Sliding Wear Behavior of Intermetallic Ti-45Al-2Nb-2Mn-(at%)-0.8vol%TiB2 Processed by Centrifugal Casting and Hot Isostatic Pressure: Influence of Microstructure

Abstract

:1. Introduction

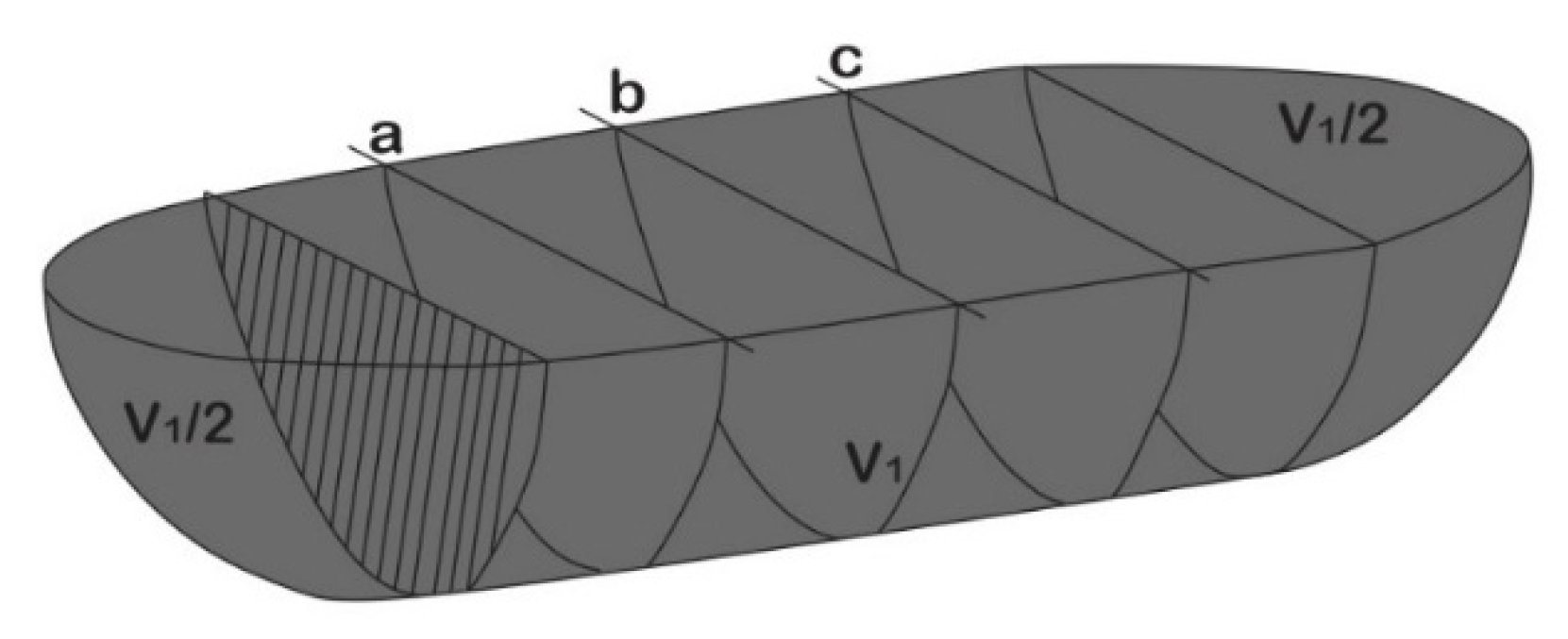

2. Materials and Methods

