Design and Application of a Twisted and Coiled Polymer Driven Artificial Musculoskeletal Actuation Module

Abstract

:1. Introduction

2. Artificial Muscle Unit Design

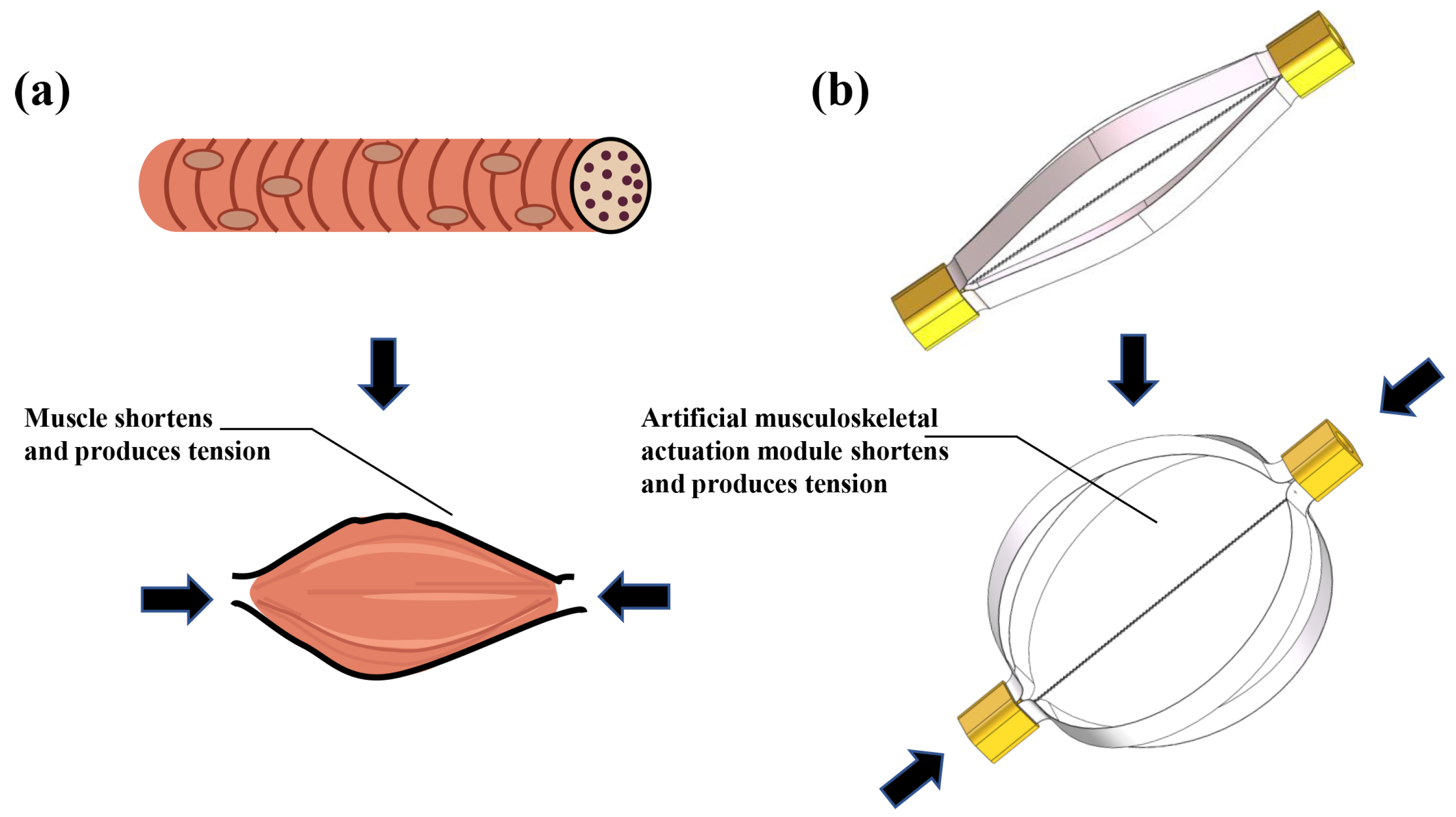

2.1. Bio-Inspiration for the Actuation Module

