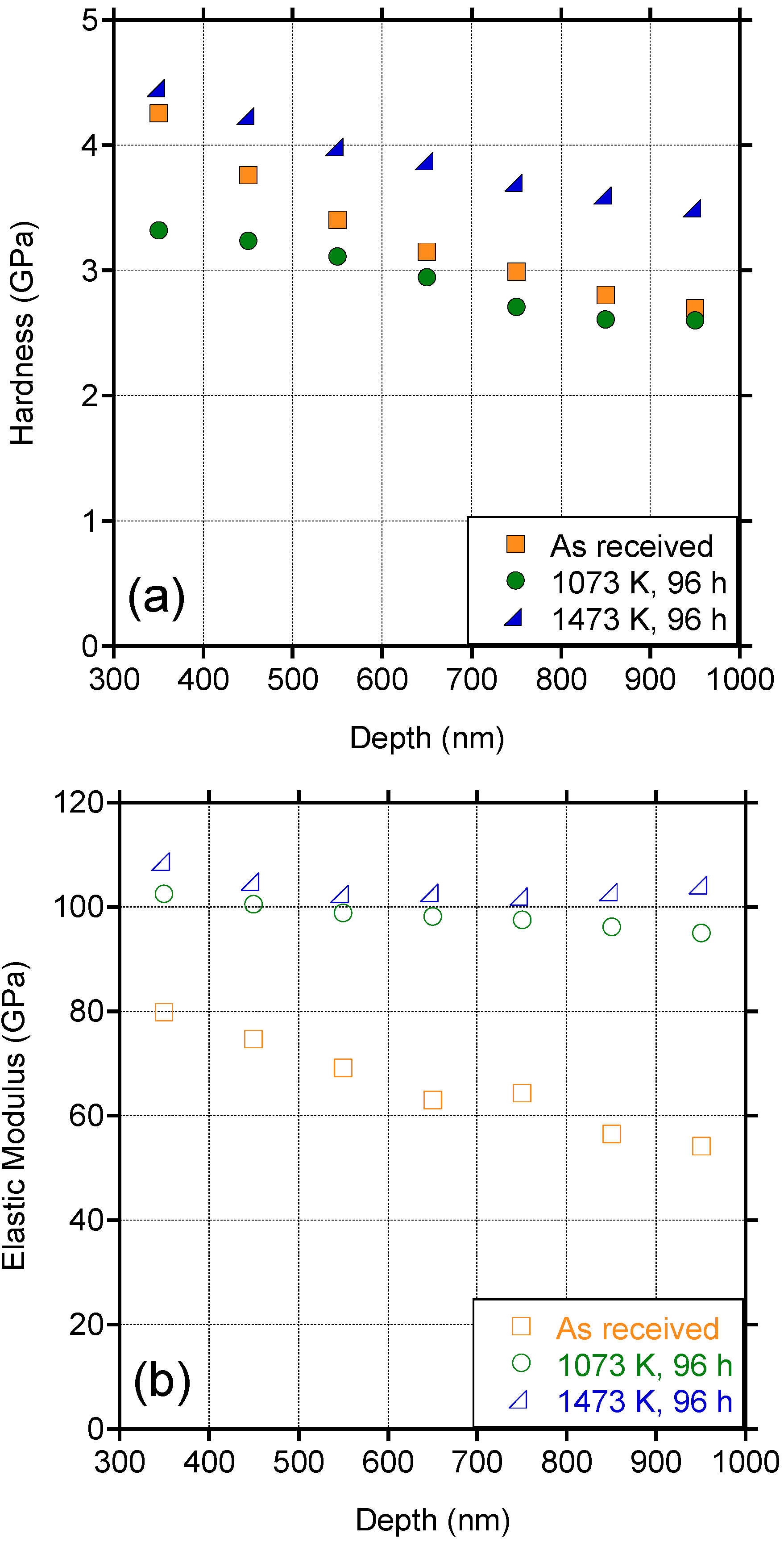

- Carburized Zry-4 substrates (96 h at 1073 K and 1473 K) showed no significant changes in the hardness or Young’s modulus values as compared to the as-received alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Testoni, R.; Bersano, A.; Segantin, S. Progress in Nuclear Energy Review of nuclear microreactors: Status, potentialities and challenges. Prog. Nucl. Energy 2021, 138, 103822. [Google Scholar] [CrossRef]