3. Results and Discussion

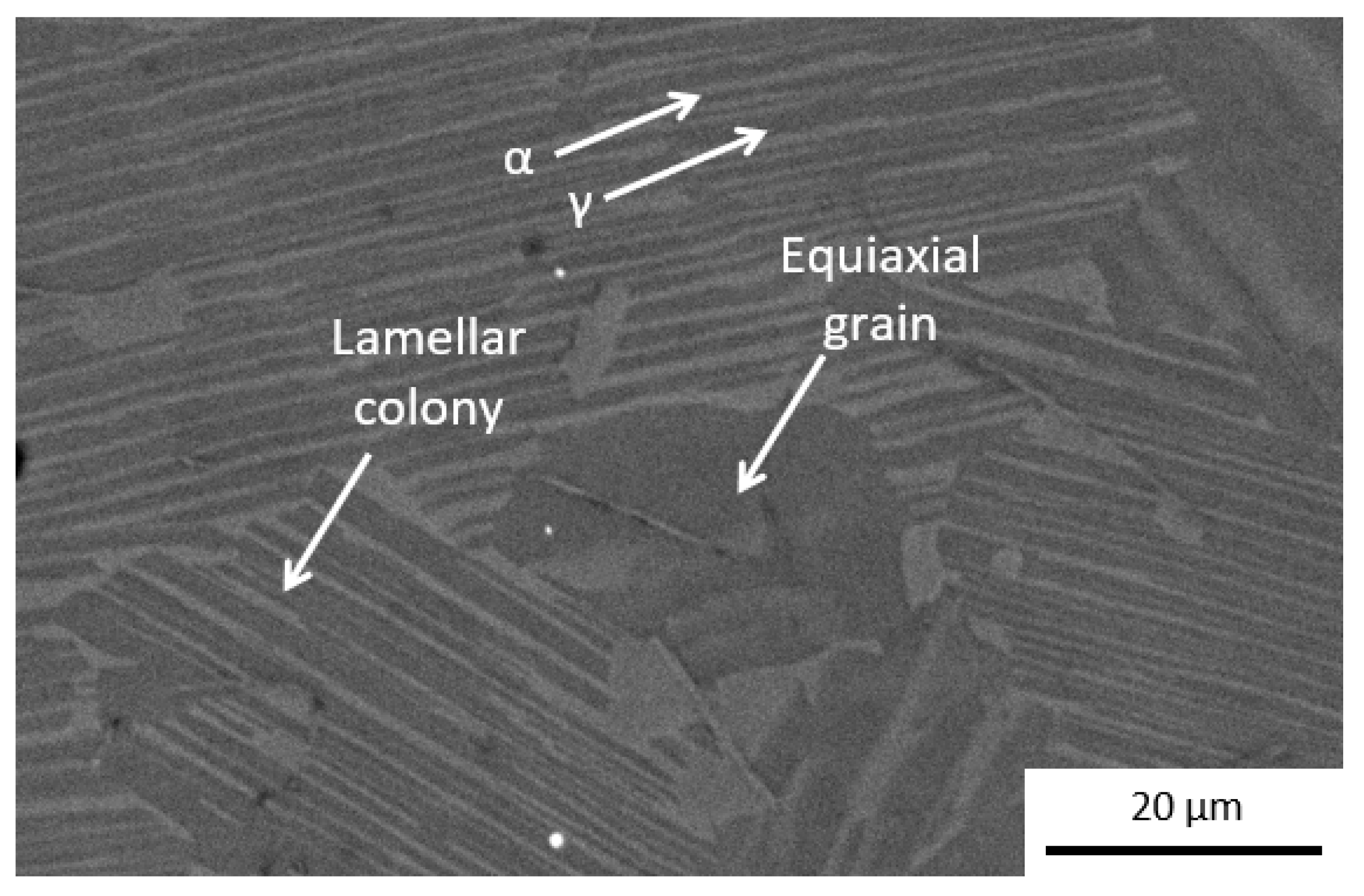

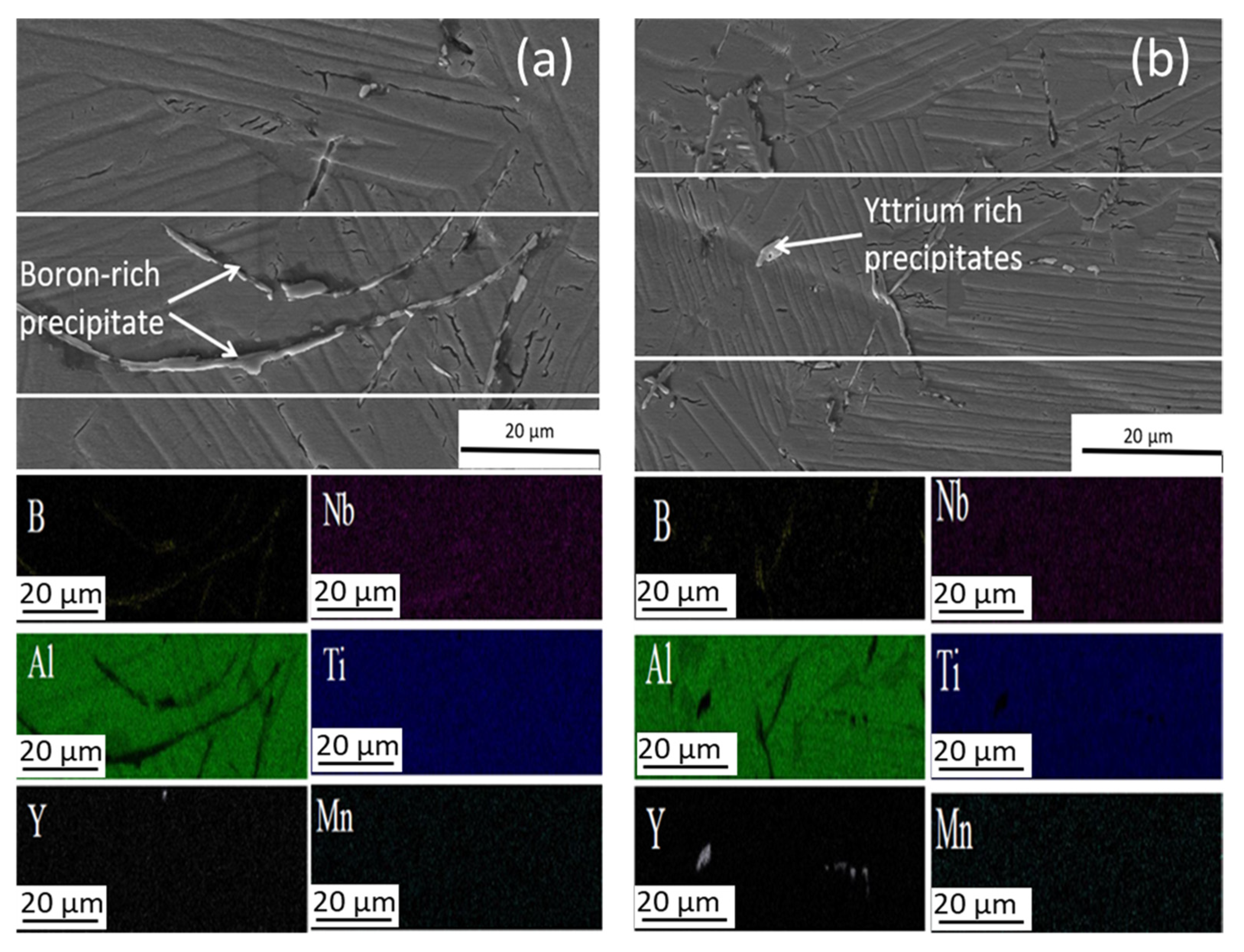

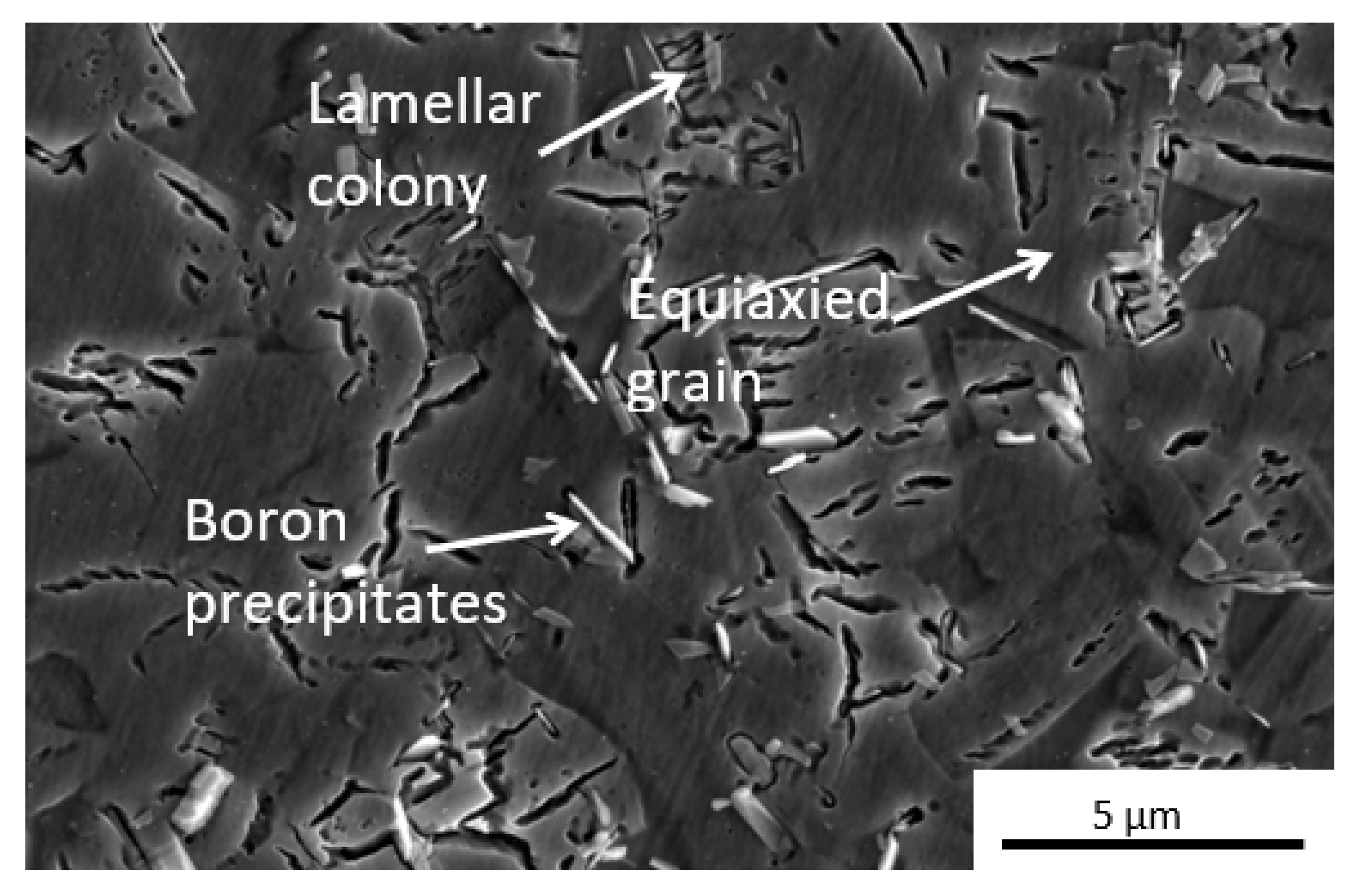

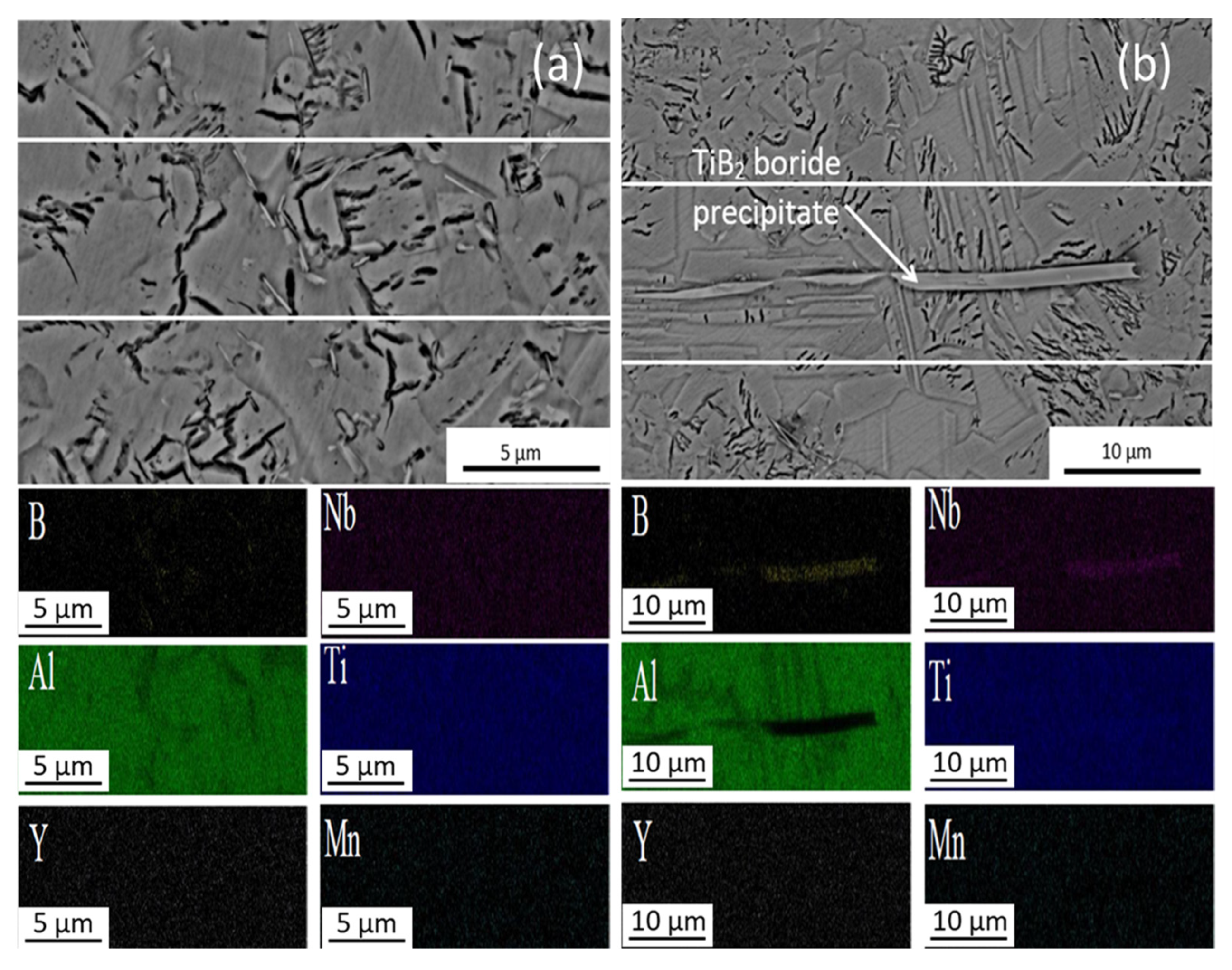

3.1. Microstructural Characterization

3.2. Hardness Characterization