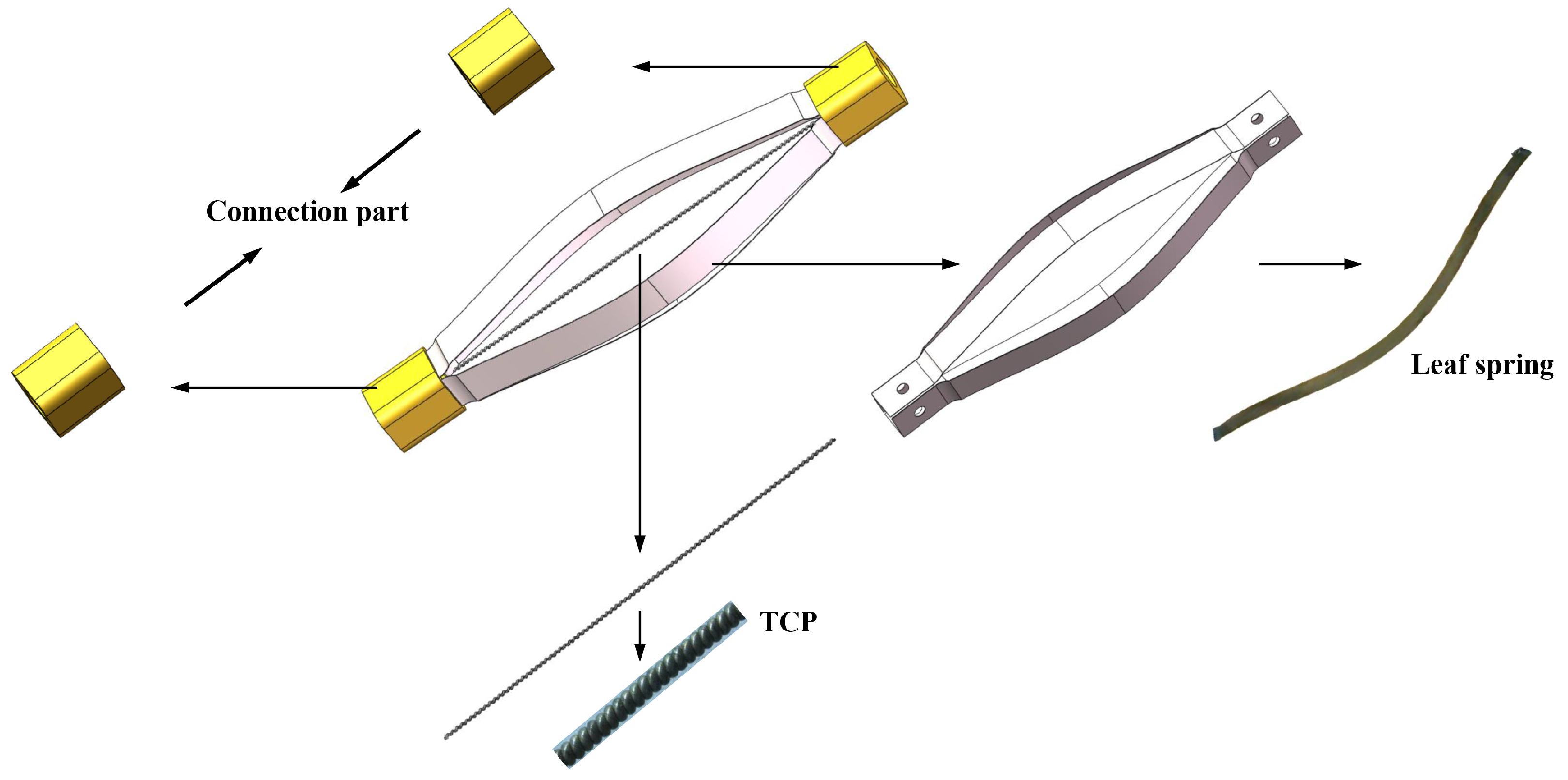

2.2. Musculoskeletal Actuation Module Design

3. Model Formulation

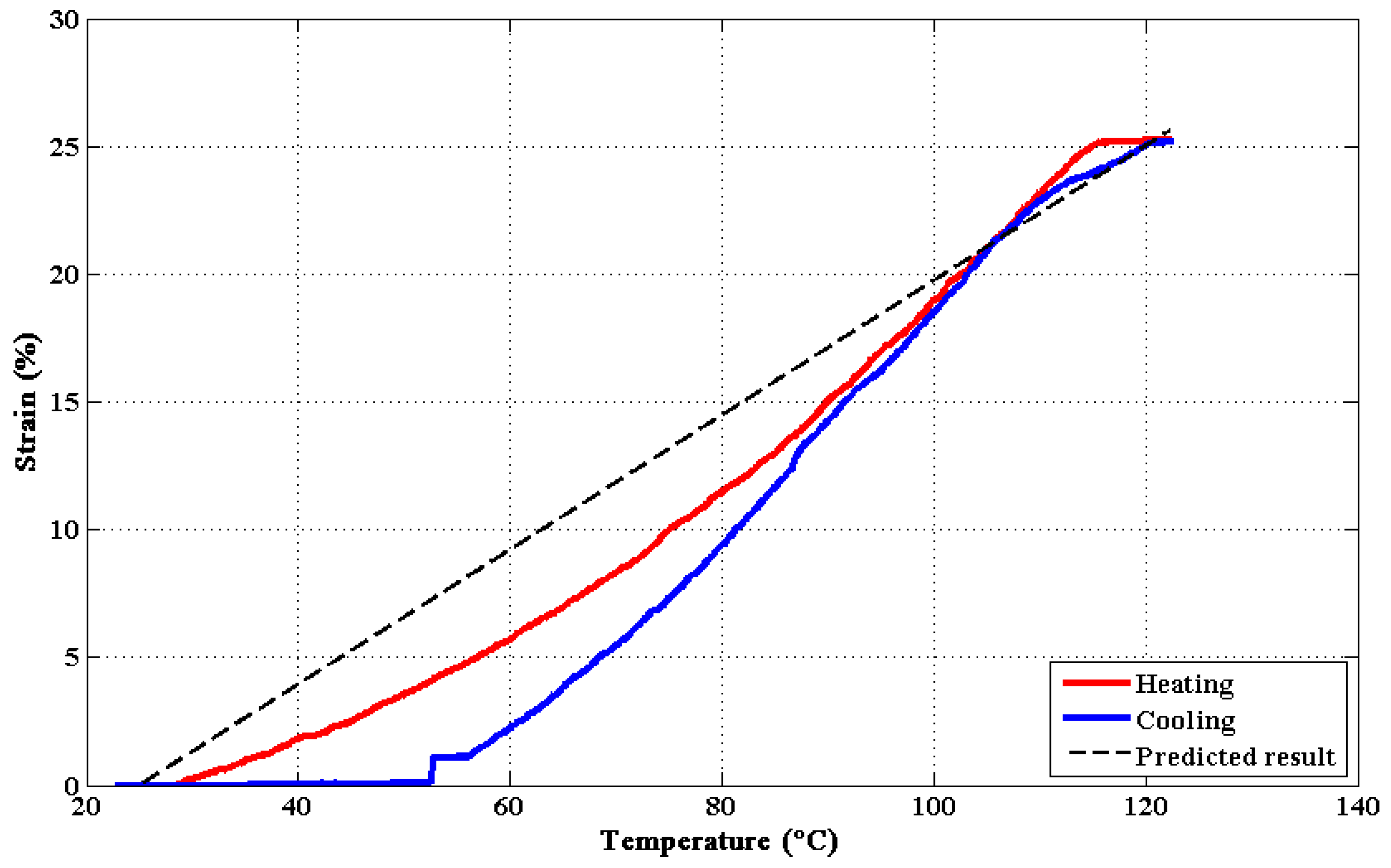

3.1. Modelling TCP Muscle

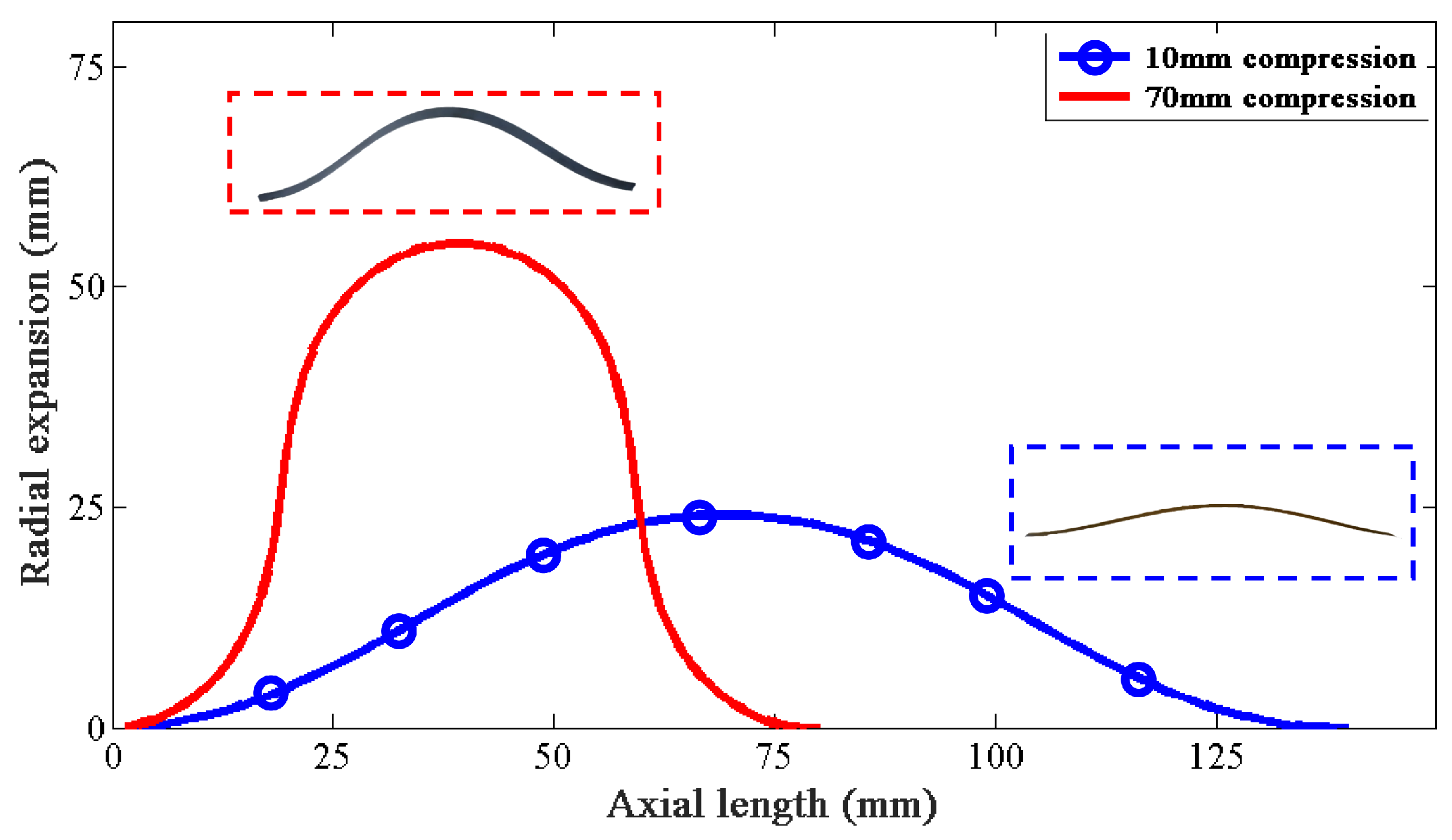

3.2. Modelling Leaf Spring

4. Results

4.1. Fabrication Process