- Kardoulaki, E.; Nizolek, T.J.; Luther, E.P.; Swartz, M. On the Interactions of Molybdenum and Graphite, a Promising Material System for Microreactors. JOM 2021, 73, 3499–3512. [Google Scholar] [CrossRef]

- Ronchi, C.; Coquerelle, M.; Blank, H.; Rouault, J.; Ronchi, C.; Coquerelle, M.; Blank, H.; Rouault, J. The Sodium-Bonding Pin Concept for Advanced Fuels Part II: Analysis of the Cladding Carburization. Nucl. Fuels 1984, 67, 73–91. [Google Scholar] [CrossRef]

- Rogozkin, B.D.; Stepennova, N.V.; Fedorov, Y.E.; Dubrovin, O.N.; Shishkov, M.G.; Alekseev, O.A.; Loushnikova, T.D.; Balakireva, S.I.; Shentiakov, V.V. Mononitride U-Pu Mixed Fuel and Its Electrochemical Reprocessing in Molten Salts; Identernation Atomic Energy Agency (IAEA): Austria, Vienna, 1987. [Google Scholar]

- Rogozkin, B.D.; Stepennova, N.M.; Proshkin, A.A. Mononitride fuel for fast reactors. At. Energy 2003, 95, 624–636. [Google Scholar] [CrossRef]

- Steinbrück, M.; Vér, N.; Groe, M. Oxidation of advanced zirconium cladding alloys in steam at temperatures in the range of 600–1200 °C. Oxid. Met. 2011, 76, 215–232. [Google Scholar] [CrossRef]

- Edsinger, K.; Murty, K.L. LWR pellet-cladding interactions: Materials solutions to SCC. JOM 2001, 53, 9–13. [Google Scholar] [CrossRef]

- Khatib-Rahbar, M.; Krall, A.; Yuan, Z.; Zavisca, M. Review of Accident Tolerant Fuel Concepts with Implications to Severe Accident Progression and Radiological Releases; United States Nuclear Regulatory Commission Office of Nuclear Regulatory Research: Washington, DC, USA, 2020. [Google Scholar]

- Alrwashdeh, M.; Alameri, S.A. SiC and FeCrAl as Potential Cladding Materials for APR-1400 Neutronic Analysis. Energies 2022, 15, 3772. [Google Scholar] [CrossRef]

- Brown, N.R.; Todosow, M.; Cuadra, A. Screening of advanced cladding materials and UN-U3Si5 fuel. J. Nucl. Mater. 2015, 462, 26–42. [Google Scholar] [CrossRef] [Green Version]

- Frazer, D.; Maiorov, B.; Carvajal-Nuñez, U.; Evans, J.; Kardoulaki, E.; Dunwoody, J.; Saleh, T.A.; White, J.T. High temperature mechanical properties of fluorite crystal structured materials (CeO2, ThO2, and UO2) and advanced accident tolerant fuels (U3Si2, UN, and UB2). J. Nucl. Mater. 2021, 554, 153035. [Google Scholar] [CrossRef]

- Murabayashi, M.; Tanaka, S.; Takahashi, Y. Thermal Conductivity and Heat Capacity of Zircaloy-2, −4 and Unalloyed Zirconium. J. Nucl. Sci. Technol. 1975, 12, 661–662. [Google Scholar] [CrossRef]

- Field, K.; Snead, M.; Yamamoto, Y.; Terrani, K. Handbook on the Material Properties of FeCrAl Alloys for Nuclear Power Production Applications; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2017. [Google Scholar]