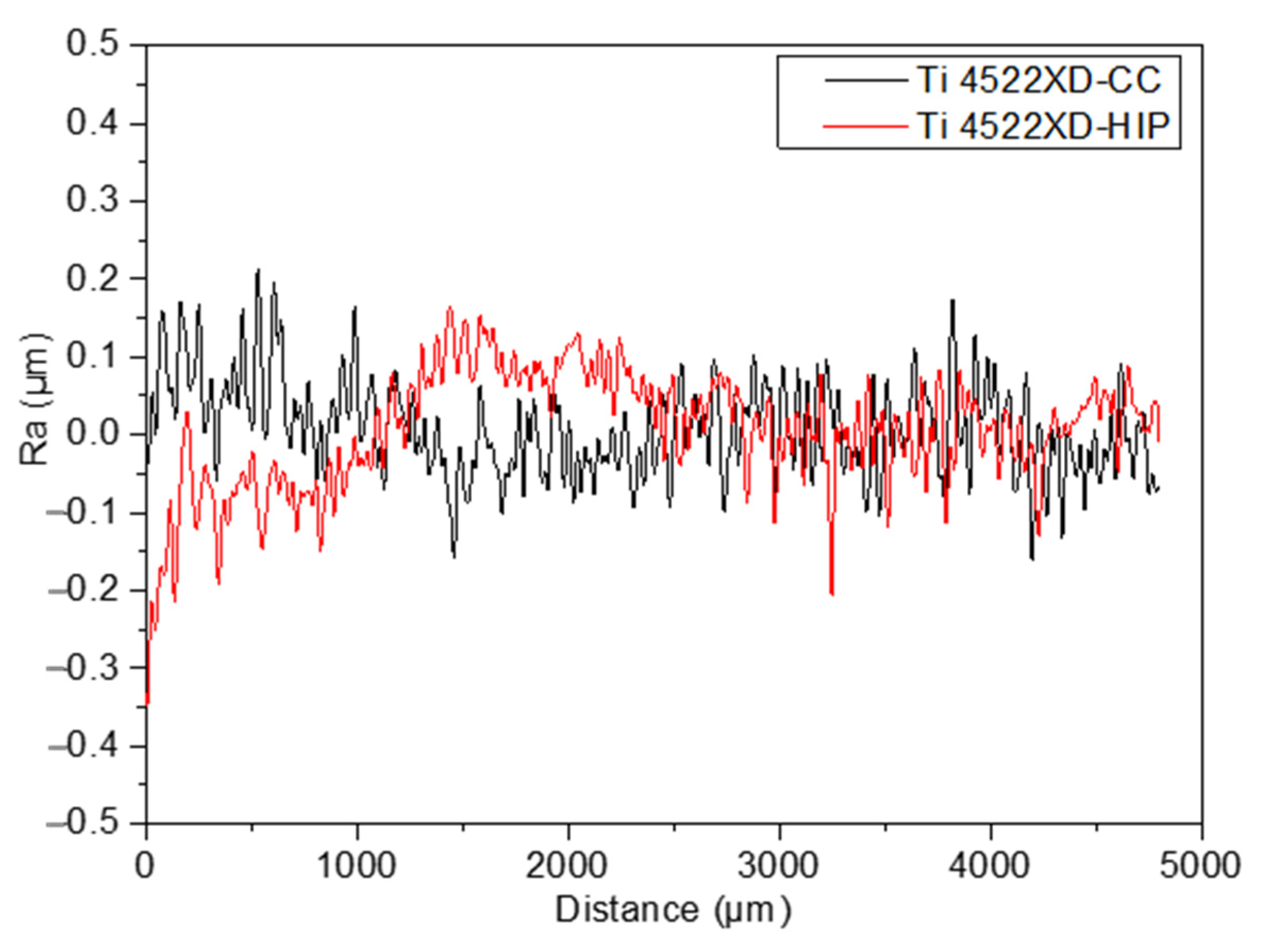

3.3. Roughness

3.4. Reciprocating Sliding Wear Test

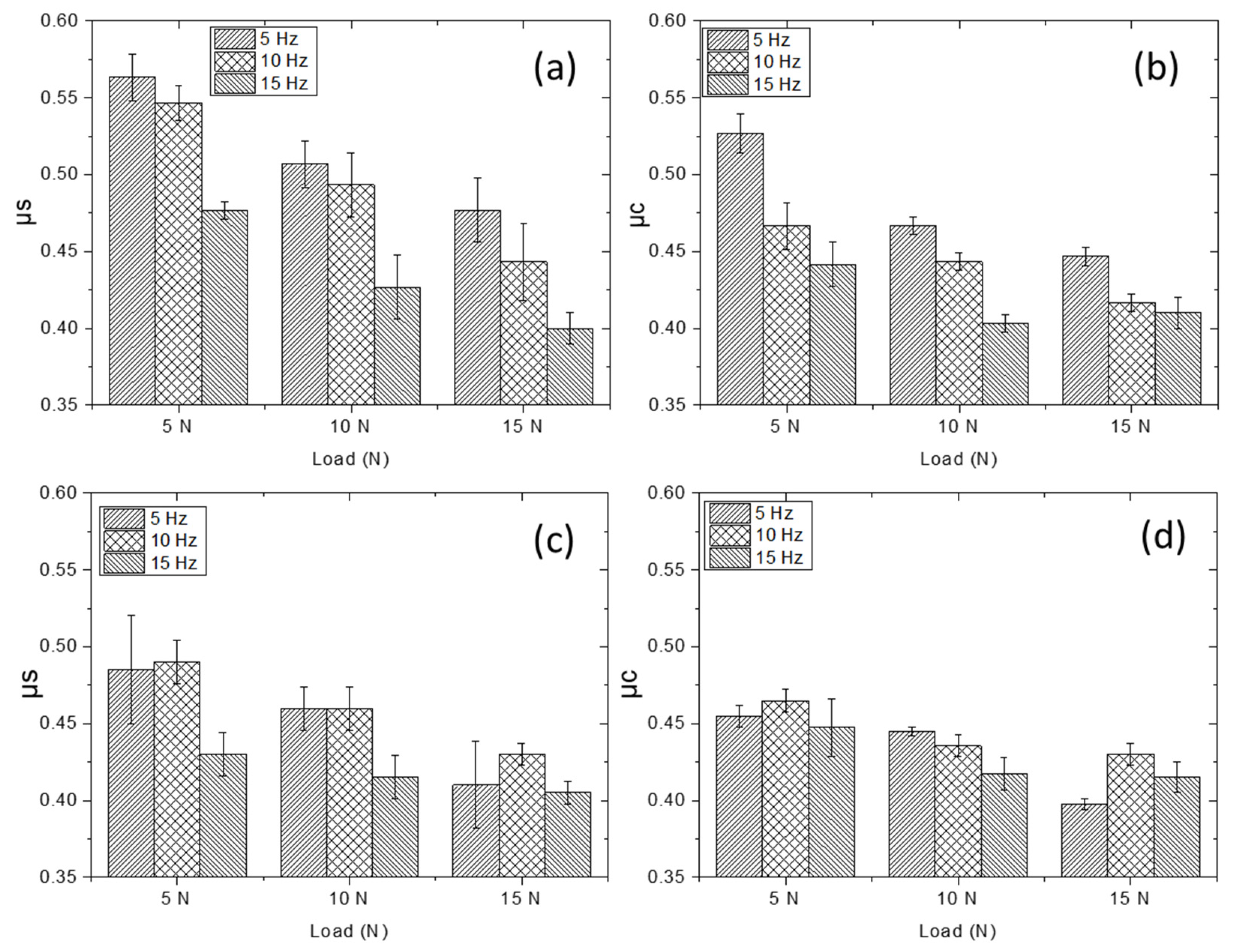

3.4.1. Coefficient of Friction

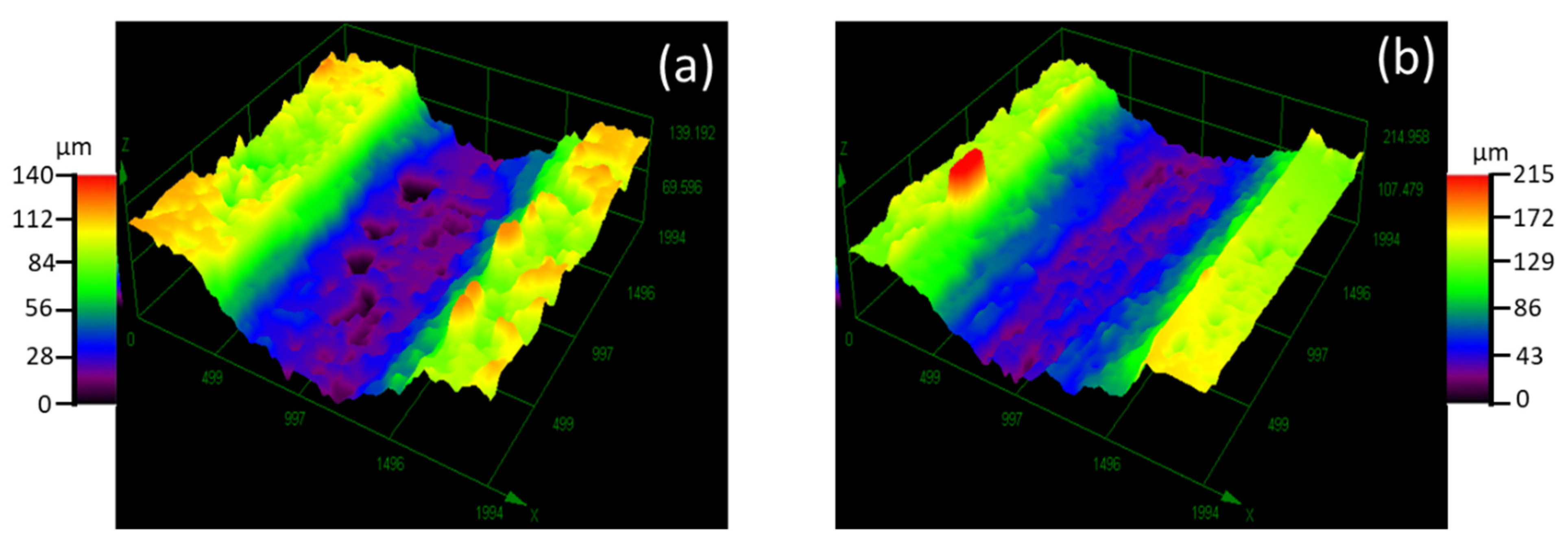

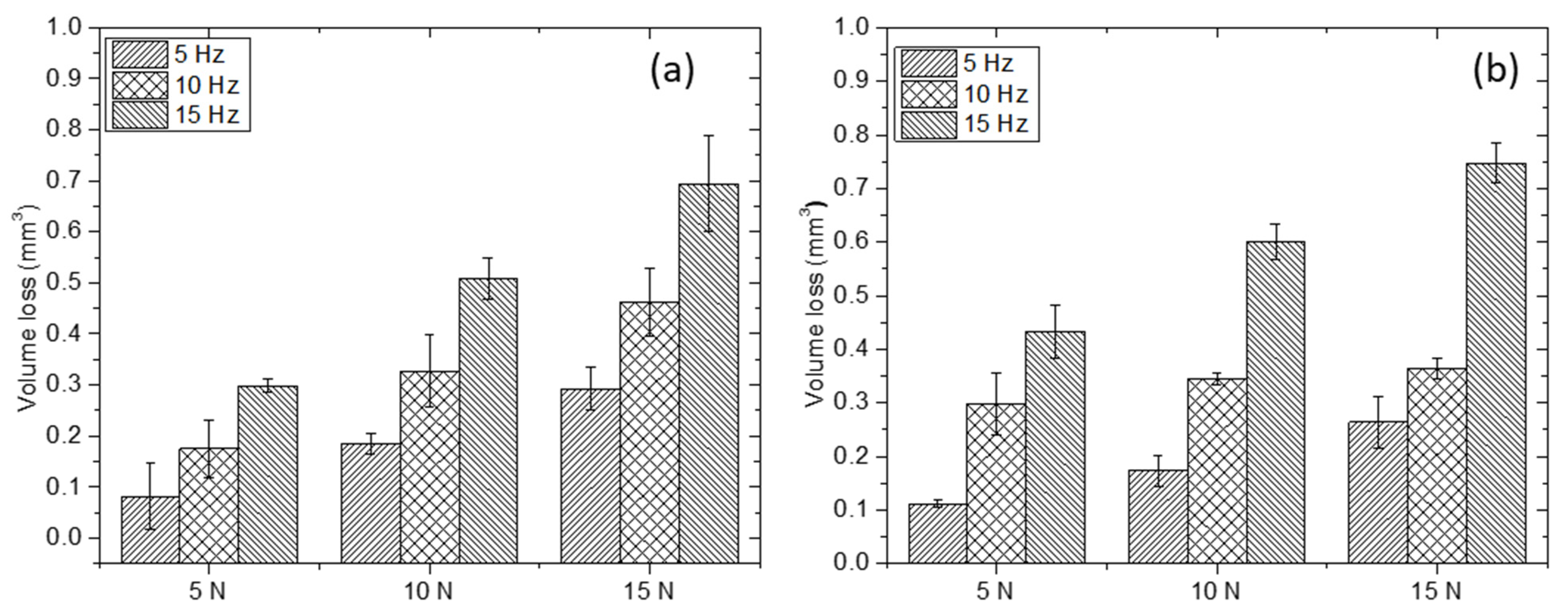