4.2. Basic Performance Test

4.2.1. The Control System

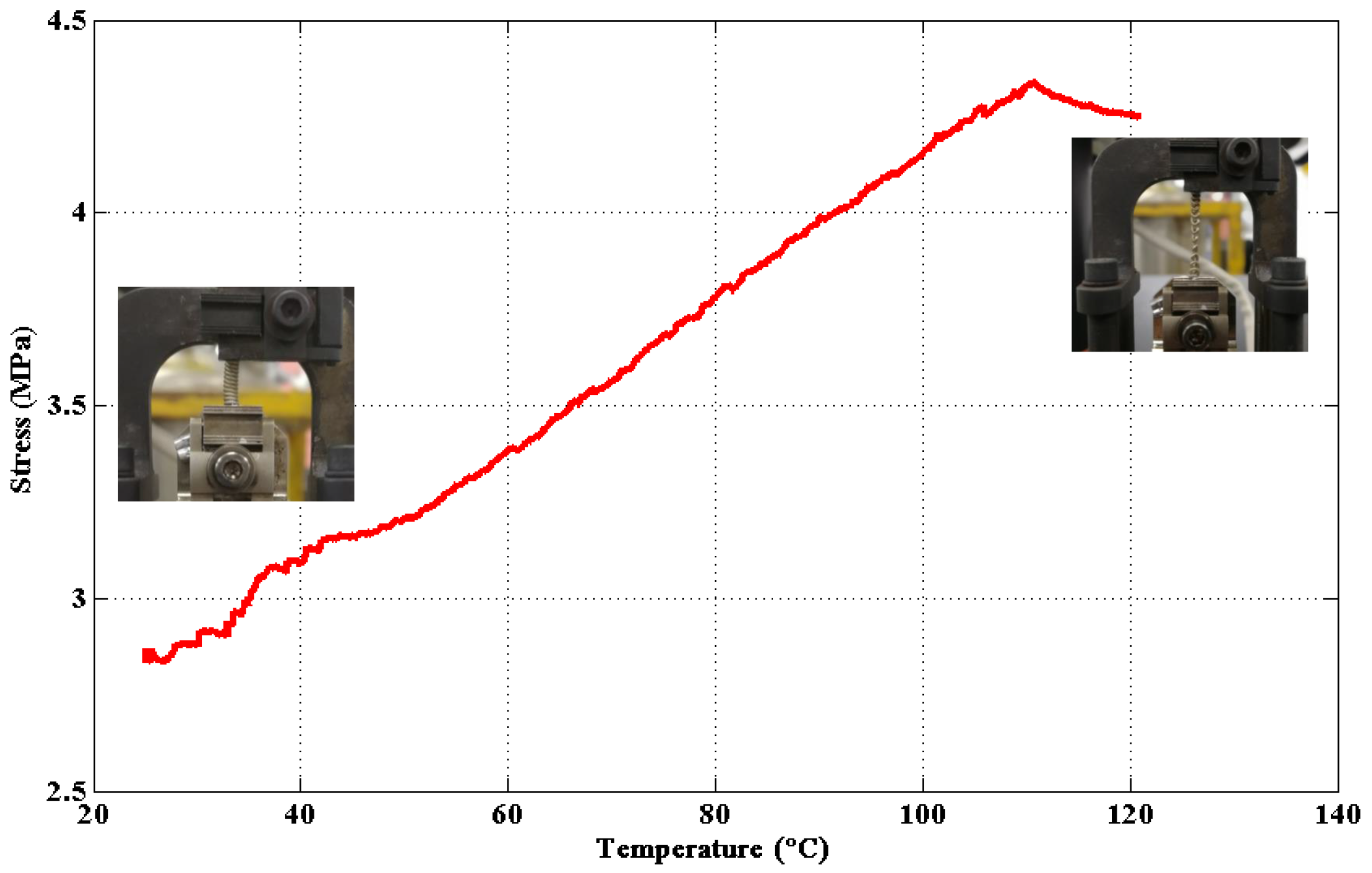

4.2.2. Single TCP Strain and Recovery Stress Test

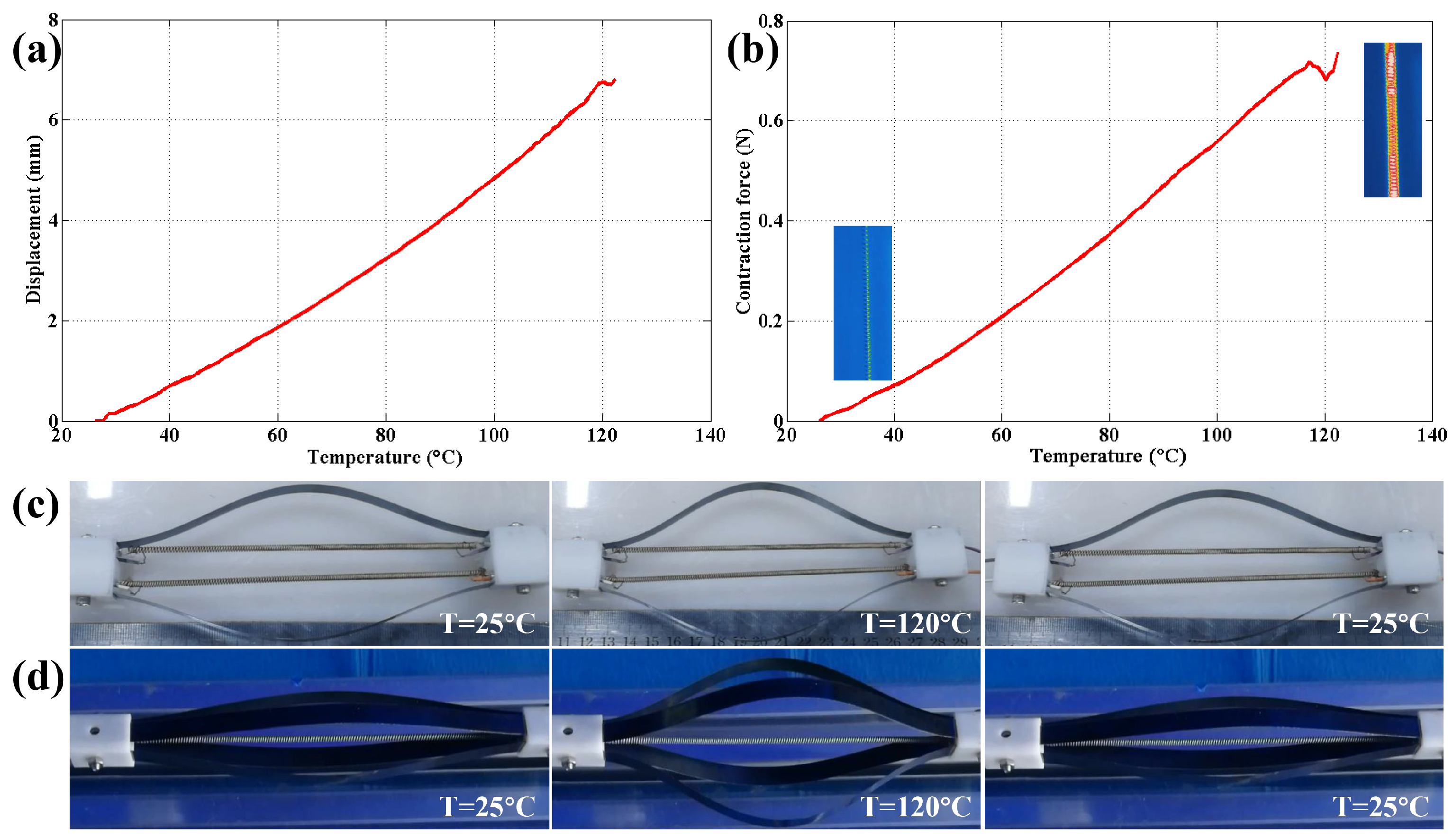

4.2.3. Musculoskeletal Actuation Module Performance Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Majidi, C. Soft-matter engineering for soft robotics. Adv. Mater. Technol. 2019, 4, 1800477. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Zhu, H.; Liu, J.; Lu, H.; Ren, Y.; Wang, M.Y. A Proprioceptive Soft Robot Module Based on Supercoiled Polymer Artificial Muscle Strings. Polymers 2022, 14, 2265. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Shatara, S.; Tan, X. Modeling of biomimetic robotic fish propelled by an ionic polymer-metal composite caudal fin. IEEE ASME Trans. Mechatron. 2010, 15, 448–459. [Google Scholar] [CrossRef]

- Bhandari, B.; Lee, G.Y.; Ahn, S.H. A review on ipmc material as actuators and sensors: Fabrications, characteristics and applications. Int. J. Precis. Eng. Manuf. 2012, 13, 141–163. [Google Scholar] [CrossRef]