- Kurata, M.; Osaka, M.; Jacquemain, D.; Barrachin, M.; Haste, T. Advances in Fuel Chemistry during a Severe Accident; Woodhead Publishing: Sawston, UK, 2020; ISBN 9780081025710. [Google Scholar] [CrossRef]

- Jönsson, B.; Lu, Q.; Chandrasekaran, D.; Berglund, R.; Rave, F. Oxidation and creep limited lifetime of kanthal APMT®, a dispersion strengthened FeCrAlMo alloy designed for strength and oxidation resistance at high temperatures. Oxid. Met. 2013, 79, 29–39. [Google Scholar] [CrossRef]

- Azevedo, C.R.F. Selection of fuel cladding material for nuclear fission reactors. Eng. Fail. Anal. 2011, 18, 1943–1962. [Google Scholar] [CrossRef]

- Suman, S.; Khan, M.K.; Pathak, M.; Singh, R.N. Investigation of elevated-temperature mechanical properties of δ-hydride precipitate in Zircaloy-4 fuel cladding tubes using nanoindentation. J. Alloys Compd. 2017, 726, 107–113. [Google Scholar] [CrossRef]

- Sun, Z.; Yamamoto, Y.; Chen, X. Impact toughness of commercial and model FeCrAl alloys. Mater. Sci. Eng. A 2018, 734, 93–101. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Jamal, M.; Morgan, M.N. Materials characterization part I: Contact area of the Berkovich indenter for nanoindentation tests. Int. J. Adv. Manuf. Technol. 2017, 92, 361–370. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Bhushan, B. A review of nanoindentation continuous stiffness measurement technique and its applications. Mater. Charact. 2002, 48, 11–36. [Google Scholar] [CrossRef]

- Tunca, B.; Lapauw, T.; Callaert, C.; Hadermann, J.; Delville, R.; Caspi, E.N.; Dahlqvist, M.; Rosén, J.; Marshal, A.; Pradeep, K.G.; et al. Compatibility of Zr2AlC MAX phase-based ceramics with oxygen-poor, static liquid lead–bismuth eutectic. Corros. Sci. 2020, 171, 108704. [Google Scholar] [CrossRef]

- Nakamura, K.; Yashima, M. Crystal structure of NaCl-type transition metal monocarbides MC (M = V, Ti, Nb, Ta, Hf, Zr), a neutron powder diffraction study. Mater. Sci. Eng. B 2008, 148, 69–72. [Google Scholar] [CrossRef]

- Hull, A.W. Crystal structures of Ti, Zr, Ce, Th, and Os. Phys. Rev. 1921, 18, 88–89. [Google Scholar]

- Wagner, C. The evaluation of data obtained with diffusion couples of binary single-phase and multiphase systems. Acta Metall. 1969, 17, 99–107. [Google Scholar] [CrossRef]

- Rosinger, H.E.; Northwood, D.O. The elastic properties of zirconium and pressure tubing materials h.e. rosinger. J. Nucl. Mater. 1979, 79, 170–179. [Google Scholar] [CrossRef]

- Gigax, J.G.; Kennas, M.; Kim, H.; Maier, B.R.; Yeom, H.; Johnson, G.O.; Sridharan, K.; Shao, L. Interface reactions and mechanical properties of FeCrAl-coated Zircaloy-4. J. Nucl. Mater. 2019, 519, 57–63. [Google Scholar] [CrossRef]

- Okamoto, H. C-Zr (Carbon-Zirconium). J. Phase Equilib. 1996, 17, 162. [Google Scholar] [CrossRef]

- Hayashi, T.; Matsuura, K.; Ohno, M. TiC Coating on Titanium by Carbonization Reaction Using Spark Plasma Sintering. Mater. Trans. 2013, 54, 2098–2101. [Google Scholar] [CrossRef] [Green Version]

- Sarian, S.; Criscione, J.M. Diffusion of carbon through zirconium monocarbide. J. Appl. Phys. 1967, 38, 1794–1798. [Google Scholar] [CrossRef]