3.4.2. Wear Track Analysis and Volume Lost

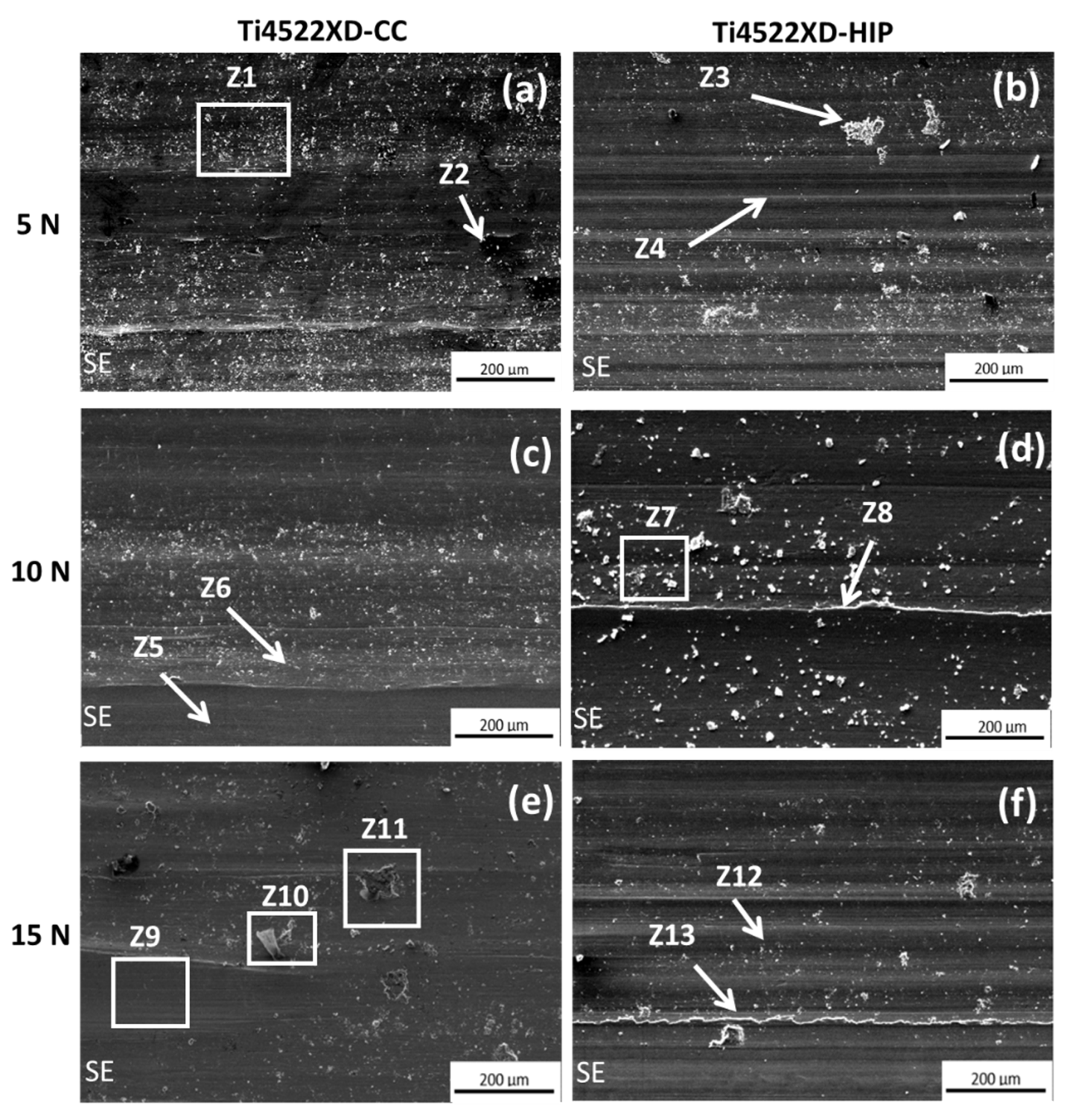

3.4.3. Wear Track Analyses by SEM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muñoz-Moreno, R.; Ruiz-Navas, E.M.; Boehlert, C.J.; Llorca, J.; Torralba, J.M.; Pérez-Prado, M.T. Analysis of crystallographic slip and grain boundary sliding in a Ti-45Al-2Nb-2Mn (At%)-0.8vol%TiB 2 alloy by high temperature in situ mechanical testing. Mater. Sci. Eng. A 2014, 606, 276–289. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Xin, L.; Ma, T.; Chang, H.; Lu, Y.; Feng, C.; Zhu, S.; Wang, F. Investigation of the role of silicon in TiAlSiN coating deposited on TiAl alloys during long-term oxidation. Corros. Sci. 2022, 204, 110394. [Google Scholar] [CrossRef]