- Chang, Y.C.; Kim, W.J. Aquatic ionic-polymer-metal-composite insectile robot with multi-dof legs. IEEE ASME Trans. Mechatron. 2013, 18, 547–555. [Google Scholar] [CrossRef]

- Chu, W.S.; Lee, K.T.; Song, S.H.; Han, M.W.; Lee, J.Y.; Kim, H.S.; Kim, M.S.; Park, Y.J.; Cho, K.J.; Ahn, S.H. Review of biomimetic underwater robots using smart actuators. Int. J. Precis. Eng. Manuf. 2012, 13, 1281–1292. [Google Scholar] [CrossRef]

- Mansour, N.A.; Jang, T.; Baek, H.; Shin, B.; Ryu, B.; Kim, Y. Compliant closed-chain rolling robot using modular unidirectional SMA actuators. Sens. Actuators A Phys. 2020, 310, 112024. [Google Scholar] [CrossRef]

- Liu, M.; Hao, L.; Zhang, W.; Zhao, Z. A novel design of shape-memory alloy-based soft robotic gripper with variable stiffness. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420907813. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Xu, M.; Li, W.; Zhang, S. Design and implementation of a soft robotic arm driven by SMA coils. IEEE Trans. Ind. Electron. 2018, 66, 6108–6116. [Google Scholar] [CrossRef]

- Woodward, M.A.; Sitti, M. Tailored Magnetic Springs for Shape-Memory Alloy Actuated Mechanisms in Miniature Robots. IEEE Trans. Robot. 2019, 35, 589–601. [Google Scholar] [CrossRef]

- Pfeil, S.; Henke, M.; Katzer, K.; Zimmermann, M.; Gerlach, G. A worm-like biomimetic crawling robot based on cylindrical dielectric elastomer actuators. Front. Robot. AI 2020, 7, 9. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liu, L.; Liu, Y.; Leng, J. Dielectric elastomer spring-roll bending actuators: Applications in soft robotics and design. Soft Robot. 2019, 6, 69–81. [Google Scholar] [CrossRef] [PubMed]

- He, T.; Wang, Z. Electro-viscoelastic performance of a tubular dielectric elastomer actuator. Int. J. Mech. Mater. Des. 2019, 15, 199–212. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, H.; Mao, J.; Chirarattananon, P.; Helbling, E.F.; Hyun, N.S.P.; Clarke, D.R.; Wood, R.J. Controlled flight of a microrobot powered by soft artificial muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef] [PubMed]

- Almubarak, Y.; Schmutz, M.; Perez, M.; Shah, S.; Tadesse, Y. Kraken: A wirelessly controlled octopus-like hybrid robot utilizing stepper motors and fishing line artificial muscle for grasping underwater. Int. J. Intell. Robot. Appl. 2022, 6, 543–563. [Google Scholar] [CrossRef]

- Hamidi, A.; Almubarak, Y.; Rupawat, Y.M.; Warren, J.; Tadesse, Y. Poly-Saora robotic jellyfish: Swimming underwater by twisted and coiled polymer actuators. Smart Mater. Struct. 2020, 29, 045039. [Google Scholar] [CrossRef]

- Yang, Y.; Kan, Z.; Zhang, Y.; Tse, Y.A.; Wang, M.Y. A novel variable stiffness actuator based on pneumatic actuation and supercoiled polymer artificial muscles. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; IEEE: Hoboken, NJ, USA, 2019; pp. 3983–3989. [Google Scholar]

- Chen, S.; Cao, Y.; Sarparast, M.; Yuan, H.; Dong, L.; Tan, X.; Cao, C. Soft crawling robots: Design, actuation, and locomotion. Adv. Mater. Technol. 2020, 5, 1900837. [Google Scholar] [CrossRef]

- Zhang, J.; Sheng, J.; O’Neill, C.T.; Walsh, C.J.; Wood, R.J.; Ryu, J.H.; Desai, J.P.; Yip, M.C. Robotic artificial muscles: Current progress and future perspectives. IEEE Trans. Robot. 2019, 35, 761–781. [Google Scholar] [CrossRef]