- Duan, Z.; Yang, H.; Satoh, Y.; Murakami, K.; Kano, S.; Zhao, Z.; Shen, J.; Abe, H. Current status of materials development of nuclear fuel cladding tubes for light water reactors. Nucl. Eng. Des. 2017, 316, 131–150. [Google Scholar] [CrossRef]

- Minato, K.; Ogawa, T.; Fukuda, K.; Nabielek, H.; Sekino, H.; Nozawa, Y.; Takahashi, I. Fission product release from ZrC-coated fuel particles during postirradiation heating at 1600 °C. J. Nucl. Mater. 1995, 224, 85–92. [Google Scholar] [CrossRef]

- Minato, K.; Ogawa, T.; Koya, T.; Sekino, H.; Tomita, T. Retention of fission product caesium in ZrC-coated fuel particles for high-temperature gas-cooled reactors. J. Nucl. Mater. 2000, 279, 181–188. [Google Scholar] [CrossRef]

- Chubb, W. Buffering of Uranium Monocarbide to Control Carbon Activity. Nucl. Sci. Eng. 1967, 29, 176–179. [Google Scholar] [CrossRef]

- Chubb, W.; Keller, D.L. Constitution of the Systems of Uranium and Carbon with Molybdenum, Niobium, Rhenium, Tungsten, and Yttrium; Battelle Memorial Institute: Columbus, OH, USA, 1964. [Google Scholar]

| Property | Zry-4 | FeCrAl (Kanthal APMT) |

|---|---|---|

| Thermal conductivity (W/m·K) | 11.96 [12] | 10.78 [13] |

| Melting temperature (K) | 2033 [14] | 1773 [15] |

| Neutron absorption cross-section [16] (barns) | 0.185 | 2.55 |

| Elastic modulus (GPa) | 99–115 [17] | 184.4 [13] |

| Hardness (GPa) | 2–3 [17] | 2.66–3.01 [18] |

| 1073 K | 1273 K | 1473 K | 1623 K | 1673 K | |

|---|---|---|---|---|---|

| (m2/h) | 0.1467 | 1.2372 | 3.2956 | 44.6798 | 79.2758 |

| A (m) | −0.4827 | −2.4193 | −1.1856 | −3.3684 | −18.546 |

| Material | Elastic Modulus (GPa) | Hardness (GPa) |

|---|---|---|

| Zry-4 | 79.84 2.8 | 4.17 |

| Zry-4 [17] | 99–115 | 2–3 |

| Zry-4 [26] | 94–96 | - |

| Zry-4 [27] | - | 3 |

| Zry-4 (carburized 1073 K, 96 h) | 101.042.01 | 3.190.24 |

| Zry-4 (carburized 1473 K, 96 h) | 106.186.37 | 4.400.46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kardoulaki, E.; Abdul-Jabbar, N.; Byler, D.; Hassan, M.M.; Mann, S.; Coons, T.; White, J. Carburization Kinetics of Zircalloy-4 and Its Implication for Small Modular Reactor Performance. Materials 2022, 15, 8008. https://doi.org/10.3390/ma15228008

Kardoulaki E, Abdul-Jabbar N, Byler D, Hassan MM, Mann S, Coons T, White J. Carburization Kinetics of Zircalloy-4 and Its Implication for Small Modular Reactor Performance. Materials. 2022; 15(22):8008. https://doi.org/10.3390/ma15228008

Chicago/Turabian StyleKardoulaki, Erofili, Najeb Abdul-Jabbar, Darrin Byler, Md Mehadi Hassan, Shane Mann, Tim Coons, and Josh White. 2022. "Carburization Kinetics of Zircalloy-4 and Its Implication for Small Modular Reactor Performance" Materials 15, no. 22: 8008. https://doi.org/10.3390/ma15228008

APA StyleKardoulaki, E., Abdul-Jabbar, N., Byler, D., Hassan, M. M., Mann, S., Coons, T., & White, J. (2022). Carburization Kinetics of Zircalloy-4 and Its Implication for Small Modular Reactor Performance. Materials, 15(22), 8008. https://doi.org/10.3390/ma15228008