- Wu, X. Review of alloy and process development of TiAl alloys. Intermetallics 2006, 14, 1114–1122. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Wereley, N.M. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Swadźba, R.; Swadźba, L.; Mendala, B.; Witala, B.; Tracz, J.; Marugi, K. Pyclik characterization of Si-Aluminide coating and oxide scale microstructure formed on γ-TiAl alloy during long-term oxidation at 950 °C. Intermetallics 2017, 87, 81–89. [Google Scholar] [CrossRef]

- Soboyejo, W.O.; Shen, W.; Lou, J.; Mercer, C.; Sinha, V.; Soboyejo, A.B.O. A probabilistic framework for the modeling of fatigue in cast lamellar gamma-based titanium aluminides. Mech. Mater. 2004, 36, 177–197. [Google Scholar] [CrossRef]

- Aguilar, J.; Schievenbusch, A.; Kättlitz, O. Investment casting technology for production of TiAl low pressure turbine blades—Process engineering and parameter analysis. Intermetallics 2011, 19, 757–761. [Google Scholar] [CrossRef]

- Moreno, R.M. In Situ Analysis of the High Temperature Deformation and Fracture Mechanisms of a γ-TiAl alloy. Ph.D. Thesis, Universidad Carlos III de Madrid, Madrid, Spain, 2014. [Google Scholar]

- McBride, D.; Humphreys, N.J.; Croft, T.N.; Green, N.R.; Cross, M.; Withey, P. Complex free surface flows in centrifugal casting: Computational modelling and validation experiments. Comput. Fluids 2013, 82, 63–72. [Google Scholar] [CrossRef]

- Li, C.Y.; Wu, S.P.; Guo, J.J.; Su, Y.Q.; Fu, H.Z. Castability of thin walled titanium alloy castings in vertical centrifugal field. Mater. Sci. Technol. 2008, 24, 1209–1213. [Google Scholar] [CrossRef]

- Liu, K.; Ma, Y.C.; Gao, M.; Rao, G.B.; Li, Y.Y.; Wei, K.; Wu, X.; Loretto, M.H. Single step centrifugal casting TiAl automotive valves. Intermetallics 2005, 13, 925–928. [Google Scholar] [CrossRef]

- Wu, Y.; Hwang, S.K. Microstructural refinement and improvement of mechanical properties and oxidation resistance in EPM TiAl-based intermetallics with yttrium addition. Acta Mater. 2002, 50, 1479–1493. [Google Scholar] [CrossRef]

- Cegan, T.; Kamyshnykova, K.; Lapin, J.; Szurman, I.; Jurica, J.; Klimantova, V. Processing and microstructure of As-Cast Ti-45Al-2W-XC alloys. Materials 2022, 15, 5049. [Google Scholar] [CrossRef] [PubMed]

- Mengis, L.; Grimme, C.; Galetz, M.C. High-temperature sliding wear behavior of an Intermetallic γ–based TiAl alloy. Wear 2019, 426–427, 341–347. [Google Scholar] [CrossRef]

- Guo, R.; Xiong, G.; Liu, J.; Wang, Y.; Davoodi, D.; Miri, R.; Tayebi, M. Tribological behavior of Ti-Al-Nb alloy with different Ta additions for high temperature applications. Mater. Lett. 2022, 330, 133324. [Google Scholar] [CrossRef]

- Fernández-Álvarez, M.; Velasco, F.; Bautista, A. Effect on wear resistance of nanoparticles addition to a powder polyester coating through ball milling. J. Coat. Technol. Res. 2018, 15, 771–779. [Google Scholar] [CrossRef] [Green Version]

- Saldívar-García, A.J.; López, H.F. Microstructural effects on the wear resistance of wrought and As-Cast Co-Cr-Mo-C implant alloys. J. Biomed. Mater. Res. Part A 2005, 74, 269–274. [Google Scholar] [CrossRef]

- Rastkar, A.R.; Bloyce, A.; Bell, T. Sliding wear behaviour of two gamma-based titanium aluminides. Wear 2000, 240, 19–26. [Google Scholar] [CrossRef]

- Tan, H.; Wang, S.; Yu, Y.; Cheng, J.; Zhu, S.; Qiao, Z.; Yang, J. Friction and wear properties of Al-20Si-5Fe-2Ni-graphite solid-lubricating composite at elevated temperatures. Tribol. Int. 2018, 122, 228–235. [Google Scholar] [CrossRef]

- Javaheri, V.; Porter, D.; Kuokkala, V.T. Slurry erosion of steel—Review of tests, mechanisms and materials. Wear 2018, 408–409, 248–273. [Google Scholar] [CrossRef]

- Kashani, M.M.; Barmi, A.K.; Malinova, V.S. Influence of inelastic buckling on low-cycle fatigue degradation of reinforcing bars. Constr. Build. Mater. 2015, 94, 644–655. [Google Scholar] [CrossRef]

- Kümmel, D.; Linsler, D.; Schneider, R.; Schneider, J. Surface engineering of a titanium alloy for tribological applications by nanosecond-pulsed laser. Tribol. Int. 2020, 150, 106376. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Kelly, G.; Khan, M.S.; Pereira, M.P.; Rolfe, B.F.; Islam, M.S. The surface temperature prediction on steel-tool steel sliding pairs. In Proceedings of the 2019 8th International Conference on Modeling Simulation and Applied Optimization (ICMSAO 2019), Manama, Bahrain, 15–17 April 2019. [Google Scholar] [CrossRef]

- Okonkwo, P.C.; Pereira, M.P.; Kelly, G.; Rolfe, B.F. Effects of temperature in relation to sheet metal stamping. In Proceedings of the 4th International Conference on Manufacturing Engineering, Quality and Production Systems, Vienna, Austria, 10–12 November 2011; pp. 114–118. [Google Scholar]

- Chaturvedi, M.; Richards, N.; Xu, Q. Electron beam welding of a Ti–45Al–2Nb–2Mn+0.8 Vol.% TiB2 XD alloy. Mater. Sci. Eng. A 1997, 239–240, 605–612. [Google Scholar] [CrossRef]

- Pereira, K.; Yue, T.; Abdel Wahab, M. Multiscale analysis of the effect of roughness on fretting wear. Tribol. Int. 2017, 110, 222–231. [Google Scholar] [CrossRef] [Green Version]