- Haines, C.S.; Lima, M.D.; Li, N.; Spinks, G.M.; Foroughi, J.; Madden, J.D.; Kim, S.H.; Fang, S.; de Andrade, M.J.; Göktepe, F.; et al. Artificial muscles from fishing line and sewing thread. Science 2014, 343, 868–872. [Google Scholar] [CrossRef]

- Haines, C.S.; Li, N.; Spinks, G.M.; Aliev, A.E.; Di, J.; Baughman, R.H. New twist on artificial muscles. Proc. Natl. Acad. Sci. USA 2016, 113, 11709–11716. [Google Scholar] [CrossRef]

- Cho, K.H.; Song, M.G.; Jung, H.; Park, J.; Moon, H.; Koo, J.C.; Nam, J.D.; Choi, H.R. A robotic finger driven by twisted and coiled polymer actuator. In Electroactive Polymer Actuators and Devices (EAPAD) 2016; SPIE: London, UK, 2016; Volume 9798, pp. 275–281. [Google Scholar]

- Yip, M.C.; Niemeyer, G. High-performance robotic muscles from conductive nylon sewing thread. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; IEEE: Hoboken, NJ, USA, 2015; pp. 2313–2318. [Google Scholar]

- Yip, M.C.; Niemeyer, G. On the control and properties of supercoiled polymer artificial muscles. IEEE Trans. Robot. 2017, 33, 689–699. [Google Scholar] [CrossRef]

- Tang, X.; Li, K.; Liu, Y.; Zhou, D.; Zhao, J. A general soft robot module driven by twisted and coiled actuators. Smart Mater. Struct. 2019, 28, 035019. [Google Scholar] [CrossRef]

- Wu, C.; Zheng, W. A Modeling of Twisted and Coiled Polymer Artificial Muscles Based on Elastic Rod Theory. Actuators 2020, 9, 25. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Zhang, Z.; Wang, H. A General Approach to the Large Deflection Problems of Spatial Flexible Rods Using Principal Axes Decomposition of Compliance Matrices. J. Mech. Robot. 2018, 10, 031012. [Google Scholar] [CrossRef]

- Chen, G.; Wang, H.; Lin, Z. Determination of the Identifiable Parameters in Robot Calibration Based on the POE Formula. IEEE Trans. Robot. 2014, 30, 1066–1077. [Google Scholar] [CrossRef]

- Tang, X.; Li, K.; Liu, Y.; Zhou, D.; Zhao, J. A soft crawling robot driven by single twisted and coiled actuator. Sens. Actuators A Phys. 2019, 291, 80–86. [Google Scholar] [CrossRef]

- Lei, Q.; Qin, L.; Liang, X.; Huang, H.; Chui, C.K.; Yeow, R.C.H.; Zhu, J. A Versatile Soft Crawling Robot with Rapid Locomotion. Soft Robot. 2019, 6, 455–467. [Google Scholar]

- Liang, C.; Wang, Y.; Yao, T.; Zhu, B. A shape memory alloy–actuated soft crawling robot based on adaptive differential friction and enhanced antagonistic configuration. J. Intell. Mater. Syst. Struct. 2020, 31, 1920–1934. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Zheng, W.; Wang, Z.; Yan, B.; Ma, J.; Fang, G. Design and Application of a Twisted and Coiled Polymer Driven Artificial Musculoskeletal Actuation Module. Materials 2022, 15, 8261. https://doi.org/10.3390/ma15228261

Wu C, Zheng W, Wang Z, Yan B, Ma J, Fang G. Design and Application of a Twisted and Coiled Polymer Driven Artificial Musculoskeletal Actuation Module. Materials. 2022; 15(22):8261. https://doi.org/10.3390/ma15228261

Chicago/Turabian StyleWu, Chunbing, Wen Zheng, Zhiyi Wang, Biao Yan, Jia Ma, and Guangqiang Fang. 2022. "Design and Application of a Twisted and Coiled Polymer Driven Artificial Musculoskeletal Actuation Module" Materials 15, no. 22: 8261. https://doi.org/10.3390/ma15228261

APA StyleWu, C., Zheng, W., Wang, Z., Yan, B., Ma, J., & Fang, G. (2022). Design and Application of a Twisted and Coiled Polymer Driven Artificial Musculoskeletal Actuation Module. Materials, 15(22), 8261. https://doi.org/10.3390/ma15228261