- Doni, Z.; Alves, A.C.; Toptan, F.; Gomes, J.R.; Ramalho, A.; Buciumeanu, M.; Palaghian, L.; Silva, F.S. Dry sliding and tribocorrosion behaviour of hot pressed CoCrMo biomedical alloy as compared with the cast CoCrMo and Ti6Al4V alloys. Mater. Des. 2013, 52, 47–57. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Yang, C.; Hu, D.; Wu, X.; Huang, A.; Dixon, M. Microstructures and tensile properties of hot isostatic pressed Ti4522XD powders. Mater. Sci. Eng. A 2012, 534, 268–276. [Google Scholar] [CrossRef]

- Cheng, J.; Yu, Y.; Fu, L.; Li, F.; Qiao, Z.; Li, J.; Yang, J.; Liu, W. Tribology International effect of TiB 2 on dry-sliding tribological properties of TiAl intermetallics. Tribol. Int. 2013, 62, 91–99. [Google Scholar] [CrossRef]

- Xu, X.; Fan, S.; Zhang, L.; Du, Y.; Cheng, L. Tribological behavior of three-dimensional needled carbon/silicon carbide and carbon/carbon brake pair. Tribol. Int. 2014, 77, 7–14. [Google Scholar] [CrossRef]

- Liu, X.; Tian, W.; Xu, W.; Liang, W.; Xu, Z. Wear resistance of TiAl intermetallics by plasma alloying and plasma carburization. Surf. Coatings Technol. 2007, 201, 5278–5281. [Google Scholar] [CrossRef]

- Shaik, M.A.; Golla, B.R. Development of highly wear resistant Cu-Al alloys processed via powder metallurgy. Tribol. Int. 2019, 136, 127–139. [Google Scholar] [CrossRef]

- Yi, Y.; Xing, J.; Ren, X.; Fu, H.; Li, Q.; Yi, D. Investigation on abrasive wear behavior of Fe–B alloys containing various molybdenum contents. Tribol. Int. 2019, 135, 237–245. [Google Scholar] [CrossRef]

- Prabhu, T.R.; Arivarasu, M.; Chodancar, Y.; Arivazhagan, N.; Sumanth, G.; Mishra, R.K. Tribological behaviour of graphite-reinforced FeNiCrCuMo high-entropy alloy self-lubricating composites for aircraft braking energy applications. Tribol. Lett. 2019, 67, 78. [Google Scholar] [CrossRef]

- Manohara, H.R.; Chandrashekharaiah, T.M.; Venkateswarlu, K.; Kori, S.A. Dry sliding wear response of A413 alloy: Influence of intermetallics and test parameters. Tribol. Int. 2012, 51, 54–60. [Google Scholar] [CrossRef]

- Yang, K.; Shi, X.; Huang, Y.; Zou, J.; Shen, Q.; Zhang, Q. A study of the tribological behavior of TiAl-10 Wt.%Ag composite based on the contact stress evolution. J. Mater. Eng. Perform. 2017, 26, 1251–1261. [Google Scholar] [CrossRef]

| Load (N) | Frequency (Hz) |

|---|---|

| 5 | 5 |

| 10 | |

| 15 | |

| 10 | 5 |

| 10 | |

| 15 | |

| 15 | 5 |

| 10 | |

| 15 |

| Material | Area | Al (wt%) | Nb (wt%) | Ti (wt%) | Mn (wt%) |

|---|---|---|---|---|---|

| Ti4522XD-CC | Equiaxial grain | 32.9 | 4.9 | 58.6 | 3.3 |

| Lamellar colony | 26.5 | 4.2 | 65.8 | 3.4 |

| Sample | Hardness (HV 0.5) |

|---|---|

| Ti 4522XD-CC | 400 ± 20 |

| Ti 4522XD-HIP | 357 ± 18 |

| Sample | Roughness Ra (μm) |

|---|---|

| Ti 4522XD-CC | 0.06 ± 0.03 |

| Ti 4522XD-HIP | 0.06 ± 0.02 |

| Sample | Area | Al (wt%) | Nb (wt%) | Ti (wt%) | Mn (wt%) | O (wt%) |

|---|---|---|---|---|---|---|

| Ti4522XD wear track | Z1 | 30.1 | 4.6 | 57.3 | 3.5 | 4.6 |

| Z3 | 28.6 | 3.8 | 55.0 | 3.0 | 9.7 | |

| Z7 | 31.2 | 4.7 | 58.3 | 2.9 | 2.8 | |

| Z10 | 32.7 | 5.4 | 52.5 | 2.8 | 6.5 | |

| Z11 | 33.5 | 3.9 | 54.9 | 3.0 | 4.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shagñay, S.; Cornide, J.; Ruiz-Navas, E.M. Sliding Wear Behavior of Intermetallic Ti-45Al-2Nb-2Mn-(at%)-0.8vol%TiB2 Processed by Centrifugal Casting and Hot Isostatic Pressure: Influence of Microstructure. Materials 2022, 15, 8052. https://doi.org/10.3390/ma15228052

Shagñay S, Cornide J, Ruiz-Navas EM. Sliding Wear Behavior of Intermetallic Ti-45Al-2Nb-2Mn-(at%)-0.8vol%TiB2 Processed by Centrifugal Casting and Hot Isostatic Pressure: Influence of Microstructure. Materials. 2022; 15(22):8052. https://doi.org/10.3390/ma15228052

Chicago/Turabian StyleShagñay, Segundo, Juan Cornide, and Elisa María Ruiz-Navas. 2022. "Sliding Wear Behavior of Intermetallic Ti-45Al-2Nb-2Mn-(at%)-0.8vol%TiB2 Processed by Centrifugal Casting and Hot Isostatic Pressure: Influence of Microstructure" Materials 15, no. 22: 8052. https://doi.org/10.3390/ma15228052

APA StyleShagñay, S., Cornide, J., & Ruiz-Navas, E. M. (2022). Sliding Wear Behavior of Intermetallic Ti-45Al-2Nb-2Mn-(at%)-0.8vol%TiB2 Processed by Centrifugal Casting and Hot Isostatic Pressure: Influence of Microstructure. Materials, 15(22), 8052. https://doi.org/10.3390/ma15228052